Patents

Literature

77results about How to "Improve the powder rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

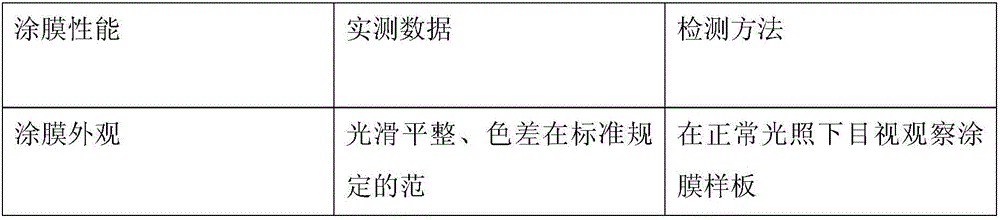

Method for electrostatic spraying of powder coating on surface of aluminum profile

InactiveCN105728302AImprove the decorative effectImprove the protective effectPretreated surfacesMetallic material coating processesSurface cleaningHardness

The invention discloses a method for electrostatic spraying of a powder coating on the surface of an aluminum profile. The method comprises the following steps that 1, the powder coating is prepared; 2, the surface of the aluminum profile is subjected to cleaning treatment; 3, passivating treatment is conducted; 4, drying is conducted; 5, electrostatic spraying is conducted; and 6, baking and curing are conducted. The method for electrostatic spraying of the powder coating on the surface of the aluminum profile is easy and convenient to operate and likely to be achieved, on the basis of the selected powder coating, through reasonable modes of surface passivating treatment, electrostatic spraying treatment and stepped baking and curing, not only is the powdering rate of electrostatic spraying effectively increased, but also the apparent quality of an obtained powder coating layer is good, and the hardness and the abrasion resistance are excellent; and meanwhile, the powder coating layer plays a good decorative effect and a protective effect on the aluminum profile, and the comprehensive performance is excellent.

Owner:TAICANG JIDA SPRAY COATING CO LTD

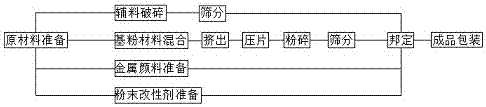

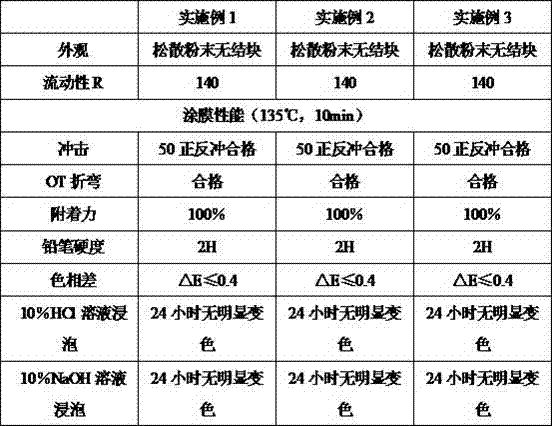

Boiling-endurable sand-ripple powder paint for coating corners of aluminum section and preparation method thereof

ActiveCN103483988AEfficient coatingImprove the powder ratePowdery paintsPolyester coatingsPolyester resinPowder coating

The invention discloses boiling-endurable sand-ripple powder paint for coating corners of an aluminum section. The paint comprises polyester resin, a curing agent, filler, conventional auxiliary, a sand ripple agent, pigment and gas-phase oxide. The invention also discloses a preparation method of the powder paint. The powder paint has an excellent coating performance on corners of an aluminum section, and has a high coating rate on corners of the aluminum section.

Owner:GUANGZHOU KINTE IND +1

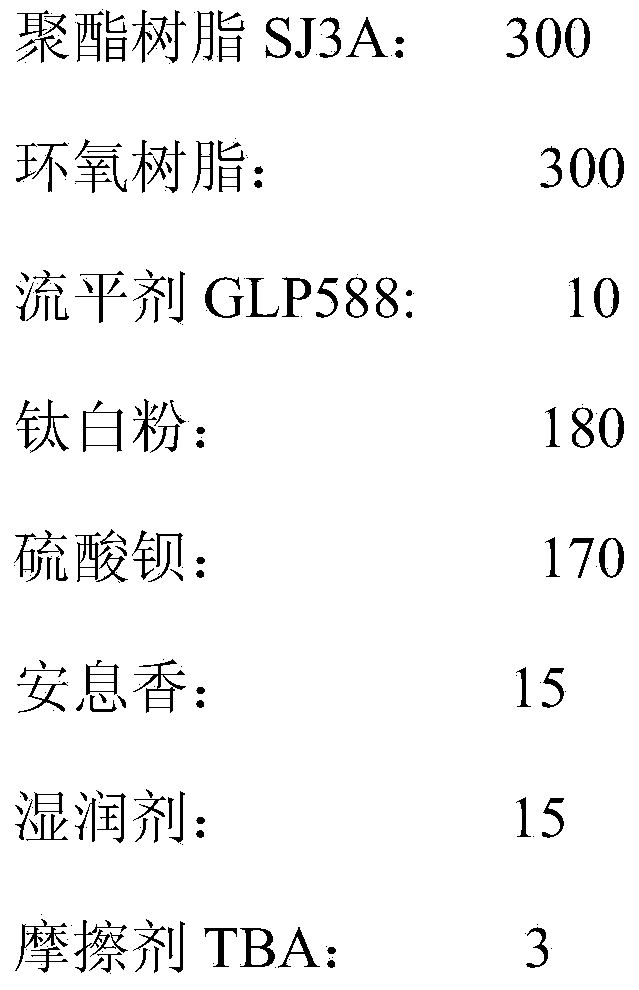

Special anticorrosive powder coating for high-decorativeness pure polyester aluminum section and preparation method of powder coating

ActiveCN104263211AGood weather resistanceImprove performanceAnti-corrosive paintsPowdery paintsMelt extrusionIsocyanuric acid

The invention discloses a special anticorrosive powder coating for a high-decorativeness pure polyester aluminum section and a preparation method of the powder coating. The powder coating comprises the following raw materials: carboxyl-terminated polyester resin, triglycidyl isocyanurate, titanium dioxide, ultrafine barium sulfate, a charging additive, a dry flow additive, benzoin, a leveling agent and a brightening agent. The preparation method mainly comprises the following steps: firstly, uniformly premixing the raw materials; secondly, performing melt extrusion; finally, performing crushing and ultrafine grinding. The powder coating prepared by the method is strong in adaptability to different thickness of coatings, and has relatively good leveling effects on thick coating (not less than 120 microns) and thin coating (not more than 60 microns); especially, the phenomena of melt falling and non-uniform thickness of powder applied to a workpiece due to influence of gravity on the powder product sprayed by vertical spraying equipment at the construction site in baking and curing processes are greatly reduced, and a paint film is excellent in appearance and free of particle phenomenon during thin coating.

Owner:西北永新涂料有限公司

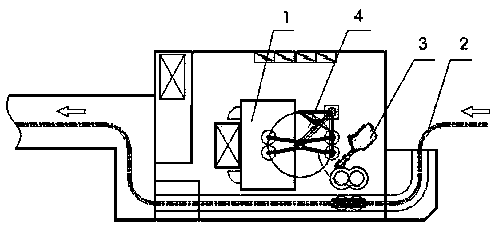

Improved wheel powder spraying line and technology

InactiveCN104174520AImprove the powder rateReduce wasteLiquid spraying plantsLiquid surface applicatorsCleaning stationEngineering

The invention discloses an improved wheel powder spraying line and technology. A conveying line (2) is arranged on the outer side of a powder spraying chamber (1); a robot (3) and a turntable (4) are arranged between the powder spraying chamber (1) and the conveying line (2); the robot (1) grabs a wheel, and the turntable (4) sends the wheel into the powder spraying chamber (1) and rolls the wheel subjected to powder spraying out of the powder spraying chamber (1). The technology comprises technological processes as follows: storing workpiece parameters, recognizing workpieces, entering a powder spraying isolation chamber, moving the workpieces out of the conveying line, transferring the workpieces into the powder spraying chamber, spraying powder on the workpieces, recovering fallen powder into powder supply equipment for recycling, finishing powder spraying, moving out the workpieces, transferring the workpieces to workpiece cleaning stations, cleaning powder in workpiece assembly positions, cleaning powder on the turntable, transferring the workpieces back to the conveying line, and curing the powder.

