Patents

Literature

84results about How to "Rapid densification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

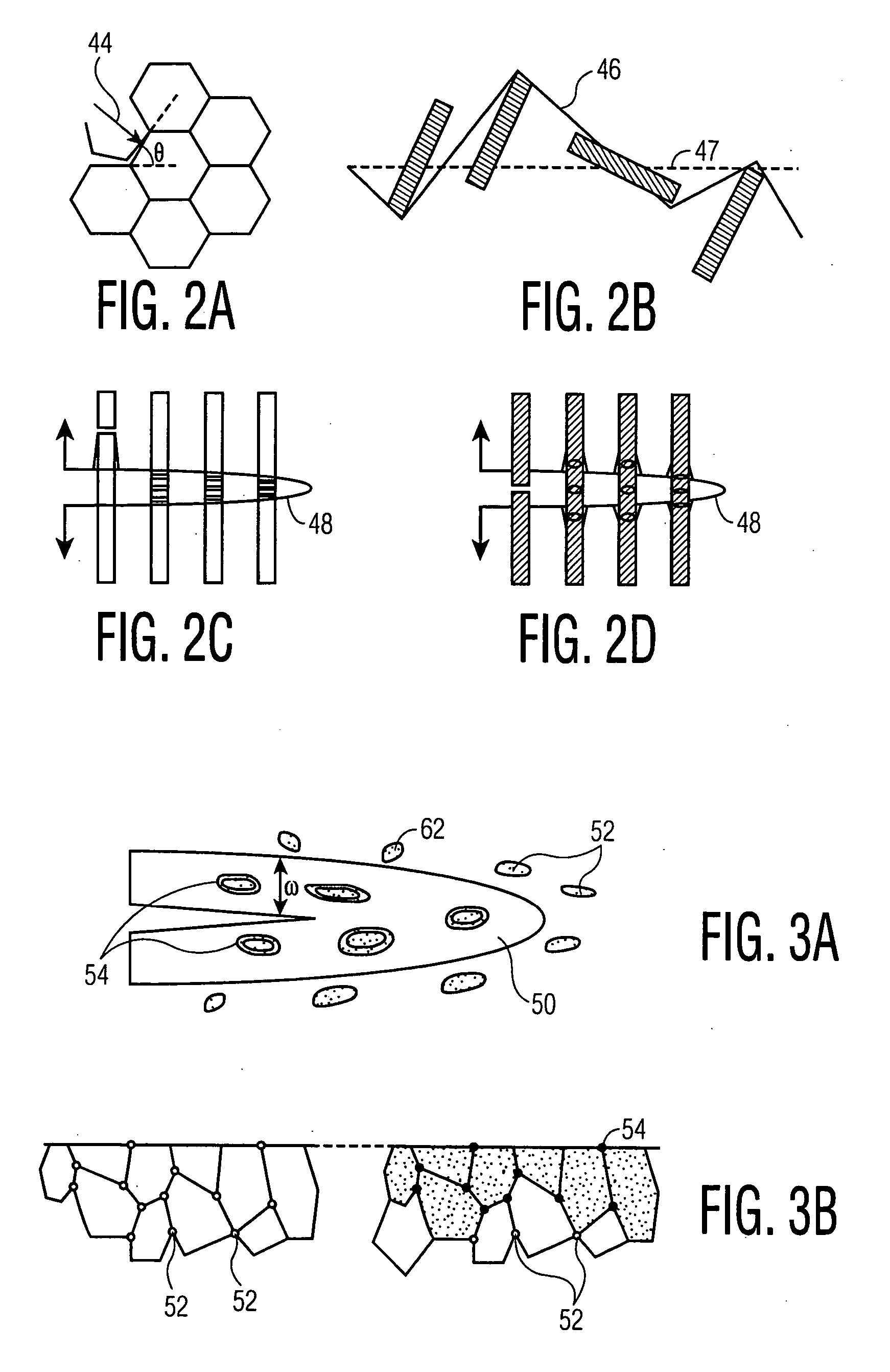

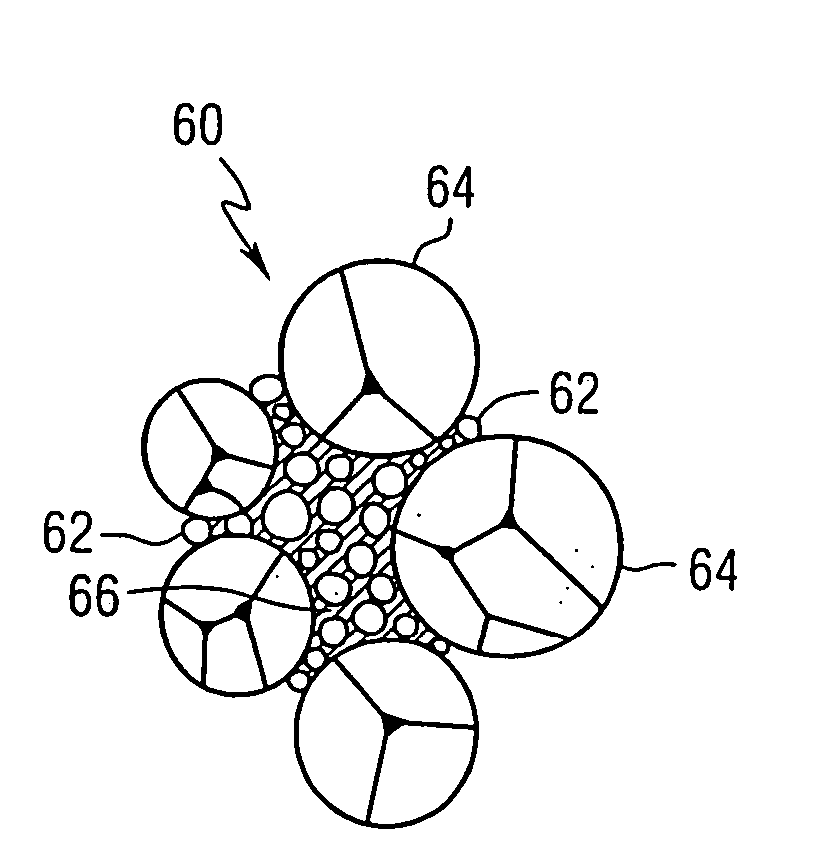

Nanocomposite ceramics and process for making the same

InactiveUS20070049484A1High hardnessImprove fracture toughnessMaterial nanotechnologyNanometreMaterials science

A nanocomposite ceramic composition and method for making the same, the composition comprising a uniform dispersion of nanosize ceramic particles composed of at least one ceramic phase, interspersed and bound throughout a tough zirconia matrix phase.

Owner:RUTGERS THE STATE UNIV

Carbon fiber preform densification by pitch infiltration followed by resin transfer molding

Method of manufacturing dense carbon-carbon composite material by: infiltrating a fibrous preform with pitch to form pitch-infiltrated preform; carbonizing the pitch-infiltrated preform; injecting resin or pitch into the preform in a mold; oxygen stabilizing the filled preform and carbonizing and heat-treating the oxygen-stabilized impregnated preform; and subjecting the preform to a single final cycle of chemical vapor deposition. This process reduces densification time as compared to comparable conventional carbon-carbon composite manufacturing procedures.

Owner:HONEYWELL INT INC

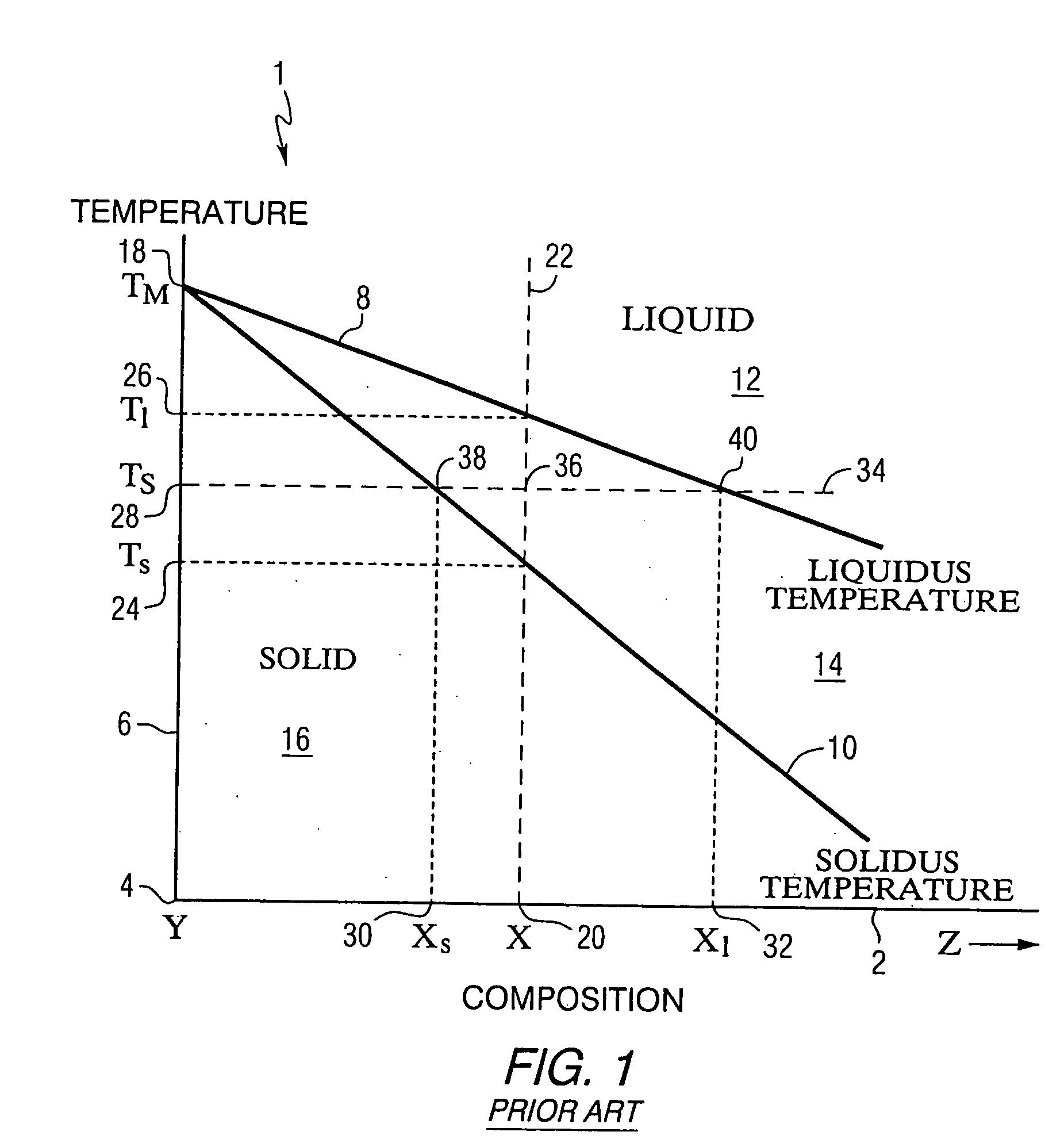

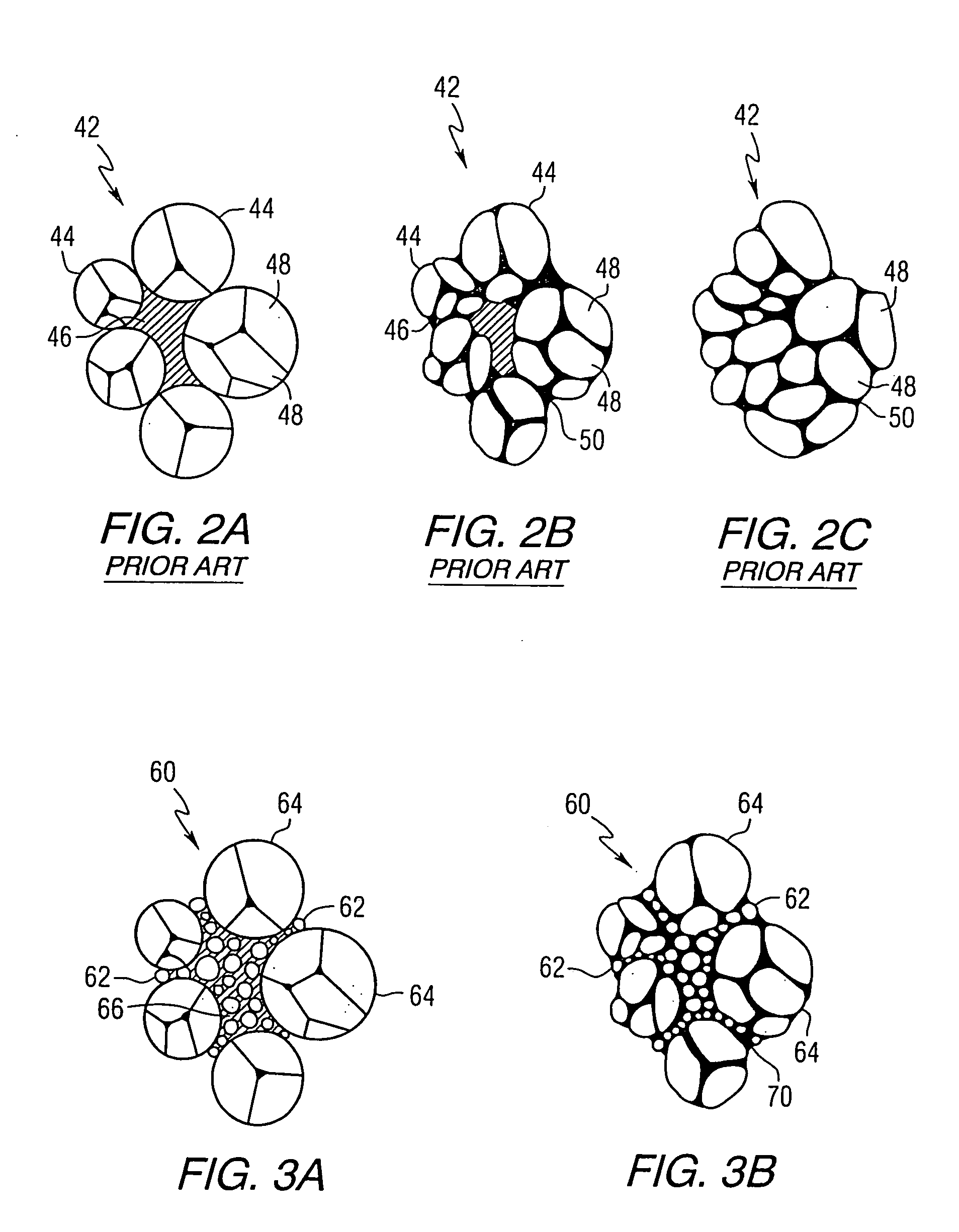

Blended powder solid-supersolidus liquid phase sintering

InactiveUS20060083652A1Deleterious effectHigh densityAdditive manufacturing apparatusTransportation and packagingPowder mixtureAlloy

A green article comprising an A-B powder mixture and methods of manufacturing such green articles and corresponding sintered articles are disclosed. The A-B powder mixture consists of a minor volume fraction of a relatively fine powder A and a complementary major volume fraction of a relatively coarse prealloyed powder B wherein the A-B powder mean particle size ratio is at least about 1:5. Metal powder A consists of one or more elemental metals or alloys which has a melting or solidus temperature above the highest sintering temperature at which the A-B powder mixture may be sintered without slumping. Prealloyed metal powder B consists of one or more alloys which are amenable to supersolidus liquid phase sintering. Green articles made from the A-B powder have a wider sintering temperature window than do articles made from prealloyed metal powder B alone.

