Patents

Literature

40results about How to "Guaranteed ejection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

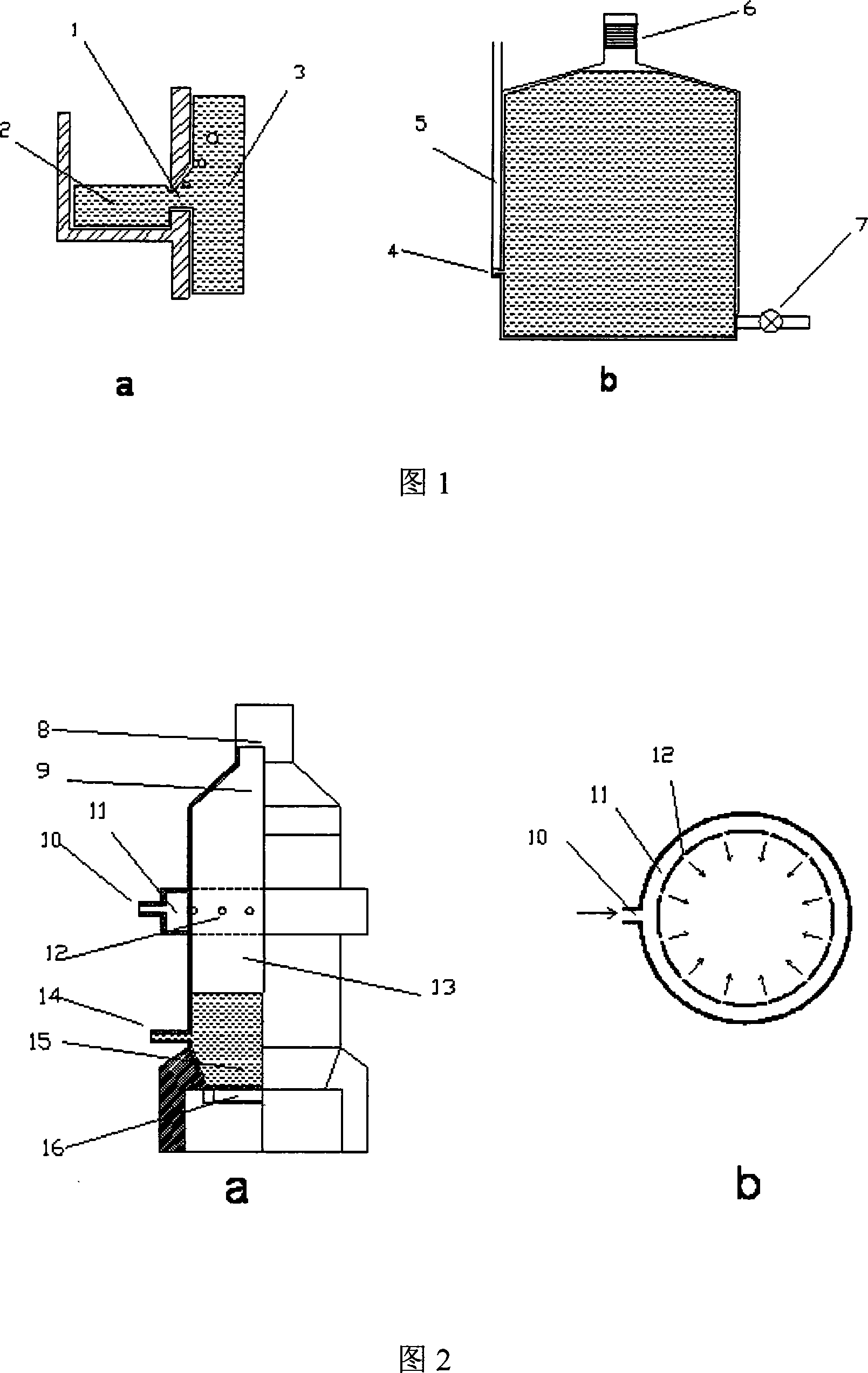

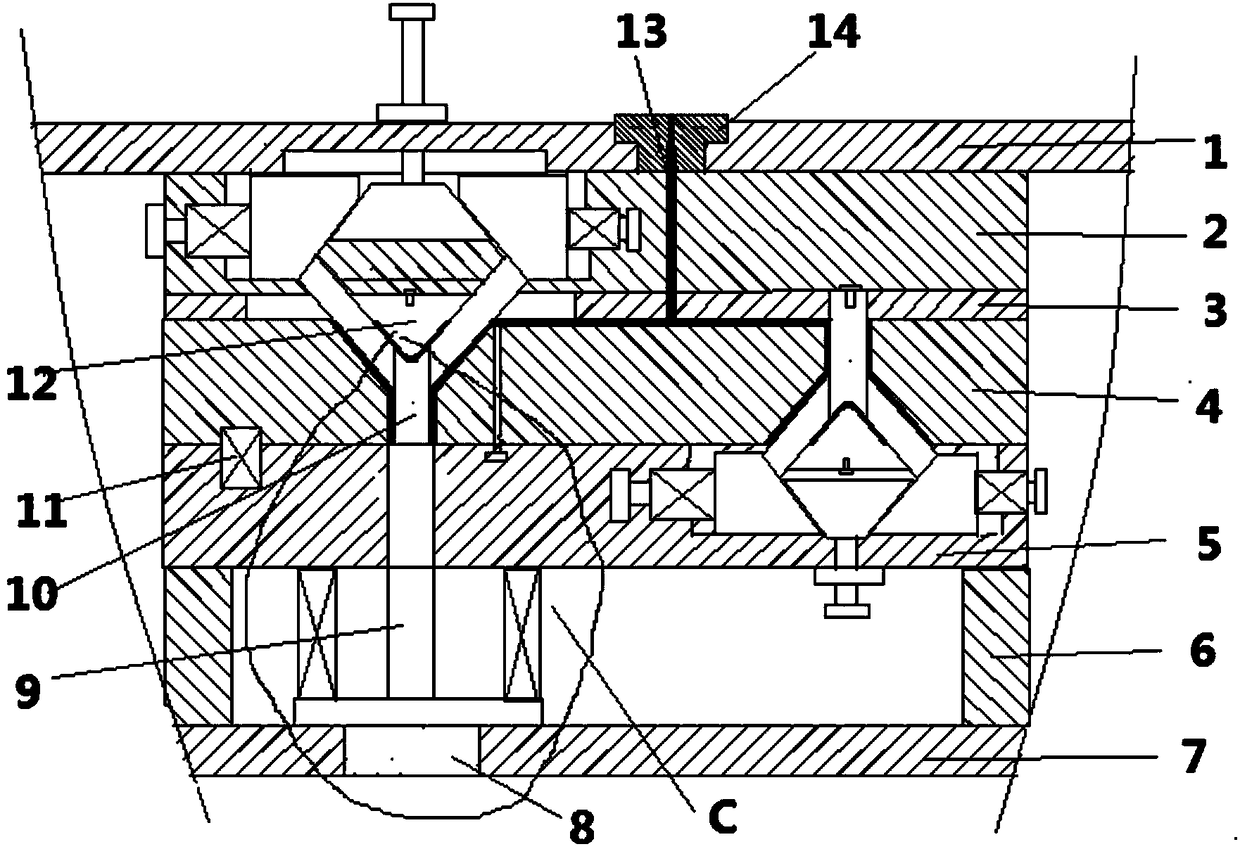

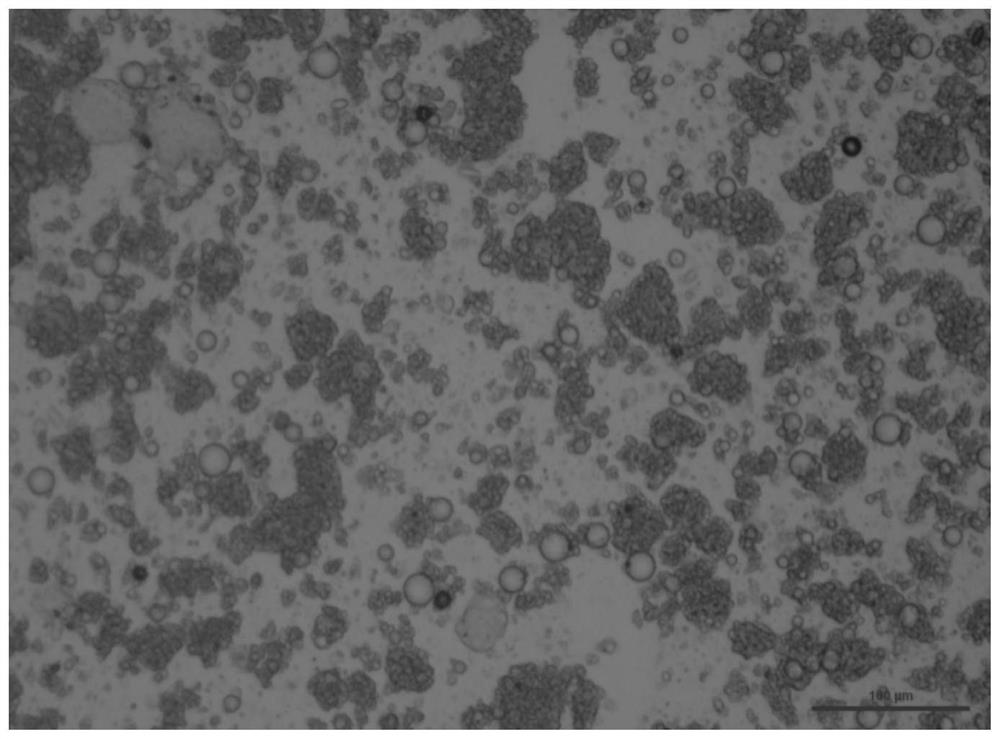

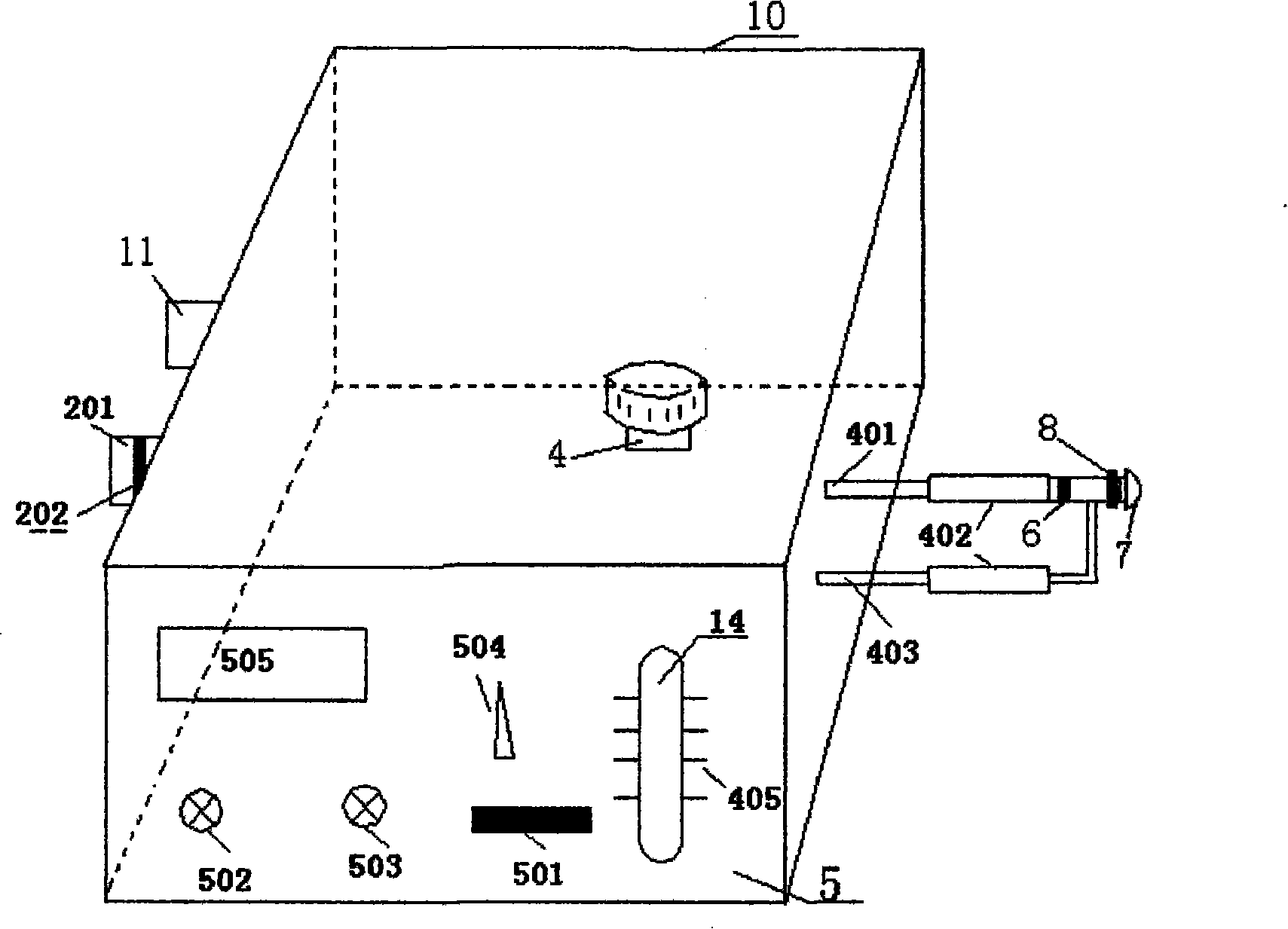

Ultrasonic-atomizing heat-decomposing compound semiconductor film preparing system

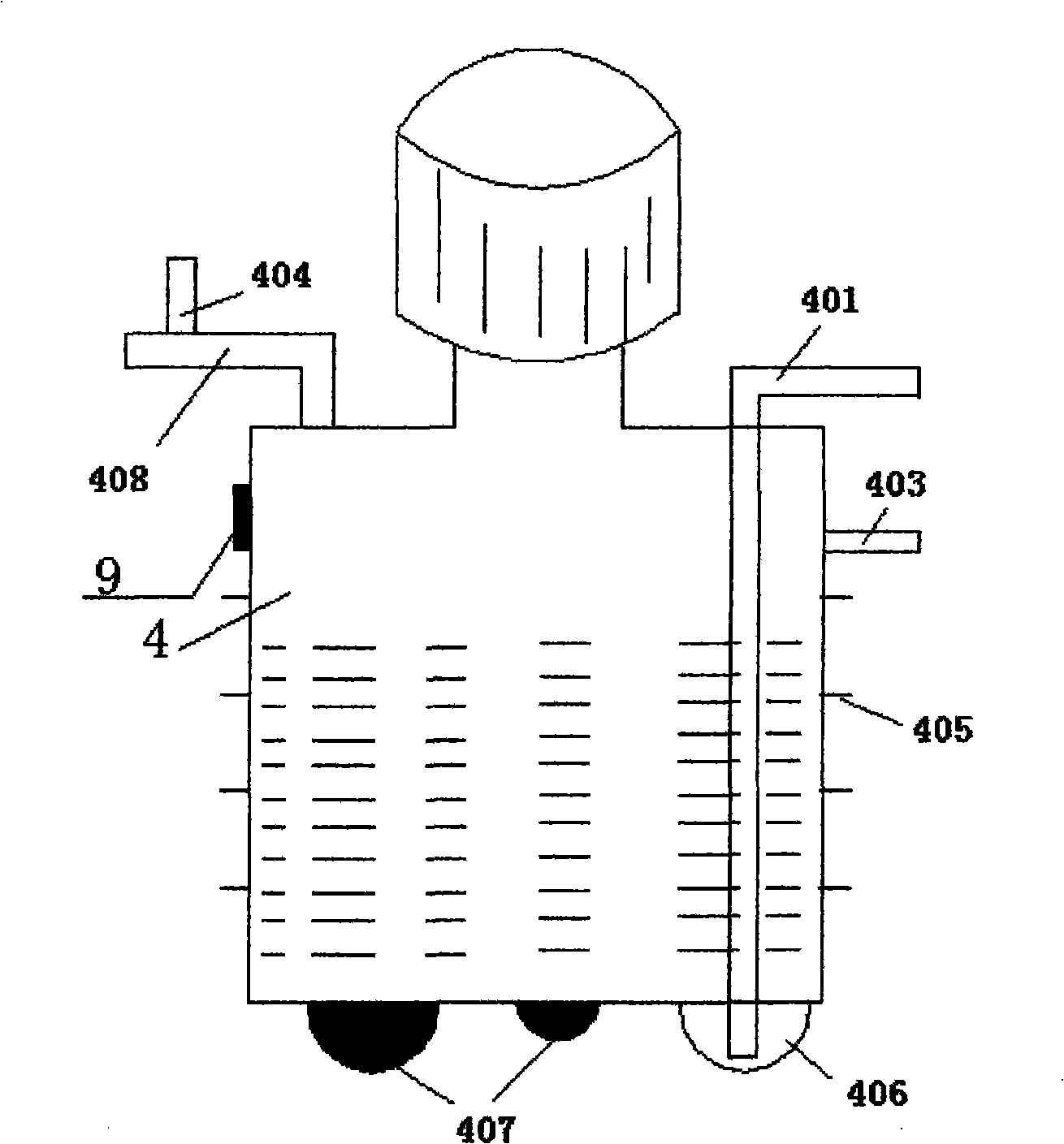

InactiveCN101070593AConstant liquid heightGuaranteed ejectionChemical vapor deposition coatingSpray nozzleVacuum pressure

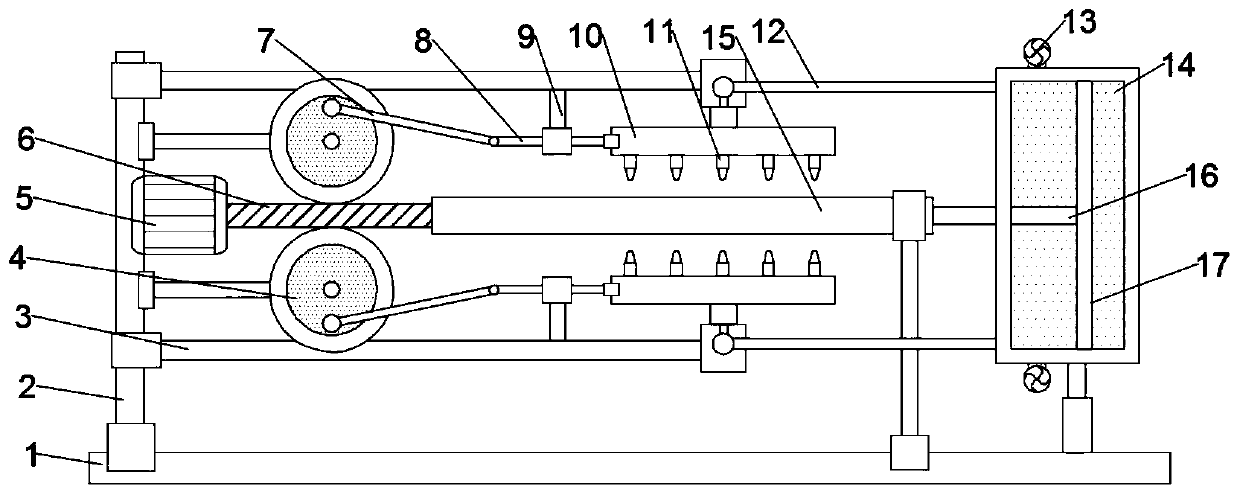

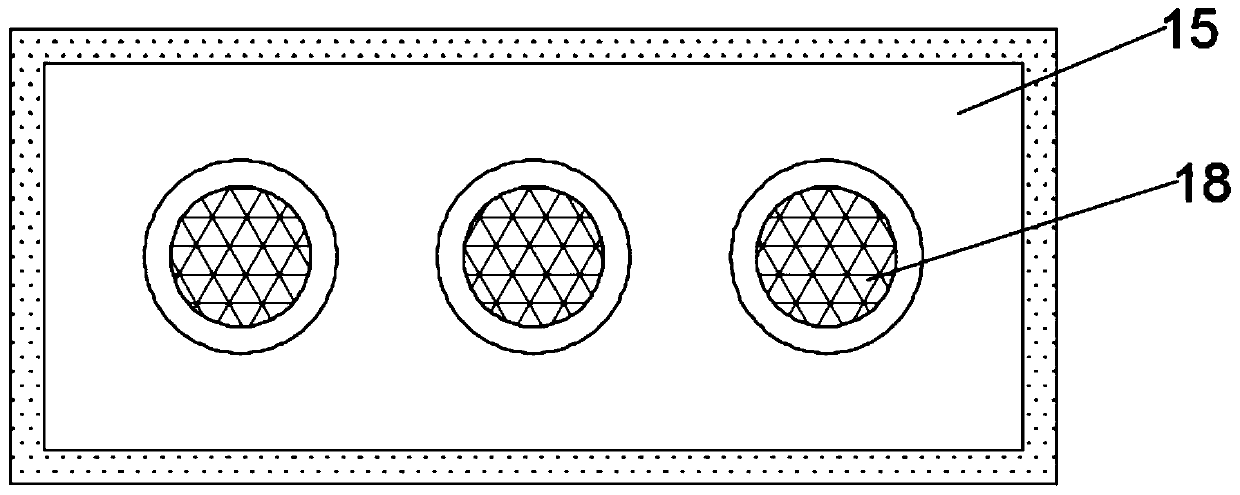

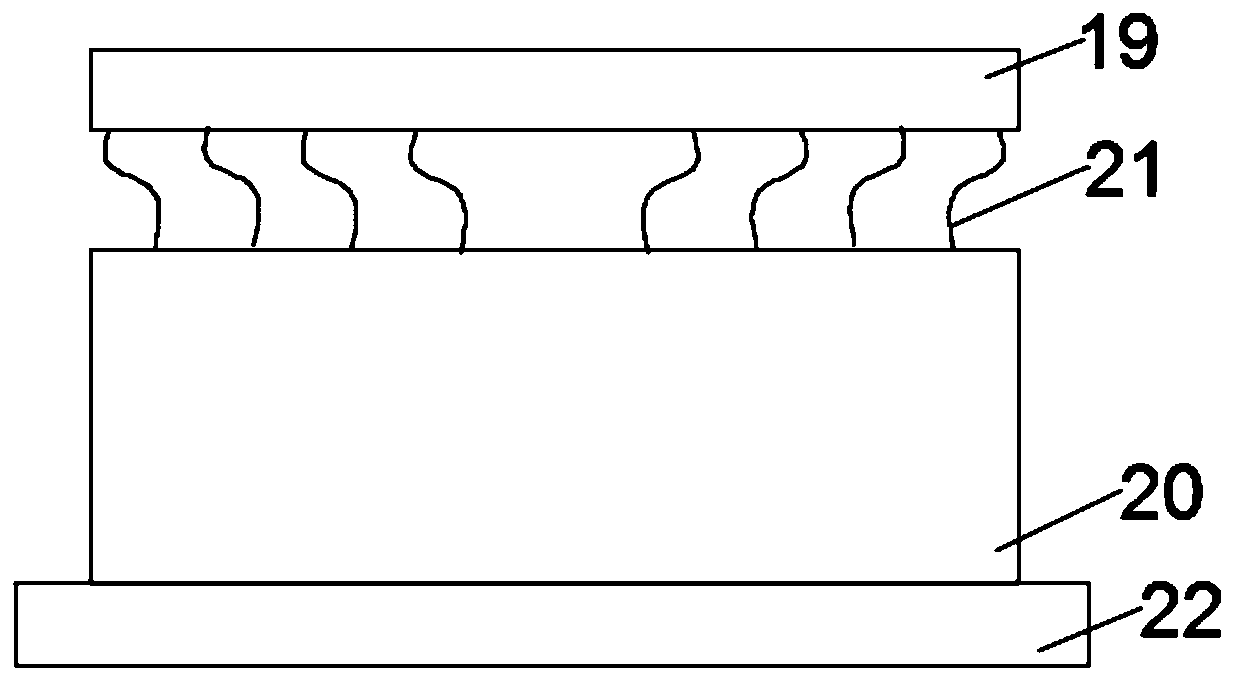

The invention relates to a preparation system of supersonic atomization thermal decomposition compound semiconductor thin film, which is used to prepare the semiconductor thin film of the oxide and the sulfide on the plane matrix. The system consists of atomization and deposit two major parts. Atomization part consists of the carrier gas source, stock solution pot, atomizing chamber and the corresponding electric circuit, while deposit part consists of sealing chamber, spray nozzle, warm table, the electrically operated transmission module, temperature control unit, vacuum manometer, and bubbling pond. Stock solution pot, atomizing chamber, spray nozzle, and sealing chamber are adopted unique design methods. The invention has the merits of cost lowly, operation stable, thin film quality to be good and so on, and the invention can apply to the scientific research and the industrial production of the oxide and the sulfide semiconductor thin film.

