Pulse electrostatic spraying device and spraying process thereof

An electrostatic spraying and pulse technology, which is applied to electrostatic spraying device, spraying device, spraying discharge device, etc., can solve the problems of inability to absorb powder coatings and poor spraying effect, and achieve the effect of high powder coating rate and good spraying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A spraying process using any one of the above-mentioned pulse electrostatic spraying devices, it also includes the following steps:

[0043] 1. Pretreatment: remove oil and dust from the workpiece;

[0044] 2. Drying: the workpiece is dried after degreasing and dust removal;

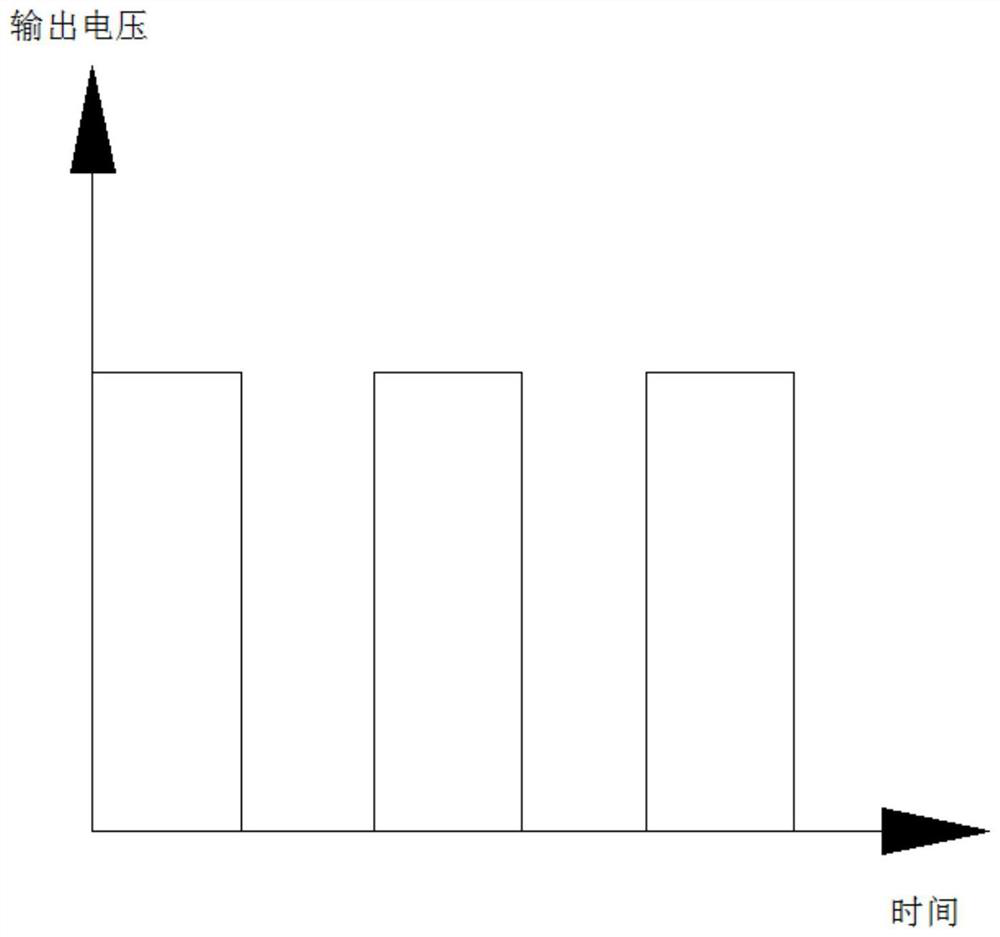

[0045] 3. Adjust the parameters of the pulse electrostatic generator: the output voltage of the pulse electrostatic generator is 30KV, the output current is 60Ma, the output frequency is 3HZ, and the duty cycle is 30%;

[0046] 4. Adjust the parameters of the powder pump: the powder output of the paint is 60g / min, the atomization amount is 10L / min, and the high-pressure air inlet pressure is 0.5Mpa;

[0047] 5. Adjust the distance between the workpiece and the pulse electrostatic discharge needle: the distance between the workpiece to be sprayed and the pulse electrostatic discharge needle is 15cm;

[0048] 6. Spraying: When spraying, move the spray gun at an average speed, the speed is 0.5m / s, ...

Embodiment 2

[0051] A spraying process using any one of the above-mentioned pulse electrostatic spraying devices, it also includes the following steps:

[0052] 1. Pretreatment: remove oil and dust from the workpiece;

[0053] 2. Drying: the workpiece is dried after degreasing and dust removal;

[0054] 3. Adjust the parameters of the pulse electrostatic generator: the output voltage of the pulse electrostatic generator is 50KV, the output current is 80Ma, the output frequency is 10HZ, and the duty cycle is 40%;

[0055] 4. Adjust the parameters of the powder pump: the powder output of the paint is 110g / min, the atomization amount is 20L / min, and the high-pressure air inlet pressure is 0.7Mpa;

[0056] 5. Adjust the distance between the workpiece and the pulse electrostatic discharge needle: the distance between the workpiece to be sprayed and the pulse electrostatic discharge needle is 15cm to 40cm;

[0057] 6. Spraying: When spraying, move the spray gun at an average speed, the speed i...

Embodiment 3

[0060] A spraying process using any one of the above-mentioned pulse electrostatic spraying devices, it also includes the following steps:

[0061] 1. Pretreatment: remove oil and dust from the workpiece;

[0062] 2. Drying: the workpiece is dried after degreasing and dust removal;

[0063] 3. Adjust the parameters of the pulse electrostatic generator: the output voltage of the pulse electrostatic generator is 80KV, the output current is 100Ma, the output frequency is 20HZ, and the duty cycle is 50%;

[0064] 4. Adjust the parameters of the powder pump: the powder output of the paint is 160g / min, the atomization amount is 30L / min, and the high-pressure air inlet pressure is 0.8Mpa;

[0065] 5. Adjust the distance between the workpiece and the pulse electrostatic discharge needle: the distance between the workpiece to be sprayed and the pulse electrostatic discharge needle is 40cm;

[0066] 6. Spraying: When spraying, move the spray gun at an average speed, the speed is 2m / s,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com