Patents

Literature

145results about How to "High process feasibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic silicon dioxide microspheres modified with diethylaminoethyl and preparation method and application thereof

ActiveCN101628224ALarge amount of extracted nucleic acidReasonable designSugar derivativesOther chemical processesMicrosphereNanoparticle

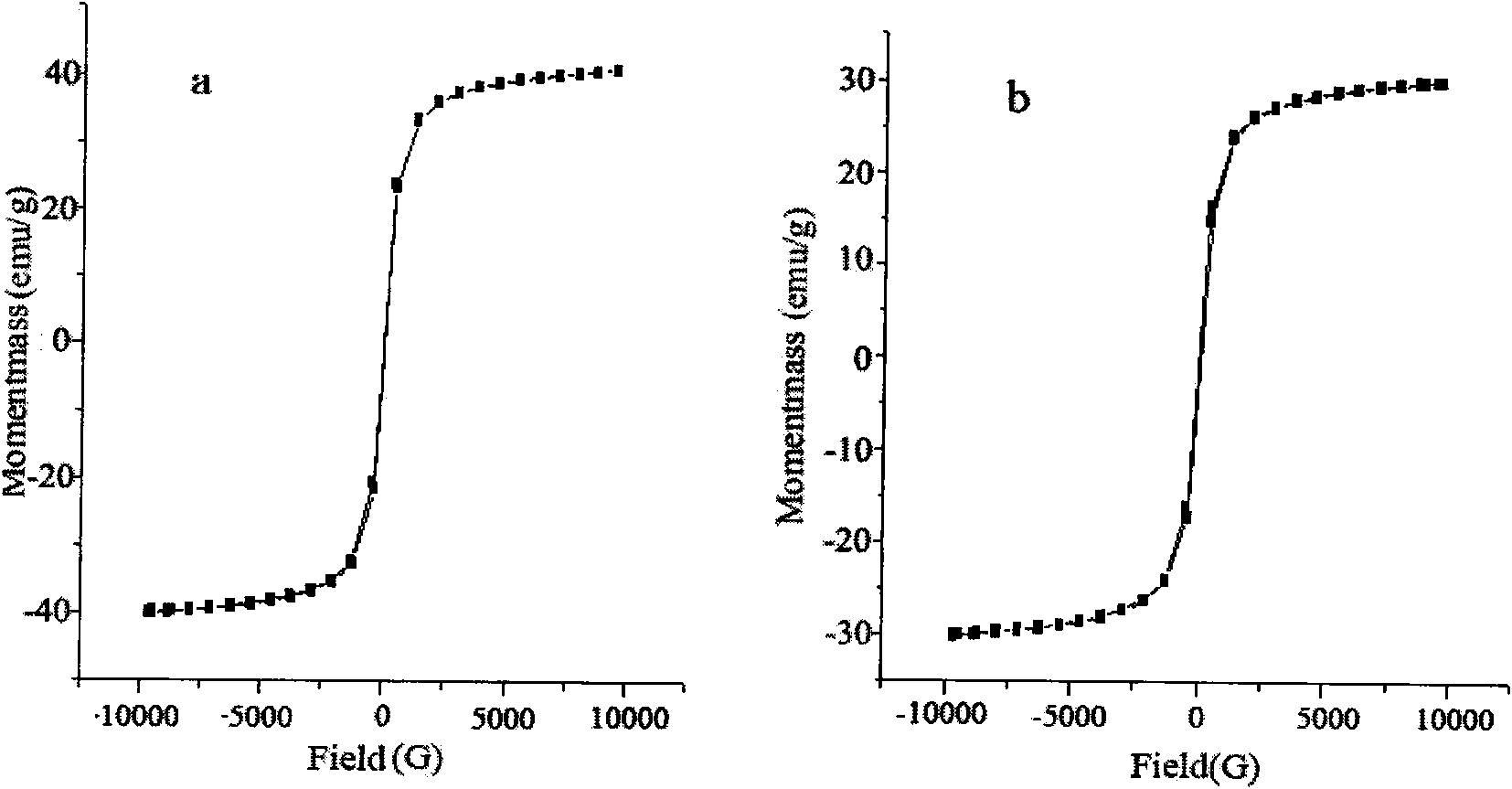

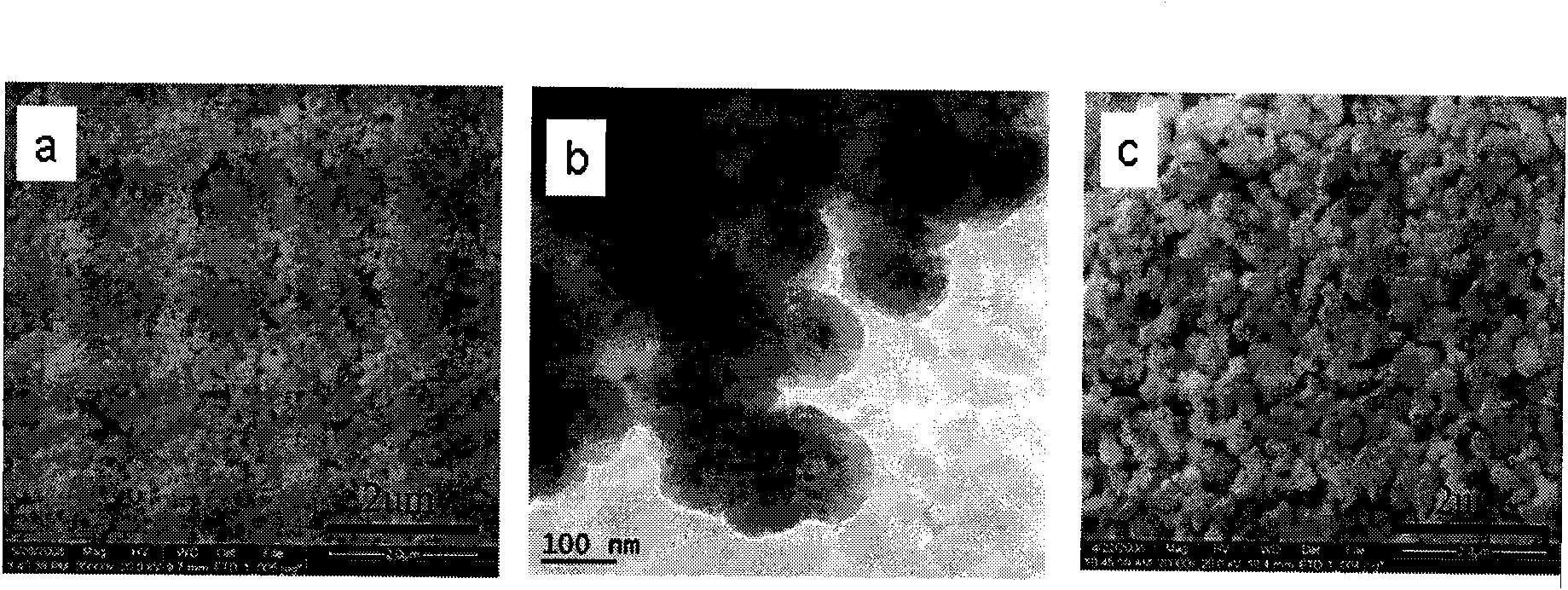

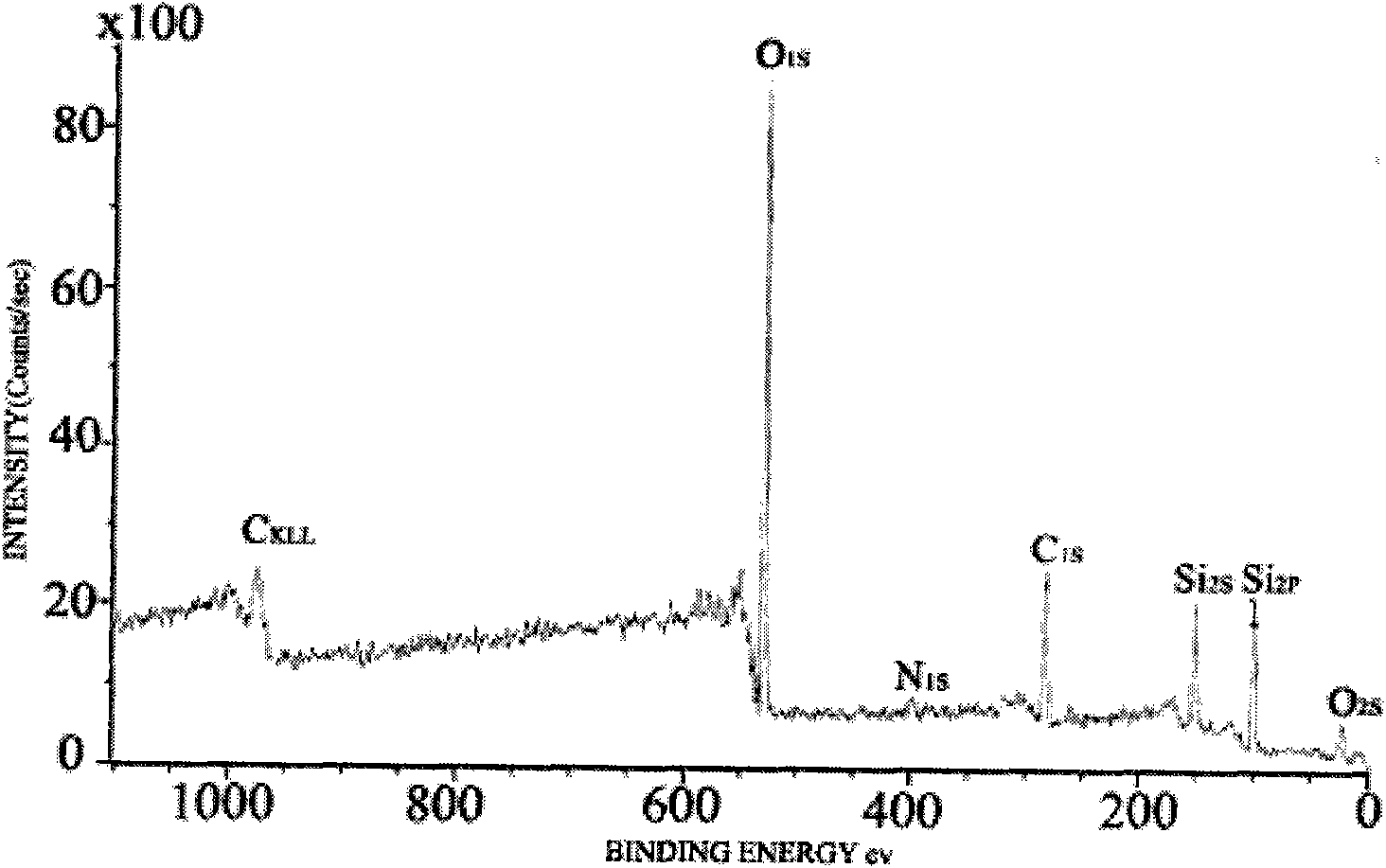

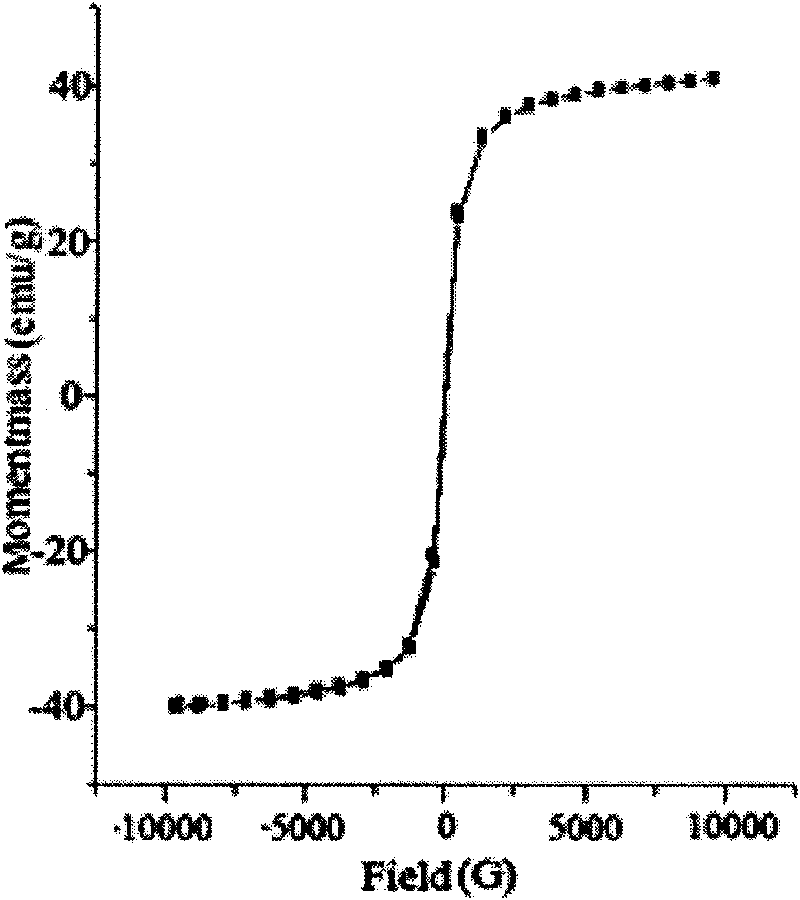

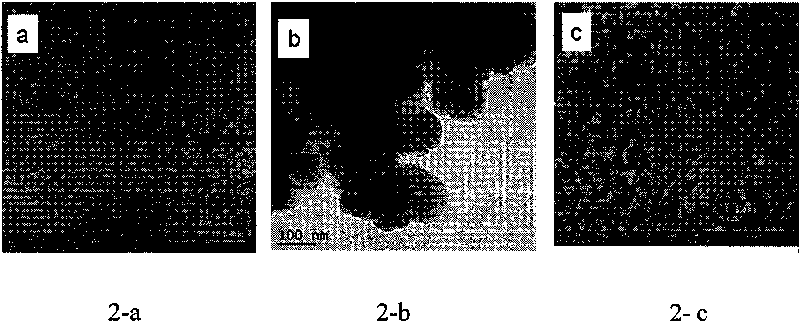

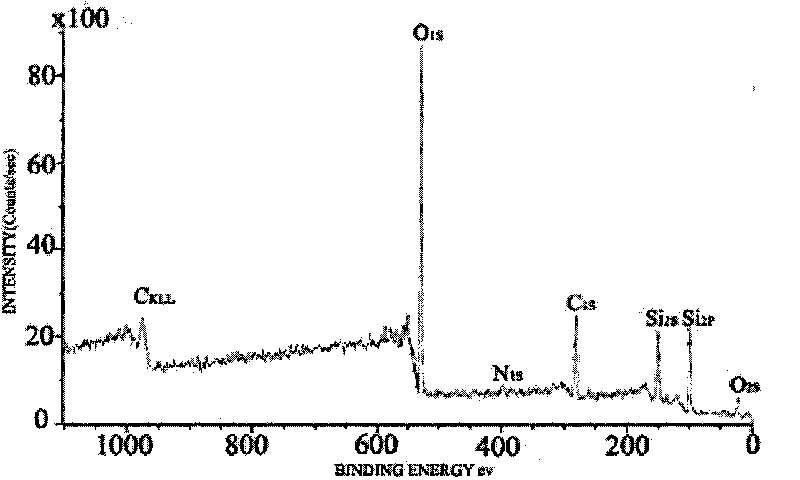

The invention relates to magnetic silicon dioxide microspheres modified with diethylaminoethyl on the surface and a preparation method and an application thereof; the sol-gel method is adopted to prepare magnetic silicon dioxide microspheres which have ferroferric oxide nanoparticles as cores and silicon source, namely tetraethoxysilane as shells; by adopting the microspheres as template, alkylene oxide coupling agent 3-glycidoxypropyltrimethoxysilane (GPTMS) as activator and diethylaminoethyl hydrochloride as functional group, the magnetic silicon dioxide microspheres modified with diethylaminoethyl (DEAE) on the surface are prepared. The method comprises the preparation of magnetic silicon dioxide microspheres, the epoxidation of magnetic silicon dioxide microspheres and the DEAE surface modification. The method solves the problems that the bindingability between the existing magnetic microspheres and nucleic acid is not high, the preparation processes are complicated and the like. The bindingability between the magnetic microspheres prepared by the method and nucleic acid is high so as to be used to separate nucleic acid from the biological sample.

