Preparation method of transparent magnesia-alumina spinel ceramic

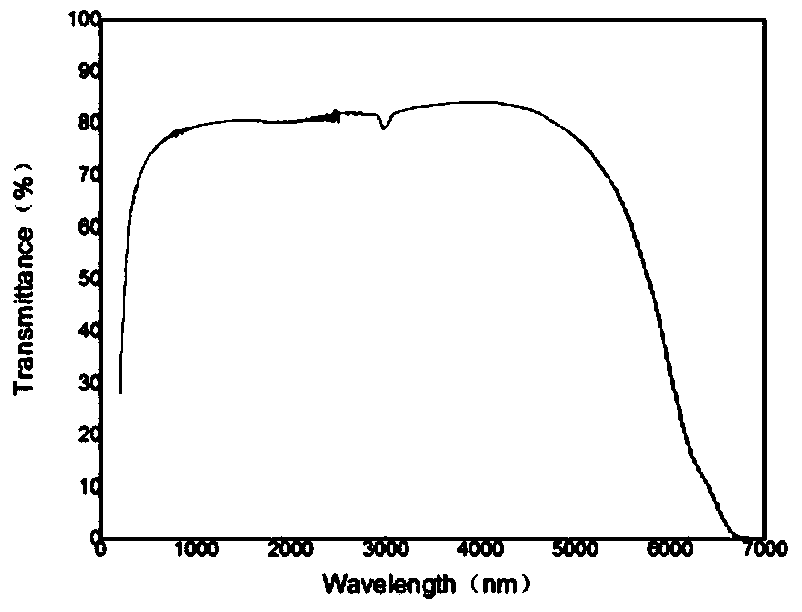

A technology of magnesia-alumina spinel and magnesia-alumina spinel powder, which is applied in the field of preparation of transparent ceramic materials, can solve the problems of lower transmittance and mechanical properties, high requirements for raw material powder, and high cost, so as to reduce production costs , good mechanical properties and optical properties, and the effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A Magnesium Aluminum Spinel Transparent Ceramic MgO·Al 2 o 3 , the preparation method is as follows:

[0039] Weigh 150g of magnesium oxide (average particle size 100nm) and α-alumina (average particle size 180nm) according to the mass percentages of 28.33% and 71.67% respectively, and add alumina balls and absolute ethanol according to the ball-to-material mass ratio of 4:1 Mix and ball mill for 24 hours, then remove the solvent by rotary evaporation, pass through a 100-mesh sieve, then sinter at 1350°C for 10 minutes in solid state reaction, and finally pass through a 200-mesh sieve to obtain MgO·Al 2 o 3 Spinel powder, the average particle size of the powder is 180nm;

[0040] The MgO·Al prepared above 2 o 3 Put the spinel powder into the graphite mold, and then put the mold into the insulation felt of the spark plasma sintering equipment to pre-press 7.5MPa. At room temperature, use a heating rate of 100℃ / min to heat the mold to 1425℃, and wait until the temper...

Embodiment 2

[0048] A Magnesium Aluminum Spinel Transparent Ceramic MgO·1.44Al 2 o 3 , the preparation method is as follows:

[0049] Weigh magnesia (average particle size 100nm) and α-alumina (average particle size 180nm) 150g in total according to the mass fraction of 21.54% and 78.46%, respectively, add alumina balls and absolute ethanol according to the ball-to-material mass ratio of 4:1 Mix and ball mill for 24 hours, then remove the solvent by rotary evaporation, pass through a 100-mesh sieve, then sinter at 1350°C for 10 minutes in solid state reaction, and finally pass through a 200-mesh sieve to obtain MgO·1.44Al 2 o 3 Spinel powder, the average particle size of the powder is 225nm;

[0050] The above-prepared MgO·1.44Al 2 o 3 Put the spinel powder into the graphite mold, and then put the mold into the insulation felt of the spark plasma sintering equipment to pre-press 7.5MPa. At room temperature, use a heating rate of 100℃ / min to heat the mold to 1400℃. When the temperature...

Embodiment 3

[0058] A Magnesium Aluminum Spinel Transparent Ceramic MgO·1.8Al 2 o 3 , the preparation method is as follows:

[0059] Weigh magnesia (average particle size 200nm) and α-alumina (average particle size 400nm) 150g in total according to the mass fraction of 18.01% and 81.99%, respectively, add alumina balls and absolute ethanol according to the ball-to-material mass ratio of 4:1 Mix and ball mill for 24 hours, then remove the solvent by rotary evaporation, pass through a 100-mesh sieve, then sinter at 1680°C for 15 minutes in solid state reaction, and finally pass through a 200-mesh sieve to obtain MgO·1.8Al 2 o 3 Spinel powder, the average particle size of the powder is 600nm;

[0060] The above-prepared MgO·1.8Al 2 o 3 Put the spinel powder into the graphite mold, and then put the mold into the insulation felt of the spark plasma sintering equipment to pre-press 7.5MPa. At room temperature, use a heating rate of 10℃ / min to heat the mold to 1300℃. When the temperature rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com