Jet type flow detection device for medical instrument

A technology of flow detection device and medical instrument, which is applied in the direction of detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effect, etc., to achieve the effect of suppressing large error of flow signal, increasing stability and satisfying accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

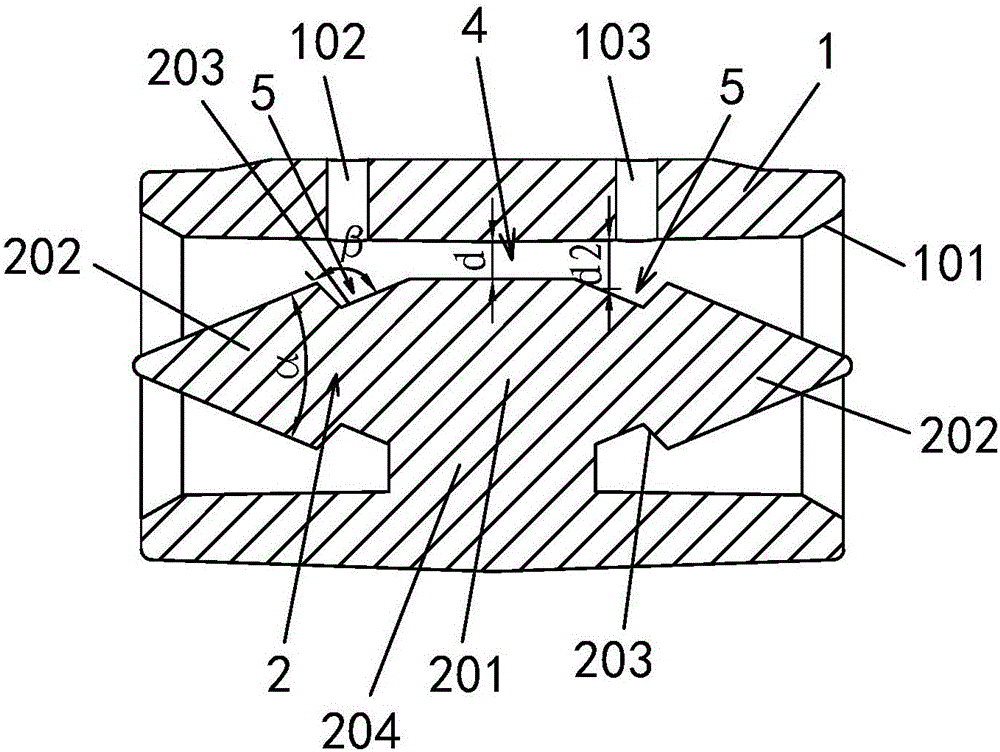

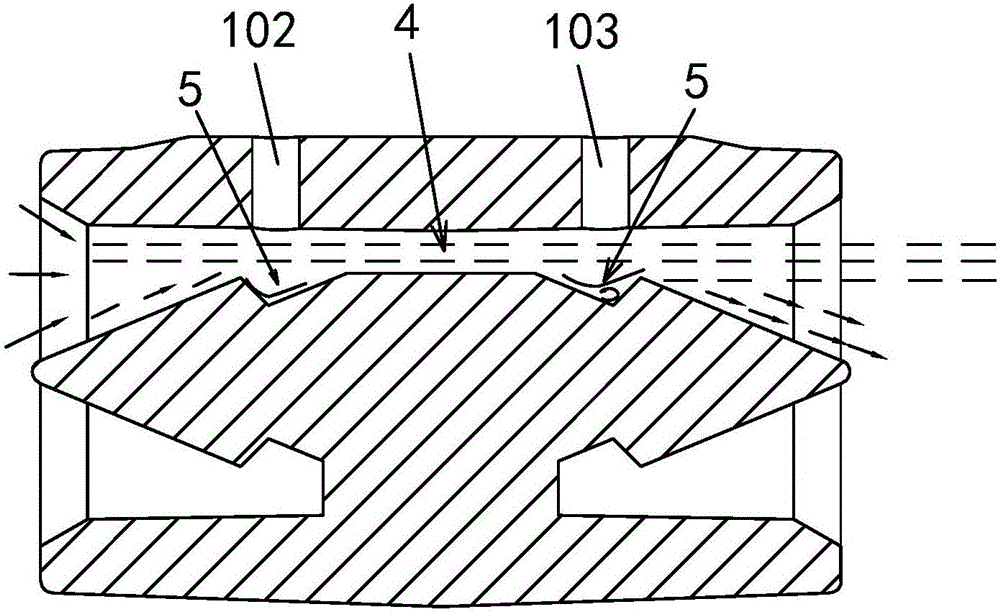

[0025] Embodiment one: see figure 1 and figure 2 Shown:

[0026] A spray flow detection device for medical instruments comprises a straight pipe body 1 and a spray body 2 arranged in the straight pipe body 1 .

