Liquid distribution mixing device used for plate shell type heat exchanger

A heat exchanger and liquid distribution technology, applied in direct contact heat exchangers, heat exchanger types, water shower coolers, etc., can solve problems such as easy blockage of hole-shaped nozzles, achieve simple structure, not easy to block, and easy to manufacture convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention and its effects will be further described below in conjunction with the accompanying drawings.

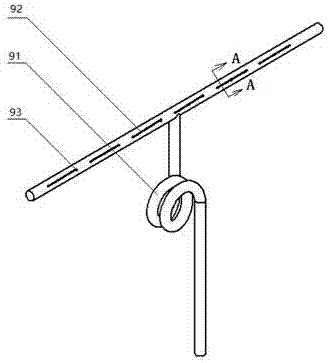

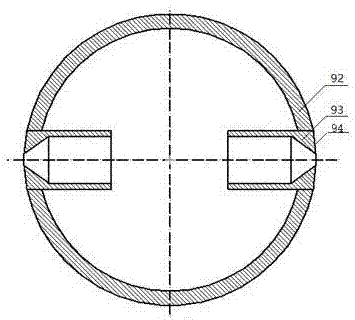

[0018] refer to figure 1 , 2 , a liquid distribution and mixing device for a plate-shell heat exchanger, comprising a liquid distributor 9 and an installation structure of the liquid distributor 9; The pipe 92 communicates with the liquid inlet pipe 91, the distribution pipe 92 is a hollow pipe with a symmetrical row of holes, and the built-in nozzle 93 is installed in the row of holes; the outlet of the built-in nozzle 93 is a long slit-shaped opening, and its end surface does not exceed the distribution The outer wall surface of the tube 92.

[0019] In order to make the flow of the fluid comfortable and the nozzle not easy to be blocked, the nozzle is designed as a long strip. At the same time, in order to facilitate processing and manufacturing, the built-in nozzle is designed as a simple structure consisting of upper and lower boards, and a thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com