Patents

Literature

101 results about "Spray cone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vision-based automatic aviation oil mist nozzle atomization angle detection device and method

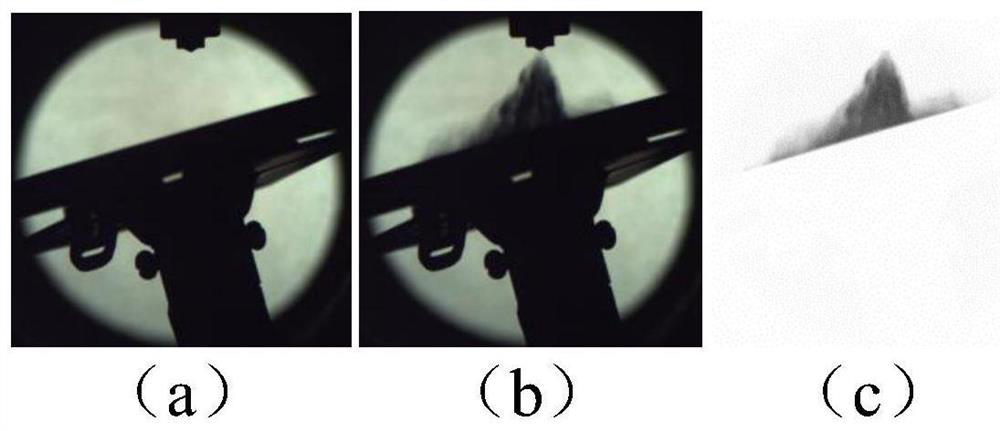

InactiveCN104634279AOpen up new fields of applicationAvoid randomnessUsing optical meansHough transformAviation