Owner:THE EX ONE

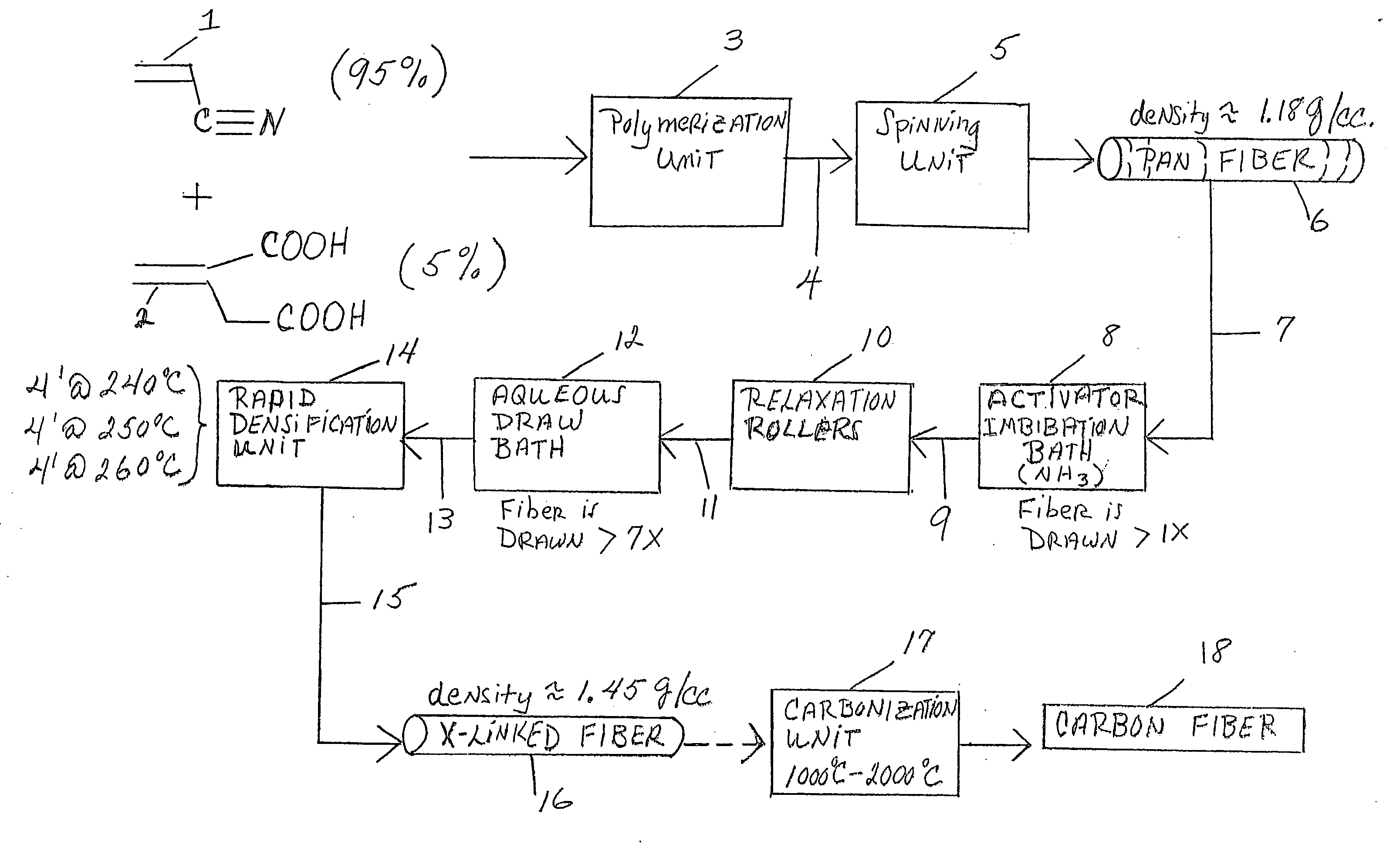

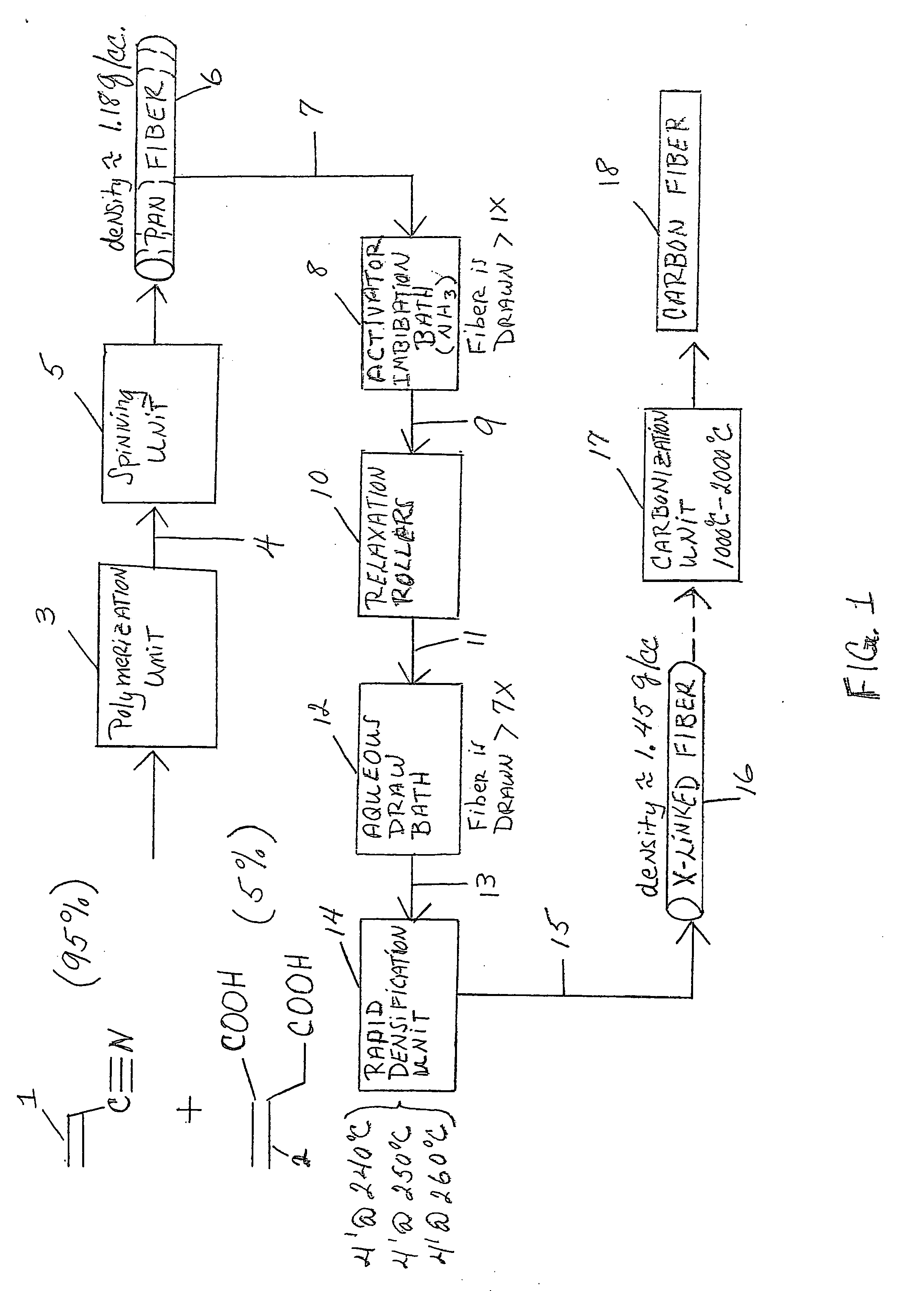

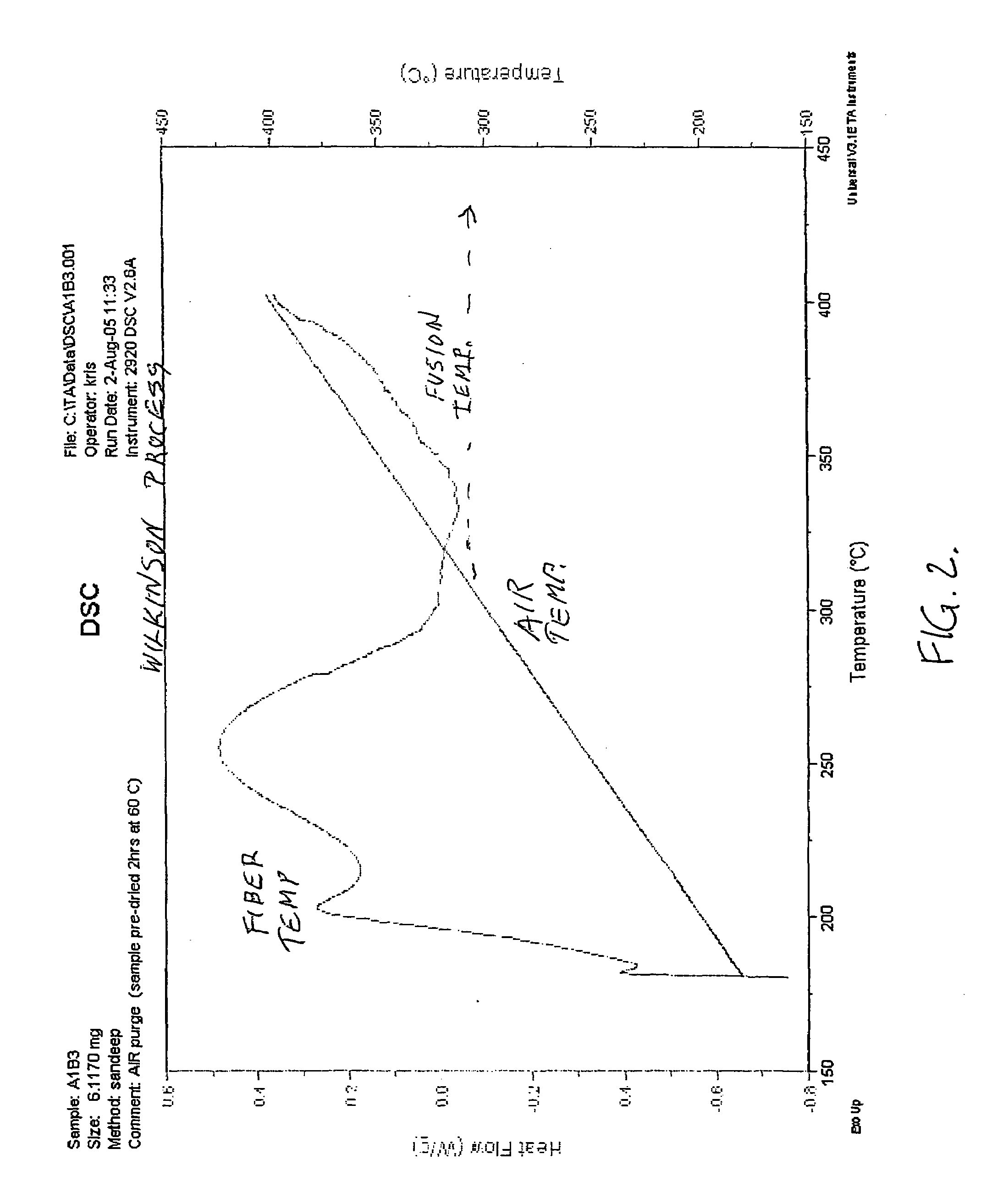

Apparatus and process for preparing superior carbon fiber

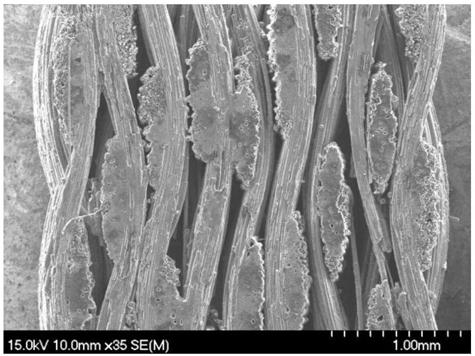

ActiveUS20090224420A1Improving efficiency and economicsRapid densificationArtificial filament heat treatmentMonocomponent synthetic polymer artificial filamentFiberPolymer science

A process for preparing superior carbon fiber including a step of rapid imbibation of densification activator from an aqueous bath; and product prepared therefrom.

Owner:INT FIBERS

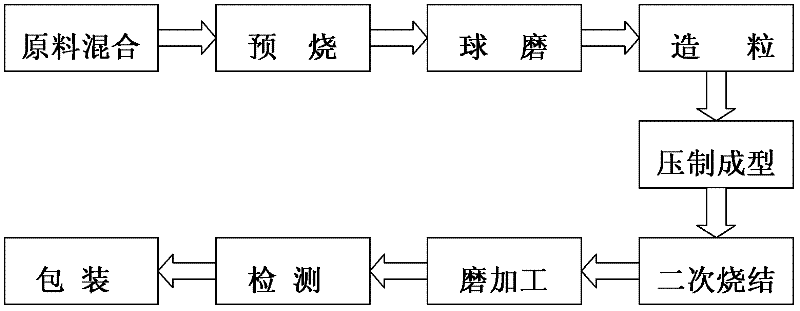

Method for producing soft magnetic ferrite core

InactiveCN102643083AImprove permeabilityLow dissipation factorEdge grinding machinesPolishing machinesInitial permeabilitySoft magnet

The invention discloses a method for producing a soft magnetic ferrite core. The method comprises the following steps of: mixing of raw materials, pre-sintering, ball milling, compression moulding, secondary sintering, grinding and detection, wherein an integral magnetic-attraction double-sided grinding machine is adopted in the grinding process. The magnetic core produced by the method has high magnetic conductivity and low loss factor, and energy sources can be saved; the magnetic core has uniform color, flat end surface and bright and clean surface; the ball milling as well as the uniformity and sphericity of the mixed material are improved; a low-temperature sintering technology is adopted, the heating rate and cooling rate of each stage are adjusted, the ferrite transformation of the material is promoted, and the grain size can be effectively controlled; and the initial permeability and temperature characteristic are improved.

Owner:ANHUI TAIDE ELECTRONICS TECH

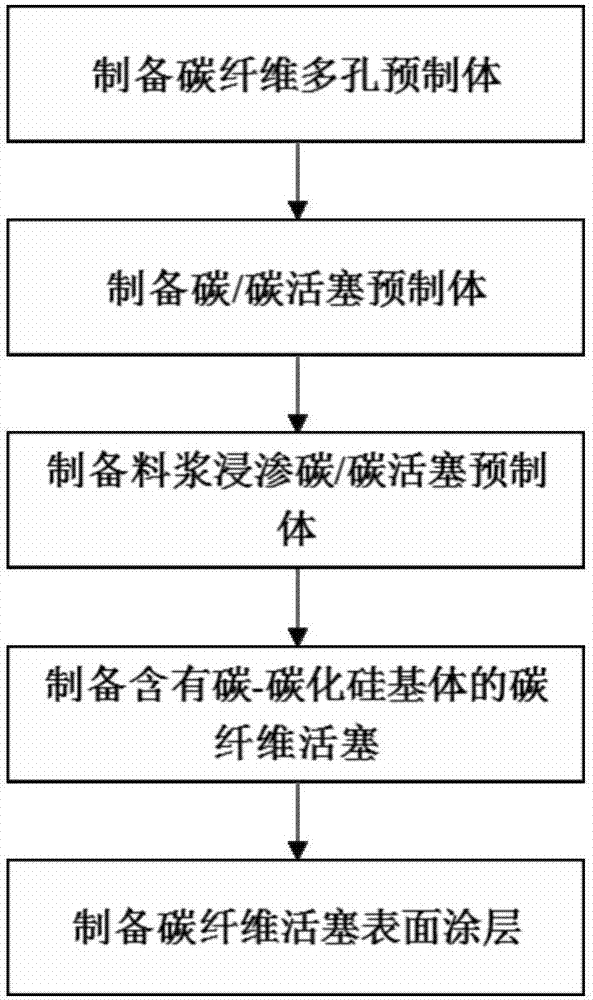

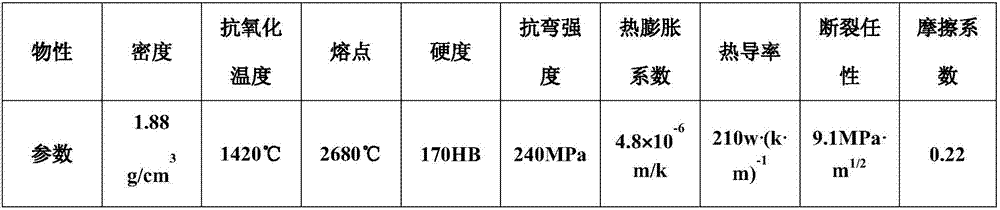

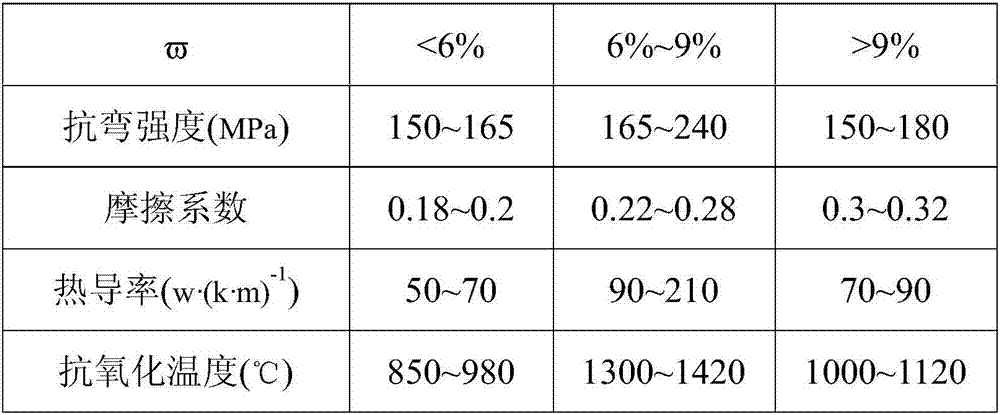

Cf/C-SiC composite material as well as preparation method and application thereof

The invention designs a composite material. The composite material comprises carbon-fiber perform, matrix carbon, filler and diamond-like carbon, wherein the matrix carbon is uniformly adhered on the carbon fiber of the perform to form the carbon-fiber perform with the matrix carbon; the filler fills the inside of the carbon-fiber perform with the matrix carbon and coats the outside of the carbon-fiber perform with the matrix carbon to form a semifinished product; the diamond-like carbon comprises a diamond-like carbon layer coated on the semifinished product; and the filler contains a Ti element, a Si element, a C element and a Mo element. The composite material has the advantages that a method of combining four processes of CVI, SI, RMI and PECVD to prepare a finished product with the advantages of high compactness, low thermal expansion coefficient and friction coefficient, high self-lubricating property, high thermal conductivity, oxidation resistance, thermal shock resistance, ablation resistance, wear resistance, high strength and toughness and the like; and simultaneously, the process is simple, the preparation period is short, the equipment requirement is low, the cost is low, net shaping can be realized and convenience is brought for large-scale industrial application.