Owner:CITIC DICASTAL

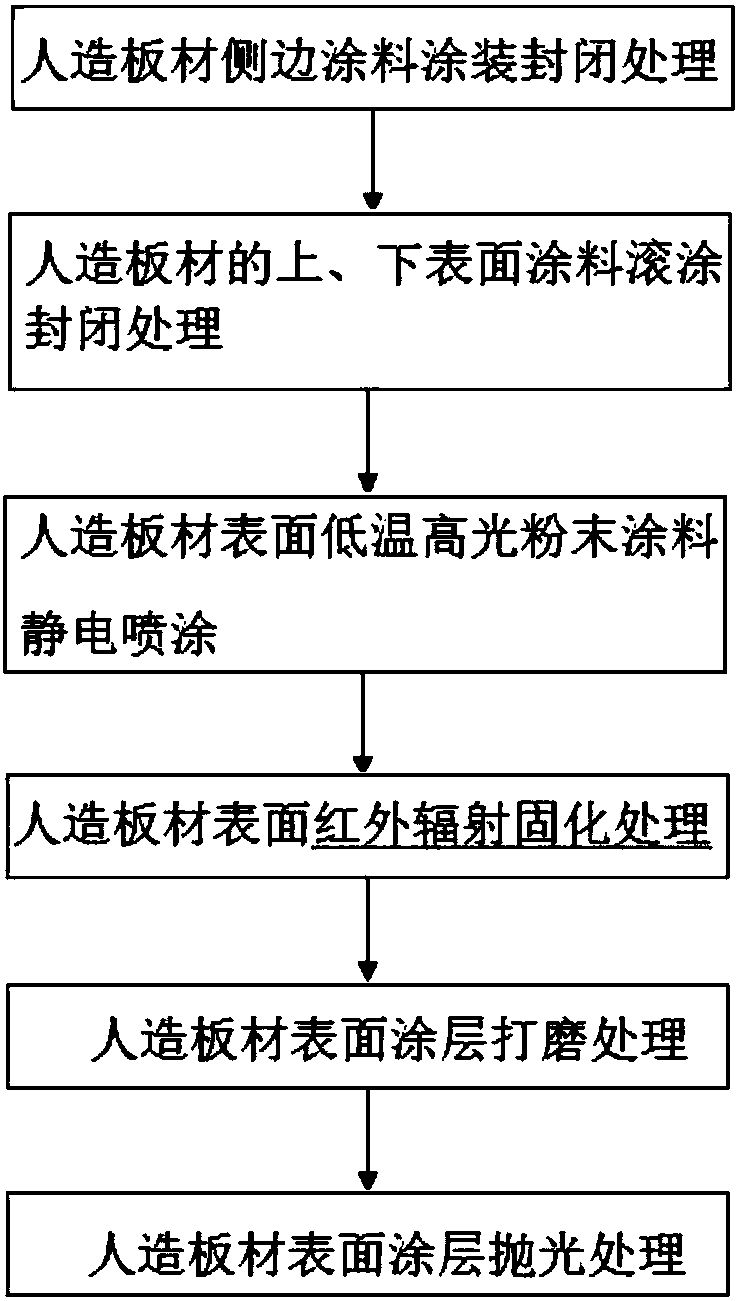

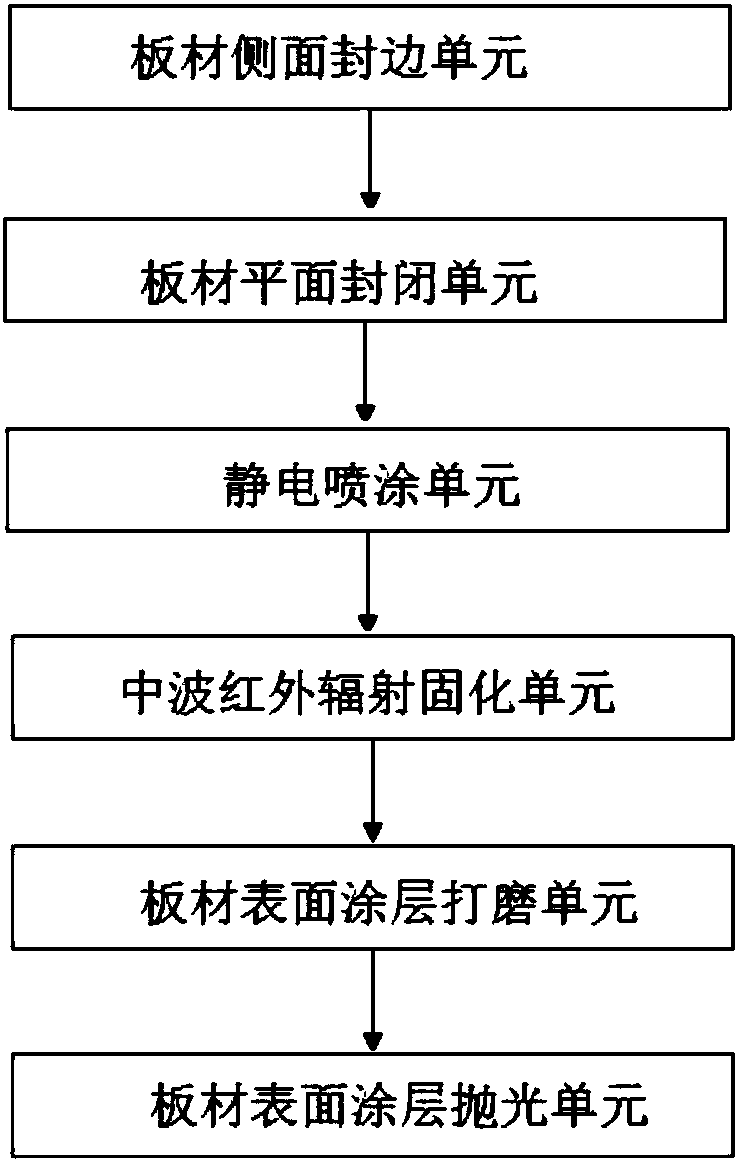

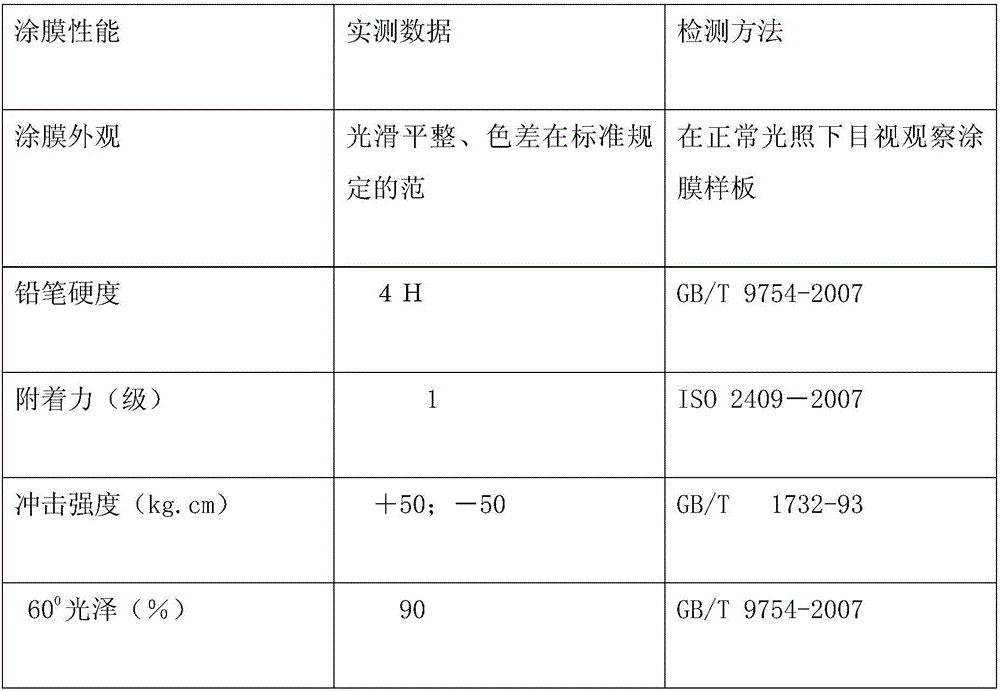

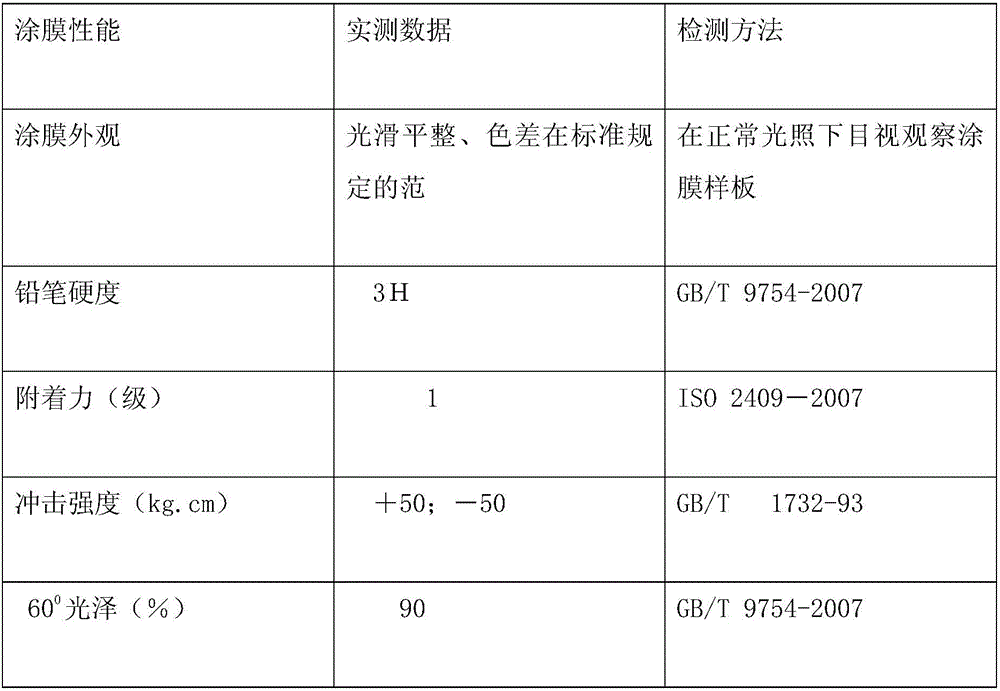

Production technology and equipment for forming specular highlight decorative effect on surfaces of artificial boards by means of powder coating

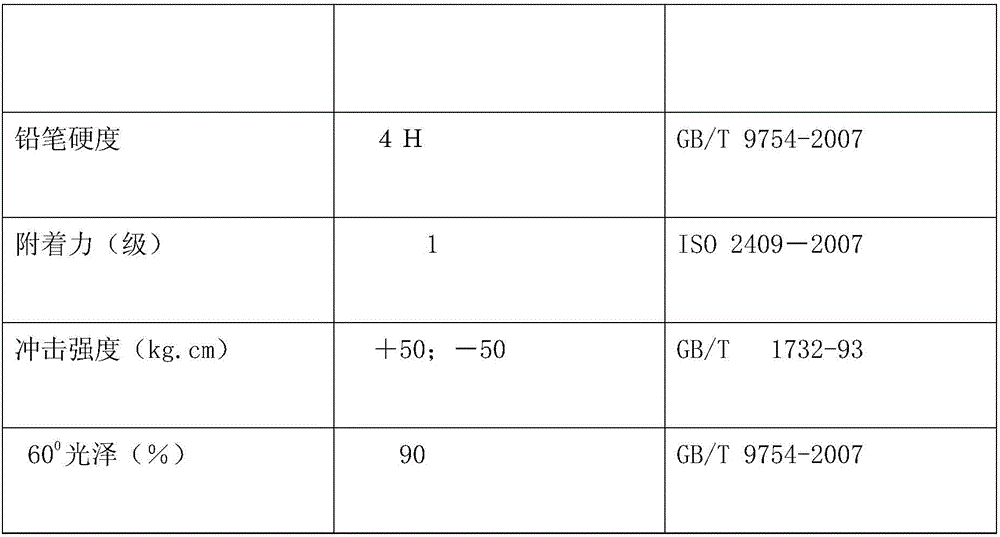

PendingCN108787388AImprove yieldImprove performancePretreated surfacesPowdery paintsRadiationHardness

The invention relates to a production technology and equipment for forming a specular highlight decorative effect on the surfaces of artificial boards by means of powder coating. The production technology is characterized in that the specular highlight decorative effect is formed by conducting the procedures such as closed pretreatment of edges, the upper surfaces and the lower surfaces, powder coating electrostatic spraying, infrared radiation curing treatment, surface coating grinding and polishing on the surfaces of the boards. The corresponding production equipment comprises a board side-edge sealing machine, a board plane rolling spraying sealing machine, an electrostatic spraying room, an infrared radiation curing furnace, a sanding machine and a buffing machine. The surface paint film of the produced artificial board has the properties that the surface paint film is free of formaldehyde and VOC and specularly super-smooth, the glossiness 60-degree angle exceeds 90 degrees, the pencil hardness exceeds 1H, the paint adhesion force reaches one level or above, and the surface paint film can pass through the over 50-time acetone-resistant wiping test.

Owner:FOSHAN YIKEJU NEW MATERIAL CO LTD

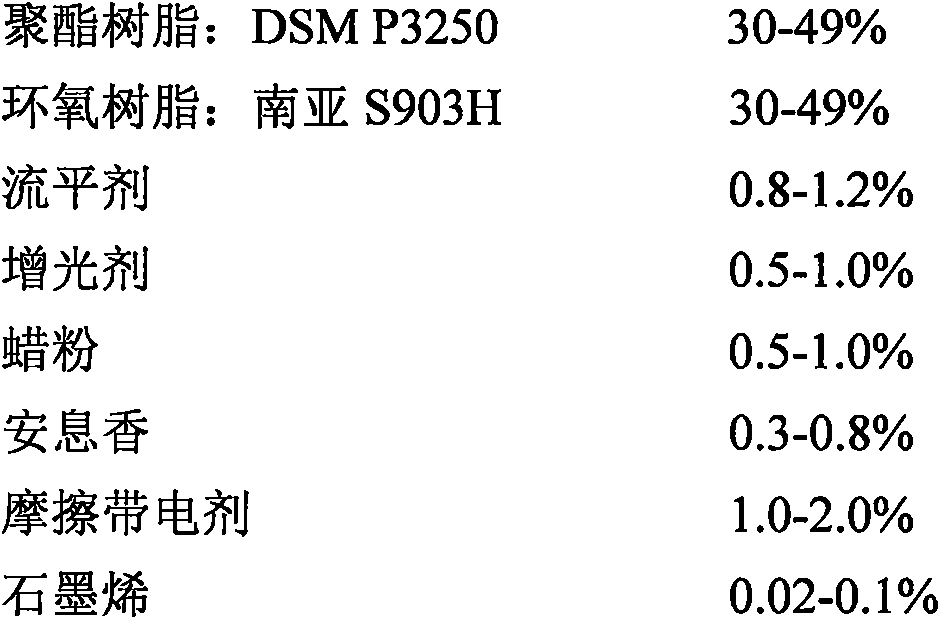

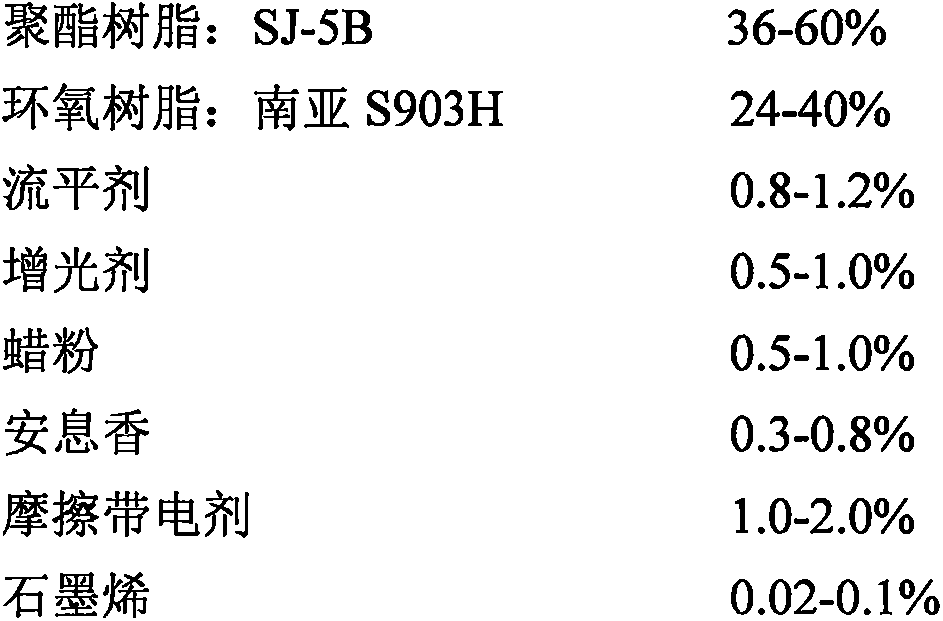

Graphene transparent powder coating for tribo gun to spray MDF plate

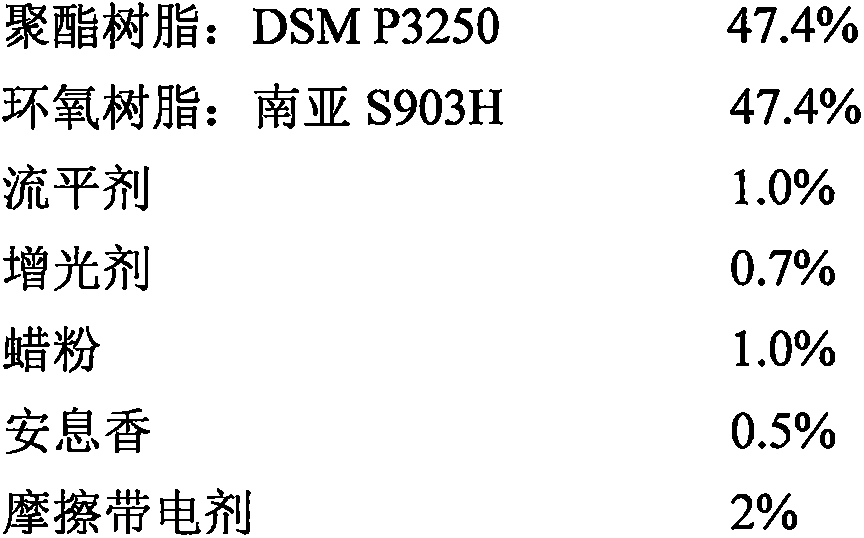

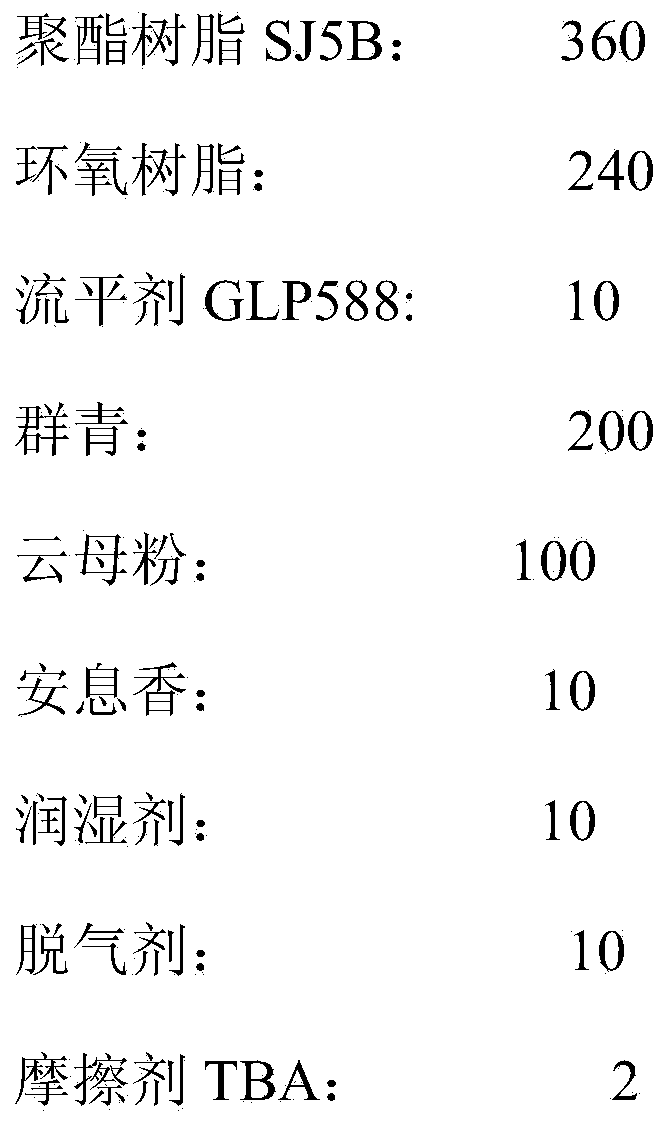

InactiveCN106634468AUniform thicknessNo powder accumulationPretreated surfacesPowdery paintsEpoxyWax

The invention relates to a transparent powder coating, specifically to a graphene transparent powder coating for tribo gun to spray an MDF plate. The graphene transparent powder coating is prepared from the following raw materials in percentages: 30 to 60% of polyester resin, 24 to 48% of epoxy resin, 0.8 to 1.2% of a leveling agent, 0.5 to 1.0% of a gloss enhancer, 0.5 to 1.0% of wax powder, 0.3 to 0.8% of benzoin, 1.0 to 2.0% of a triboelectric charging additive and 0.02 to 0.1% of graphene. According to the invention, powder coating is realized by using a tribo gun through addition of the triboelectric charging additive; by adopting a method of spraying a powder coating with the tribo gun, no Faraday effect is generated; meanwhile, no free ions are generated; charged powder ions may not mutually exclude; a formed coatingn film has good leveling properties; and through addition of graphene, the transparent powder coating can be improved in glossiness, adhesive force, water resistance, conductivity, flexibility, etc.