Owner:XI AN JIAOTONG UNIV

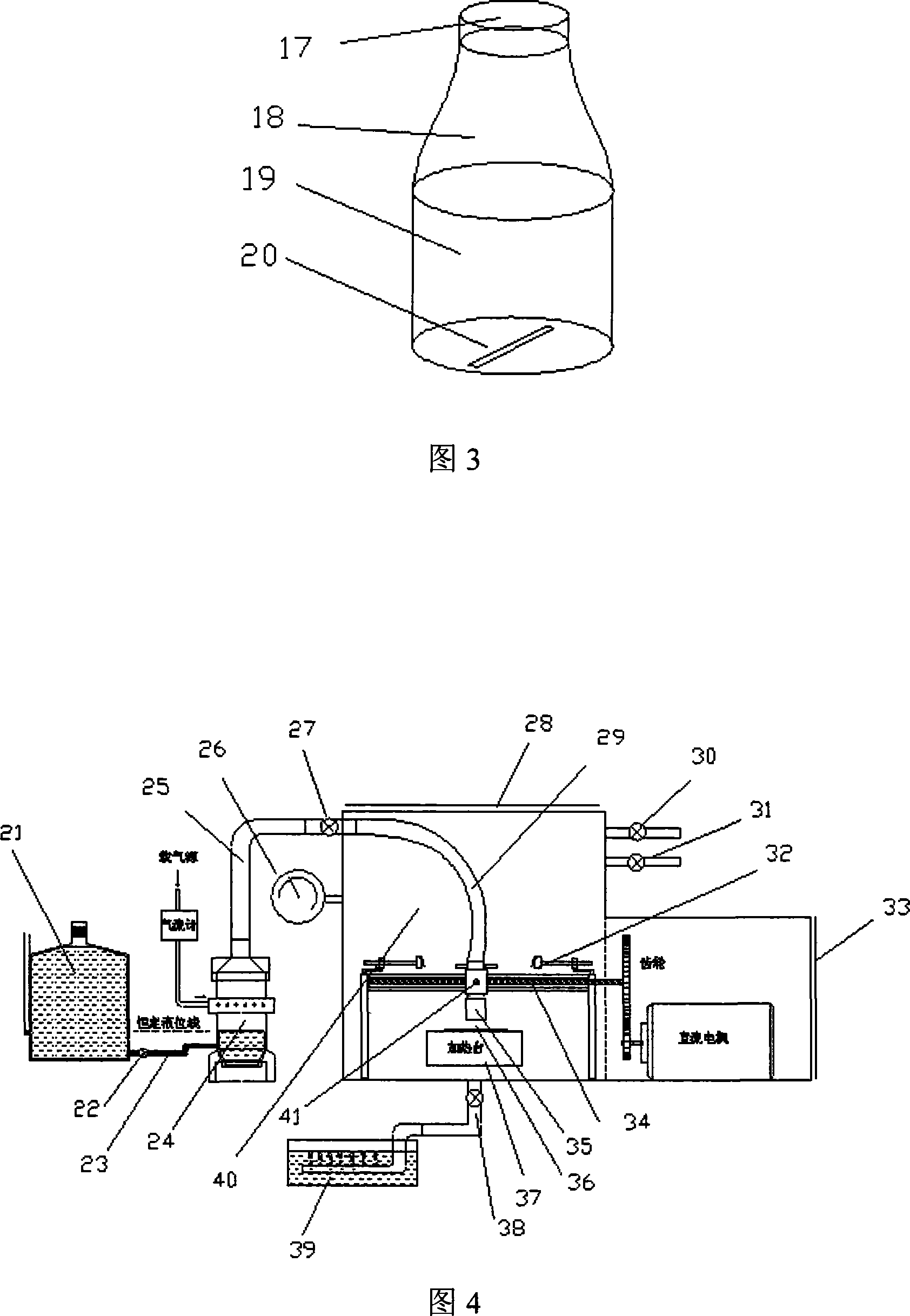

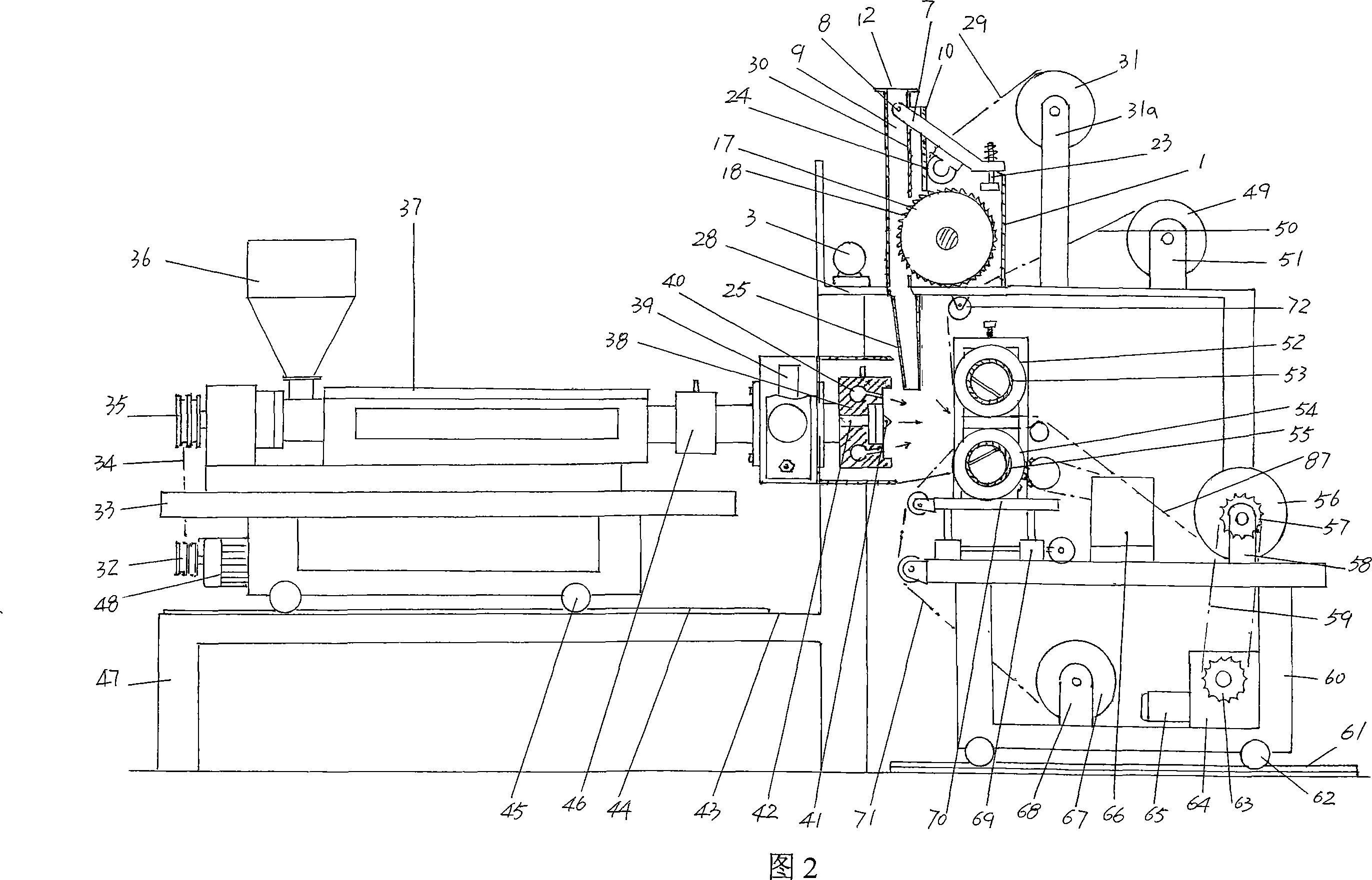

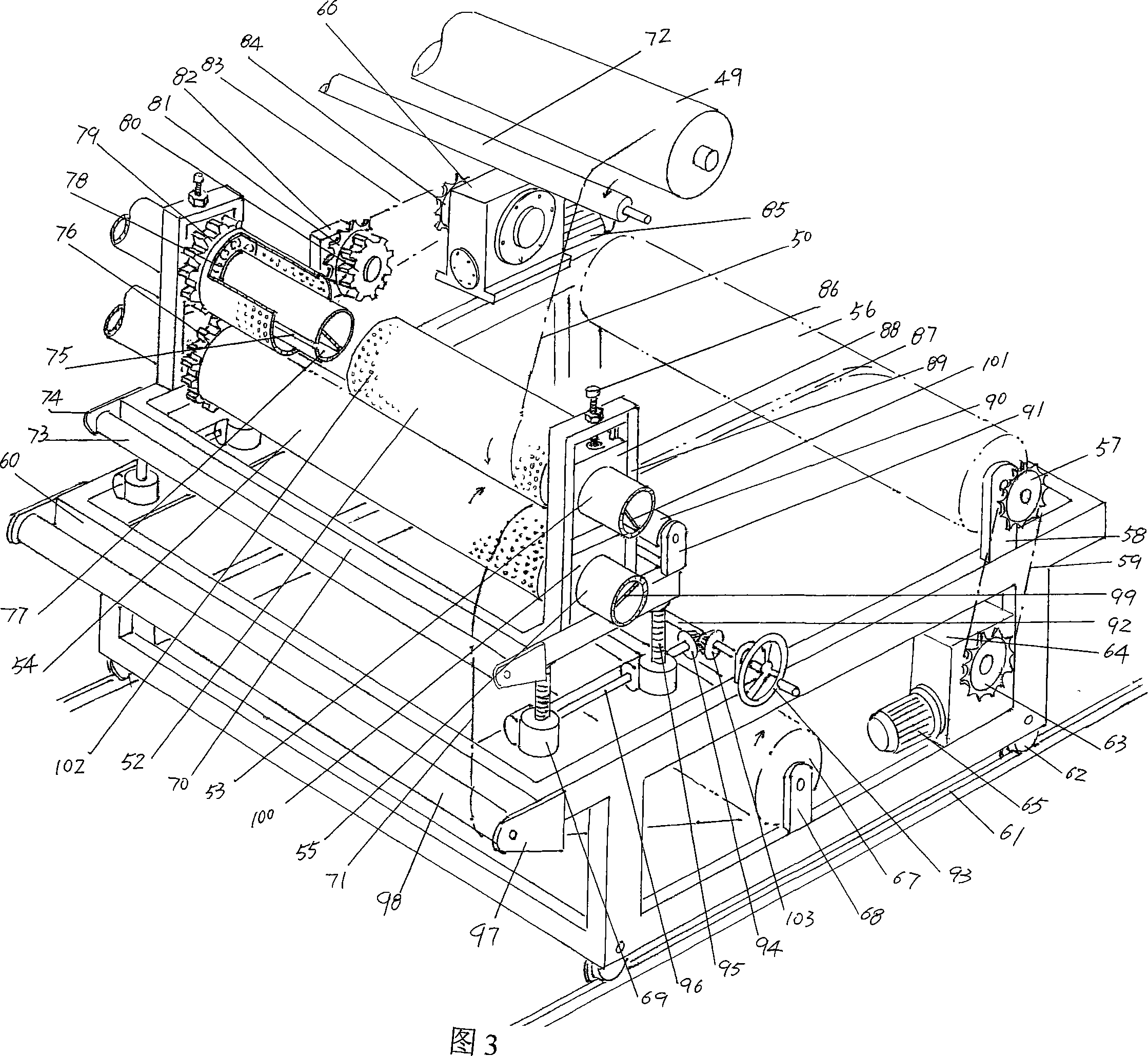

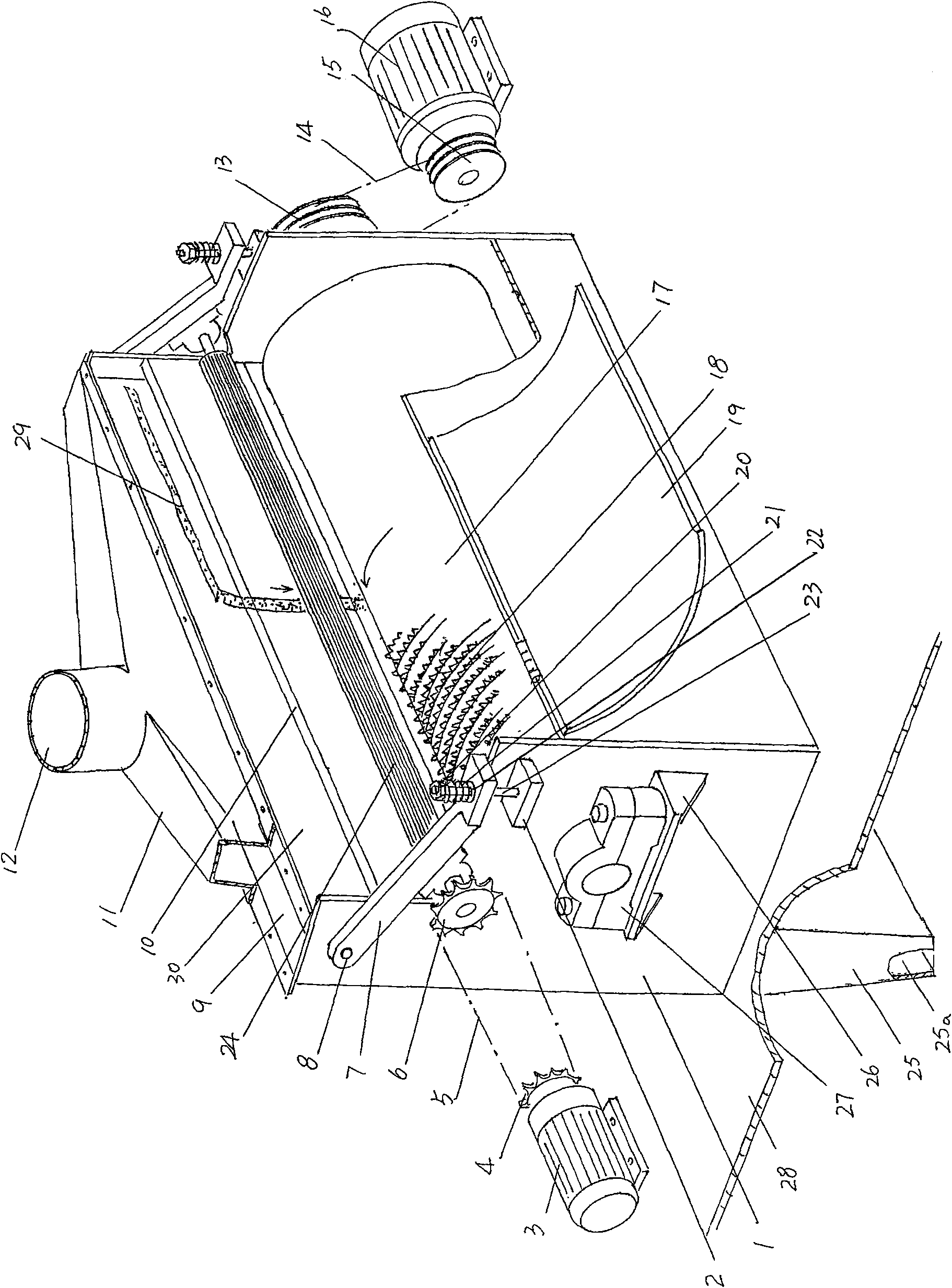

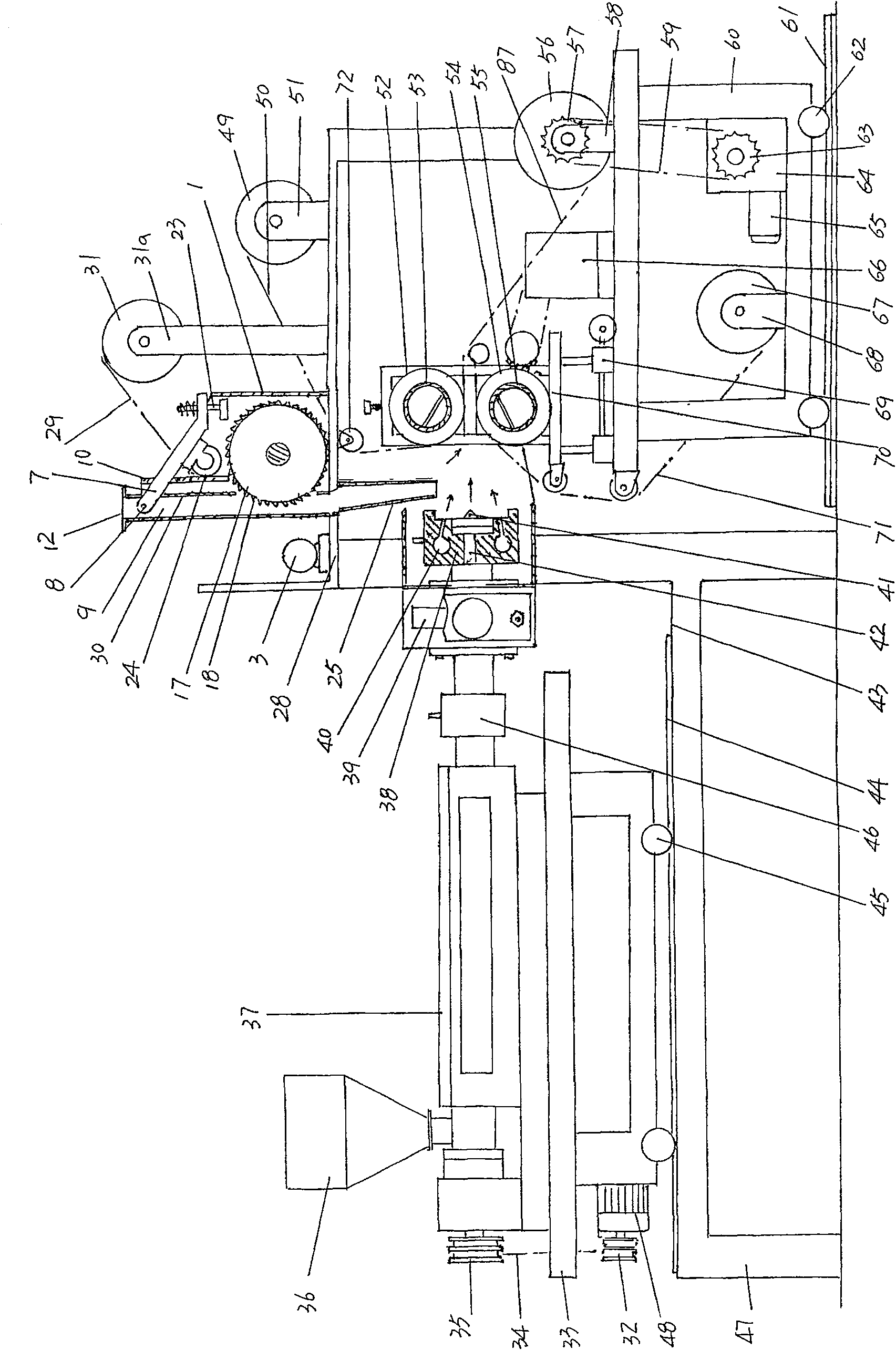

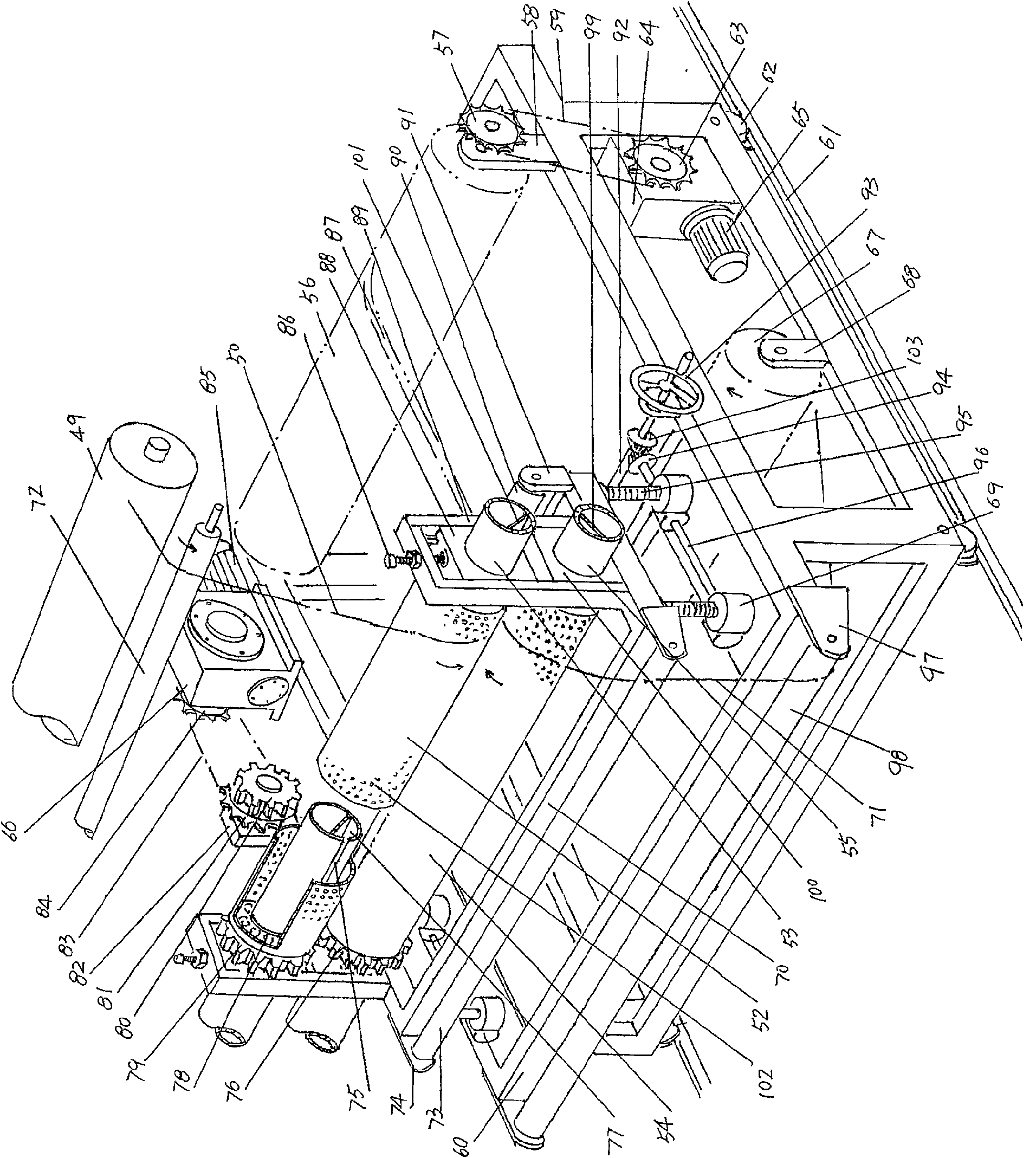

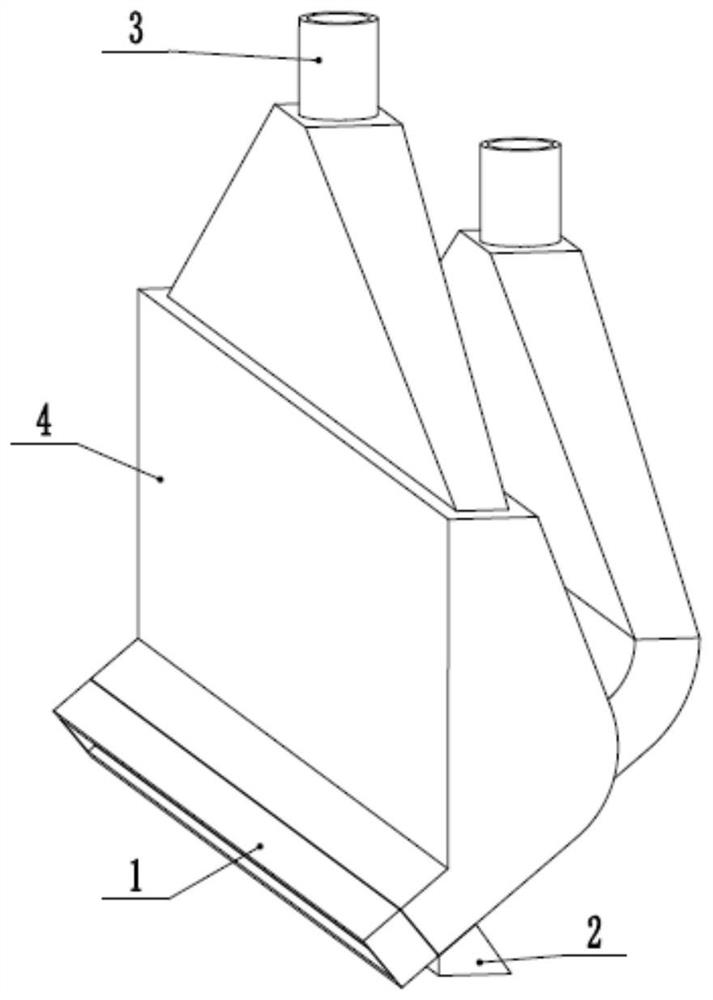

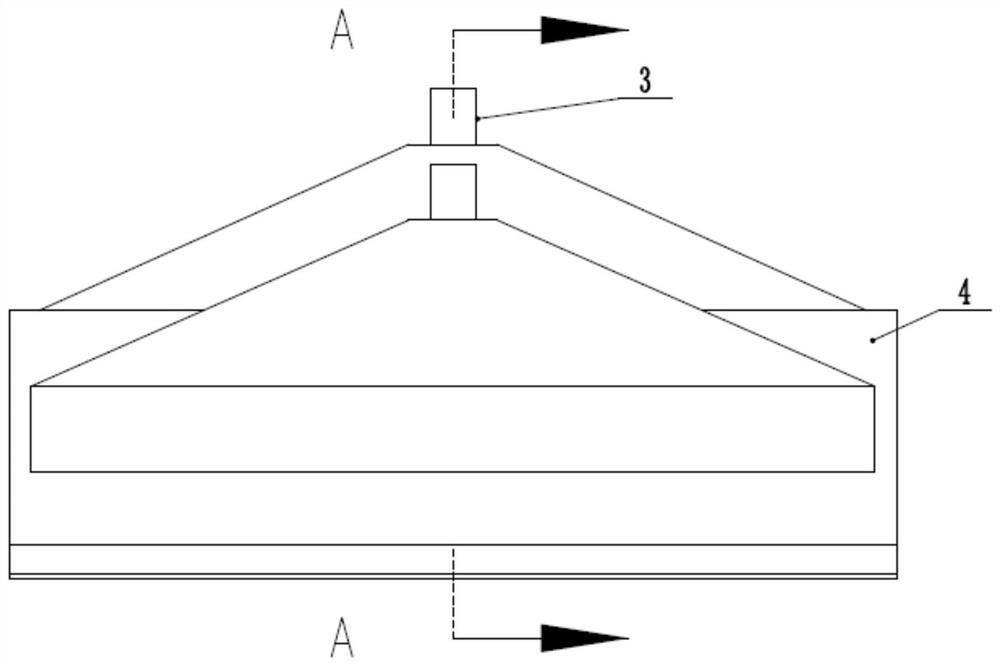

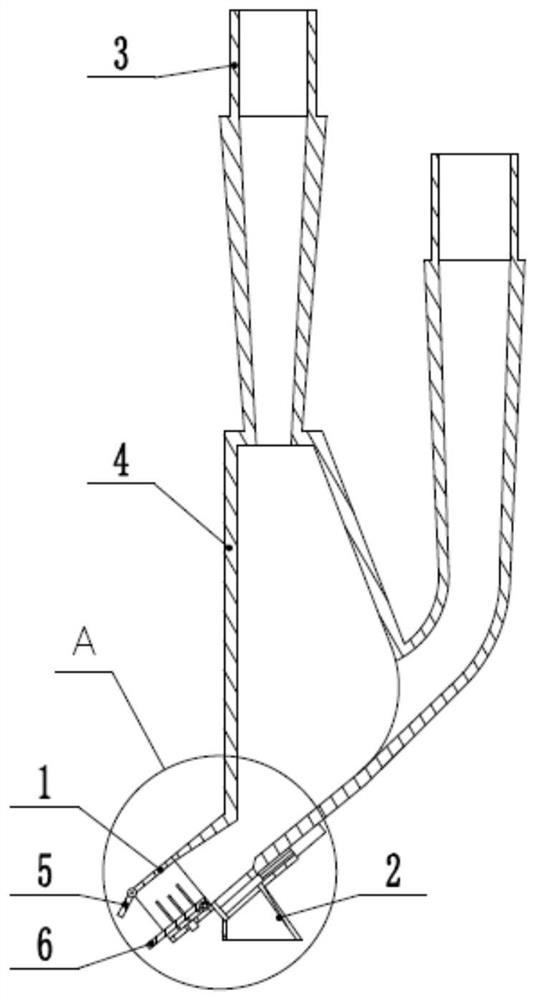

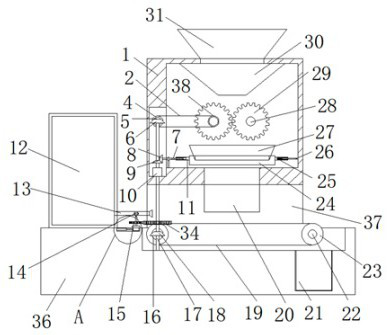

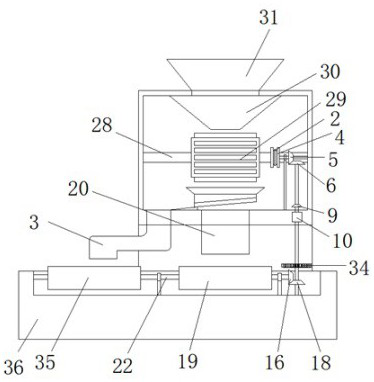

Staple fiber delivery mechanism for melt blown nonwoven cloth processor

A short fiber transportation mechanism of a melting blow nonwoven cloth processing machine belongs to the nonwoven machinery technology field, comprising a box body, a wool carding roller, an airflow groove, a backup plate and a cotton driving roller. The mechanism is characterized in that an airflow cover is extendedly arranged on the upper part of the airflow groove, the top center of the airflow cover is funneled into an air inlet, the lower part of the airflow groove extends to the lower part of a working platform and forms a further flatly shrunk cotton spraying tube; the cotton driving roller is connected onto the outer wall of the lengthwise corresponding box wall of the box body; the carding roller is inserted into the airflow groove. The mechanism has the advantages that the cotton driving roller can be adapted to driving thickness-varied short fiber cotton blankets; the airflow carrying short fiber can be guaranteed to be sprayed out from the cotton spraying tube which extends to the lower part of the working platform and corresponds to a melted extrusion structure, and brought together with the hot melted fibers extruded by the melted extrusion machine to conglutinate into a melting blow fiber layer.

Owner:常熟市伟成非织造成套设备有限公司

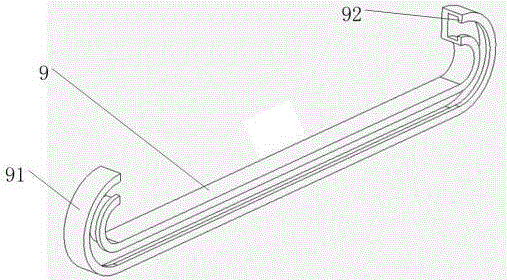

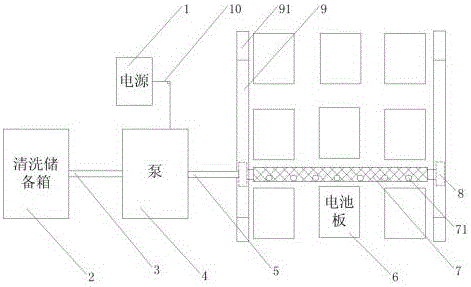

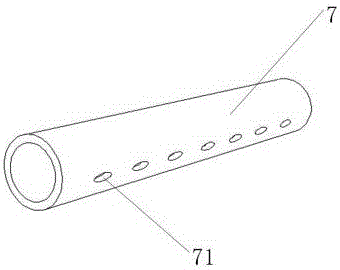

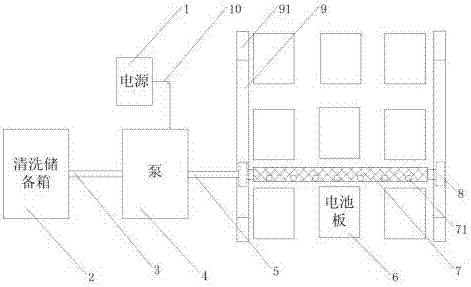

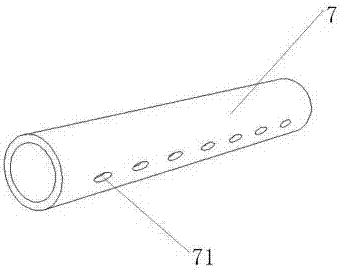

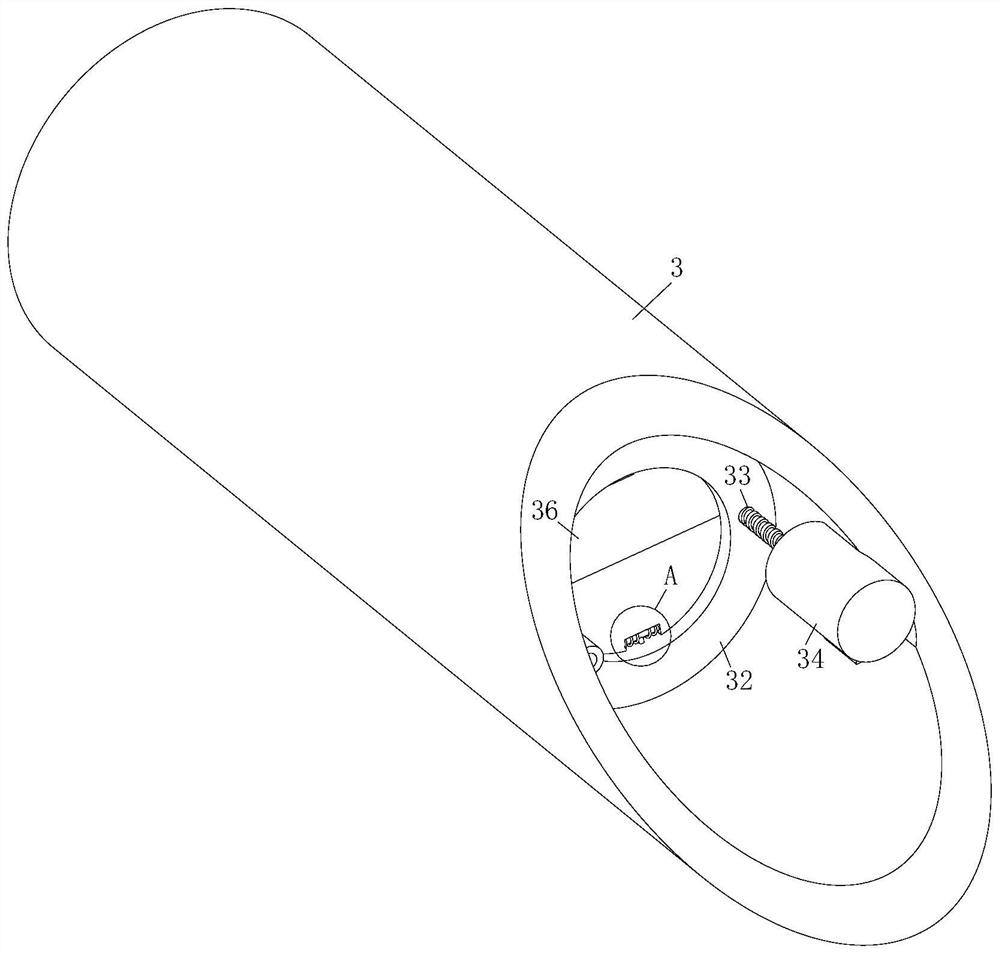

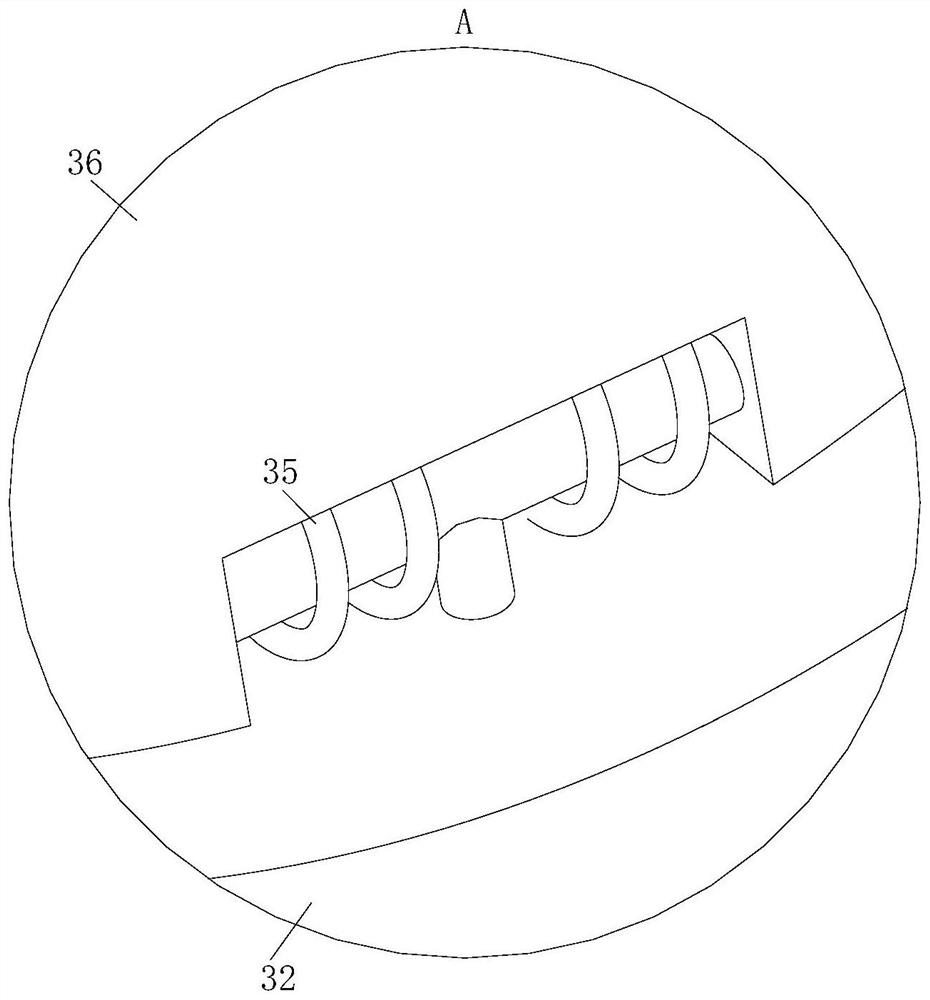

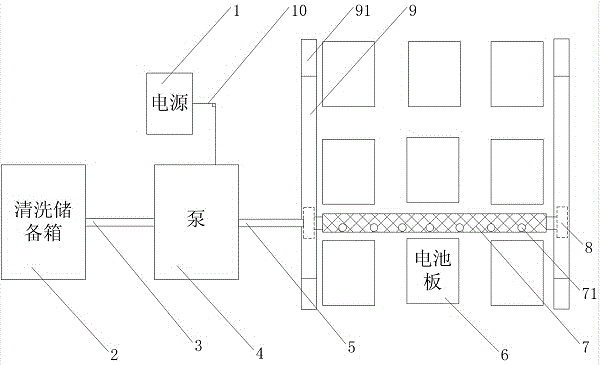

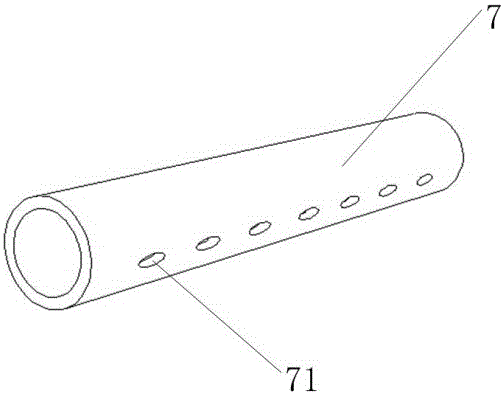

Cleaning method of solar cell panel

ActiveCN105880244APrevent agingAchieve large area cleaning effectPhotovoltaicsFlexible article cleaningCells panelCleaning methods

