Coating process of self-eruption type nano waterproof coating

A waterproof coating and coating process technology, applied in the direction of coating, device for coating liquid on the surface, surface pretreatment, etc., can solve the problems of poor waterproof performance, poor waterproof effect of fabrics, etc. The effect of ensuring waterproof performance and improving practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

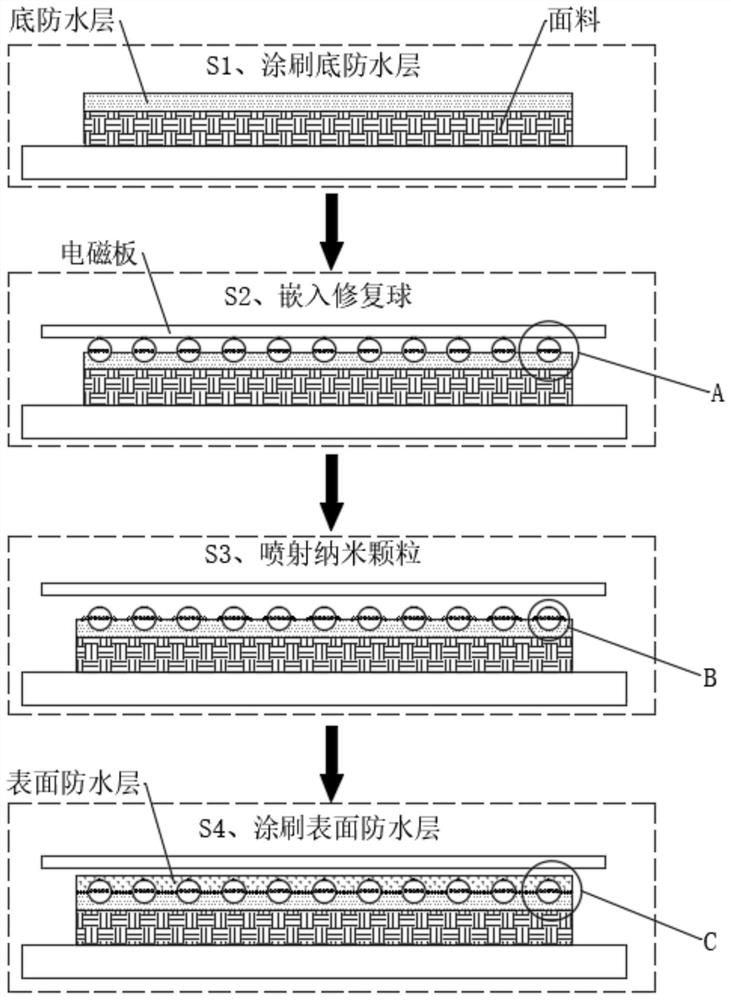

[0045] see Figure 1-4 , a coating process for a self-spraying nanometer waterproof coating, comprising the following steps:

[0046] S1. Brushing the bottom waterproof layer: place the fabric flat, and paint a layer of waterproof paint on the surface of the fabric as the bottom waterproof layer;

