Method for preparing graphene reinforcing boron carbide ceramic material

A boron carbide ceramic and graphene technology, applied in the field of ceramic materials, can solve the problems of low density, high brittleness, low flexural strength and fracture toughness, etc., achieve good dispersibility and stability, stable enhancement and toughening effect, and process Feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

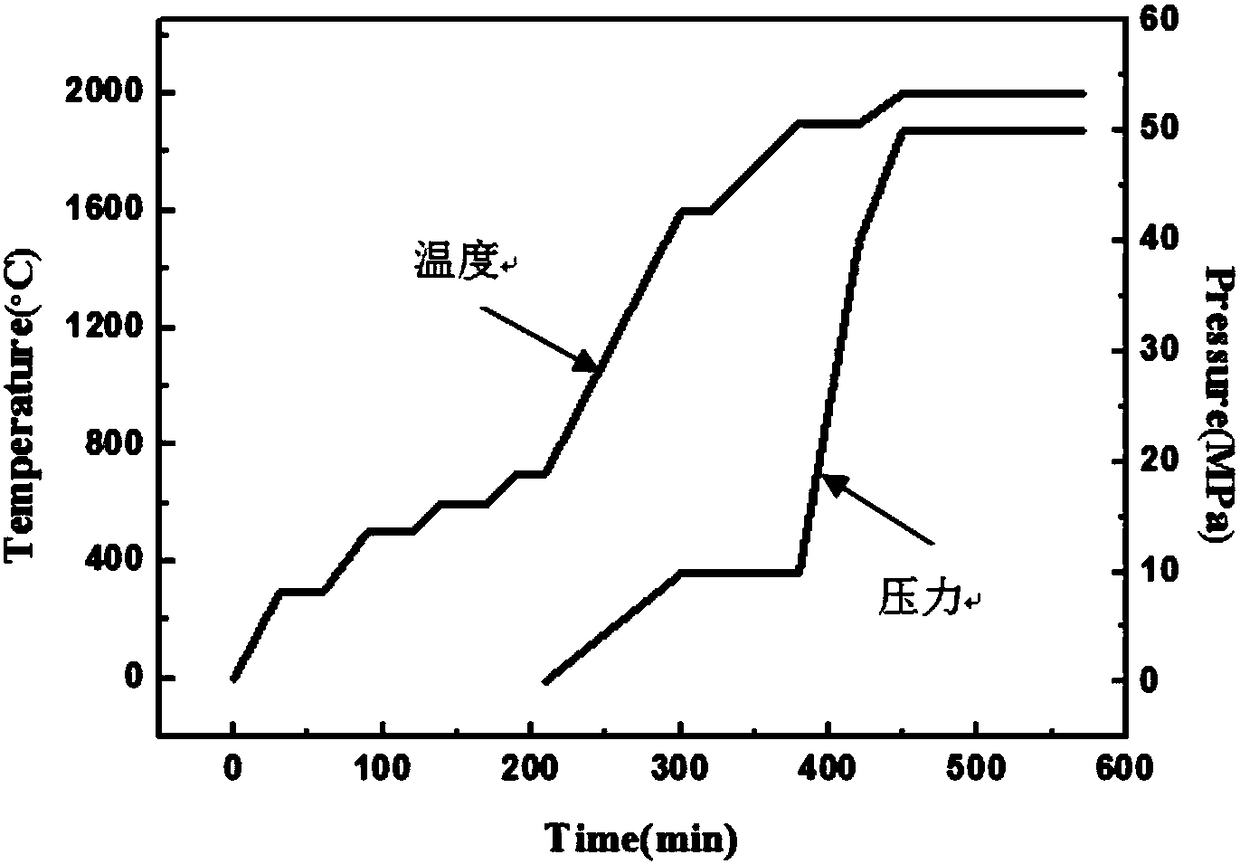

Image

Examples

Embodiment 1

[0014] Embodiment 1 A kind of preparation method of graphene reinforced boron carbide ceramic material:

[0015] 1..1 Raw materials: boron carbide powder (d50=2±0.2μm, purity ≥99%); graphene is graphene oxide (GO), the number of layers of graphene is 7-10 layers, and the purity is 99.8%;

[0016] 1.2 Process steps:

[0017] Step 1) preparation of dispersant aqueous solution: a certain amount of N-methylpyrrolidone (NMP) with a purity of 99.9% is added to deionized water, so that the concentration of dispersant aqueous solution is 1% (N-methylpyrrolidone: deionized water = 1:100ml), put the well-proportioned dispersant aqueous solution on an ultrasonic cleaner for ultrasonic dispersion for 15 minutes, so that N-methylpyrrolidone can be evenly dispersed in water, so that the subsequent graphene oxide can be better dispersed in water.

[0018] Step 2) dispersion of graphene: dispersion of graphene: take boron carbide powder and graphene oxide to be added, wherein, the weight of ...

Embodiment 2

[0022] Embodiment 2 product performance test

[0023] The ceramic material obtained by the preparation method of the graphene-enhanced boron carbide ceramic material obtained in Example 1 is subjected to a performance test, and the graphene / B4C composite material density is 2.52 ± 0.01g / cm 3 ;Hardness: HV3350±50;

[0024] Bending strength: 500±20MPa; fracture toughness 5±0.5MPa m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com