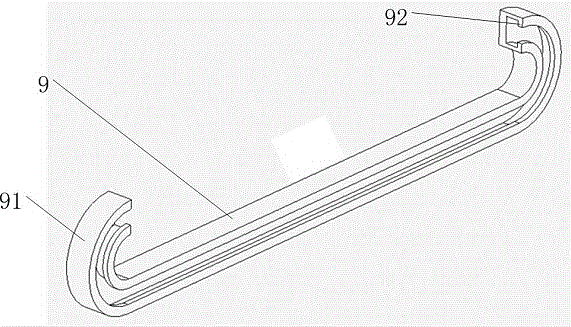

The invention discloses a cleaning method of a solar cell panel. A cleaning device comprises a power source, a pump, a pump pipe, a cleaning storage box, a plastic hose, a cleaning barrel and a cleaning track. The power of the pump is provided by the power source. The cleaning storage box contains cleaning fluid. The pump sucks cleaning fluid form the cleaning storage box through the pump pipe, pressurizes the cleaning fluid and conveys the cleaning fluids to the cleaning barrel through the plastic hose. The main body of the cleaning barrel is of a hollow structure with a hole. One end of the cleaning barrel is connected with the pump through the plastic hose, and the other end of the cleaning barrel is closed. The outer surface of the cleaning barrel is provided with a detachable and replaceable brush sleeve. High-pressure cleaning fluid is sprayed out of the hole in the cleaning barrel to clean the surface of the cell panel, and meanwhile reaction of spraying cleaning fluid pushes the cleaning barrel to reciprocate along the cleaning track. According to the cleaning method, the surface of the solar cell panel can be automatically cleaned, no complex track driving mechanism is adopted, the generating efficiency of a solar power station can be improved, labor is saved, the cleaning effect is improved, and the operation cost is obviously reduced.

