Ultrasonic-atomizing heat-decomposing compound semiconductor film preparing system

A technology of thin film preparation and ultrasonic spraying, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of non-dense film formation, uneven thickness, uneven mixing, etc., and achieve improved stability and improved Purity, the effect of improving film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

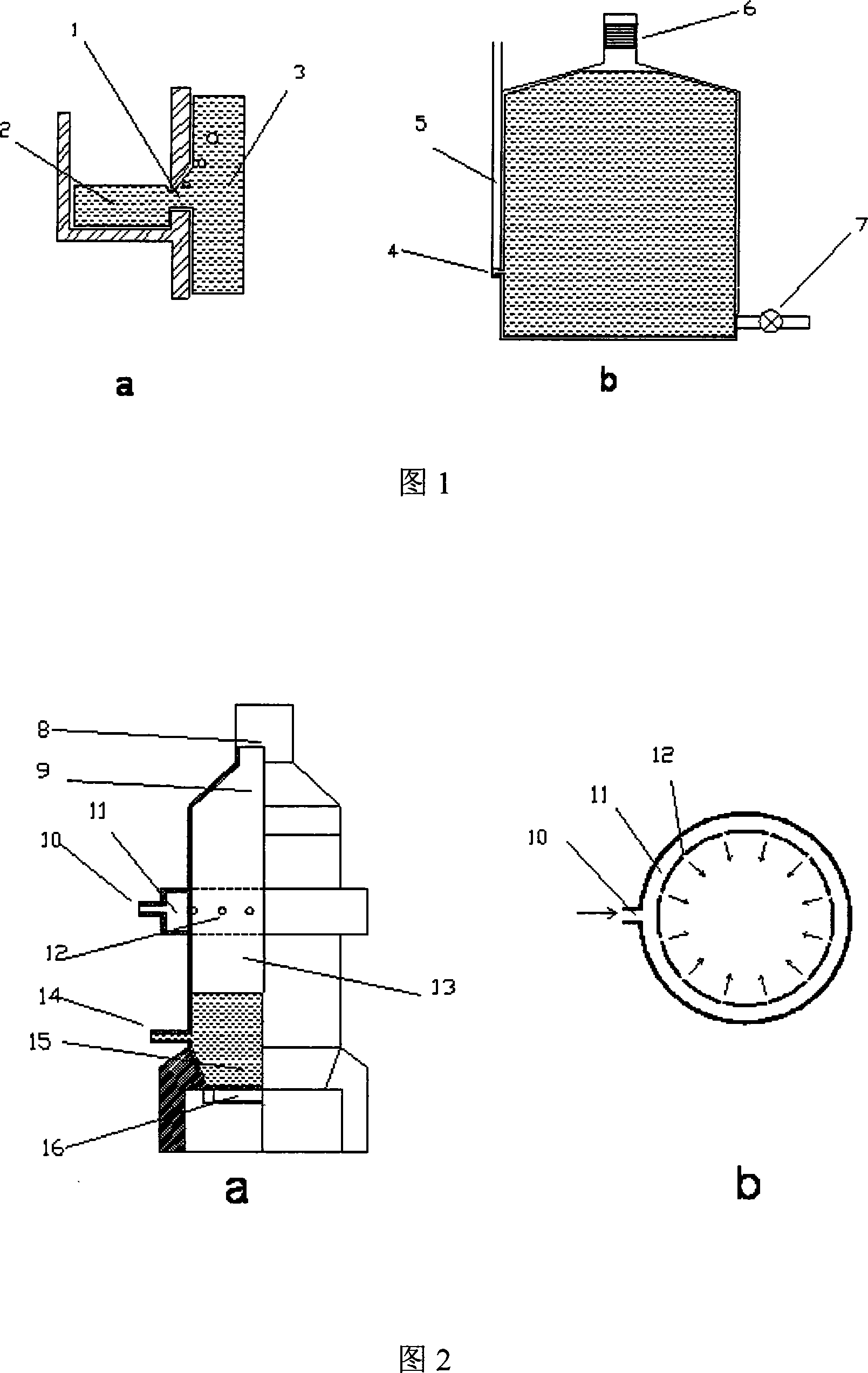

[0030] Example 1, the preparation of ZnO thin film (do not remove air influence)

[0031] Preparation of precursor solution: configure 0.05mol L -1 of zinc acetate ((CH3COO) 2 Zn) aqueous solution 200ml. Close the liquid outlet 7 of the liquid storage tank, open the liquid inlet 6, pour in the solution, do not fill it up, and leave a small amount of gas at the top. Seal the liquid inlet 6. After opening the valve 22 of the liquid outlet 7, the solution will flow into the atomization chamber 24, and the liquid level at the upper end of the liquid storage tank 21 will drop to generate a negative pressure. The height of the liquid level (that is, the distance from the atomizing sheet 16 to the liquid level) is 3 cm.