Owner:XIANGTAN UNIV

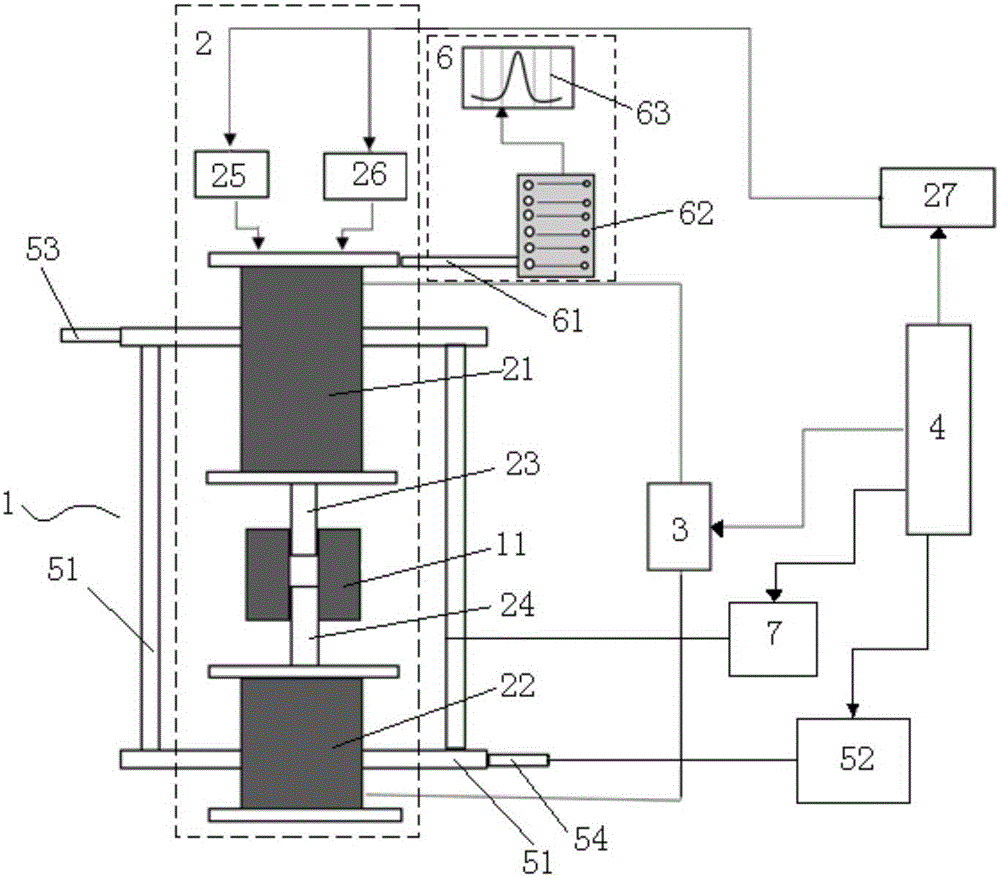

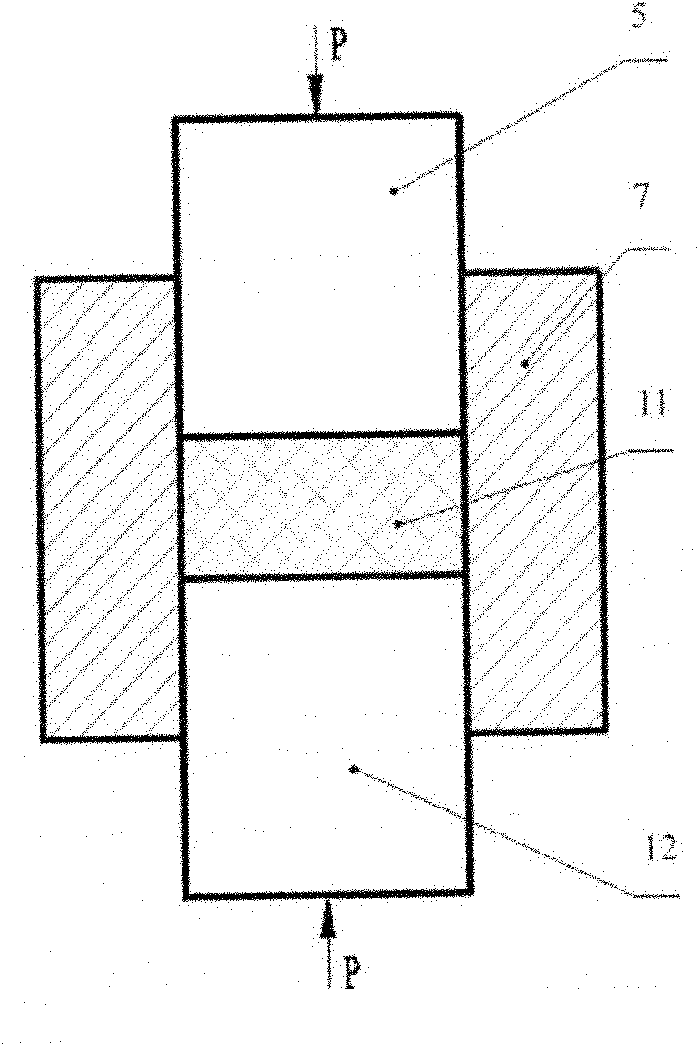

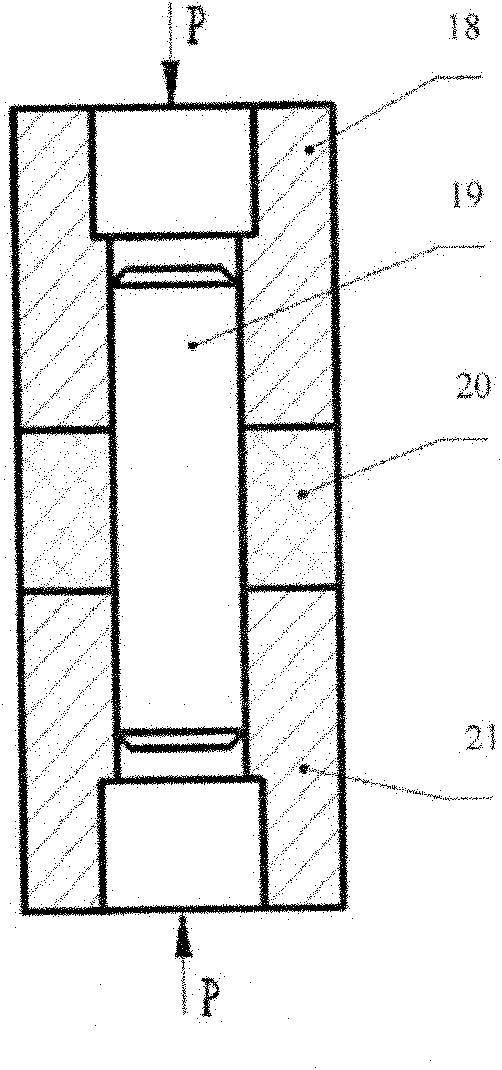

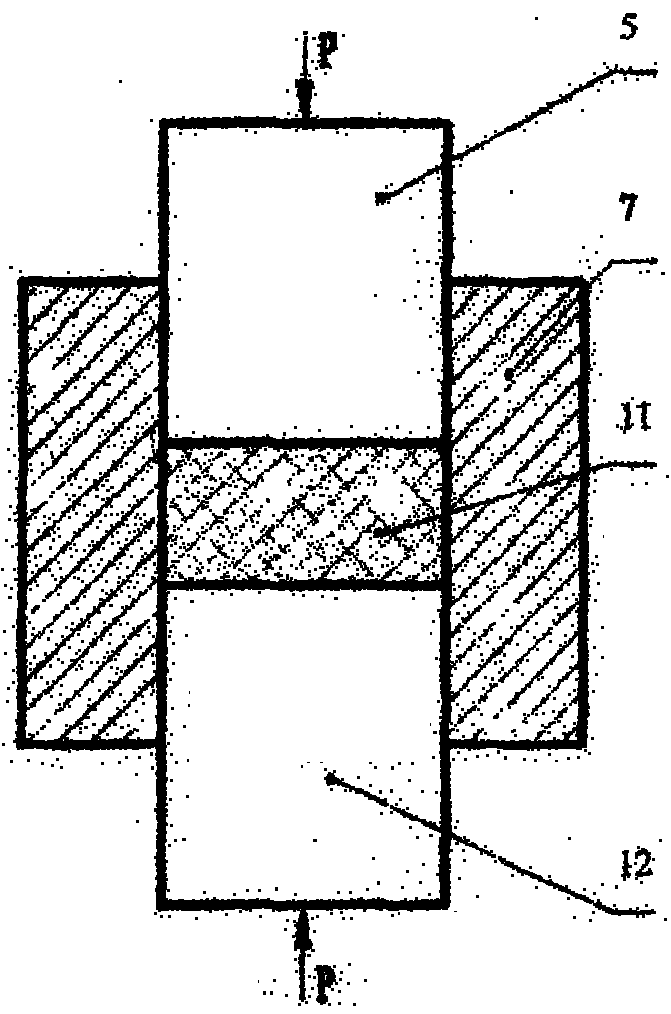

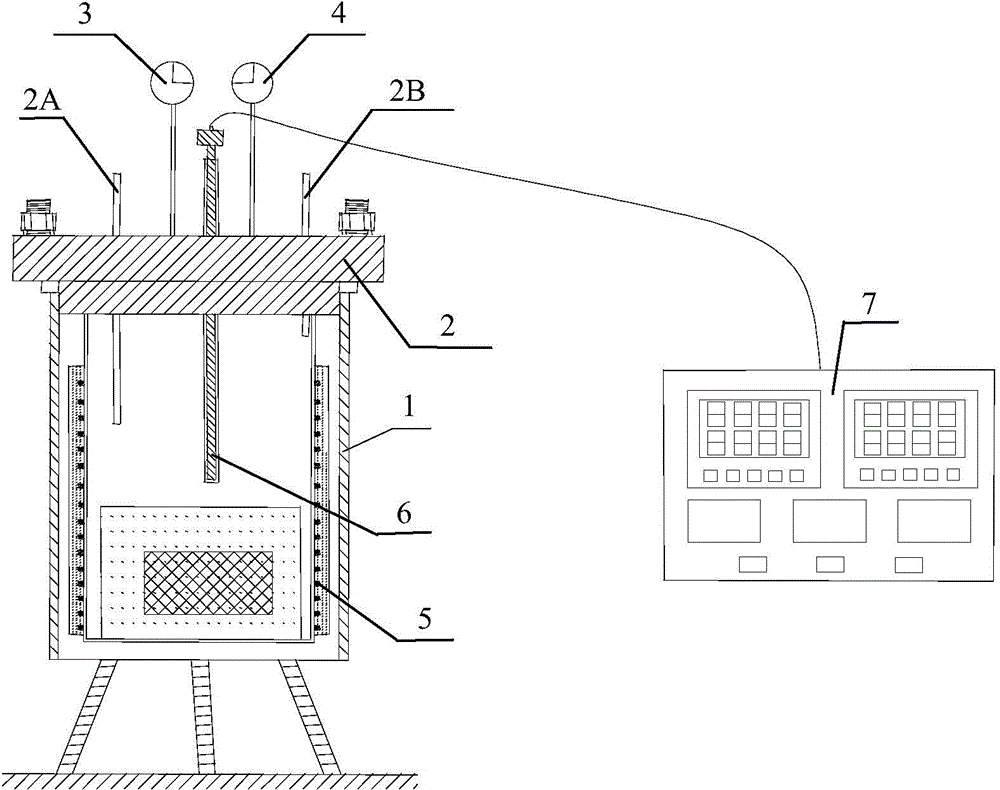

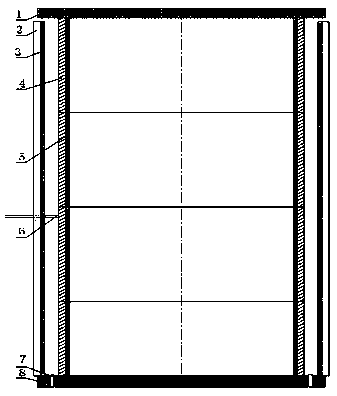

Dynamic pressure electric pulse double-field control sintering furnace and sintering method

ActiveCN105135873ALower sintering temperatureShorten the sintering timeMuffle furnacesMaintainance of heating chambersElectrical impulseDynamic pressure

The invention relates to a dynamic pressure electric pulse double-field control sintering furnace and a sintering method. The sintering furnace comprises a furnace body, a dynamic pressure system, a pulse current generator and a sintering controller. The furnace body is connected with the dynamic pressure system and the pulse current generator. The dynamic pressure system and the pulse current generator are both connected to the sintering controller. A die is arranged in the furnace body. The dynamic pressure system comprises an upper press head electrode, a lower press head electrode, an upper press head, a lower press head, a constant pressure control module, a dynamic pressure control module and a pressure master control module. The dynamic pressure system is connected with the sintering controller. The pulse current generator is connected with the upper press head electrode and the lower press head electrode and connected with the sintering controller as well. The sintering controller controls the dynamic pressure system and the pulse current generator to generate the adjustable dynamic pressure for a material to be sintered and conduct plasma pulse current sintering on the material to be sintered. The dynamic pressure electric pulse double-field control sintering furnace and the sintering method can be widely applied to sintering of the high-performance material.

Owner:TSINGHUA UNIV

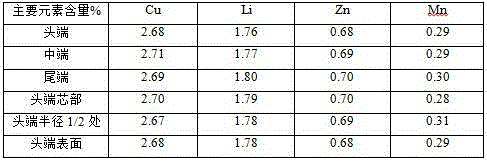

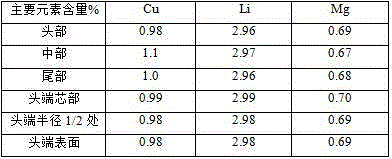

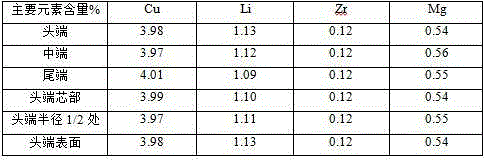

Method for manufacturing three-dimensional large-size aluminum-lithium alloy round ingot through spray forming

The invention relates to aluminum-lithium alloy, in particular to a method for manufacturing a three-dimensional large-size aluminum-lithium alloy round ingot through spray forming. Ar atomization is adopted, spray forming is carried out on aluminum-lithium alloy melt which is subjected to gas removing, slag removing, refining and filtering, and a cylindrical ingot blank is formed; through optimization combination of adjustment of the spraying angle, atomization air pressure, the melt superheating temperature, the receiving disc descending speed and the rotating speed, rapid, precise and compact forming of the aluminum-lithium alloy melt is achieved, and the forming rate is not lower than 10 kg / min; the obtained ingot blank is regular in shape, high in compactness and free of chemical component macrosegregation, and the diameter of the ingot blank can reach phi 650 mm; the yield of the large-size aluminum-lithium alloy ingot blank produced through the method is more than 80%.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

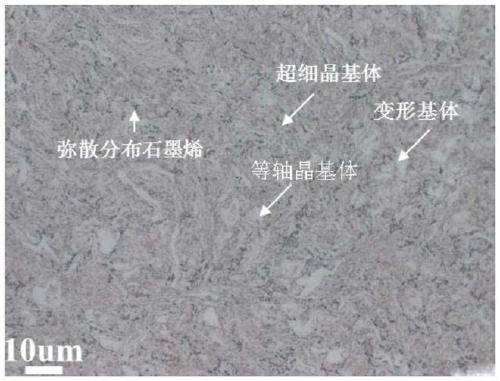

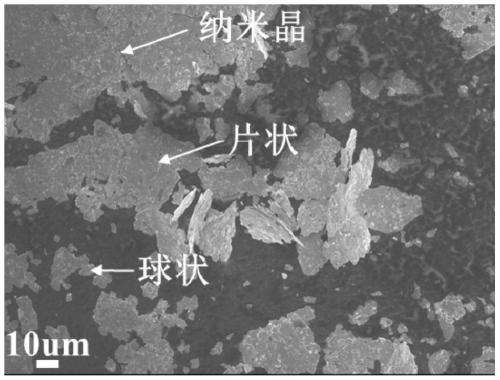

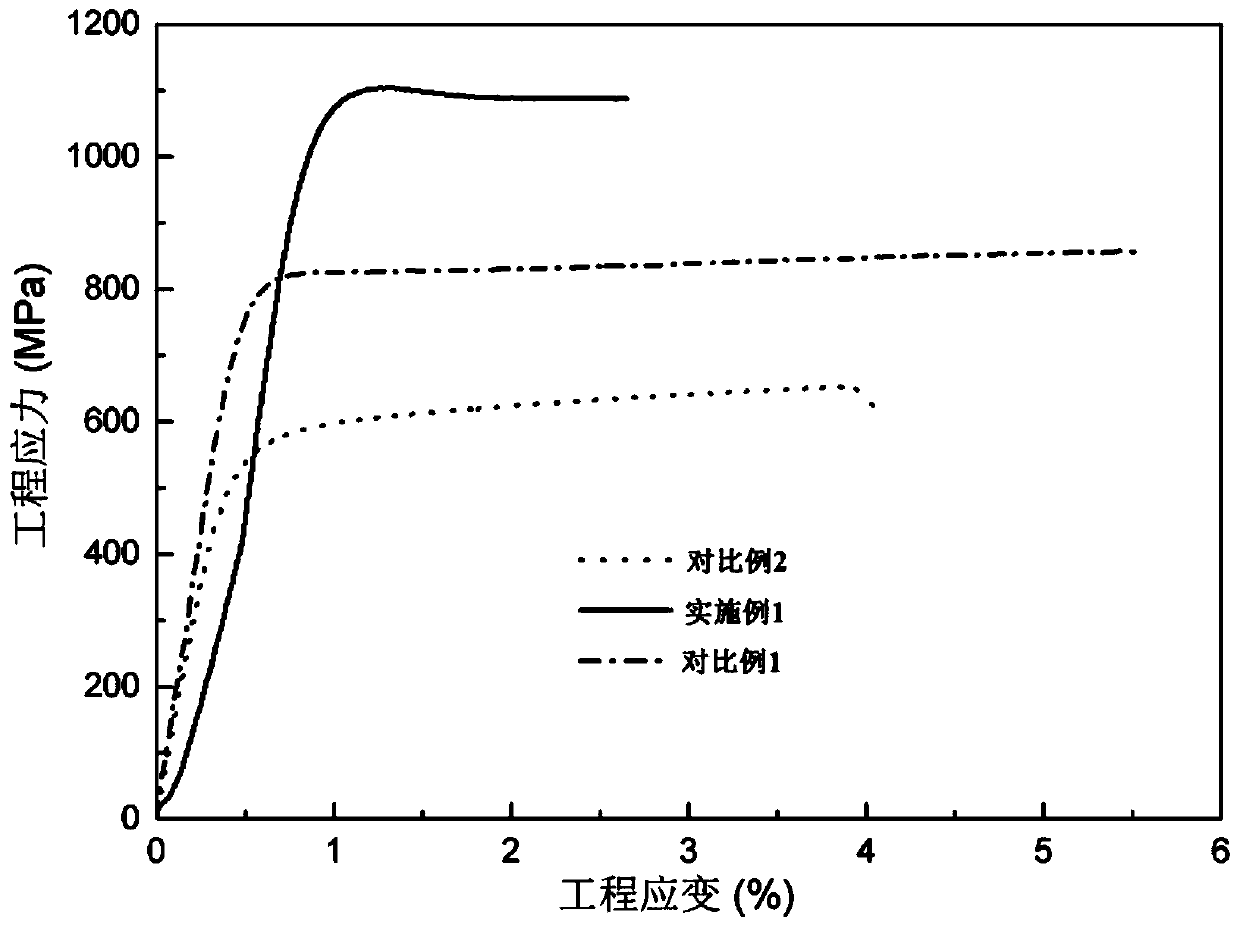

Preparation method of graphene enhanced FCC-type high-entropy alloy

ActiveCN111534712AImprove strong plasticityGood strength and plasticity matchingHigh entropy alloysGraphite

The invention discloses a preparation method of a graphene enhanced FCC-type high-entropy alloy. The method comprises the steps that 1, FCC-type high-entropy alloy powder is prepared by a gas atomization method; 2, the FCC-type high-entropy alloy powder is subjected to ball milling and then dried; 3, the dried FCC-type high-entropy alloy powder is mixed with graphene nanoflakes, then composite powder is obtained by ball milling; and 4, the composite powder is subjected to spark plasma sintering, and the graphene enhanced FCC-type high-entropy alloy is obtained after cooled in a furnace. According to the preparation method, short-time high-energy ball milling is adopted, so that the FCC-type high-entropy alloy powder forms multi-scale lamellar structures and produces fine nanocrystals, combined with low-energy ball milling, the graphene nanoflakes are completely and evenly dispersed between the lamellar structures, the graphene enhanced FCC-type high-entropy alloy with multi-scale crystals is prepared, the strengthening effect is effectively enhanced, and the good matching of strength and plasticity is achieved.