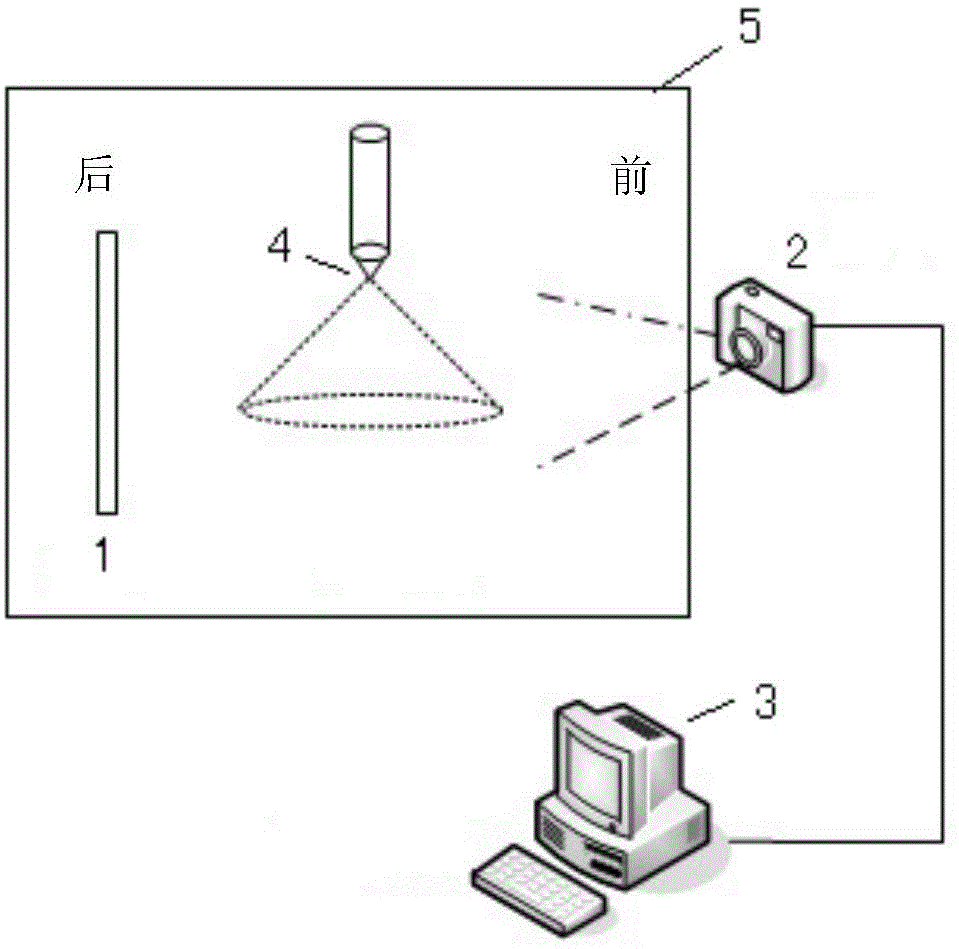

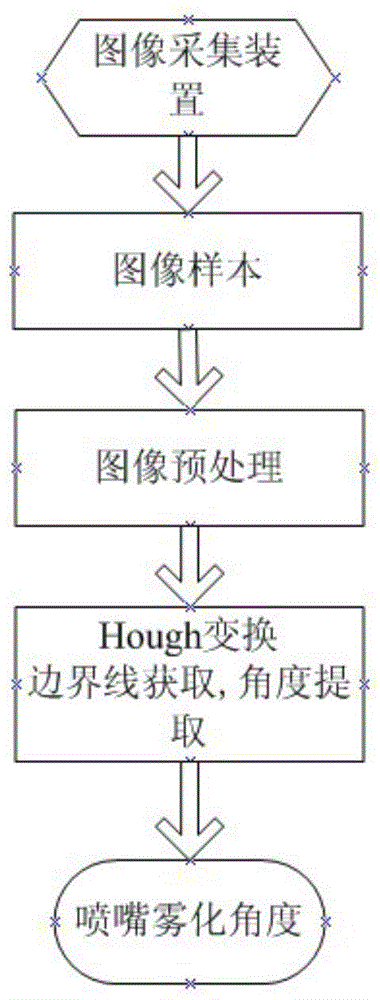

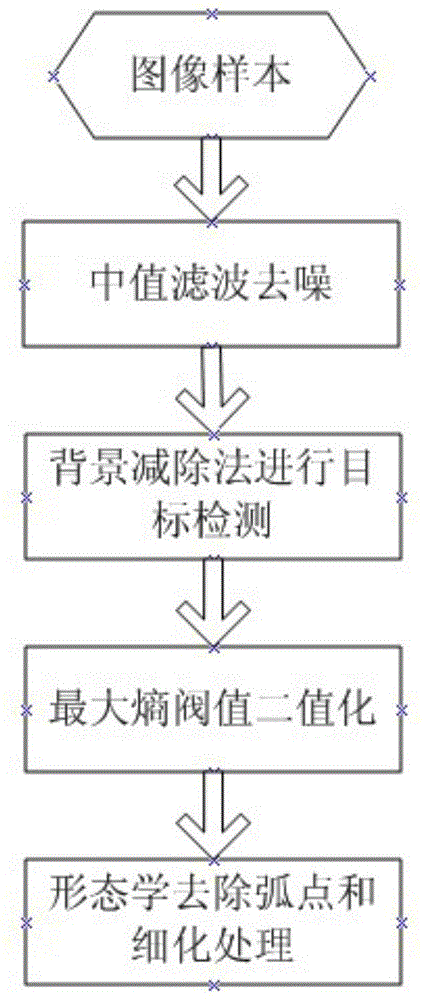

The invention relates to a vision-based automatic aviation oil mist nozzle atomization angle detection device. A light source is arranged inside a tank, and an industrial camera is arranged on the outer side of the tank, connected with an explosion-proof computer through an internal digital I / O (input / output) trigger interface card and used for shooting spray of the oil mist nozzle fixed in the tank. A detection method includes the following steps that the industrial camera shoots a digital image of a spray cone angle by receiving an external trigger signal and sends the digital image to the explosion-proof computer; the explosion-proof computer preprocesses the digital image to obtain a binary image; the binary image is subjected to Hough transform to obtain a boundary of degrees of the cone angle and the degrees of the cone angle. By the device and method, the problem about randomness of manual measurement of the aviation nozzle is solved, accuracy is improved, reliability in measurement is guaranteed, and automation level is heightened.