Owner:平邑经发科技服务有限公司

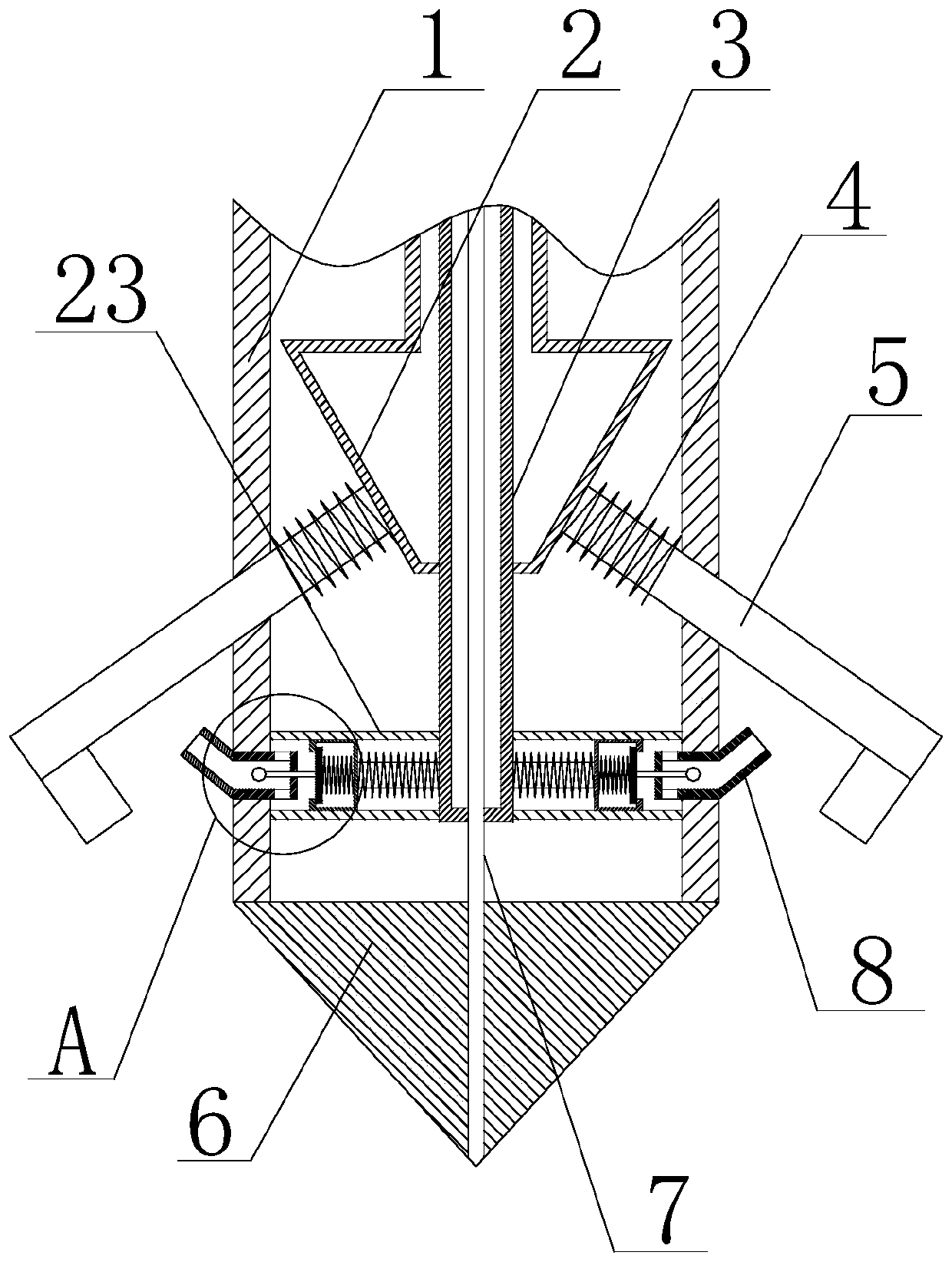

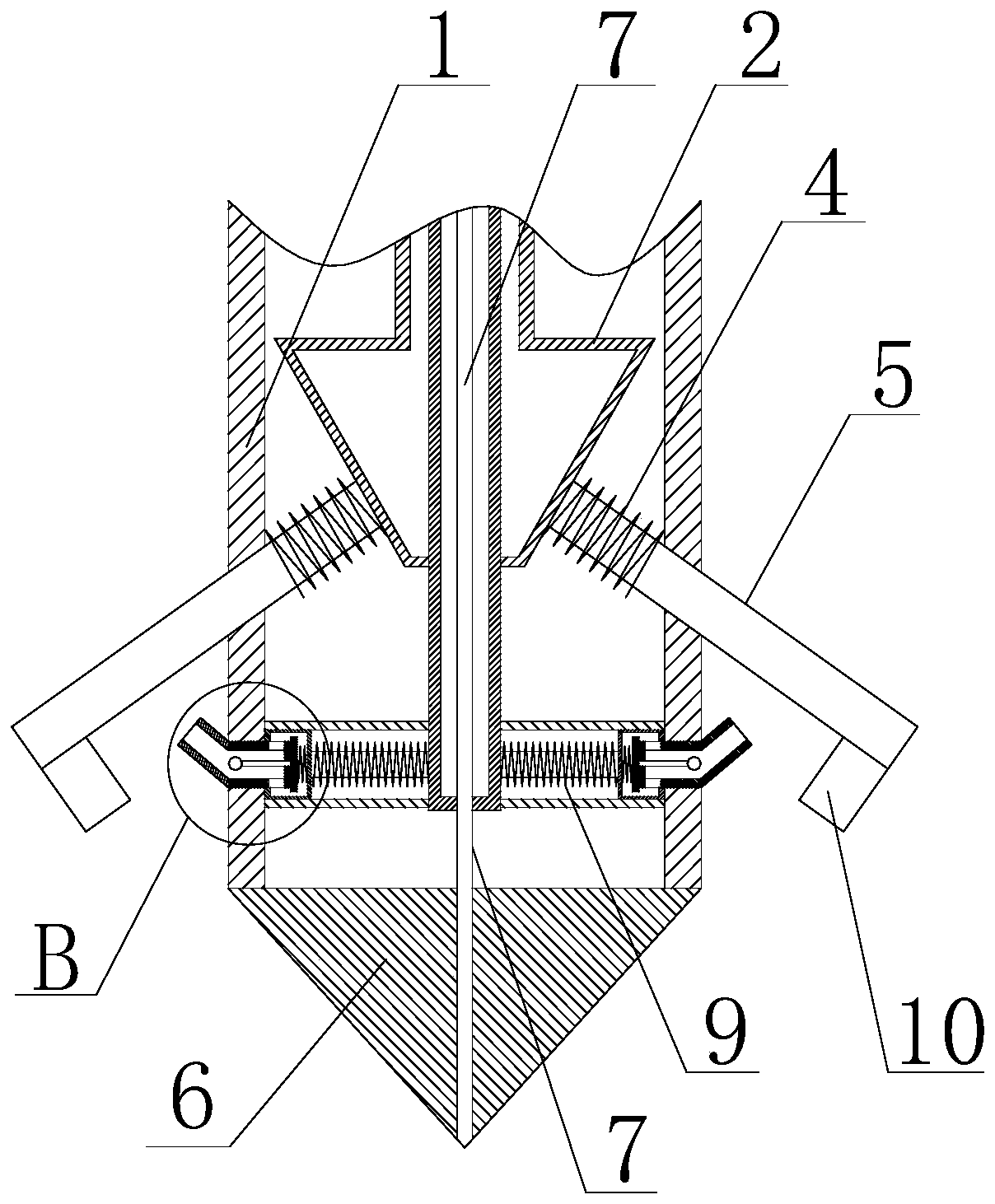

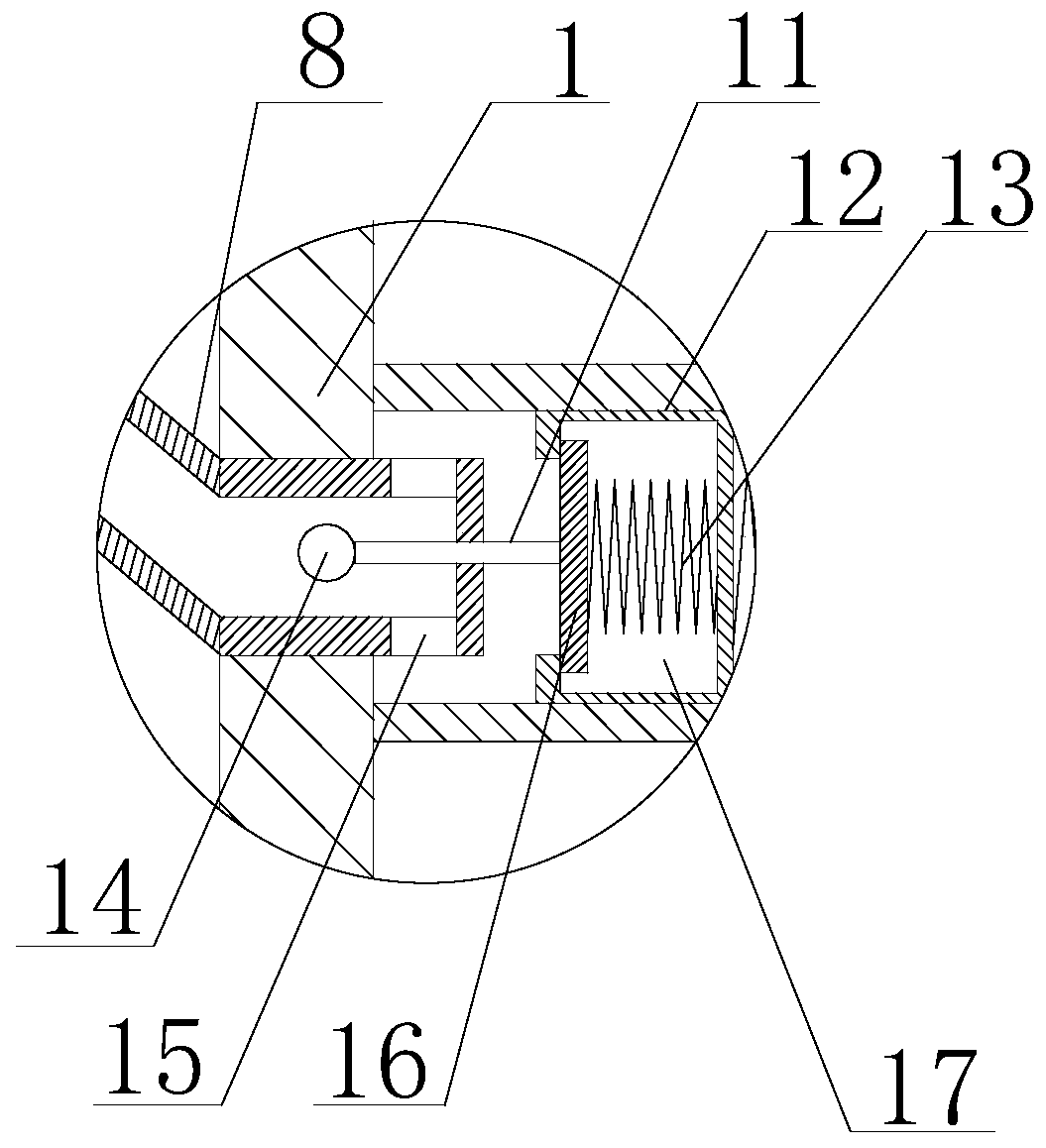

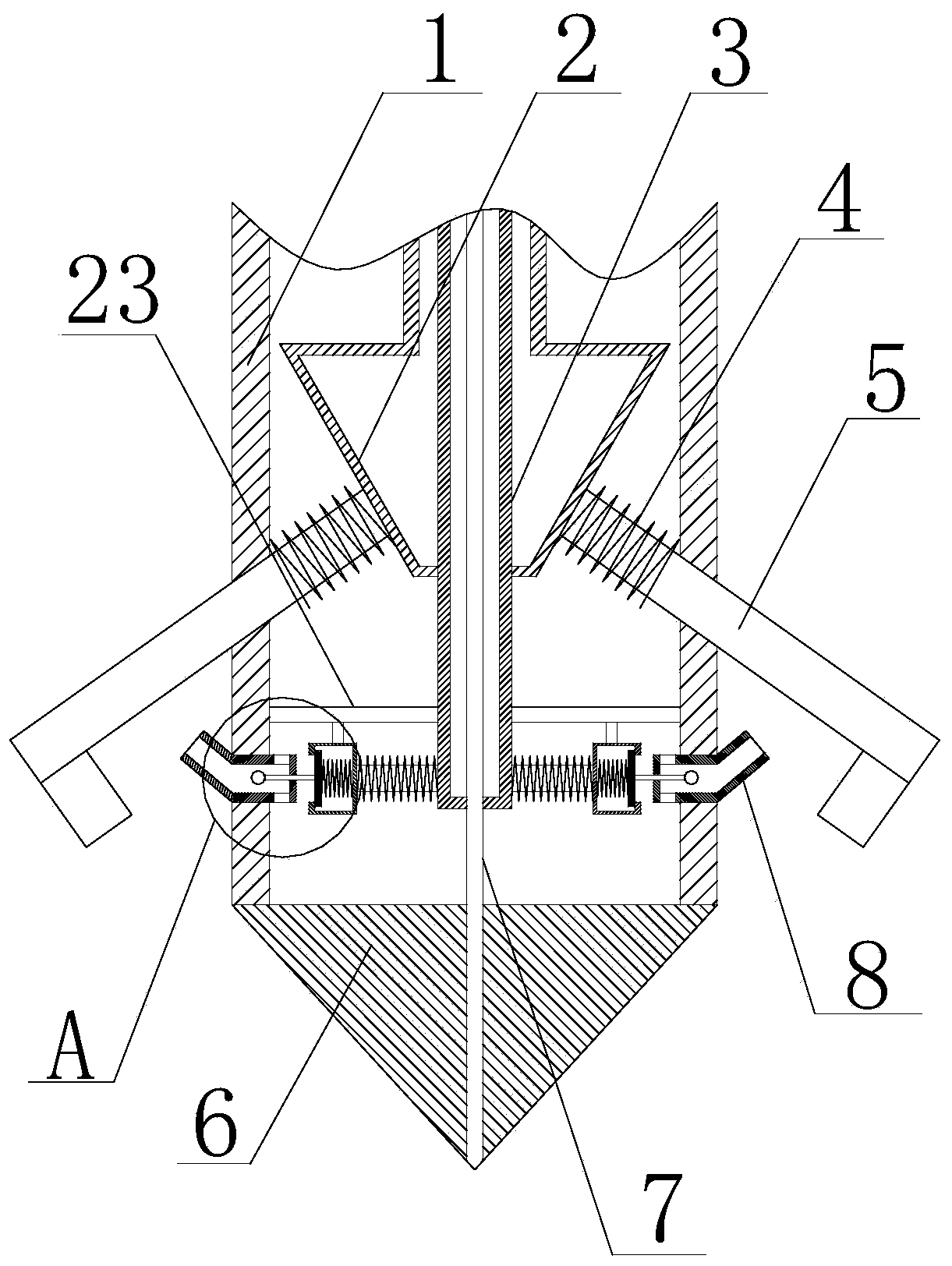

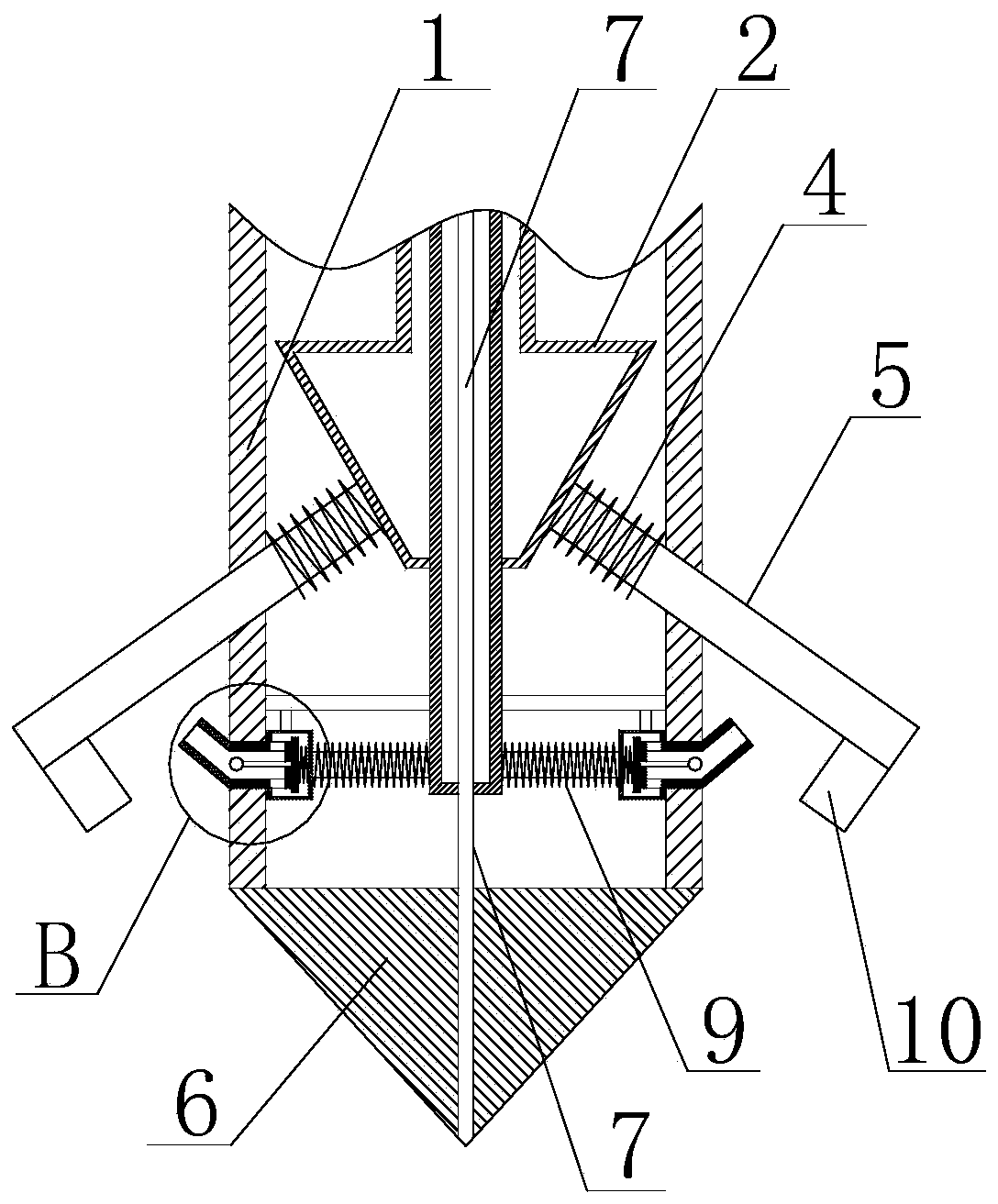

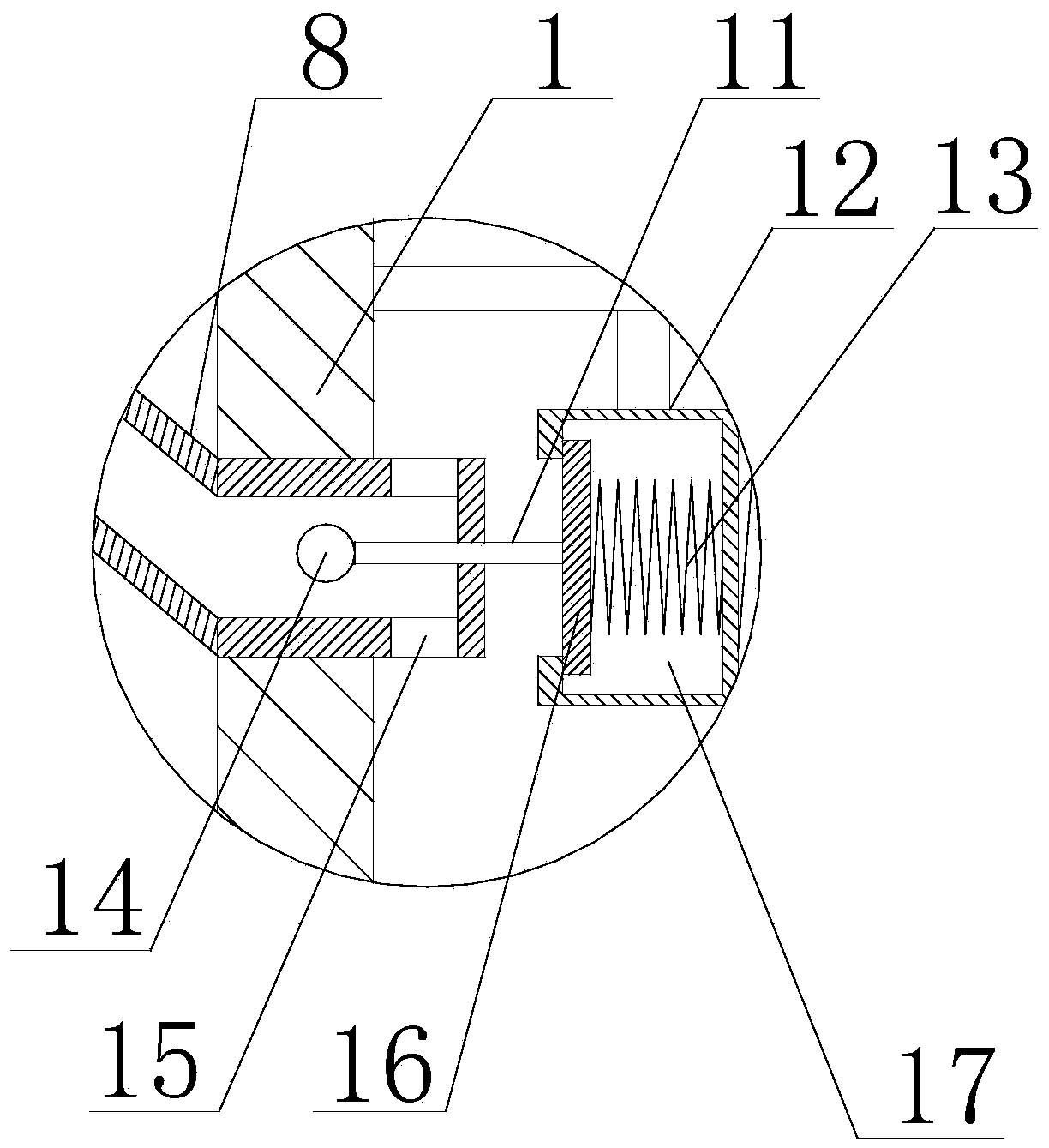

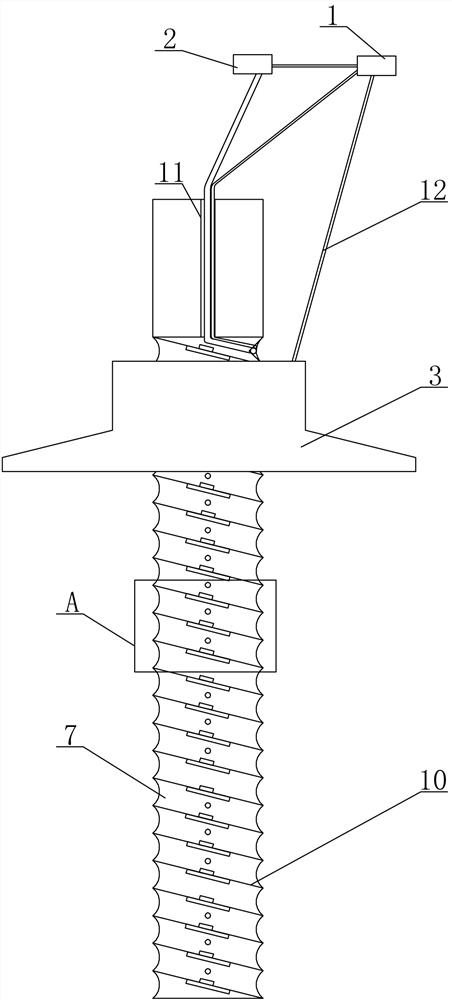

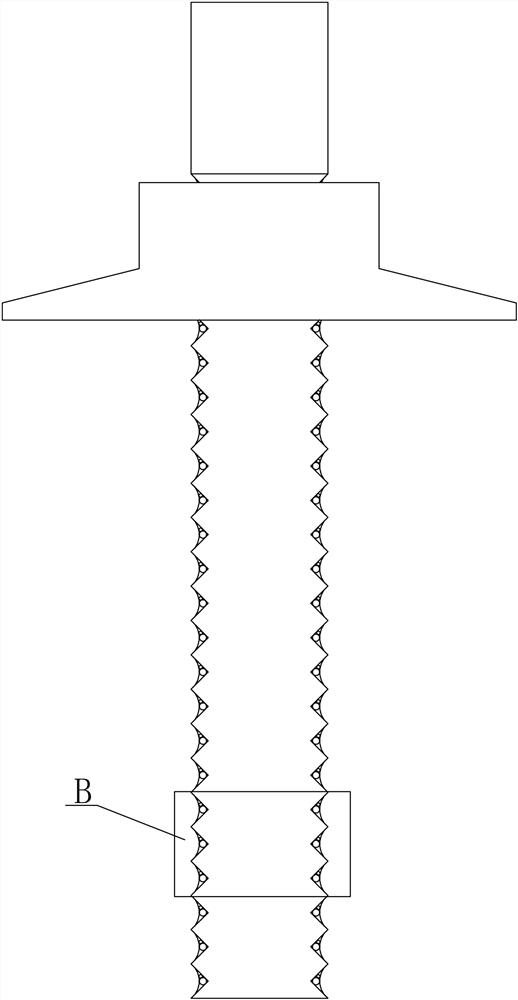

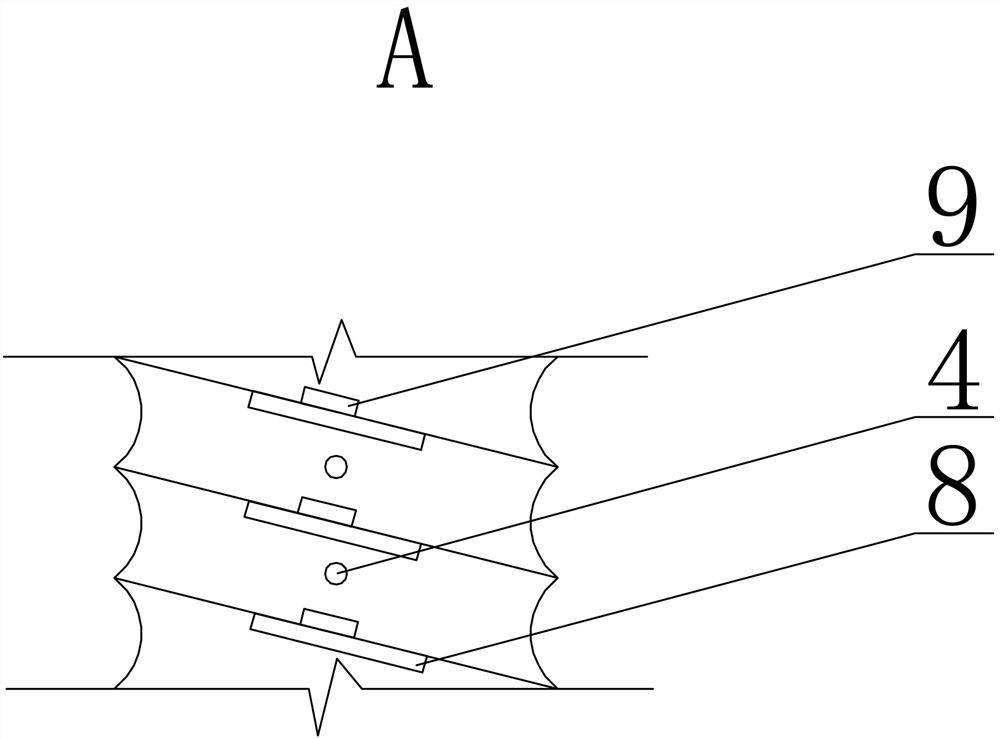

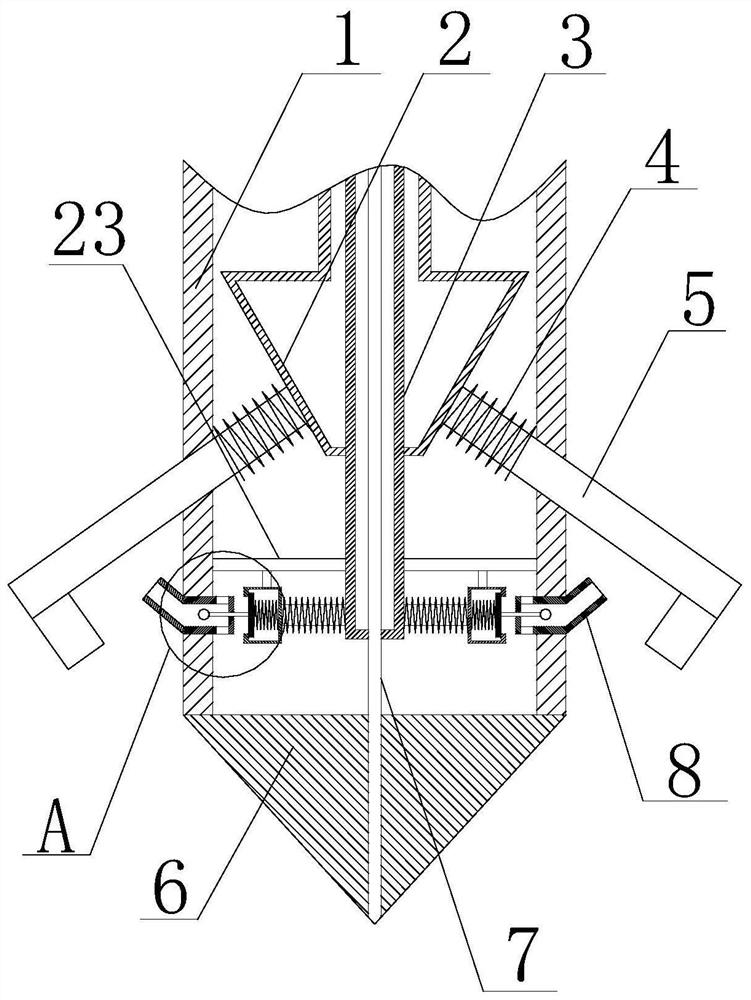

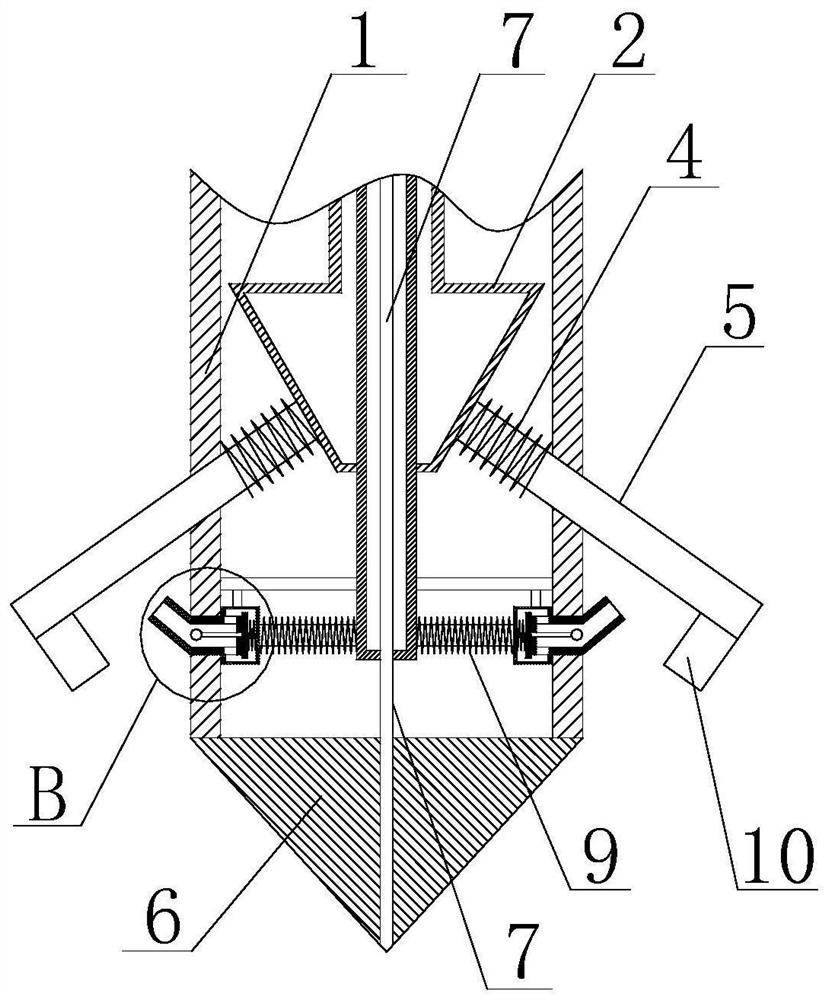

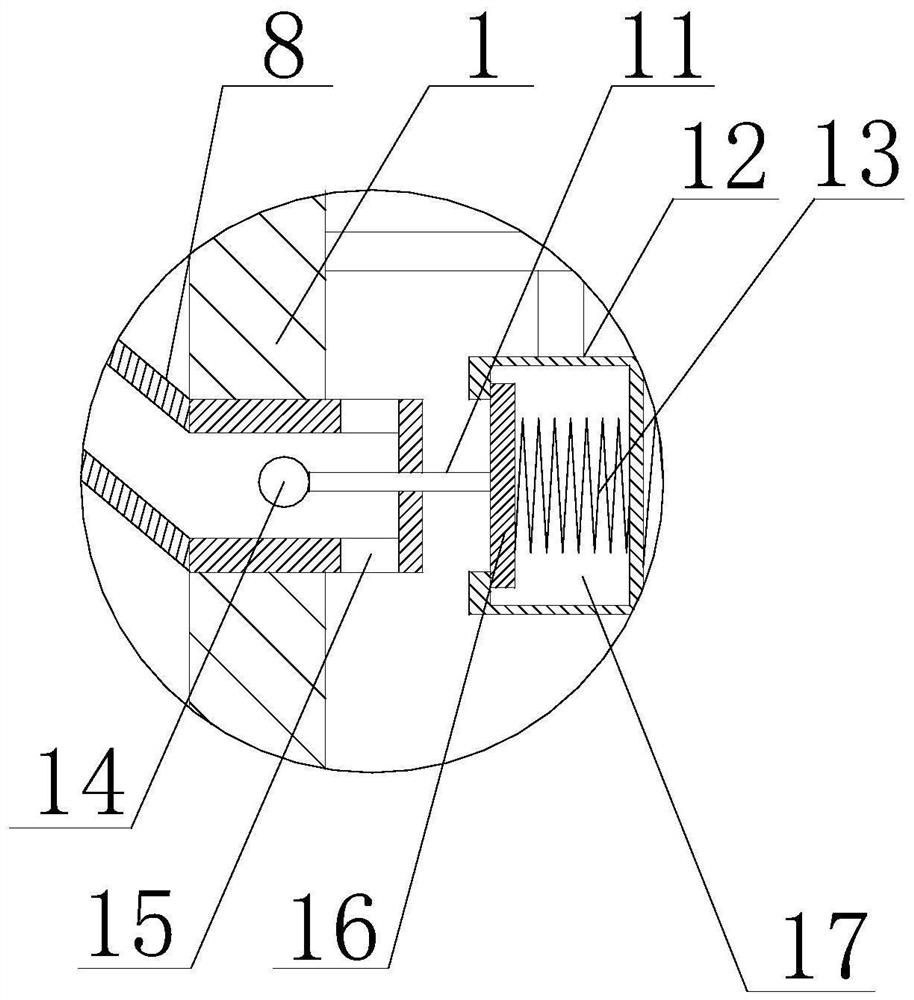

Method for using high-pressure rotary jet grouting pile nozzle for road and bridge construction

ActiveCN111254924AFlexible adjustment of extension lengthReal-time adjustment of extension lengthDrill bitsBulkheads/pilesDrill bitGrout

The invention discloses a method for using a high-pressure rotary jet grouting pile nozzle for road and bridge construction. The high-pressure rotary jet grouting pile nozzle comprises a rod body anda conical head, wherein the rod body is internally of a cavity structure, a grout conveying pipe is arranged in the cavity, a moving assembly is also arranged in the cavity of the rod body, the circumferential outer wall of the rod body is further provided with a plurality of drill blades, when the moving assembly moves towards the conical head, the moving assembly can push the drill blades to move in the direction away from the rod body, baffles are arranged on the side walls, facing the conical head, of the drill blades, stretchable pipes are further arranged in the cavity of the rod body, one ends of the stretchable pipes communicate with the grout conveying pipe, the other ends of the stretchable pipes are provided with joints, the circumferential outer wall of the rod body is furtherprovided with nozzle assemblies with the number same as the number of the drill blades, one ends of the nozzle assemblies face the drill blades, and the other ends of the nozzle assemblies are locatedin the cavity of the rod body. According to the method, the diameter of a pile hole drilled by the drill bit can be adjusted, then different use requirements can be met, meanwhile, it is guaranteed that in the drilling-down process of the drill bit, mud and stones in soil can be prevented from blocking the grout conveying pipe, and the construction efficiency is improved.

Owner:湖北晟弘建设工程有限公司

Staple fiber delivery mechanism for melt blown nonwoven cloth processor

A short fiber transportation mechanism of a melting blow nonwoven cloth processing machine belongs to the nonwoven machinery technology field, comprising a box body, a wool carding roller, an airflowgroove, a backup plate and a cotton driving roller. The mechanism is characterized in that an airflow cover is extendedly arranged on the upper part of the airflow groove, the top center of the airflow cover is funneled into an air inlet, the lower part of the airflow groove extends to the lower part of a working platform and forms a further flatly shrunk cotton spraying tube; the cotton driving roller is connected onto the outer wall of the lengthwise corresponding box wall of the box body; the carding roller is inserted into the airflow groove. The mechanism has the advantages that the cotton driving roller can be adapted to driving thickness-varied short fiber cotton blankets; the airflow carrying short fiber can be guaranteed to be sprayed out from the cotton spraying tube which extends to the lower part of the working platform and corresponds to a melted extrusion structure, and brought together with the hot melted fibers extruded by the melted extrusion machine to conglutinate into a melting blow fiber layer.

Owner:常熟市伟成非织造成套设备有限公司

Method for cleaning solar panels

ActiveCN105880244BPrevent agingAchieve large area cleaning effectPhotovoltaicsFlexible article cleaningCells panelSolar power

The invention discloses a cleaning device and a cleaning method for a solar cell panel. The cleaning device comprises a power supply, a pump, a pump tube, a cleaning storage box, a plastic hose, a cleaning barrel and a cleaning rail, wherein the power of the pump is provided by a power supply; a cleaning liquid is held in the cleaning storage box; the pump sucks the cleaning liquid form the cleaning storage box through the pump tube, pressurizes the cleaning liquid, and then conveys the cleaning liquid to the cleaning barrel through the plastic hose; the main body portion of the cleaning barrel is a holed hollow structure, one end of the main body portion is connected with the pump through the plastic hose, the other end of the main body portion is closed, and the outer surface of the main body portion is a detachable brush sleeve; the high-pressure cleaning liquid is ejected from the hole of the cleaning barrel to clean the surface of the cell panel, meanwhile, the reaction of ejecting for the cleaning liquid pushes the cleaning barrel to move along a cleaning rail. The device is capable of automatically cleaning the surface of the solar cell panel, avoiding use of a complex rail transmission mechanism, increasing the power generation efficiency of a solar power station, saving labour, improving cleaning effect, and obviously reducing operation cost.

Owner:PINGYI JINGFA TECH SERVICE CO LTD

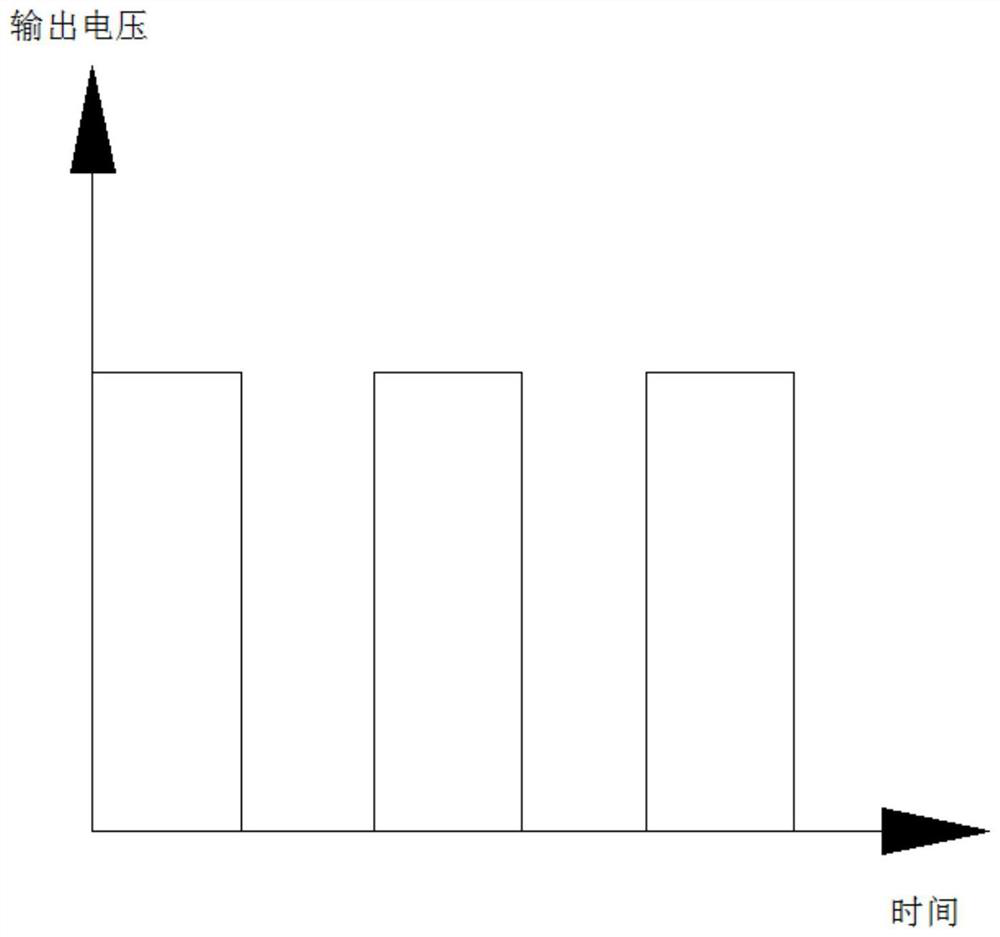

Pulse electrostatic spraying device and spraying process thereof

PendingCN112517260AAchieve sprayingImprove spraying effectSpraying power supplyPretreated surfacesElectrical connectionPowder coating

The invention discloses a pulse electrostatic spraying device and a spraying process thereof. The pulse electrostatic spraying device comprises a gun shell and a powder pipe; the left end of the powder pipe extends into the right end of the gun shell; a coating outlet communicated with the powder pipe is formed in the front end of the gun shell, and the pulse electrostatic spraying device comprises a pulse electrostatic discharge needle and a pulse electrostatic generator; the pulse electrostatic discharge needle is arranged at the coating outlet, and the pulse electrostatic generator is electrically connected with the pulse electrostatic discharge needle; the powder coating enters from the powder pipe and is ejected from the coating outlet, and the pulse electrostatic discharge needle charges the powder coating intermittently. According to the pulse electrostatic spraying device and the spraying process thereof provided by the invention, spraying of non-metallic workpieces and poor electric conductors is achieved, and the spraying effect is good.

