Spray emulsion product containing silicate and sodium surfactin and preparation method thereof

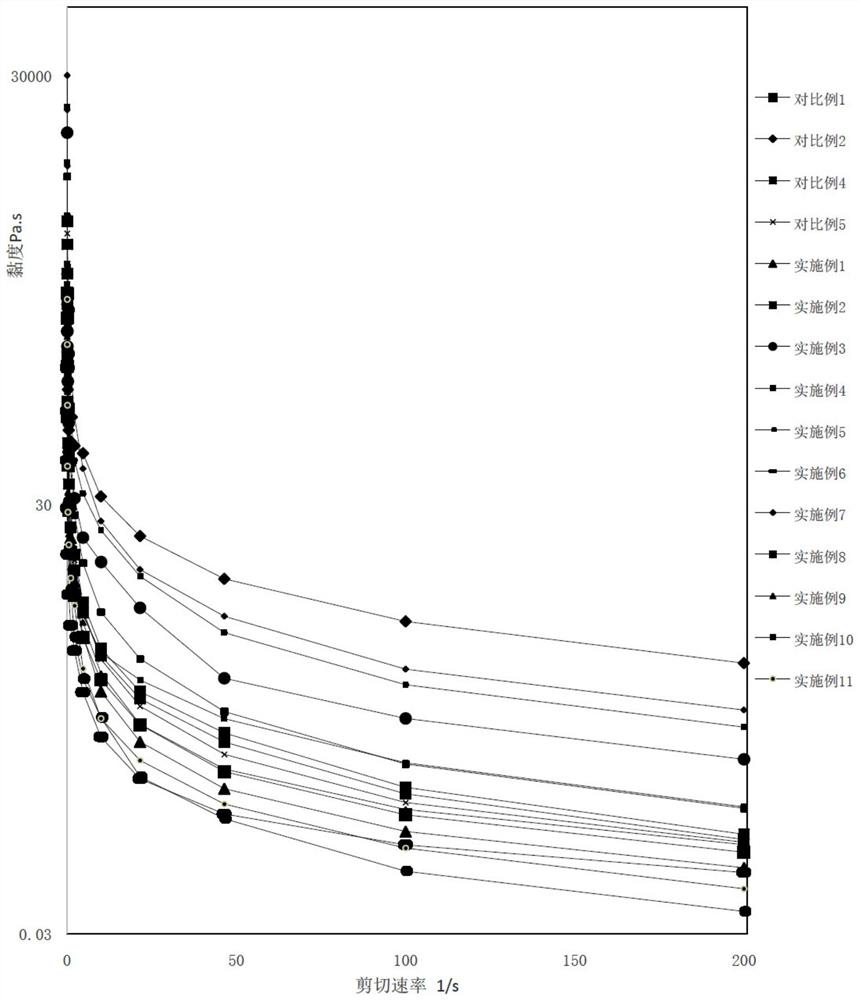

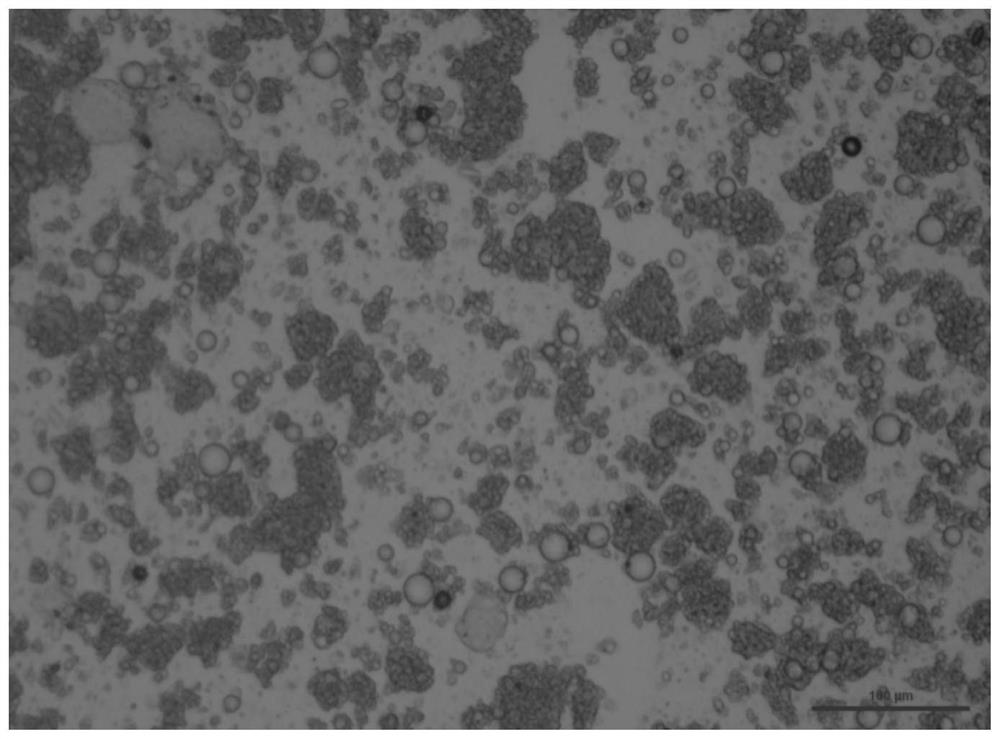

A technology of sodium subtilisin and silicate, which is applied in cosmetic preparations, preparations for skin care, cosmetics, etc., can solve the problems of high emulsion viscosity and cannot be sprayed, and achieves small emulsion particle size, easy absorption, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