Owner:中国科学院沈阳计算技术研究所有限公司

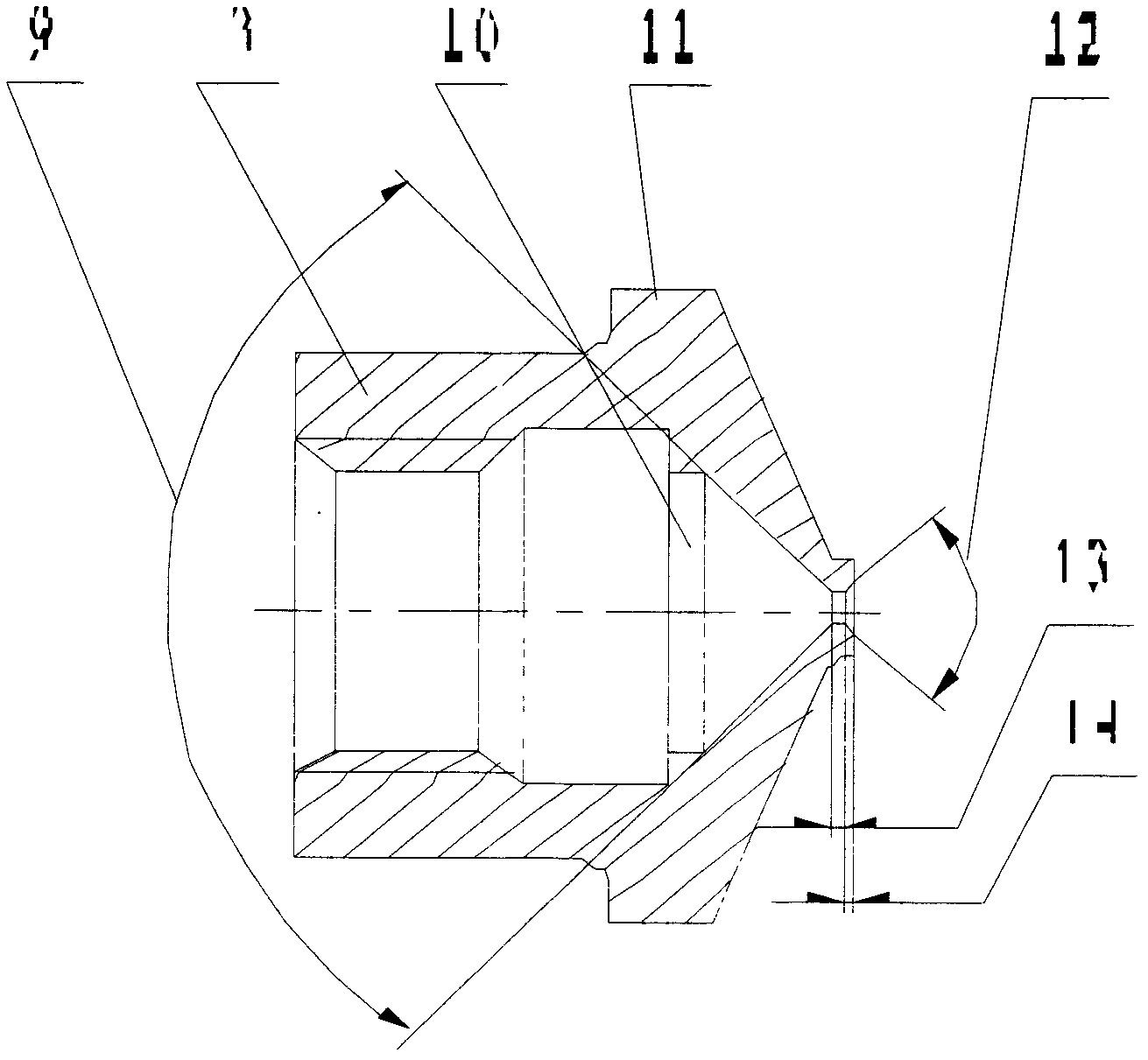

Double-oil-circuit fuel nozzle

ActiveCN103134079APerformance unchangedIncrease fuel supplyContinuous combustion chamberSpray coneCombustion chamber