Owner:江门市博涂环保机电科技有限公司

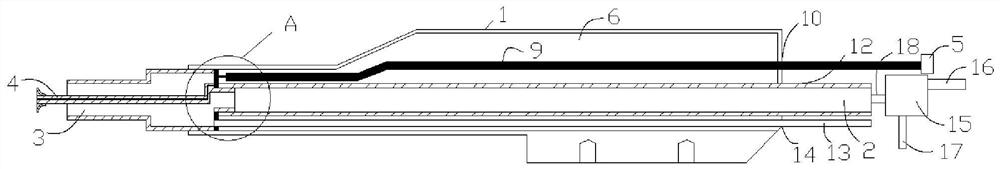

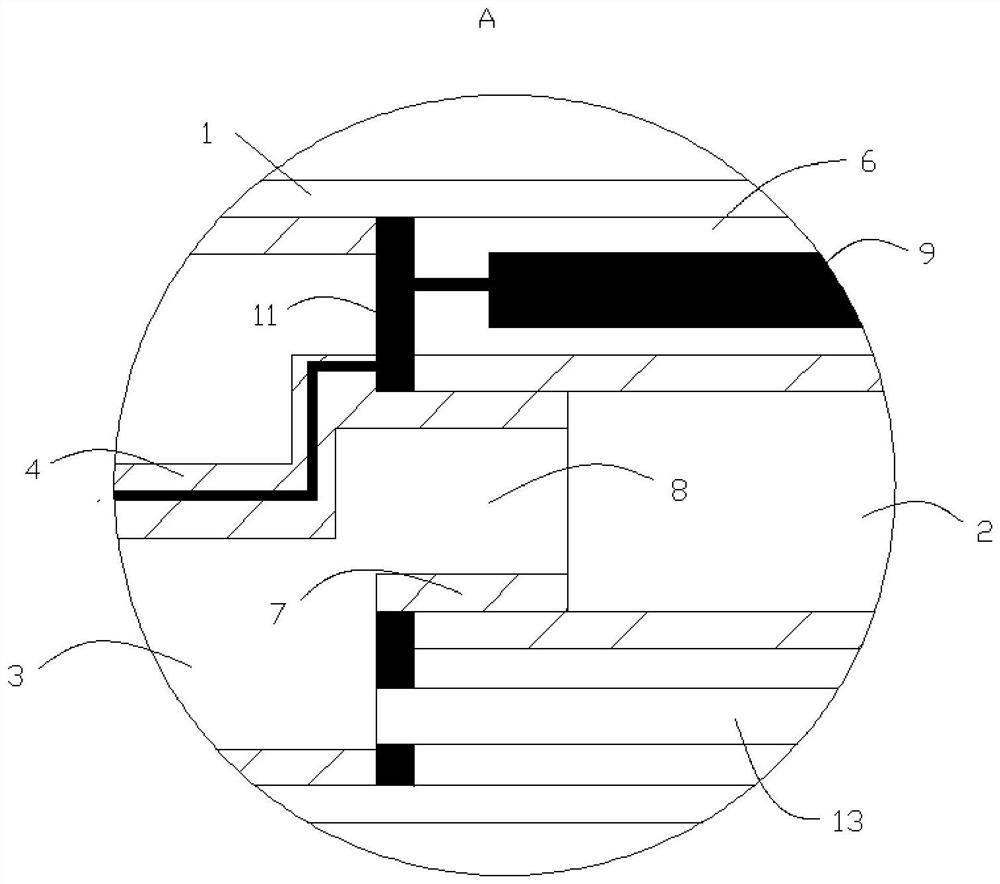

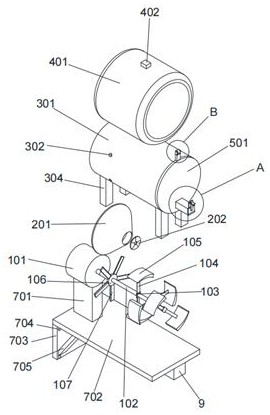

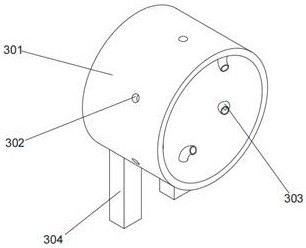

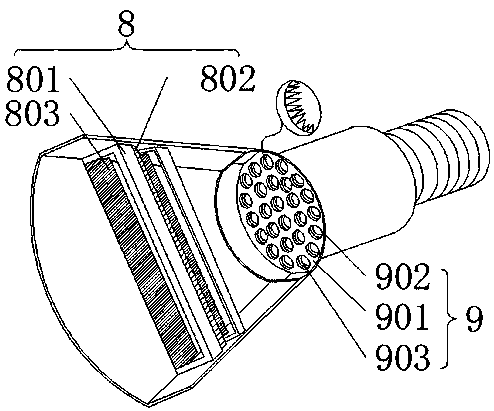

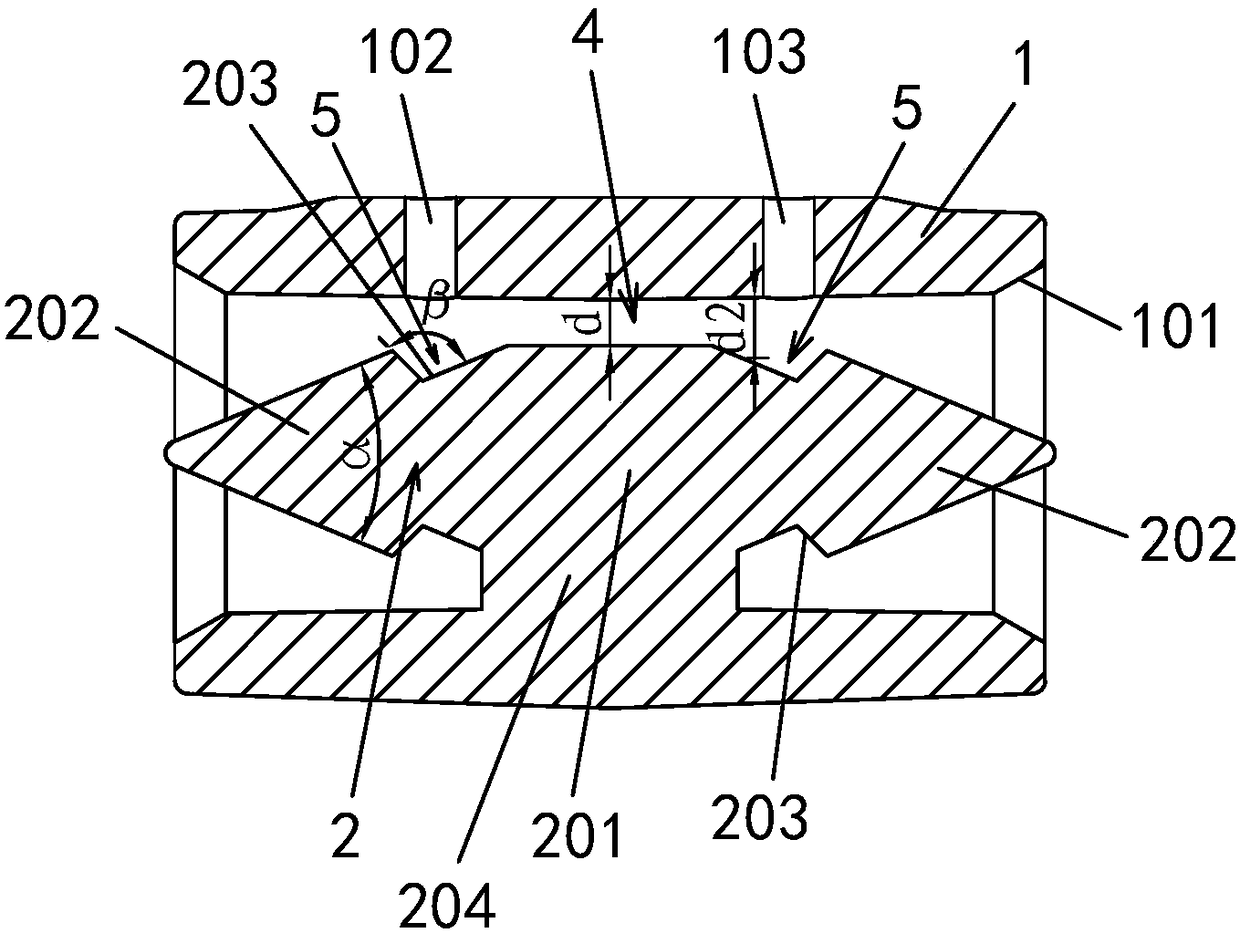

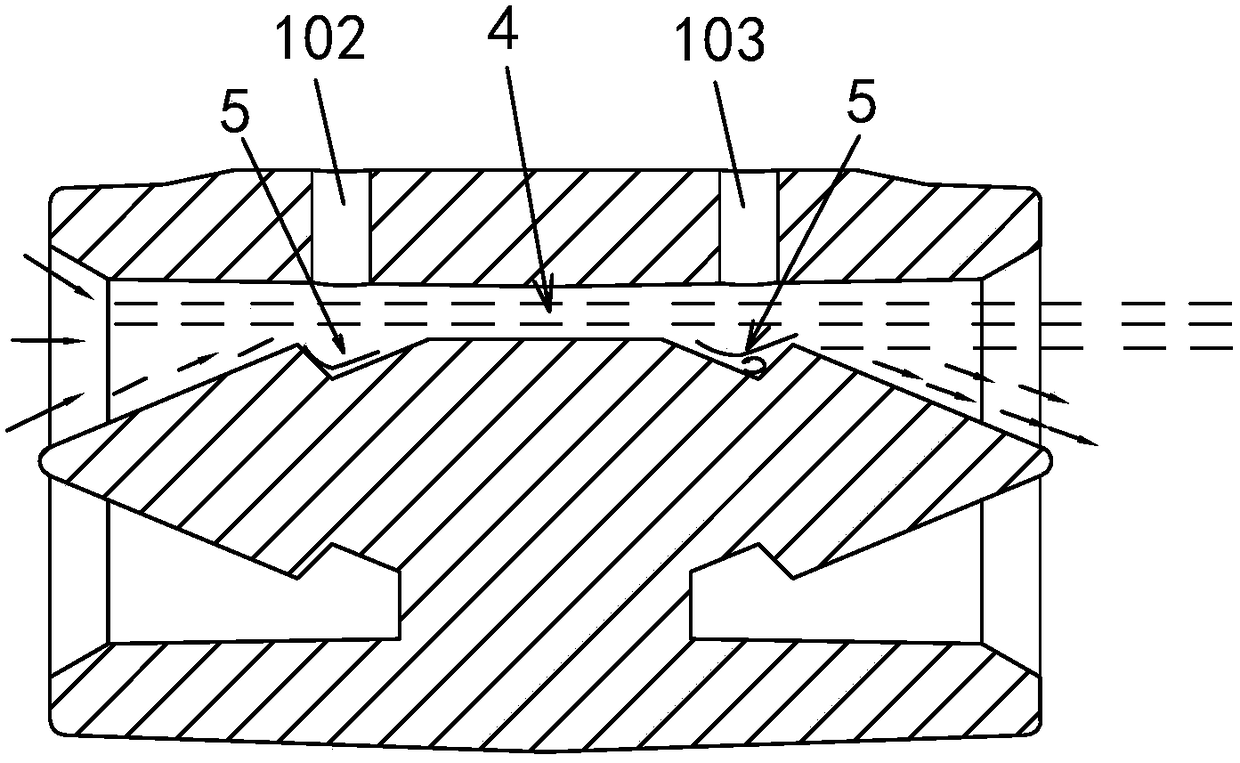

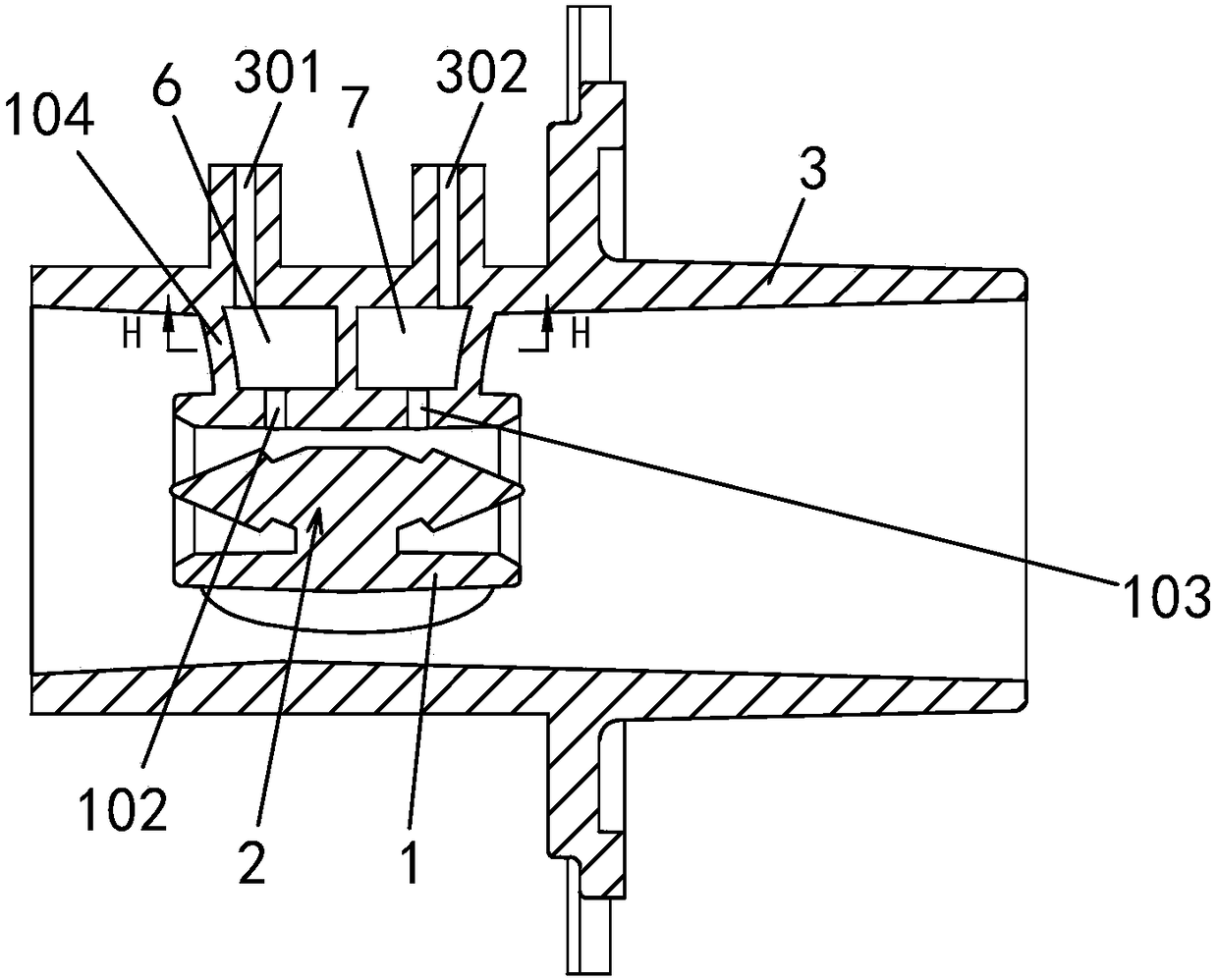

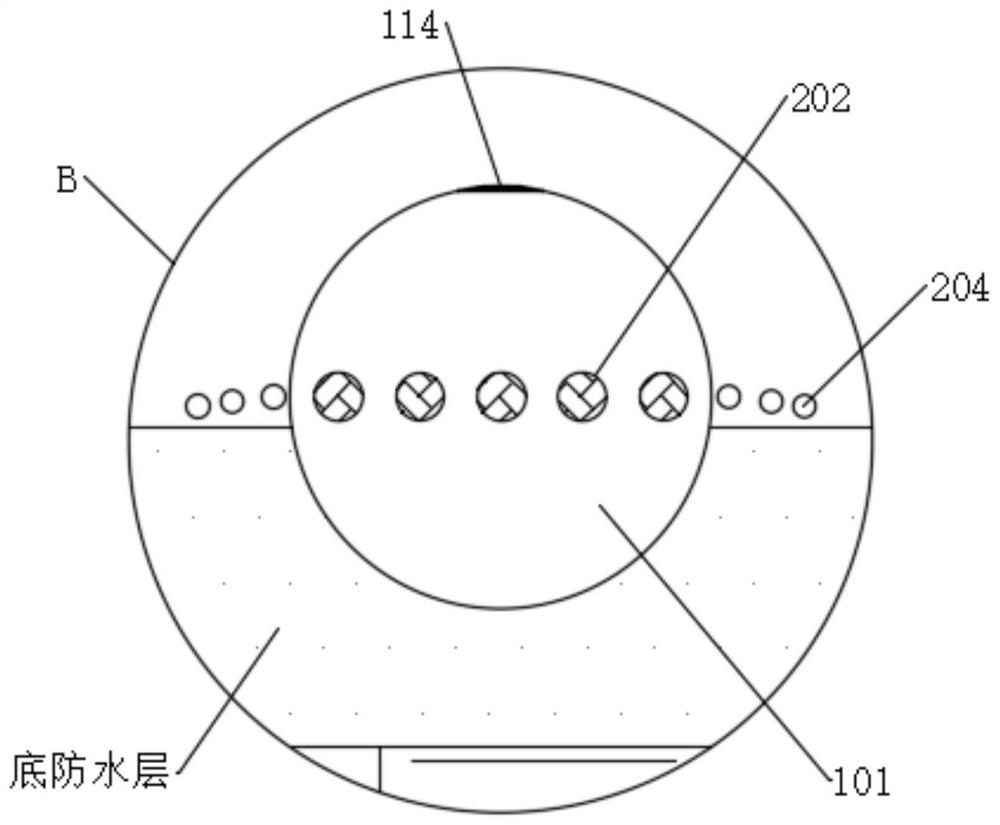

Jet type flow detection device for medical instrument

ActiveCN105698878AGuaranteed ejectionImprove stabilityVolume/mass flow by differential pressureMedical physicsEngineering

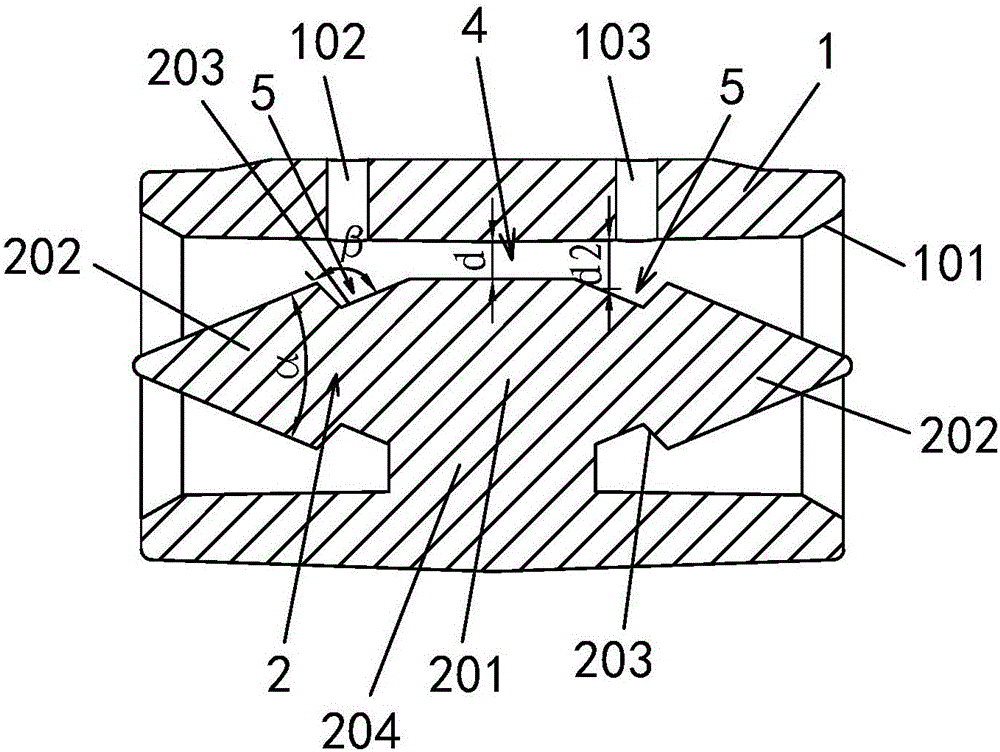

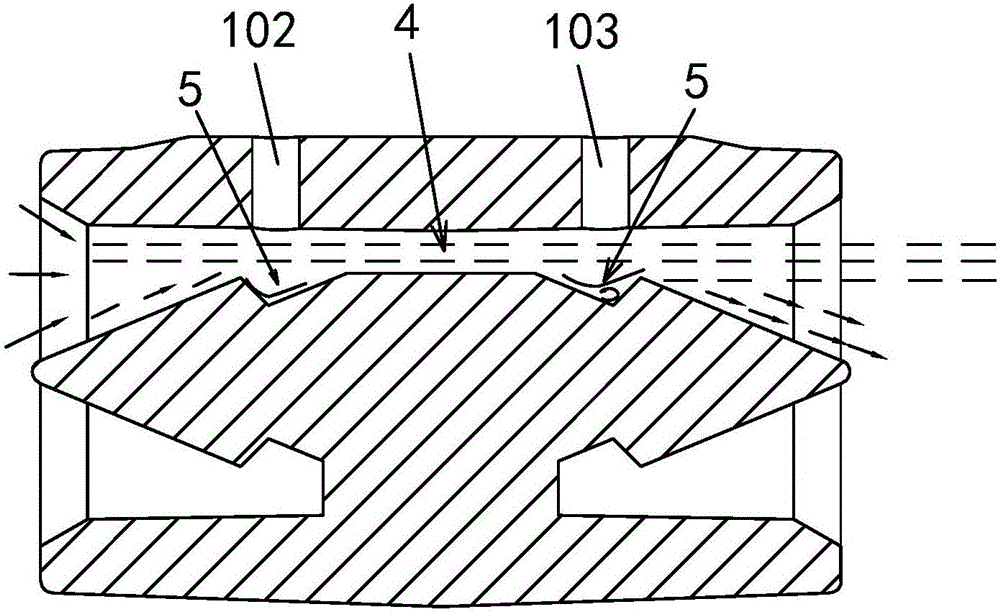

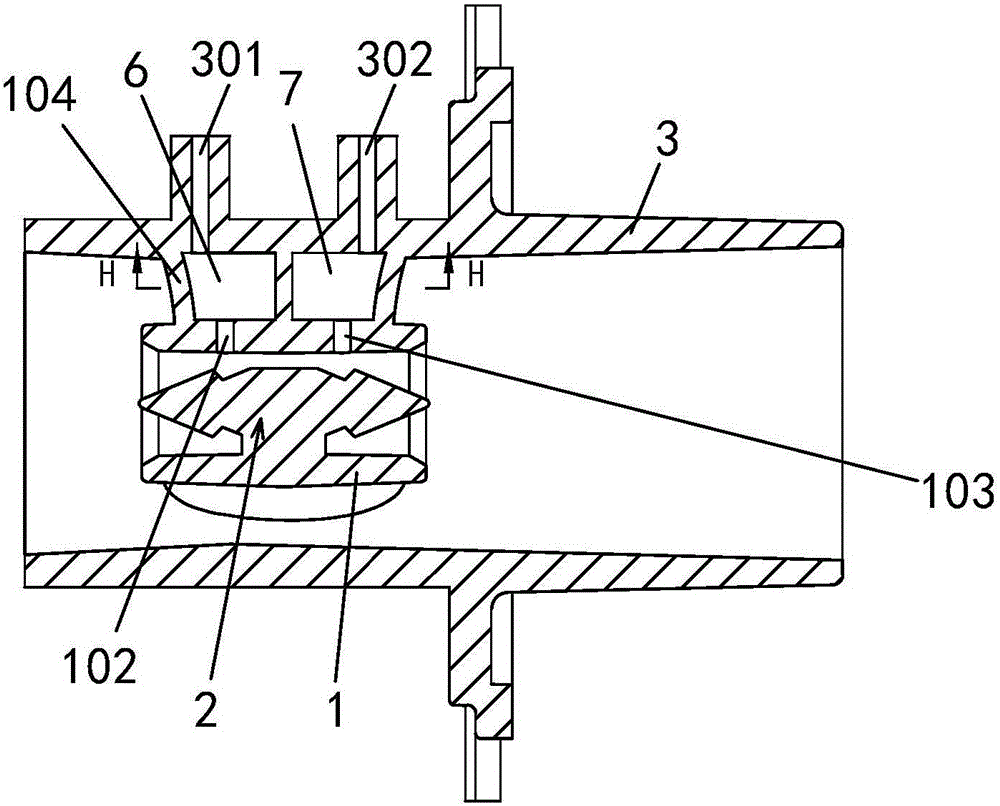

A jet type flow detection device for a medical instrument is characterized in that the device comprises a straight pipe (1) and a jet body (2) arranged in the straight pipe (1); the straight pipe (1) is arranged in the flowing direction of fluid; the jet body (2) comprises a straight section middle part (201) and jet cones (202) located at the two ends of the straight section middle part (201) in the flowing direction of the fluid, the two jet cones (202) are symmetrically arranged in a front-back mode in the flowing direction of the fluid, and the cone apex angle alpha of each jet cone (202) is 10-50 degrees; an air flow gathering and compressing area (4) is formed between the inner wall of the straight pipe (1) and the straight section middle part (201) of the jet body (2); an upstream pressure tapping (102) is formed in the position, corresponding to the cone bottom of one jet cone (202), on the straight pipe (1); a downstream pressure tapping (103) is formed in the position, corresponding to the cone bottom of the other jet cone, on the straight pipe (1).The jet type flow detection device meets the requirements of the medical instrument for high precision, small errors and miniaturization of flow detection devices.

Owner:JIANGSU YUYUE MEDICAL EQUIP&SUPPLY CO LTD +3

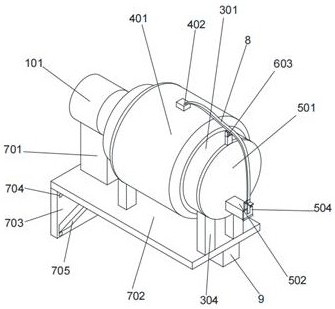

Metal part polishing device

InactiveCN112589551APolished evenlyImprove applicabilityRevolution surface grinding machinesGrinding drivesPolishingEngineering

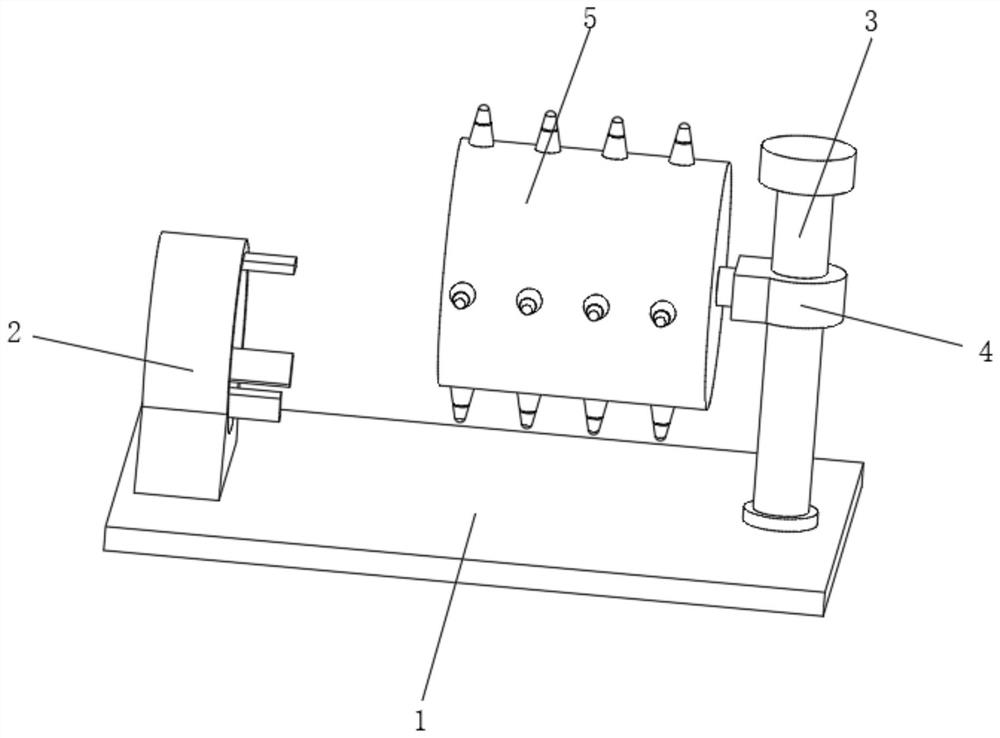

The invention discloses a metal part polishing device. The device comprises a supporting bottom plate, wherein a three-jaw chuck is fixedly connected to the left side of the top of the supporting bottom plate, a limiting supporting rod is fixedly connected to the middle of the right side of the top of the supporting bottom plate, the outer surface of the limiting supporting rod is sleeved with a driving supporting device, a surface polishing cylinder is fixedly connected to the output end of the left side of the driving supporting device, a polishing adjusting mechanism is fixedly connected toone side of the interior of the surface polishing cylinder, collecting and guiding mechanisms are evenly fixedly connected to the outer surface of the surface polishing cylinder, and active supply mechanisms are evenly and fixedly connected to positions, located between the collecting and guiding mechanisms, of the inner surface of the surface polishing cylinder at equal intervals. The inventionrelates to the technical field of metal part machining. According to the metal part polishing device, a metal part is completely sleeved with equipment to be machined, and pollution of metal dust to amachining environment in the machining process is reduced.

Owner:胡玉双

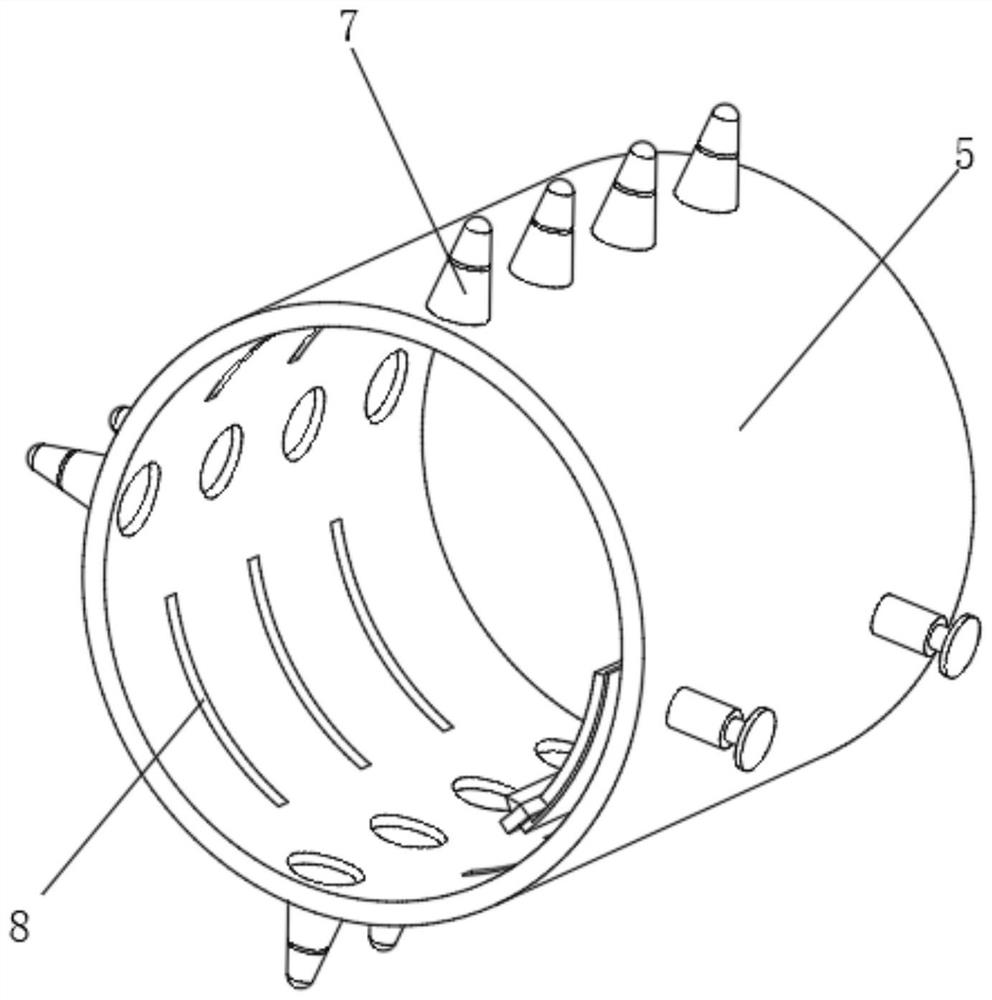

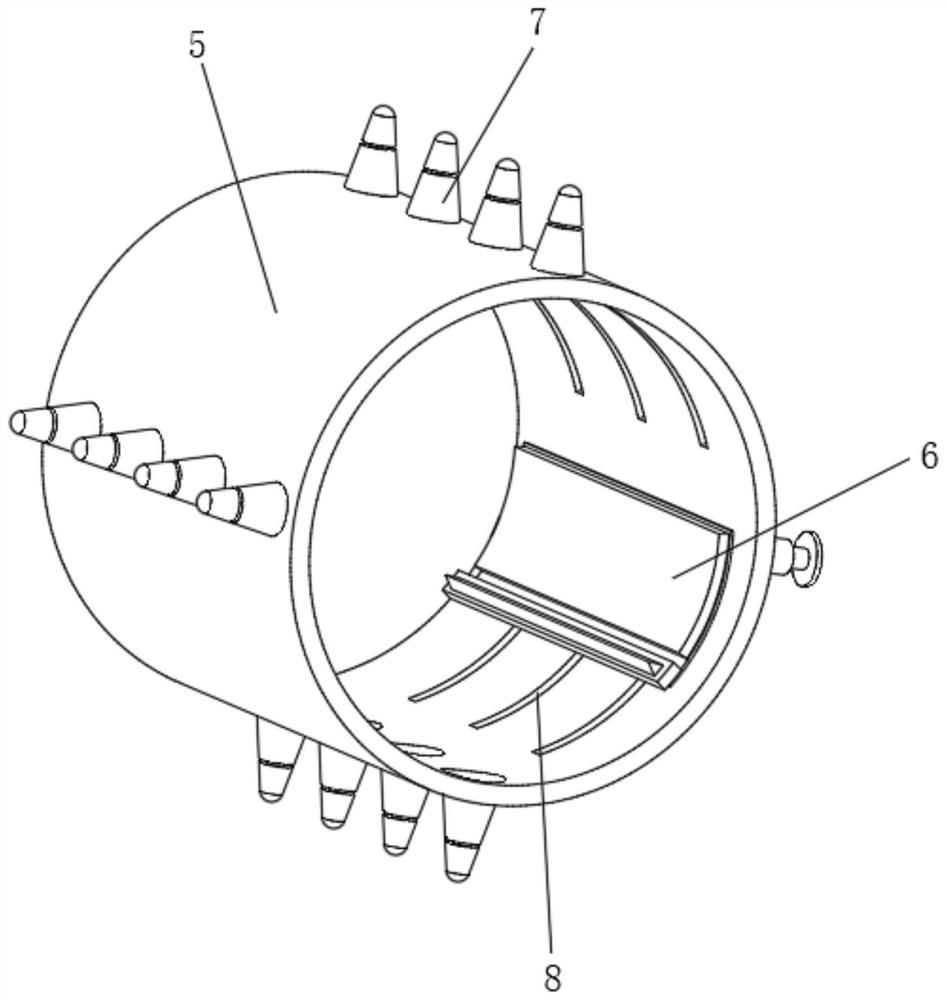

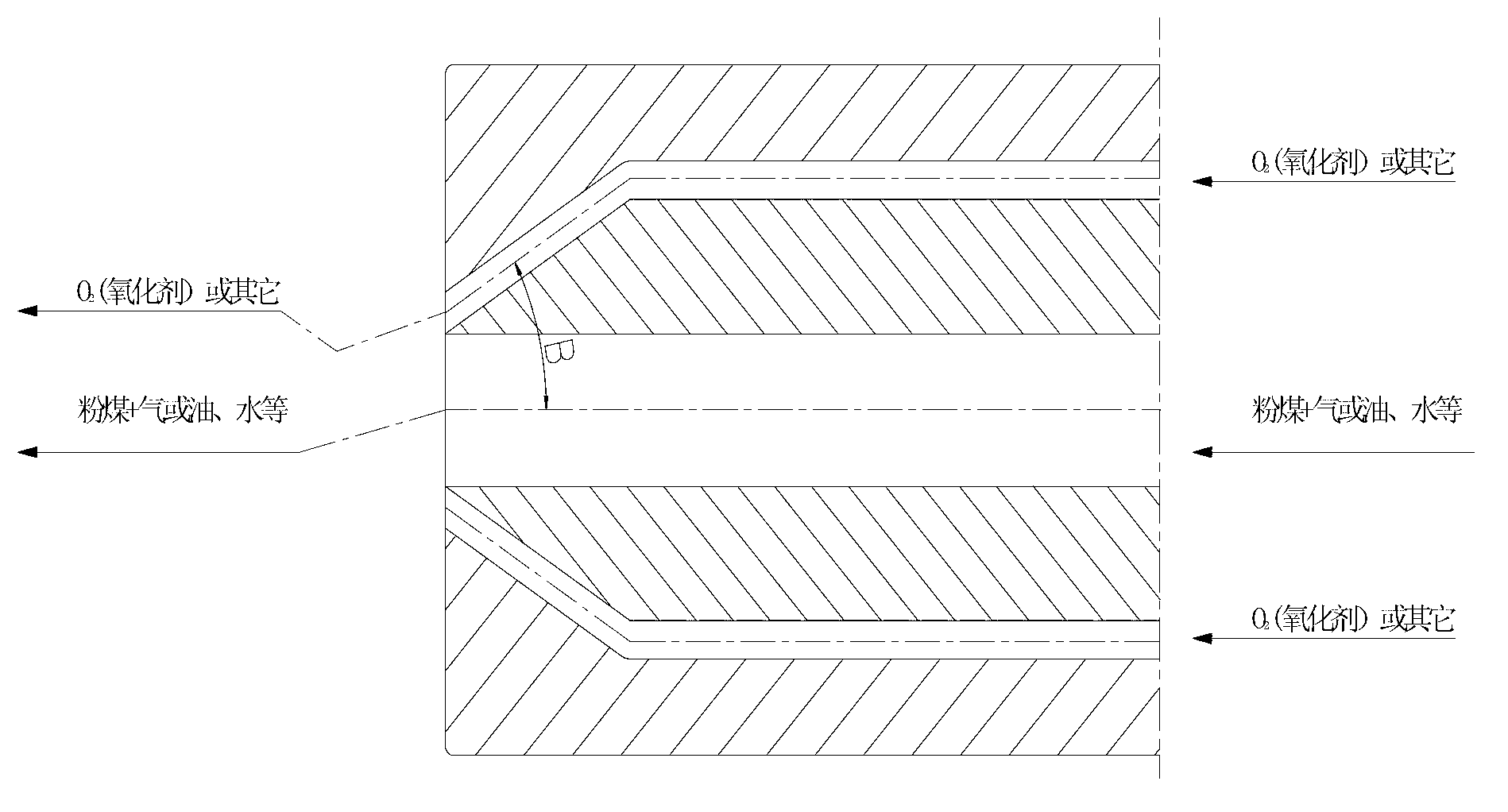

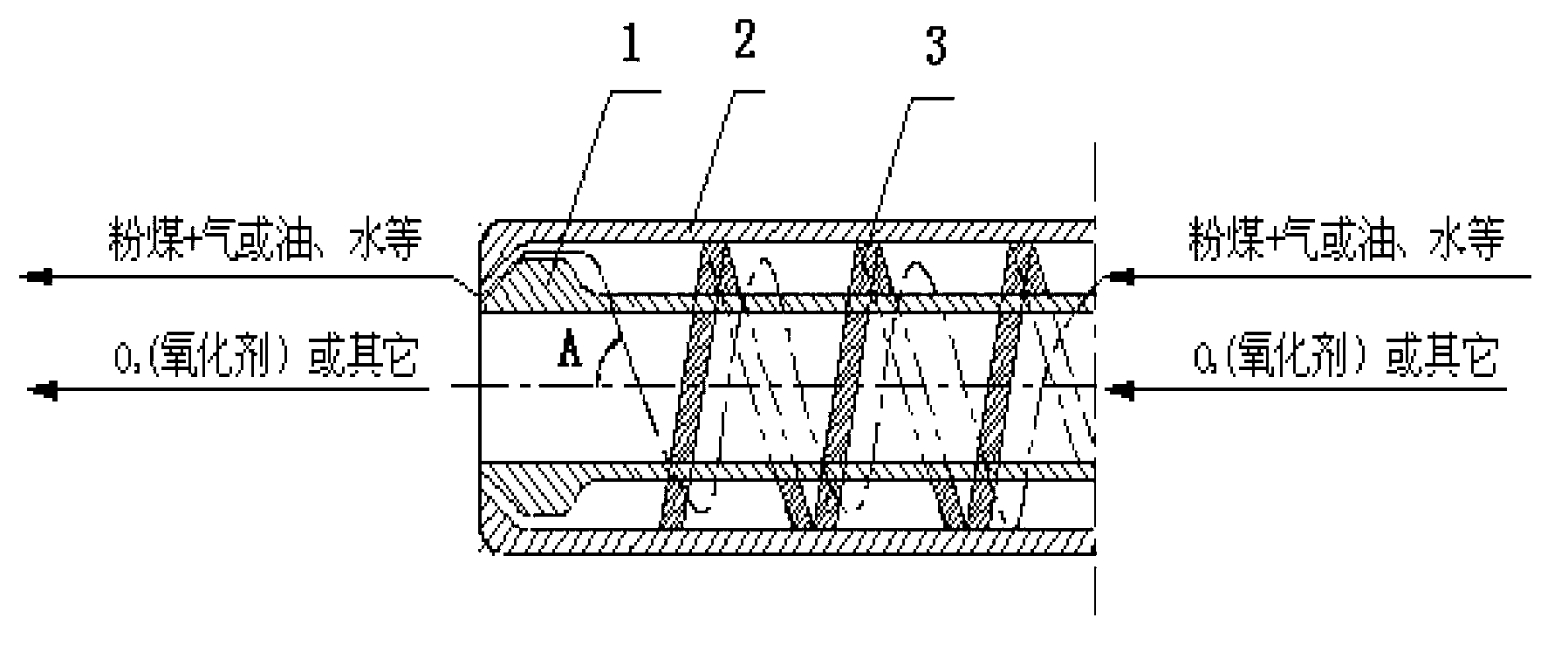

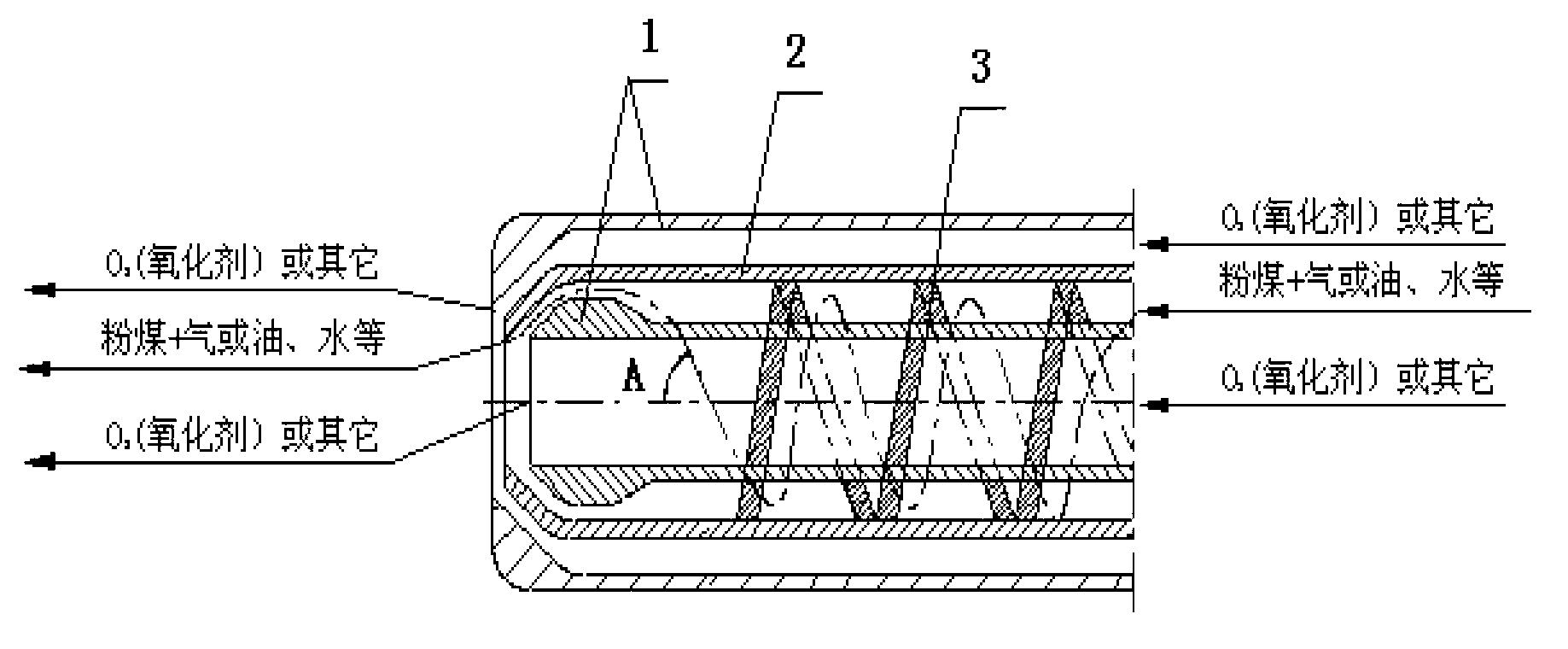

Novel cyclone atomizing device for pulverized-coal burner

InactiveCN103017163AGuaranteed ejectionImprove atomization effectPulverulent fuel combustion burnersCycloneCoal dust

The invention provides a novel cyclone atomizing device for a pulverized-coal burner. Spiral partition boards are distributed between the outer side of an oxygen tube of a burner body and the inner side of a coal dust tube, an included angle A between the spiral partition board and the central line of the burner body is within 10 degrees to 80 degrees, and an arc-shaped lug boss is arranged at an outlet of the oxygen tube. The novel cyclone atomizing device for the pulverized-coal burner is good in atomization effect and simple in processing and manufacturing, and can meet various process demands of the coal chemical industry.

