Technology for carrying out electrostatic coating on base of non-conductor

A non-conductor, electrostatic spraying technology, used in devices and coatings that apply liquid to the surface, can solve the problems of difficult electrostatic spraying, complex procedures, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

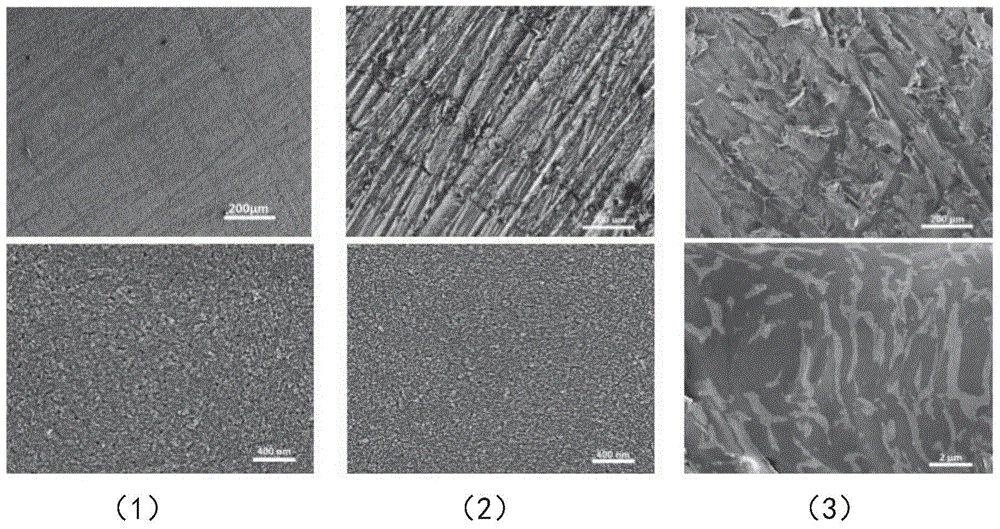

[0025] The present invention achieves the purpose of uniform conduction by performing superhydrophilic modification on glass and spraying water, so that it is suitable for electrostatic spraying. Proceed as follows.

[0026] (1) Take 300*300*2mm ordinary flat glass, and use 100# water sand to fully and repeatedly stagger and polish it until there is no obvious reflection.

[0027] (2) Soak the above glass in an alkali bucket for 3 hours, then take it out, and rinse it with tap water until the water flows down flat.

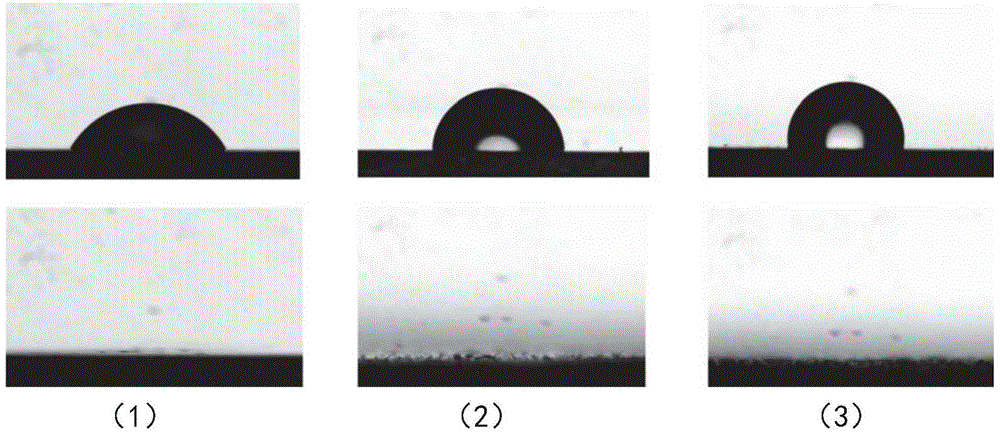

[0028] (3) Using a spray device, spray the surface treatment solution on the glass obtained in (2) until it is fully covered. Then let dry. At this point, the water droplets can spread sufficiently on the surface.

