Preparation method of SiCf/SiC composite material with SiC coating layer

A composite material and coating technology, applied in the field of nuclear SiCf/SiC composite material preparation, can solve the problems affecting the hydrothermal corrosion resistance of SiC composite materials, low density of SiC composite materials, restricting the commercial application of SiC, etc. Controllable, improve hydrothermal corrosion resistance, and improve the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

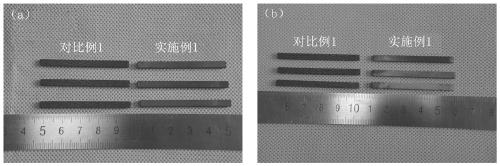

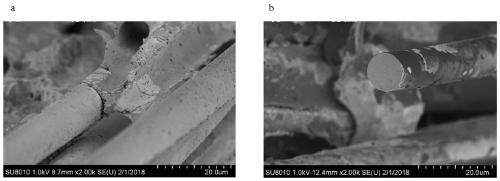

Embodiment 1

[0039] A SiC with SiC coating of this embodiment f / SiC composite material preparation method, comprises the following steps:

[0040] S1. Preparation of SiC fiber braided parts:

[0041] The domestic third-generation KD-S type SiC fiber with a chemical dosage ratio is close to the three-dimensional four-way (3D4d) weaving method to obtain a SiC fiber braid.

[0042] Preparation of S2, PyC interface coating:

[0043] Put the SiC fiber braid obtained in step S1 into a CVD furnace, and the raw material gas is C 3 h 6 , the carrier gas is high-purity argon, C 3 h 6 The flow rate is 2L·min -1 , the flow rate of argon gas is 2L·min -1 , the deposition temperature is 1000°C, the deposition pressure is 2000Pa, the deposition time is 2 hours, and the thickness of the PyC coating is about 200nm.

[0044] S3, PIP process densification:

[0045] S3-1. Densify the SiC fiber braid after the deposition of the PyC interface coating obtained in step S2 according to the following proc...

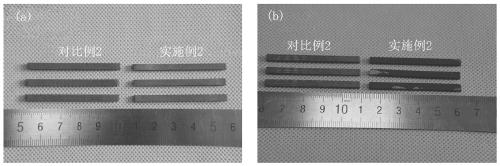

Embodiment 2

[0057] A SiC with SiC coating of this embodiment f The preparation method of the / SiC composite material is basically the same as that of Example 1, the only difference being that the cracking temperature in the densification process of the PIP process is 1600°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com