Owner:XIAN GOLDMAG NANOBIOTECH

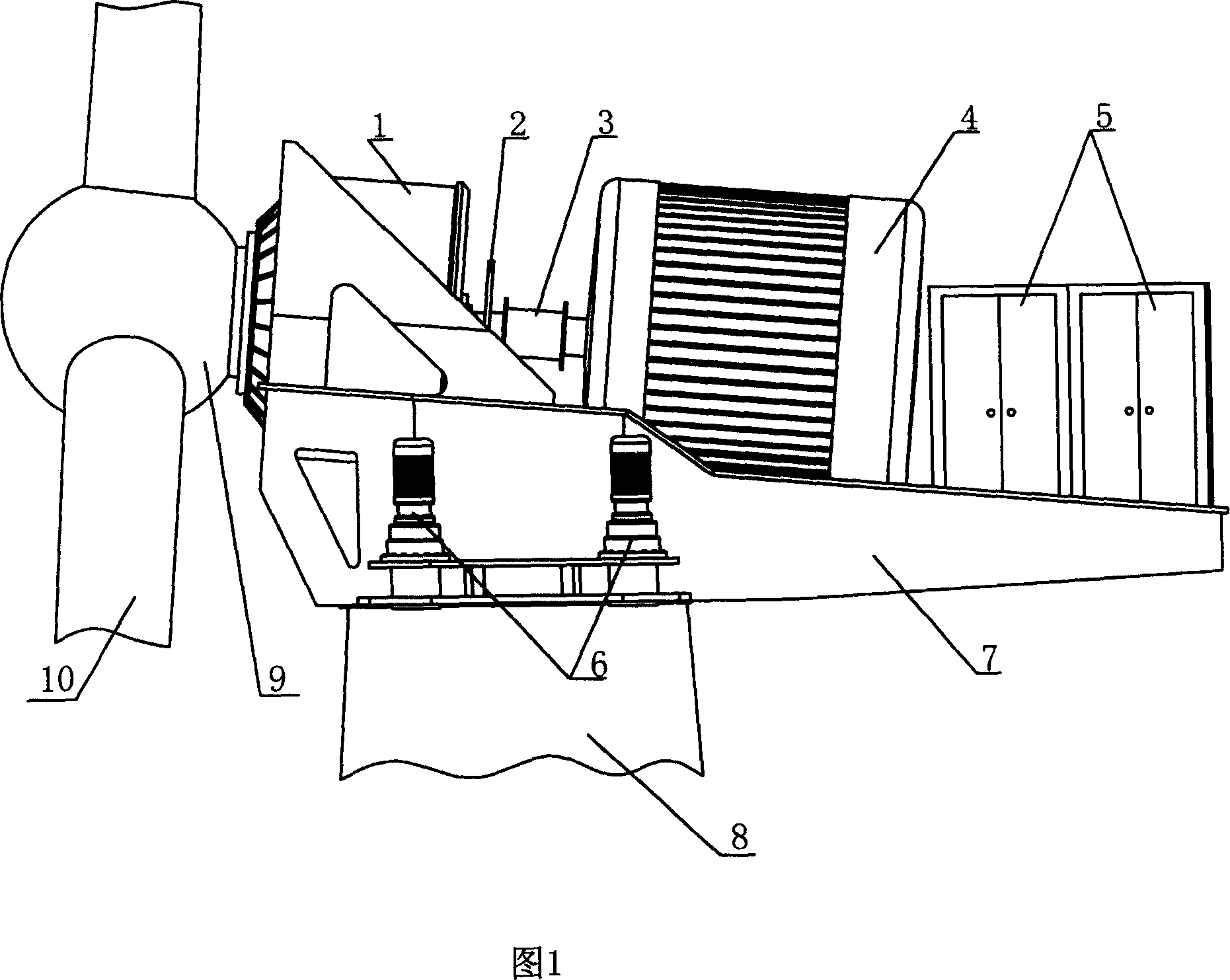

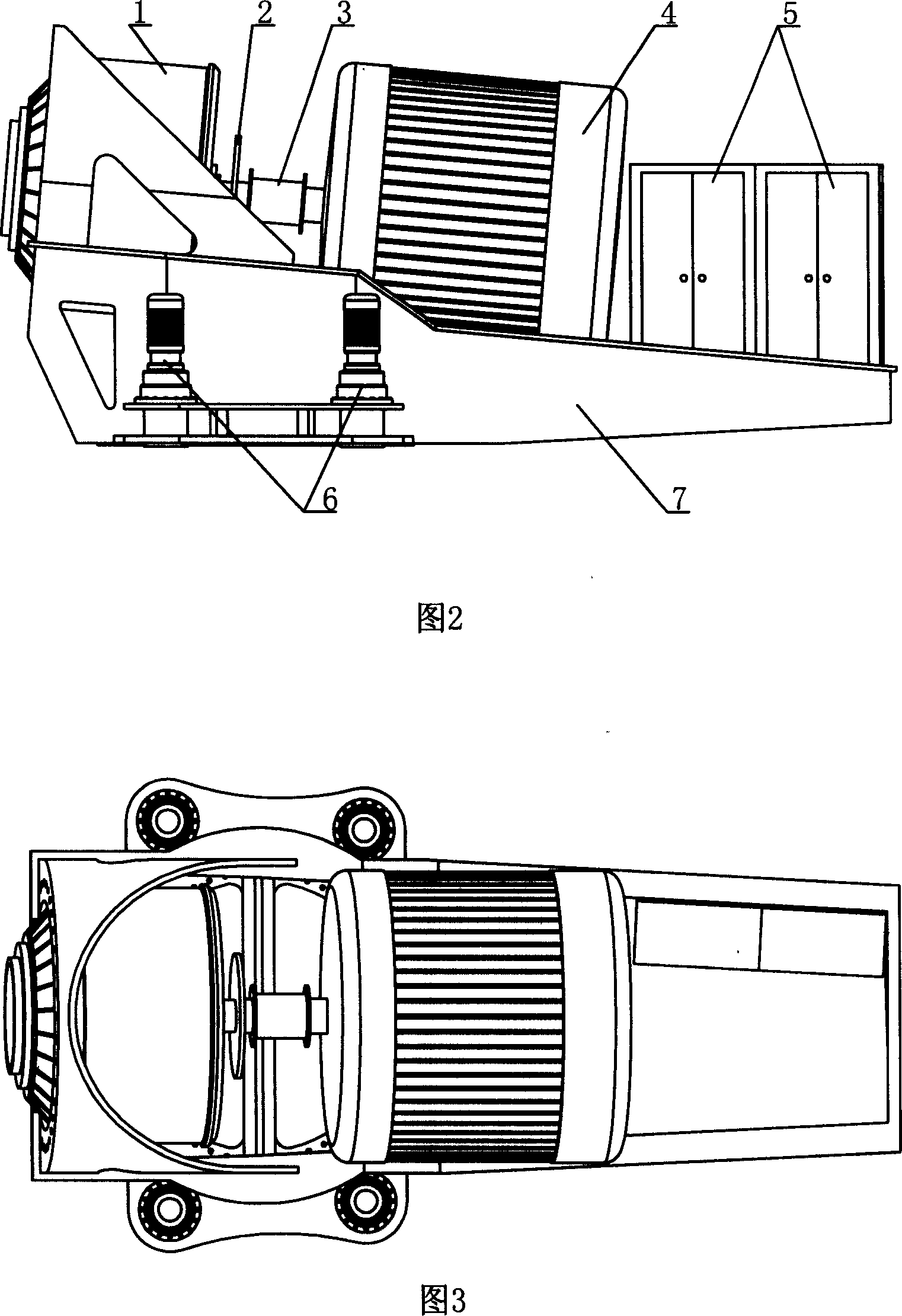

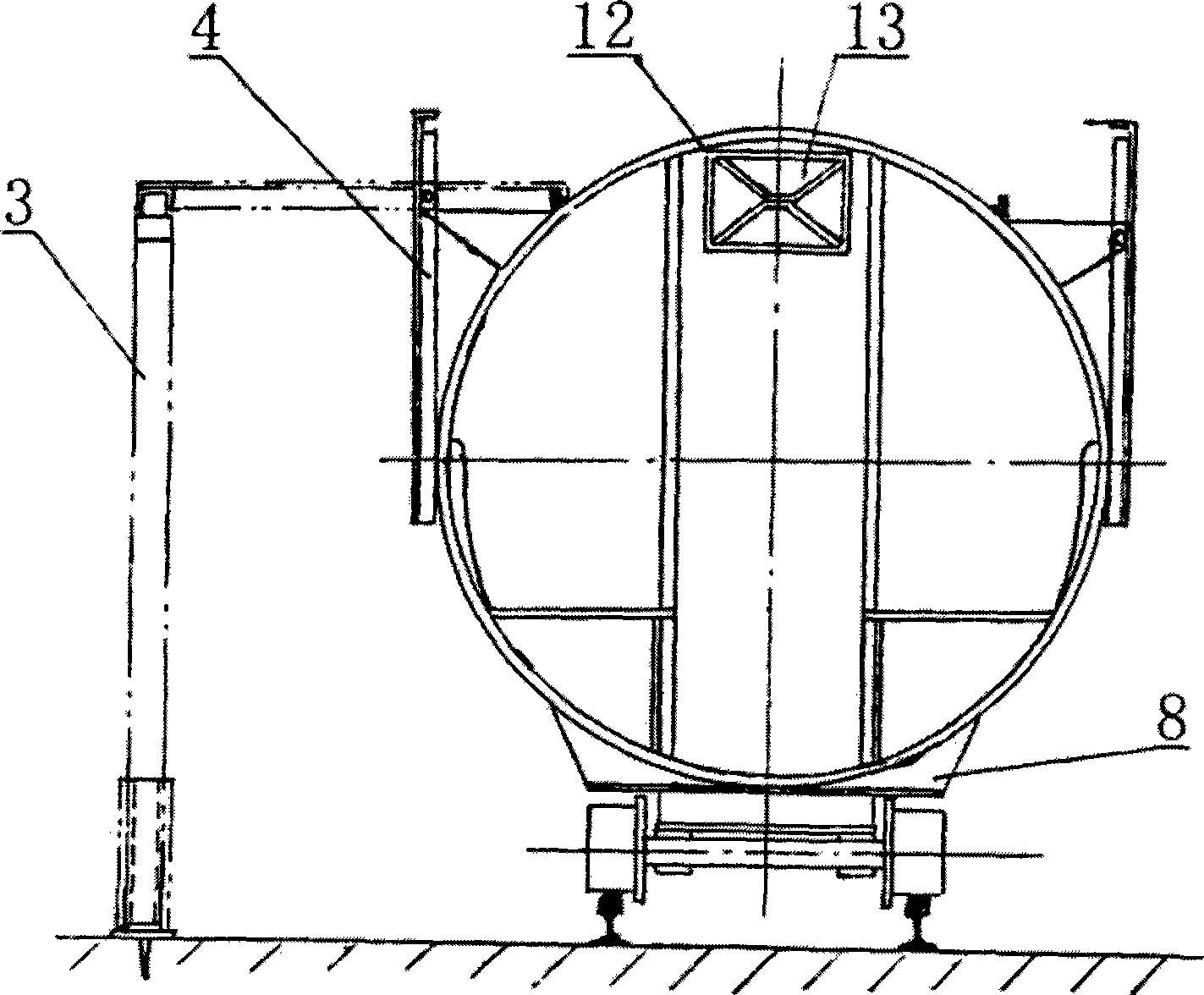

Megawatt semi-direct driving wind-power generator group

InactiveCN101016881AReduce axial playStable structureWind motor controlMachines/enginesNacelleLow speed

A megawatt-level semi-direct driving wind generator comprises a wind wheel, a distance changer, a main axle, a speed accelerating box, a coupler, a generator, a cabin chassis, a bias motor and a control system. The chassis is fixed with the bias motor and the generator, the accelerating box is fixed with the side wall of the chassis, the accelerating box is first-stage planet accelerating gear box, and the motor is low-speed permanent magnetic three-phase synchronous generator. The invention can stabilize the transmission of transmitter, reduce impact, and reduce sealing demand or the like, with adjustable installed height, simple structure, high strength and accurate angle control on distance change as 0.1 degree, to output constant power.

Owner:SHENYANG POLYTECHNIC UNIV

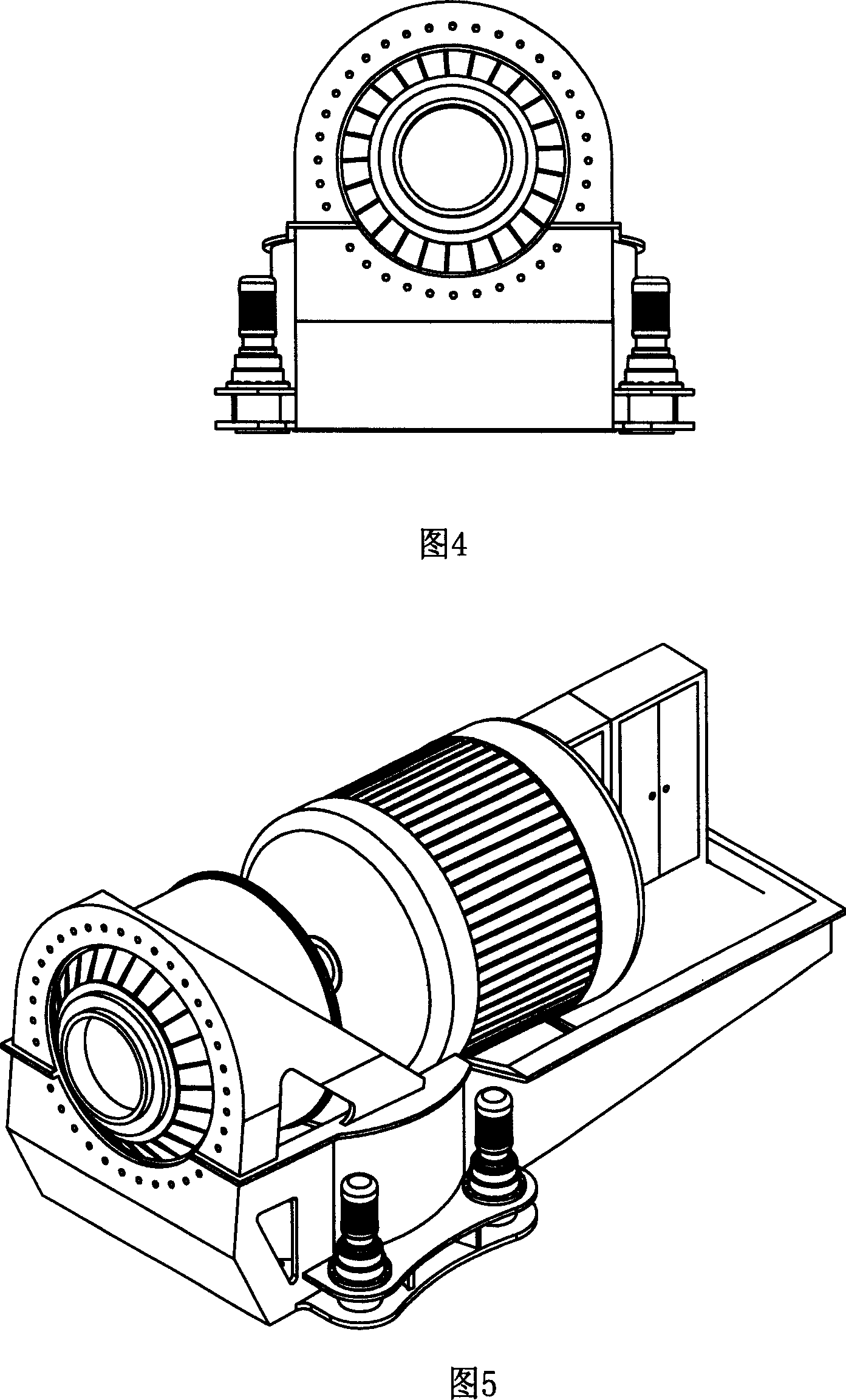

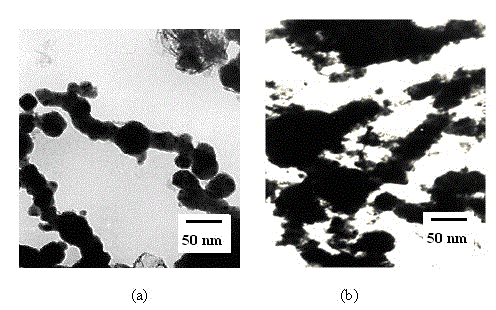

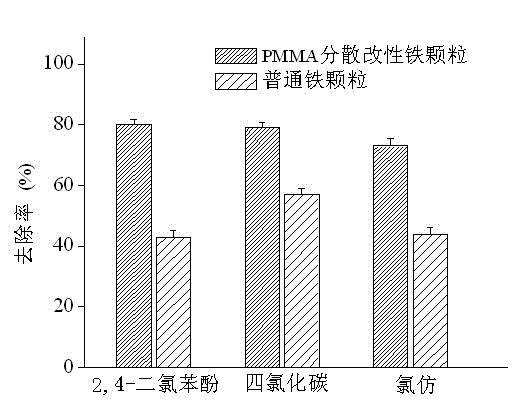

Preparation method of dispersant modified iron nanoparticles

InactiveCN102614918AImprove stabilityLow degree of reunionOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsEnvironmental mediaOrganic compound

The invention discloses a preparation method of dispersant modified iron nanoparticles. According to the preparation method, high polymer, a cationic surfactant or anionic polymer electrolyte is used as a dispersant to perform surface modification on particles in a preparation process of the iron nanoparticles so as to prepare the dispersant modified iron nanoparticles. The iron nanoparticles prepared by the method have good dispersion stability; the hard agglomeration of the iron nanoparticles in an aqueous medium is reduced; the dispersion degree of the iron nanoparticles is increased; the method can also be used for performing dispersion modification on iron base bimetallic particles; and the method can be applied to pollution remediation of chlorinated organic compounds in an environmental medium and has broad application prospect.

Owner:KUNMING UNIV OF SCI & TECH

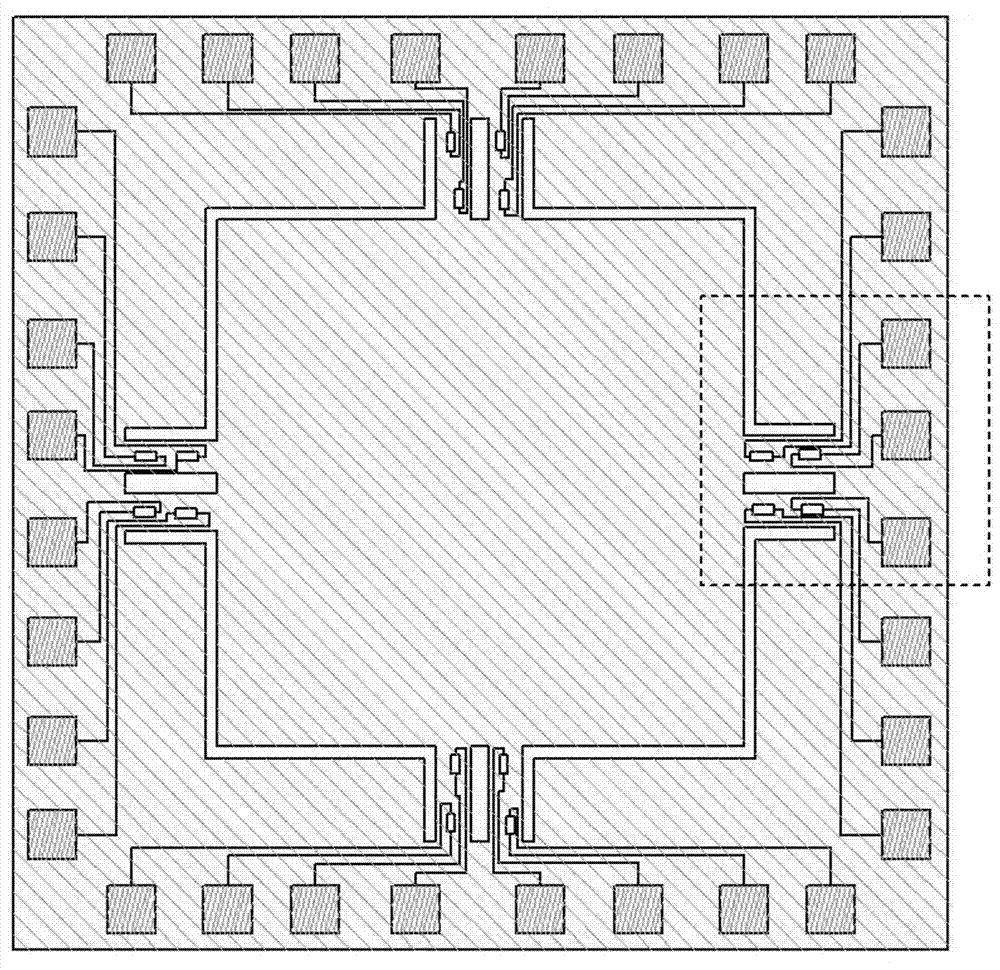

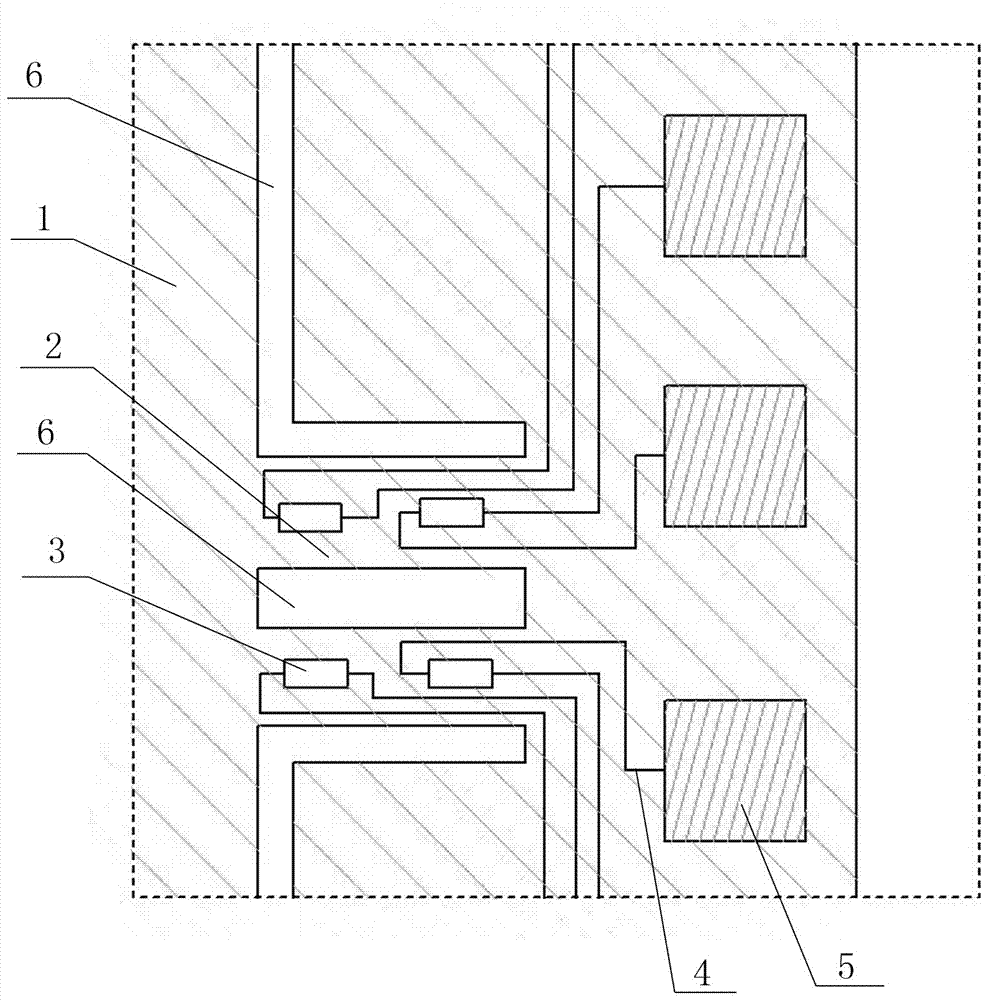

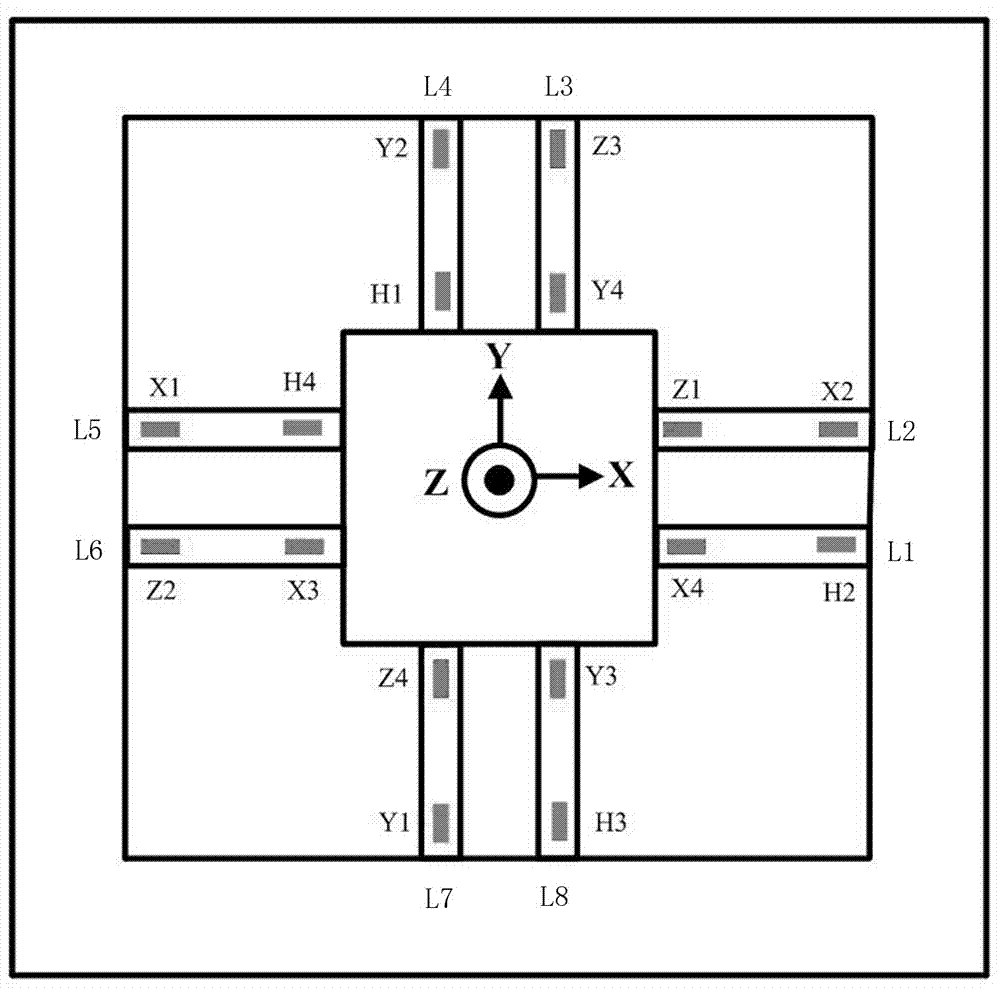

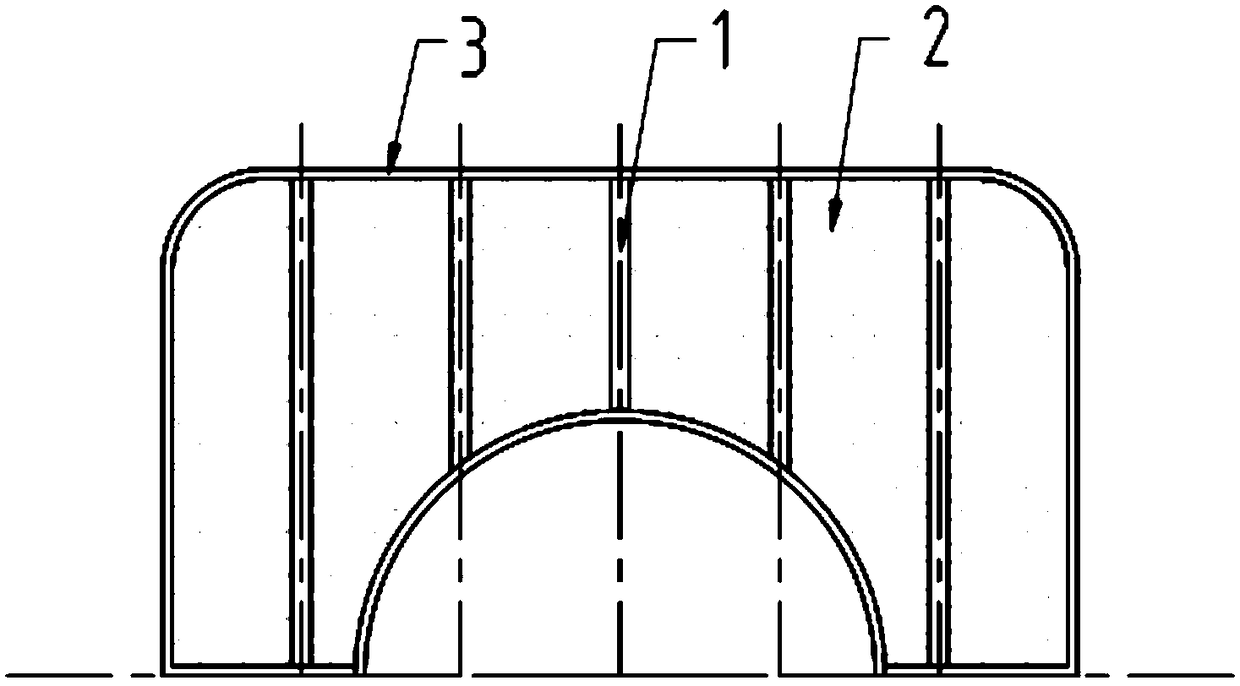

Piezoresistive tri-axial acceleration sensor with anti-overload capability and preparation method thereof

InactiveCN107290567AAnti-overload capacity reachesSimple structureTelevision system detailsAcceleration measurement using interia forcesClassical mechanicsAcceleration Unit

The invention discloses a piezoresistive tri-axial acceleration sensor with an anti-overload capability. The sensor comprises a substrate; a mass block (1) and eight rectangular beams (2) are formed at the center of the substrate through etching; four edges of the upper part of the mass block (1) are integrally connected with the substrate through the rectangular beams (2), namely, the right edge of the mass block (1) is connected with the frame of the substrate through the beam L1 and the beam L2, and the upper edge of the mass block (1) is connected with the frame of the substrate through the beam L3 and the beam L4, the left edge of the mass block (1) is connected with the frame of the substrate through the beam L5 and the beam L6, and the lower edge of the mass block (1) is connected with the frame of the substrate through the beam L7 and the beam L8; and anti-overload gaps (6) are left between the beams, between the edges of the mass block and the substrate, and between the beams and the substrate. According to the piezoresistive tri-axial acceleration sensor with the anti-overload capability of the invention, the anti-overload capability of the tri-axial acceleration sensor in the X direction, Y direction and Z direction of the Cartesian coordinate system is realized by means of limiting the displacement of the mass block.