Owner:燕园众欣纳米科技(北京)有限公司

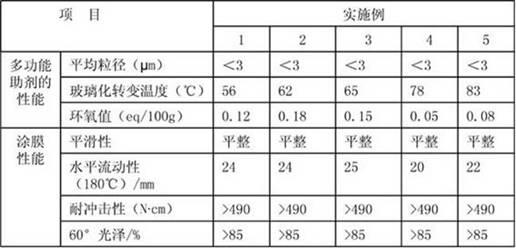

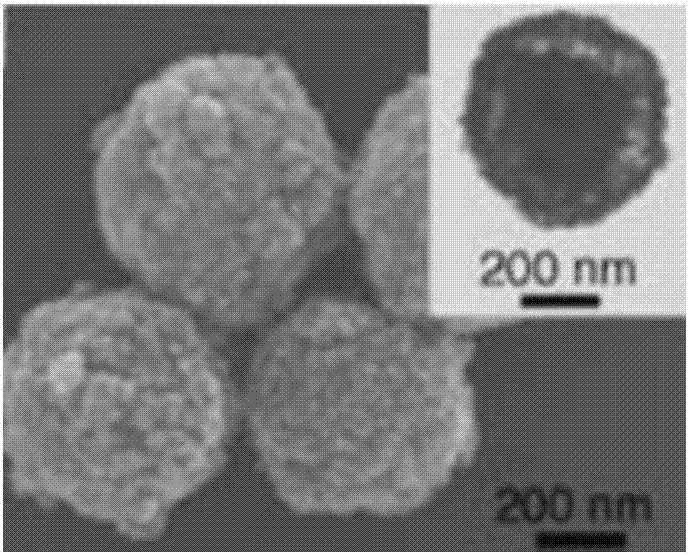

Method for preparing multifunctional power coating additive with core-shell structure

InactiveCN102060955AGood storage stabilityImprove the level ofPowdery paintsSodium bicarbonateGlycidyl methacrylate

The invention relates to a method for preparing a multifunctional power coating additive with a core-shell structure. The method comprises the steps of: A. uniformly mixing butyl methacrylate (BMA), methyl methacrylate (MMA) and lauryl mercaptan as a core monomer; B. uniformly mixing butyl methacrylate (BMA), methyl methacrylate (MMA), glycidyl methacrylate (GMA) and lauryl mercaptan as a shell monomer; C. adding water, lauryl sodium sulfate and sodium bicarbonate in a reactor, uniformly stirring to raise temperature, dripping the core monomer and ammonium persulfate, and maintaining the temperature; dripping the shell monomer and ammonium persulfate, and maintaining the temperature; cooling and filtering to obtain white acrylic ester core-shell polymer latex, wherein the solid content in the latex is 40-50%, and the conversion rate of the monomer is higher than 90%; and D. adding a calcium chloride aqueous solution, separating, washing with water, and drying to obtain a white powdery solid product. The additive is used for power coatings without being molten and granulated, can be added directly for use, and has the environmentally friendly characteristic.

Owner:HEFEI UNIV OF TECH

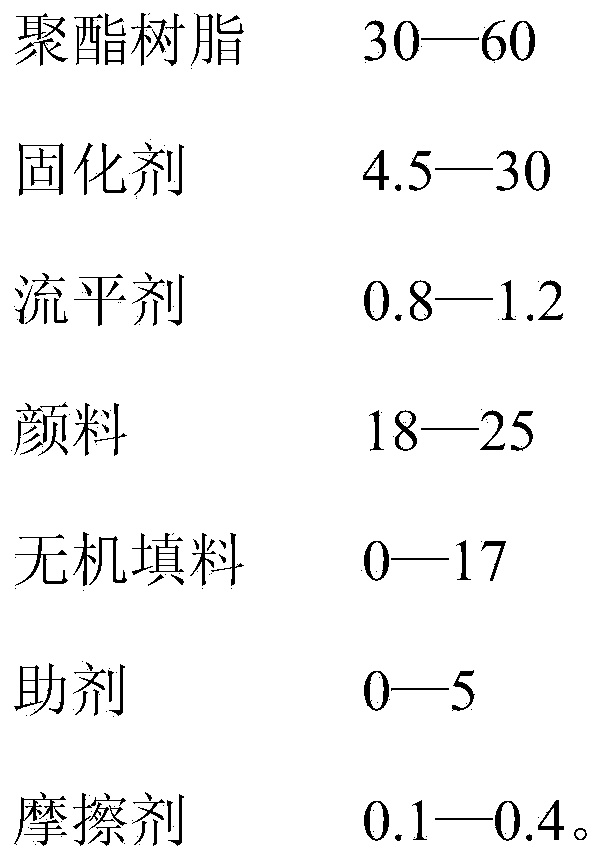

Powder coating sprayed through friction gun

InactiveCN104277683AImprove the powder rateAvoid the Faraday EffectPowdery paintsPolyester coatingsAdjuvantMetallurgy

The invention discloses a powder coating sprayed through a friction gun. The powder coating comprises the following substances in parts by weight: 30-60 parts of polyester resin, 4.5-30 parts of curing agent, 0.8-1.2 parts of flatting agent, 18-25 parts of pigment, 0-17 parts of inorganic filler, 0-5 parts of adjuvant and 0.1-0.4 part of friction agent. Due to the introduction of the friction agent, a great difference between dielectric constants of the powder coating and a material (polymer PTFE material) for preparing the pipe wall and a friction rod of the friction gun is generated in the frictional spraying process, so that the powder coating can be perfectly adsorbed on a workpiece after being electrified by virtue of friction with the material in the friction gun under the drive of dry airflow; in addition, the frictional electrification way is adopted, so that the Faraday effect generated by a corona field is avoided, and all corners of the workpiece can be completely coated by the powder coating. Meanwhile, compared with an electrostatic spraying way, the powder coating has the advantages that the powdering rate of the workpiece is higher, and a cured coating film is more excellent in flatting effect.

Owner:ANHUI SHENJIAN NEW MATERIALS

Anti-static polyether ketone ketone powder coating and preparation method thereof

ActiveCN106675360ALow densityImprove conductivityPolyether coatingsPowdery paintsSpray coatingKetone

The invention relates to a polyether ketone ketone powder coating, and concretely relates to an anti-static polyether ketone ketone powder coating and a preparation method thereof. The coating is prepared from polyether ketone ketone resin and a conductive agent with the mass ratio being (99 to 99.8) : (1 to 0.2), wherein the conductive agent is a compound conductive material prepared by coating the surface of a carbon-series conductive filler with silver powder. The anti-static polyether ketone ketone powder coating provided by the invention adopts the compound conductive material as the conductive agent, so that the conductivity of the anti-static polyether ketone ketone powder coating is better than the conductivity of a carbon-series conductive agent which is independently used according to the same usage amount, and compared with a metal series, the density of the conductive agent is smaller, and the power utilization rate during electrostatic spraying is high; the anti-static polyether ketone ketone powder coating is prepared by adopting a hot bonding technology, the conductive agent and the base resin are dispersed uniformly and bonded tightly, and the recycled powder coating can be reutilized without the need for re-treating, so that the waste is reduced; an electrostatic spraying coating has the alternative conductivity being 7.10*10<8> to 3.25*10<4>s / m under the frequency of 103Hz, and has an anti-static function.

Owner:SHANDONG KAISHENG NEW MATERIALS

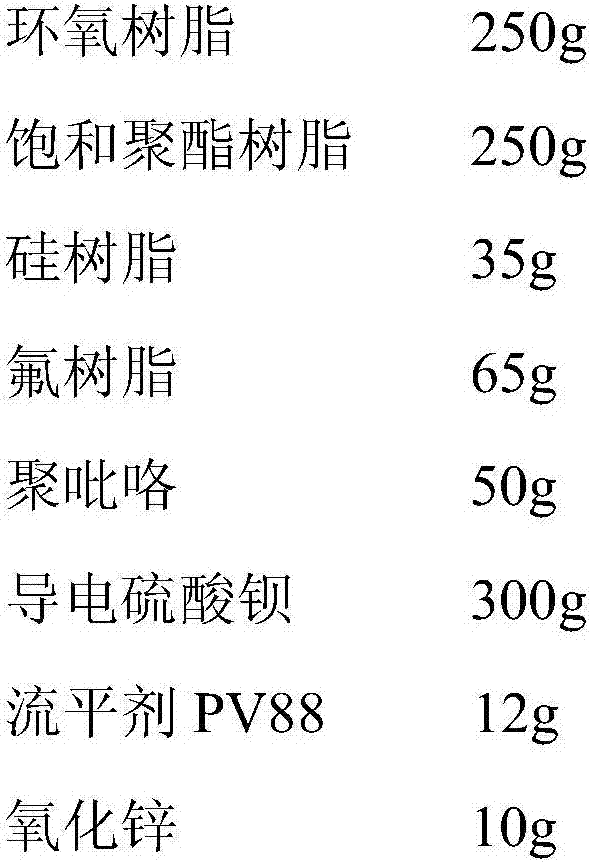

Dust-proof and anti-fouling powder coating, preparation method and application thereof and dust-proof and anti-fouling product

PendingCN107033731AExcellent dust-proof, anti-static, anti-fouling, easy-to-clean performanceLower volume resistivityAntifouling/underwater paintsPaints with biocidesConductive polymerPowder coating

The invention relates to the field of powder coatings and discloses a dust-proof and anti-fouling powder coating, a preparation method and an application thereof and a dust-proof and anti-fouling product. In terms of 1,000 parts by weight of the powder coating, the powder coating is prepared from 400-750 parts by weight of matrix resin, 200-500 parts by weight of filler, 10-80 parts by weight of a general additive, 20-100 parts by weight of a conductive polymer, 10-100 parts by weight of an anti-static auxiliary and 0-50 parts by weight of a pigment. The dust-proof and anti-fouling powder coating has excellent dust-proof, anti-static and anti-fouling performance and is easy to clean.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG

Nanopowder coating with super abrasion resistance

InactiveCN105733419AImprove wear resistanceGood film formingPowdery paintsPolyester coatingsNano siliconPolyester resin

The invention discloses a nanometer super wear-resistant powder coating, which comprises the following raw materials: polyester resin, low-density nanometer wear-resistant powder, titanium dioxide, curing agent, barium sulfate, leveling agent, brightener and charging agent, according to Calculated by mass percentage, polyester resin accounts for 55%-60%, low-density nano wear-resistant powder accounts for 15%-20%, titanium dioxide accounts for 8%-12%, curing agent accounts for 2%-5%, and barium sulfate accounts for 4%. -6%, leveling agent accounts for 2%-4%, brightener accounts for 1%-3%, and booster accounts for 1%-2%. The low-density nano-nano powder is made of nano-silicon carbide and nano-silicon nitride mixture. Through the above method, the present invention has excellent wear resistance and film-forming performance, and the powder coating rate is high when electrostatic spraying is adopted, and the obtained film layer can be uniform, smooth and smooth.

Owner:TAICANG JIDA SPRAY COATING CO LTD

Technology for carrying out electrostatic coating on base of non-conductor

ActiveCN104941885AIlliquidImprove the powder rateLiquid surface applicatorsCoatingsEpoxyEnvironmental resistance

The invention provides a technology for carrying out electrostatic coating on a surface of a non-conductor. The non-conductor comprises glass, plastic and the like. Ordinary low-temperature epoxy polyester powder coating which is sold on the market is adopted, the coating is divided into two parts, namely conductive treating and the electrostatic coating. The technology comprises the specific steps of polishing, cleaning, super-hydrophilic embellishing, tap water atomizing, the electrostatic coating and solidifying. The conductive workpiece surface is required by the electrostatic coating. Due to the fact that a conductive water film which is even, extremely thin and free of fluidity is formed on the workpiece surface, the technical limitation that the electrostatic coating is carried out on the surface of a non-conductive insulating body is solved. Due to the fact that the water film is even and free of the fluidity, the influence on powder adhering by water flowing is avoided. Before heating and melting are carried out on powder, the water film is evaporated rapidly, and a bubble or a hole is prevented from forming in a painting film. The technology has the advantages of being environmentally protected, low in cost, low in energy consumption, simple in procedures, high in powder utilization, and even in coating layer.

