A method of using high-pressure rotary grouting pile nozzles for road and bridge construction

A technology of high-pressure rotary grouting piles and nozzles, which is applied in the direction of drill bits, sheet pile walls, earthwork drilling and mining, etc. It can solve the problems of manpower and time consumption, cement slurry cannot flow out normally, and reduce construction efficiency, so as to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

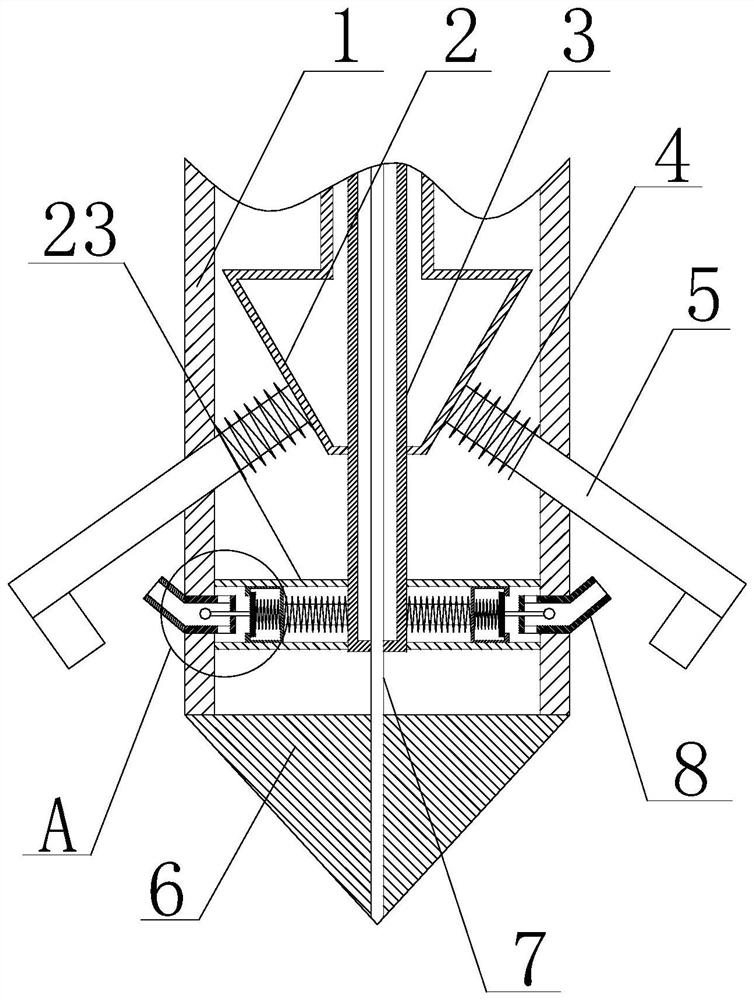

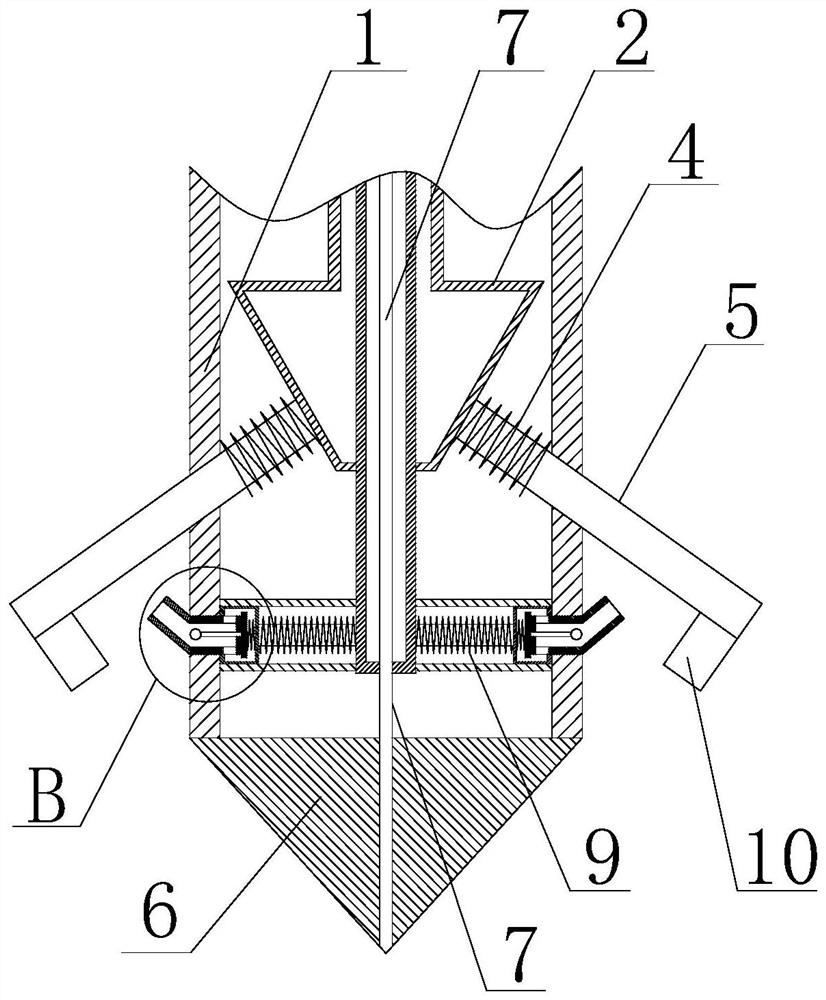

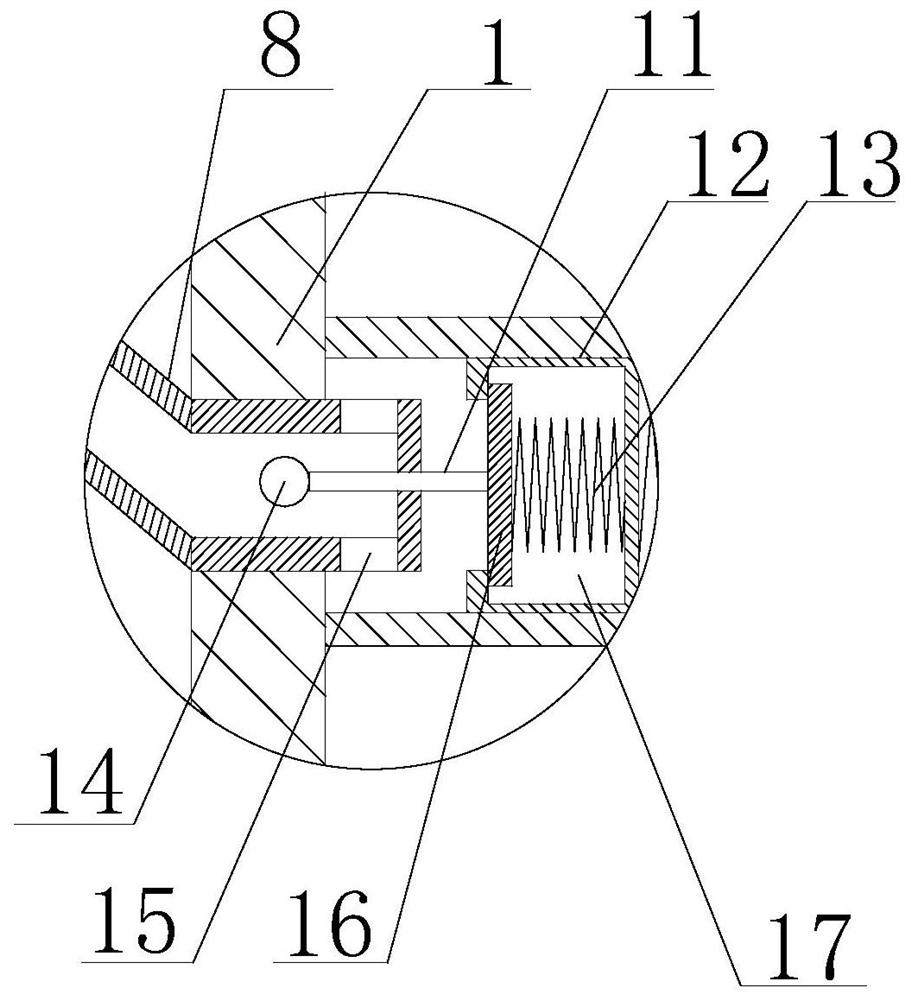

[0055] Such as Figure 1 to Figure 5 shown, including the following steps:

[0056] 1) Install the rod body 1 on the high-pressure rotary grouting pile machine;

[0057] 2) Use a water pump to feed high-pressure water into the liquid storage chamber 21 of the cone 22, and the high-pressure water pushes the movable assembly to move along the axial direction of the slurry delivery pipe 3, and pushes the drill blade 5 to extend out of the rod body 1;

[0058] 3) Adjust the protruding length of the drill blade 5 according to the inner diameter of the pile hole to be drilled;

[0059] 4) Use the high-pressure rotary grouting pile machine to drive the drill bit to rotate, and carry out drilling operations on the soil;

[0060] 5) When the cone head 6 needs to expand the inner diameter of the pile hole during the drilling process, continue to inject high-pressure water into the liquid storage chamber 21 of the cone 22 to force the cone 22 to push the drill blade 5 to protrude outwa...

Embodiment 2

[0069] On the basis of Embodiment 1, the movable assembly 2 includes a conical member 22 and a connecting pipe 20, the conical member 22 is located at the bottom of the connecting pipe 20, and a liquid storage cavity 21 is arranged in the conical member 22, and the liquid storage The cavity 21 communicates with the connecting pipe 20, and the slurry delivery pipe 3 is inserted through the connecting pipe 20 and the liquid storage chamber 21 in sequence.

Embodiment 3

[0071] On the basis of Embodiment 1, the drill blade 5 is further provided with a first elastic member 4 , and the first elastic member 4 is sleeved on the drill blade 5 and located in the cavity of the rod body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com