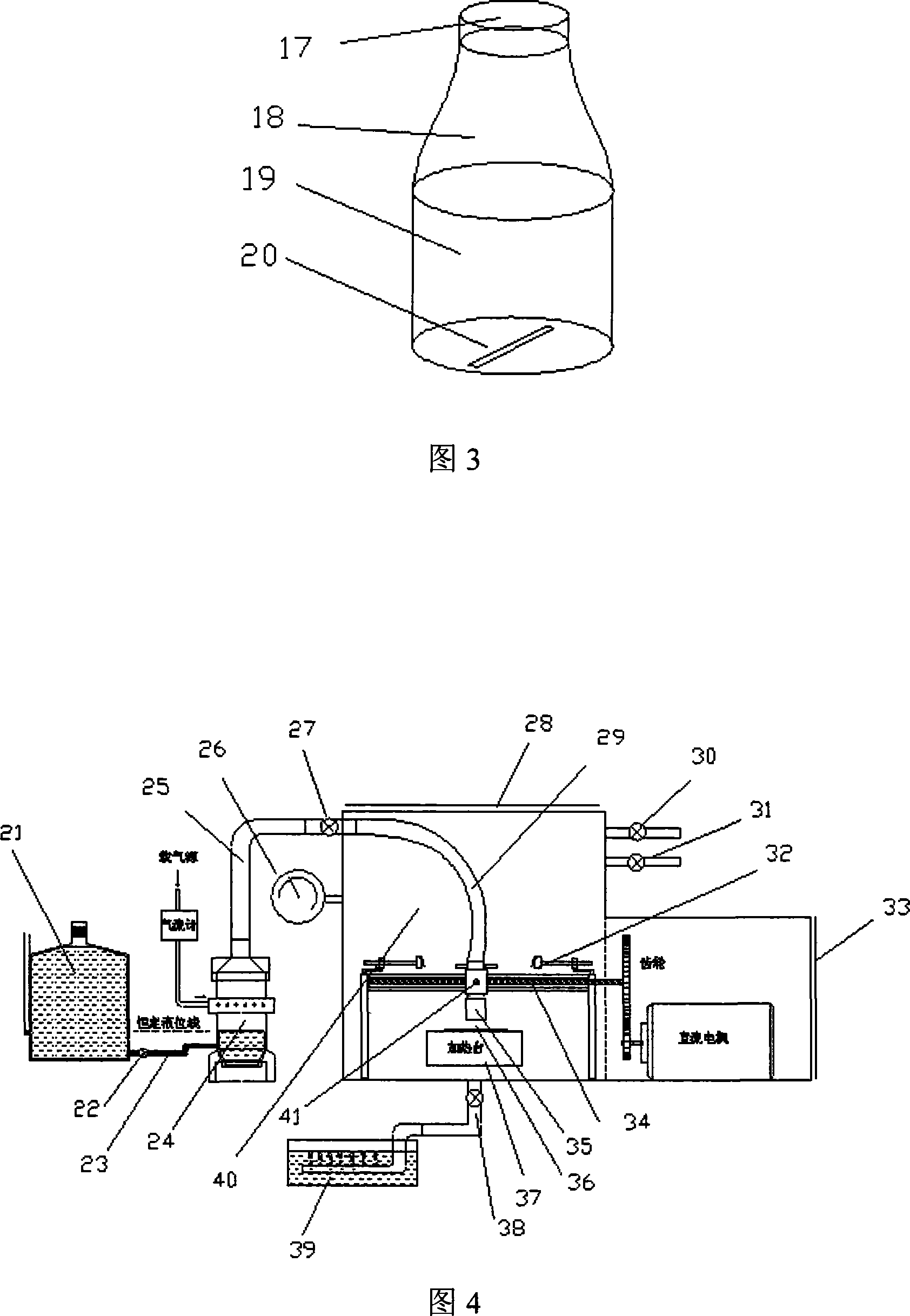

[0032] Thermally decomposed coating: place the substrate 36 (ITO conductive glass, 20 mm×20 mm×1 mm in size) with the conductive side upward on the heating table 37 and fix it. The position of the limit switch 32 is adjusted with reference to the substrate 36 s...

example 2

[0033] Example two, the preparation of CdS thin film (exhausting air to remove the influence of oxygen)

[0034] Preparation of precursor solution: configure cadmium chloride (CdCl 2 ) (concentration is 0.05mol / L) thiourea ((NH 2 ) 2 CS) (concentration of 0.055mol / L (10% excess)) aqueous solution. The process of loading the precursor solution is the same as that of Example 1.

[0035] Air removal: first open the upper operation opening 28 of the deposition chamber 40 to place the substrate 36 and adjust the position of the limit switch 32 in the same manner as Example 1, and then close the upper operation opening 28 of the deposition chamber 40. Close the pumping port 30 and the air inlet 31 valves, open the gas mist inlet 27, the waste gas outlet 38 valves, open the carrier gas, and adjust to a certain flow rate (0.16m 3 / h) Purging the atomization chamber 24 and the aerosol delivery pipe 25 for ten minutes to remove the air in the atomization chamber 24 and the aerosol d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com