Owner:BEIJING NATURE STONE SCI TECH DEVP

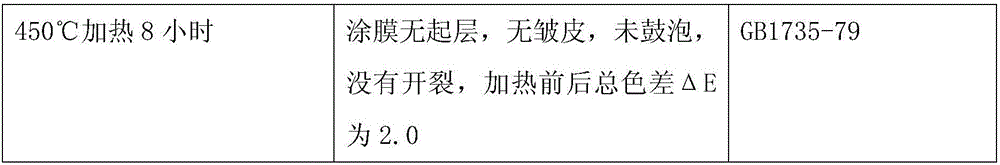

Heat-resisting powder coating for auto vent pipe and preparing method thereof

InactiveCN105949964AImprove corrosion resistanceImprove wear resistanceAnti-corrosive paintsPowdery paintsEpoxyBoron nitride

The invention provides heat-resisting powder coating for an auto vent pipe. The heat-resisting powder coating is prepared from, by weight, 10-20 parts of organosilicon-modified epoxy resin, 80-90 parts of o-cresol formaldehyde epoxy resin, 10-20 parts of hydroxyl polyester resin, 10-15 parts of polyisocyanate, 10-12 parts of polyester polyol, 1-2 parts of silane coupling agent, 1-2 parts of antioxidant 1010, 4-6 parts of ethylene propylene diene monomer, 3-5 parts of silicon carbide, 1-2 parts of boron nitride, 15-20 parts of mica powder, 2-3 parts of 2,6-tert-butyl-4-methylphenol, 0.5-1.0 part of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 15-18 parts of superfine barium sulfate, 8-10 parts of carbon black, 0.5-0.7 part of benzoin and 1-2 parts of performance additive. The coating is high in heat resistance, low in curing temperature, short in curing time, high in adhesive force and resistant to acid and alkali, and can be applied to coating of the auto vent pipe, and a coating film is high in levelling property and good in appearance.

Owner:合肥燕美新材料科技有限公司

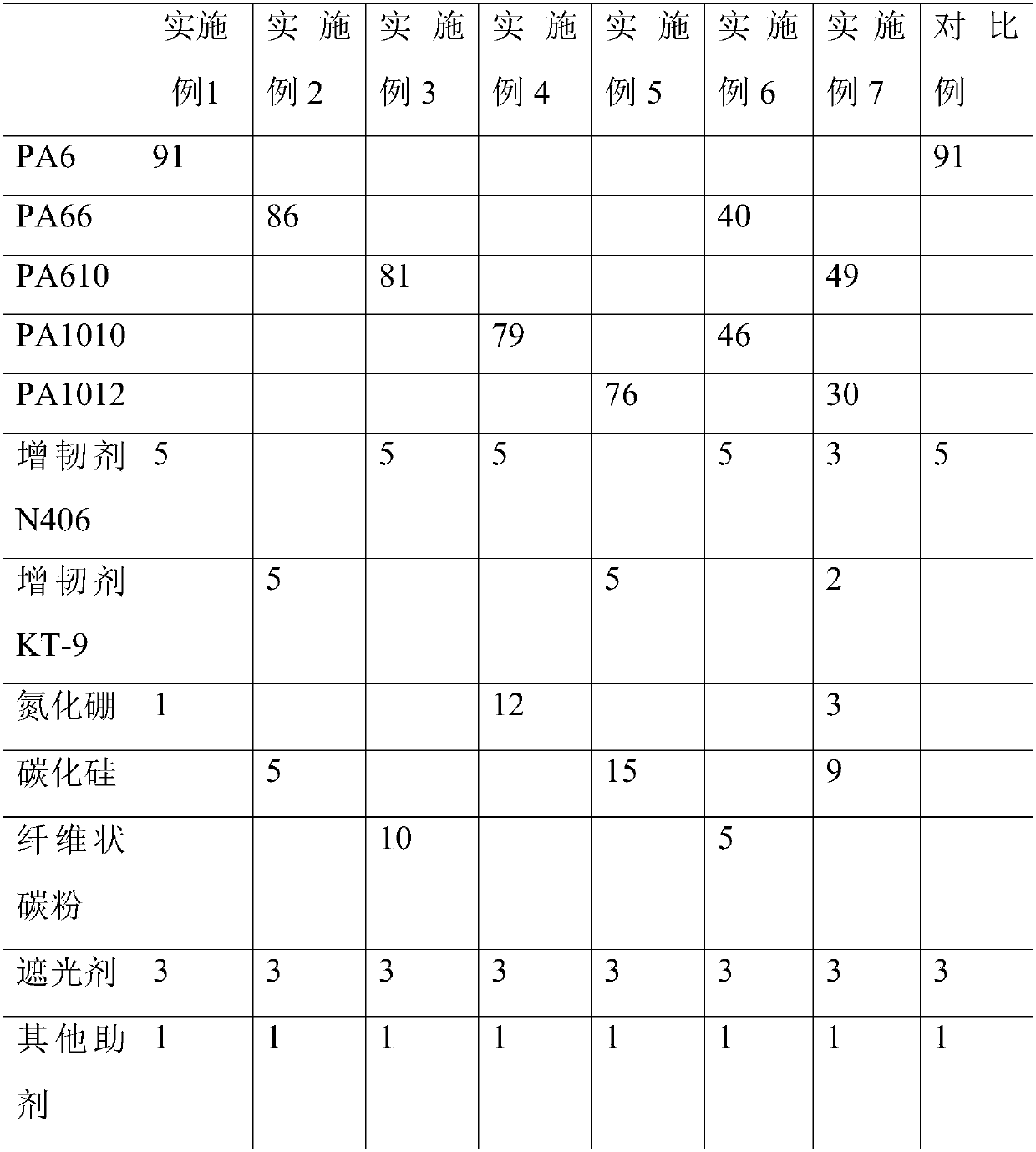

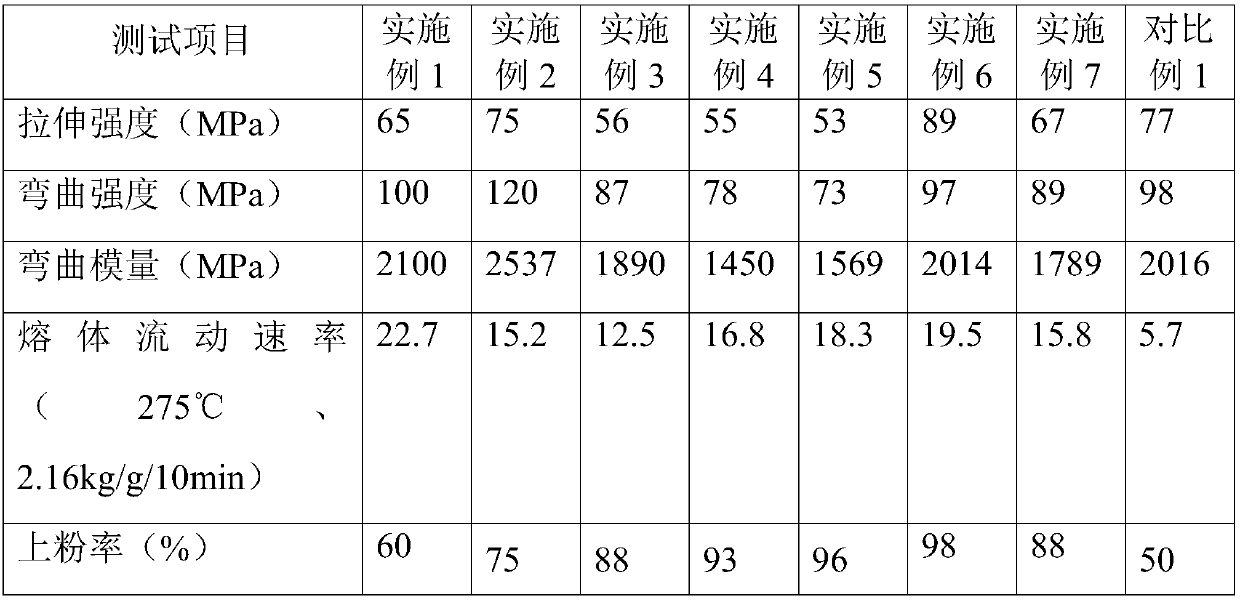

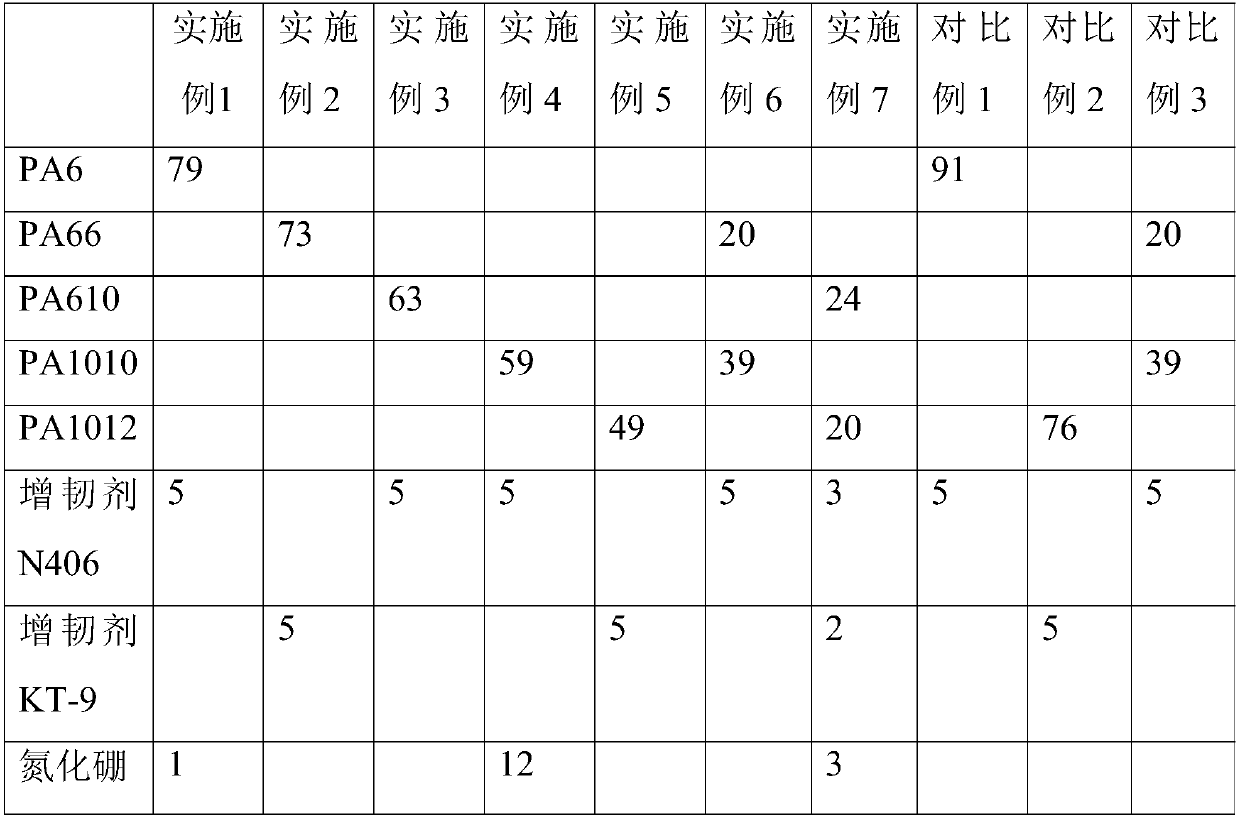

Modified polyamide powder coating and preparation method thereof

InactiveCN109575790AHigh mechanical strengthIncrease productionPowdery paintsPolyamide coatingsPolyamideMechanical property

The invention provides a modified polyamide powder coating and a preparation method thereof. The modified polyamide powder coating comprises, by weight, 40-94 parts of polyamide resin, 3-25 parts of flexibilizers, 1-15 parts of powdering modifiers, 0.5-6 parts of light-screening agents and 0.05-5 parts of other auxiliaries. The modified polyamide powder coating has the advantages of excellent mechanical property and high powdering rate.

Owner:TIANJIN KINGFA NEW MATERIAL

Powder coating with good weather resistance and method for preparing powder coating

InactiveCN106047059AImprove performanceGood storage stabilityRubber derivative coatingsPowdery paintsDiethylene glycol monobutyl etherFiber

The invention provides powder coating with good weather resistance. The powder coating is made of, by weight, 50-60 parts of epoxy resin, 20-30 parts of acrylic resin, 3-4 parts of diethyl glutaric anhydride, 1-2 parts of imidazole, 4-6 parts of chlorinated rubber, 0.1-0.4 part of hindered amine light stabilizers, 0.2-0.4 part of benzotriazole light stabilizers, 0.3-0.5 part of tetrabutyl amine-di-[methyl orthophthalic disulfide] complex copper, 12-16 parts of sepiolite powder, 3-5 parts of short fibers, 10-15 parts of carbon black, 2-3 parts of mica powder, 1-2 parts of diethylene glycol monobutyl ether, 10-15 parts of precipitated barium sulfate, 2-4 parts of castor oil, 2-4 parts of aluminum powder, 0.5-1.0 part of benzoin, 0.2-0.5 part of 2, 6-tert-butyl-4-methylphenol, 0.1-0.3 part of bis-n-dodecanol ester and 3-5 parts of modifying auxiliaries. The powder coating has the advantages that the powder coating is high in application property and adhesion and short in curing time, the weather resistance of the powder coating can reach 20 years, and films are good in leveling property and appearance.

Owner:合肥燕美新材料科技有限公司

Antibacterial and antiviral aluminum alloy and preparation method thereof

InactiveCN111978827AGrowth inhibitionInhibition of reproductionAntifouling/underwater paintsPretreated surfacesAnti bacterialAntibacterial agent

The invention provides an antibacterial and antiviral aluminum alloy and a preparation method thereof. The aluminum alloy comprises an aluminum alloy matrix and an antibacterial and antiviral coatingarranged on the surface of the aluminum alloy matrix, wherein the antibacterial and antiviral coating comprises the following raw materials in parts by mass: 65-85 parts of resin, 15-25 parts of a filling material, 27.5-42.5 parts of an auxiliary agent, 4-6 parts of powder hydroxide, 1-2 parts of an inorganic antibacterial agent and 1-2 parts of an organic antibacterial agent. The antibacterial and antiviral coating is arranged on the surface of the aluminum alloy, so the antibacterial and antiviral aluminum alloy has excellent antibacterial and antiviral effects; an electrostatic vacuum spraying method used in the preparation method provided by the invention is high in powdering rate and small in coating usage amount, so the coating purchasing cost is reduced; a large amount of waste of coatings in a traditional process is avoided; environmental pollution is reduced; and environmental friendliness and energy conservation are achieved.