Owner:ZHONGBEI UNIV

Method for preparing magnetic silica microspheres with surfaces modified by cations

ActiveCN101723389ACause lossLarge amount of extracted nucleic acidSilicaPreparing sample for investigationEpoxyMicrosphere

The invention relates to a method for preparing magnetic silica microspheres with surfaces modified by cations, and the number of electric charges of the modified cations varies with pH of solution. Ethyl orthosilicate is hydrolyzed to generate the magnetic silica microspheres by a sol-gel method in the presence of Fe3O4 nanoparticles. Epoxy silane reagent of 3-Glycidoxypropyltrimethoxy silane (GPTMS) is adopted to activate magnetic silica microparticles, and the cationic modifying agent with the pKa value within 4 to 8 is used as functional group, therefore, the magnetic silica microspheres with surfaces modified by cations are prepared by covalent interaction. The method comprises the preparation of the magnetic silica microspheres, the epoxidation of the magnetic silica microspheres and the cationic modification on the surfaces of the magnetic silica microspheres. The magnetic microspheres prepared by the method are used for separating nucleic acid from biological samples according to the variation of the electric charges on the surfaces.

Owner:XIAN GOLDMAG NANOBIOTECH

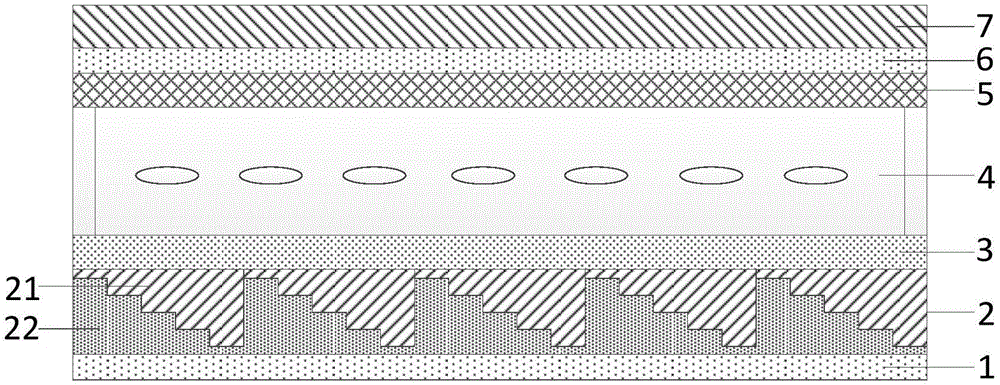

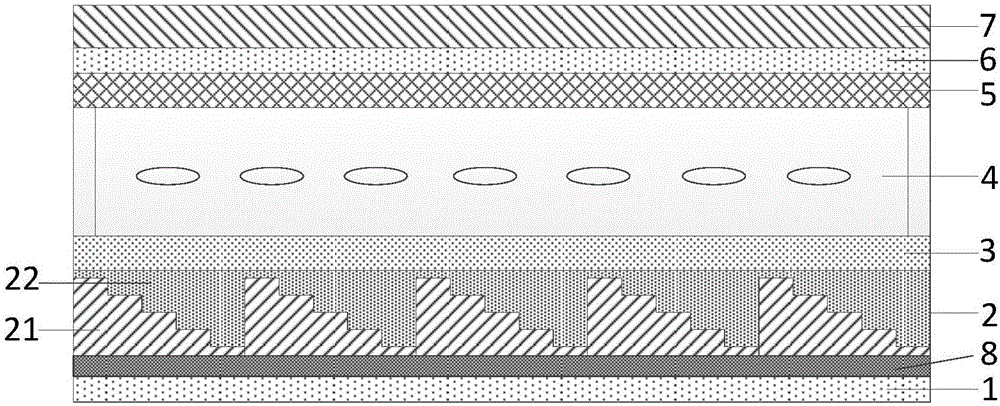

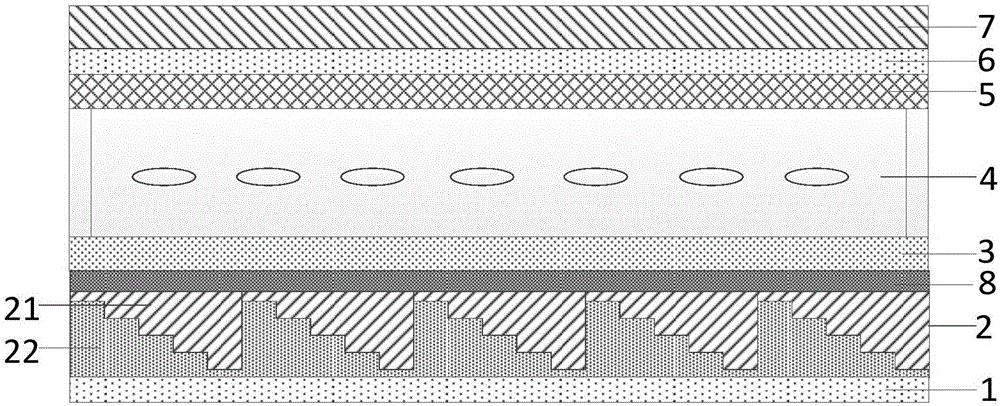

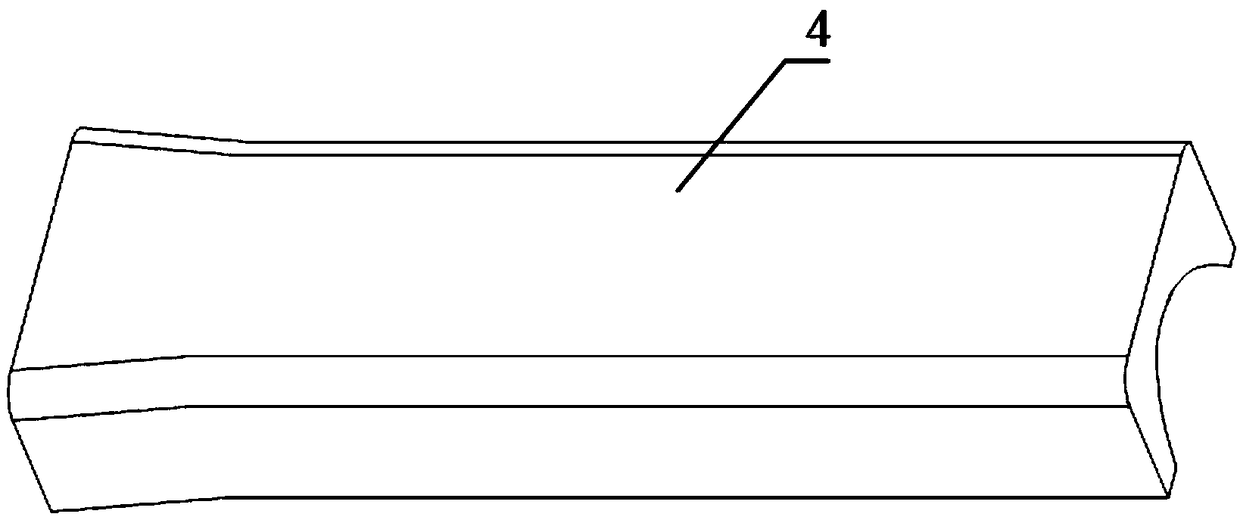

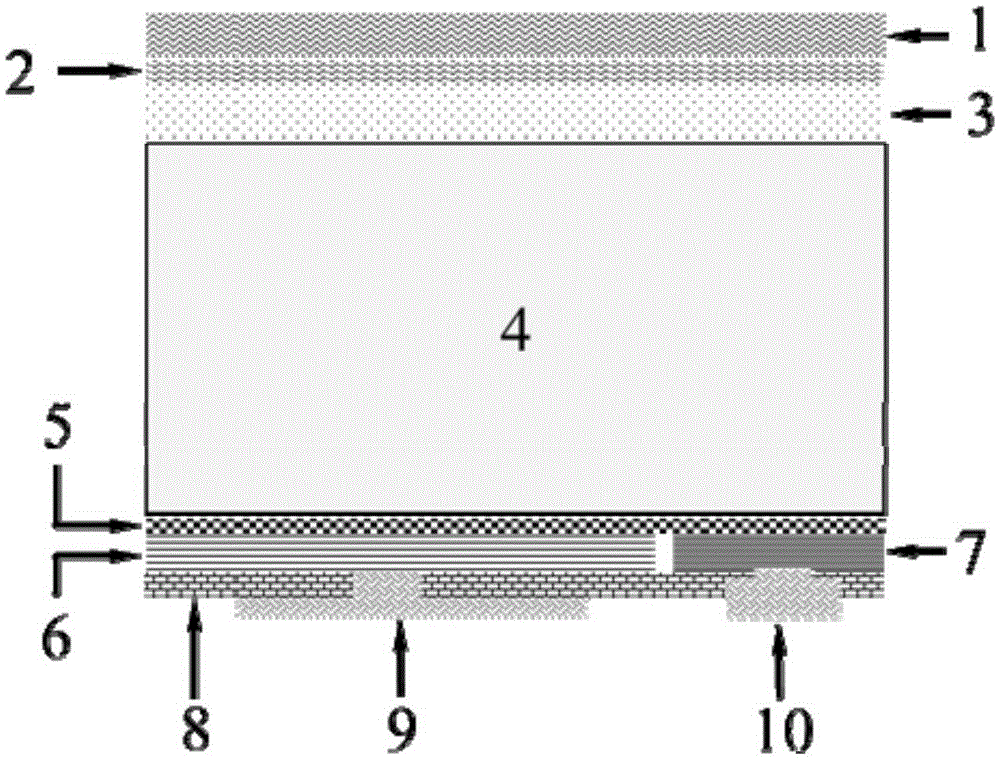

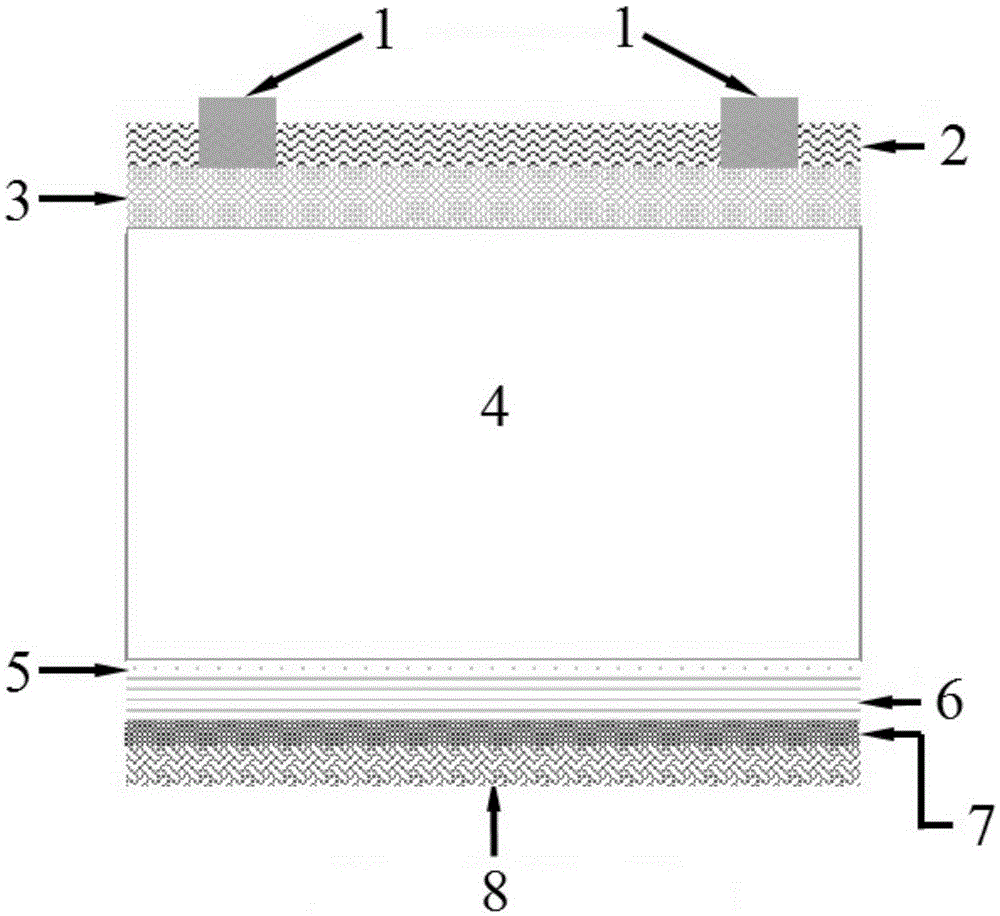

Display panel and manufacturing method thereof and display device

PendingCN105974647AShorten the imaging distanceHigh process feasibilitySolid-state devicesNon-linear opticsLiquid-crystal displayGrating

The embodiment of the invention provides a display panel and a manufacturing method thereof and a display device. The display panel comprises a nano light splitting film arranged between an array substrate and a first Polaroid. The nano light splitting film comprises a plurality of light splitting units distributed in an array, and each light splitting unit corresponds to at least one sub-pixel unit. Each light splitting unit comprises a multi-order grating structure and is used for splitting light corresponding to at least one sub-pixel unit to obtain light in one or more preset colors. A nano light splitting element is applied to the display panel so that a color film layer of a liquid crystal display device can be omitted, transmittance of the liquid crystal display device is increased, and color quality of the display device is improved on the condition that cost is not greatly increased.

Owner:BOE TECH GRP CO LTD

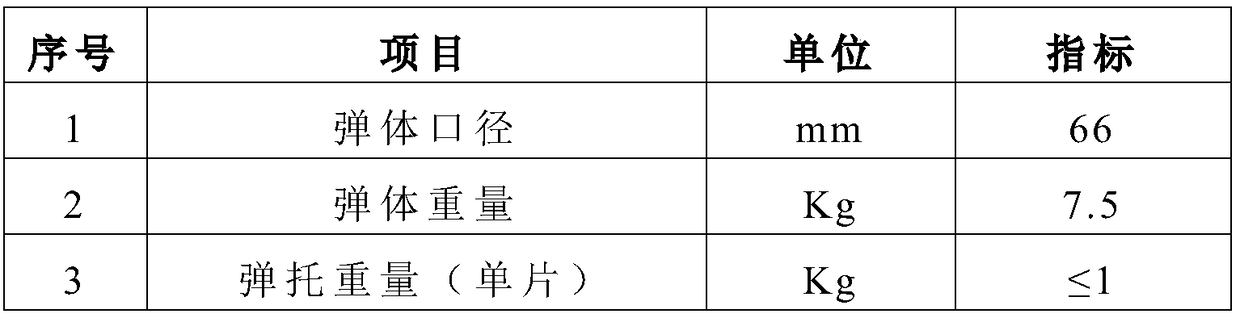

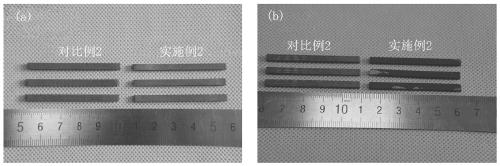

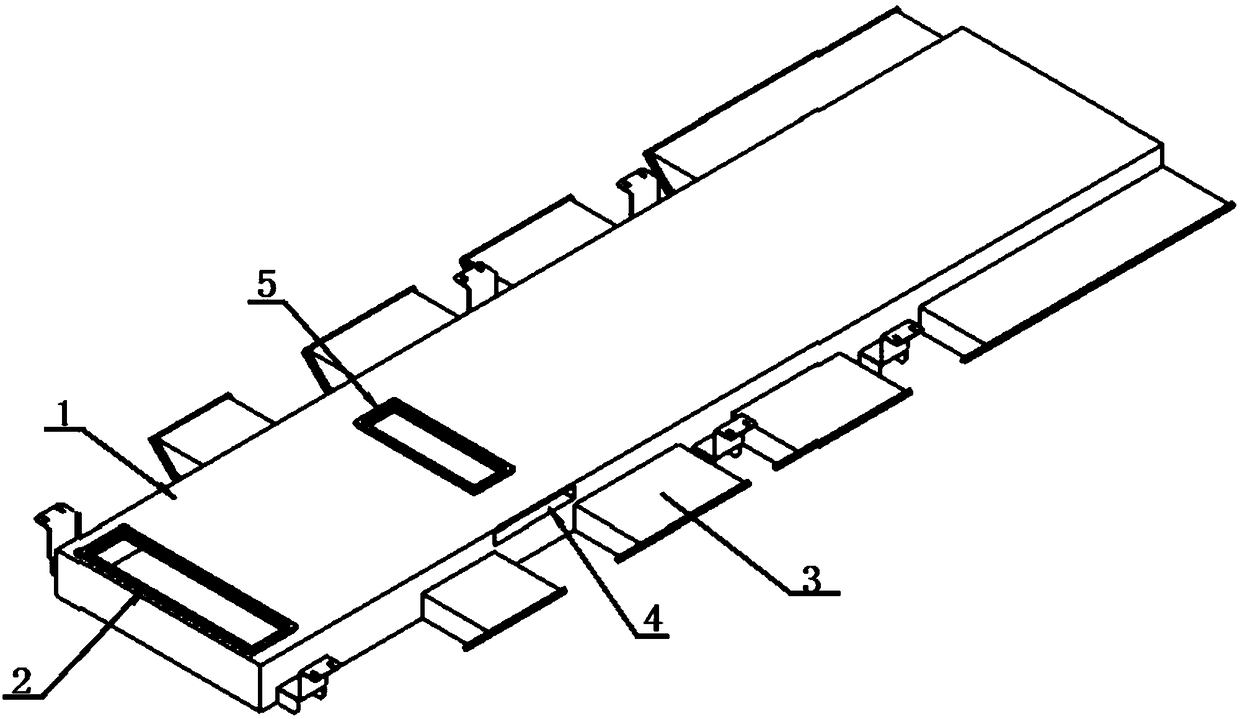

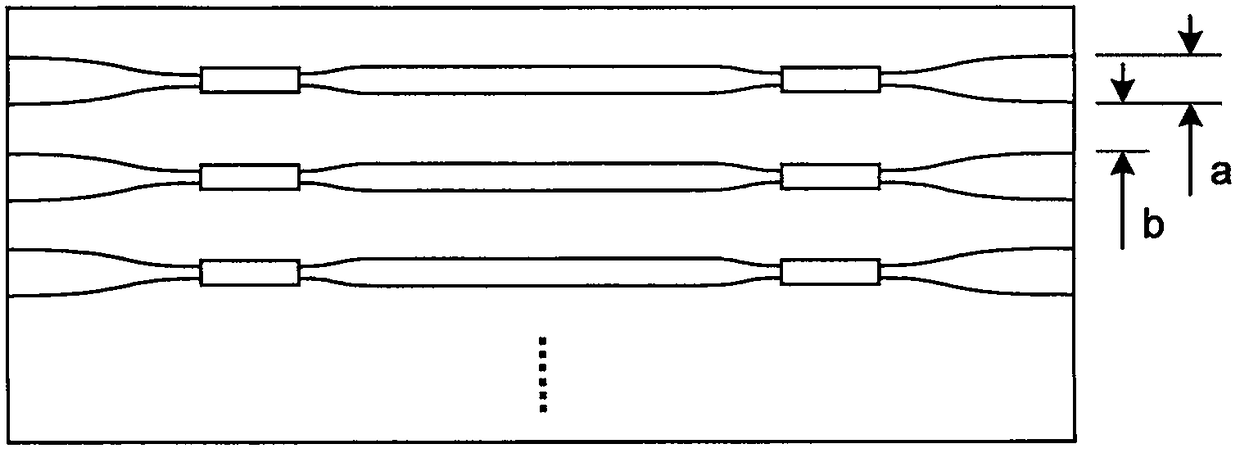

Light composite sabot and manufacturing method thereof

The invention discloses a light composite sabot and a manufacturing method thereof. The light composite sabot comprises a sabot sandwich structure and a skin laying on the surface of the sabot sandwich structure, wherein the sabot sandwich structure is manufactured by alternately bonding and processing n reinforcing ribs and (n+1) foam boards. The manufacturing method comprises the following stepsthat (1) the thickness of the skin, and the thickness and number of the reinforcing ribs and the foam boars are set; (2) the reinforcing ribs are manufactured through fiber materials A in a layer laying mode; (3) the foam boards and the reinforcing ribs are bonded together alternately through adhesives and heat and solidified into a sandwich structure blank board; (4) a sabot sandwich structure with the needed structural size are machined; (5) the skin is manufactured through fiber materials B in a layer laying mode, and the fiber materials B coated with shaping agents are laid on the surfaceof the sabot sandwich structure coated with the adhesives layer by layer, and a preformed body of the sabot is obtained; and (6) product forming is conducted through a resin transfer molding technology, and then the sabot product is obtained. According to the light composite sabot and the manufacturing method thereof, the weight reduction effect is remarkable, under the same using condition, thespeed of ammunitions is higher, and the power of the ammunitions is larger.

