Novel cyclone atomizing device for pulverized-coal burner

An atomization device and pulverized coal technology, which are applied to burners, burners, combustion methods and other directions for burning powder fuels, can solve problems such as the inability to meet various process requirements, and achieve improved atomization effect, combustion efficiency, and stability. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

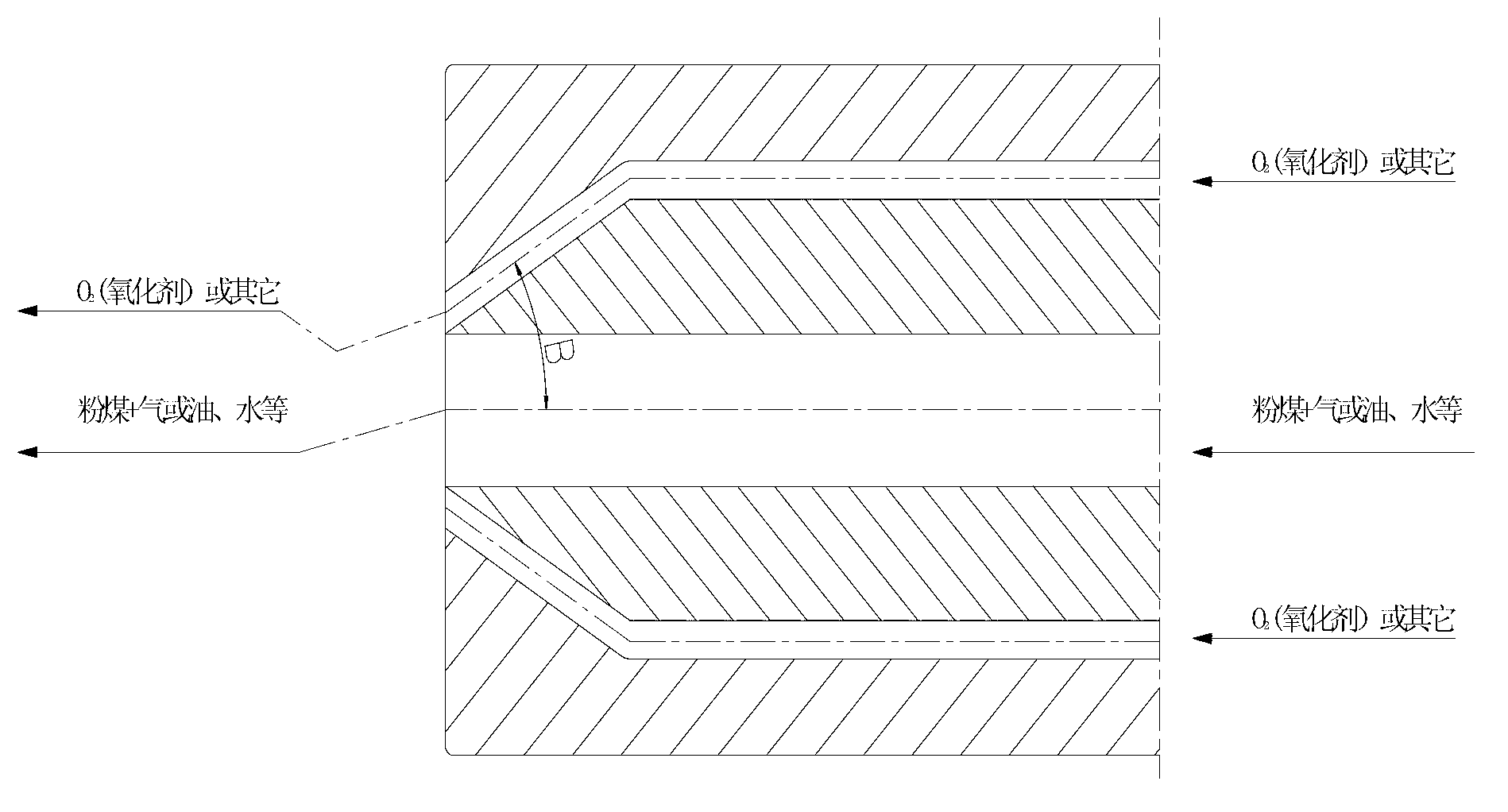

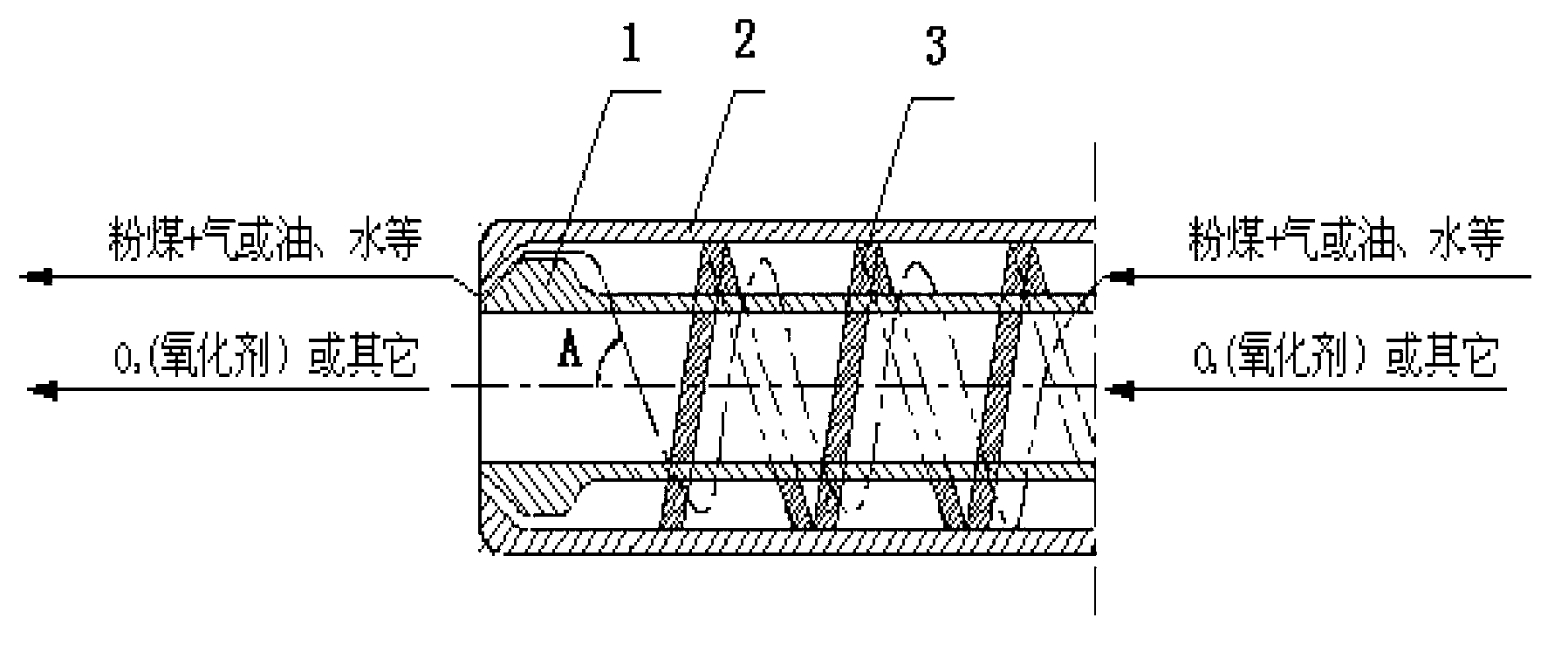

