Separator capable of controlling particle size distribution in high-precision mode

A particle size distribution, high-precision technology, used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve the problem of wide particle size distribution curve of main grinding powder, affecting the quality of finished powder and reducing product quality. In order to improve the product quality and powder rate, the structure design is reasonable and simple, and the content is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

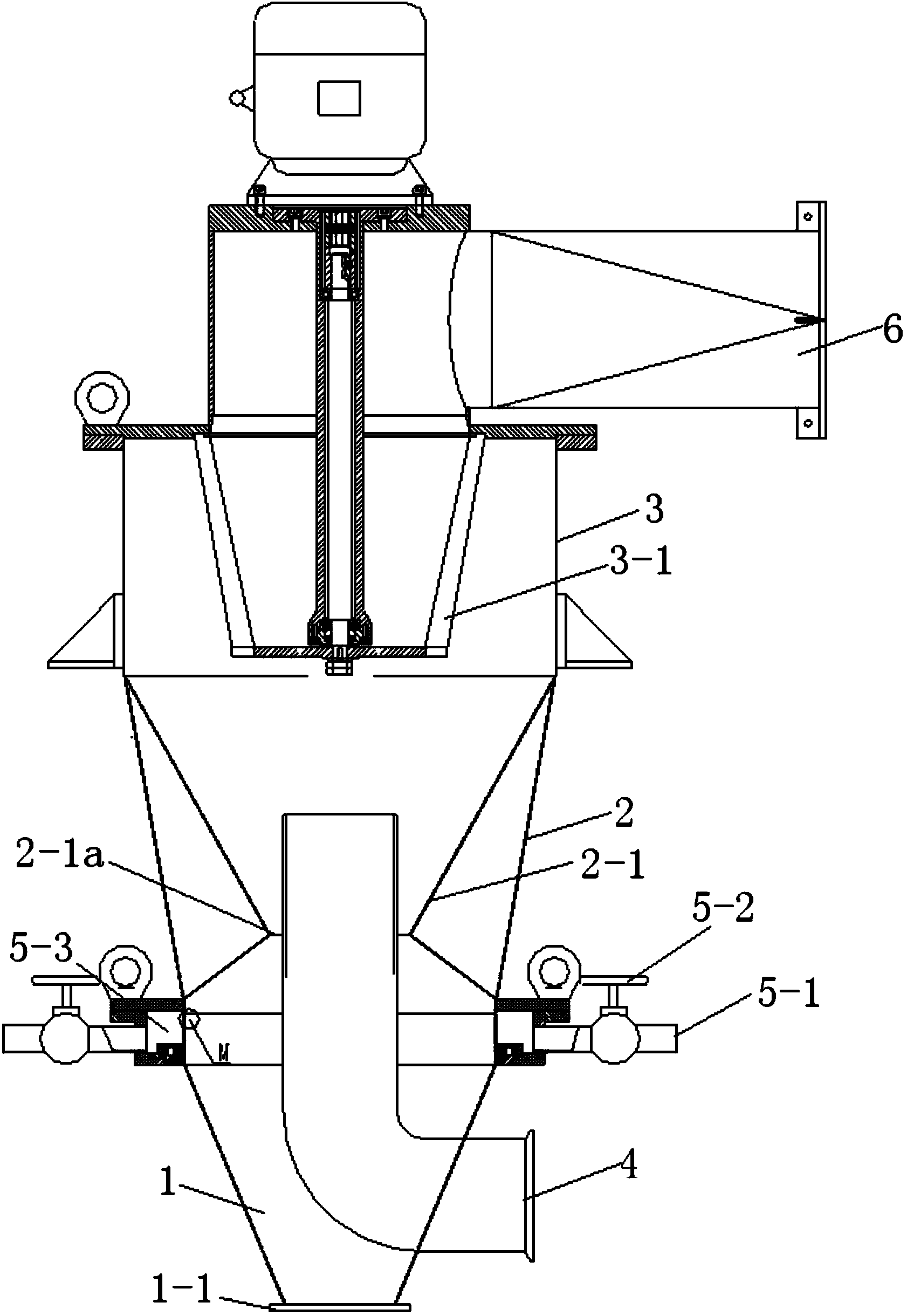

