Anti-wear injection device for resin molding

A resin molding and injection device technology, applied in the direction of coating, etc., can solve the problems of reducing the service life of the mold and the wear of the mold, and achieve the effects of prolonging the service life, improving smoothness and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

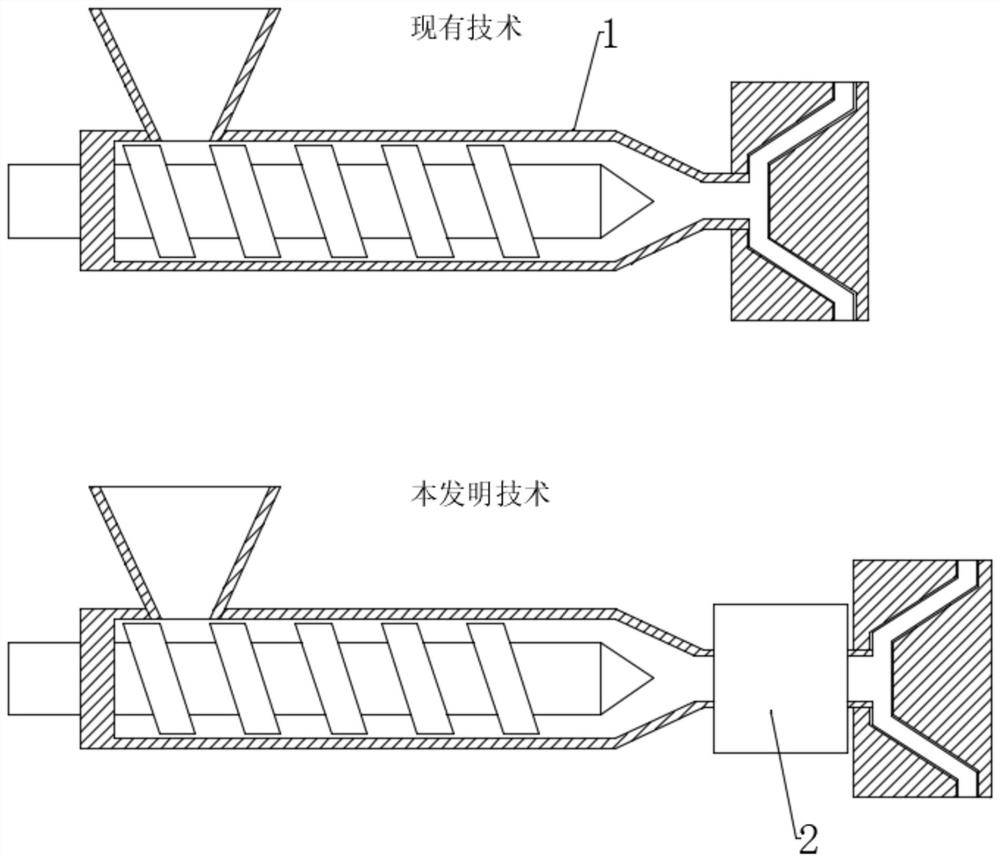

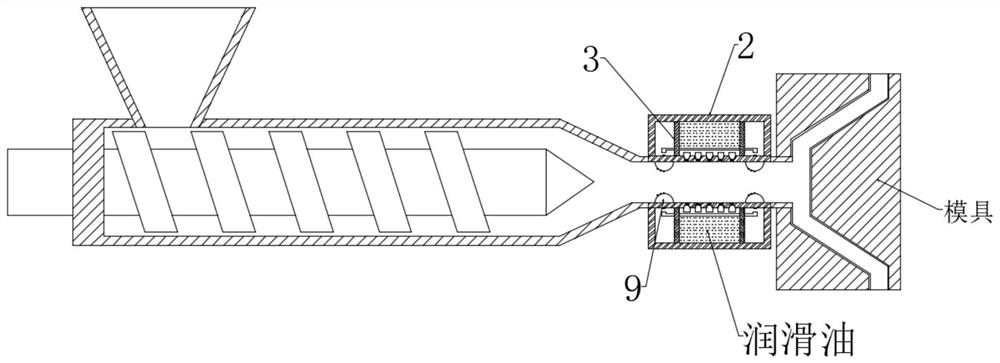

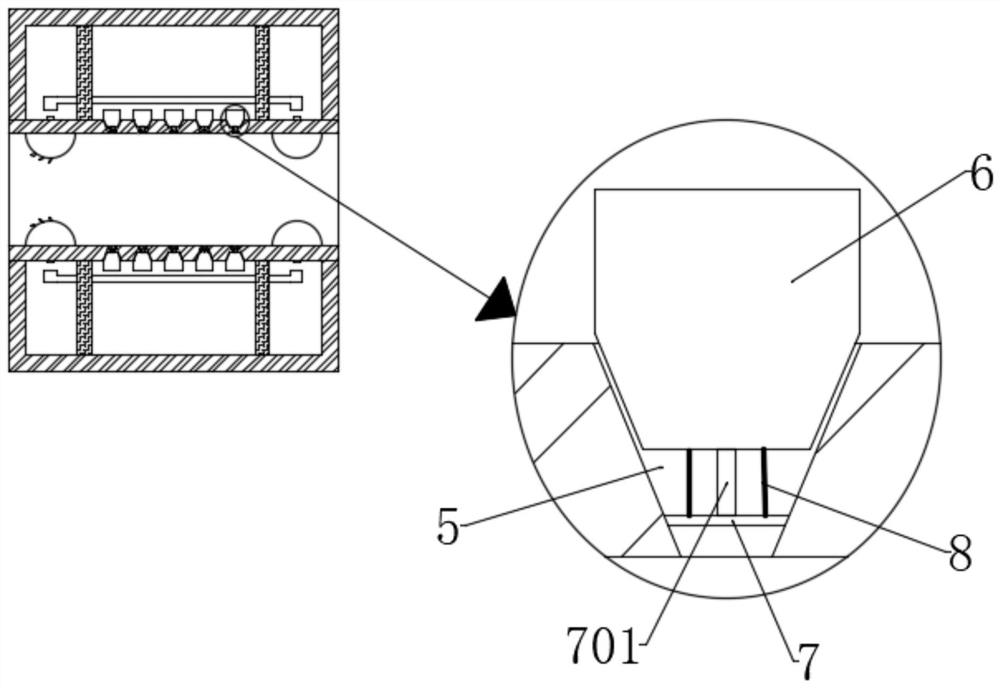

[0045] see Figure 1-8 , an injection unit for wear-resistant resin molding, see figure 1 , 2 , including an injection molding machine body 1 and a mould, and a wear-reducing processing part is communicated between the injection molding machine body 1 and the mould. There are two partitions 3, and lubricating oil is filled between the two partitions 3 (select the type that does not react with the resin, which can be selected according to actual needs), and the top of the shell 2 is equipped with an automatic oil supply system (because it is not There is technology, so it is not shown in the figure), it is for the convenience of real-time oil supply to the shell 2, the filling amount of lubricating oil inside the shell 2 is 80%-100%, because the shell 2 is cylindrical, in order to ensure that all The lubricating oil can flow out of the oil outlet 5 of the casing, so it is necessary to ensure that there is a sufficient amount of lubricating oil in the casing 2;

[0046] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com