Owner:湖北三江航天江北机械工程有限公司

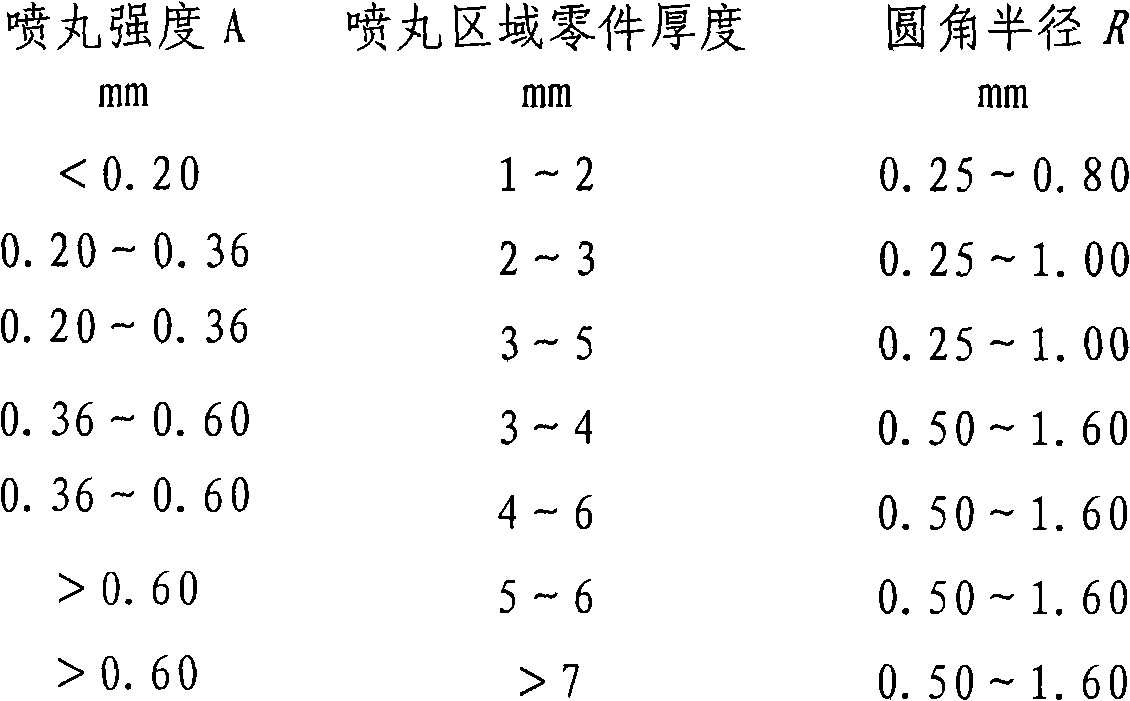

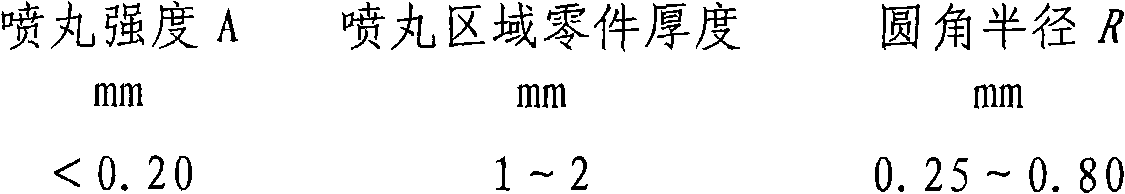

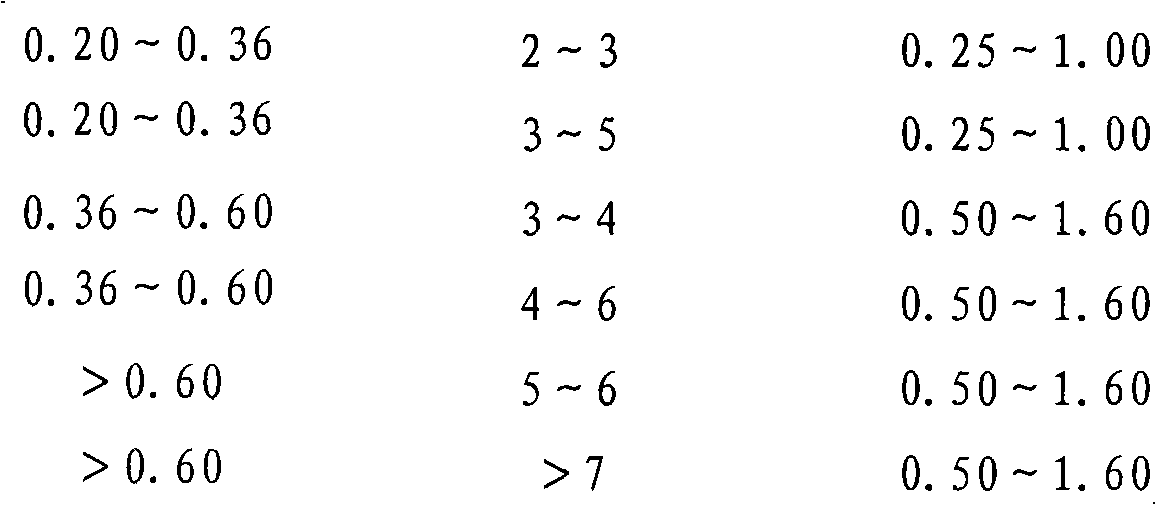

Compound strengthening method of small hole in ultrahigh strength steel part

ActiveCN101962706AImprove fatigue resistanceImprove reliabilityHigh surfaceUltimate tensile strength

The invention relates to the improvement of a surface strengthening method of a small hole in an ultrahigh strength steel part, belonging to surface strengthening technologies. The improved surface strengthening method is characterized by respectively conducting shot peening strengthening on a hole wall and extrusion strengthening on a hole mouth. The strengthening process comprises the following steps of: rounding the hole mouth; shot-peening the hole wall; and extruding the hole mouth. The invention combines the advantages of high surface quality reliability and good process implementation feasibility of the shot peening strengthening and the advantages of deep strengthening layer and good strengthening effect of the hole mouth extrusion, and the fatigue resistance of the small hole in the ultrahigh strength steel part is improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

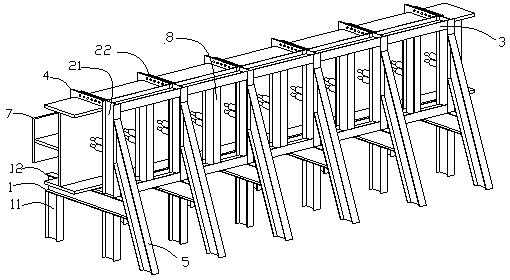

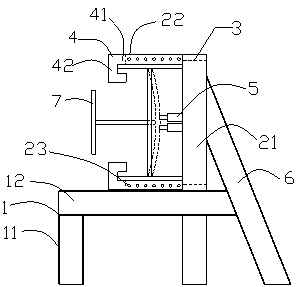

Welded combined T-shaped steel column correcting device and method

The invention discloses a welded combined T-shaped steel column correcting device and method. The correcting device is composed of multiple correcting units which are on the same straight line. Each correcting unit comprises a platform support, two L-shaped clamps and a jack. Each platform support is formed by welding two stand columns and a cross beam. A vertical beam is arranged on the upper surface of each cross beam, wherein each vertical beam is perpendicular to the corresponding cross beam. The two ends of each vertical beam are provided with two rectangular connecting blocks, wherein every two rectangular connecting blocks are parallel with the corresponding cross beam. Each connecting block is uniformly provided with multiple threaded holes. Each L-shaped clamp is integrally formedby a transverse plate and a vertical plate. Each transverse plate is provided with threaded holes matched with the threaded holes in the connecting blocks. Threaded connecting pieces penetrate the threaded holes in the transverse plates and the threaded holes in the connecting blocks, so that the two L-shaped clamps are fixedly connected with the two connecting blocks correspondingly. Each jack is arranged between the corresponding vertical beam and a to-be-corrected welded H-shaped profile steel web plate. A base of each jack tightly jacks the corresponding vertical beam. The stroke end of each jack tightly jacks the corresponding to-be-corrected welded H-shaped profile steel web plate. The welded combined T-shaped steel column correcting device has the advantages of being simple in structure, easy to operate, low in cost, high in efficiency and the like.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

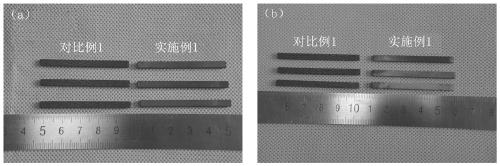

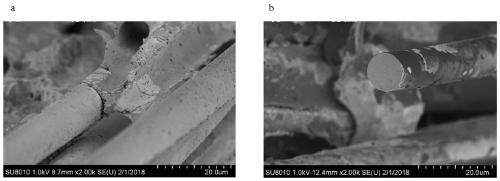

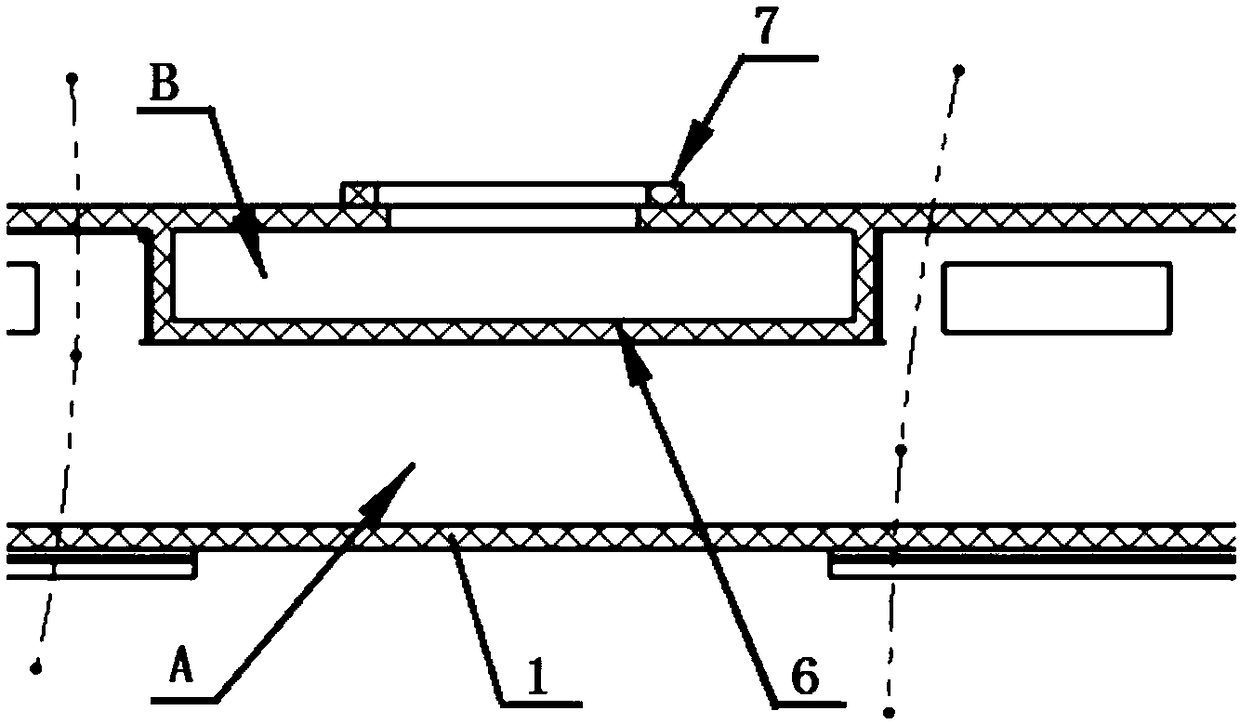

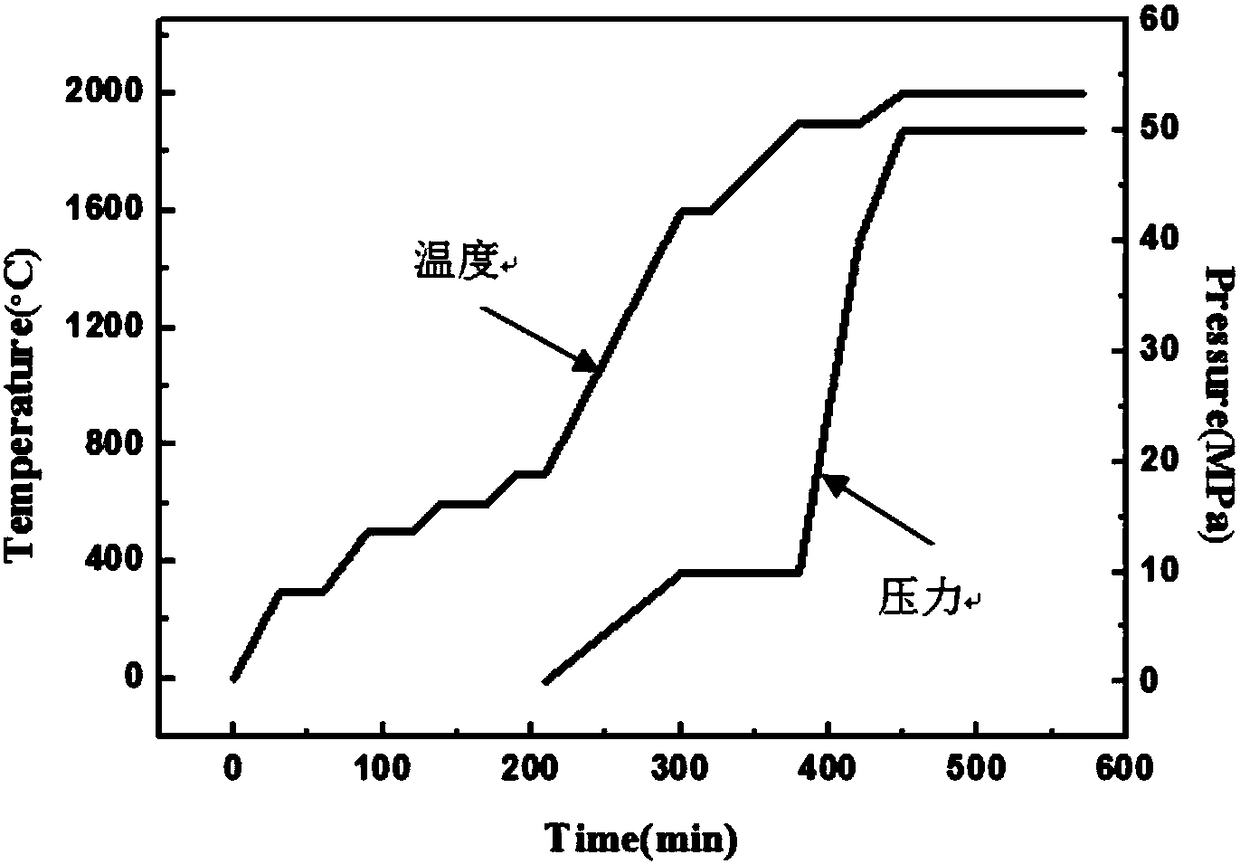

Preparation method of SiCf/SiC composite material with SiC coating layer

PendingCN109400169AImprove hydrothermal corrosion resistanceHigh densityPyrolytic carbonChemical vapor deposition

The invention discloses a preparation method of a SiCf / SiC composite material with a SiC coating layer. The preparation method comprises the following steps: S1, weaving SiC fiber into a SiC fiber weaving piece; S2, depositing a pyrolytic carbon interface coating layer on the surface of the SiC fiber of the SiC fiber weaving piece, thus obtaining a SiC fiber weaving piece with the interface coating layer; S3, carrying out densification treatment on the SiC fiber weaving piece with the interface coating layer through a precursor infiltration and pyrolysis technology, thus obtaining the SiCf / SiCcomposite material, wherein the temperature during pyrolysis is 1400 to 1800 DEG C; S4, depositing the SiC coating layer on the surface of the SiCf / SiC composite material through a CVD (Chemical Vapor Deposition) technology, thus obtaining a hydrothermal corrosion-resistant SiCf / SiC composite material with the SiC coating layer. The SiCf / SiC composite material with the SiC coating layer, preparedby the preparation method disclosed by the invention has hydrothermal corrosion resistance.

Owner:NAT UNIV OF DEFENSE TECH

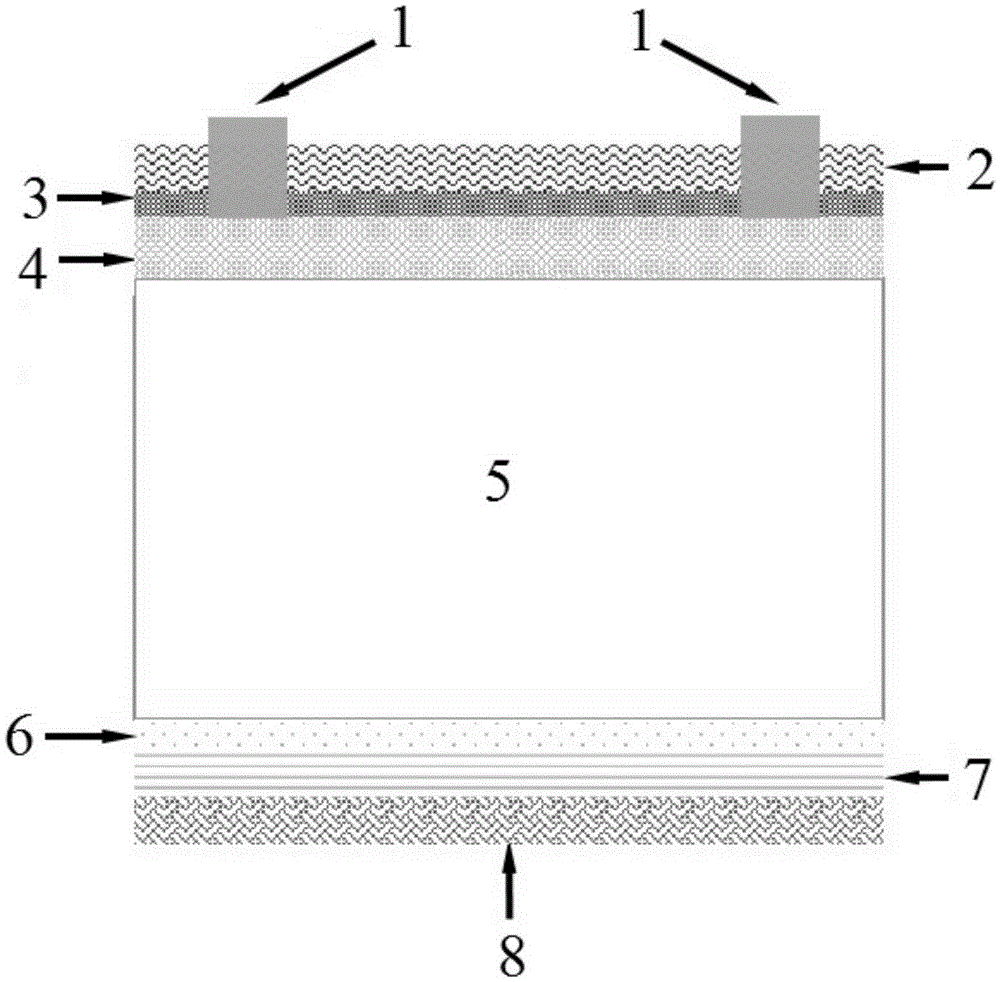

Back-surface tunnel oxidation and passivation inter-digitated type back-to-back contact battery production method

InactiveCN106784069AChange interface qualityReduce surface recombinationFinal product manufactureSemiconductor devicesSlurrySilicon dioxide

The invention relates to a back-surface tunnel oxidation and passivation inter-digitated type back-to-back contact battery production method, comprising: removing the damage layer of a silicon wafer and making velvets; and then forming an N + front surface field on the front surface of the silicon wafer; removing the phosphor silicate glass (PSG) layer and performing edge insulation and back polishing; growing an ultra-thin tunnel oxide layer SiO2 on the back of the silicon wafer; forming an inter-digitated type polysilicon layer composed of a polysilicon layer of B-doped and P-doped pairs; depositing an aluminum oxide layer and a hydrogenated amorphous silicon nitride passivation antireflective layer on the surface of the N + front surface field; and growing a silicon layer on the back side of the wafer; printing Ag / Al slurry on the back side of the battery corresponding to the B-doped region through the use of the screen printing method; printing the Ag slurry in the P-doped region; and then, drying the slurries in an oven. The invention utilizes an ultra-thin tunnel oxidation SiO2 layer and an interdigitated phosphorous-doped and boron-doped silicon layer, which greatly alters the interface quality of the silicon substrate and greatly reduces the composition of the back surface metal and the semiconductor surface.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

Manufacture method of high-efficiency cell with front emission junction and backside tunneling oxidation and passivation contact

InactiveCN106784128AReduce surface recombinationImprove electrical performance parametersFinal product manufactureSemiconductor devicesElectricitySurface concentration

The invention relates to a manufacture method of a high-efficiency cell with a front emission junction and backside tunneling oxidation and passivation contact. Texturing is carried out after removing a damage layer of a silicon chip, a B-doped P+ emission junction of a low surface concentration is formed, an ultrathin tunneling oxide layer SiO2 and a P-doped polysilicon layer are grown in the back side of the silicon chip after edge insulation and backside polishing, an alumina layer is deposited in the surface of the P+ emission junction, a hydrogenated amorphous silicon nitride passivation antireflection layer is grown in the front side of the silicon chip in a PECVD or magnetron sputtering method, a Ag / Al slurry is printed in the front side of the silicon chip, a full aluminum backfield Al-BSF structure is formed in the back side of the silicon chip, and a drying furnace is used to implement drying. Compared with the prior art, the ultrathin tunneling oxide SiO2 layer (<2nm) and the P-doped silicon layer are used to reduce metal-semiconductor surface combination in the backside greatly, and the manufacture method has the obvious advantage that electric performance parameters can be improved greatly on the basis that the method is compatible with a traditional cell manufacturing technology.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

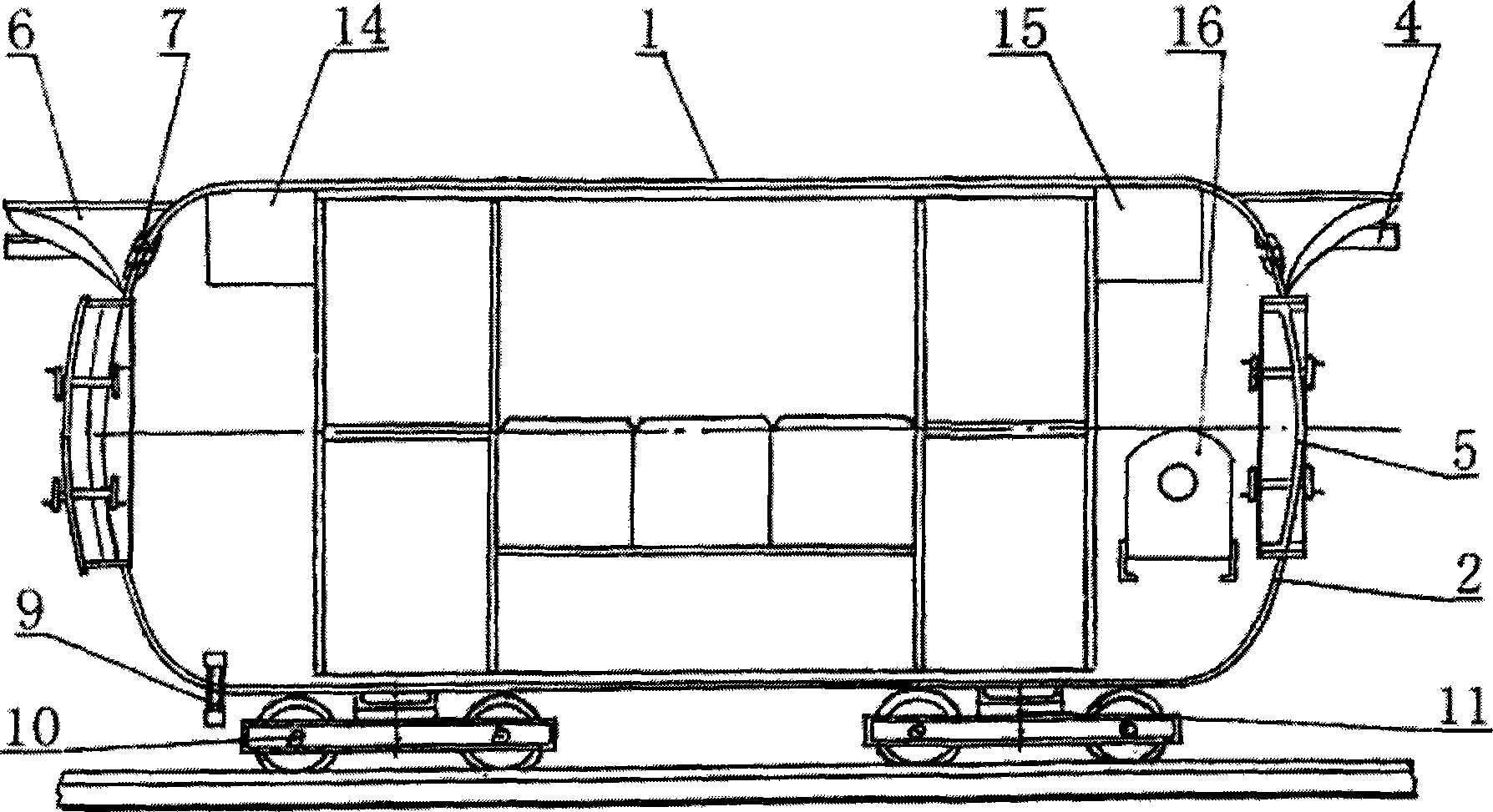

Down-hole danger-removing rescue capsule

InactiveCN101519974AHigh process feasibilityMature and reliable technical measuresSafety equipmentsHuman wasteCommunications system

The invention relates to a down-hole danger-removing rescue capsule, relating to the technical field of danger-removing rescue. The technical problem to be solved is to remove dangers in operation construction sites under mines. The danger-removing rescue capsule comprises a steel hollow sealing capsule, a passive life support system and a communication which can connect communication cables of a command center in communication equipment in the capsule; two ends of the capsule are provided with at least one unsealing capsule door; the capsule is internally provided with a fireproof insulating layer; the capsule is provided with at least one observing window; the bottom part of the capsule is provided with at least one group of rail wheels; the capsule is provided with a communication crossing capsule part; the capsule is externally provided with a lifting lug; and the passive life support system comprises an air regenerating device, a carbon monoxide removal device, an air purifying device, food, drinking water safeguarding articles, and a body excretion disposal device. The down-hole danger-removing rescue capsule has long period for removing dangers, low cost for manufacturing and operating, long service life and high cost performance.