Owner:西安稀有金属材料研究院有限公司 +1

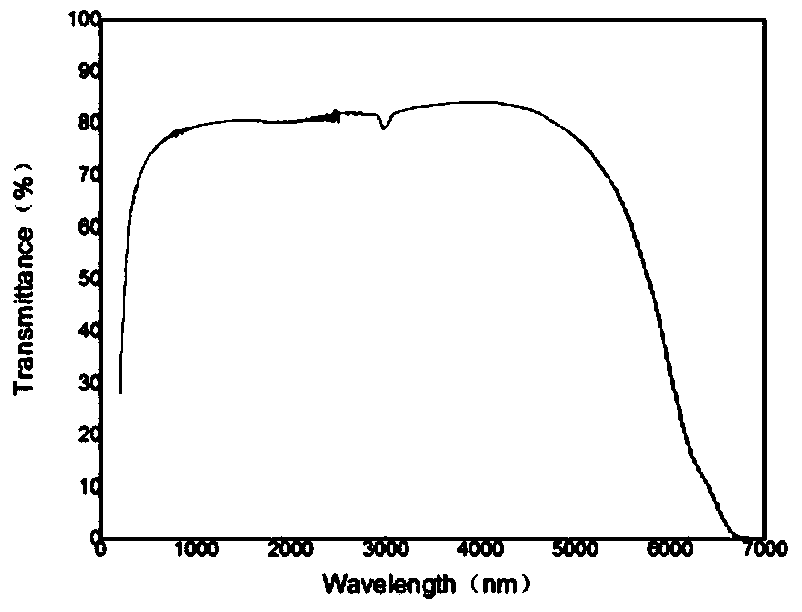

Preparation method of transparent magnesia-alumina spinel ceramic

The invention provides a preparation method of transparent magnesia-alumina spinel ceramic MgO.nAl2O3, wherein n is larger than or equal to 1 and smaller than or equal to 2. The method specifically comprises the steps as follows: 1) MgO powder and alpha-Al2O3 are mixed and ball-milled, a solvent is removed, sieving is performed, and magnesia-alumina spinel powder is obtained after a high-temperature solid-phase reaction and sieving; 2) the magnesia-alumina spinel powder is placed in a graphite mold, the graphite mold is placed in spark plasma sintering equipment for forming and pre-sintering,and a pre-sintered body is obtained; 3) the pre-sintered body is placed in a muffle furnace to be sintered again, natural cooling is performed, and a pore-closed sintered body is obtained; 4) the pore-closed sintered body is subjected to hot isostatic pressing sintering treatment, a sintered sample is polished, and the transparent magnesia-alumina spinel ceramic is obtained. By means of the method, the sample composition can be controlled, high compactness can be obtained without addition of a sintering aid, large-scale industrial production can be performed through sintering in non-pressure air, and the production cost can be reduced.

Owner:WUHAN UNIV OF TECH

VPI-RTM-CVD brake disc preform densification

Method of manufacturing dense carbon-carbon composite material by: infiltrating a fibrous preform with pitch to form pitch-infiltrated preform; carbonizing the pitch-infiltrated preform; injecting resin or pitch into the preform in a mold; oxygen stabilizing the filled preform and carbonizing and heat-treating the oxygen-stabilized impregnated preform; and subjecting the preform to a single final cycle of chemical vapor deposition. This process reduces densification time as compared to comparable conventional carbon-carbon composite manufacturing procedures.

Owner:HONEYWELL INT INC

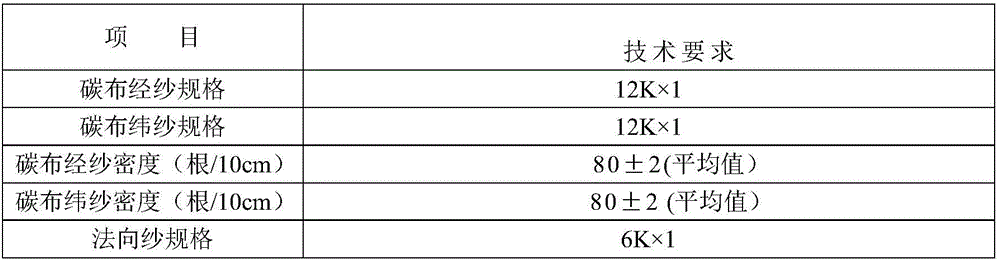

Method for rapidly densifying high-density full-gaseous phase pyrolytic carbon-based carbon/carbon composite materials

The invention relates to a method for rapidly densifying high-density full-gaseous phase pyrolytic carbon-based carbon / carbon composite materials, comprising the following steps of: densifying a 2D or quasi-3D prefabricator to 1.50-1.70 g / cm<3> by using the conventional CVI (Chemical Vapor Infiltration) to obtain carbon / carbon composite materials using full-coarse layer structure pyrolytic carbon as base carbon; then pressurizing to 30-50 MPa step by step after heating the carbon / carbon composite materials to 2300 DEG C-2700 DEG C, controlling the strain of a pressing direction not to be greater than 8%, and unloading step by step after keeping the pressure for 5-10 minutes; and cooling carbon / carbon workpieces along with a furnace to obtain the carbon / carbon composite materials with the density not less than 1.8 g / cm. The method has the advantages of simple process and convenient operation, is used for rapidly densifying the C / C composite materials through high-temperature hot pressing on the basis of the full-gaseous phase pyrolytic carbon-based carbon / carbon composite materials, is especially suitable for manufacturing high-performance C / C composite aviation brake discs, and is also suitable for manufacturing carbon ceramic composite material disc parts in principle.

Owner:CENT SOUTH UNIV

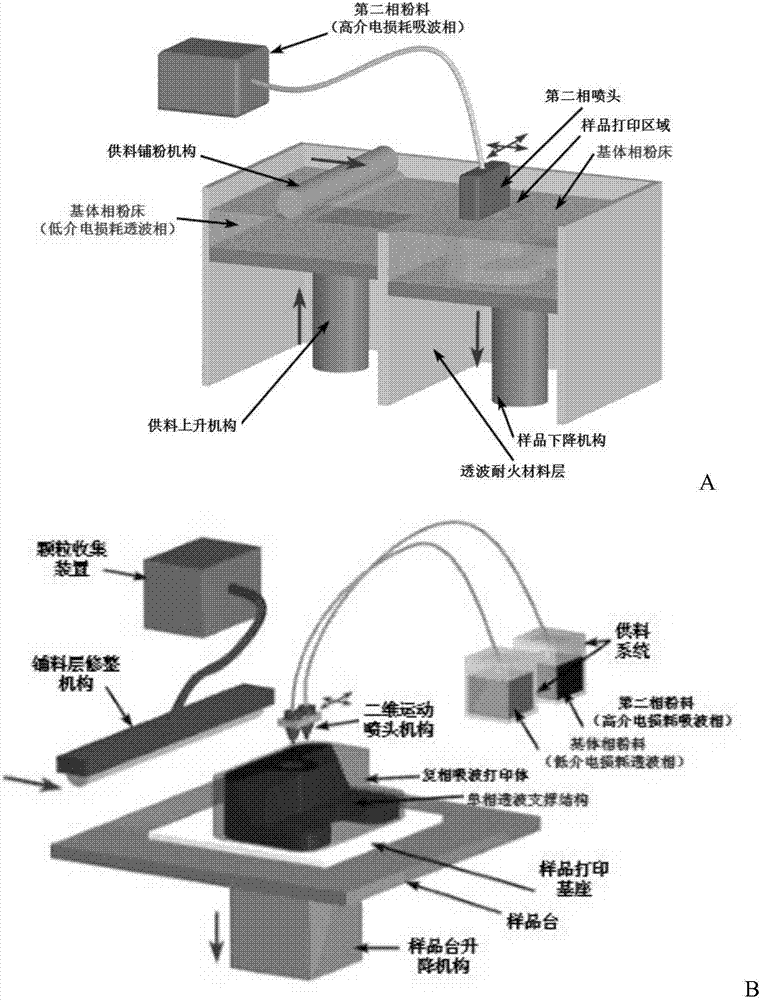

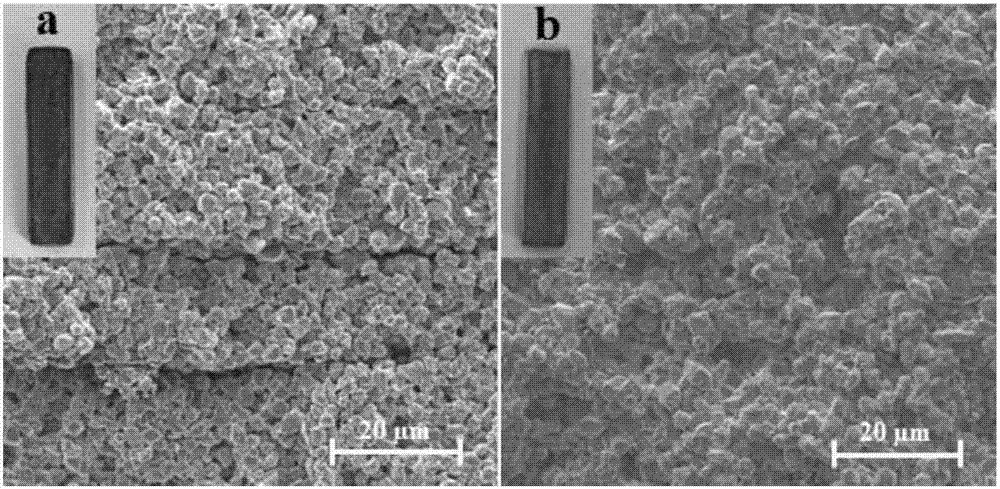

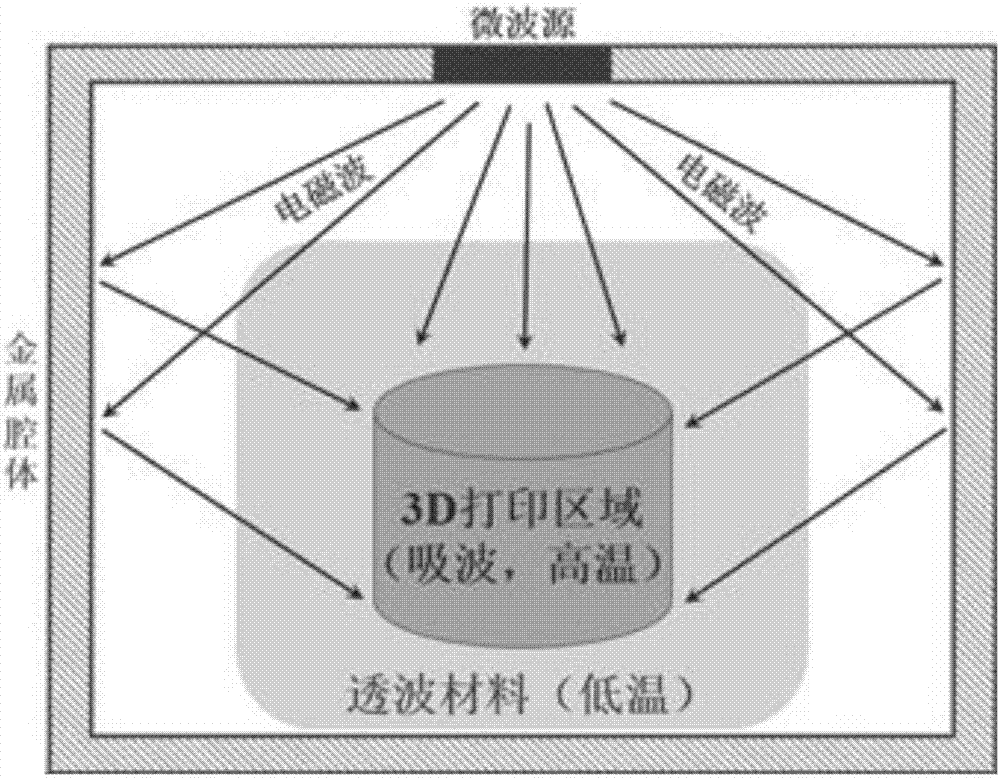

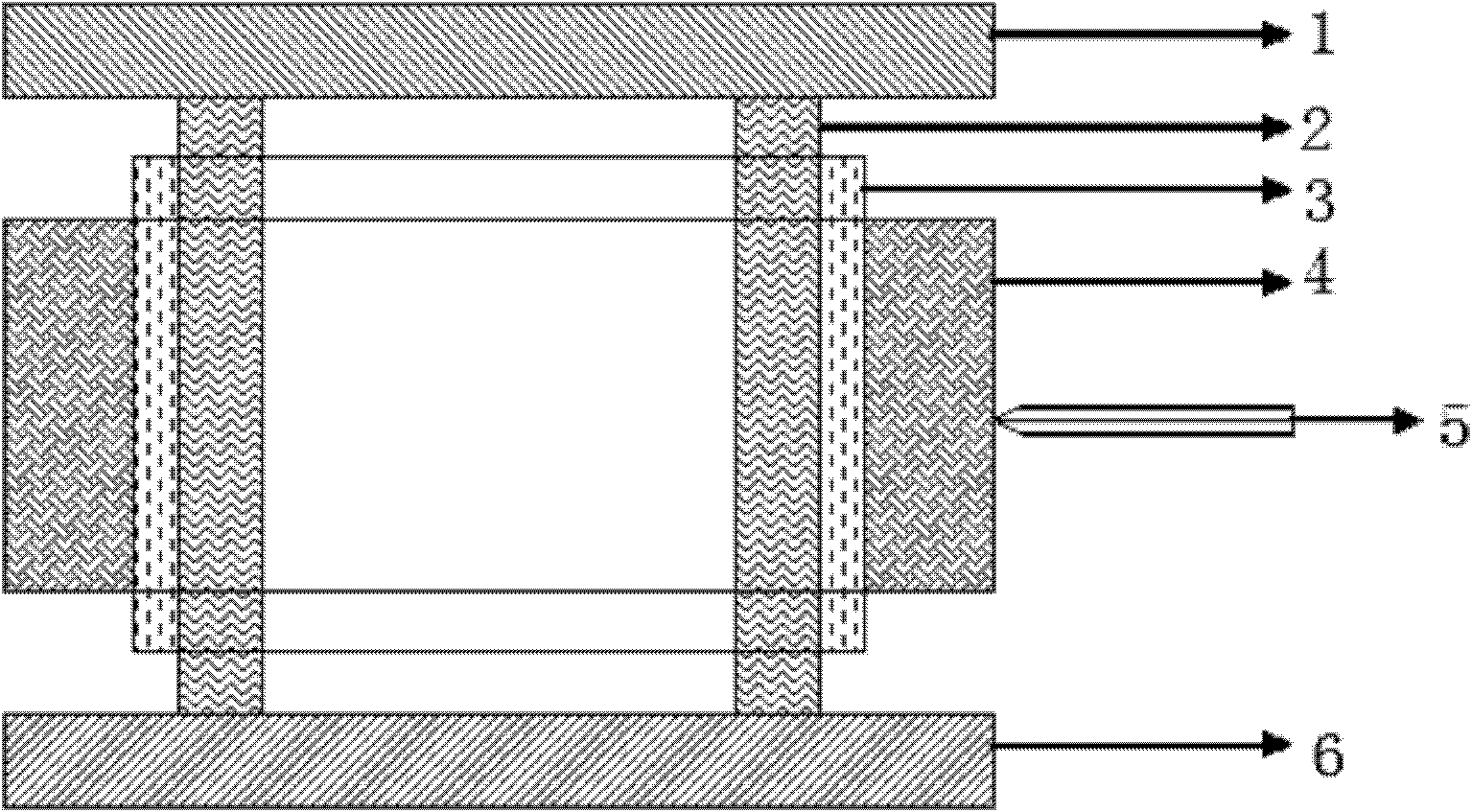

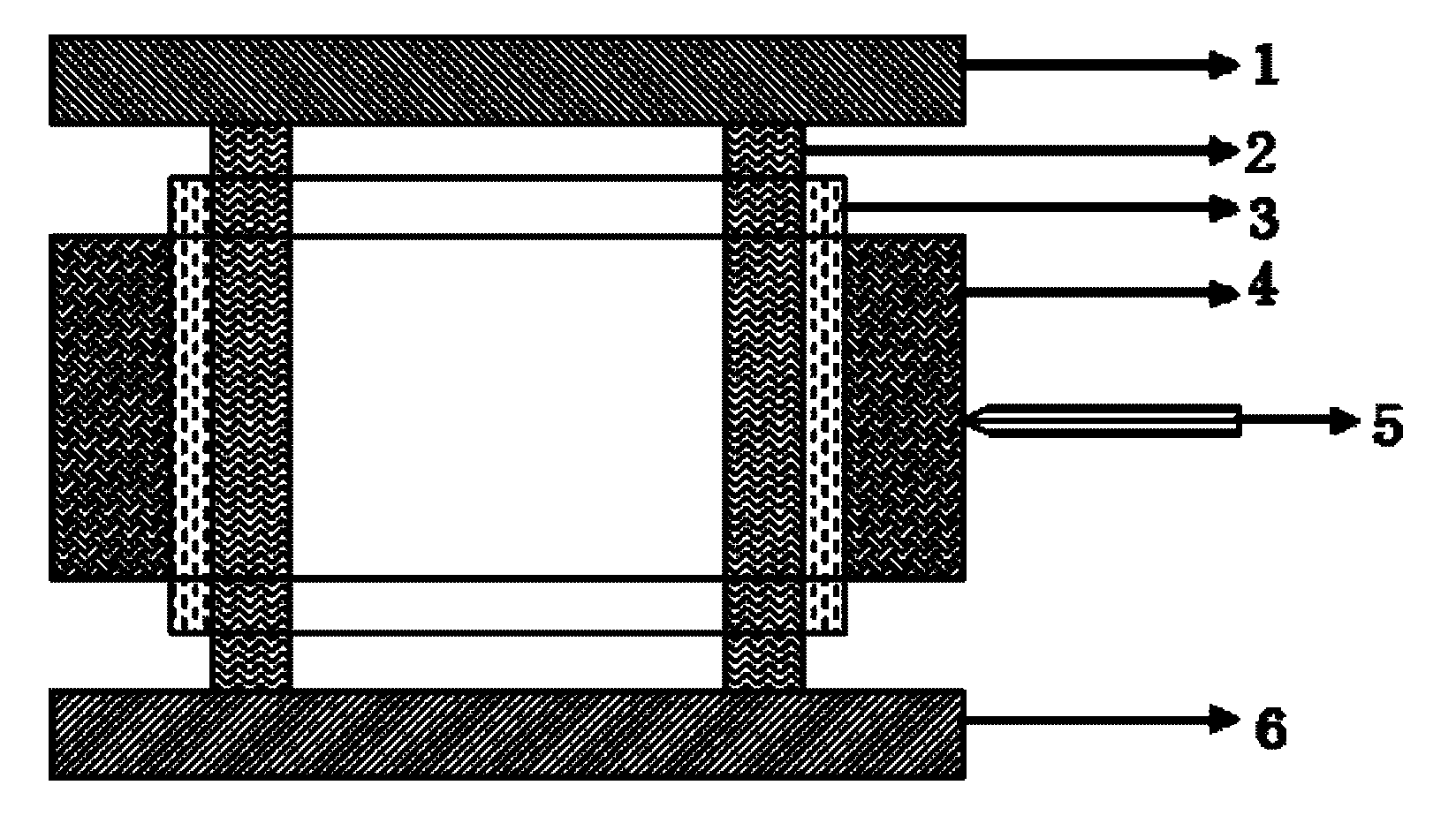

3D printing method for ceramic material

InactiveCN107216153AEnables selective heatingAchieve solidificationAdditive manufacturing apparatusElectricityMicrowave

The invention provides a 3D printing method for a ceramic material. The 3D printing method comprises the following steps: A) distributing a material with high dielectric loss into the powder of a material with low dielectric loss so as to form a printing body; and B) placing the printing body obtained in the step A) in a microwave electromagnetic field for curing and sintering of the printing body. The 3D printing method provided by the invention is based on the characteristics of selective heating and integral heating of electromagnetic waves; when a supporting structure totally wraps the printing body, selective heating, curing and sintering of a printing area are realized, and structural uniformity is improved; meanwhile, outfield auxiliary effect can promote mass transfer process, so rapid densification of the ceramic material is realized; and a microstructure different from the microstructures of conventional sintering products can be obtained while the macrostructure of the shape of the ceramic material is designed, controllable manufacturing of organizational structures of different sizes can be realized, and thus, structure-function integrated designing and manufacturing of the ceramic material is realized. The 3D printing method has the characteristics of simple raw material treatment and low printing cost and has the potential of industrial application.