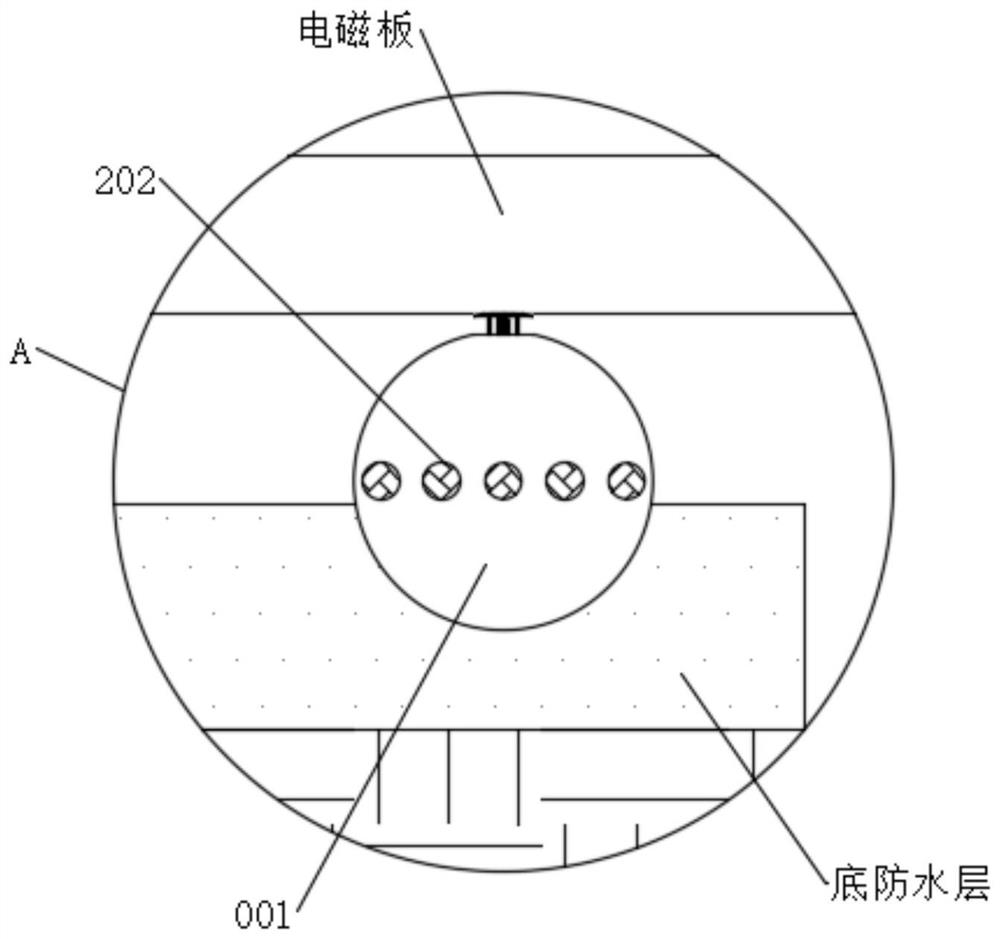

[0047] S2. Embedding repair balls: Before the bottom waterproof layer is solidified, power on the electromagnetic board, so that multiple spray repair balls 001 are evenly arranged on the bottom of the electromagnetic board under the action of magnetic attraction, and press down on the electromagnetic board to spray materials The repair ball 001 is embedded in the bottom waterproof layer;

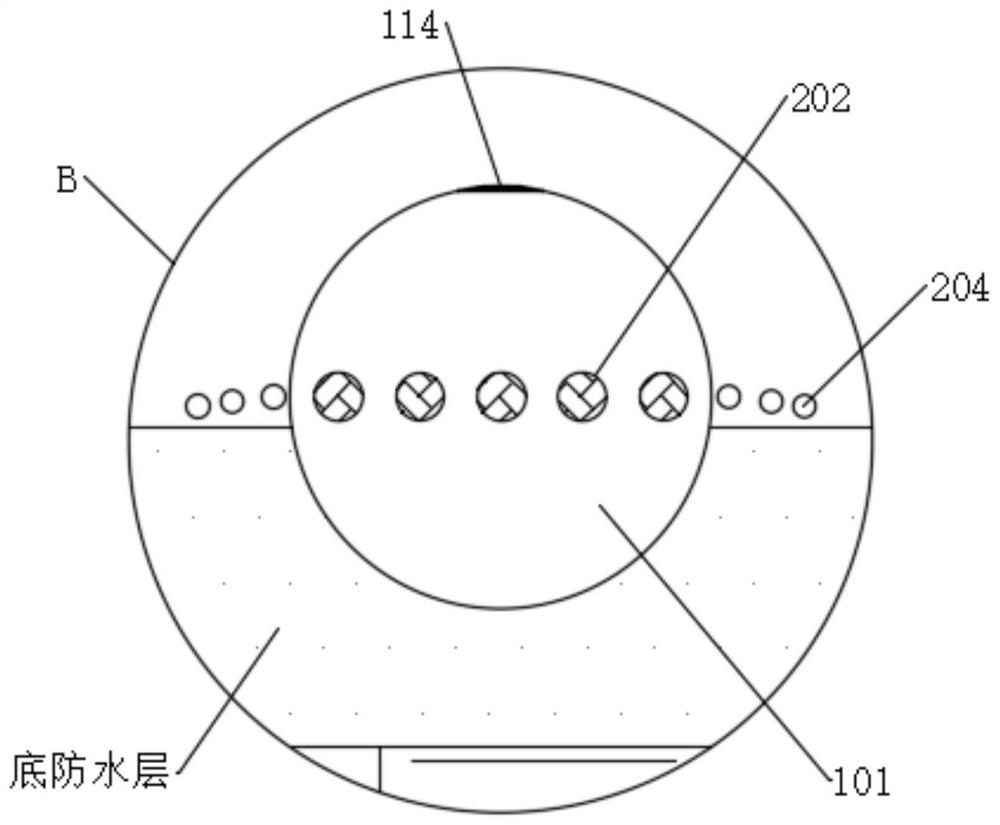

[0048] S3. Spraying nanoparticles: After the bottom waterproof layer is solidified and formed, change the direction of the current to reverse the polarity of the electromagnetic plate, and under the action of magnetic repulsion, make the spray repair ball 001 spray hydrophobic nanoparticles 204 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com