Owner:蔡建 +1

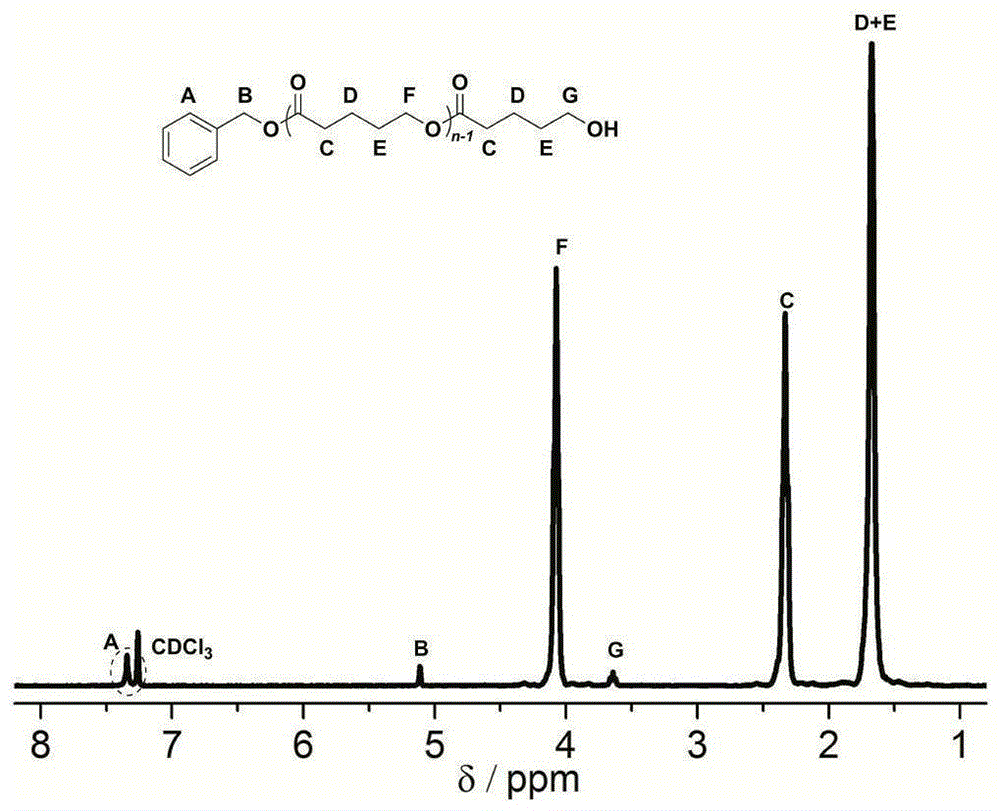

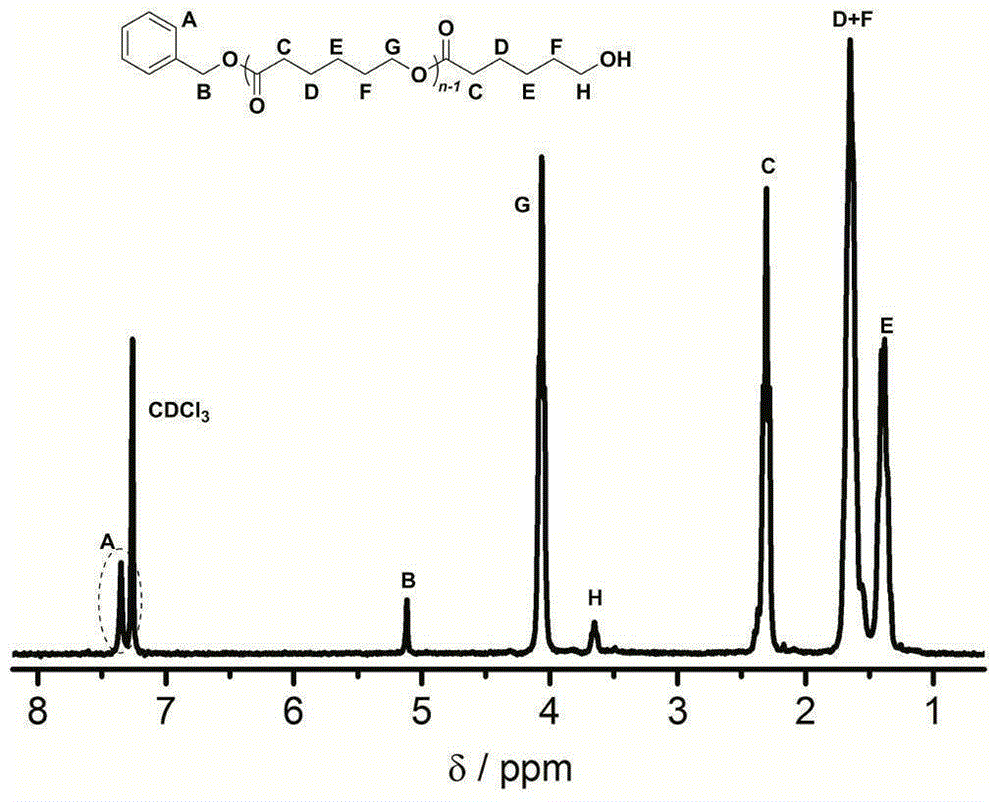

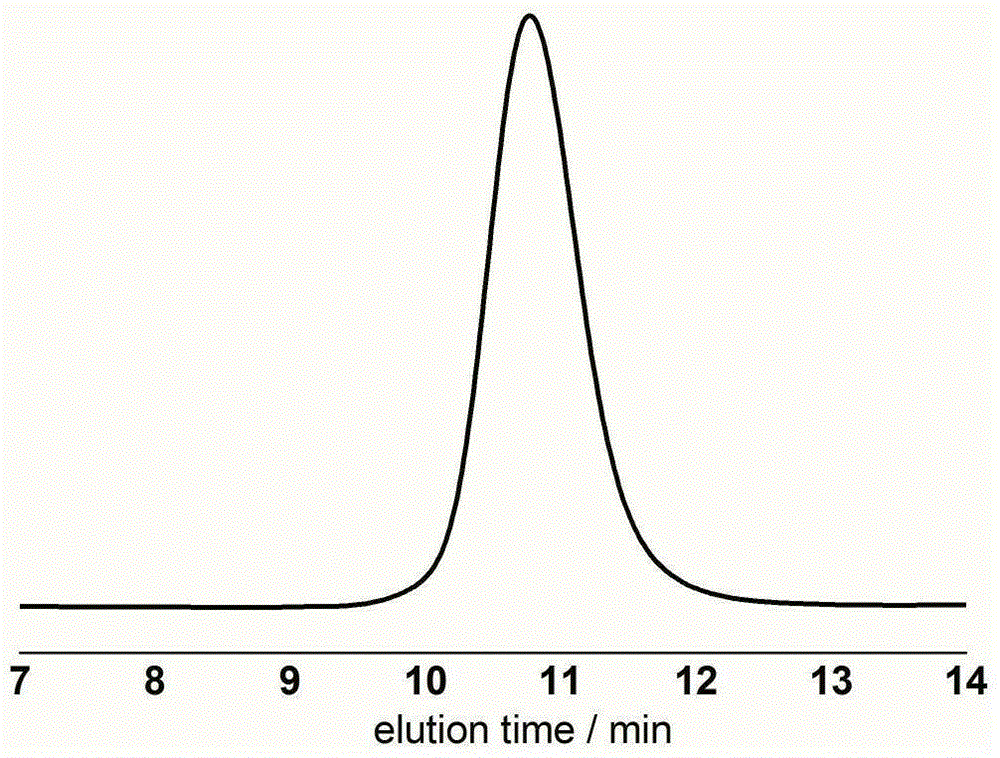

Method for preparing polylactone

The invention discloses a preparation method of polylactone and belongs to the technical field of organocatalysis and high polymer materials. By the use of a catalyst (gamma-resorcylic acid) which is natural and safe, is not sensitive to the environment, is commercially available and is cheap and has an ideal catalytic effect, polyvalerolactone and polycaprolactone are prepared at 0-200 DEG C in the presence or in the absence of a solvent, so as to obtain a high polymer biodegradable material having large molecular weight and narrow dispersity and containing no metal impurities. Thus, defects of a catalyst commonly used in industry in aspects of safety, price, sensitivity to the environment and catalytic effect are overcome, and a simple, mild, effective and cheap polymerization method is provided. A high polymer material prepared by the method can be applied in fields of drug carrier, nanoreactor, film, material interface and the like, has biodegradability and is an environmentally-friendly material.

Owner:NANJING UNIV OF TECH

Back emitter junction back-surface tunnel oxidation and passivation contact efficient battery production method

InactiveCN106784129AReduce surface recombinationImprove electrical performance parametersFinal product manufacturePhotovoltaic energy generationSlurryEngineering

The invention relates to a back emitter junction back-surface tunnel oxidation and passivation contact efficient battery production method, comprising: removing the damage layer of a silicon wafer and making velvets; and then performing edge insulation and back polishing; growing an ultra-thin tunnel oxide layer SiO2 on the back of the silicon wafer; using the PECVD method or other CVD methods to grow a B-doped polysilicon layer on the ultra-thin tunnel oxide layer SiO2; depositing an aluminum oxide layer on the surface of the B-doped polysilicon layer; growing a hydrogenated amorphous silicon nitride passivation antireflective layer on the front surface of the silicon wafer; and finally, printing Ag slurry on the front surface of the silicon wafer to form an all-aluminum back-field A1-BSF structure at the back surface. Compared with the prior art, the method could replace the N type back emitter crystalline silicon battery back point contact mechanism through the utilization of an ultra-thin tunnel oxide layer SiO2 and a B-doped polysilicon layer. Such a composed layer could greatly reduce the composition of the back surface metal and the semiconductor surface.

Owner:SHANGHAI SHENZHOU NEW ENERGY DEV

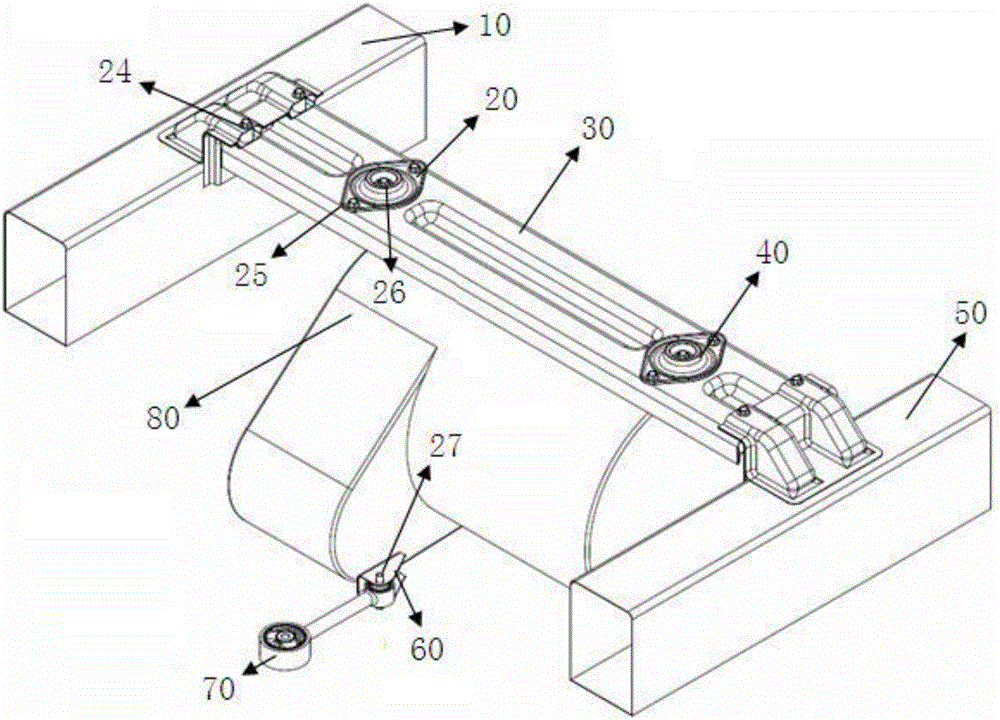

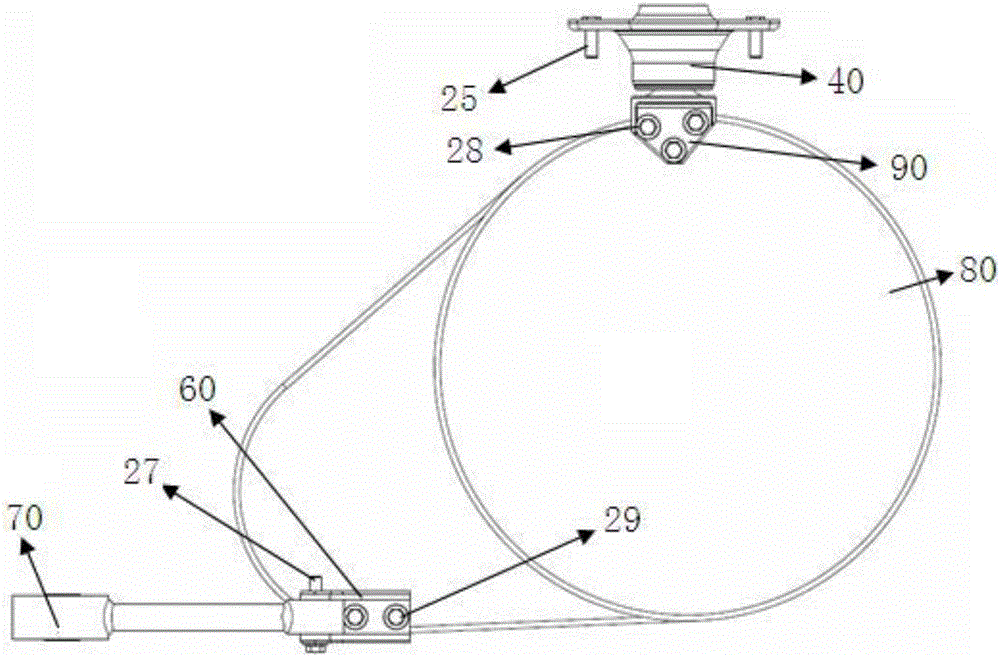

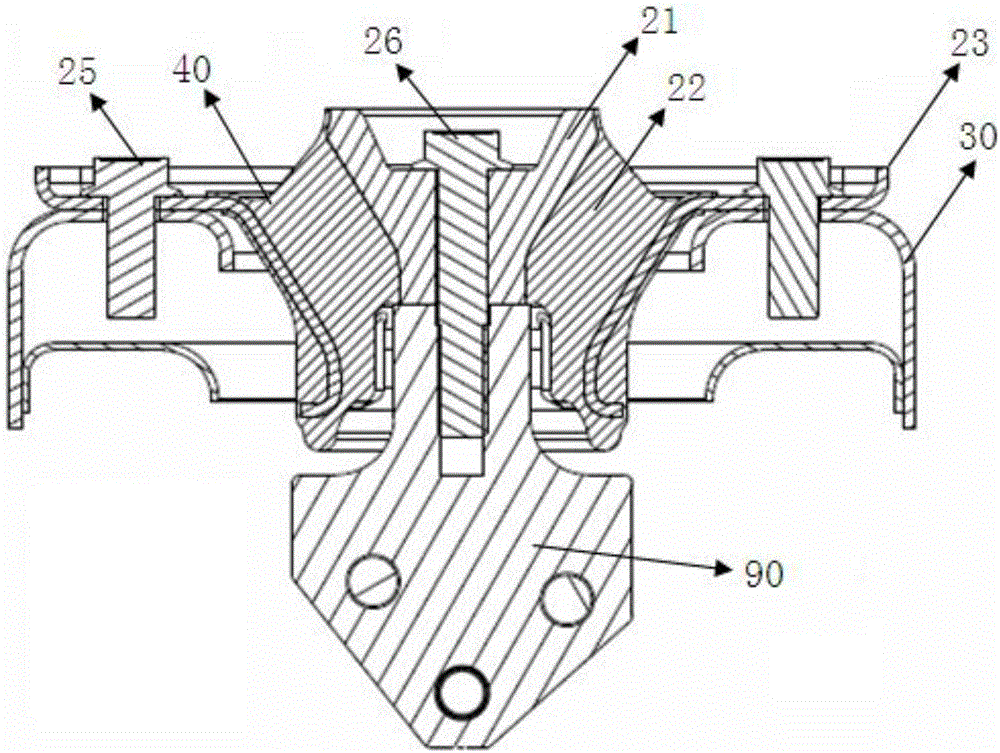

Electric automobile power assembly suspension system

PendingCN106696669AEasy to installReasonable structureJet propulsion mountingInternal combustion mountingVehicle frameEngineering

The invention relates to an electric automobile power assembly suspension system which comprises a right suspension (40), a left suspension (20), a rear suspension (70), a crossbeam (30) and a power assembly (80). The power assembly (80) is connected to the position below the crossbeam (30). The left end and the right end of the crossbeam (30) are connected to an automobile body left longitudinal beam (10) and an automobile body right longitudinal beam (50). The left suspension (20) and the right suspension (40) are connected to the crossbeam (30). The bottom ends of the left suspension (20) and the right suspension (40) are connected to the power assembly (80) through second supports (90). The rear suspension (70) is connected to the power assembly (80) through a first support (60), and the other end of the rear suspension (70) is connected to an auxiliary automobile frame of an automobile. The electric automobile power assembly suspension system is simple and reliable in structure, reasonable in arrangement, good in technological feasibility, simple and reasonable in installation and assembly and excellent in performance, the weight can be reduced by about 20%, and cost can be saved by about 25%.

Owner:MAGNA STEYR AUTOMOTIVE TECHNOLOGY (SHANGHAI) LTD

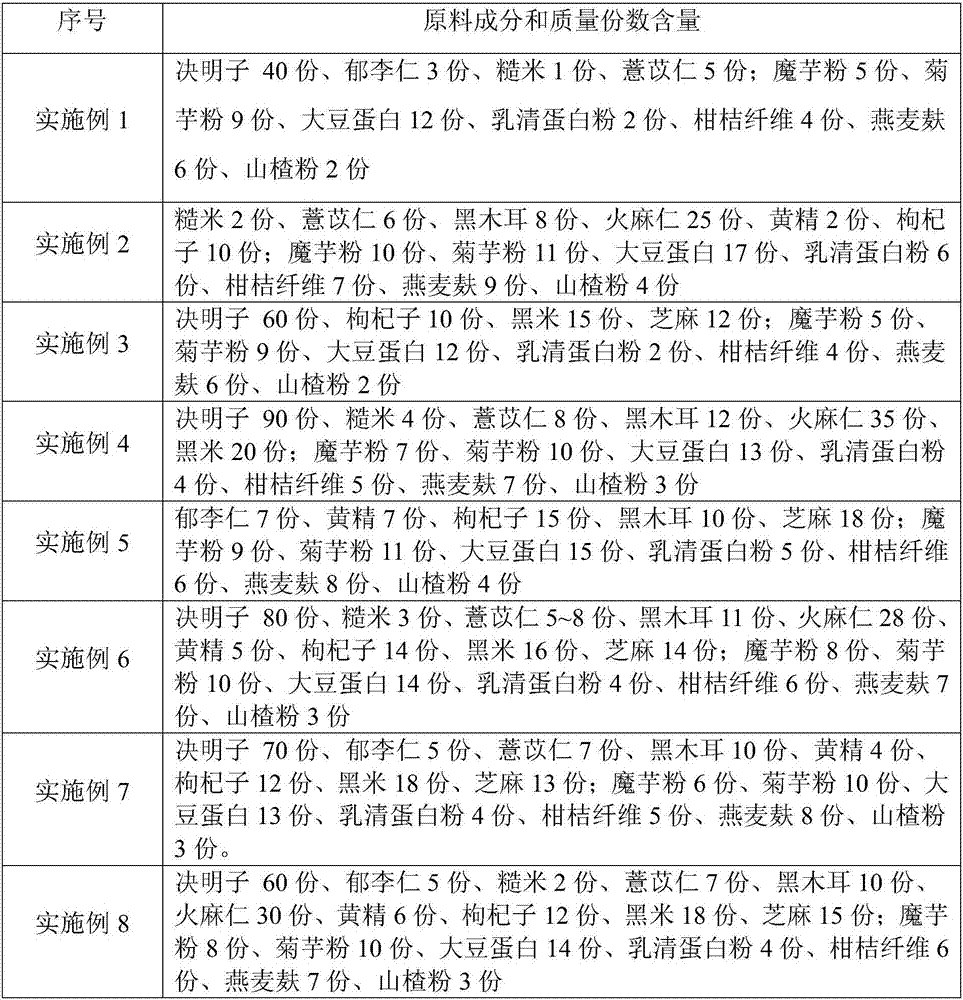

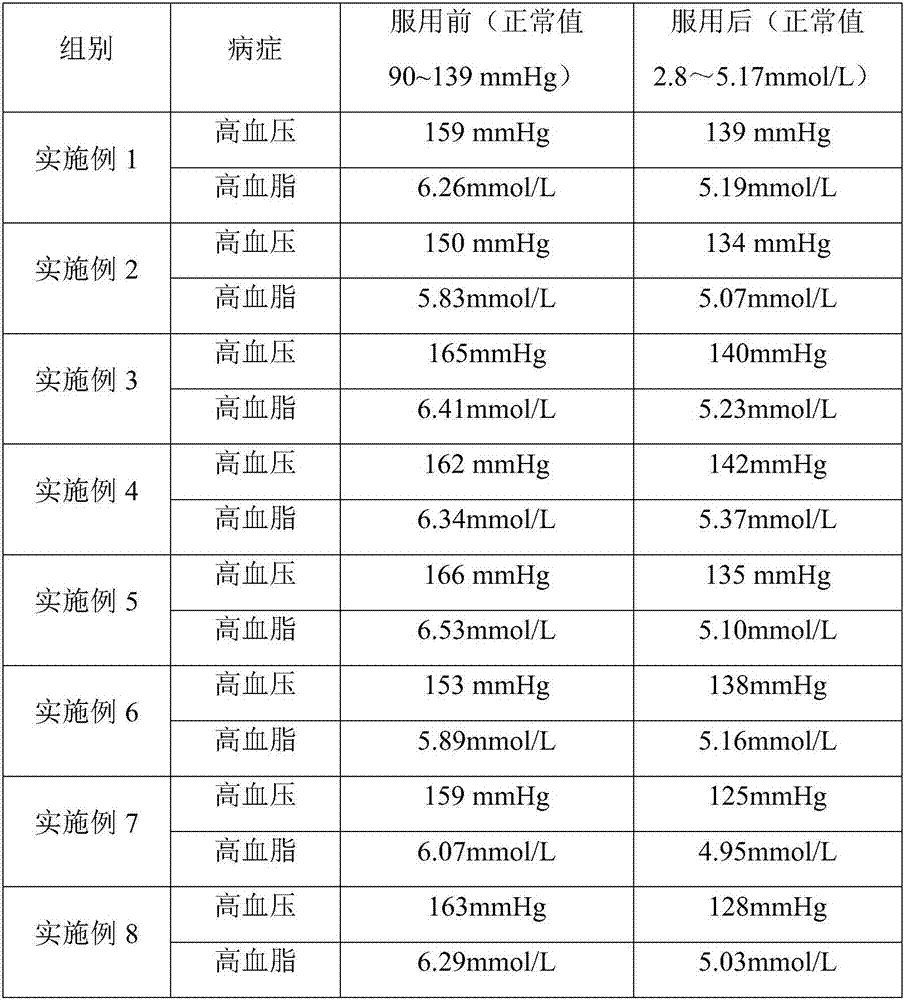

Plant composite enzyme and preparation method thereof

ActiveCN107183688AGood effectRegulate gut floraFood ingredient functionsPhysiological functionWhey protein powder

The invention provides a plant composite enzyme. The plant composite enzyme comprises main materials and auxiliary materials, wherein the main materials are selected from at least four types of semen cassiae, semen pruni, brown rice, semen coicis, black fungus, fructus cannabis, rhizoma polygonati, fructus lycii, black rice and sesame; the auxiliary materials comprise konjaku flour, jerusalem artichoke flour, soybean protein, whey protein powder, citrus fiber, oat bran and hawthorn powder. The plant composite enzyme has the advantages that the main raw materials are traditional Chinese medicines with medicine and food homology property, are fermented and processed, and are matched with other beneficial raw materials; by adopting the technical scheme, the main functions of relaxing bowel, clearing intestines and detoxifying, adjusting balance of intestinal flora, and balancing and nourishing intestines are realized, and other multiple physiological function of assisting for reducing blood glucose and blood pressure and the like are realized.