Owner:GUANGDONG UNIV OF TECH

Quick carbon deposition method of carbon/carbon material member

ActiveCN101798078ASolve the problem that the movement needs to punch holes in the productIntegrity guaranteedFiberCarbon fibers

The invention provides a quick carbon deposition method of a carbon / carbon material member, which comprises the following steps: (1) putting a carbon fiber preform into a high-temperature graphitizing furnace for high-temperature pretreatment; (2) fixedly connecting the carbon fiber preform with a heating unit, and isolating the carbon fiber preform from the heating unit by an isolator; (3) putting the carbon fiber preform and the heating unit assembly into a deposition chamber, putting a thermocouple on the external surface of the carbon fiber preform, vacuumizing for eliminating atmosphere firstly, and then, introducing reaction gas; and (4) heating the heating unit, and carrying out vapor deposition of carbon for 20-200h to prepare the carbon / carbon material member once. In the method of the invention for preparing the carbon / carbon member, the thermocouple only needs to be put on the external surface of the member, thus the member does not need to be perforated in the process of preparation, and the integrity of the member can be kept. The method of the invention has short production cycle and low process cost, can realize the purpose of quick densification, and is suitable for large-scale production in batches.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

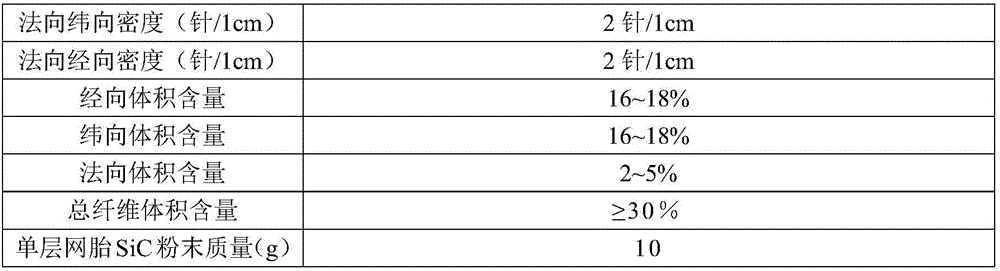

Preparation method of SiCf/SiC composite material with SiC coating layer

PendingCN109400169AImprove hydrothermal corrosion resistanceHigh densityPyrolytic carbonChemical vapor deposition

The invention discloses a preparation method of a SiCf / SiC composite material with a SiC coating layer. The preparation method comprises the following steps: S1, weaving SiC fiber into a SiC fiber weaving piece; S2, depositing a pyrolytic carbon interface coating layer on the surface of the SiC fiber of the SiC fiber weaving piece, thus obtaining a SiC fiber weaving piece with the interface coating layer; S3, carrying out densification treatment on the SiC fiber weaving piece with the interface coating layer through a precursor infiltration and pyrolysis technology, thus obtaining the SiCf / SiCcomposite material, wherein the temperature during pyrolysis is 1400 to 1800 DEG C; S4, depositing the SiC coating layer on the surface of the SiCf / SiC composite material through a CVD (Chemical Vapor Deposition) technology, thus obtaining a hydrothermal corrosion-resistant SiCf / SiC composite material with the SiC coating layer. The SiCf / SiC composite material with the SiC coating layer, preparedby the preparation method disclosed by the invention has hydrothermal corrosion resistance.

Owner:NAT UNIV OF DEFENSE TECH

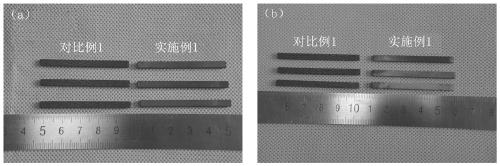

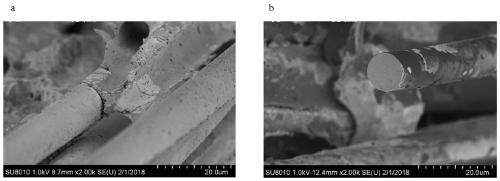

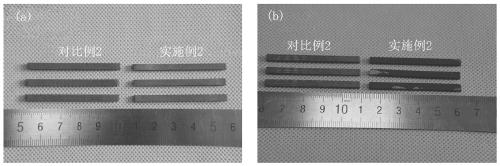

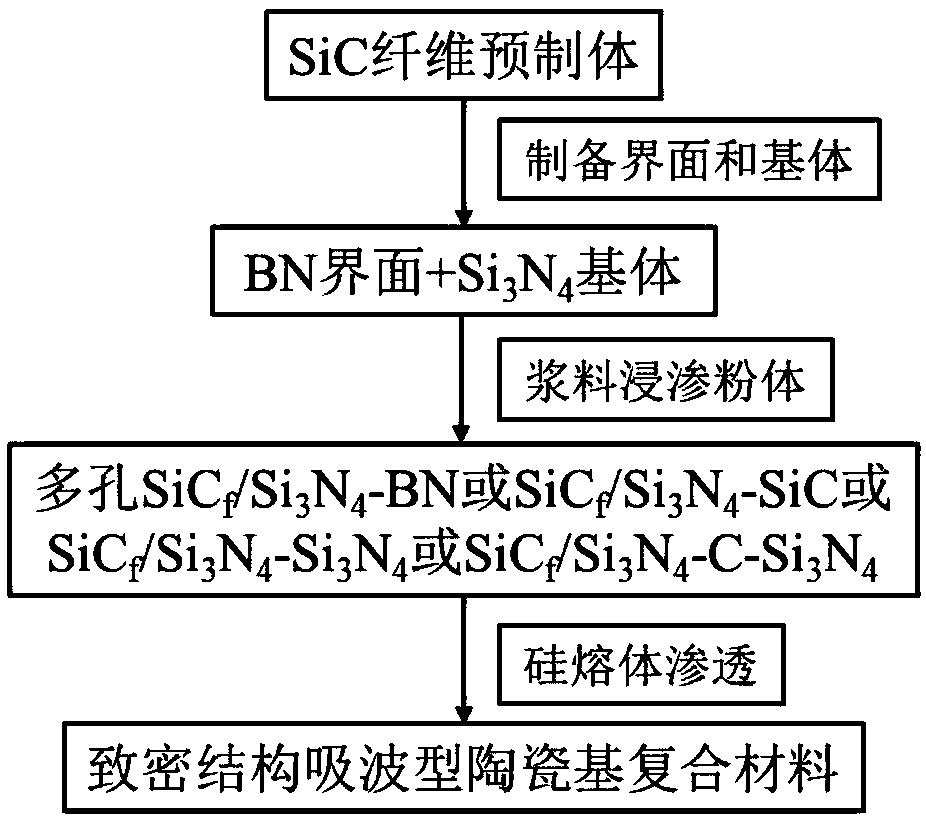

Rapid preparation method of high-temperature-resistant structured wave-absorbing ceramic matrix composite material

ActiveCN109020588AShorten the manufacturing cycleReduce manufacturing costImpedance matchingSic fiber

The invention relates to a rapid preparation method of a high-temperature-resistant structured wave-absorbing ceramic matrix composite material. The SI+RMI process is adopted to prepare a SiC fiber-reinforced silicon-based ceramic matrix composite material. Firstly, Si3N4 powder, BN powder, SiC powder, or C + Si3N4 mixed powder is respectively introduced into a SiC fiber preform through the SI process; and then, through the RMI process, a silicon melt is infiltrated into the composite material to be combined with or react with the above powder respectively so as to generate a Si3N4-Si matrix,a Si-B-N matrix, a SiC-Si matrix or a Si-C-N matrix, and an electromagnetic impedance matching type matrix (such as Si3N4-Si, Si-B-N, etc.) or an electromagnetic wave-absorbing type matrix (such as SiC-Si, Si-C-N, etc.) which meets the requirements of the structure wave-absorbing ceramic matrix composite material is prepared. Rapid densification of the composite material is realized, preparation cycle of the composite material is effectively shortened, and density and mechanical / wave-absorbing properties of the composite material are improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

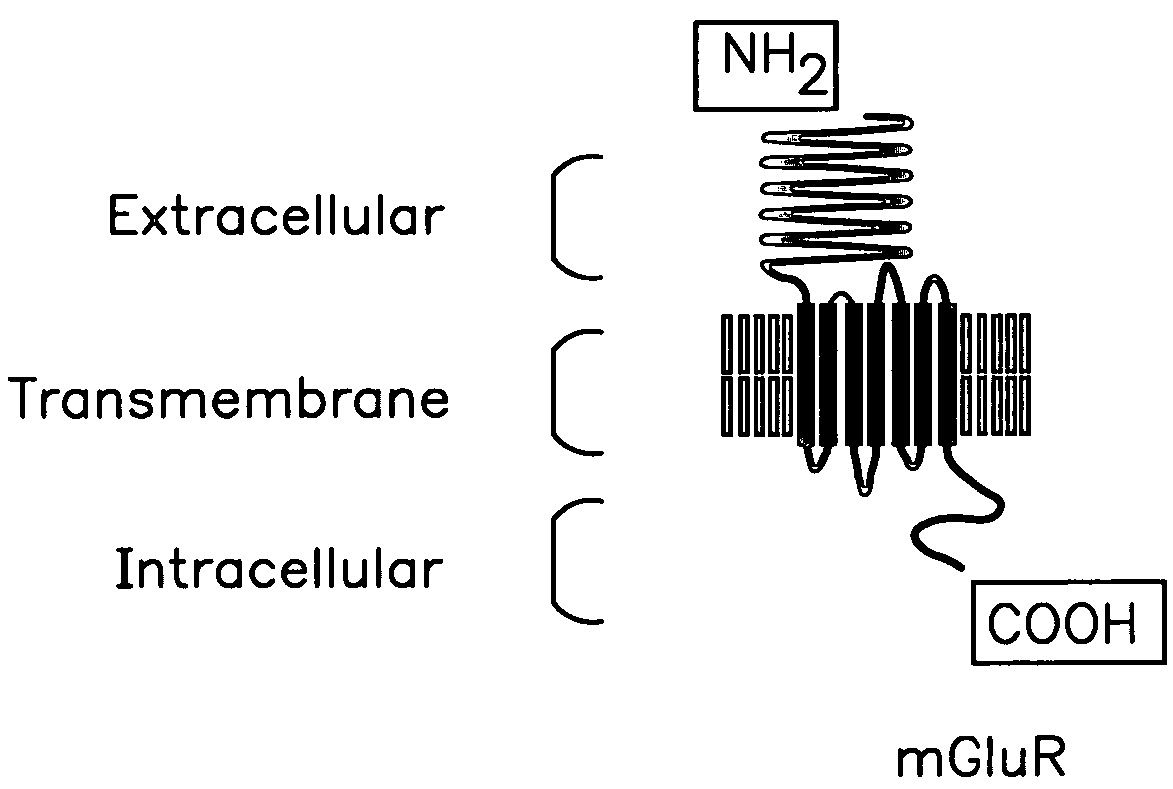

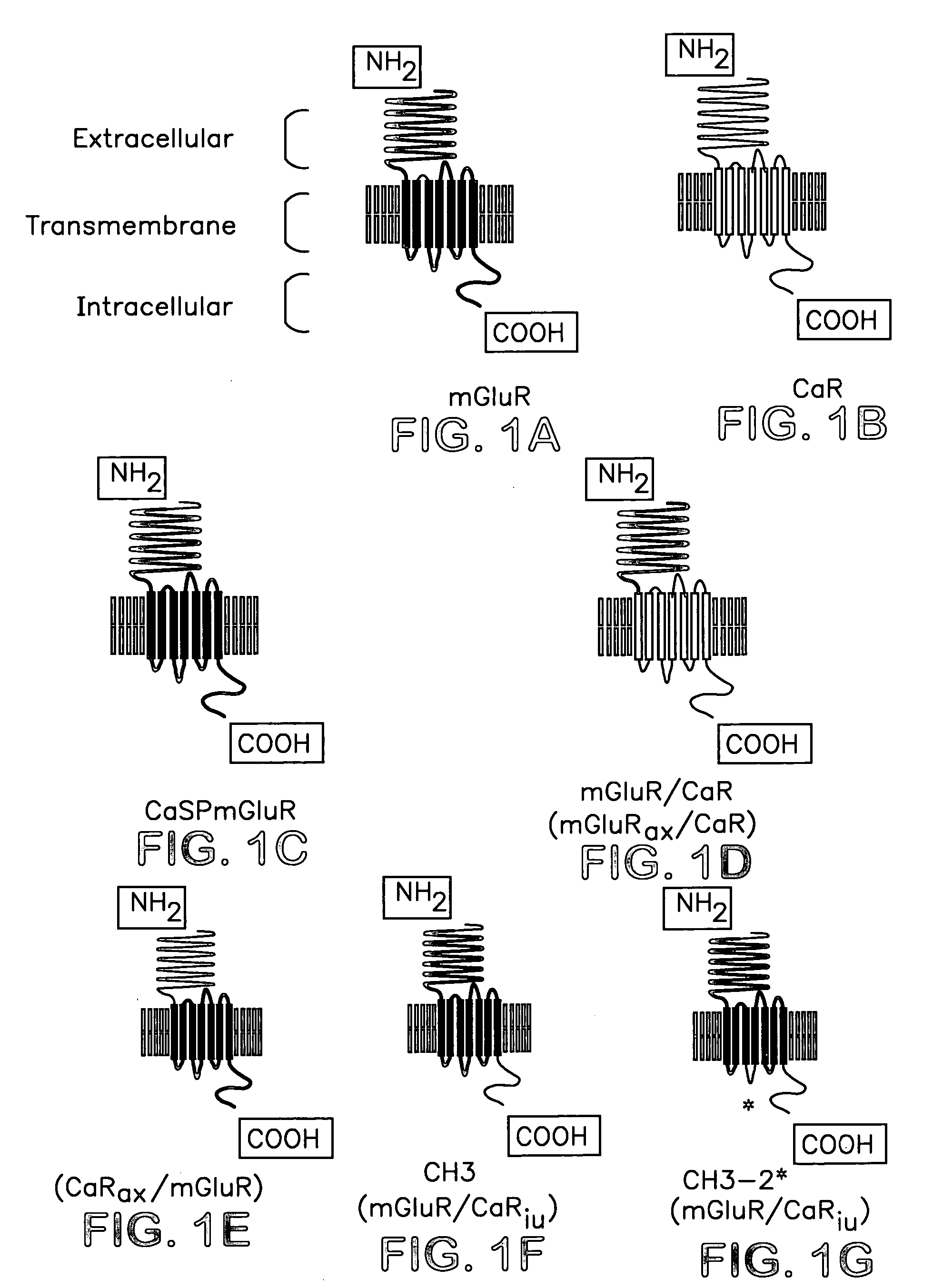

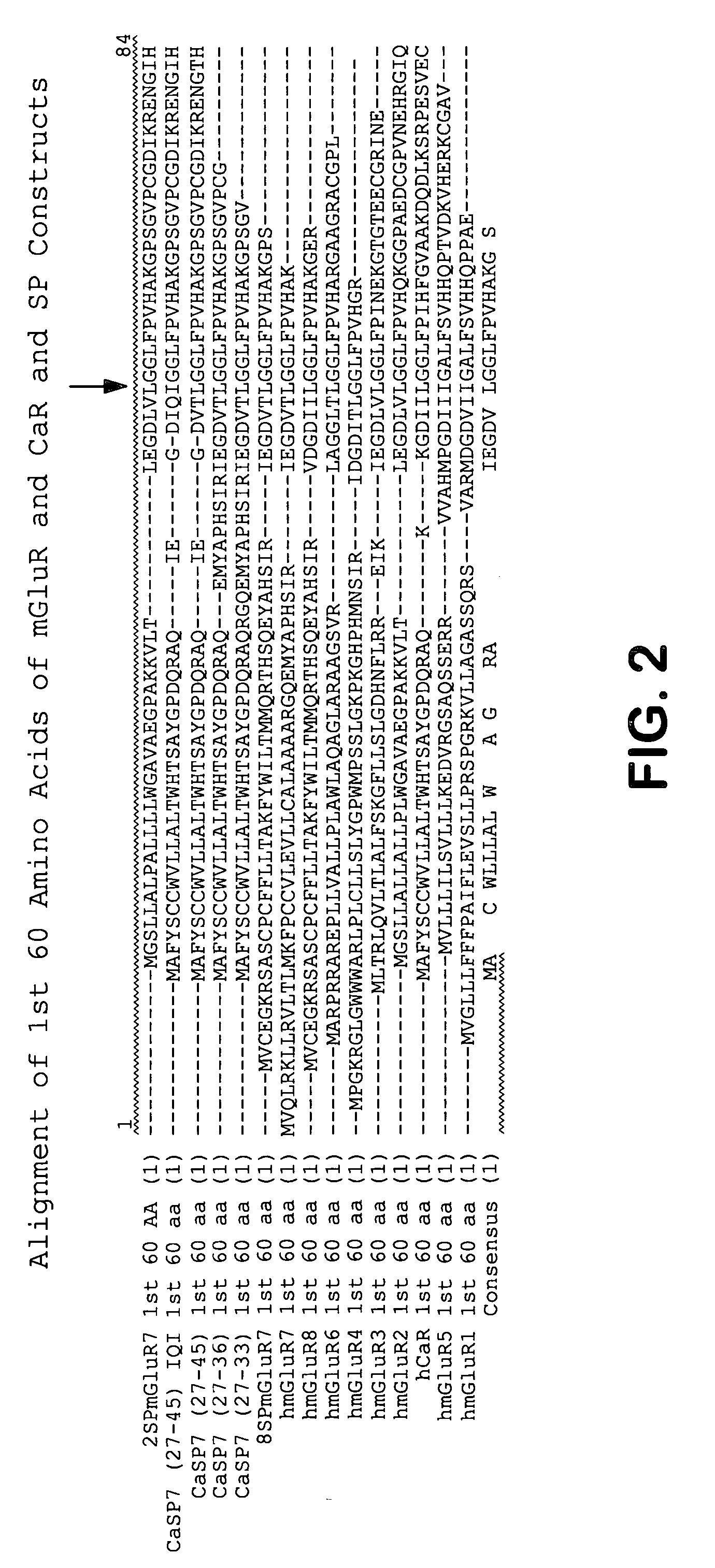

Chimeric metabotropic glutamate receptors and uses thereof

InactiveUS20050186658A1High expressionImprove the level ofPeptide/protein ingredientsAntibody mimetics/scaffoldsMuscle relaxantAnalgesic effect

The present invention provides chimeric receptors that include an extracellular domain from a metabotropic glutamate receptor and a non-native signal peptide, e.g., a calcium receptor signal peptide. The invention also includes methods of preparing such chimeric receptors, and methods of using such receptors to identify and characterize compounds which modulate the activity of metabotropic glutamate receptors. The invention also relates to compounds and methods for modulating metabotropic glutamate receptor activity and binding to metabotropic glutamate receptors. Modulation of metabotropic glutamate receptor activity can be used for different purposes such as treating neurological disorders and diseases, inducing an analgesic effect, cognition enhancement, and inducing a muscle-relaxant effect.