[0027] see figure 1 As shown, the straight pipe body 1 is arranged along the fluid flow direction, and the spray body 2 includes a straight-segment-shaped middle part 201 and spray cones 202 located at both ends of the straight-segment-shaped middle part 201 in the fluid flow direction. Front and rear symmetry in the flow direction, the apex angle α of the spray cone 202 is 10°-50°, preferably 20-50°, and the best example is 22.5° or 45° 。 The injection body 2 is supported and connected to the inner wall of the straight pipe body 1 by one or more support ribs 204 . When there are multiple support ribs 204 , the plurality of support ribs 204 are evenly distributed in the circumferential direction of the straight pipe body 1 .

[0028] see figure 1 As shown, the ...

Embodiment 3

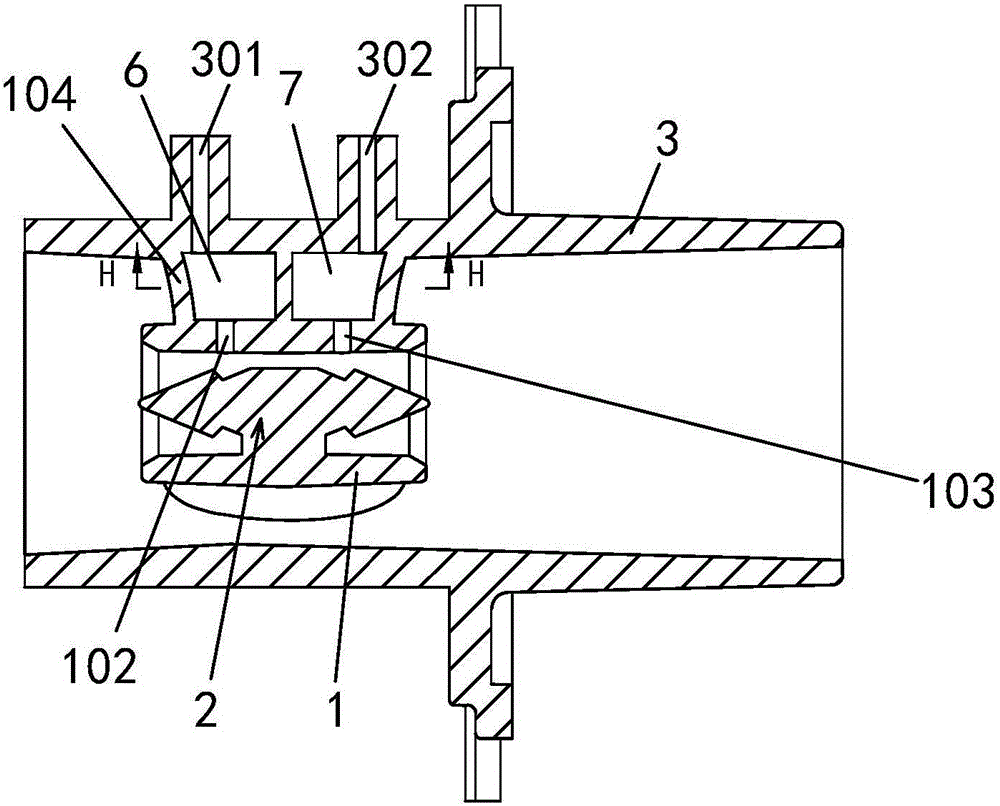

[0041] Embodiment three: see Figure 8 Shown:

[0042] A spray flow detection device for medical instruments comprises a straight pipe body 1 and a spray body 2 arranged in the straight pipe body 1 . The difference from the second embodiment is that a through hole 205 is opened in the center of the jet body 2 along the fluid flow direction as a flow channel, so that besides the flow channels on the periphery of the jet body, a flow channel is also added in the center of the jet body. The number of the through holes 205 is not limited, and may be multiple.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com