Modified oxide, powder coating and its preparation method and application

A powder coating and oxide technology, applied in the field of powder coatings, can solve problems such as affecting product appearance, poor leveling performance of powder coatings, etc., to meet decorative requirements, solve agglomeration, and improve the effect of powder coating rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

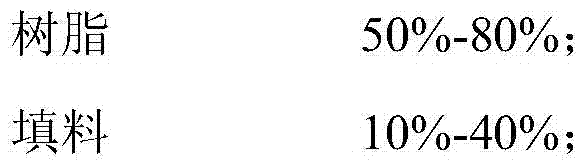

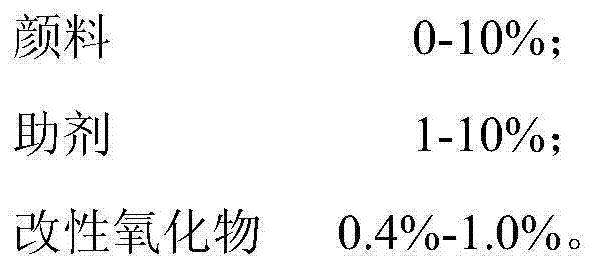

Method used

Image

Examples

preparation example Construction

[0061] The preparation method of the modified oxide in the modified example comprises the following steps:

[0062] a. Mix and stir the oxide, triethanolamine fatty acid quaternary ammonium salt, and acetone to dissolve all the oxide and modifier to obtain a mixture; the addition amount of triethanolamine fatty acid quaternary ammonium salt is 2.6% of the oxide mass. %; the amount of acetone added so that the oxide, triethanolamine fatty acid quaternary ammonium salt can be completely dissolved;

[0063] b. Control the temperature of the mixture to ≤50°C, and stir to evaporate the solvent;

[0064] c. Grinding the mixture after the volatile solvent to a particle size of 10-100nm to obtain a modified oxide;

[0065] Among them, the oxide is obtained by mixing nano fumed silica and alumina C at a mass ratio of 1:2.2.

[0066] The obtained powder coating is used for the spraying of the metal back cover of the TV set, and the spraying effect is shown in Table 3.

Embodiment

[0084] The preparation method of modified oxide in the embodiment comprises the following steps:

[0085] a, mixing and stirring the oxide, ester-based quaternary ammonium salt, and ethanol to dissolve the oxide and modifier to obtain a mixture; the addition of triethanolamine fatty acid quaternary ammonium salt is 2.6% of the oxide mass in terms of oxide mass; The amount of acetone added is enough to completely dissolve the oxide and triethanolamine fatty acid quaternary ammonium salt;

[0086] b. Control the temperature of the mixture to ≤50°C, and stir to evaporate the solvent;

[0087] c. Grinding the mixture after the volatile solvent to a particle size of 10-100nm to obtain a modified oxide;

[0088] Among them, the oxide is obtained by mixing fumed silica and alumina C at a mass ratio of 1:2.2.

[0089] Gained modified oxide and other raw materials are weighed according to the embodiment 1-7 in table 4 respectively, and then the powder coating is prepared according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com