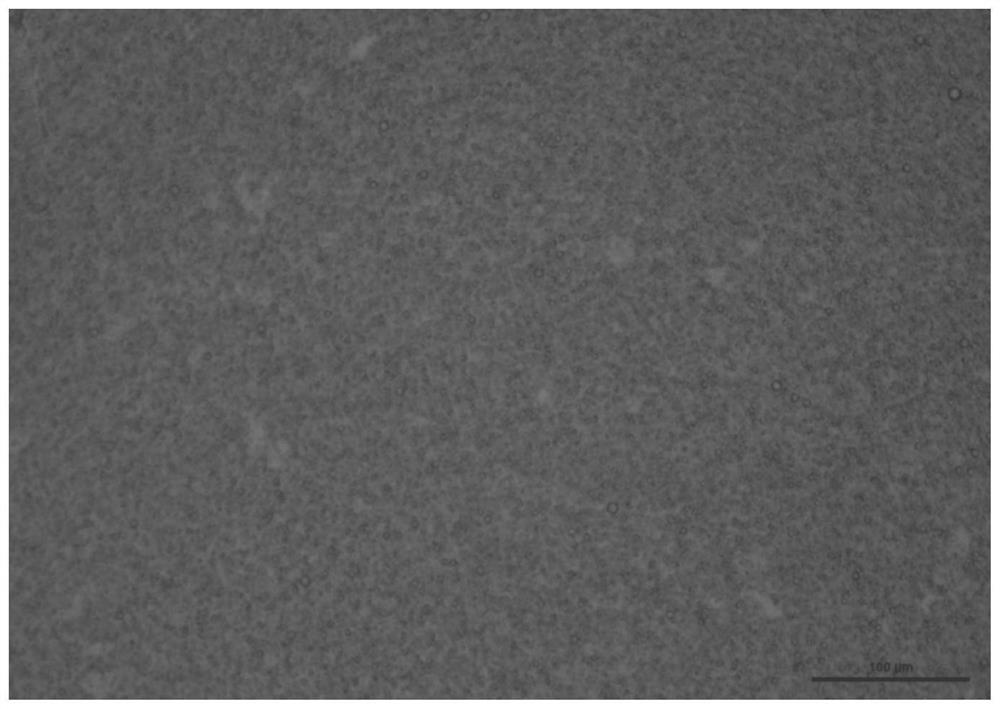

Examples

Embodiment 1

[0045](1) Weigh 0.5 g of subtilisin sodium powder, add it to 10 g of glycerin and mix, slowly add 10 g of caprylic acid / capric triglyceride, stir well, form a uniform and stable liquid, and obtain phase A;

[0046] (2) At room temperature, weigh 77.5g of deionized water into a beaker, keep stirring, slowly add 2g of magnesium aluminum silicate, and wait until the powder is fully dispersed to form a uniform and stable liquid to obtain phase B;

[0047] (3) At room temperature, slowly add phase A to phase B and keep stirring until the mixed system becomes a uniform and stable 100g liquid. Fill it and let it stand for 10 minutes to form non-flowing solid milk (O / W).

Embodiment 2

[0049] (1) Weigh 0.5 g of subtilisin sodium powder, add it to 10 g of glycerin and mix, slowly add 10 g of caprylic acid / capric triglyceride, stir well, form a uniform and stable liquid, and obtain phase A;

[0050] (2) At room temperature, weigh 77.5 g of deionized water into a beaker, keep stirring, slowly add 2 g of sodium magnesium lithium silicate, and wait until the powder is fully dispersed to form a uniform and stable liquid to obtain phase B;

[0051] (3) At room temperature, slowly add phase A to phase B and keep stirring until the mixed system becomes a uniform and stable 100g liquid. Fill it and let it stand for 10 minutes to form non-flowing solid milk (O / W).

Embodiment 3

[0053] (1) Weigh 0.5 g of subtilisin sodium powder, add it to 10 g of glycerin and mix, slowly add 10 g of caprylic acid / capric triglyceride, stir well, form a uniform and stable liquid, and obtain phase A;

[0054] (2) At room temperature, weigh 74.5g of deionized water into a beaker, keep stirring, slowly add 5g of magnesium aluminum silicate, and wait until the powder is fully dispersed to form a uniform and stable liquid to obtain phase B;

[0055] (3) At room temperature, slowly add phase A to phase B and keep stirring until the mixed system becomes a uniform and stable 100g liquid. Fill it and let it stand for 10 minutes to form non-flowing solid milk (O / W).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com