Owner:XIAN AEROSPACE YUANZHENG FLUID CONTROL

An automatic fire extinguishing device for corridor fire detection

ActiveCN113262405BImprove fire extinguishing effectNo manual operation requiredFire rescueFire alarm smoke/gas actuationElectric machineAutomatic fire suppression

The invention discloses an automatic fire extinguishing device for corridor fire detection and relates to the technical field of fire emergency equipment. The automatic fire extinguishing device for fire detection in corridors includes a motor, a connecting shaft is fixedly connected to the front side of the rotating shaft of the motor, and a central block is fixedly connected to the circumferential side of the connecting shaft, and is characterized in that: the upper and lower surfaces of the central block are fixedly connected with a connecting shaft. Rod, the side of one end of the connecting rod away from the central block is fixedly connected with a stirring block, and the circumferential side of the connecting shaft is fixedly connected with a fan blade, the fan blade is located at the rear side of the central block, and the front side of the fan blade is provided with an air inlet plate, which solves the problem of Most of the corridors of existing old buildings do not have the equipment to deal with fire in time. After the electric vehicle catches fire at night, the residents cannot find it in time. They will not find it until the flame or smoke diffuses upstairs. At this time, the best escape has been missed. And the timing of fire extinguishing has caused a lot of damage to people and property.

Owner:帕沃电子技术有限公司

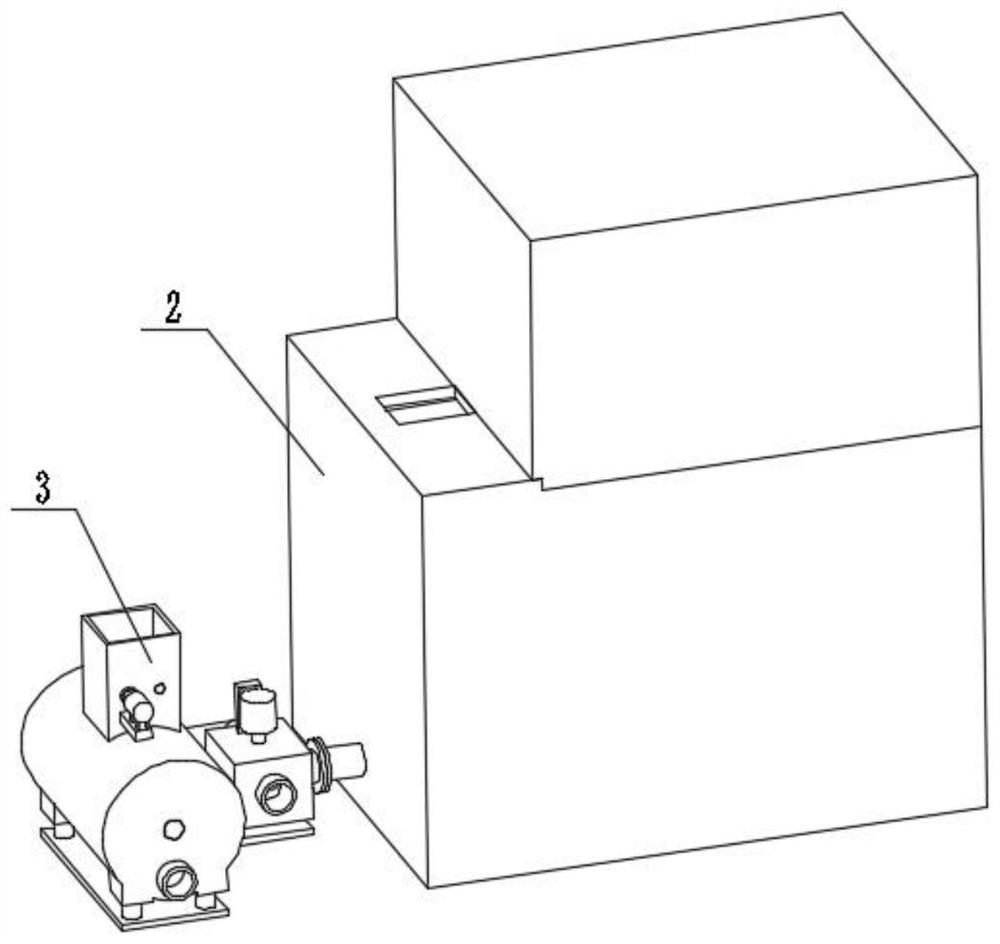

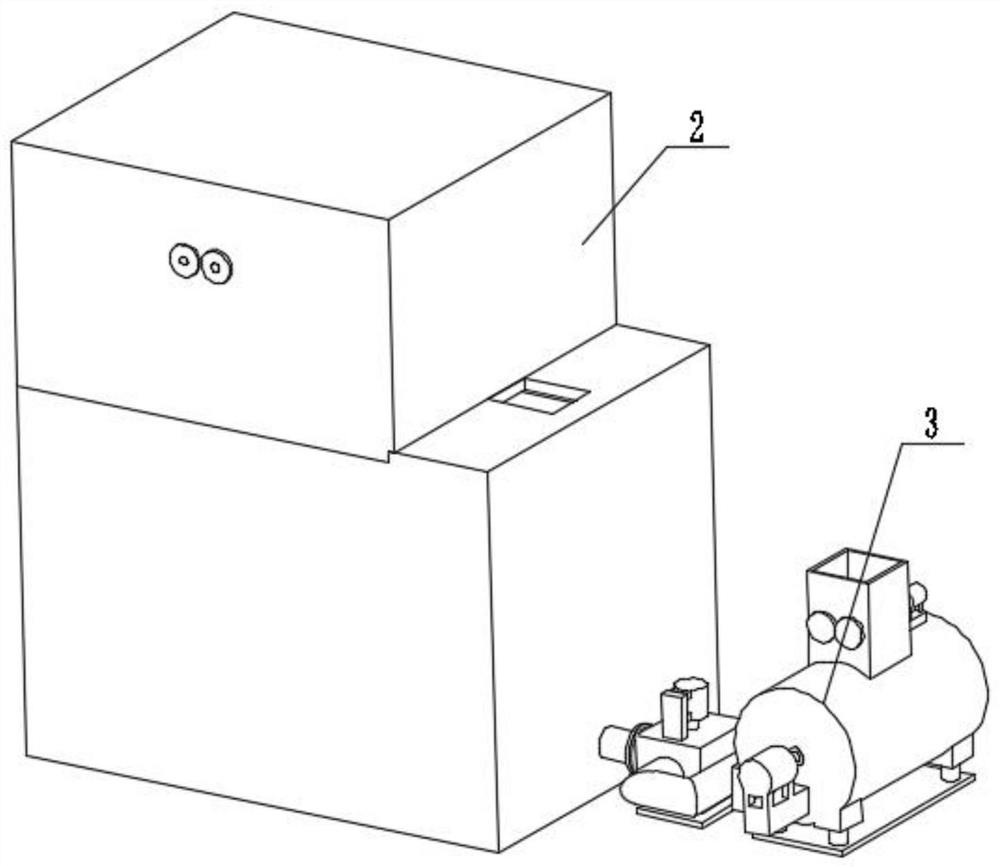

Surgical instrument disinfection treatment and recovery equipment

InactiveCN113350542AGuaranteed ejectionEject evenlySolid waste disposalMixing methodsMedical wasteEnvironmental engineering

The invention relates to disinfection equipment, and particularly relates to surgical instrument disinfection treatment and recovery equipment. The surgical instrument disinfection treatment and recovery equipment comprises a disinfection mechanism, a box body mechanism and a garbage treatment mechanism. The equipment can ensure that a disinfectant is sprayed out, the disinfectant can be sprayed out uniformly, the equipment can select the purpose of discharging waste liquid, the equipment can be used for medical waste treatment, the disinfection mechanism is connected with the box body mechanism, and the disinfection mechanism is connected with the garbage treatment mechanism.

Owner:高凤琴

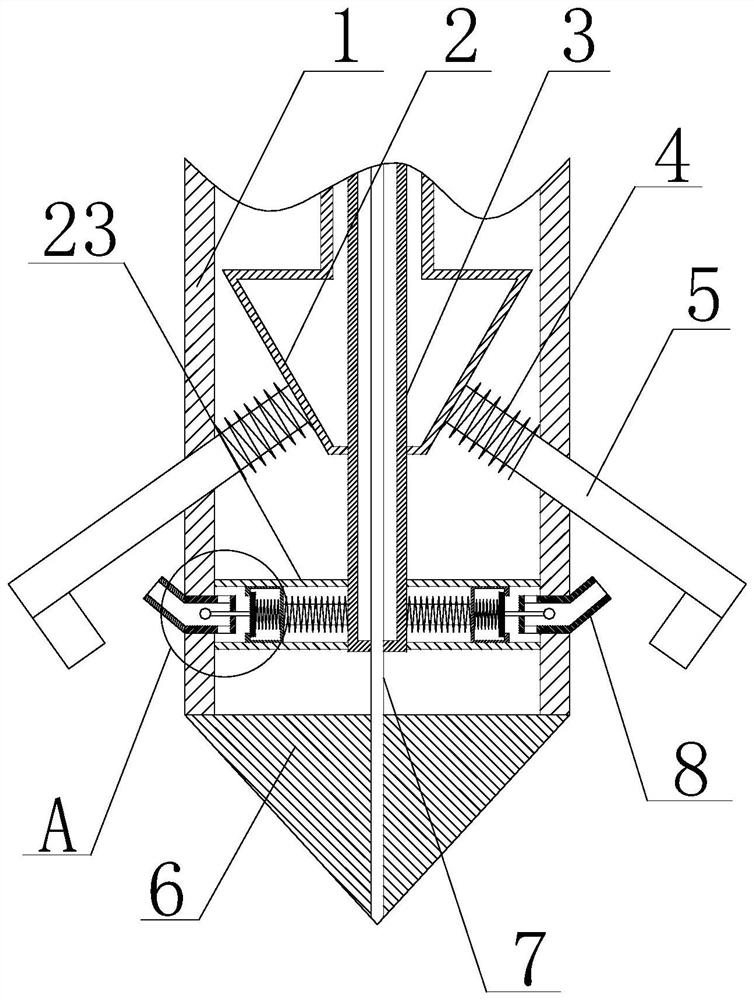

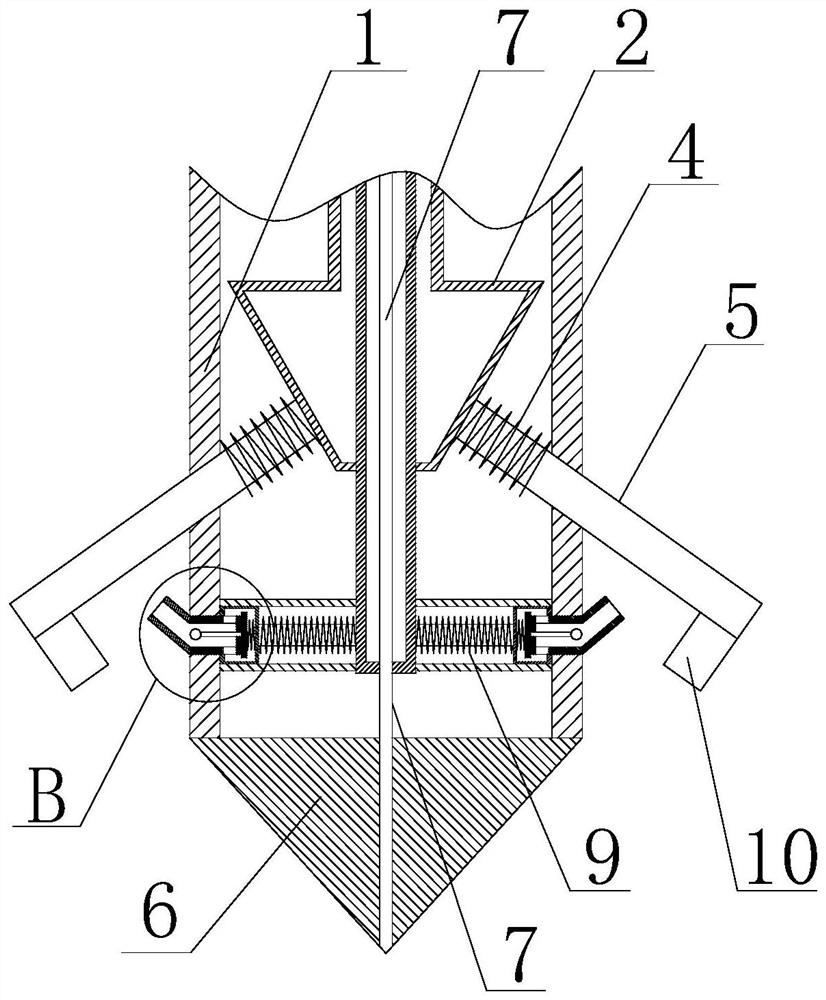

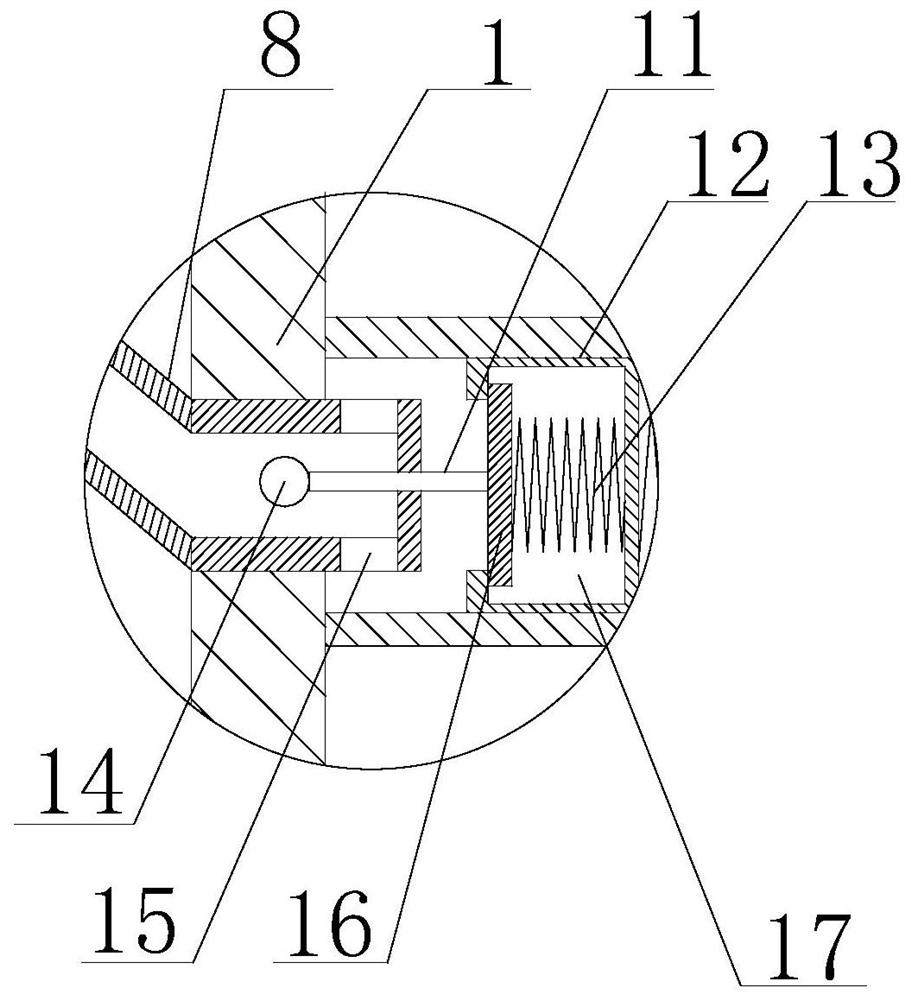

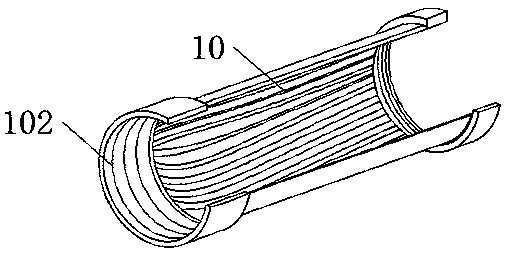

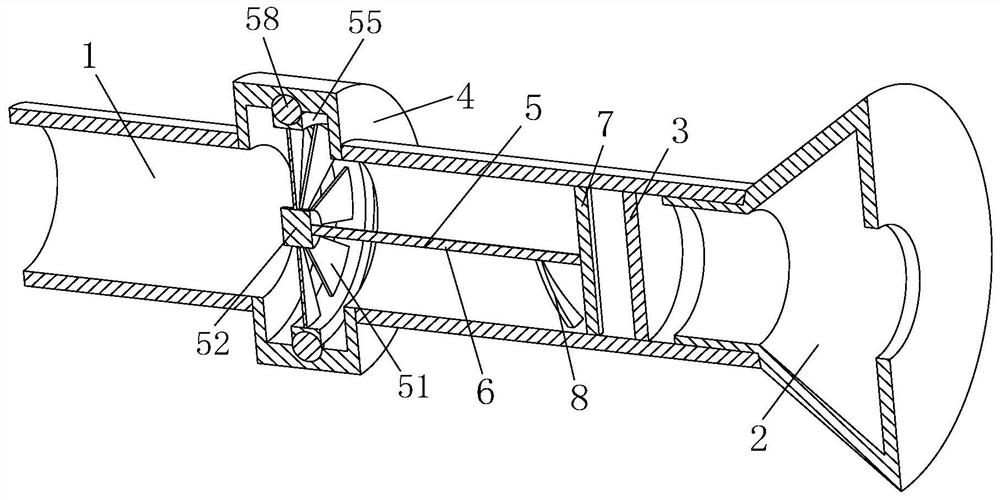

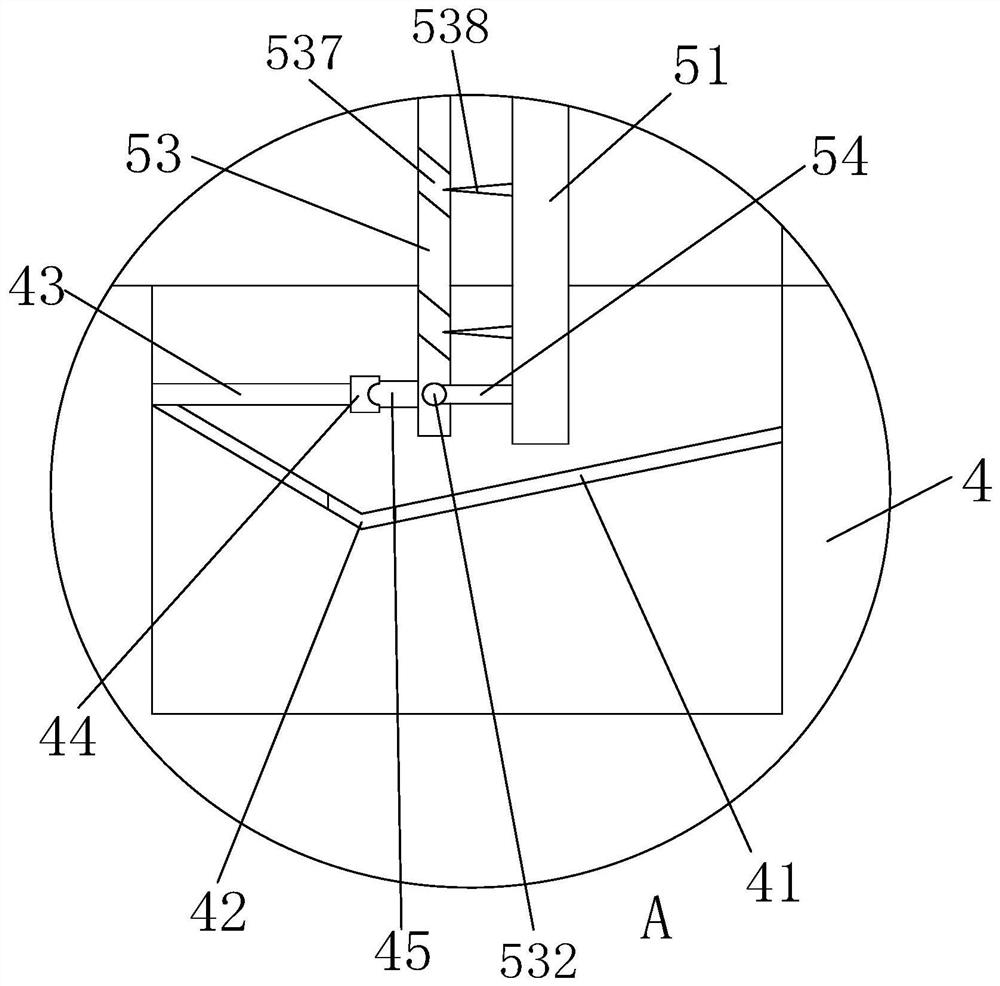

High-pressure jet grouting pile drill bit based on road and bridge construction application

ActiveCN111155933AImprove functionalityAdjustable lengthEarth drilling toolsDrill bitsSprayerStructural engineering

The invention discloses a high-pressure jet grouting pile drill bit based on road and bridge construction application. The high-pressure jet grouting pile drill bit comprises a rod body and a conicalhead, wherein the rod body is of a cavity structure, and a slurry conveying pipe is arranged in the cavity; a movable assembly is further arranged in the cavity of the rod body, a plurality of drill blades are further arranged on the circumferential outer wall of the rod body, when the movable assembly moves in the direction of the conical head, the movable assembly can push the drill blades to move in the direction away from the rod body, and baffles are arranged on the side walls, facing the conical head, of the drill blades; and telescopic pipes are further arranged in the cavity of the rodbody, one ends of the telescopic pipes communicate with the slurry conveying pipe, a connector is arranged at the other ends of the telescopic pipes, sprayer assemblies as many as the drill blades are further arranged on the circumferential outer wall of the rod body, one ends of the sprayer assemblies face the drill blades, and the other ends of the sprayer assemblies are located in the cavity of the rod body. According to the high-pressure jet grouting pile drill bit, the diameter of a pile hole drilled through the drill bit can be adjusted, different use requirements are met, meanwhile, itis guaranteed that in the downward drilling process of the drill bit, mud and stone in soil can be prevented from blocking the slurry conveying pipe, and therefore the construction efficiency is improved.