Owner:南京同曦同康抗菌材料科技有限公司

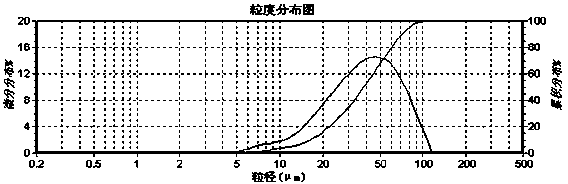

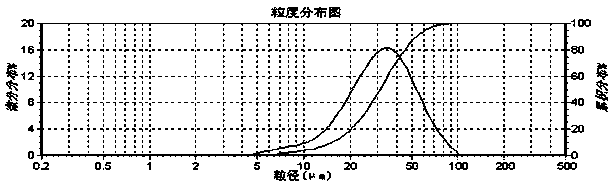

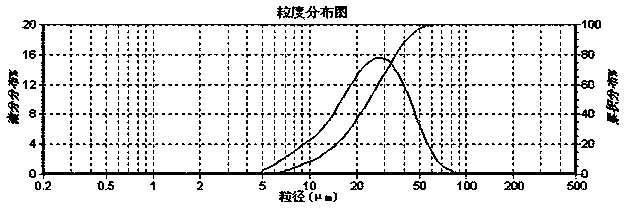

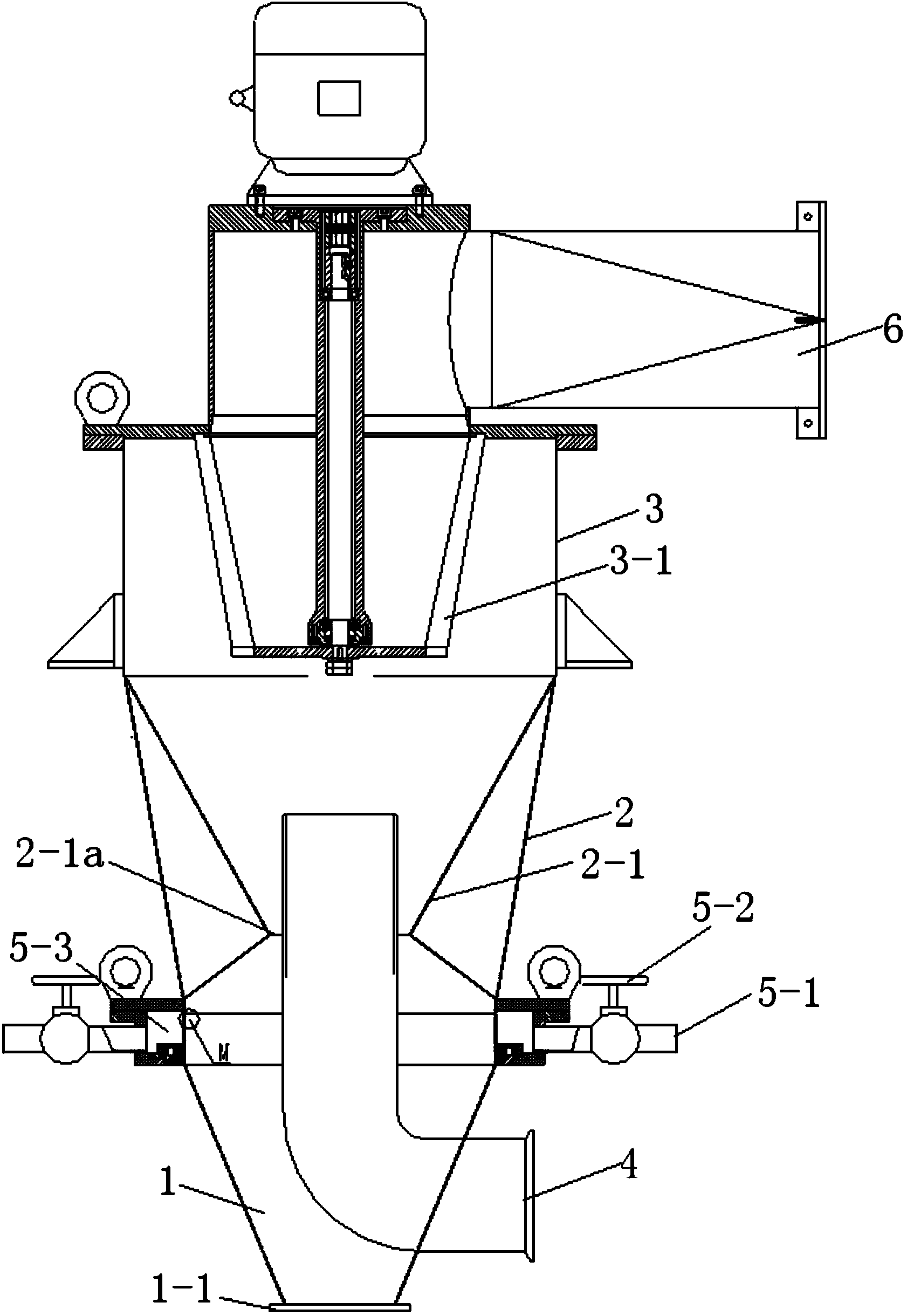

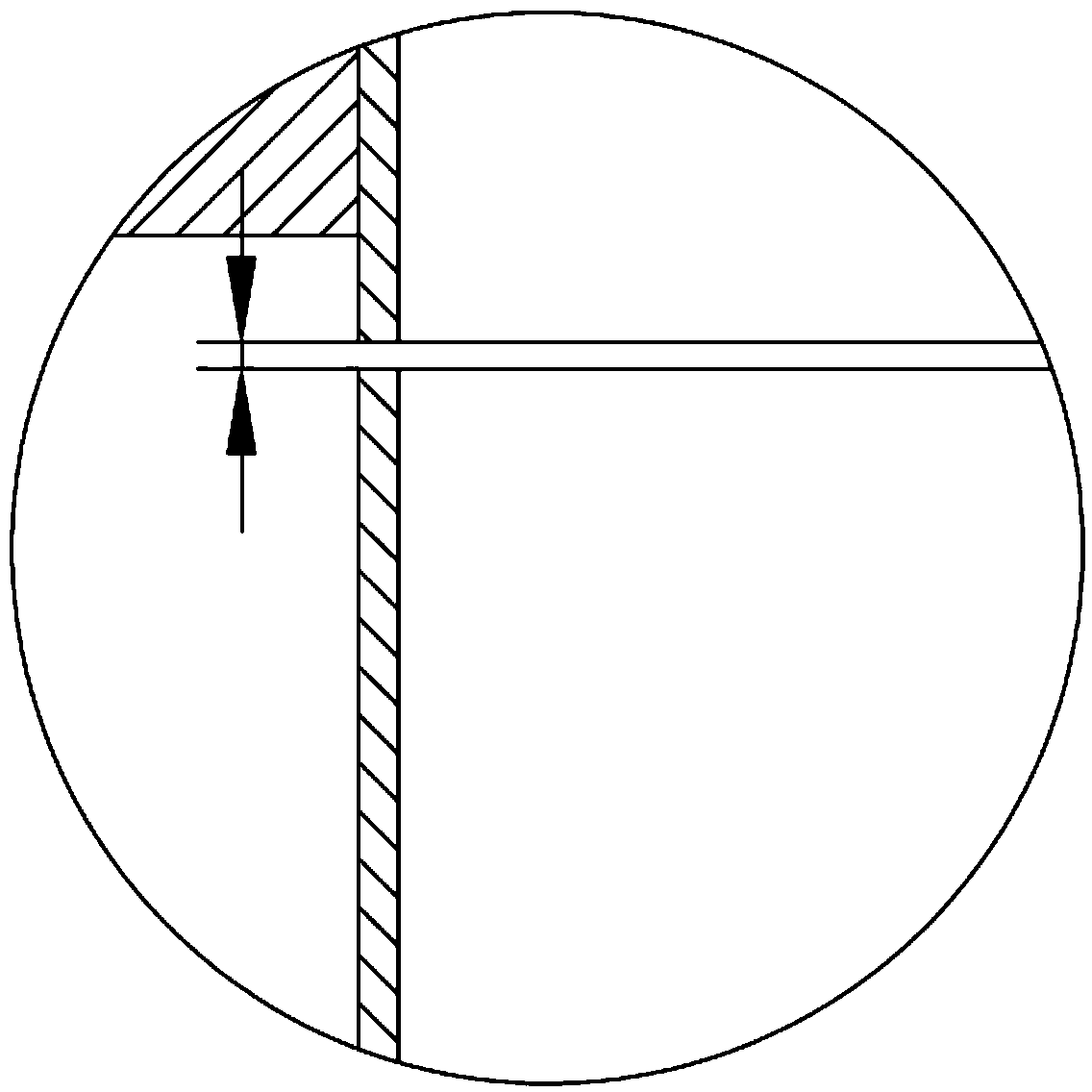

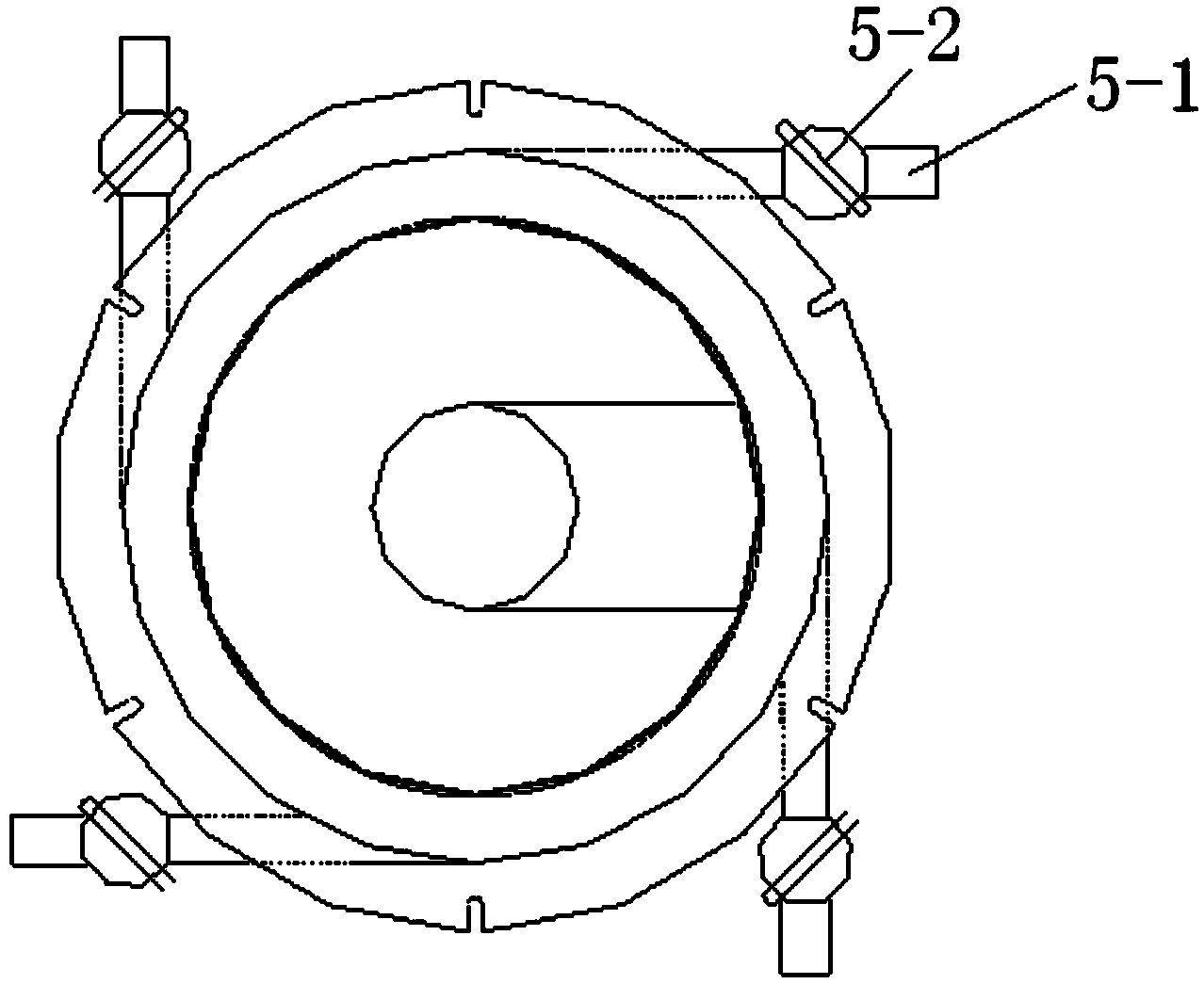

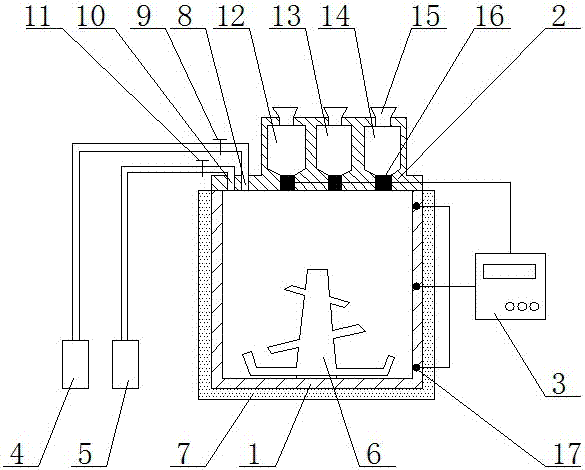

Separator capable of controlling particle size distribution in high-precision mode

ActiveCN104368528ASimple and reasonable structural designIncrease contentGas current separationMicrometerEngineering

The invention belongs to the technical field of powder coating classifying equipment and relates to powder particle classifying equipment, in particular to a separator capable of controlling particle size distribution in a high-precision mode. The separator capable of controlling the particle size distribution in the high-precision mode comprises a discharge hopper, a separation chamber, a classification chamber and a feed pipe, and is characterized in that a gap allowing tiny air flow to pass is formed in the connection portion of the discharge hopper and the separation chamber, the periphery of the gap is provided with a pneumatic control assembly communicated with an external air source, and the pneumatic control assembly comprises a pneumatic pipeline, a control valve and an air flow buffer air chamber, wherein the pneumatic pipeline is connected to the gap in the tangent direction, and the air flow buffer air chamber surrounds the gap. The separator greatly increases the controllability over particle size distribution, is high in separation accuracy, increases the content of powder with the particle size smaller than 10 micrometers in the powder, and further improves product quality and the powdering rate.