Owner:河北中佳本草生物技术有限公司

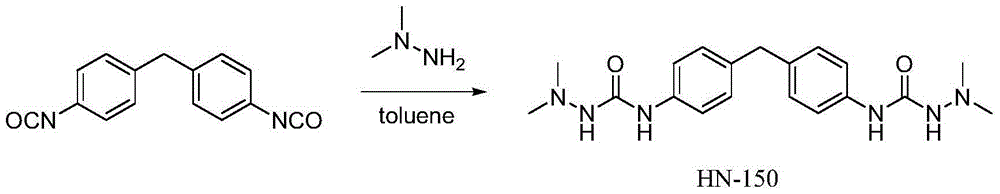

Preparation method of anti-yellowing agent HN-150

InactiveCN104151205ASimple preparation processLow equipment requirementsOrganic chemistryOrganic solventUnsymmetrical dimethylhydrazine

The invention provides a preparation method of an anti-yellowing agent HN-150. The preparation method comprises the following steps: respectively dissolving unsymmetrical dimethylhydrazine and diphenyl methane diisocyanate in an organic solvent while stirring, mixing, filtering, washing, drying and the like to obtain a final product. The preparation method provided by the invention has the advantages that the operation is simple, raw materials are low in price, a process is simple and convenient, the environmental pressure is small, the product is high in yield and purity, and the like.

Owner:SHAOXING UNIVERSITY

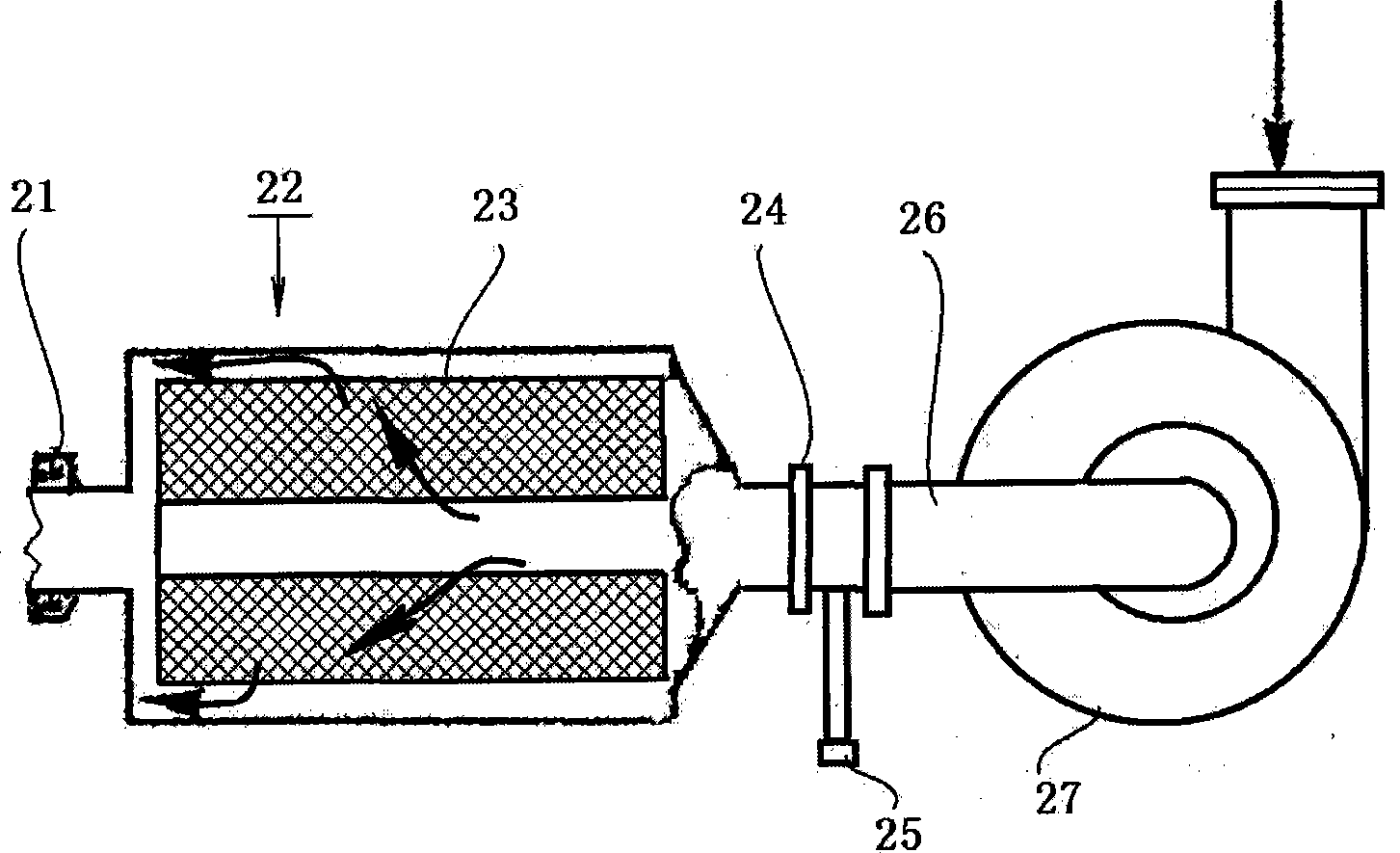

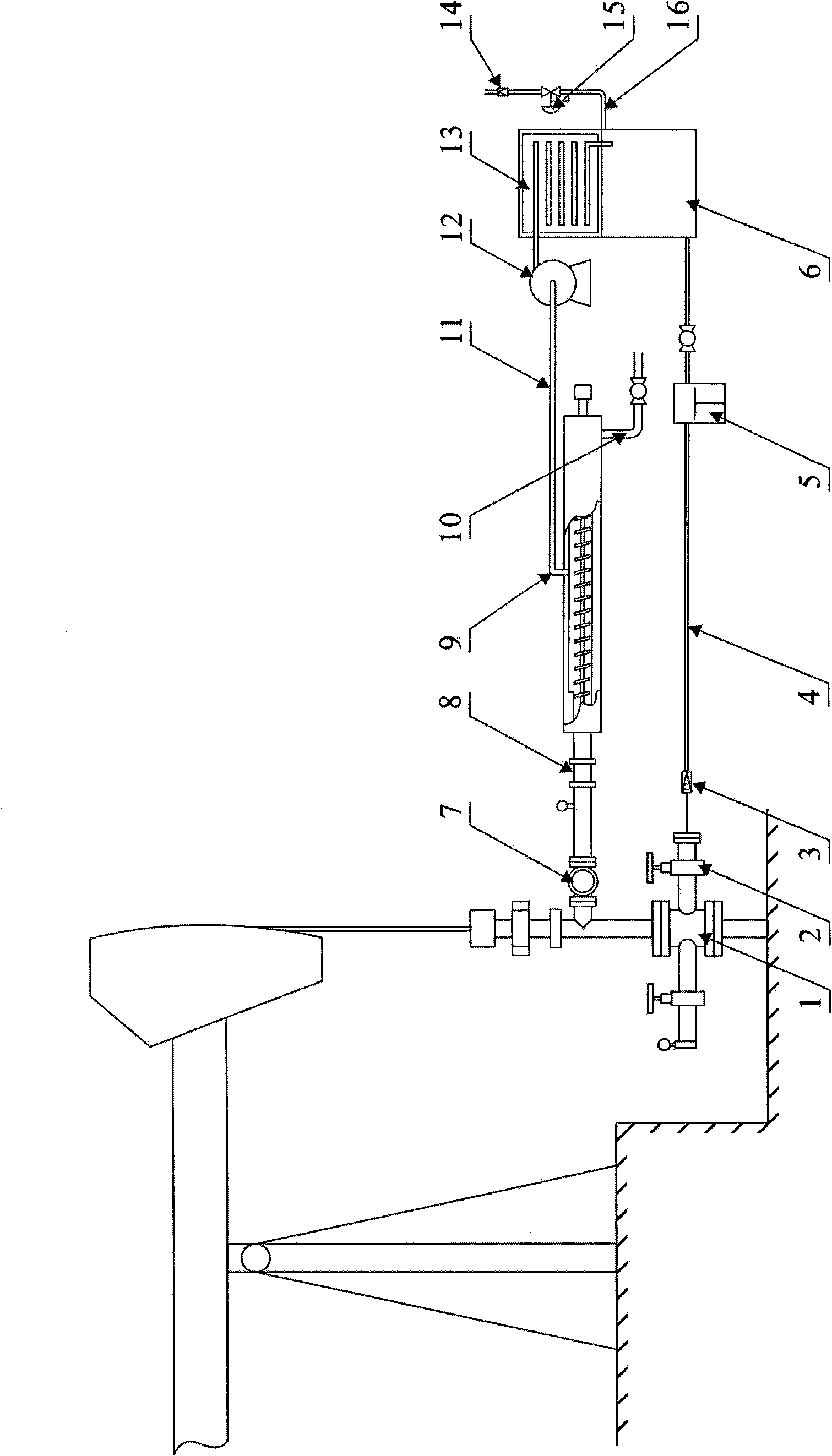

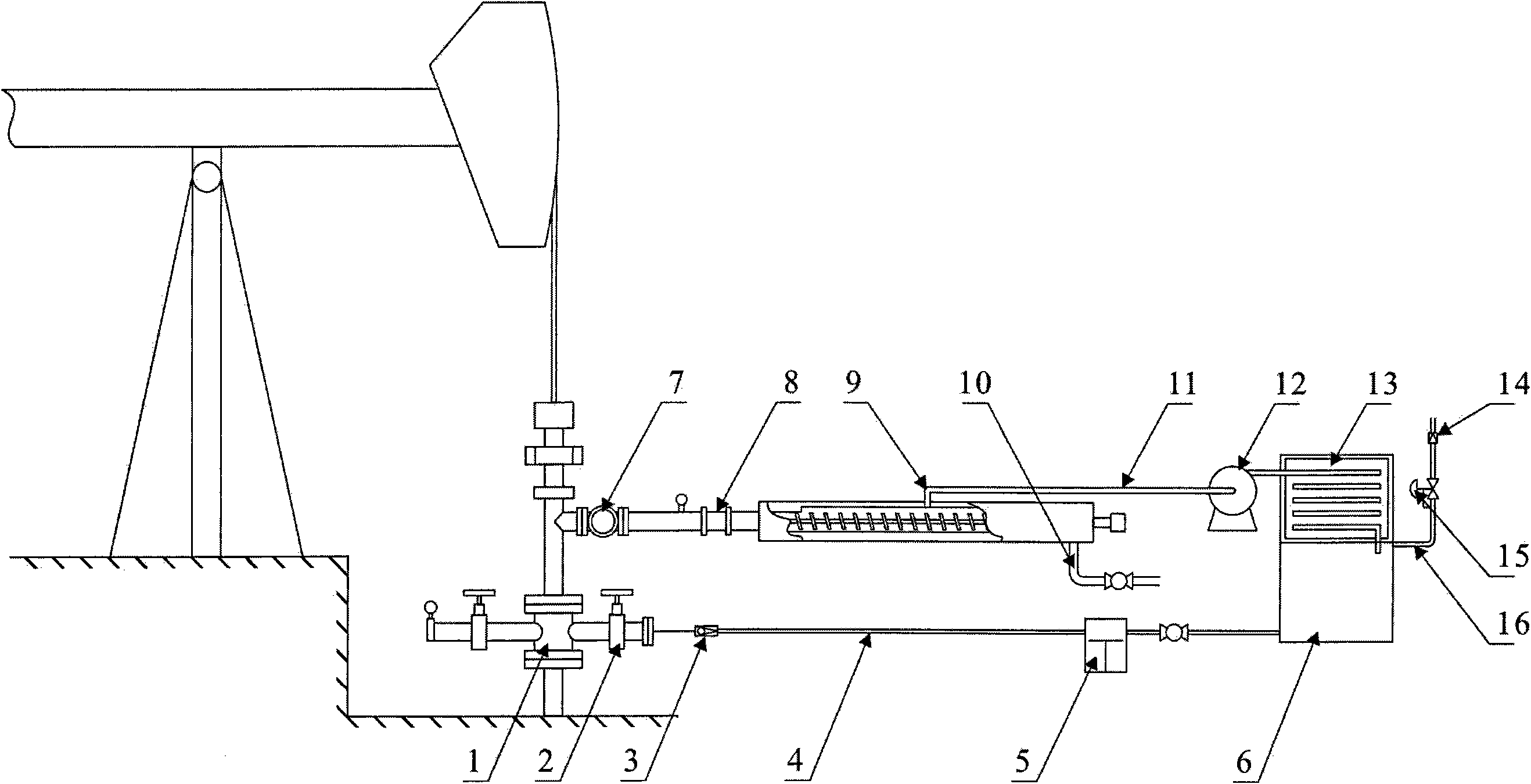

Application of dimethyl ether and process and device employing dimethyl ether to assist production of heavy oil

The invention discloses application of dimethyl ether and a process and a device employing the dimethyl ether to assist the production of heavy oil. The dimethyl ether is used as a heavy oil production assistant agent for assisting the process for producing the heavy oil. The process comprises the following steps of: selecting the heavy oil production assistant agent; injecting the dimethyl ether; collecting crude oil; separating the dimethyl ether; liquefying and recovering the dimethyl ether; and recycling the dimethyl ether in a closed mode. In the process, the dimethyl ether is selected as the heavy oil production assistant agent, has extensive sources, causes no damage to a production layer, does not influence the quality of the crude oil, does not cause pollutions to the environment, can be recycled, and has high economic benefit; by injecting the dimethyl ether liquid to reduce the viscosity of the heavy oil, the efficiency of an oil pumping unit can be significantly improved, and the heavy oil recovery ratio is improved; and the process employing the dimethyl ether to assist the production of the heavy oil has convenient equipment installation, not only can be used for an individual well and an oil production platform but also can be used for an oil production block, and has very strong technology feasibility and suitability.