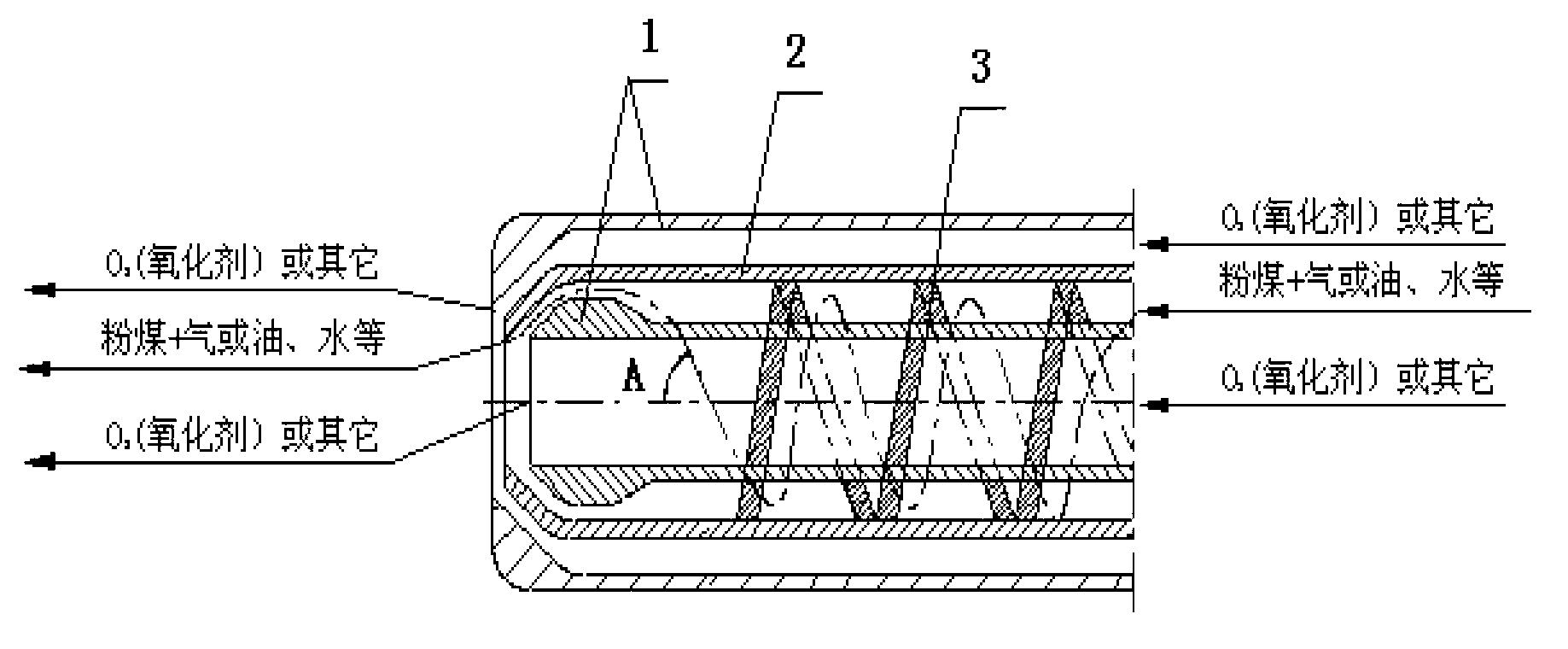

[0017] A new type of pulverized coal burner swirling atomization device has two implementation modes, the first mode is as follows diagram 2-1 As shown, the spiral partition 3 is distributed between the outside of the oxygen pipe 1 and the inside of the pulverized coal pipe 2, so that several swirl structures are formed in the pulverized coal passage, so that the medium such as pulverized coal or oil flows along the spiral partition. The space channel defined by 3 rotates and flows at an angle A. Angle A is the angle formed between the spiral partition 3 and the center line of the burner body, and is between 10° and 80°. At the same time, the oxygen pipe 1 is equipped with an arc-shaped boss at the outlet, so that the pulverized coal channel at the outlet shrinks and becomes smaller, so as to increase the speed of pulverized coal or oil and other media after they are ejected from the burner body, so that the media can be more powerfully connected with oxygen. (Oxidant) etc. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com