Owner:王树波

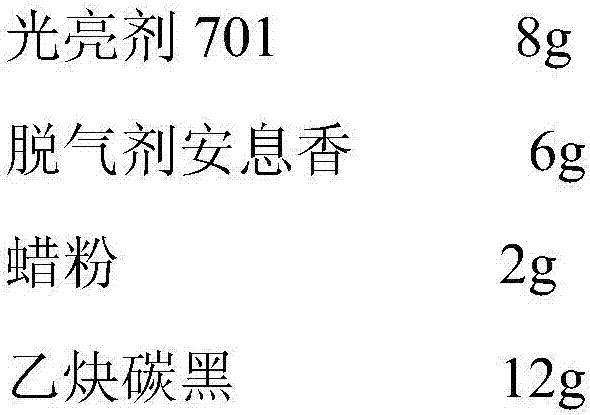

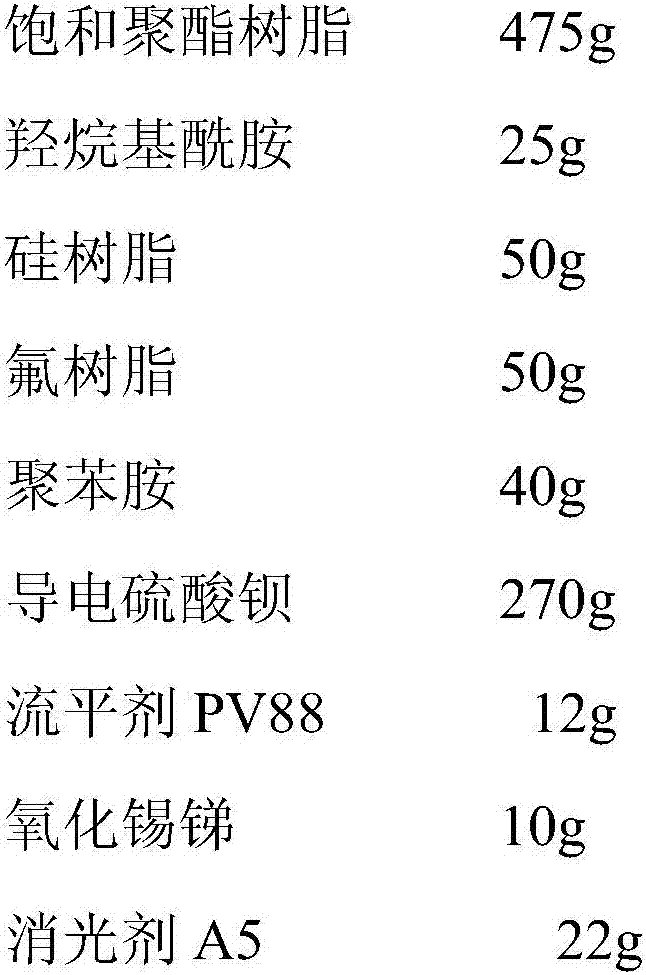

Heat-resistant and flame-resistant powder coating for gas-cooker body surface layer and preparing method thereof

InactiveCN105860783AGood chemical stabilityGood adhesionFireproof paintsAnti-corrosive paintsMethacrylatePolyvinylpyrrolidone

The invention provides a heat-resistant and flame-resistant powder coating for a gas-cooker body surface layer. The heat-resistant and flame-resistant powder coating is prepared from, by weight, 8-10 parts of organic silicon resin, 10-20 parts of thermosetting fluorocarbon resin, 20-30 parts of hydroxyl polyester resin, 2-4 parts of isocyanate curing agent, 1-2 parts of 3-glycidoxypropyltrimethoxysilane, 5-8 parts of ferric oxide, 4-6 parts of ethylene-propylene-diene monomer, 5-10 parts of silica micropowder, 2-4 parts of zinc oxide, 4-6 parts of zirconium oxide, 15-20 parts of kaolin fine powder, 1-2 parts of bi-( 3,5-tertiary butyl-4-hydroxy phenyl ) sulfide, 5-8 parts of magnesium hydroxide, 8-10 parts of aluminum hydroxide, 0.5-1.0 part of 2-ethylhexyl methacrylate, 1-2 parts of polyvinylpyrrolidone, 0.2-0.4 part of acrylic ester flatting agent, 6-8 parts of carbon black and 3-4 parts of modified assistant. The heat-resistant and flame-resistant powder coating is good in heat resistance and flame resistance, low in curing temperature, short in curing time, good in coating flatting performance, high in adhesive force, good in coating appearance and resistant to acid and alkali, and can be applied to the gas-cooker body surface layer.

Owner:合肥燕美新材料科技有限公司

Anti-ageing composite paint

ActiveCN103965738AImprove wear resistanceGood weather resistancePolyurea/polyurethane coatingsLignin material coatingsCarbon blackPolyethylene

The invention relates to anti-ageing composite paint which is characterized by comprising the following components in parts by weight: 40-60 parts of epoxy resin, 20-40 parts of styrene-acrylic emulsion, 6-12 parts of p-toluenesulfonic acid, 15-25 parts of sebacic dihydrazide, 2-8 parts of elm bark fiber, 30-50 parts of polyurethane, 8-15 parts of polyethylene micropowder wax, 1-5 parts of poly(butyl acrylate), 1-5 parts of dispersing agent, 1-5 parts of defoaming agent, 50-70 parts of titanium dioxide, 30-40 parts of iron oxide, 80-120 parts of zinc oxide powder, 10-20 parts of nano aluminum oxide and 5-10 parts of high-color carbon black. The paint provided by the invention is high in hardness and strength, and favorable in wear resistance, weather resistance and ageing resistance; a coated film is tough, resistant to acid and alkali and high in flexibility; the paint improves the dispersivity and flowability of the mixture system, has favorable compatibility with epoxy resin, is short in fusing time after mixing, and can also reduce the density of powdered paint; and the paint improves the painting rate, increases the coating area and lowers the production cost.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Fluorocarbon powder coating for outdoor iron towers, and preparation method thereof

InactiveCN110776794AGood weather resistanceImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesPolymer scienceMeth-

The invention discloses a fluorocarbon powder coating for outdoor iron towers, and a preparation method thereof. The fluorocarbon powder coating is prepared from, by weight, 35-45 parts of polyvinylidene fluoride resin, 8-12 parts of polytetrafluoroethylene resin, 12-16 parts of super weather-proof polyester resin, 20-30 parts of cycloaliphatic epoxy resin, 12-18 parts of acrylic resin, 12-18 parts of epoxy modified alkyd resin, 2-5 parts of polyhexamethylene guanidine, 3-6 parts of modified graphene, 6-10 parts of nano-silica, 0.5-3 parts of nano-alumina, 4-10 parts of barium sulfate, 1.8-2.4parts of silane coupling agent KH-792, 0.2-0.4 part of calcium stearate, 0.3-0.5 part of benzoin, 0.5-1 part of a leveling agent and 4-8 parts of a TGIC curing agent. The fluorocarbon powder coatinghas the advantages of excellent mechanical properties and super strong weather resistance, super strong chemical resistance and super strong leveling property, and has the characteristics of crackingresistance, aging resistance and long service life when applied to outdoor iron towers, and the preparation method is simple, and can achieve industrial production.

Owner:广西凯威铁塔有限公司

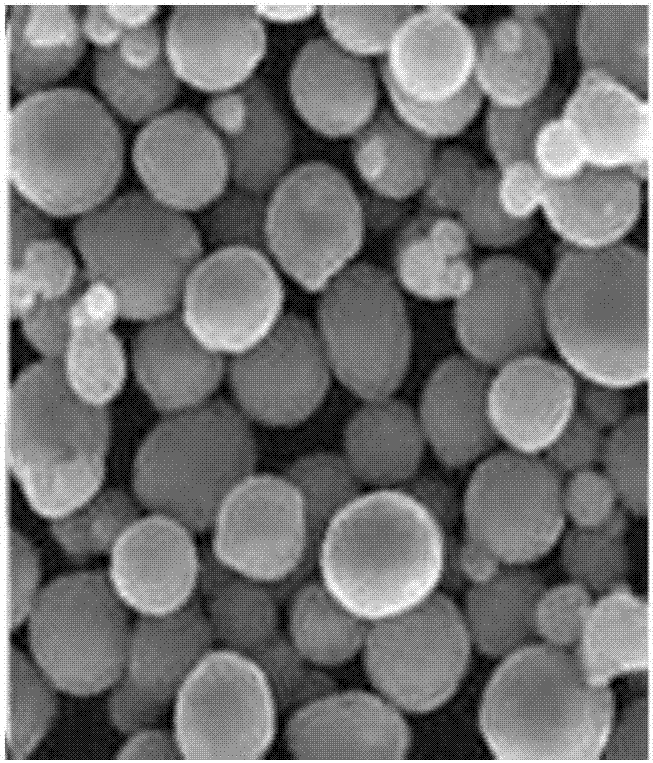

Silicon film coated aluminum pigment as well as preparation method and application thereof

InactiveCN107502002AWon't breakUniform colorPowdery paintsPigment treatment with organosilicon compoundsWeather resistanceNetwork structure

The invention discloses silicon film coated aluminum pigment as well as a preparation method and application thereof. The silicon film coated aluminum pigment is aluminum pigment coated with a Si-O-Si film having N layers of network structures, every two adjacent network structures are connected with each other by means of a coupling agent, and N is more than or equal to 3. The silicon film coated aluminum pigment can be used only when being dry mixed with a powder coating, so that the coating rate is increased; a binding process is not needed, so that the problems of caking scrap and poor bonding effects which are caused by difficult control of the process can be avoided, the aluminum pigment is not damaged, and the metallic luster effect is guaranteed; furthermore, after the aluminum pigment is sprayed, the twinkle effect of a paint film is improved; in addition, the paint film is high in surface hydrophobicity, so that the acid and alkali resistance and weather resistance of the paint film are greatly improved. The coupling agent comprises long chains of polycarbon and functional groups; in a reaction process, the long-chain carbon has a steric hindrance effect and the hydrolyzed functional groups contain charges of the same properties, so that the particles of the aluminum pigment do not agglomerate by means of adsorption, and the phenomenon of caking scrap is avoided.

Owner:长沙族兴新材料股份有限公司

Preparation method for copper rotating target material

ActiveCN111455371AUnlimited size thicknessUnlimited coating thicknessVacuum evaporation coatingSputtering coatingCopper coatingSand blasting

The invention discloses a preparation method for a copper rotating target material. The preparation method for the copper rotating target material comprises the following steps that (1) copper powderis prepared; (2) a back pipe is subjected to surface sand blasting treatment; and (3) the back pipe subjected to sand blasting treatment is mounted on a rack, the back pipe is driven to rotate and move in the axial direction by the rack, cold spraying process parameters are set, the copper powder is sprayed to the surface of the back pipe through a spray gun to form a copper coating, and the copper rotating target material is obtained after the copper coating reaches the required thickness. The copper rotating target material prepared through the preparation method is high in relative density,adjustable in coating thickness and high in copper powder comprehensive powdering rate.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