Owner:SUINING HUAXU TECH

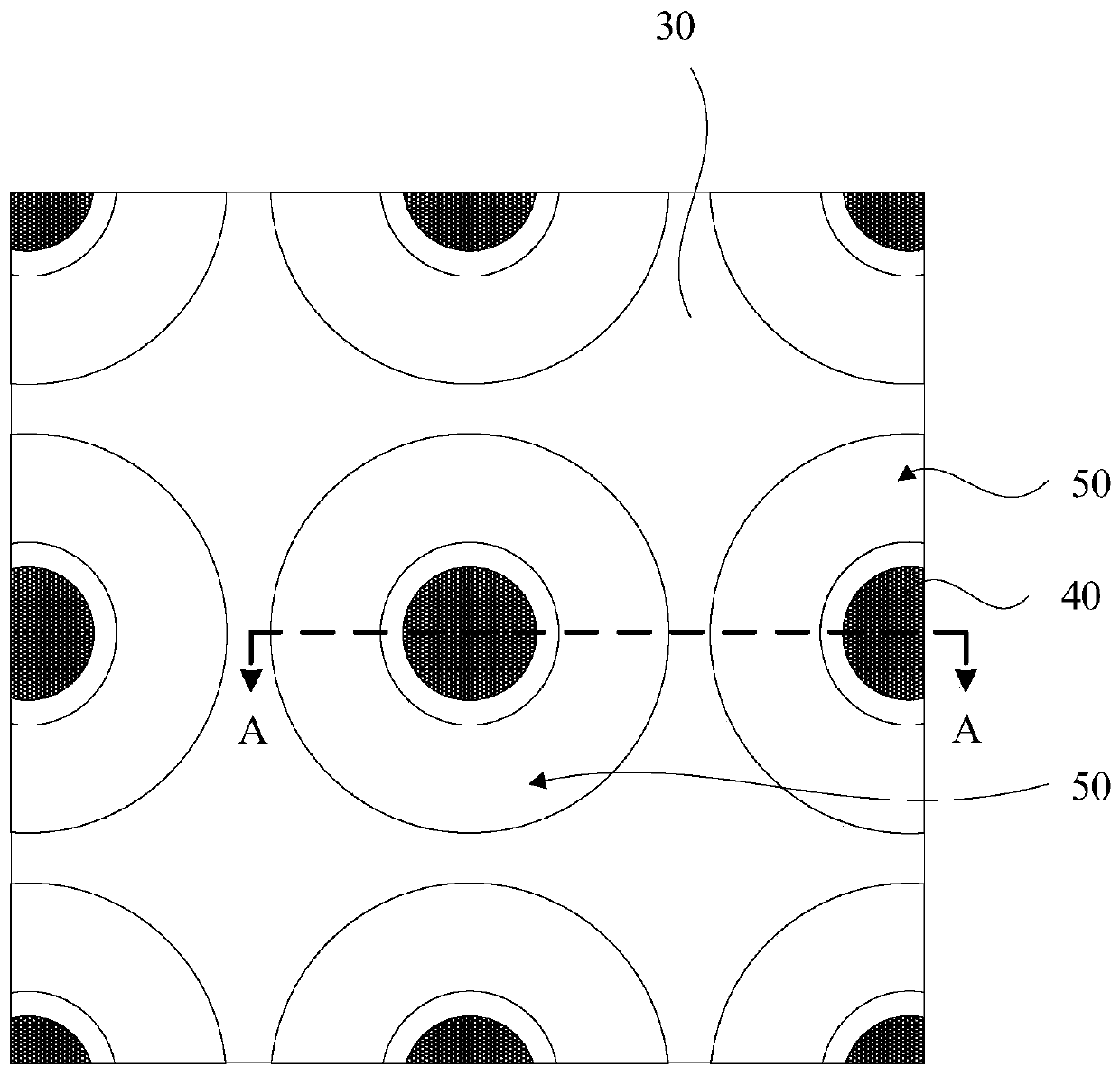

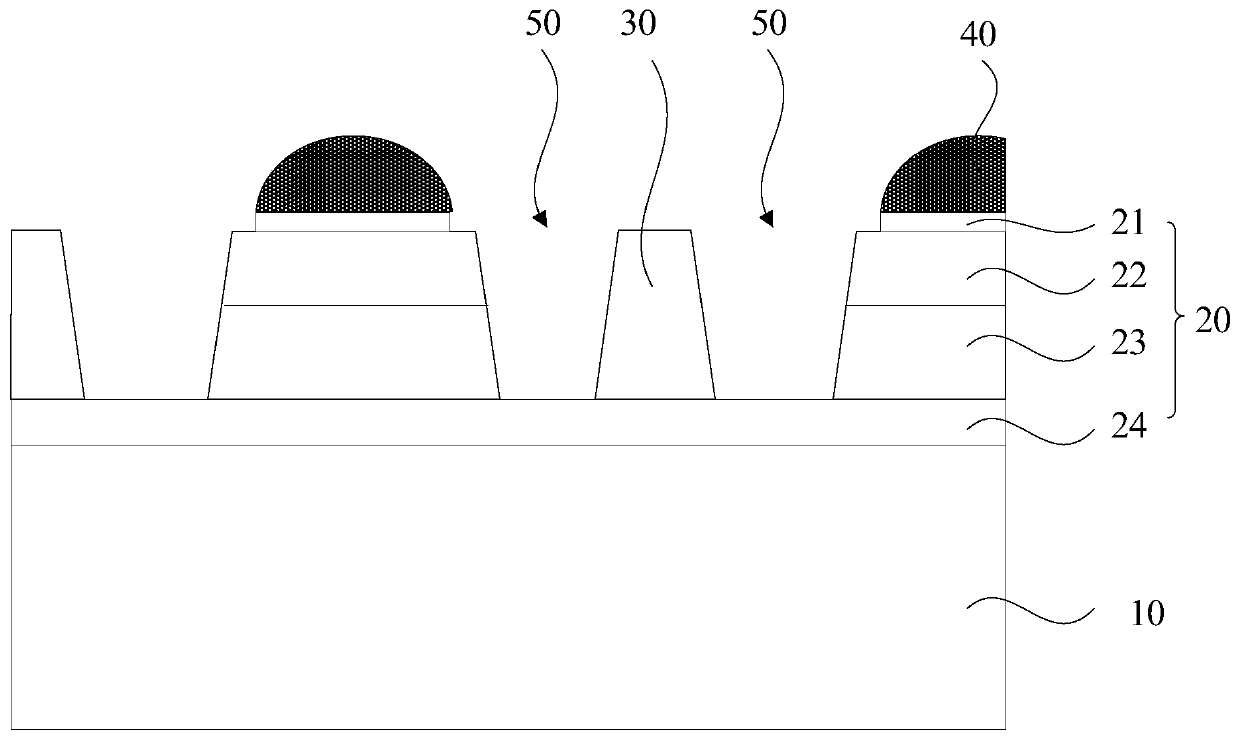

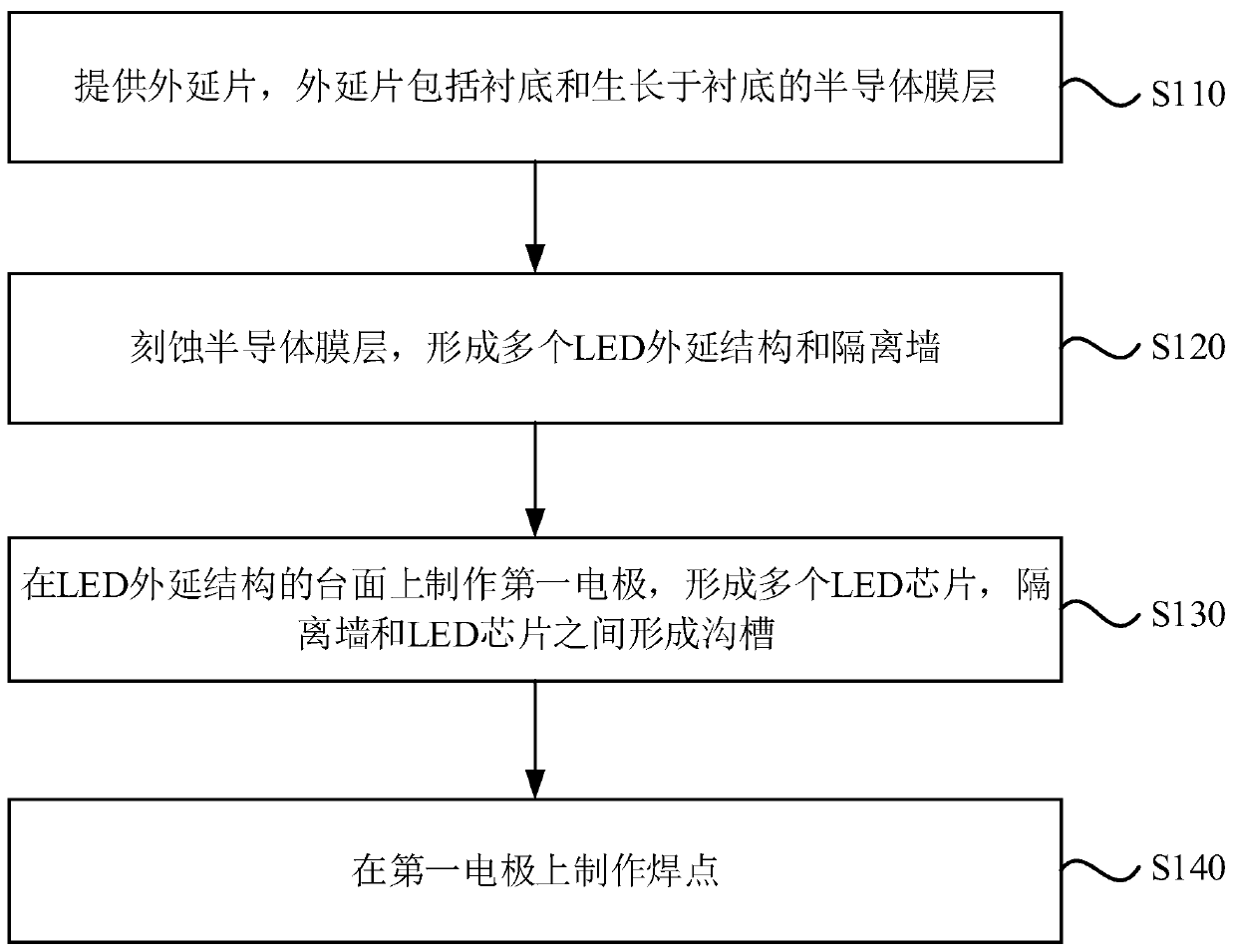

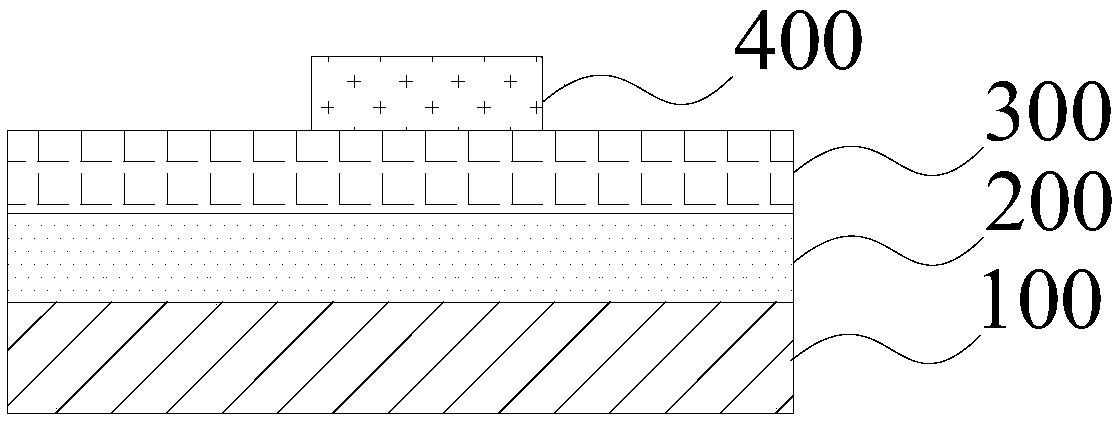

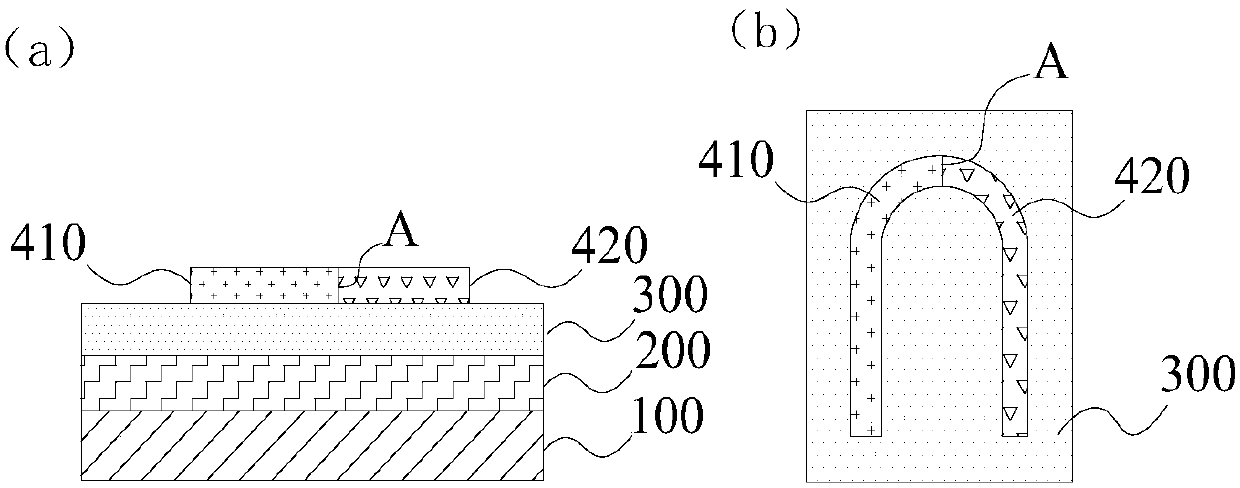

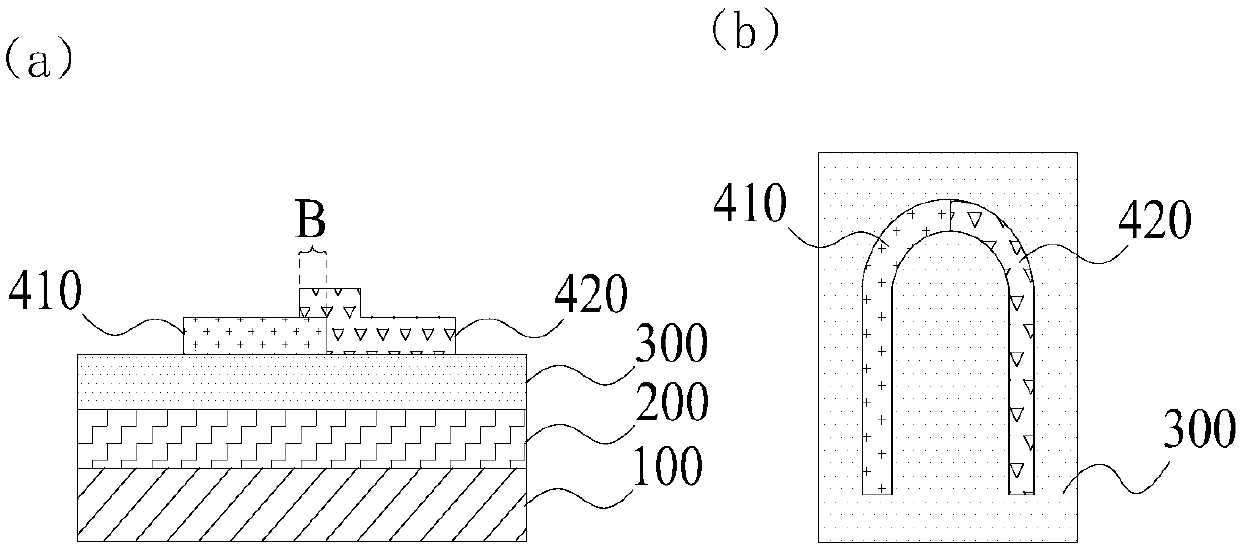

Light-emitting diode chip array and display panel

ActiveCN110416246APrevent lateral expansionAvoid shortingSolid-state devicesSemiconductor devicesEngineeringLight-emitting diode

The embodiment of the invention discloses a light-emitting diode chip array and a display panel. The light-emitting diode chip array comprises a substrate, a plurality of light-emitting diodes on thesubstrate, isolation walls and welding spots, wherein each light-emitting diode includes a first electrode; trenches are formed between the isolation walls and the light-emitting diodes; and the welding spots are respectively located on the first electrodes. The embodiment of the invention realizes an effect of avoiding an electrode short circuit between adjacent LED chips, and improves the bonding yield. The light-emitting diode chip array provided by the embodiment of the invention has the advantages of simple structure and simple and feasible process, and is conducive to improving the process feasibility of the light-emitting diode chip array and the reliability of the display panel.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

Preparation method of enteromorpha prolifera dietary fiber

ActiveCN106108033AReduce the loss of active ingredientsImprove extraction efficiencyFood scienceChemistryWater soluble

The invention provides a preparation method of enteromorpha prolifera dietary fiber. The preparation method of the enteromorpha prolifera dietary fiber specifically comprises the following steps: washing and soaking dry enteromorpha prolifera with purified water so as to remove salt and impurities; dewatering the clearly washed enteromorpha prolifera by carrying out extruding, putting the dewatered enteromorpha prolifera into a reaction tank, and adding a weak acid solution so as to carry out degradation; filtering the enteromorpha prolifera after the acid hydrolysis, temporarily storing the produced filtrate, and rinsing the generated filter residues by using water until the filter residues are neutral; sending the filter residues into a fermentation tank, and adding a Seawin Biotech complex bacteria preparation so as to carry out fermentation; carrying out high-temperature high-pressure sterilizing after the completion of the fermentation, carrying out filtering after the sterilizing, and obtaining a filtrate; and then, combining the produced filtrate with the previous temporarily stored filtrate, and carrying out alcohol precipitating, filtrating, drying and crushing, so that water-soluble dietary fiber is prepared. Moreover, bleaching, water-washing, drying and ultrafine crushing are performed on the remaining sterilized filter residues, so that water-insoluble dietary fiber is prepared. The preparation method is high in extraction efficiency, high in product purity, simple in operation steps, strong in practicability and relatively low in cost; thus, the preparation method is suitable for preparing dietary fiber by carrying out large-scale treatment on enteromorpha prolifera.

Owner:青岛海大生物集团股份有限公司

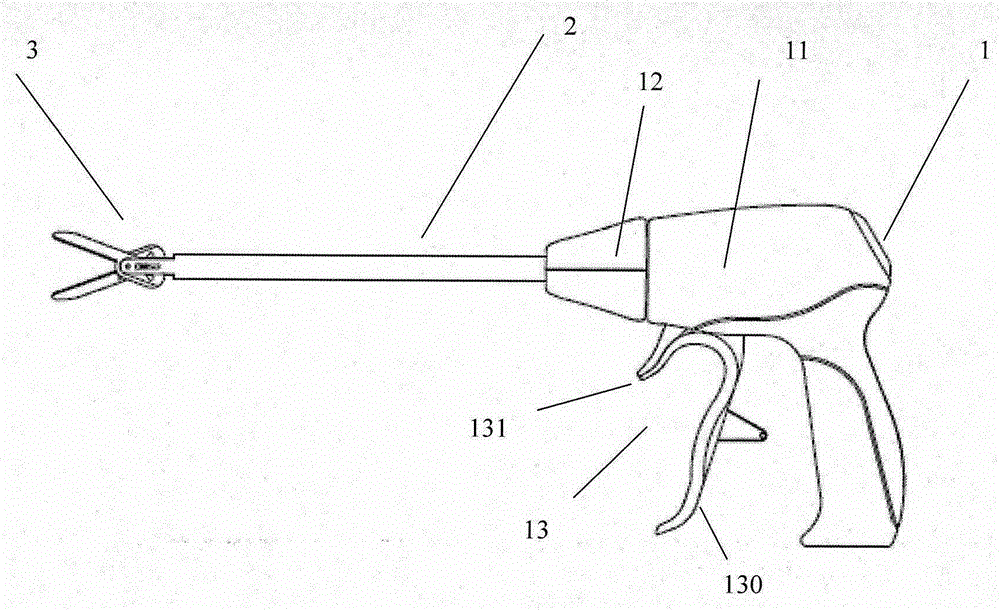

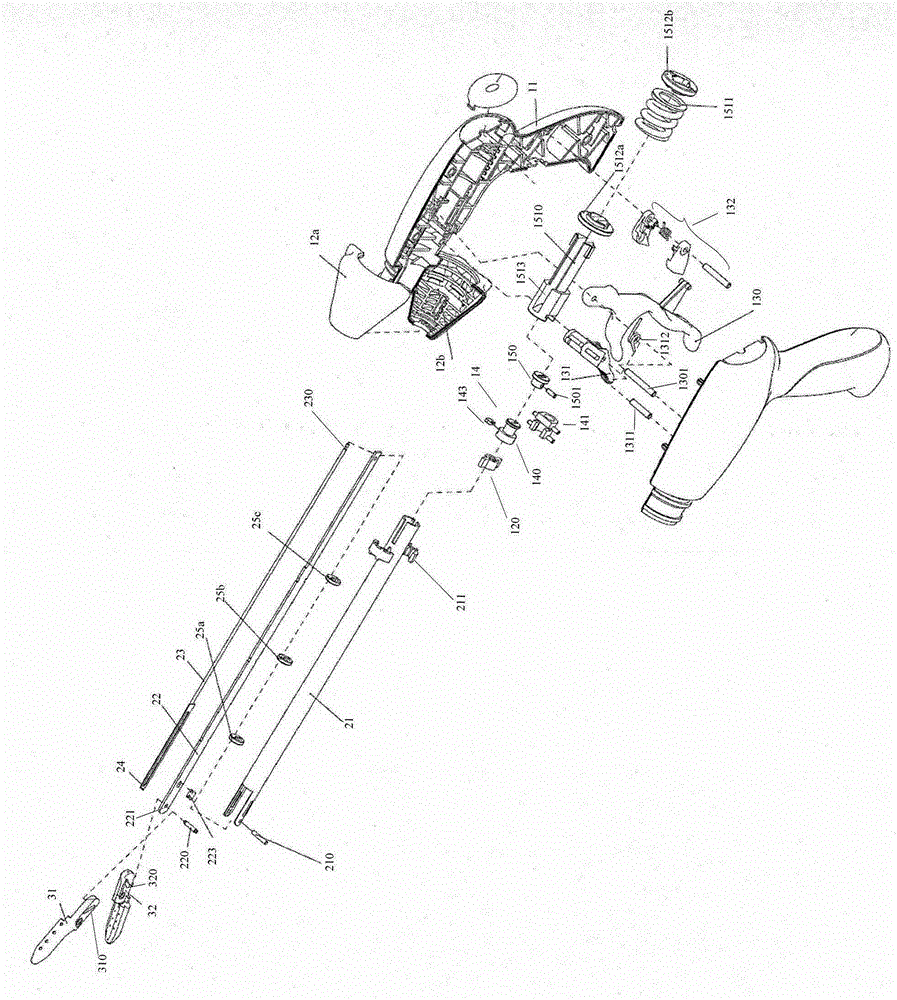

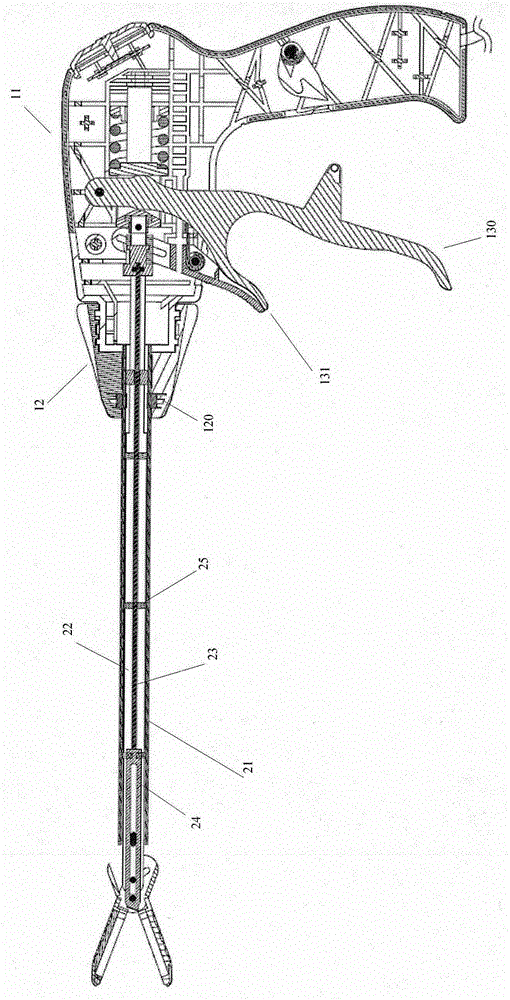

High-frequency electric surgical operating instrument and driving device thereof

ActiveCN106264714AReduce frictionReduce the burden onSurgical instruments for heatingElectrosurgeryEngineering

The invention discloses a high-frequency electric surgical operating instrument. The high-frequency electric surgical operating instrument comprises a handheld component which comprises a trigger unit and is used for generating driving, a connection rod which extends from the handheld component to the far end, and a clamping device which is arranged at the far end of the connection rod and is used for clamping a tissue, wherein the connection rod comprises an outer sleeve, a pull rod and a tool push rod; the near end of the outer sleeve is connected with the far end of the handheld component; the far end of the outer sleeve is connected with the clamping device; the pull rod is arranged in the outer sleeve and is of a platy structure; the trigger unit drives the pull rod to move so as to further control the clamping device to be opened and closed; the tool push rod and the pull rod are arranged side by side; a cutter is arranged at the far end of the tool push rod. As the pull rod is of the platy structure which replaces the sleeve structure in the prior art, and the tool push rod and the pull rod are arranged in the outer sleeve side by side, the space in a gun tube is saved; the pull rod is of the platy structure which enhances the part intensity, so that the service lives of the parts such as the pull rod are prolonged, and the fault rate of the electric surgical operating instrument is reduced.

Owner:REACH SURGICAL

Multifunctional air duct for rail vehicle

InactiveCN109178003ASimple structureEasy to installRailway heating/coolingEconomic shortageWaste management

The invention relates to a multifunctional air duct for a rail vehicle, comprising an air duct body with an air supply cavity, an air supply inlet and an air outlet arranged in the air duct body, wherein the air duct body is further provided with a waste discharge cavity, a waste discharge inlet and an waste discharge outlet communicated with the waste discharge cavity; the waste discharge cavityis isolated from the air supply cavity. As the multifunctional air duct integrates the functions of air supply and waste discharge, an integral structure is formed, thus solving the problems of shortage of vehicle installation space, great design difficulty and difficult installation process.

Owner:CRRC NANJING PUZHEN CO LTD

Method for preparing graphene reinforcing boron carbide ceramic material

The invention adopts addition of graphene to toughen boron carbide ceramic. The mechanism of the graphene reinforcing and toughening is crack deflection, branch, bridge connection, fracture, pulling out and the like. Different from the one-dimensional toughening of fibers, nanotubes, whiskers and the like which are aggregated easily in the past, the graphene is a two-dimensional material, can significantly reduce the mutual attraction among graphene sheets to avoid agglomeration through surface modification and decoration, and has very good dispersity and stability in some liquid mediums. Forexample, the surface of oxidized graphene contains a large amount of oxygen-containing functional groups such as hydroxide radicals, carboxyl and the like, and a stable and disperse graphene solutioncan be prepared; the graphene solution is mixed with ceramic matrix slurry, a graphene ceramic mixed raw material with a good implantation effect can be obtained, therefore, the reinforcing and toughening effects of the graphene ceramic mixed raw material are relatively stable, and the technological feasibility is better.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

Thermocouple, preparation method thereof, and electric appliance

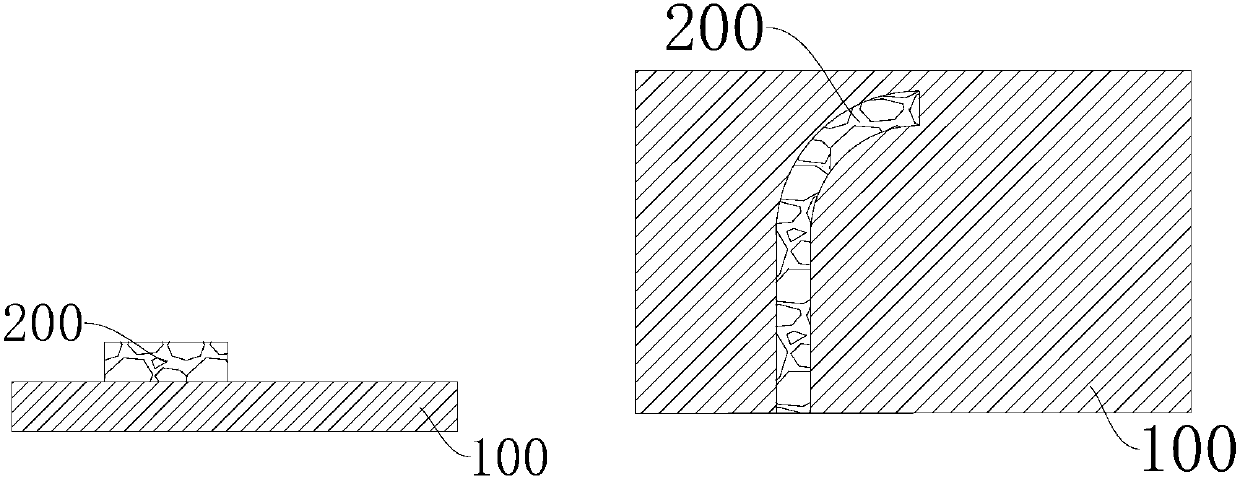

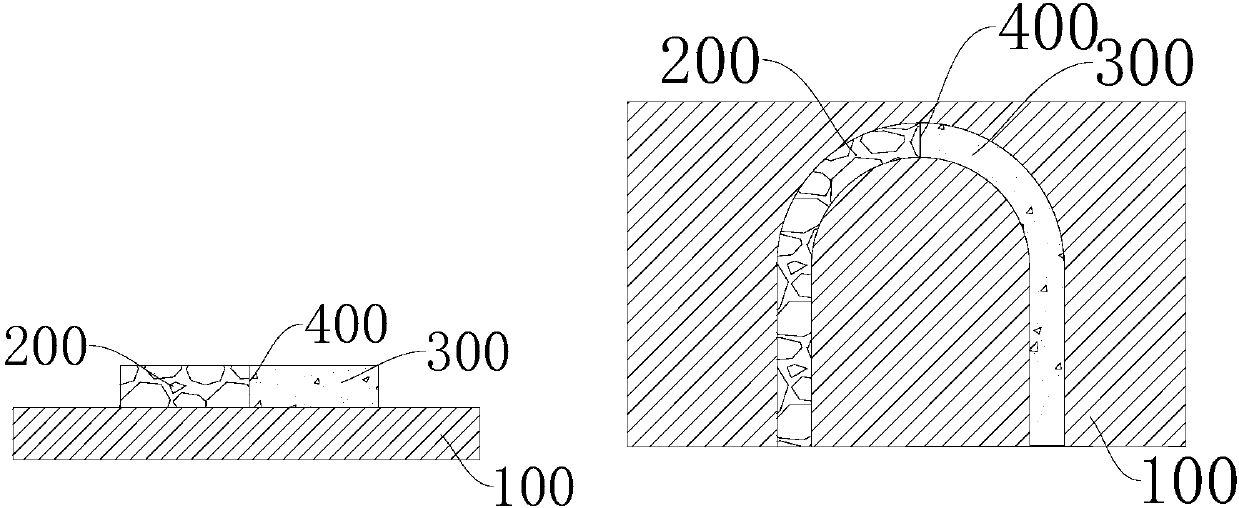

ActiveCN110129851AImprove performanceConvenient oxidation treatmentAnodisationMolten spray coatingPore diameterTemperature resistance

The invention discloses a thermocouple, a preparation method thereof, and an electric appliance. The thermocouple comprises a metal substrate, an oxide film layer, an insulation coating and an electrode layer; at least part of the surface of the metal substrate is covered with the oxide film layer, the surface of the oxide film layer is covered with the insulation coating, and the electrode layeris arranged on the side, away from the metal substrate, of the insulation coating, wherein the pore diameter of the insulation coating is not greater than 10 nm. Therefore, the binding performance ofthe insulation coating and the metal substrate in the thermocouple is excellent, the insulation coating is good in high temperature resistance and corrosion resistance, and stability is good; and theinsulation coating is good in compactness and excellent in insulation performance.