Owner:ASTRAZENECA AB

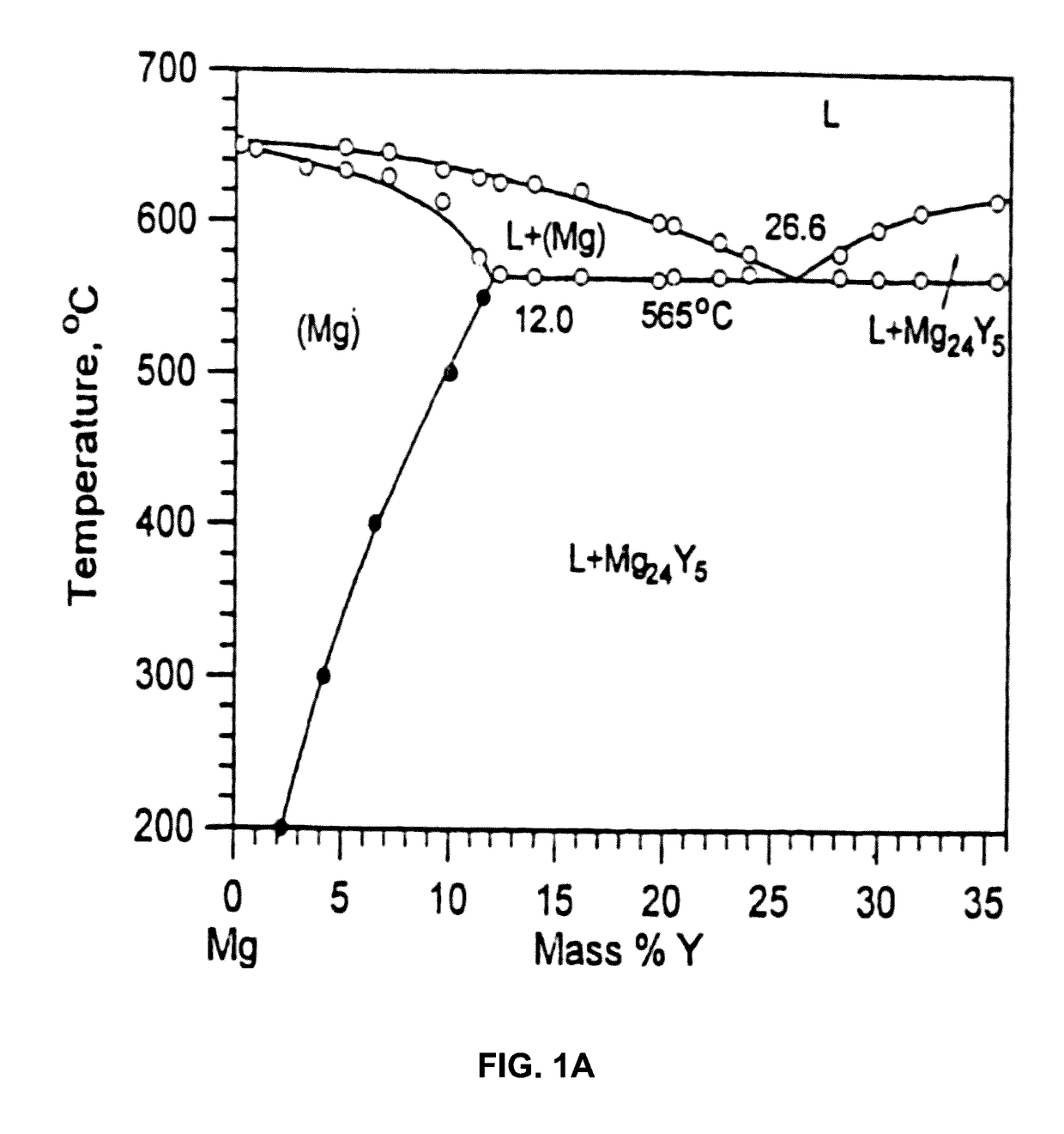

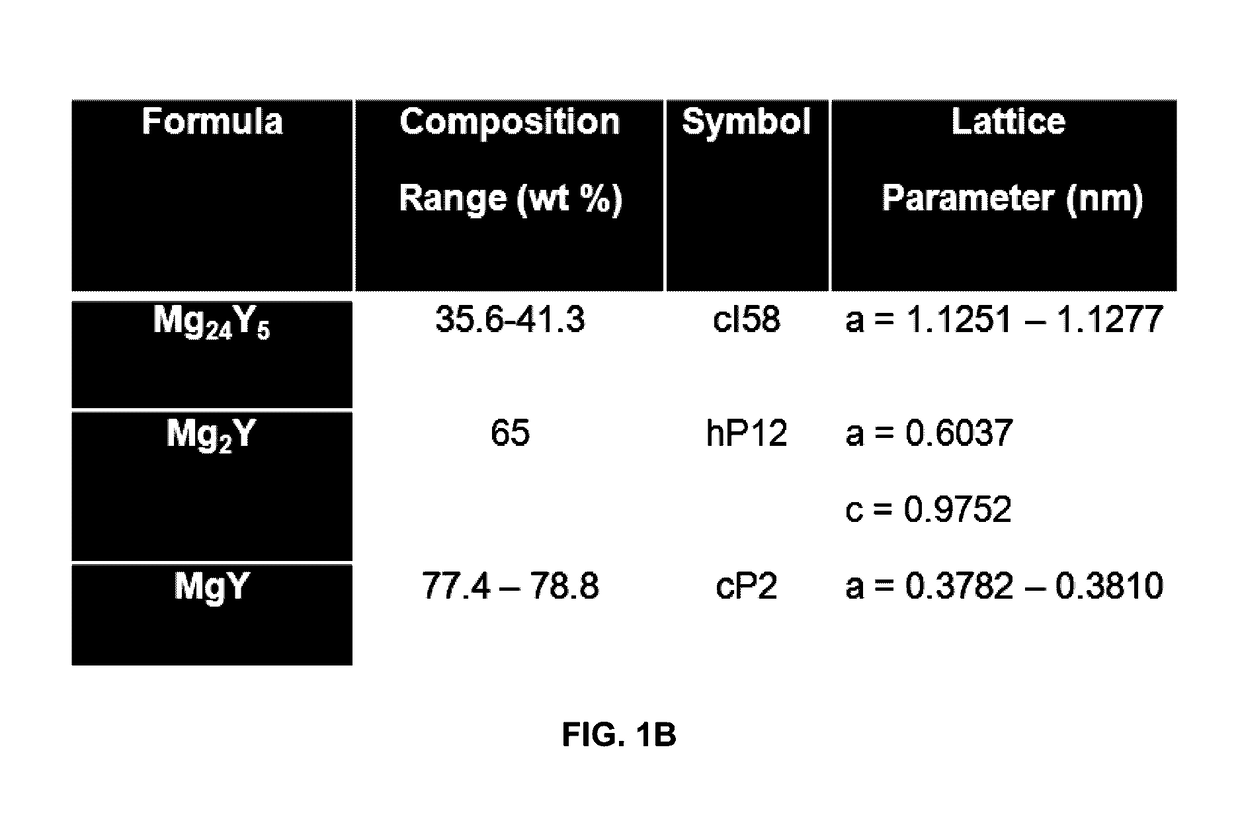

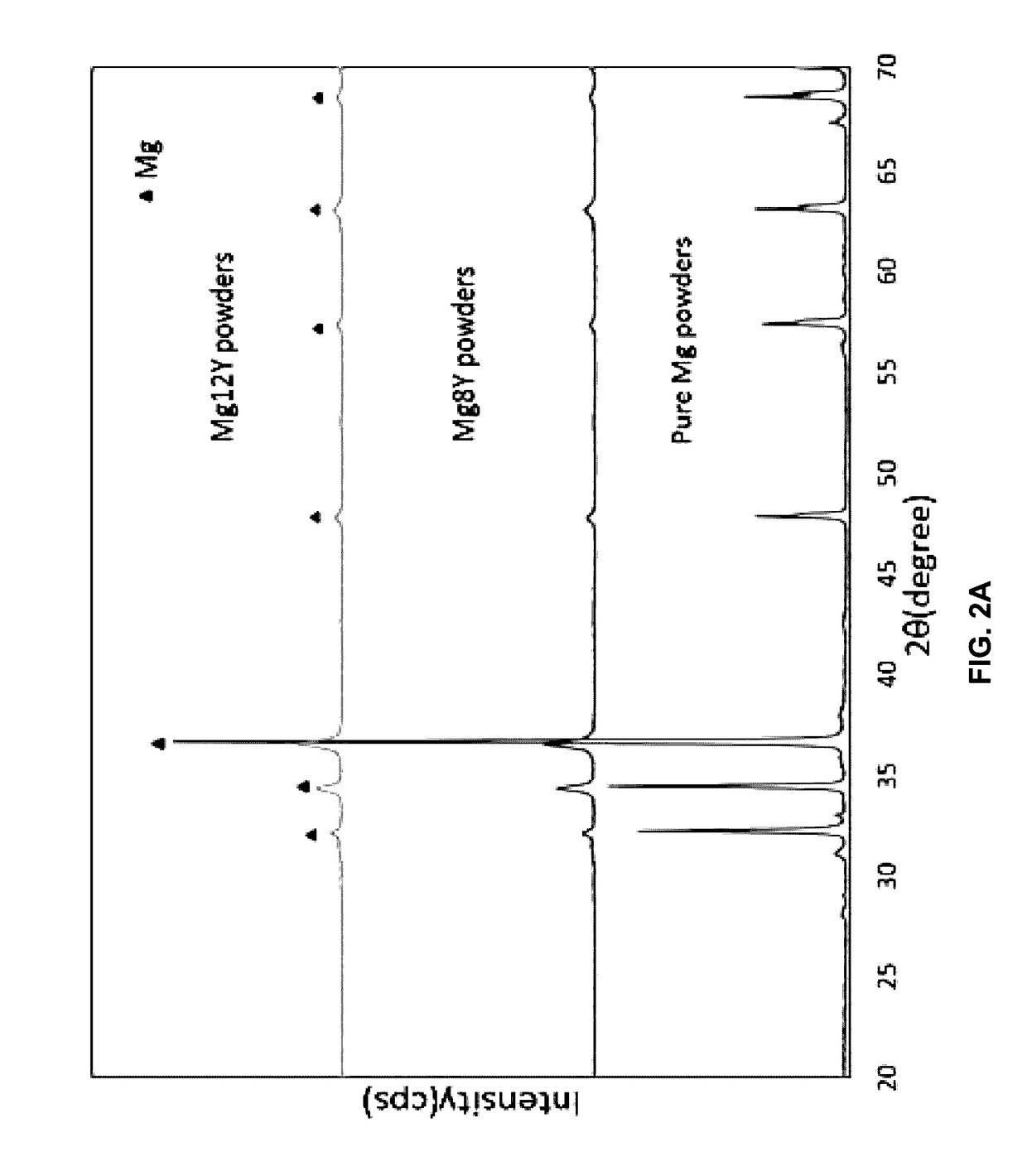

Biodegradable Magnesium Alloys and Composites

ActiveUS20170072103A1Reduce probabilityRapid densificationAdditive manufacturingSurgeryBiodegradable magnesium

Biodegradable, magnesium alloys and composites, articles produced therefrom, methods of making the same, and methods of using the same are described.