[0029] (4) Using a spraying device, spray tap water on the above-mentioned glass until it is fully covered and there is no water flow.

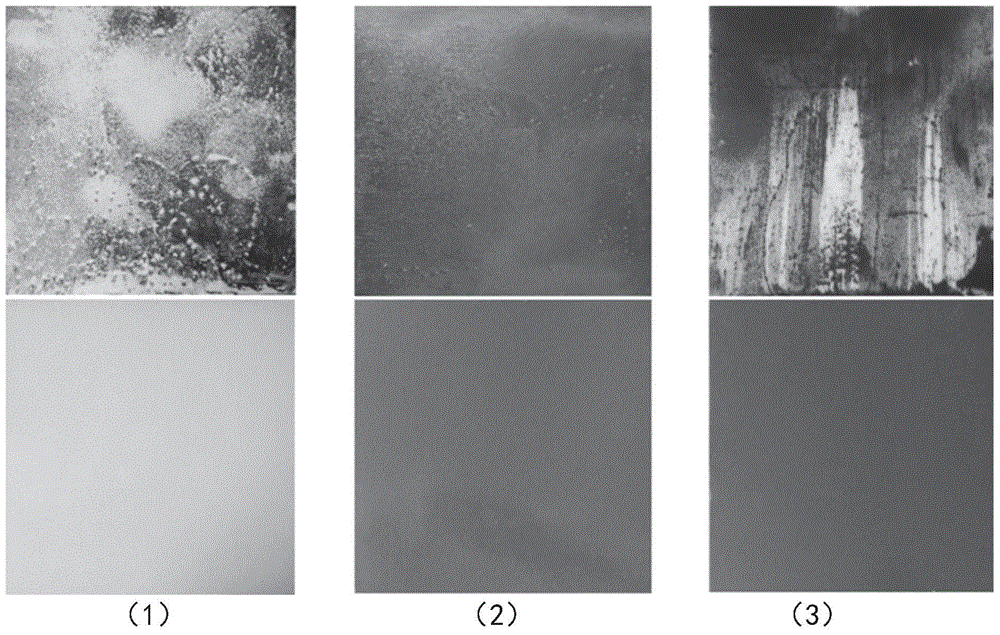

[0030] (5) Ground the above glass and place it in the powder spraying room with an inclination of 75°. Adjust ...

Embodiment 2

[0033] The present invention achieves the purpose of uniform conduction by performing superhydrophilic modification on polycarbonate and spraying water, so that it is suitable for electrostatic spraying. Proceed as follows.

[0034] (1) Take a 300*300*1mm ordinary polycarbonate flat plate, and use 300# water sand to fully and repeatedly stagger it until there is no obvious reflection.

[0035] (2) The above-mentioned glass is fully rinsed with tap water. and let dry.

[0036] (3) Using a spray device, spray the surface treatment solution on the polycarbonate flat plate obtained in (2) until it is fully covered. Then let dry. At this point, the water droplets can spread sufficiently on the surface.

[0037] (4) Using a spray device, spray tap water on the above polycarbonate plane until it is fully covered and there is no water flow.

[0038] (5) Ground the polycarbonate above and place it in the powder spraying room with an inclination of 75°. Adjust the powder spraying ...

Embodiment 3

[0041] The present invention achieves the purpose of uniform conduction by performing superhydrophilic modification on polypropylene and spraying water, so that it is suitable for electrostatic spraying. Proceed as follows.

[0042] (1) Take a 300*300*5mm ordinary polypropylene plate, and use 300# water sand to fully and repeatedly stagger and polish it until there is no obvious reflection.

[0043] (2) The above-mentioned polypropylene plate was fully rinsed with tap water. and let dry.

[0044] (3) Using a spray device, spray the surface treatment solution on the polypropylene obtained in (2) until it is fully covered. Then let dry. At this point, the water droplets can spread sufficiently on the surface.

[0045] (4) Using a spraying device, spray tap water on the above-mentioned polypropylene until it is fully covered and there is no water flow.

[0046] (5) Ground the above workpiece and place it in the powder spraying room with an inclination of 75°. Adjust the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com