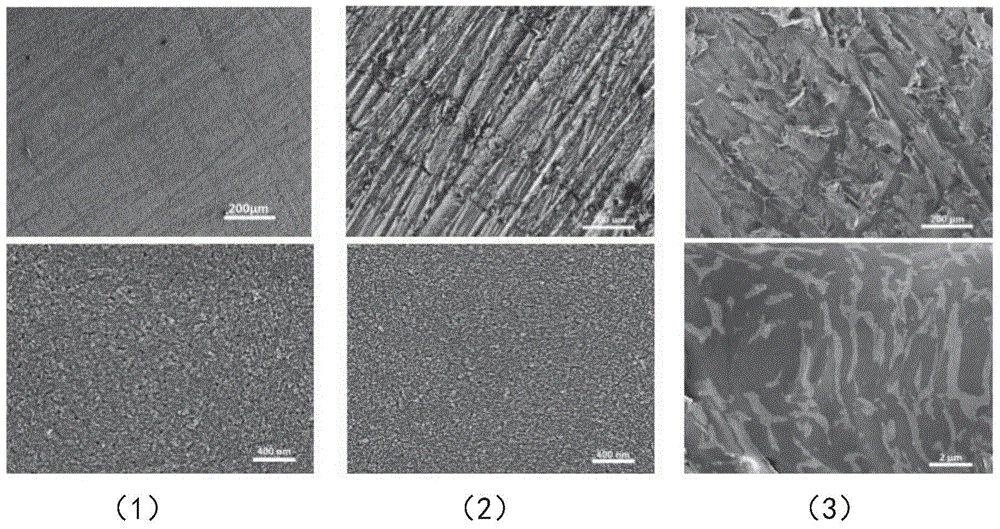

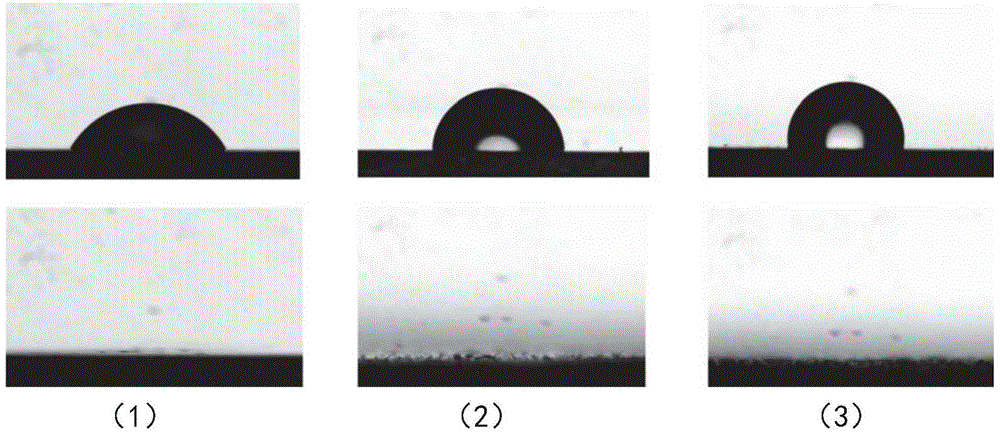

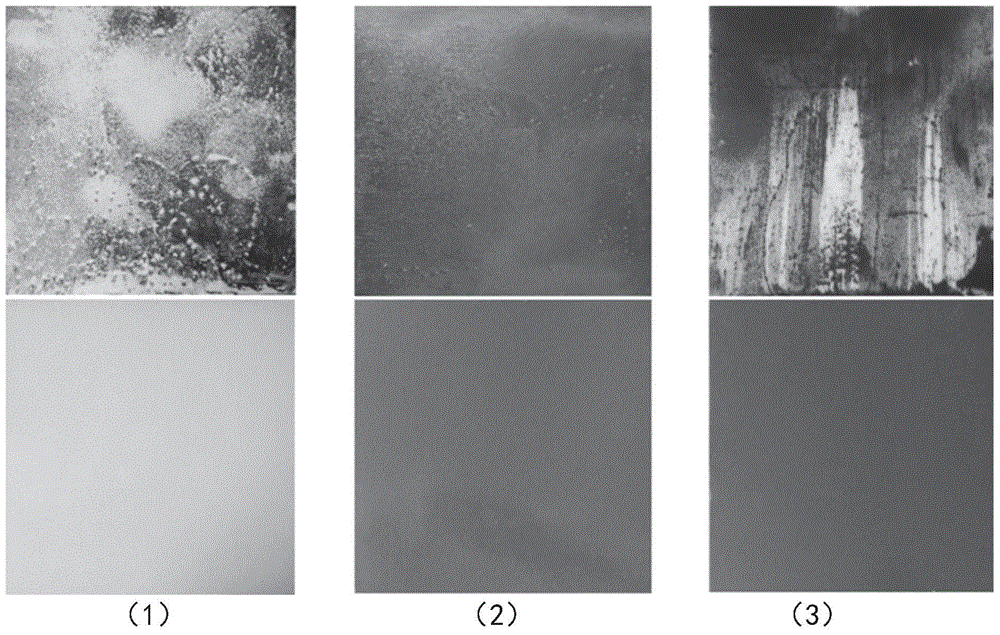

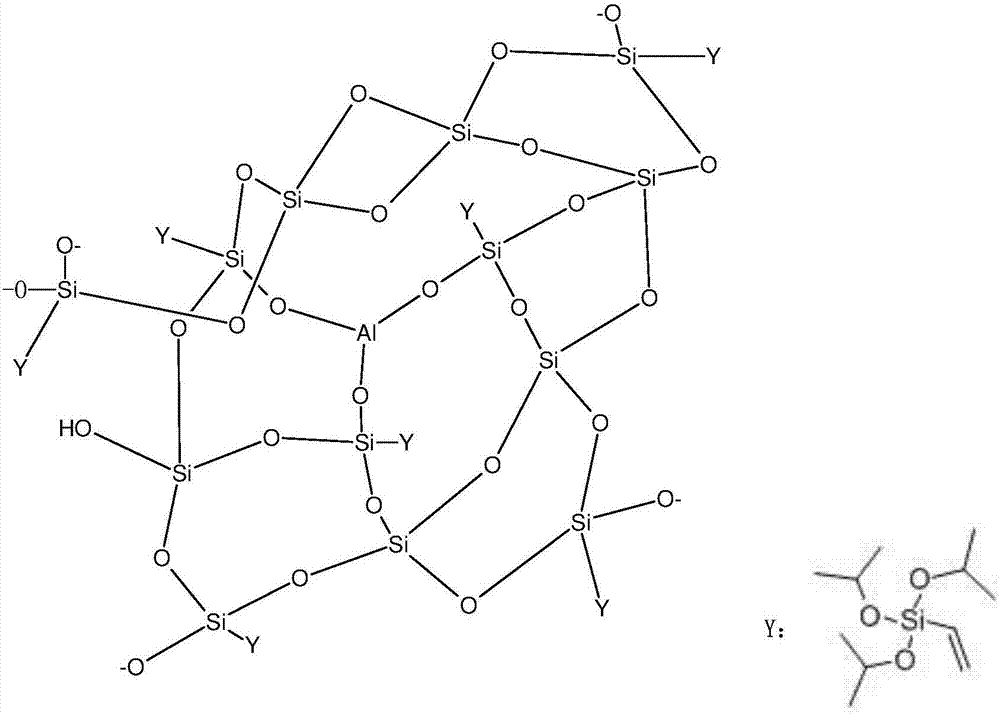

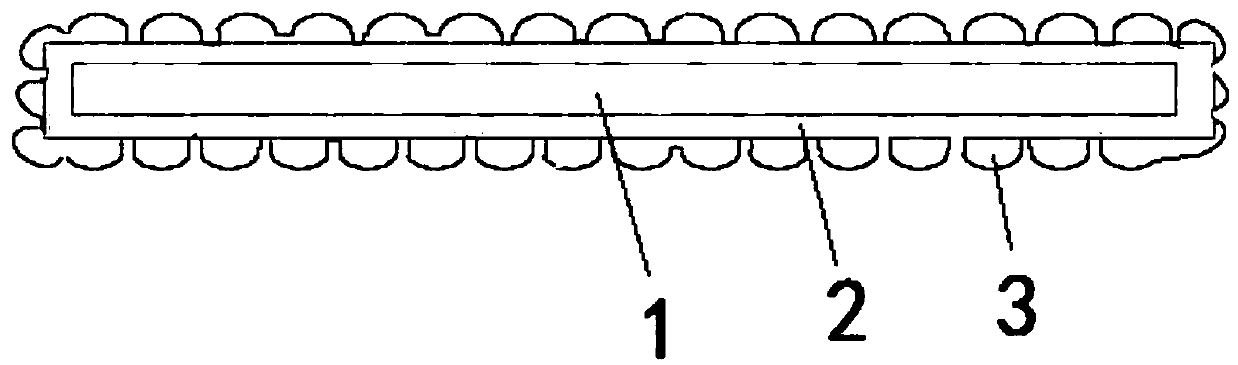

Modified oxide and powder coating, and preparation methods and applications thereof

ActiveCN104788997AImprove the level ofHigh glossAnti-corrosive paintsPowdery paintsGas phaseMixed materials

The invention belongs to the powder coating field, and specifically relates to a modified oxide and a powder coating, and preparation methods and applications thereof. The invention aims to provide the modified oxide which can balancedly improve the levelling property and fluidization of the powder coating, and the preparation method thereof, and the powder coating prepared by the modified oxide. The preparation method of the modified oxide comprises the following steps: a, dissolving an oxide and a modifier by a solvent to obtain a mixed material; b, controlling the mixed material temperature, and stirring to volatilize the solvent; and c, grinding the mixed material obtained by volatilizing the solvent in the step b into the modified oxide with the particle size of 10-100 nm, wherein the oxide of the step a is at least one of nano fumed silica and alumina C.

Owner:四川长虹技佳精工有限公司

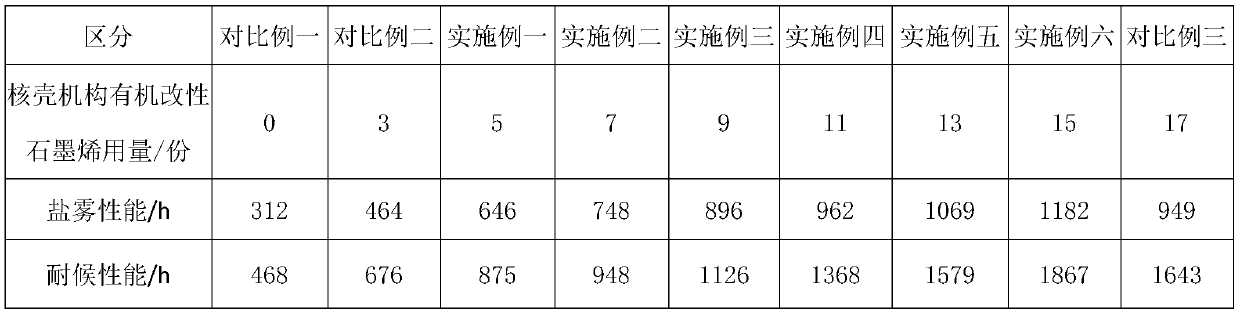

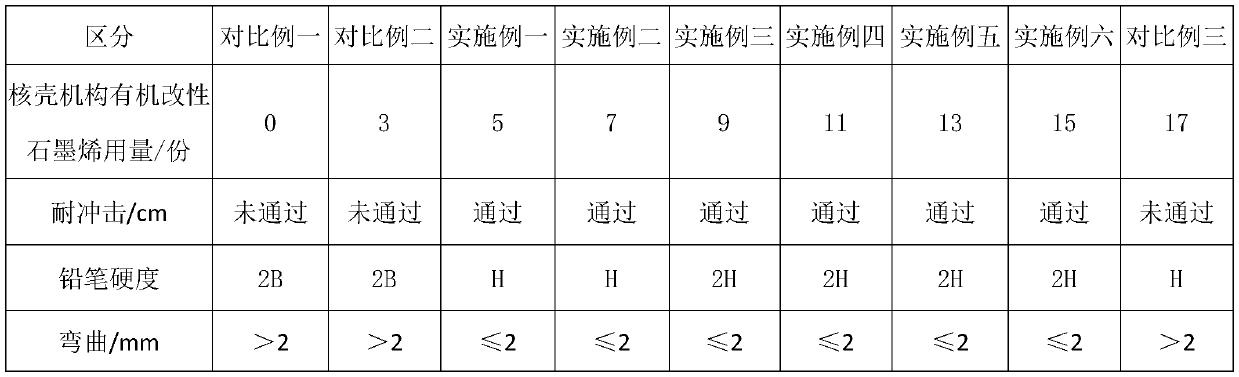

Preparation method of organically modified graphene with core-shell structure, anticorrosive powder coating and preparation method of anticorrosive powder coating

ActiveCN110643205AConductiveHelps with secondary arrangementAnti-corrosive paintsPigment treatment with macromolecular organic compoundsXylylenePolymer science

The invention discloses a preparation method of organically modified graphene with a core-shell structure, an anticorrosive powder coating and a preparation method of the anticorrosive powder coating.The preparation method of the organically modified graphene with the core-shell structure comprises the following steps: dissolving graphene, polyamide wax and polyethylene wax in a mixed solution ofxylene and ethyl acetate, carrying out uniform stirring, and carrying out freeze-drying to obtain primary modified graphene; and adding the primary modified graphene into a polytetrafluoroethylene emulsion, and carrying out freeze-drying to obtain organic modified graphene with the core-shell structure. Through the preparation method of the organically modified graphene with the core-shell structure, graphene can be organically modified twice to form the core-shell structure; and the prepared organic modified graphene with the core-shell structure is applied to the anticorrosive powder coating, so that corrosion resistance, weather resistance and mechanical properties of the coating are effectively improved.

Owner:JIANGSU HUAGUANG POWDER

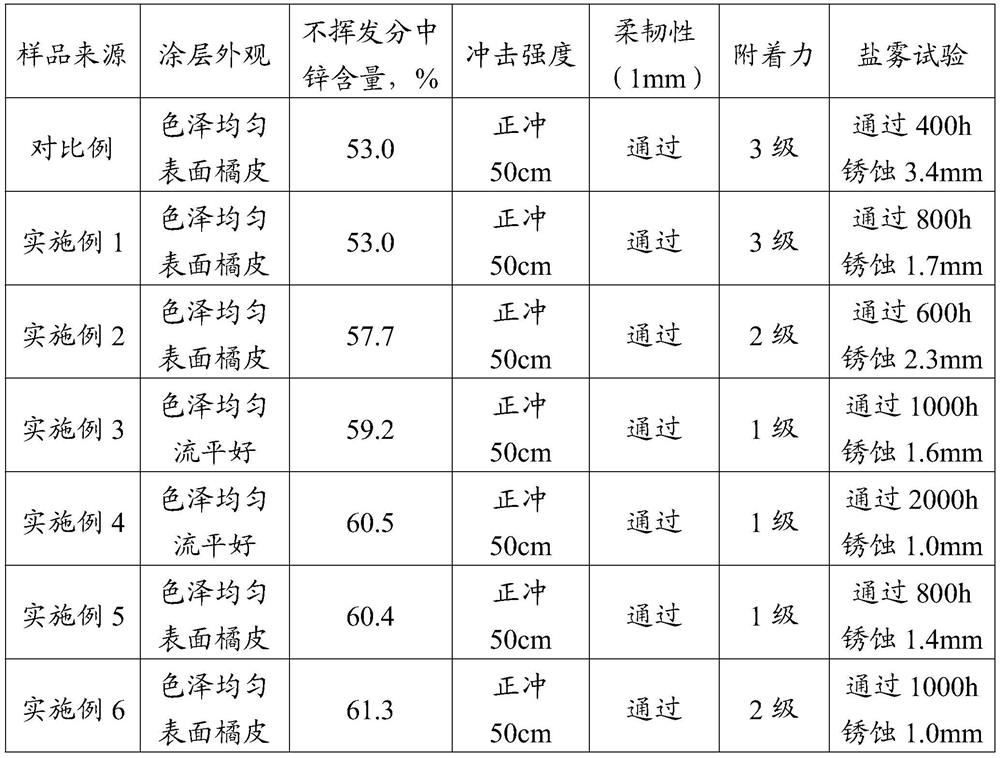

Zinc-rich powder coating as well as preparation method and application thereof

PendingCN114213937AWill not emitGood flexibilityLiquid surface applicatorsAnti-corrosive paintsPtru catalystFirming agent

The invention provides a zinc-rich powder coating as well as a preparation method and application thereof, and belongs to the technical field of coatings. The zinc-rich powder coating provided by the invention is prepared from the following preparation raw materials in parts by weight: 20 to 50 parts of epoxy resin, 0.5 to 2.0 parts of a curing agent, 0.05 to 0.5 part of a catalyst, 60 to 75 parts of zinc powder, 0.05 to 0.1 part of conductive powder, 0.4 to 1.2 parts of a flatting agent, 0.1 to 0.5 part of a degassing agent and 0.1 to 0.5 part of an electricity increasing agent. The zinc-rich powder coating does not discharge VOC in the use process, and is environment-friendly; the conductive powder is added, so that electrons can be transmitted in the cathode protection stage, the corrosion current density is reduced, and a zinc-rich coating formed after the zinc-rich powder coating is cured has excellent salt spray resistance; meanwhile, the zinc-rich coating is good in flexibility, impact resistance and adhesive force and good in appearance.

Owner:北京碧海云智新材料技术有限公司

Preparation method for spherical monocrystal tungsten powder for thermal spraying

ActiveCN106077696APromote growthControl grain sizePolycrystalline material growthFrom solid statePorosityThermal spraying

The invention discloses a preparation method for a spherical monocrystal tungsten powder for thermal spraying. The preparation method comprises the following steps: firstly adding a certain amount of a mixture of lithium carbonate and sodium chloride in an ammonium tungstate solution as a mother solution, and concentrating to obtain a precursor through heating drying; then selecting a spherical tungsten powder as a mother crystal, adding the spherical tungsten powder in the precursor according to a certain ratio, uniformly mixing, and then placing the mixture in a tubular reduction furnace and carrying out hydrogen gas reduction, and then sequentially carrying out ultrasonic cleaning, vacuum drying and grinding spheroidization to prepare an intermediate; and carrying out airflow classification on the prepared intermediate to obtain the spherical monocrystal tungsten powder. The preparation method disclosed by the invention is simple in process equipment and high in production efficiency; and the prepared spherical monocrystal tungsten powder has a perfect crystal, compact particles, a high sphericity degree, high flowability, a high purity, a high coating hardness, a high powder-applying rate and a low porosity.