Owner:GUANGDONG MIDEA WHITE HOME APPLIANCE TECH INNOVATION CENT CO LTD +1

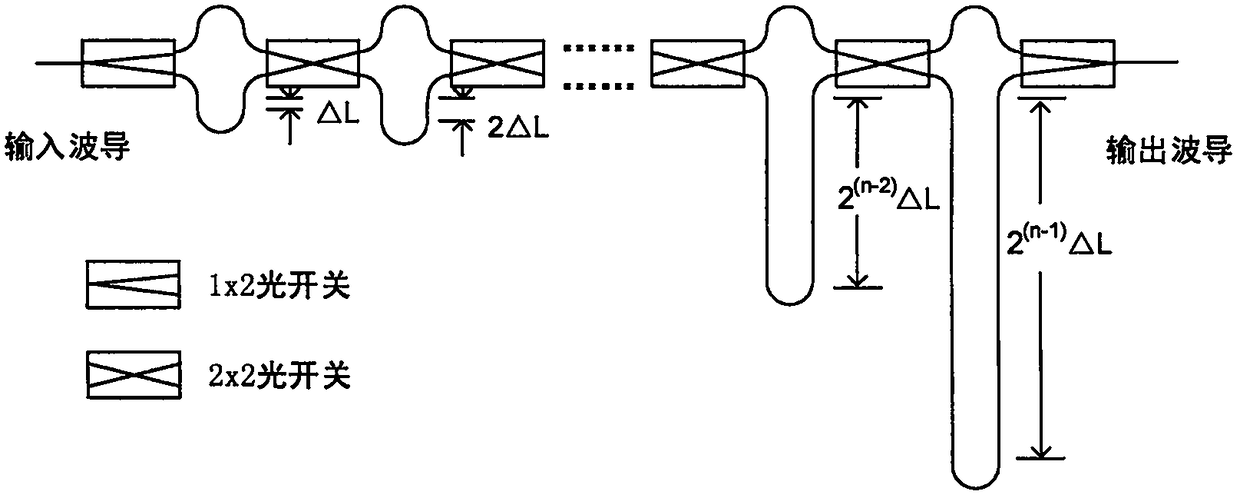

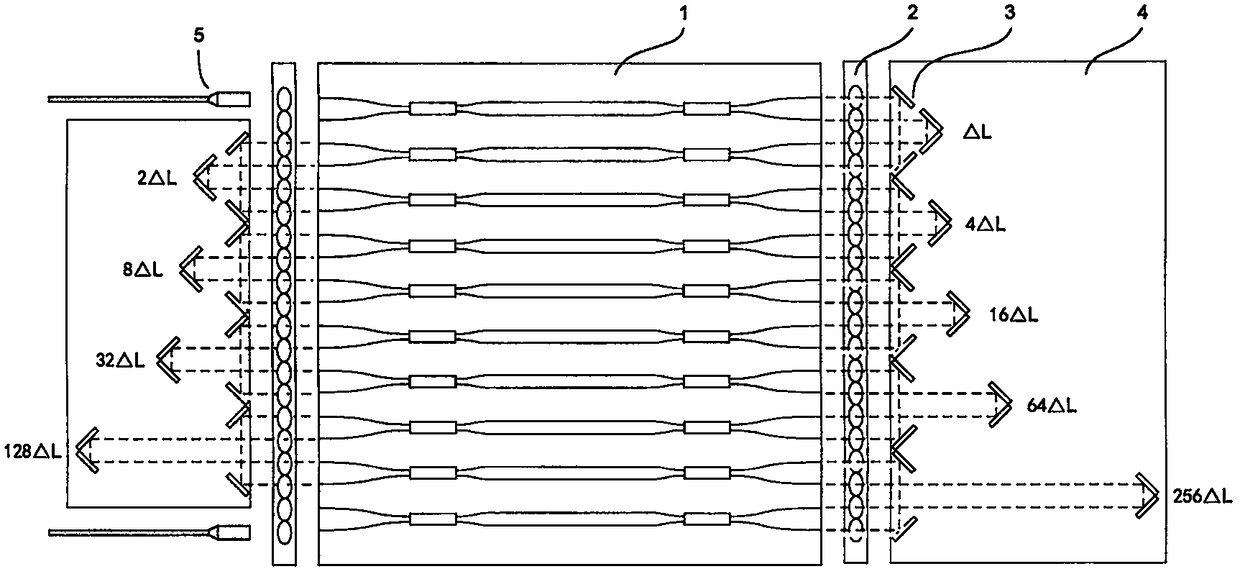

High precision N-bit dimmable delay

PendingCN108227079AImproved delay step sizeImproved delay accuracyCoupling light guidesNon-linear opticsRadar systemsTime delays

The invention provides a high precision N-bit dimmable delay. The high precision N-bit dimmable delay is mainly composed of an optical switch chip, a collimating lens array, a free space delay module,an input and output optical fiber pigtail and a pedestal. The optical switch chip is an array integration of a plurality of optical switch units. The free space delay module realizes integration of multiple levels of time delay units. High efficient coupling of the optical switch chip and the free space delay module is realized through lens array. And finally the dimmable delay having a ps levelstep length over 10-bit is realized. the invention has advantages of high delay precision, large bandwidth, small size, low weight, easy technique implementation and the like, and is suitable for light-operated phased array radar systems and especially for application in fields of onboard and space-borne radars and the like.

Owner:SHANGHAI SILIGHT TECH

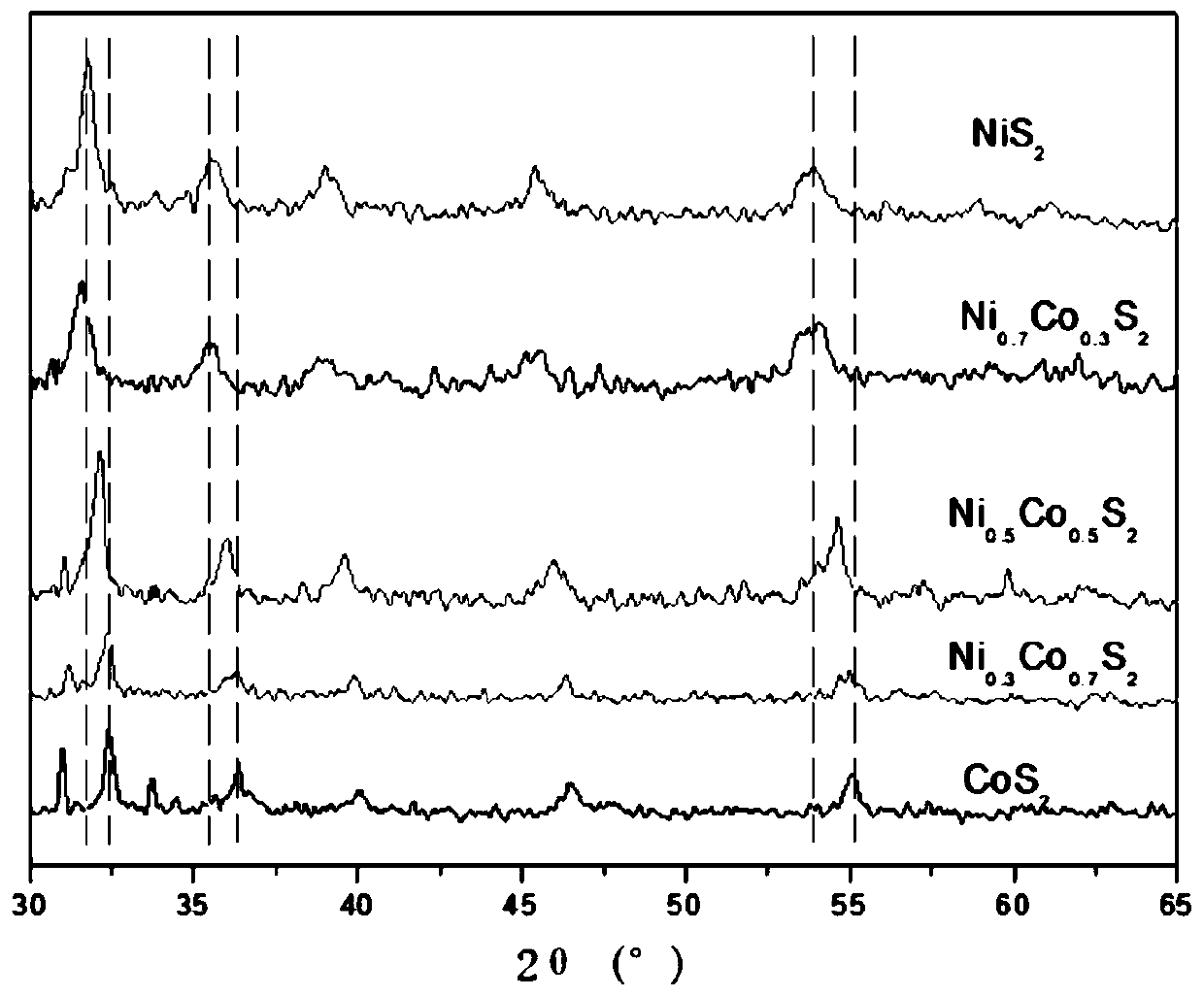

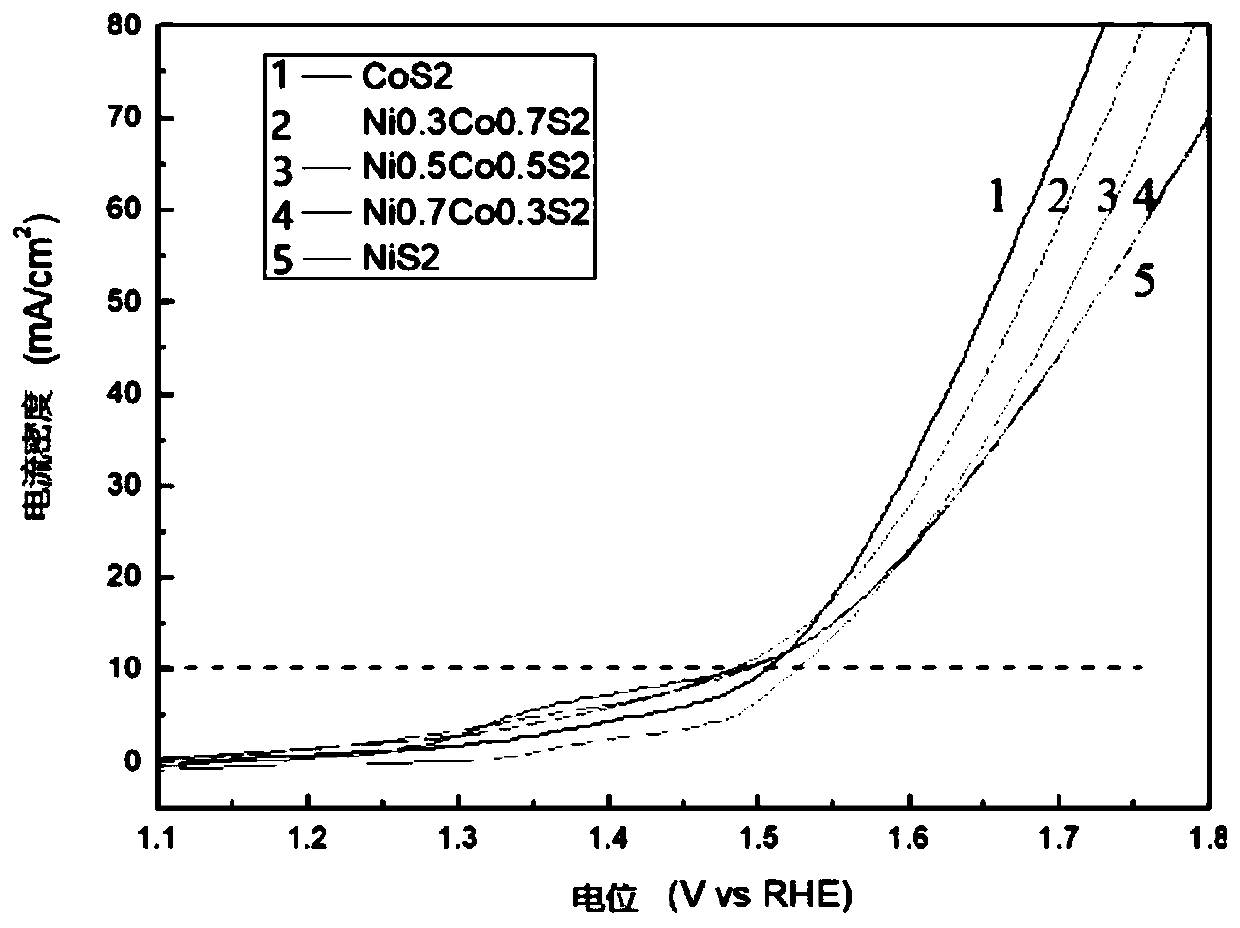

Nickel-cobalt disulfide composite material and preparation method and application thereof

ActiveCN111111699ASimple equipmentEasy to operatePhysical/chemical process catalystsCell electrodesOrganic solventSulfidation

The invention discloses a nickel-cobalt disulfide composite material and a preparation method and application thereof. The preparation method comprises the following steps: dissolving a nickel source,a cobalt source and elemental sulfur in an organic solvent under stirring to obtain turbid liquid; transferring the turbid liquid into a reaction container; after sealing, carrying out reacting for 1to 24 h at 120 to 200 DEG C; and carrying out solid-liquid separation, washing, filtering and drying to obtain the nickel-cobalt disulfide composite material. The phase of the nickel-cobalt disulfidecomposite material is cobalt disulfide (CoS<2>), nickel disulfide (NiS<2>) or a cobalt-nickel disulfide composite phase (Ni<x>Co<1-x>S<2>). According to the method, required equipment is simple, preparation cost is low, and used raw materials are green, non-toxic and environment-friendly; and the method provided by the invention is simple to operate and controllable in conditions, particularly, no solvent with high viscosity is adopted, solid-liquid separation is easy, and process feasibility is high.

Owner:赛帝迦(山东)科技有限公司

Contact temperature measuring sensor, preparation method thereof, and cooking equipment

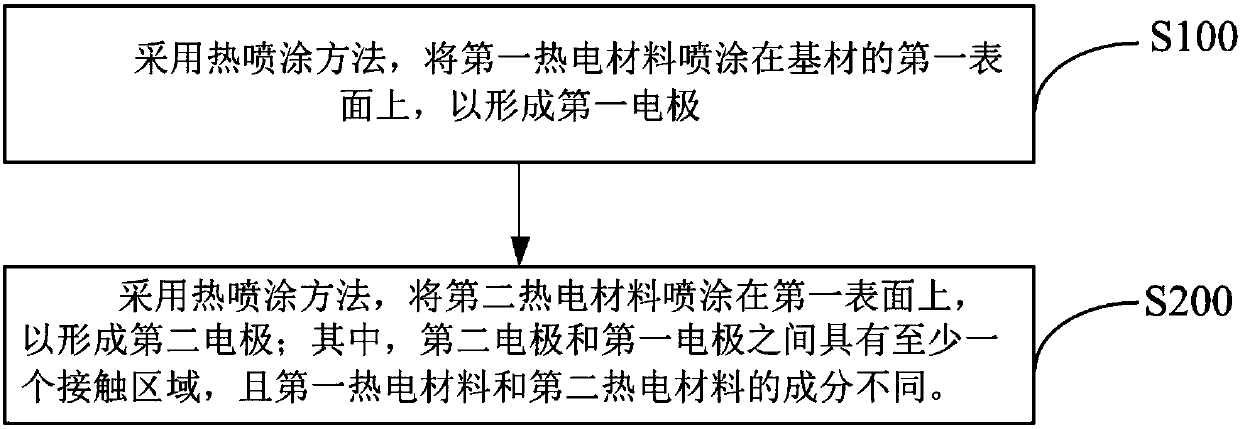

PendingCN110129706AReduce control precision requirementsImprove experienceThermometer detailsMolten spray coatingThermoelectric materialsThermal spraying

The invention provides a contact temperature measuring sensor, a preparation method thereof, and cooking equipment. The preparation method of the contact temperature measuring sensor comprises the steps that a thermal spraying method is adopted to spray a first thermoelectric material on the first surface of a substrate, so that a first electrode is formed; and the thermal spraying method is adopted to spray a second thermoelectric material on the first surface, so that a second electrode is formed, wherein one or more contact areas are arranged between the second electrode and the first electrode, and the ingredients of the first thermoelectric material and the second thermoelectric material are different. The preparation method of the contact temperature measuring sensor is easy and convenient to operate and easy to realize, the requirements for control precision of technological parameters are low, feasibility is high, reliability is good, the cost is low, the production efficiencyis high, and actual industrial production is easy.

Owner:MIDEA GRP CO LTD

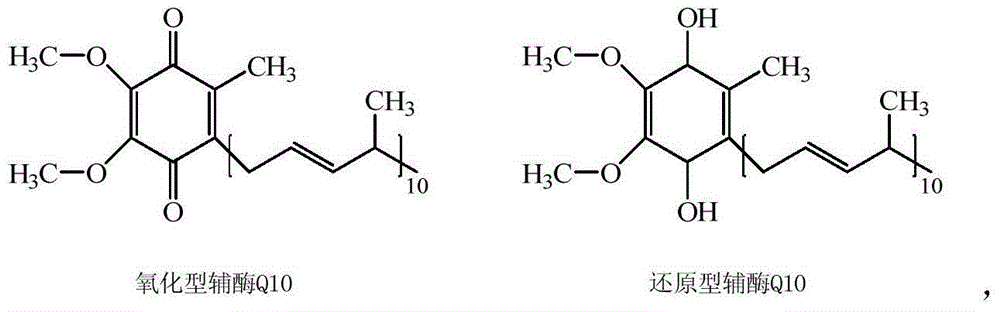

Preparation method for reductive coenzyme Q10

InactiveCN104892370AAdequate responseRapid responseOrganic chemistryOrganic compound preparationElectrolysisSynthesis methods

The invention discloses a method for preparing reductive coenzyme Q10 from oxidative coenzyme Q10. In most conventional production processes for reductive coenzyme Q10, iron powder, zinc dust and sodium hydrosulfite are employed and are all solids, reduction reaction is heterogeneous phase reaction, so workshop operation is inconvenient and reaction time is long. According to the method provided by the invention, oxidative coenzyme Q10 is used as a raw material, stannous chloride is used as a reducing agent, a small amount of acid is added drop by drop so as to control a reaction system to be weakly acidic, continuous stirring reaction is carried out in a solvent at 50 to 70 DEG C, then nitrogen is introduced for protection, and purifying and crystallization are carried out after completion of the reaction so as to obtain the reductive coenzyme Q10 with a purity of no less than 95%; and the stannous chloride is recovered through electrolysis after completion of the reaction, obtained stannous chloride is reused for reduction of coenzyme Q10, so reutilization and continuous reaction are realized. The reductive coenzyme Q10 prepared in the invention has high purity and is safe and reliable; and the reducing agent is regenerable and reusable, so the method is environment-friendly and is a green coenzyme Q10 synthesis method.

Owner:ZHEJIANG NHU CO LTD

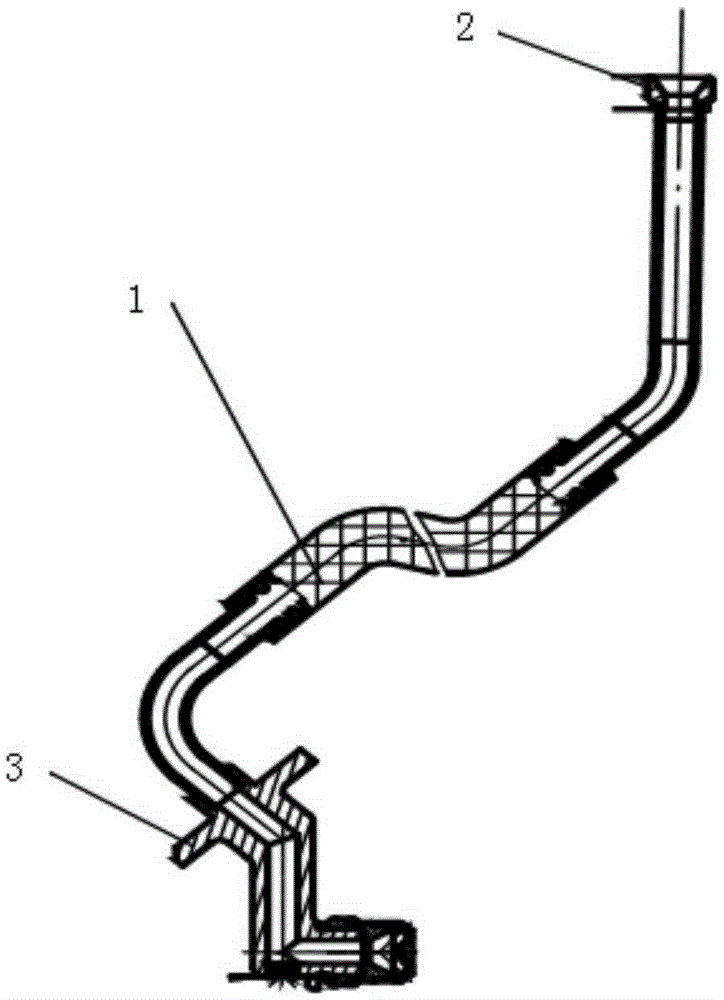

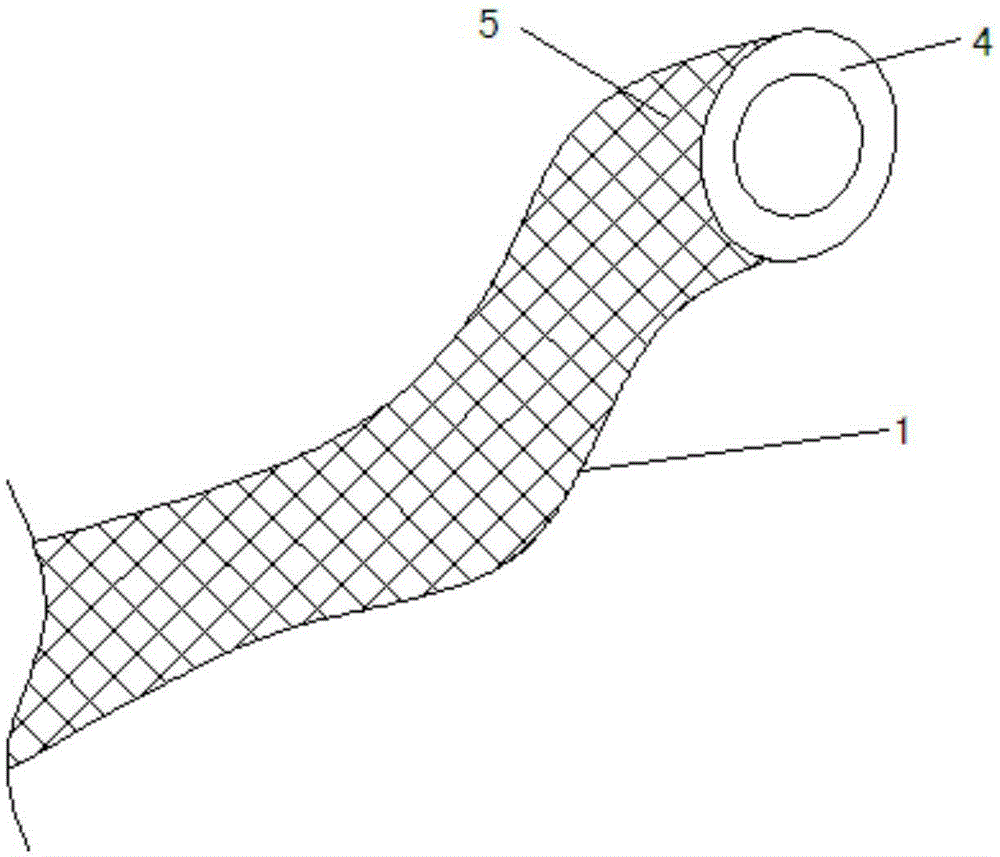

Long-neck gas fuel spray nozzle capable of being adjusted in multiple angles

InactiveCN105299693AReliable structural designCompact designContinuous combustion chamberThermal deformationProduct gas

The invention discloses a long-neck gas fuel spray nozzle capable of being adjusted in multiple angles. The long-neck gas fuel spray nozzle comprises a metal hose, wherein a pipe connector is fixedly connected to one end of the metal hose, and a fuel gas spray nozzle body is fixedly connected with the other end of the metal hose. The metal hose comprises a corrugated pipe which is wrapped by a layer of metal mesh surface. The metal hose is inserted into the fuel gas spray nozzle body and is connected with the fuel gas spray nozzle body in a welded manner. The wall thickness of the corrugated pipe ranges from 0.3 mm to 0.5 mm. The metal mesh face is formed by weaving metal wires, and materials are 1Cr18Ni9Ti. The metal mesh face and the end of the corrugated pipe are fixedly connected. By means of the design that the metal hose is directly welded to the spray nozzle body, assembling of pipe connectors in a gas turbine is reduced; by means of the flexible connection manner, the displacement, generated in the working process of the gas turbine, of a combustion chamber casing part and an outer duct casing part and thermal deformation of a pipeline are automatically adjusted, and the phenomenon that due to rigid connection, assembling stress is generated due to manufacturing deviation, and cracking accidents are caused due to vibration can be avoided; and the spray nozzle body and a fuel gas branch pipe can be conveniently connected, the structure is compact, and the integral design requirement of the gas turbine is met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com