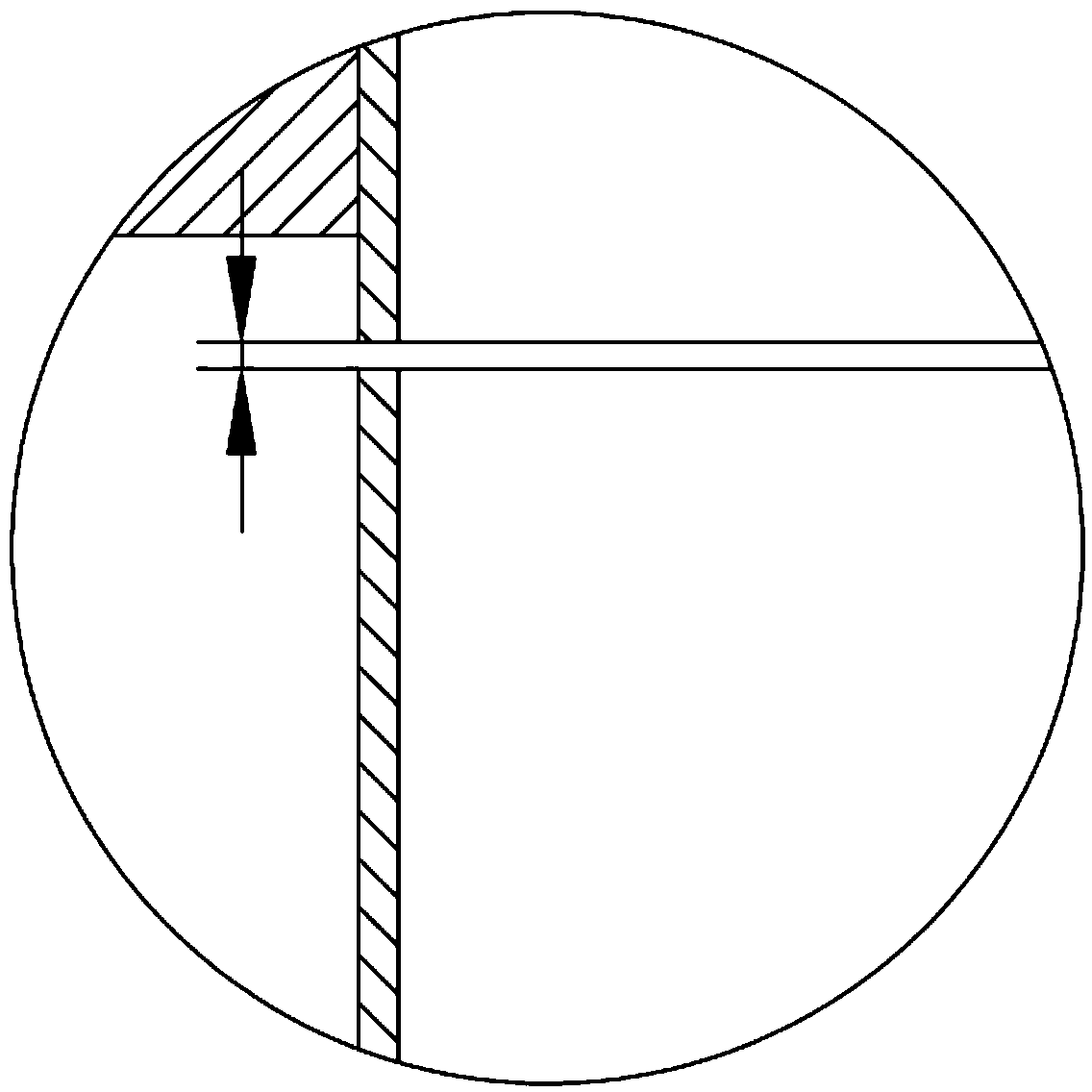

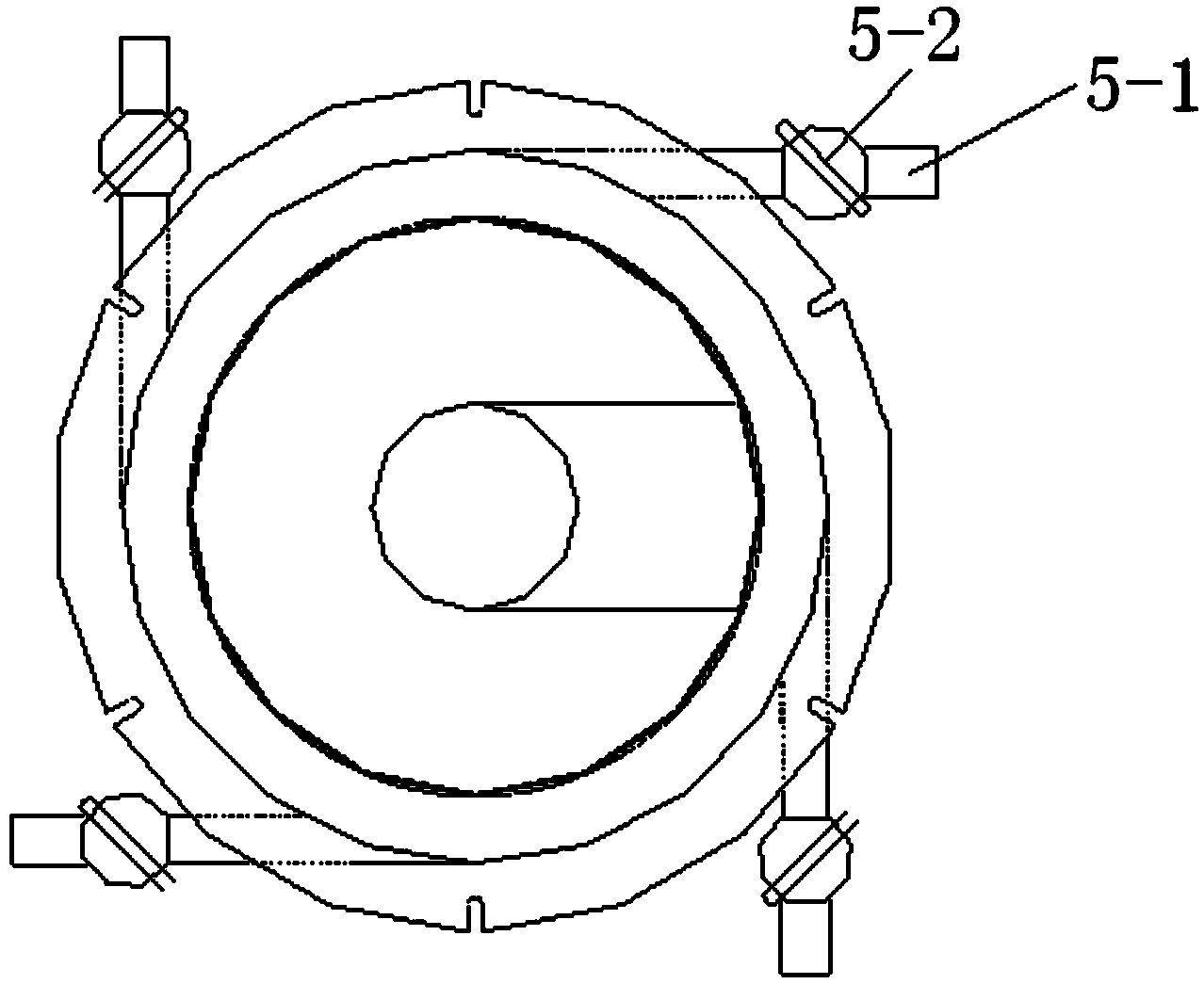

[0019] A high-precision separator for controlling particle size distribution in this embodiment reference Figure 1-3 , including a discharge hopper 1, a separation chamber 2, a classification chamber 3 and a discharge port 6 interconnected from bottom to top, the bottom of the discharge hopper 1 has a discharge port 1- 1. The separation chamber 2 is connected to the top of the discharge hopper 1, and there is a diversion cone 2-1 shaped like an hourglass inside, and the powder is guided and discharged into the lower discharge hopper 1 by the diversion cone 2-1; The classification chamber 3 is erected above the separation chamber 2, and a classifier 3-1 is arranged inside, and a discharge port 6 is connected to the output on one side of the top; the feed pipe 4 runs through the outlet from bottom to top. The hopper 1 extends to the inside of the separation chamber 2; the connection between the hopper 1 and the separation chamber 2 is provided with a gap L for the passage of ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com