Owner:SHANGHAI YUANFENG UNDERGROUND ENG TECH

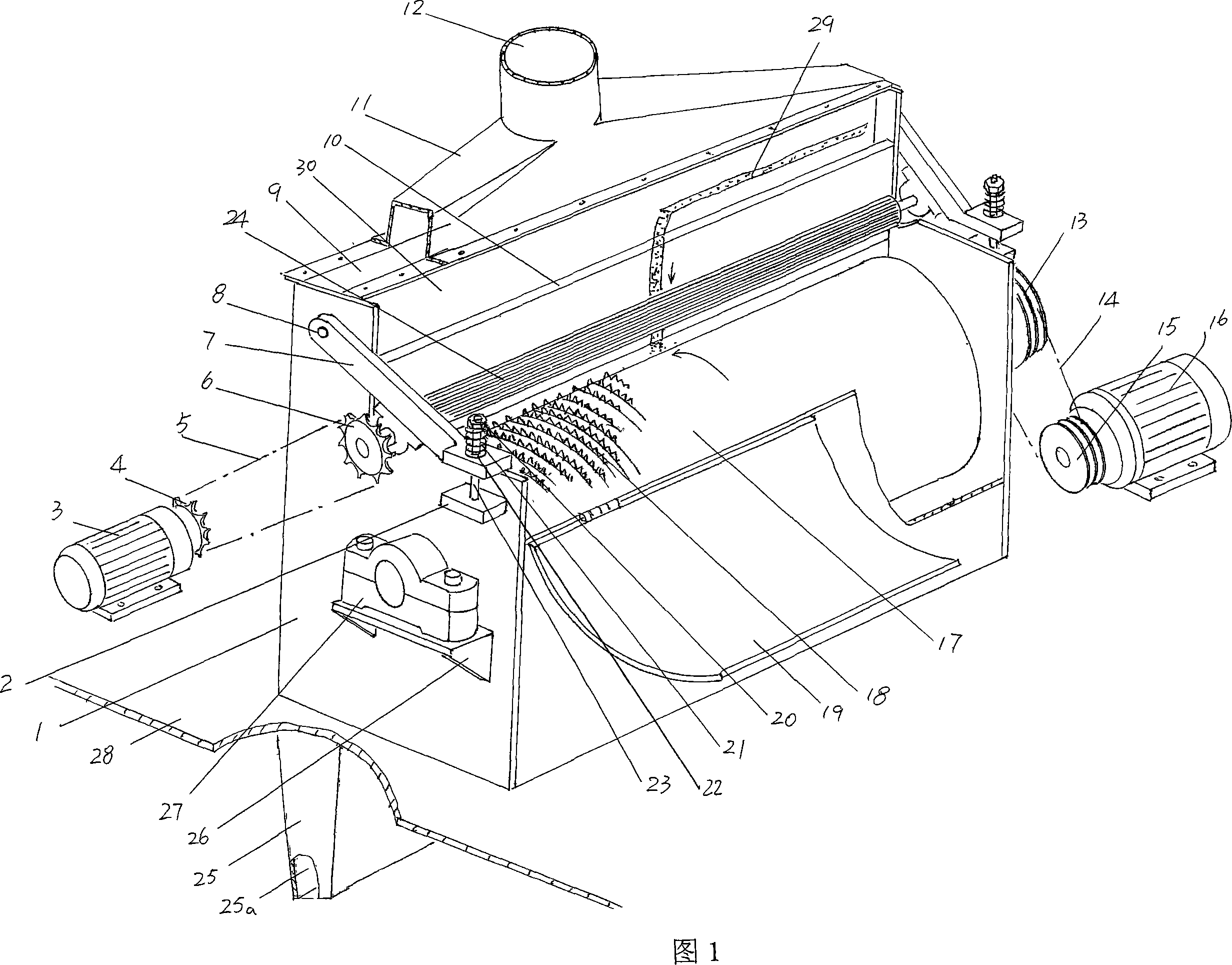

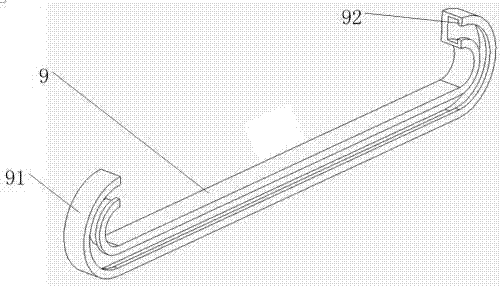

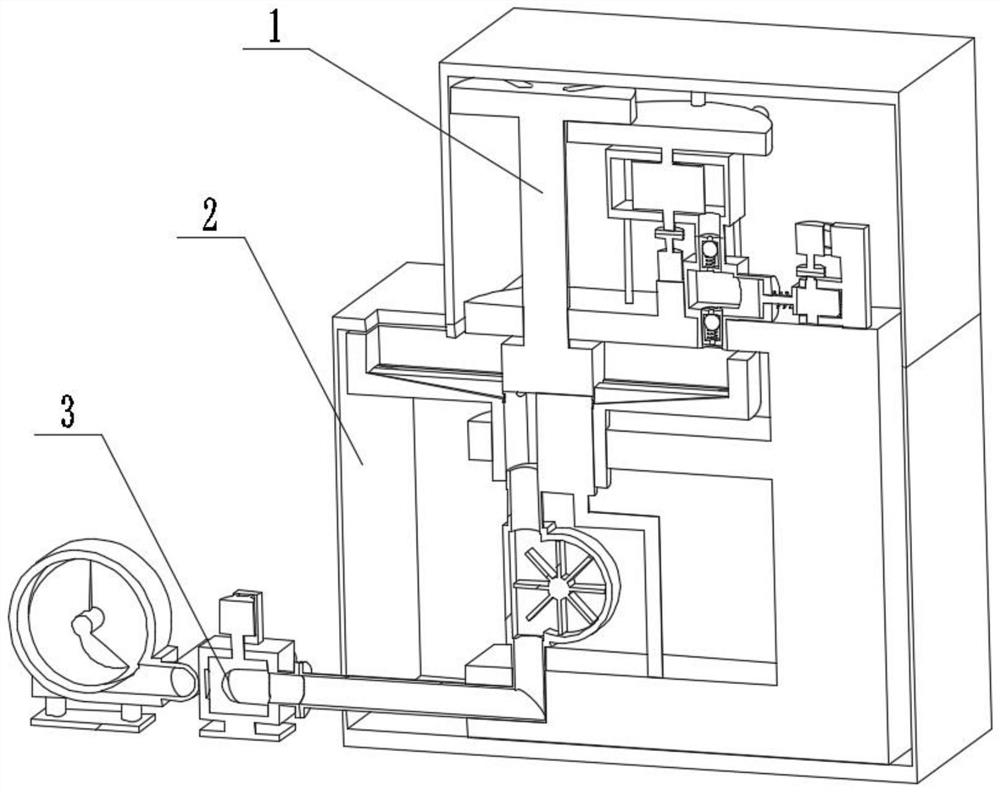

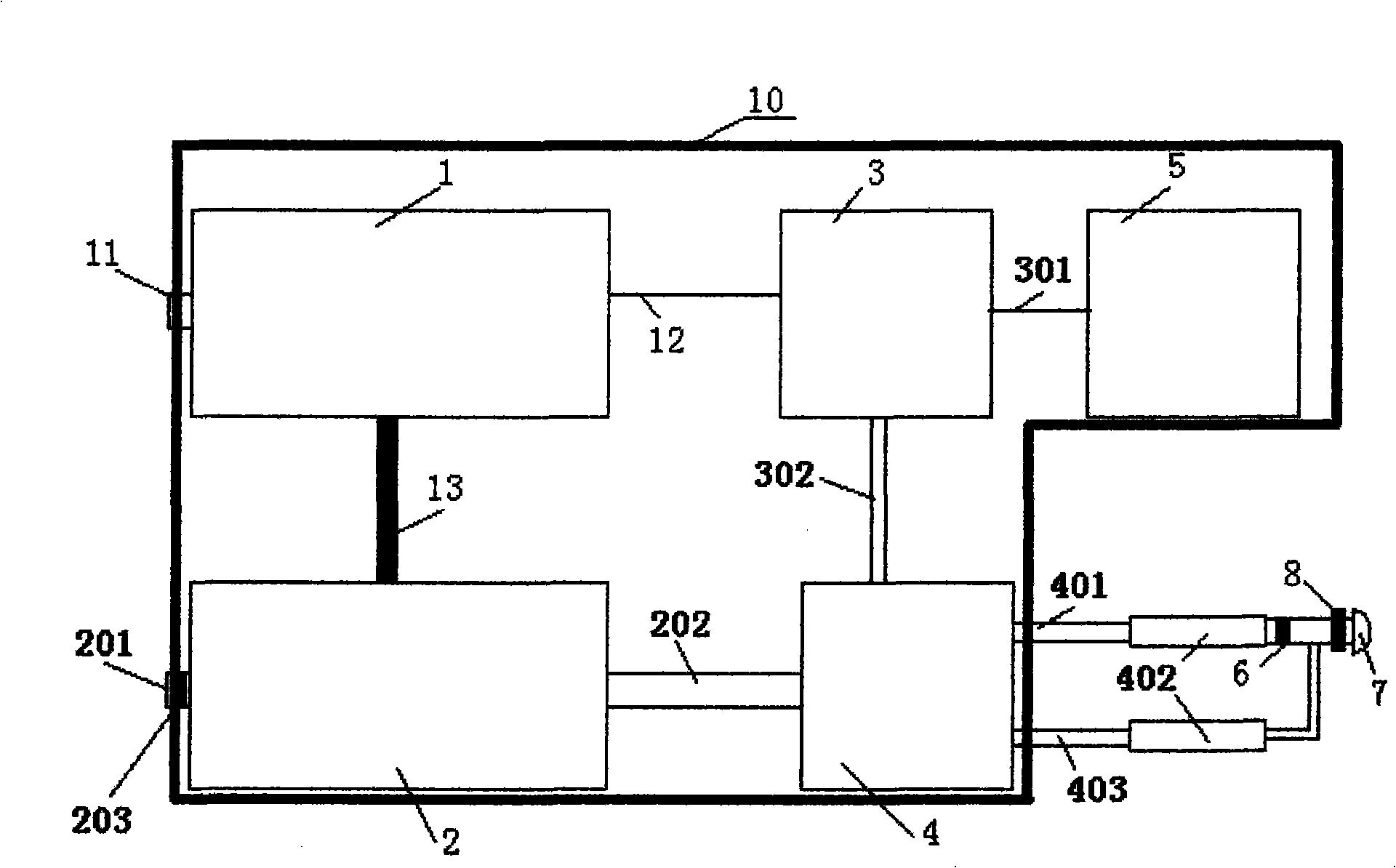

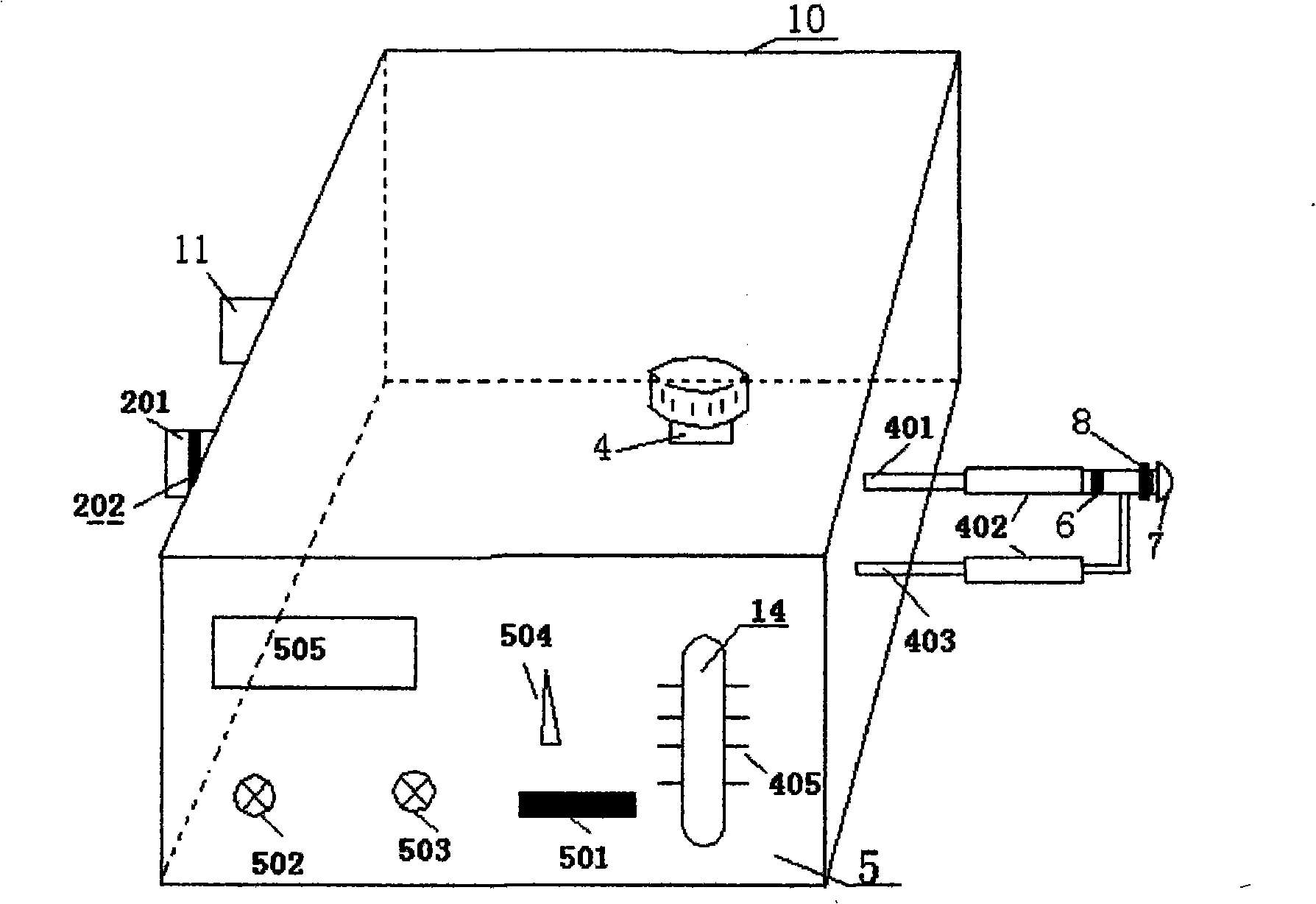

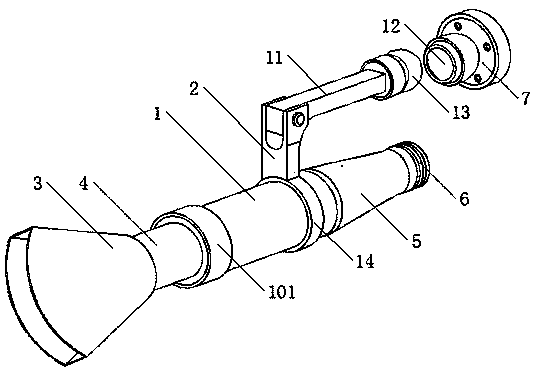

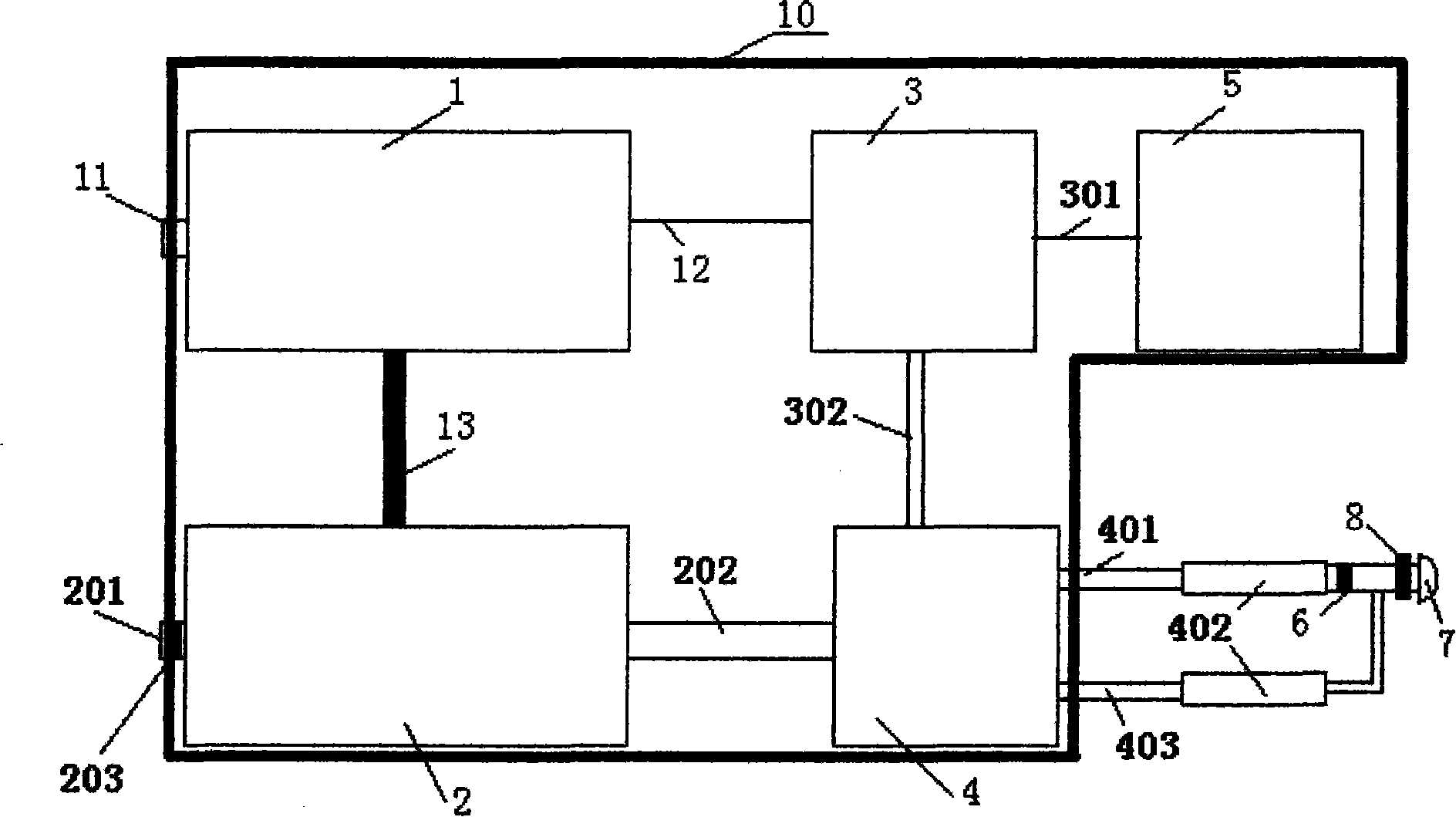

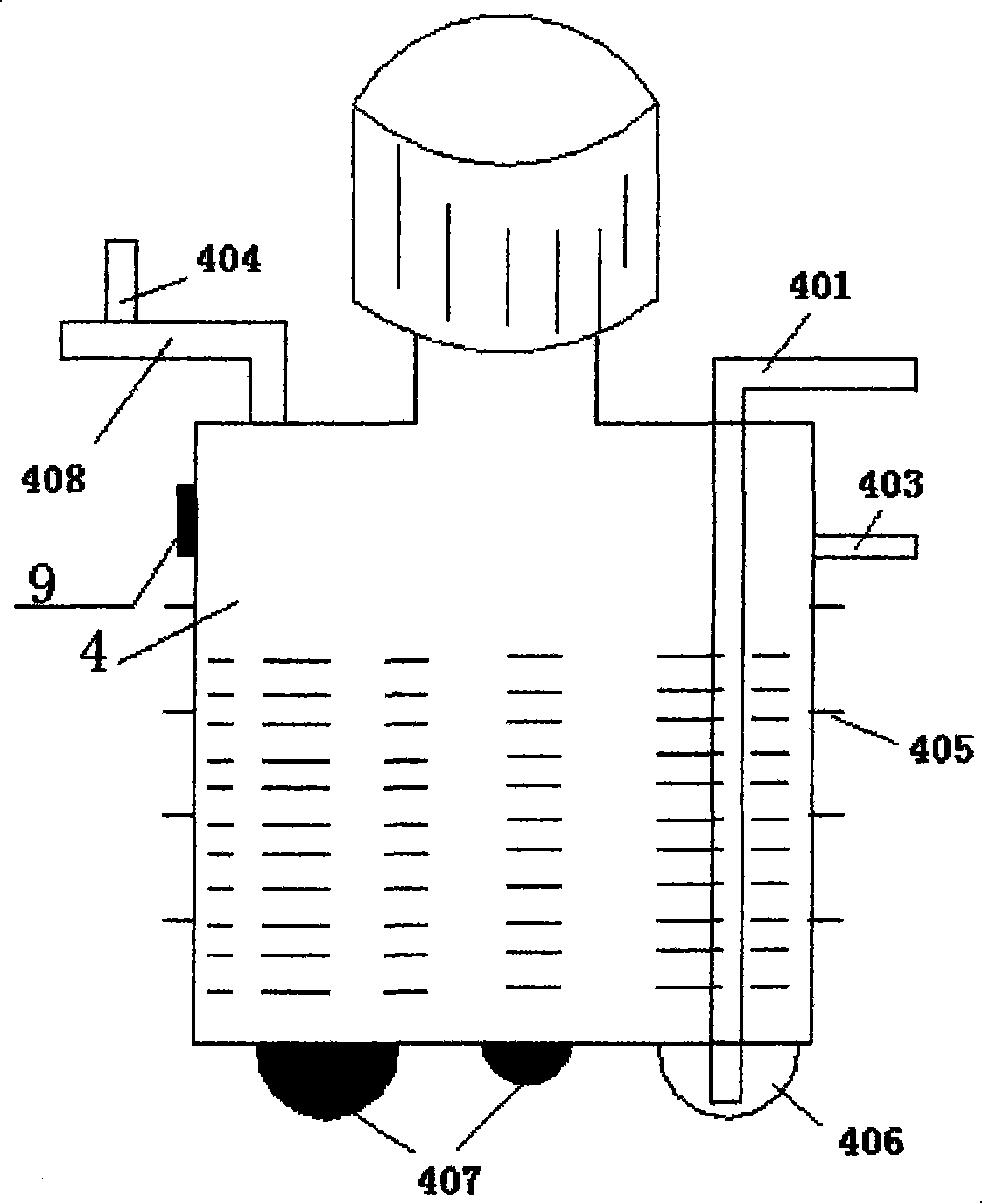

Intelligent electronic oral cavity and laryngopharynx surface anesthesia atomizer

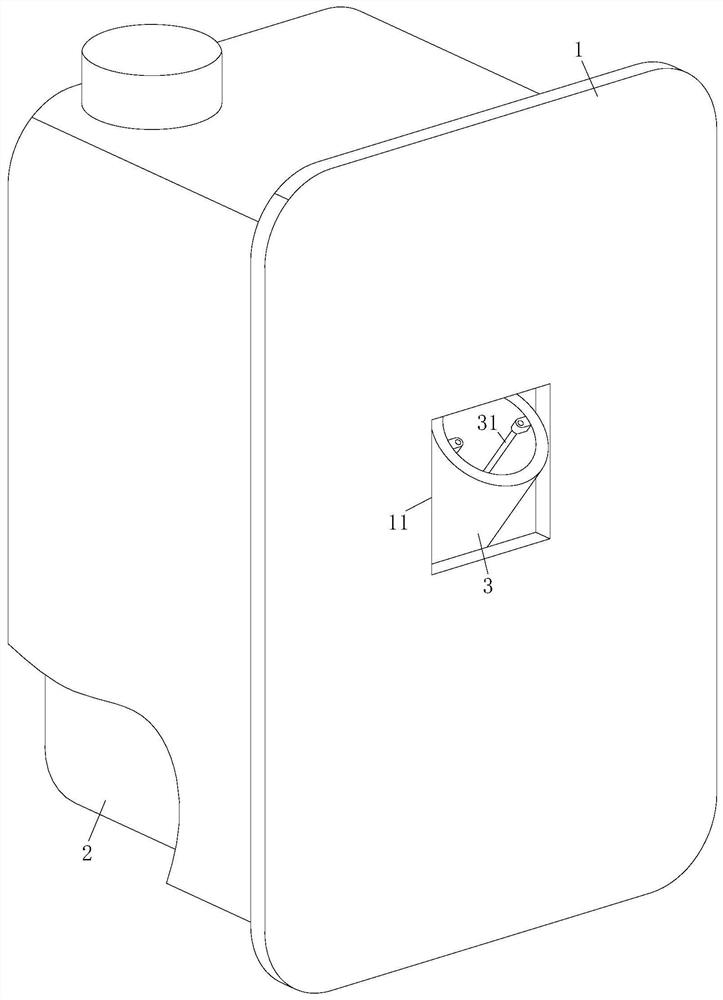

InactiveCN101264362AIntelligent pressure controlFast and accurate pressure regulationAnaesthesiaMedical atomisersThroatSprayer

The invention relates to an intelligent electronic anesthesia sprayer for the surface of oral and throat, belonging to the equipment of medical service, which at least comprises a medical solution bottle (4), an oil-free compressor (2), a nozzle (7), an intelligent controller (3) and a variable-frequency motor (1). The intelligent electronic anesthesia sprayer is characterized in that: an intake interface (408) of the medical solution bottle compressor, a medical solution outgoing interface (401), and an oxygen outgoing interface (403) are arranged on the medical solution bottle (4); the oil-free compressor (2), a hose for air or oxygen passing through are connected with the intake interface (408) of the medical solution bottle compressor; the nozzle (7) is communicated with the medical solution outgoing interface (401) and the oxygen outgoing interface (403); the intelligent controller (3) is used for measuring the pressure in the medical solution bottle (4) and comparing with the preset pressure value, to computer the output voltage value to control the rotational speed of the variable-frequency motor (1); the variable-frequency motor (1) is used for controlling the output work of the oil-free compressor (2) according to the output voltage of the intelligent controller (3). The intelligent electronic anesthesia sprayer has the advantages of convenient use, short operation time, controllable spray medical solution, and ability to continuously and uniformly spray foggy medical solution.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

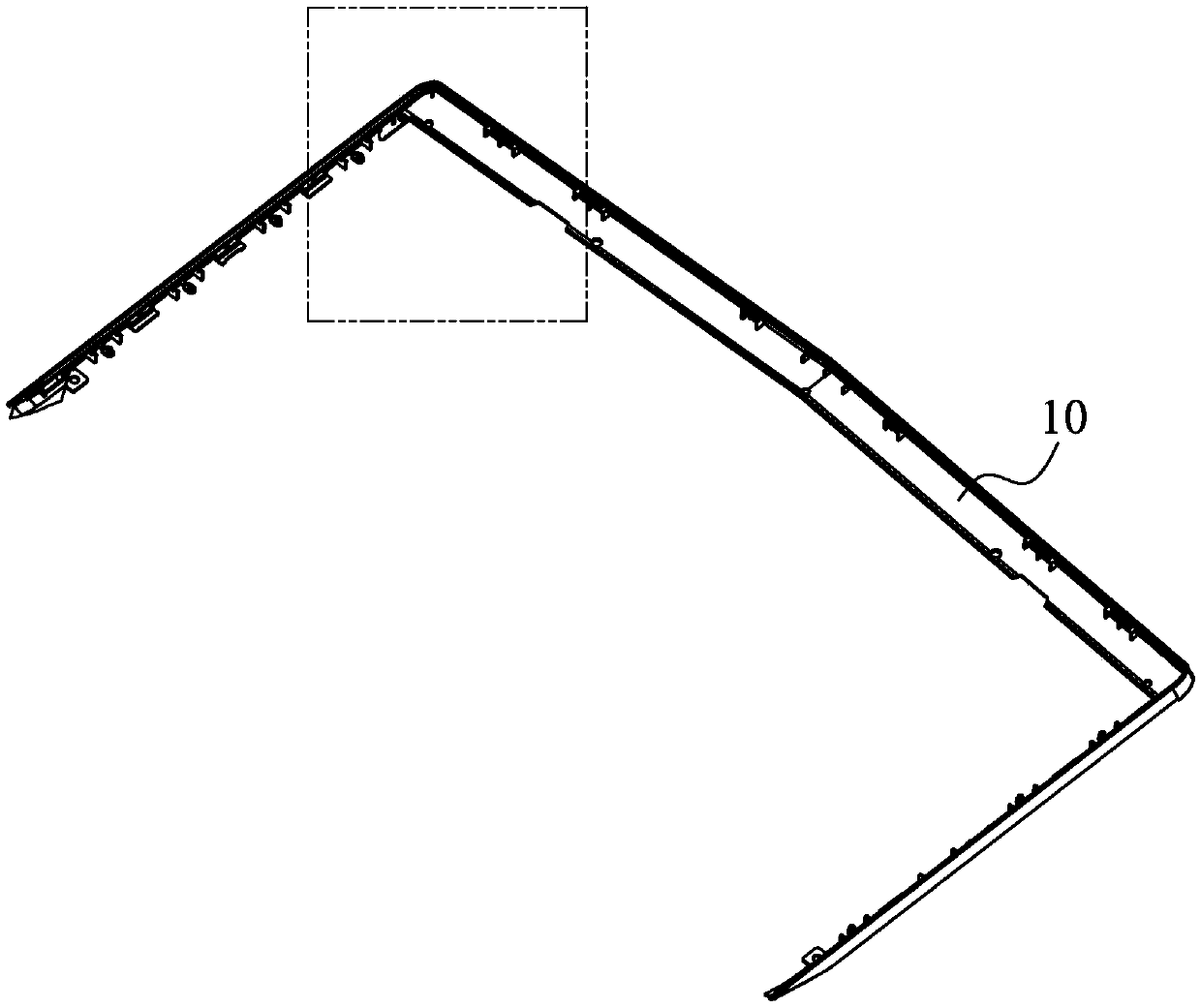

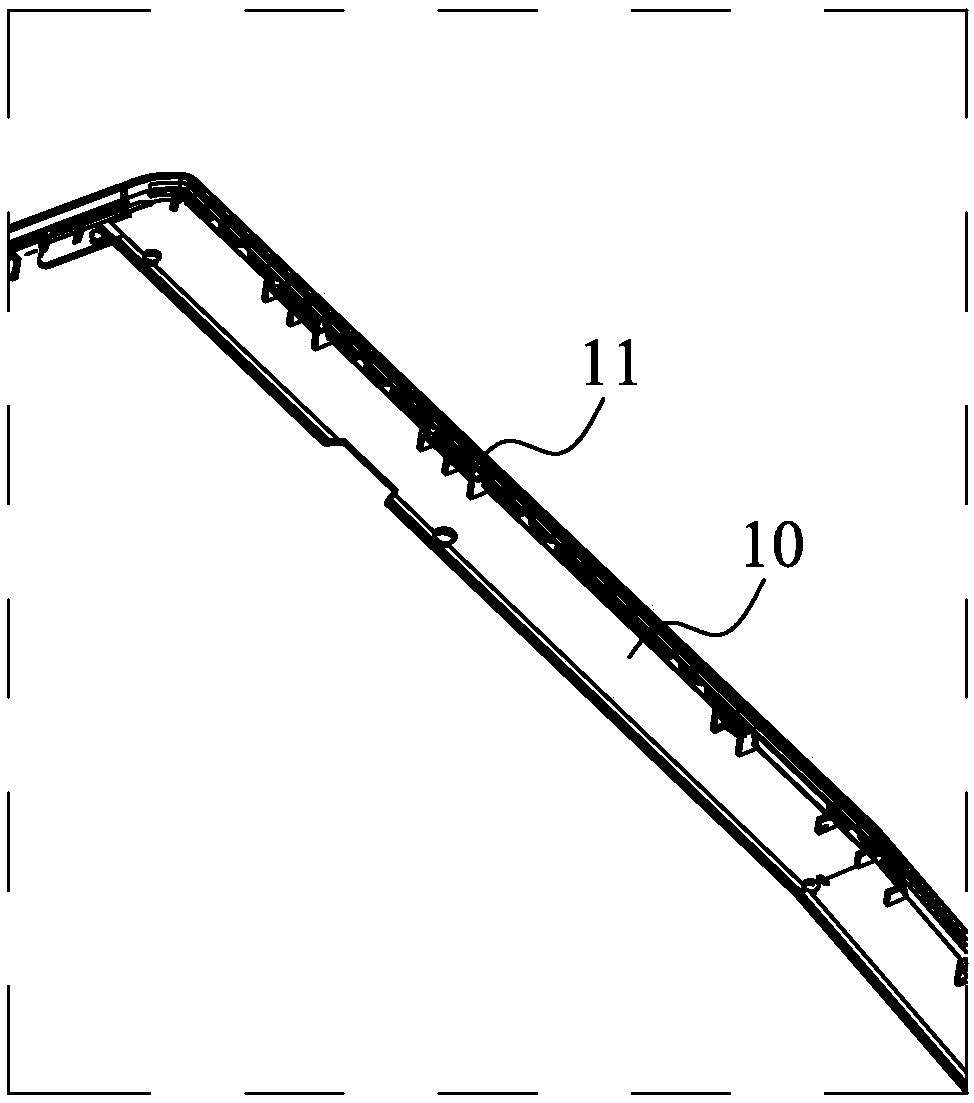

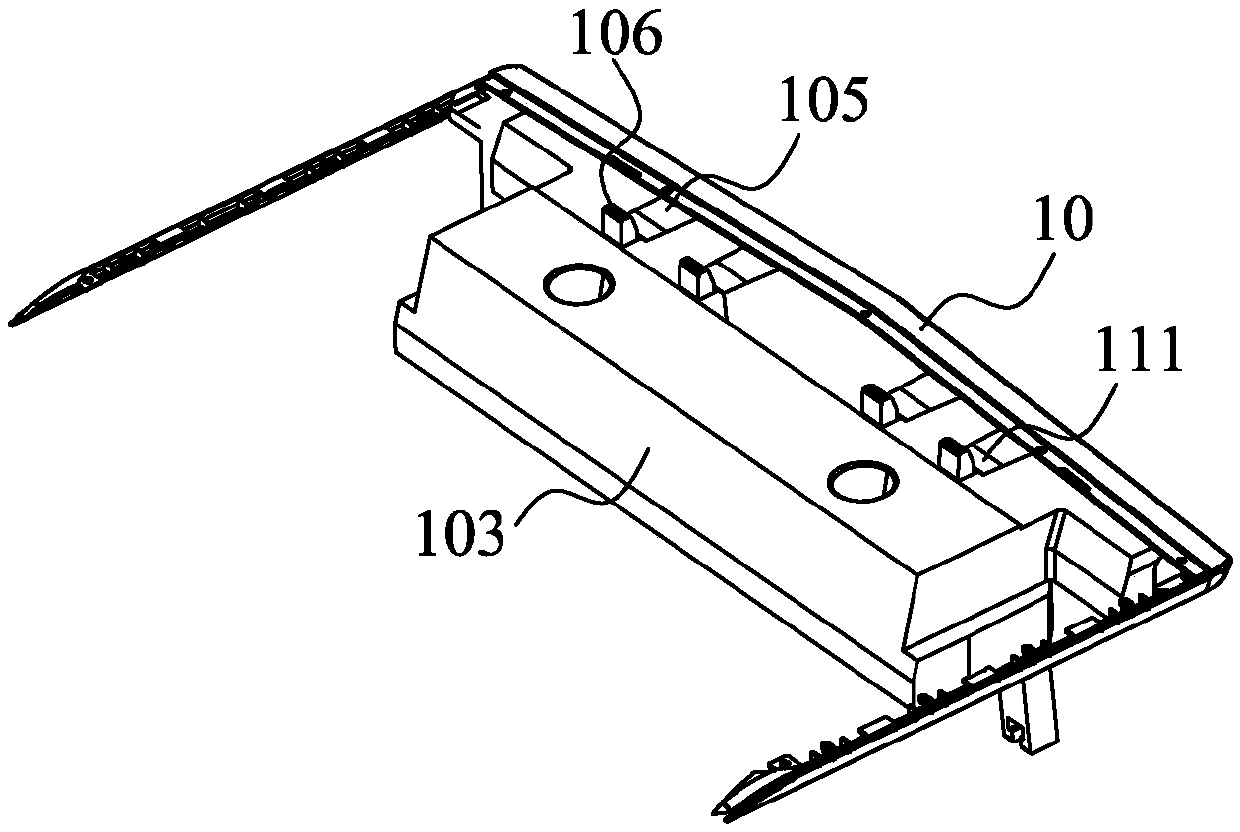

Whole surface inverted hook release structure

The invention provides a whole surface inverted hook release structure comprising an outer sliding block insert core arranged on the outer side of a product so as to mold the appearance of the product, an outer sliding block body connected with the outer sliding block insert core, a first oblique guide column arranged in the outer sliding block body for pushing the outer sliding block body to move, an inner sliding block insert core arranged on the inner side of the product so as to mold inverted hooks on the inner side of the product, a second oblique guide column arranged in the inner sliding block insert core for pushing the inner sliding block insert core to move, oblique pins of which the tail ends are arranged in a male template and connected with ejector pins of a mould, limiting insert cores and insert pins; the product is formed on one side of the head end of each oblique pin; one end of each limiting insert core is arranged in a male mould core, and the other end of each limiting insert core is arranged in the inner sliding block insert core, and provided with a vertical side face; and one end of each insert pin abuts against the vertical side face of the corresponding limiting insert core. According to the whole surface inverted hook release structure, through arrangement of the oblique pines and the insert pins, the whole surface inverted hooks of the product can bereleased; and not only can the product be ensured to be pushed out through the oblique pins, but also the product is not bonded when the inner sliding block insert core and the oblique pins are released.