Owner:UNIVERSITY OF TOLEDO

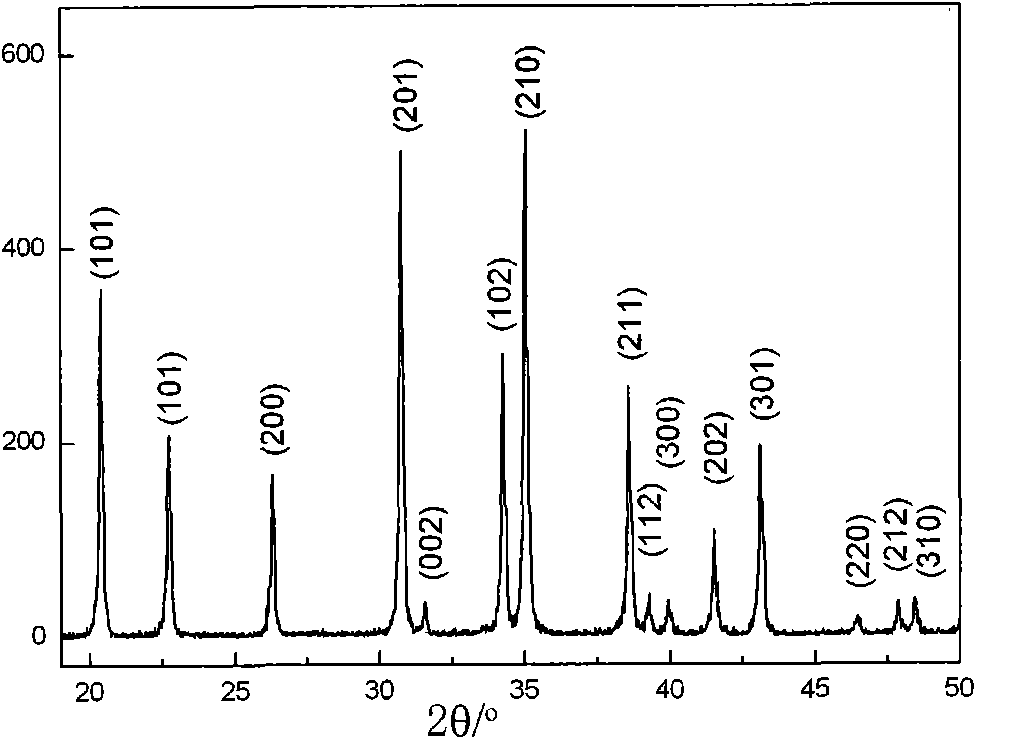

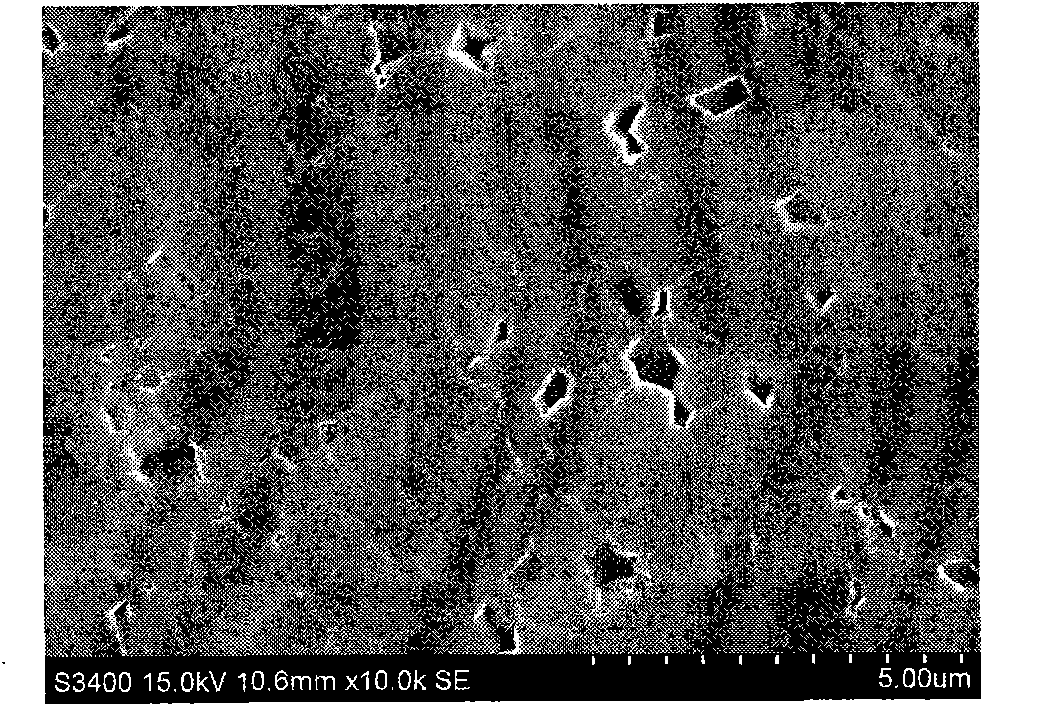

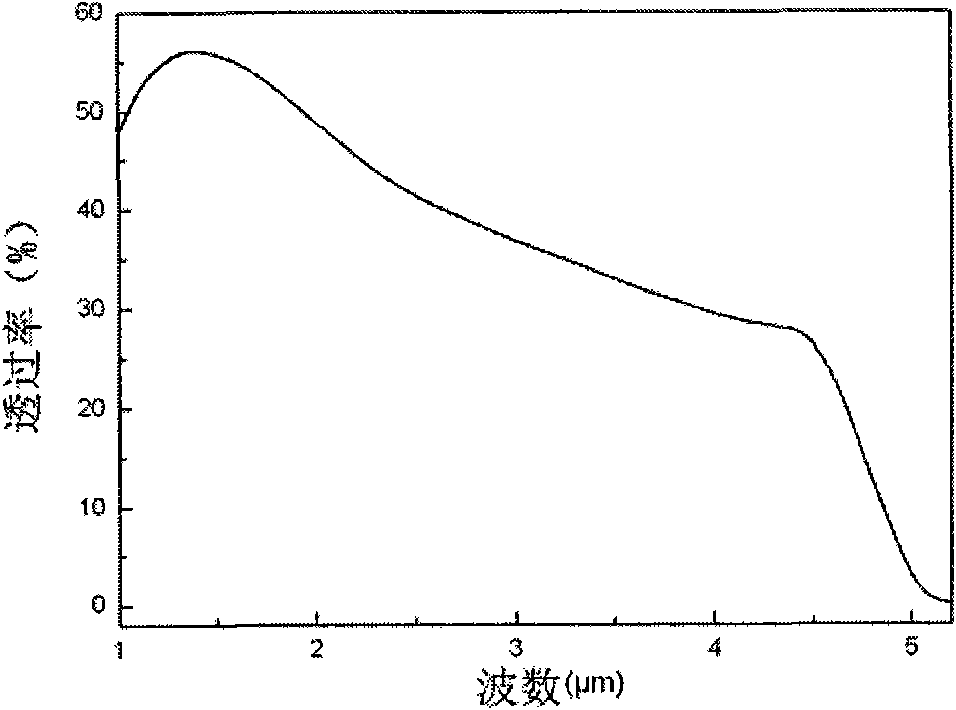

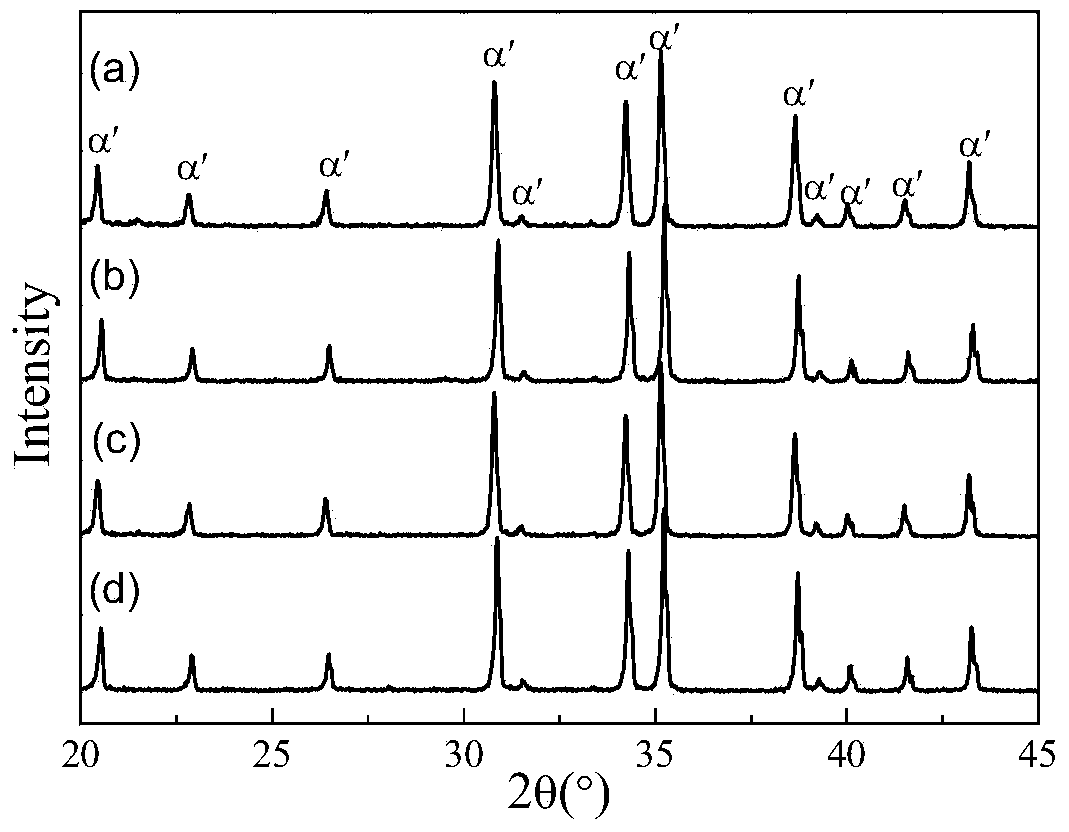

Method for fast preparing translucent Li-alpha-SiAlON ceramic material

The invention relates to a method for fast preparing a translucent Li-alpha-SiAlON ceramic material, comprising the following steps of: selecting and mixing materials of alpha-Si3N4, AlN, alpha-Al2O3 and Li2CO3 according to a general formula of LimSil2-m-nAlm+nOnN16-n, wherein m is larger than 0.4 and less than 2.0, and n is larger than 0.8 and less than 2.0; carrying out ball milling and drying, grinding and screening with a 200-mesh sieve; putting the processed mixture in a discharge plasma sintering furnace at the sintering pressure not less than 20MPa and under the protection of N2 gas, raising the temperature to 950-1050 DEG C, preserving the temperature for 1-3 minutes, then raising the temperature to 1600-1850 DEG C for sintering for 0-20 minutes, and cooling along with the furnace; cutting, grinding and polishing till a mirror surface is formed. The discharge plasma sintering method has simple process, fast temperature raising, low sintering temperature, short time and low energy consumption. The prepared translucent Li-alfa-SiAlON ceramic material has excellent infrared transparency.

Owner:WUHAN UNIV OF TECH

Method for rapidly preparing C/SIC ceramic composite material with pre-introduced matrix

The invention discloses a method for rapidly preparing a C / SIC ceramic composite material with a pre-introduced matrix, and relates to a ceramic matrix composite material and a preparing method thereof. According to the method, the structure of a fabric body is improved, mold pressing and matrix pre-introducing method are creatively provided, the period of the C / SIC ceramic composite material prepared with the PIP technology is greatly shortened, and therefore the aim that the preparing cost is reduced is achieved. The method includes the steps of fabric body processing, fabric body pretreating, precursor soaking, solidifying, mold pressing, high-temperature splitting, soaking, solidifying and splitting; after the increased mass is smaller than 1% of the raw mass, soaking and splitting are stopped, and material preparing is completed. According to the C / SIC ceramic composite material, on the premise that the production period is shortened by 30% to 50%, and the cost is reduced by 30% to 40%, the highest bending strength can reach 325 MPa, and the highest tensile strength can reach 180 MPa.

Owner:湖北三江航天江北机械工程有限公司

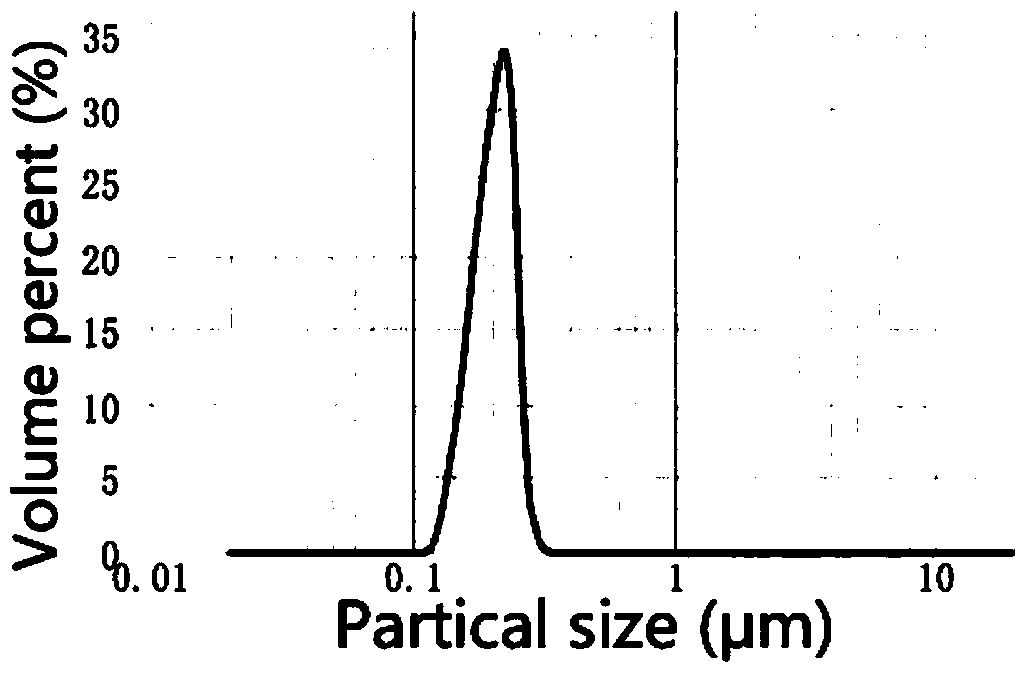

Rapid low-temperature preparation method for Y-alpha-SiAlON transparent ceramics

The invention relates to a rapid low-temperature hot-pressing sintering method for transparent Y-alpha-SiAlON ceramics, and belongs to the field of transparent ceramic material preparation. The method comprises the following steps: firstly, batching on the basis of an alpha-SiAlON composition design, preparing ultrafine mixed powder by adopting a planetary ball mill, and preparing the transparent Y-alpha-SiAlON ceramics by utilizing the obtained ultrafine mixed powder by adopting the technologies of high-temperature slow pressurizing and cooling with pressure, high-temperature rapid nitrogen-filling, high-temperature rapid heating and rapid cooling. According to the method, the densification process of the alpha-SiAlON ceramics is greatly promoted by adopting the technology of preparing the transparent Y-alpha-SiAlON ceramics by the ultrafine mixed powder, the sintering time is effectively shortened, the sintering temperature is remarkably reduced, and the rapid low-temperature sintering of the alpha-SiAlON ceramics is realized.

Owner:DALIAN MARITIME UNIVERSITY

Method for preparing tungsten slab by low-temperature sintering

ActiveCN105478745AWell mixedHigh sintering activation energyTransportation and packagingMetal-working apparatusHigh densityHydrogen atmosphere

The invention discloses a method for preparing a tungsten slab by low-temperature sintering. The method comprises the following steps: (1) mixed tungsten powder is prepared; (2) the mixed tungsten powder is pressed to a slab by a cold isostatic pressing mode; and (3) under hydrogen atmosphere, the slab is heated and sintered, and is naturally cooled to obtain the tungsten slab. The method uniformly mixes the tungsten powder with three particle size ranges in proportion; on the one hand, excellent filling capacity is realized, higher pressing blank density is obtained, and higher sintering density is obtained; and on the other hand, quick actuation of densification process at a lower temperature is guaranteed, and the highest sintering temperature and insulation time are reduced; and in addition, through controlling the slab sintering temperature and time, the phenomenon of difficult elimination of a core hole of the sintered slab caused by the surface dentification speed of the sintered slab far faster than the core dentification speed due to excessive fast heating speed or shorter insulation time in medium-low-temperature phase can be prevented, and each part of the slab has better structure uniformity and higher density.

Owner:XIAN REFRA TUNGSTEN & MOLYBDENUM

High-strength aluminum nitride ceramic substrate and preparation method thereof

The invention relates to the technical field of ceramic materials, and provides a high-strength aluminum nitride ceramic substrate and a preparation method thereof. The high-strength aluminum nitride ceramic substrate comprises the following raw materials by weight: 78-85 parts of modified aluminum nitride powder, 36-42 parts of a solvent, 1.2-2 parts of a dispersant, 8-11 parts of a binder and 2-4 parts of a plasticizer; and the aluminum nitride ceramic substrate is prepared through the procedures of ball milling, vacuum foaming, tape casting, isostatic pressing, rubber discharging, primary sintering and secondary sintering in sequence. The thermal conductivity of the prepared aluminum nitride ceramic is 180 W / (m.K) or above, the bending strength is 520 MPa or above, and the problem that the bending strength of the aluminum nitride ceramic is not high in the prior art is solved.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

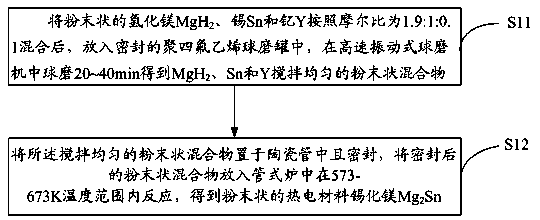

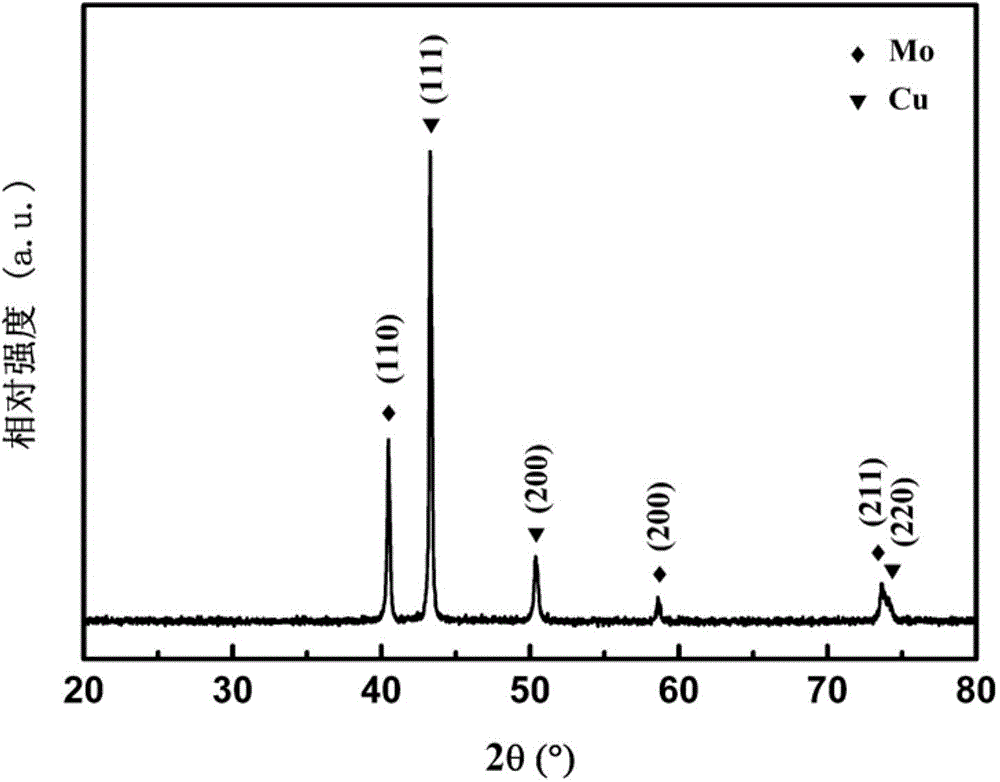

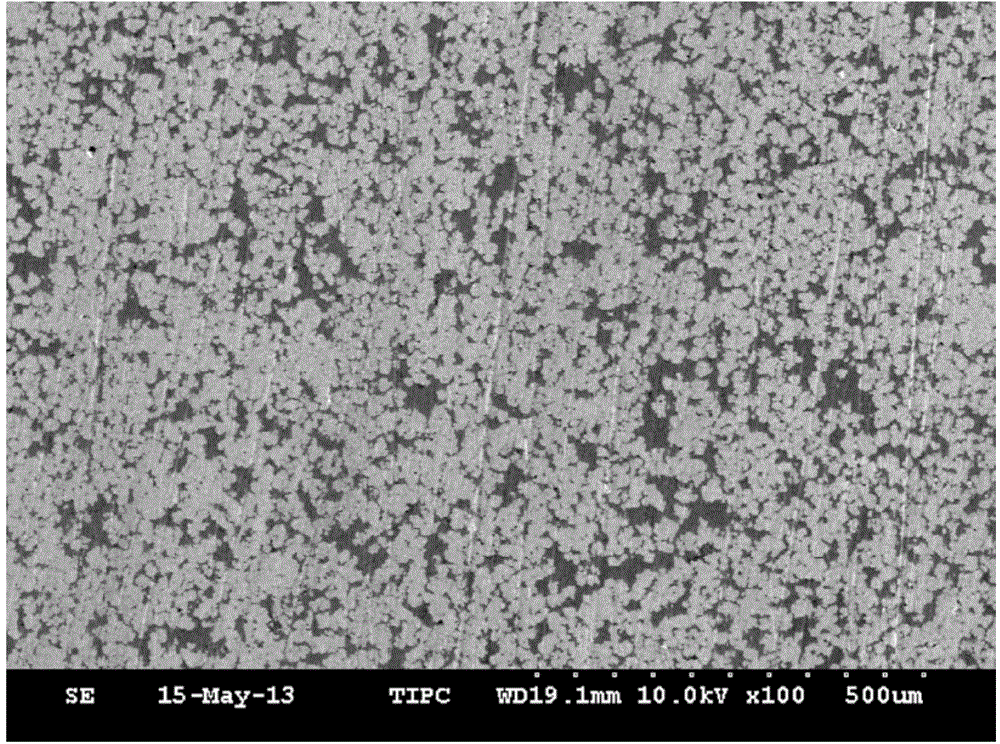

Thermoelectric material Mg2Sn and preparation method thereof

The invention relates to a thermoelectric material Mg2Sn and a preparation method thereof, belonging to the technical field of inorganic materials. The invention is characterized in a high-thermoelectric-property thermoelectric material prepared at low temperature and a preparation method thereof. The method comprises the following steps: mixing powdery MgH2, Sn and Y in a mol ratio of 1.9:1:0.1, putting in a sealed teflon ball milling tank, and carrying out ball milling in a high-speed vibrating ball mill for 20-40 minutes to obtain a powdery MgH2-Sn-Y uniform mixture; and sealing the powdery uniform mixture in a ceramic pipe, putting the sealed powdery mixture in a pipe furnace, and reacting at 573-673 K to obtain the powdery thermoelectric material Mg2Sn.

Owner:TAIYUAN UNIV OF TECH

Method for preparing hot pressed sintered high-density magnesium oxide target

The invention discloses a method for preparing a hot pressed sintered high-density magnesium oxide target and mainly solves the technical problems of easiness in transformation, low rate of finished products, higher cost and low purity of the target in the prior art. The method comprises the following steps of: a, weighing nano-sized magnesia powder with a certain amount and high purity, and selecting a mould which has the same diameter as the target prepared according to the requirement; b, placing the mould into a hot-pressing sintering furnace body, charging by a vibration funnel method, measuring and ensuring that the stack heights of the powders in the mould are the same; and c, vacuumizing, heating and pressurizing, and maintaining pressure until the sintered size of the magnesium oxide target is a design value. The method has a simple preparation process and can quickly enable the product to be densified; the prepared product has the advantages of high density, fine grain and the like; other impurities cannot be introduced; the product is difficult to deform and crack during sintering; the rate of finished products is high; and the high-density high-purity magnesium oxide target can be prepared by the method.

