Welded combined T-shaped steel column correcting device and method

A technology of T-shaped steel and H-shaped steel, which is applied in the field of correcting devices for welded combined T-shaped steel columns, can solve the problems of no operating space, difficult correction, high energy consumption, etc., and achieve simple and safe operation, low manufacturing cost, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

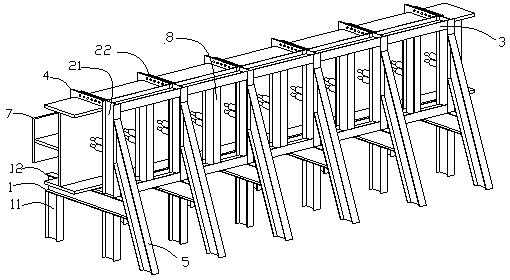

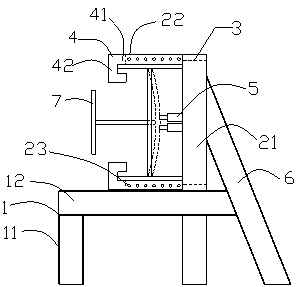

[0030] see figure 1 and figure 2 , a straightening device for welding combined T-shaped steel columns, the straightening device is composed of several straightening units and all the straightening units are arranged side by side on the same straight line, each straightening unit includes a platform support 1, two L-shaped clamps 4 and a jack 5, The platform support is welded into a "∏" shape by two columns 11 and a crossbeam 12, a vertical beam 21 perpendicular to the crossbeam 12 is arranged on the upper surface of the crossbeam 12, and two rectangular parallel to the crossbeam 12 are arranged at the two ends of the vertical beam 21. Connecting block 22, the distance between the two connecting blocks 22 is equal to the sum of the width of the welded H-shaped steel web and the thickness of the two flanges of the welded combined T-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com