Owner:SUZHOU MITAC PRECISION TECH

Dust removing device for external surface of electronic product

InactiveCN109877108APlay the role of buffer protectionAchieve filteringDispersed particle filtrationCleaning using gasesAir compressionMotor drive

The invention discloses a dust removing device for the external surface of an electronic product, and belongs to the technical field of electronic products. The problem that the external surface of the electronic product cannot be sufficiently cleaned due to the fact that existing dust removing devices remove dust mainly through an industrial fan; the dust removing device for the external surfaceof the electronic product is characterized in that the dust removing device for the external surface of the electronic device comprises a supporting base, a vertical plate, a working motor, an air compression cavity, and a product placing plate; the left side of the upper surface of the supporting base is fixedly welded to the vertical plate, the working motor is fixedly installed at the middle position of the right side wall of the vertical plate, and a worm is fixedly welded to the output end of the working motor; and the right end of the worm extends into the product placing plate, the wormis connected with the product placing plate in a screwed mode, and the air compression cavity is formedin the right side of the product placing plate. The dust removing device for the external surface of the electronic device has the advantages of being energy saving and environment-friendly, and the dust removing efficiency on the external surface of the electrical product is improved by the working motor driving the product placing plate to move left and right and spraying of gas.

Owner:湖南悟空信息科技有限公司

Anti-blocking device of intelligent online grain moisture meter

PendingCN112595757AImprove stabilityGuaranteed cleanlinessHollow article cleaningMaterial resistanceElectric machineryEnvironmental engineering

The invention relates to the technical field of blockage prevention of grain moisture meters, in particular to an anti-blocking device of an intelligent online grain moisture meter, and the device comprises a case, a moisture meter body, a feeding cylinder and a controller; the moisture meter body and the feeding cylinder are fixedly connected to the interior of the case; one end of the feeding cylinder is communicated with the moisture meter body; a rectangular opening is formed in one side wall of the case; the other end of the feeding cylinder extends out of the rectangular opening, a sliding rod is fixedly connected to the inner wall of the feeding cylinder, and an annular plate is slidably connected into the feeding cylinder; the annular plate is in sliding connection with the slidingrod; the annular plate is driven by a motor to scrape the inner wall of the feeding cylinder, and meanwhile, the annular plate is opened and matched with a baffle plate under the action of airflow and materials, so that the cleanness of the inner wall of the feeding cylinder in the moisture meter body is ensured, and the blockage of the feeding cylinder and the influence on the use of the moisture meter body due to adhesion of caked materials to the inner wall of the feeding cylinder are prevented; and the use stability of the moisture meter body is improved.

Owner:ANHUI OCEAN AUTOMATION EQUIP

A cleaning device and cleaning method for solar panels

ActiveCN104201980BPrevent agingAchieve large area cleaning effectPhotovoltaicsFlexible article cleaningCells panelHigh pressure

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

A method of using high-pressure rotary grouting pile nozzles for road and bridge construction

ActiveCN111254924BImprove functionalityReal-time adjustment of extension lengthDrill bitsBulkheads/pilesPipeDrill bit

The invention discloses a method for using a high-pressure rotary jet grouting pile nozzle for road and bridge construction. The high-pressure rotary jet grouting pile nozzle comprises a rod body anda conical head, wherein the rod body is internally of a cavity structure, a grout conveying pipe is arranged in the cavity, a moving assembly is also arranged in the cavity of the rod body, the circumferential outer wall of the rod body is further provided with a plurality of drill blades, when the moving assembly moves towards the conical head, the moving assembly can push the drill blades to move in the direction away from the rod body, baffles are arranged on the side walls, facing the conical head, of the drill blades, stretchable pipes are further arranged in the cavity of the rod body, one ends of the stretchable pipes communicate with the grout conveying pipe, the other ends of the stretchable pipes are provided with joints, the circumferential outer wall of the rod body is furtherprovided with nozzle assemblies with the number same as the number of the drill blades, one ends of the nozzle assemblies face the drill blades, and the other ends of the nozzle assemblies are locatedin the cavity of the rod body. According to the method, the diameter of a pile hole drilled by the drill bit can be adjusted, then different use requirements can be met, meanwhile, it is guaranteed that in the drilling-down process of the drill bit, mud and stones in soil can be prevented from blocking the grout conveying pipe, and the construction efficiency is improved.

Owner:湖北晟弘建设工程有限公司

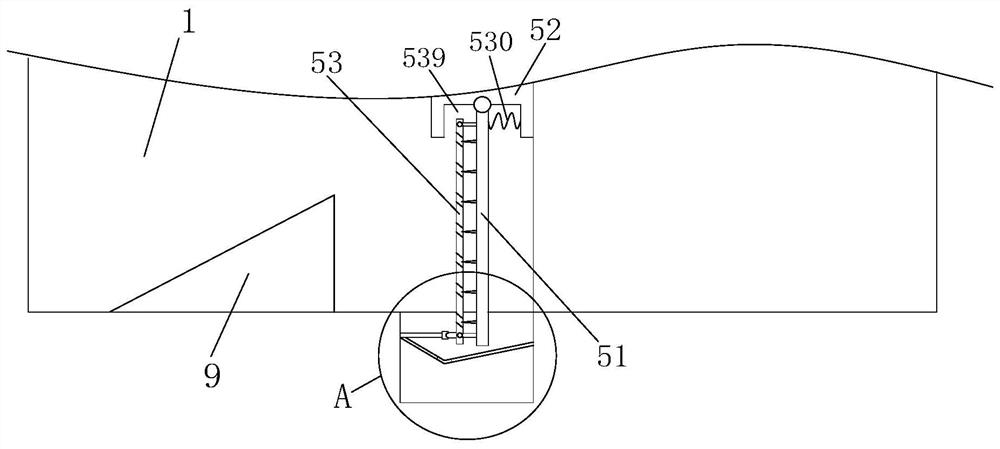

Self-adjusting bolt device and method for strengthening layered wading rock mass in hydrofluctuation zone

ActiveCN112160319BStress real-time monitoringGuaranteed stability and securityMeasurement devicesSpraying apparatusSoil scienceFoaming agent

The invention discloses a self-adjusting bolt device and a method for reinforcing a layered wading rock mass in a wading zone. The bolt is sleeved with a stress adjusting tray for applying tension force to it, and an external thread is processed on the bolt. , the outer thread is wound with a foaming agent conveying pipe for conveying the foaming agent, and the foaming agent conveying pipe is provided with a foaming agent ejection port for releasing the foaming agent; the outer thread is wound with an optical fiber , the anchor rod is pasted with a stress-strain sensor for monitoring the stress between the anchor rod and the rock mass and a water content detection sensor for monitoring the water content of the gap between the anchor rod and the rock mass; the stress-strain sensor is controlled by optical fibers and equipment The water content detection sensor is connected to the control end of the equipment through a signal line. This bolt can monitor the stress between the bolt and the rock mass in real time, obtain the way of rock mass failure, and fill in the adjacent rock mass that loses the middle thin layer in time.

Owner:CHINA THREE GORGES UNIV

A high-pressure rotary grouting pile drill bit based on the application of road and bridge construction

ActiveCN111155933BImprove functionalityAdjustable lengthEarth drilling toolsDrill bitsStructural engineeringSlurry

The invention discloses a high-pressure rotary grouting pile drill bit based on the application of road and bridge construction, which includes a rod body and a conical head. components; the outer wall of the rod body is also provided with a number of drill blades, when the movable assembly moves towards the direction of the cone head, the movable assembly can push the drill blades to move away from the rod body, and the side walls of the drill blades facing the direction of the cone head There is a baffle; there is also a telescopic tube in the cavity of the rod body, one end of the telescopic tube is connected with the slurry delivery pipe, and the other end is provided with a joint. One end of the assembly is facing the drill blade, and the other end is located in the cavity of the rod body. The invention can adjust the diameter of the pile hole drilled by the drill bit to meet different use requirements, and at the same time ensure that the drill bit can prevent the mud and stones in the soil from blocking the slurry delivery pipe during the drilling process, thereby improving the construction efficiency.

Owner:SHANGHAI YUANFENG UNDERGROUND ENG TECH

Air heater special for car washer

PendingCN114312678AImprove drying efficiencyEasy to sprayCleaning apparatus for vehicle exteriorsThermodynamicsAir volume

The invention relates to the technical field of automatic car washers, in particular to a special air heater for a car washer. The air heater special for the car washing machine comprises an air heater body and an air blowing device, an air outlet device comprises a cleaning fluid injection part and an air blowing part, the bottom of the cleaning fluid injection part is in through connection with the middle of the air blowing part, a first air outlet is formed in the lower end of the air blowing part, and a second air outlet is connected to the lower side of the air blowing part. The first air outlet is provided with an air volume adjusting assembly, and the second air outlet is provided with a sealing assembly. The air blower is connected with the air blowing device, the lower portion of the air blowing device is connected with the first air outlet and the second air outlet, the air outlet area of the first air outlet can be adjusted, redundant water on the surface of an automobile is blown away through the first air outlet, the remaining water on the surface of the automobile is blow-dried through the second air outlet, and the drying efficiency of the automobile washing machine can be greatly improved.

Owner:车泊喜智能科技(山东)有限公司

Electric self-travelling multi-function film sprayer nozzle

PendingCN109967280ALight in massEnhances fluidity and water pressureLiquid spraying apparatusEngineeringMultiple function

The invention discloses an electric self-travelling multi-function film sprayer nozzle. The electric self-travelling multi-function film sprayer nozzle comprises a main pipe, a supporting arm, and a moving seat, a bearing sleeve is welded to the bottom end of the supporting arm, the bearing sleeve is connected to the surface of the main pipe in a sleeving mode, the bearing sleeve keeps the relative movable connection with the main pipe, the end of a moving arm is connected to the top end of the supporting arm through a rivet, and a round head is arranged at the other end of the moving arm; andthrough heads are respectively arranged at the two ends of the main pipe, a thread is formed in the inner side of each through head, a connecting pipe and a hose are respectively connected with the threads in a matched mode, and a primary scraping filtering mechanism and a secondary scraping filtering mechanism are arranged in a duckbilled head. Compared with an existing film sprayer nozzle, thespraying direction of the nozzle can be effectively controlled, meanwhile, the water pressure of the nozzle is higher, the fact that the spraying mist is uniform and powerful can be ensured, more importantly, the impurities in the fluid liquid-state film can be effectively removed, and the nozzle blocking due to the accumulation cannot happen.

Owner:GANSU HUARUI AGRI

A Y-shaped tee injection mold with simple ejection structure

Owner:佛山市科硕精密注塑有限公司

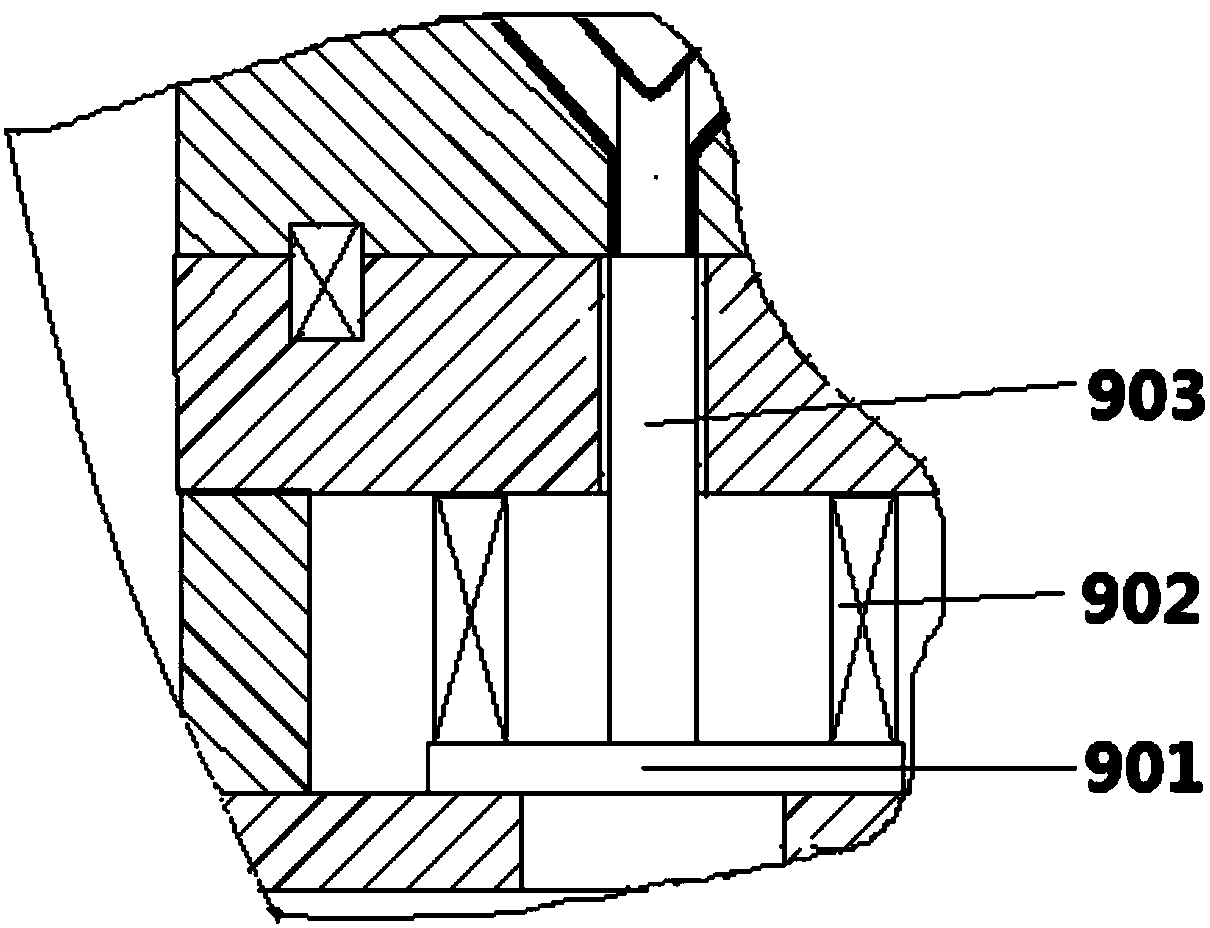

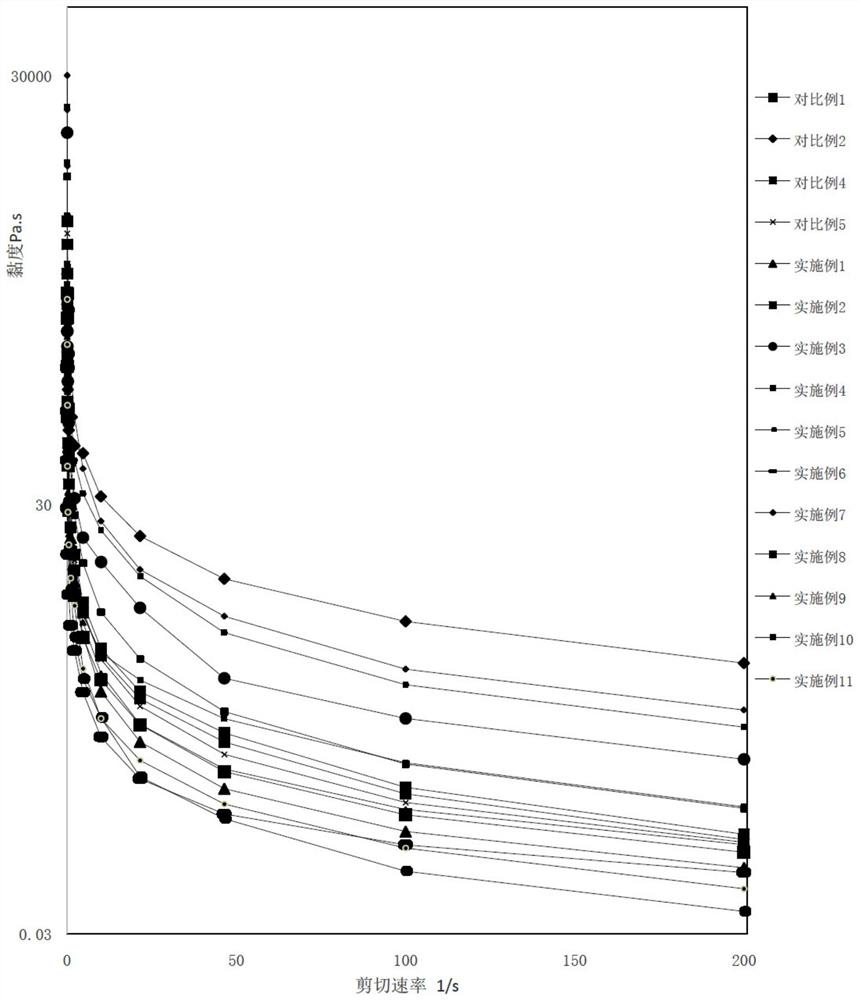

Spray emulsion product containing silicate and sodium surfactin and preparation method thereof

ActiveCN113712827ASolve the problem of not being able to sprayHigh viscosityCosmetic preparationsToilet preparationsSurfactinOil phase

The invention belongs to the field of daily cosmetics, and discloses a spray emulsion product and a preparation method thereof, and the spray emulsion product contains silicate and sodium surfactin. The invention provides a high-viscosity emulsion product in a spray form for the first time, sodium surfactin and silicate raw materials are introduced into the emulsion product, the problem that the emulsion cannot be sprayed out due to high viscosity is solved, the traditional thinking mode that only hydrophilic raw materials or only low-viscosity flowing liquid can be sprayed is broken, and the emulsion is endowed with good stability; meanwhile, the spray emulsion as an emulsion product can contain an oil phase, so that more oil-soluble functional active matters can be applied to a spray formula, and the defect that an existing water-based emulsion product must be matched with a grease-containing product for use is overcome.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD

Jet-type flow detection device for medical instruments

ActiveCN105698878BGuaranteed ejectionImprove stabilityVolume/mass flow by differential pressureJet flowMiniaturization

Owner:JIANGSU YUYUE MEDICAL EQUIP&SUPPLY CO LTD +3

Waste collection device for building materials

InactiveCN111940034ASolve the problem of production volumeAutomatic crush taskSievingScreeningArchitectural engineeringWaste collection

The invention discloses a waste collection device for building materials, relates to the technical field of waste collection, and provides the following scheme for solving the problems that existing building waste cannot be crushed and classified in time, and the dust generation amount in the waste treatment process cannot be reduced. The waste collection device comprises a base, and two first rotating shafts are rotatably connected to the interior of the base; a first roller is fixedly arranged at the outside of the first rotating shafts in a sleeving mode; a first conveying belt is arrangedoutside the first roller in a sleeving mode; a first collecting box is fixedly connected below the first conveying belt; a first bevel gear is fixedly arranged at the outside of the first rotating shaft located on the left side in a sleeving mode; and a second roller is fixedly arranged at the outside of the first rotating shaft in a sleeving mode. According to the waste collection device for thebuilding materials provided by the invention, automatic grinding can not only be achieved, the collection and classification of the building waste are facilitated, but also the waste is automaticallyconveyed to the collecting box, thus manual transportation is avoided, manpower is saved, water spraying is continued, and a large amount of dust is avoided.

Owner:安徽宝润环保节能建材有限公司

Intelligent electronic oral cavity and laryngopharynx surface anesthesia atomizer

InactiveCN101264362BIntelligent pressure controlFast and accurate pressure regulationAnaesthesiaMedical atomisersThroatSprayer

The invention relates to an intelligent electronic anesthesia sprayer for the surface of oral and throat, belonging to the equipment of medical service, which at least comprises a medical solution bottle (4), an oil-free compressor (2), a nozzle (7), an intelligent controller (3) and a variable-frequency motor (1). The intelligent electronic anesthesia sprayer is characterized in that: an intake interface (408) of the medical solution bottle compressor, a medical solution outgoing interface (401), and an oxygen outgoing interface (403) are arranged on the medical solution bottle (4); the oil-free compressor (2), a hose for air or oxygen passing through are connected with the intake interface (408) of the medical solution bottle compressor; the nozzle (7) is communicated with the medical solution outgoing interface (401) and the oxygen outgoing interface (403); the intelligent controller (3) is used for measuring the pressure in the medical solution bottle (4) and comparing with the preset pressure value, to computer the output voltage value to control the rotational speed of the variable-frequency motor (1); the variable-frequency motor (1) is used for controlling the output work of the oil-free compressor (2) according to the output voltage of the intelligent controller (3). The intelligent electronic anesthesia sprayer has the advantages of convenient use, short operation time, controllable spray medical solution, and ability to continuously and uniformly spray foggy medical solution.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

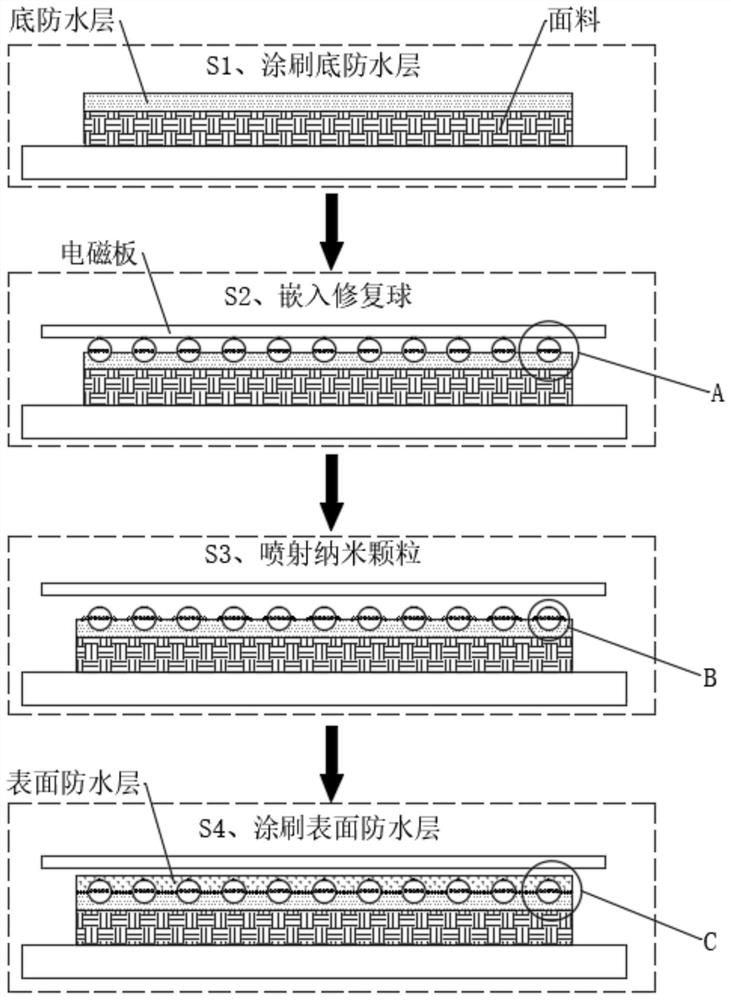

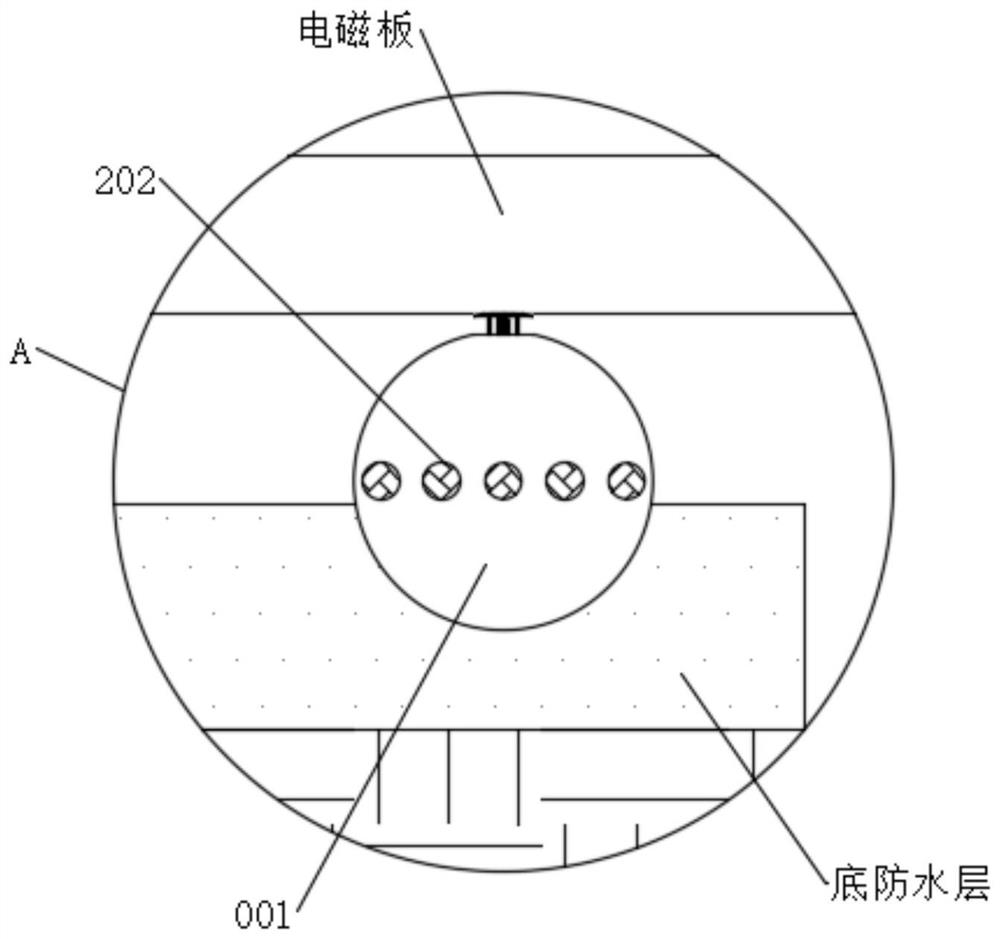

Coating process of self-eruption type nano waterproof coating

InactiveCN113304976AImprove waterproof performanceGuaranteed waterproof performancePretreated surfacesSpecial surfacesNanoparticleEngineering

The invention discloses a coating process of a self-eruption type nano waterproof coating, and belongs to the technical field of coating process. The coating process of the self-eruption type nano waterproof coating is creatively provided with an eruption repairing ball, in the coating process, under an action of magnetic repulsive force between an electromagnetic plate and a linkage magnet, an elastic ball bag can be extruded to spray out hydrophobic nanoparticles, and the hydrophobic nanoparticles are sprayed out; therefore, a layer of the hydrophobic nanoparticles is automatically laid between a surface waterproof layer and a bottom waterproof layer, waterproof performance of the waterproof layers can be remarkably improved, when the surface waterproof layer is locally damaged, the linkage magnet can drive a material pressing piston plate and a flexible rubber sheet to move upwards and extrude waterproof paint under driving of elastic force of the elastic ball bag, so that the waterproof coating flows out from the top end of a material guide pipe and flows to a damaged part of the waterproof layer along the surface of the top end of a sealing cover plate to fill and repair the damaged part, so that the damaged part can be repaired in time, the waterproof performance of the fabric is guaranteed, and the damaged part can be effectively prevented from being further expanded.

Owner:龚海军

Drip-proof sprayer nozzle

The invention relates to the technical field of sprayers, and discloses a drip-proof sprayer nozzle. The drip-proof sprayer nozzle comprises a connecting pipe, wherein one end of the connecting pipe communicates with a nozzle; the drip-proof sprayer nozzle is characterized in that a filter screen is further arranged at one side, close to the nozzle, of the interior of the connecting pipe; a filter ring communicating with the connecting pipe is arranged in the middle of the connecting pipe; and a filter assembly is rotationally connected to the interior of the filter ring, and the filter assembly comprises filter fan blades rotationally arranged in the filter ring. According to the drip-proof sprayer nozzle, liquid to be sprayed out through the nozzle can be filtered in the using process, impurities in the liquid are prevented from blocking a nozzle hole of the nozzle, in the filtering process, filter plates and the filter fan blades are impacted through water flow to drive the filter plates to rotate, and when the filter plates rotate to the lower end, under the action of a sliding base and a protruding block, the filter plates swing, and impurities blocked in filter tanks are pushed out and fall into a partition plate under the action of ejector pins, so that dripping caused by blockage of the nozzle hole of the nozzle is avoided.

Owner:余姚市杰明喷雾器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com