Owner:沈阳临德陶瓷研发有限公司

Method for preparing molybdenum copper alloy by combustion synthesis in high gravity field

The invention belongs to the technical field of combustion synthesis, and particularly relates to a method for preparing molybdenum copper alloy by combustion synthesis in a high gravity field. The method of the invention adopts Al-CuO as a reaction system, and adopts Cu, Mo, and B2O3 as diluents. High temperature thermite reaction between various raw materials is induced in a high gravity field (500-5000g); rapid separation, densification, and cooling of the products of ceramic melt and metal melt of the thermite reaction in the high gravity field is realized to obtain a ceramic solid and a metal solid; and the pure copper layer at one end of the metal solid is cut to obtain the molybdenum copper alloy. The method of the invention has the characteristics of simple process, short preparation period, low cost, and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

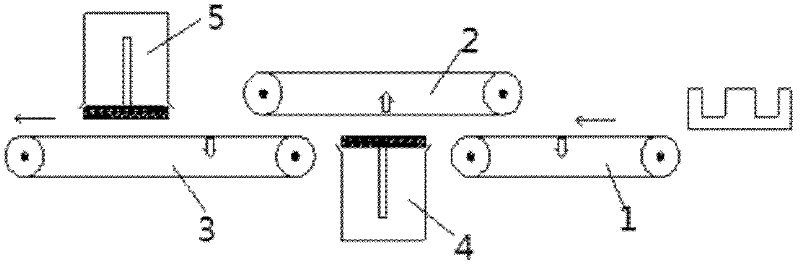

Carbon fiber precast body liquid phase soaking and densifying method

The invention provides a carbon fiber precast body liquid phase soaking and densifying method and belongs to a C / C composite material molding process which is used for solving the problems of low material soaking efficiency and increased treatment periods caused by part of pitch discharged out from a precast body in an existing liquid phase soaking, carbonizing and densifying process. The method comprises a soaking step, a low-temperature treatment step and a high-temperature carbonizing step. According to the method, the carbon fiber precast body is taken as a reinforcement body, high-temperature modified pitch is taken as a substrate soaking agent, pressurized soaking equipment is adopted for performing C / C material liquid phase soaking and densifying treatment, an existing liquid phase soaking method is adopted, the C / C material density is up to over 1.5g.cm<-3>, and densifying treatment of 8-10 periods is needed; by virtue of the technical process, only 3-4 periods are needed. The pressurized soaking equipment adopted in the method is simple in structure, easy to operation and capable of greatly improving the soaking efficiency, shortening the densifying period and realizing rapid C / C material densification.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Preparation method of low-modulus and high-toughness silver-containing titanium alloy

The invention discloses a preparation method of low-modulus and high-toughness silver-containing titanium alloy. The preparation method comprises the following steps: 1, carrying out low-energy ball-milling mixing on titanium alloy powder and nano silver powder to obtain mixed powder, wherein the titanium alloy powder is in the micrometer scale and the nominal composition of the titanium alloy powder is Ti-3Zr-2Sn-3Mo-25Nb; 2, sintering the mixed powder to form silver-containing titanium-based sintering blanks; and 3, carrying out hot-rolling treatment on the silver-containing titanium-based sintering blanks to obtain silver-containing titanium alloy profile. According to the preparation method, low-energy ball-milling mixing is adopted to uniformly disperse nano silver powder on the surface of titanium alloy powder, so that during the sintering process, nano silver powder is uniformly diffused and solid-solution of nano silver powder is carried out on titanium alloy matrix, segregation of the Ag element is effectively avoided, dispersing uniformity of Ag in silver-containing titanium alloy profile is improved, the plasticity is not damaged while ensuring that the strength of the silver-containing titanium alloy profile is improved, and the low elasticity modulus characteristic is kept.

Owner:西安稀有金属材料研究院有限公司

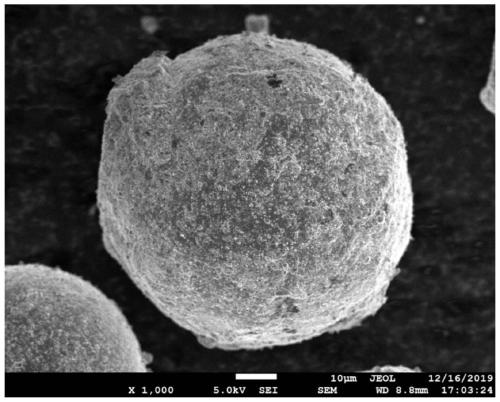

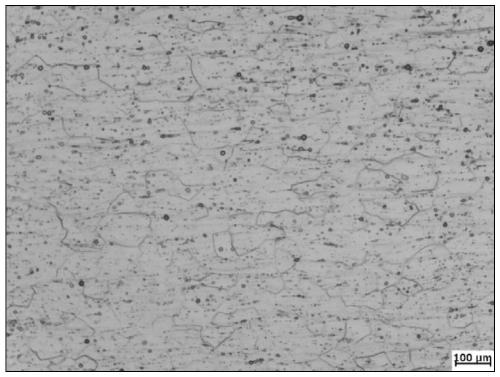

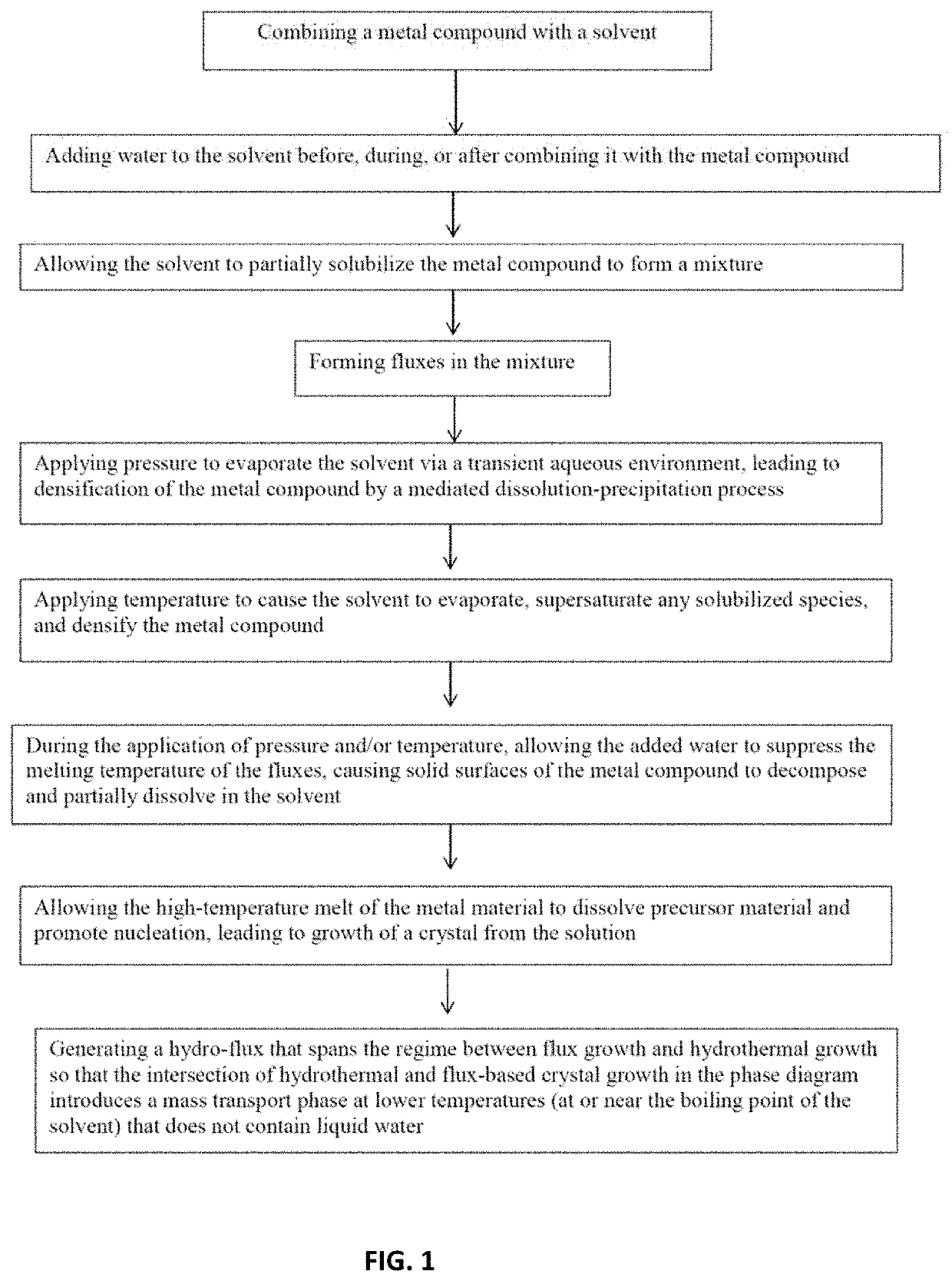

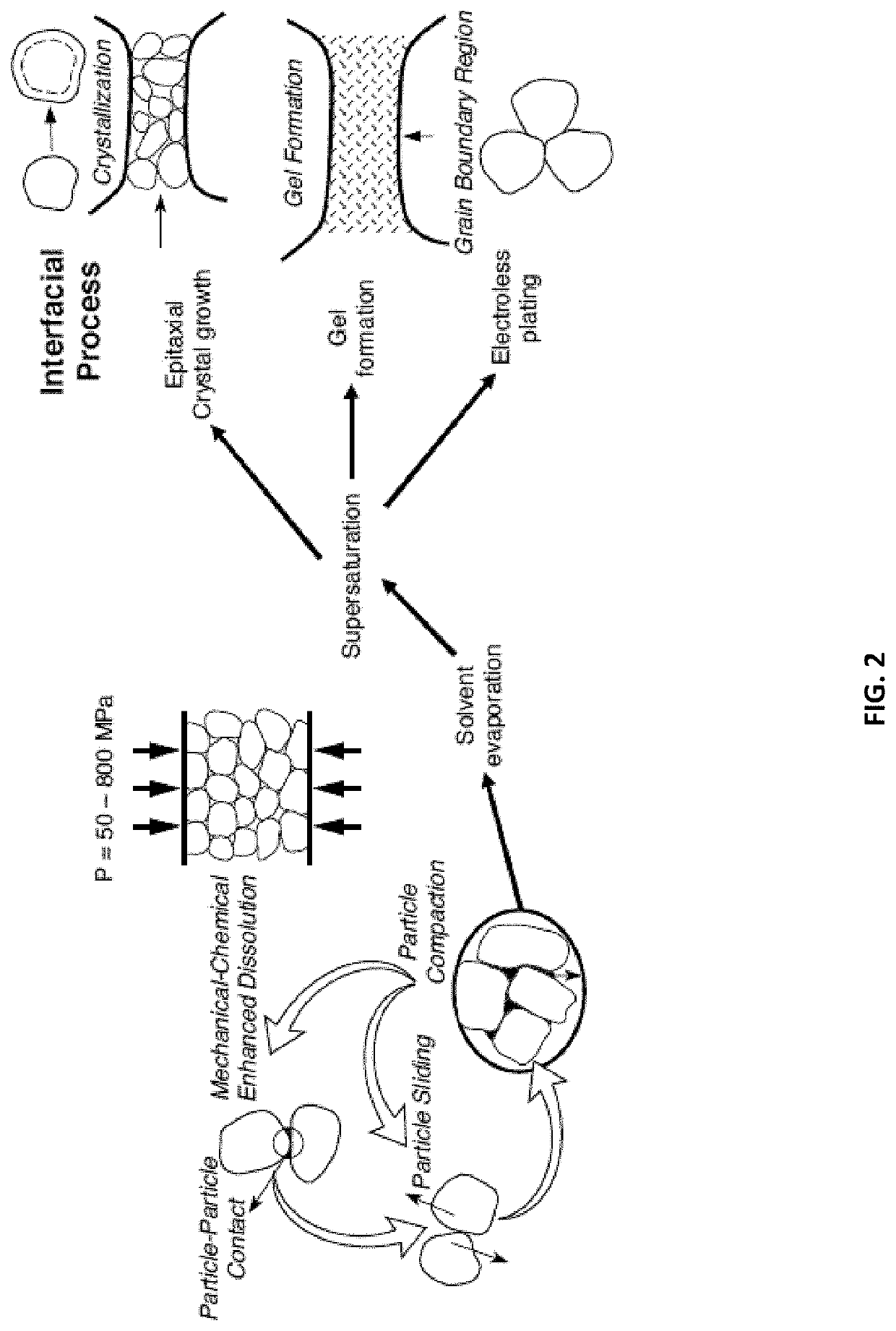

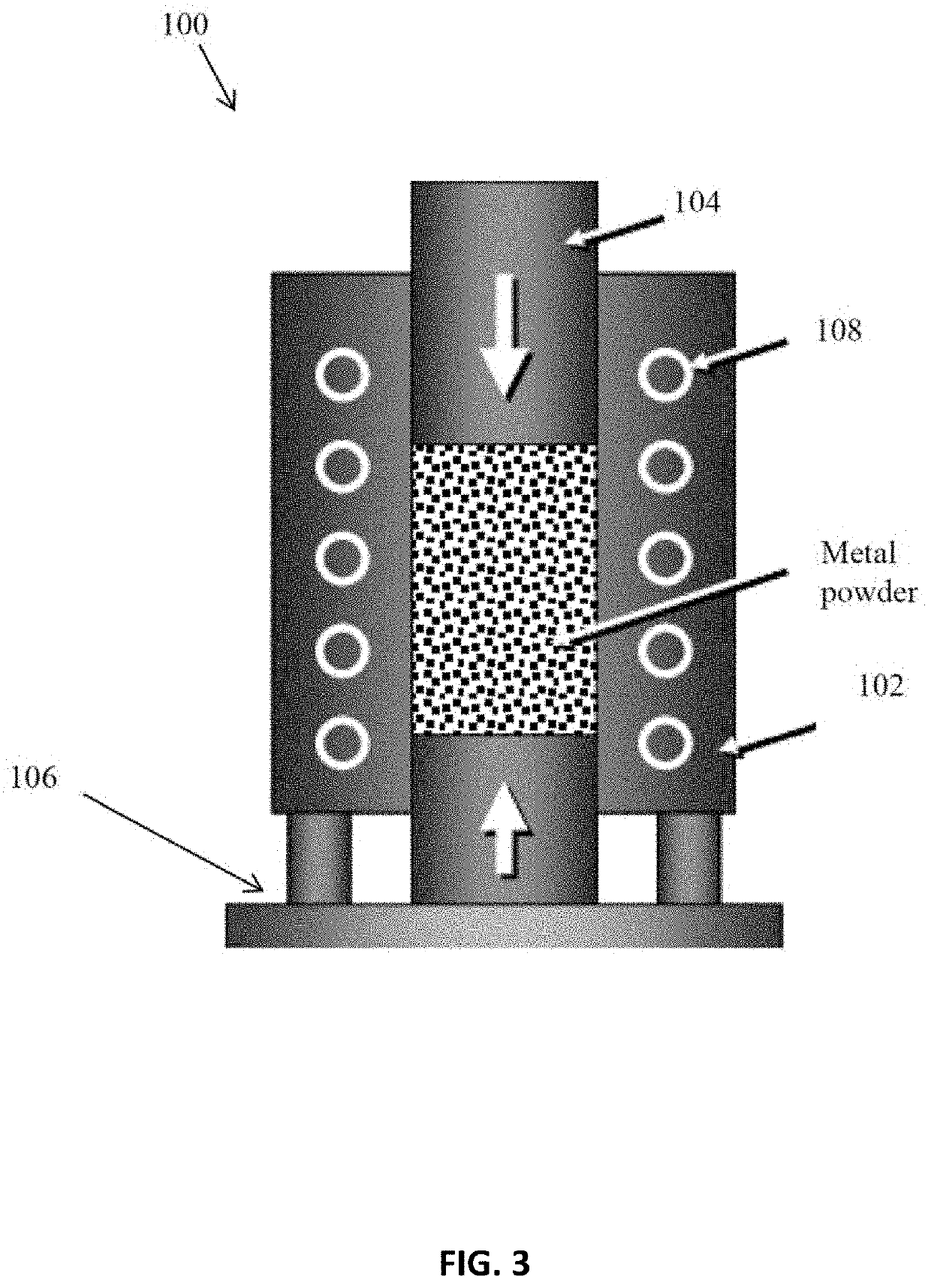

Cold sintering process for densification and sintering of powdered metals

PendingUS20220226895A1Suppression temperatureReduce compactionFrom normal temperature solutionsTransportation and packagingCrystal systemAqueous solution

Embodiments can relate to an improved hydroflux, additive or electroless plating assisted densification cold sintering process to densify powdered metals at lower compaction pressures and lower temperatures (e.g., 520 MPa and 140° C.). The process can involve inducing dissolution precipitation mechanisms at powder interfaces by introducing a transport phase (formed by the introduction of water during the process to suppress melting temperatures) that is not an aqueous solution. Particle interfaces in the cold sinter fuse together by the presence of the additional transport phase, thereby reducing the temperatures and pressures needed for compaction. Some embodiments involve the use of elements to form a eutectic at the desired low temperature, thereby stabilizing certain crystal structure shapes of isometric crystal systems, inducing rapid densification, and facilitating pore smoothing. Embodiments of the process can be used to generate a green compact via sintering that exhibits improved green strength.

Owner:PENN STATE RES FOUND

Quick low-cost CVD compacting method for carbon/carbon composite material

InactiveCN108220913AUniform and denseRapid densificationChemical vapor deposition coatingCarbon compositesOperability

The invention discloses a quick low-cost CVD compacting method for a carbon / carbon composite material. The method comprises the following steps: assembling a preform and an inner core mold tougher forhigh-temperature pre-treatment; placing the treated perform and inner core mold between upper and lower graphite electrodes of a deposition chamber of CVD equipment; and carrying out heating and introducing carbon source gas for 40-200h to prepare a carbon / carbon composite material product at one time. The method disclosed by the invention has the advantages and characteristics that 1, the methodintegrates advantages of a temperature differential method, a gas limiting method and a spontaneous heating characterized deposition process, so that influence of crusting of pyrolytic carbon on thesurface layer on deposition and compaction can be prevented effectively, the ability of the carbon source gas diffused to the perform is enhanced, and the deposition efficiency can be improved greatly; 2, the problem that density is not uniformly increased is solved, and the product quality is consistent; 3, the production energy consumption is low and the process and production cost is relativelylow; 4, the control degree of an air flow is high, and the utilization ratio of gas is high; 5, the perform and the graphite inner core mold are easily demolded, so that the operability is good; and6, the density state of the product can be controlled precisely, so that an accurate product effect is obtained.

Owner:AEROSPACE RUITIAN CARBON MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com