Owner:LUOYANG GOLDEN EGRET GEOTOOLS

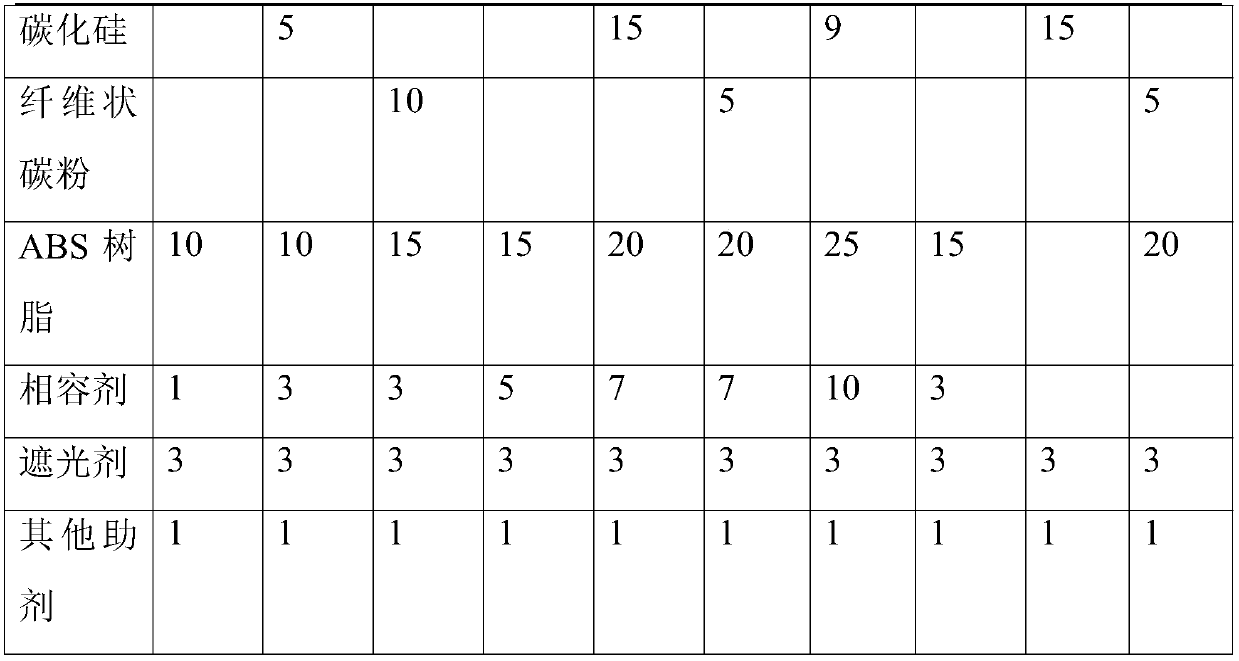

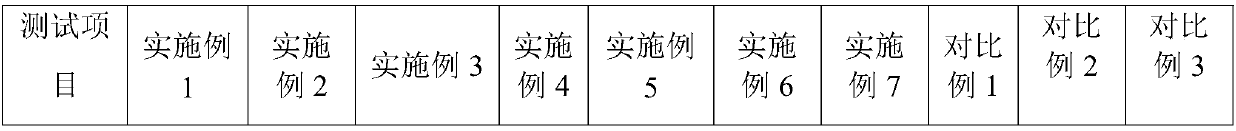

PA/ABS alloy powder coating and preparation method thereof

InactiveCN109609024AImproved notched impact toughnessGood lookingPowdery paintsPolyamide coatingsAlloyToughening

The invention provides a PA / ABS alloy powder coating and a preparation method thereof. The PA / ABS alloy powder coating comprises the following raw materials in parts by weight: 30-54 parts of polyamide resin, 10-25 parts of ABS, 1-10 part of compatibilizer, 3-25 parts of toughening agent, 1-15 parts of powdering modifier, 0.5-6 parts of sunscreen, and 0.05-5 parts of other additives. The inventionrelates to the PA / ABS alloy powder coating and the preparation method thereof, and aims to achieve the effect that the powder coating has a high powdering rate and excellent notched impact toughness.

Owner:TIANJIN KINGFA NEW MATERIAL

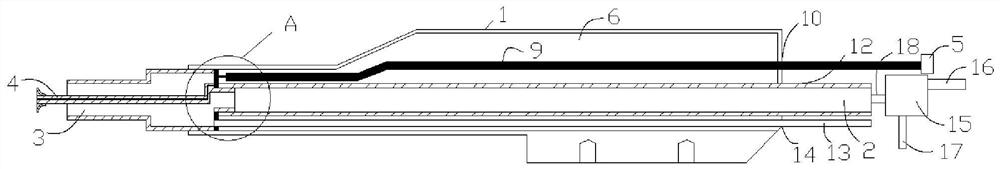

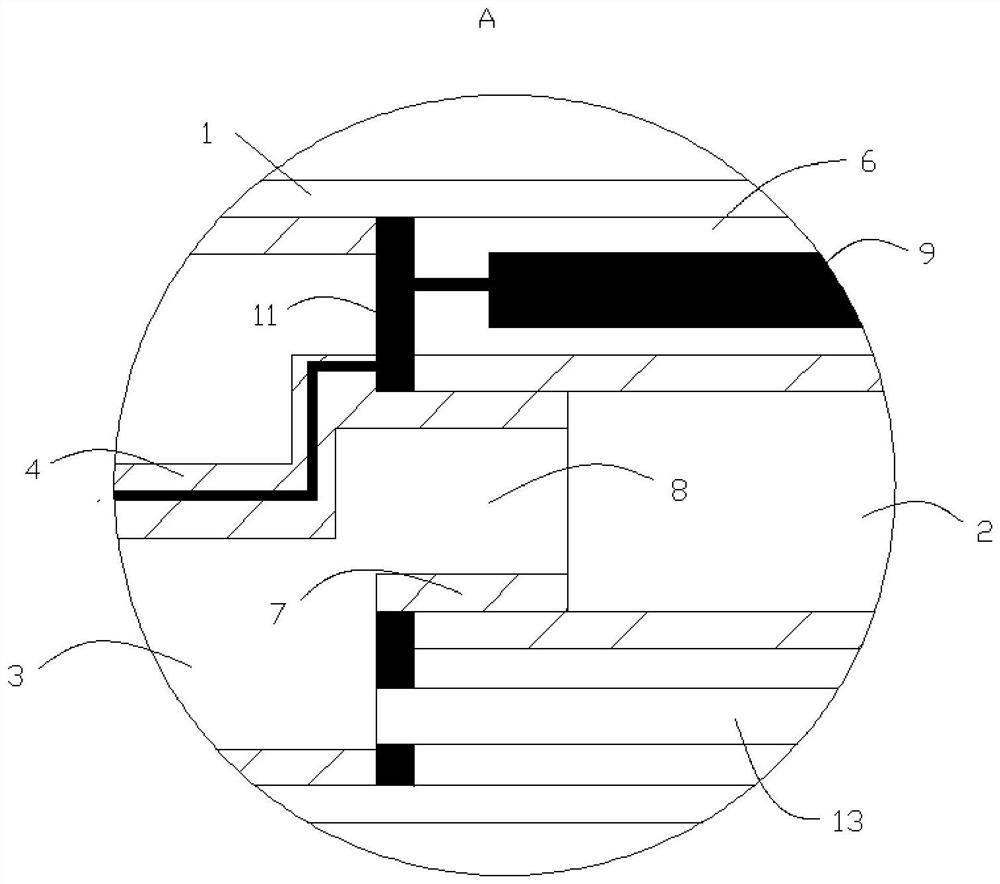

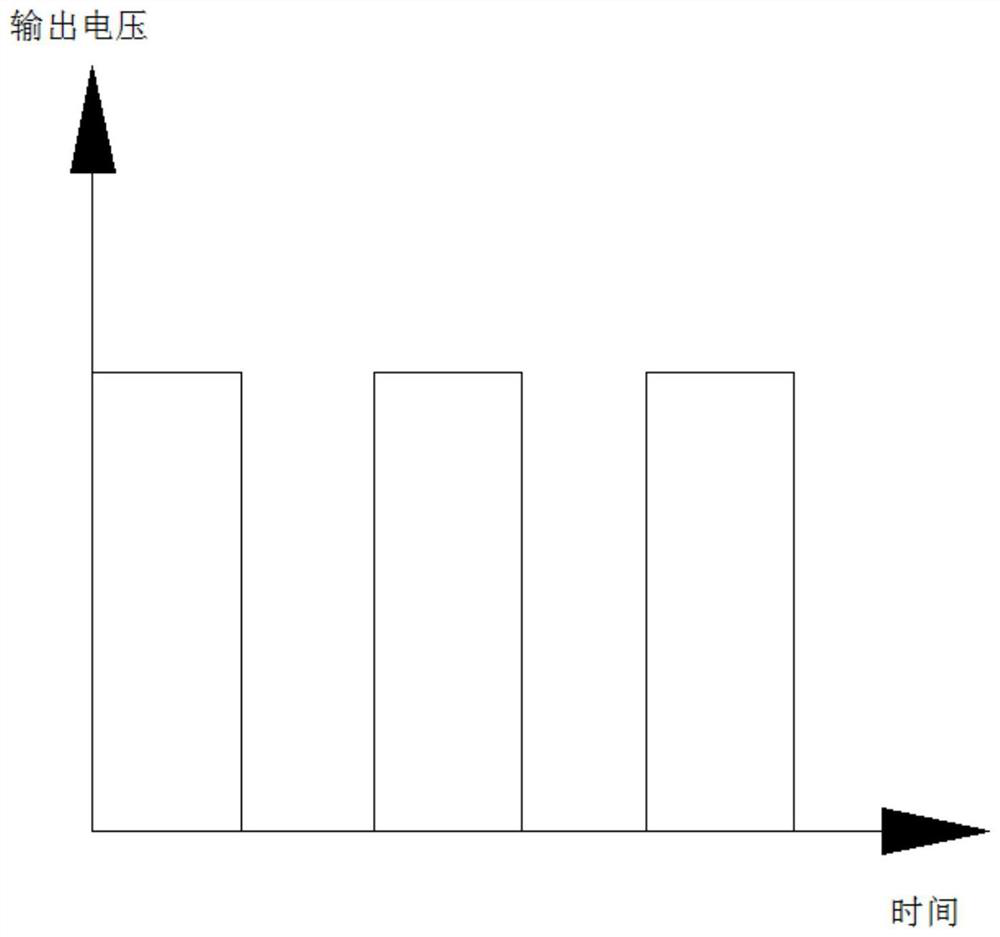

Pulse electrostatic spraying device and spraying process thereof

PendingCN112517260AAchieve sprayingImprove spraying effectSpraying power supplyPretreated surfacesElectrical connectionPowder coating

The invention discloses a pulse electrostatic spraying device and a spraying process thereof. The pulse electrostatic spraying device comprises a gun shell and a powder pipe; the left end of the powder pipe extends into the right end of the gun shell; a coating outlet communicated with the powder pipe is formed in the front end of the gun shell, and the pulse electrostatic spraying device comprises a pulse electrostatic discharge needle and a pulse electrostatic generator; the pulse electrostatic discharge needle is arranged at the coating outlet, and the pulse electrostatic generator is electrically connected with the pulse electrostatic discharge needle; the powder coating enters from the powder pipe and is ejected from the coating outlet, and the pulse electrostatic discharge needle charges the powder coating intermittently. According to the pulse electrostatic spraying device and the spraying process thereof provided by the invention, spraying of non-metallic workpieces and poor electric conductors is achieved, and the spraying effect is good.

Owner:江门市博涂环保机电科技有限公司

Acid and alkali resistant metal powder coating and preparation method thereof

ActiveCN107459912AAvoid corrosionImprove corrosion resistanceAnti-corrosive paintsChemical/physical/physico-chemical stationary reactorsAcrylic resinMetal powder

The invention discloses an acid and alkali resistant metal powder coating and a preparation method thereof. The powder coating comprises the following used materials in parts by mass: 35-45 parts of bisphenol A epoxy resin, 25-35 parts of hydroxy acrylic resin, 15-20 parts of phenolic resin, 2-4 parts of 2-methylimidazole, 9-12 parts of aluminum-silver powder, 2 parts of a sand ripple agent, 16-18 parts of titanium dioxide, 12-14 parts of calcium carbonate, 0.5 part of benzoin and 0.4 part of white carbon black. The prepared powder material has excellent acid and alkali resistance, and due to usage of an automatic feed bonding machine in the preparation process, the obtained powder has high and stable quality.

Owner:ZHANGJIAGANG JIANGNAN POWDER COATING

Preparation method of carbon nanostructure reinforced explosion-proof surface material

InactiveCN108624187ALarge specific surface areaHigh surface energyPowdery paintsEpoxy resin coatingsEpoxyIntrinsic safety

The invention discloses a carbon nanostructure reinforced explosion-proof surface material which is excellent in barrier explosion-proof performance and can be industrially produced, and a preparationmethod thereof, and particularly discloses a carbon material (such as graphene) reinforced epoxy powder paint and preparation method thereof. The paint is characterized by comprising 2 to 5wt per thousand of carbon nanometer material. According to the paint, a modified carbon material is added in a specific silane epoxy additive, an additive material is sufficiently refined through a tertiary grinding and dispersion technology, carbon material is intensively dispersed, an epoxy powder paint finished product is obtained through traditional technologies of crushing and sieving, and reinforced explosion-proof barrier powder paints with different trace contents and ratios are sufficiently prepared. The paint belongs to special coating developed for an HAN (Hypostasis Anch Noexplosion) barrierexplosion-proof technology, can effectively prevent explosion of inflammable, explosive, gaseous and liquid dangerous chemicals caused by fortuitous accidents (such as static electricity, welding, shooting, collision and faulty operation) during storage and transportation, and thoroughly solves the intrinsic safety problem of the inflammable, explosive, liquid and gaseous dangerous chemicals during storage and transportation. The high-performance explosion-proof paint can be widely applied to military products and military and civilian products, such as vehicle manufacture, military vehicle armor, military helmets and building curtain walls.

Owner:常州博碳环保科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com