The invention relates to a double-oil-circuit fuel nozzle, in particular to a double-oil-circuit large-spray-cone-angle fuel nozzle. The double-oil-circuit fuel nozzle mainly comprises a nozzle shell body, a main oil circuit nozzle, a main oil circuit swirler and a vice oil circuit swirler. A main oil circuit swirling chamber is formed by the main oil circuit swirl and an inner cavity of the main oil circuit nozzle, a vice oil circuit swirling chamber is formed by a head cone-shaped body of the vice oil circuit swirler and a convergence taper angle of the inner cavity of the main oil circuit swirler, and a cooling air channel is designed on the main oil circuit nozzle. The problem that an aero-engine combustor is wide in fuel supply range is well resolved, a spray cone angle of the fuel nozzle is increased by 10 degrees to 15 degrees, and the effects of nozzle cooling and nozzle surface carbon deposition blowing down are achieved.

Owner:中国航发贵阳发动机设计研究所

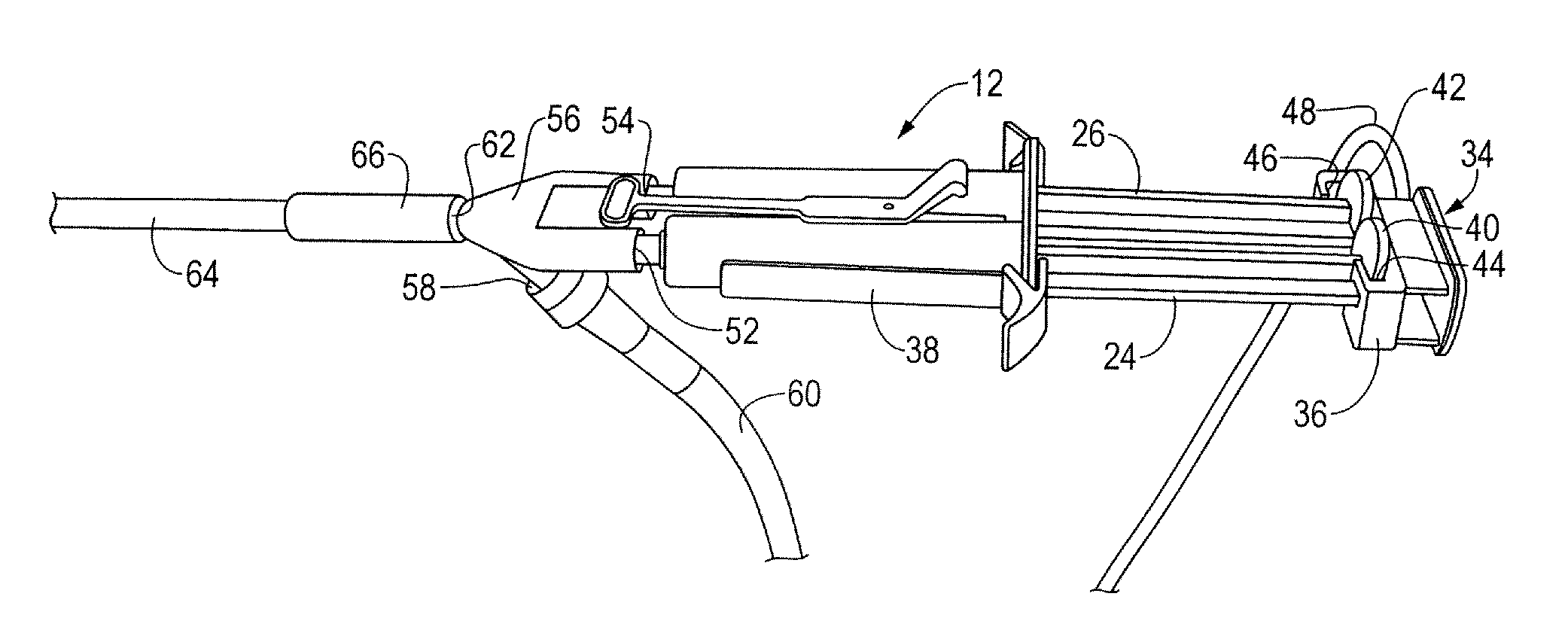

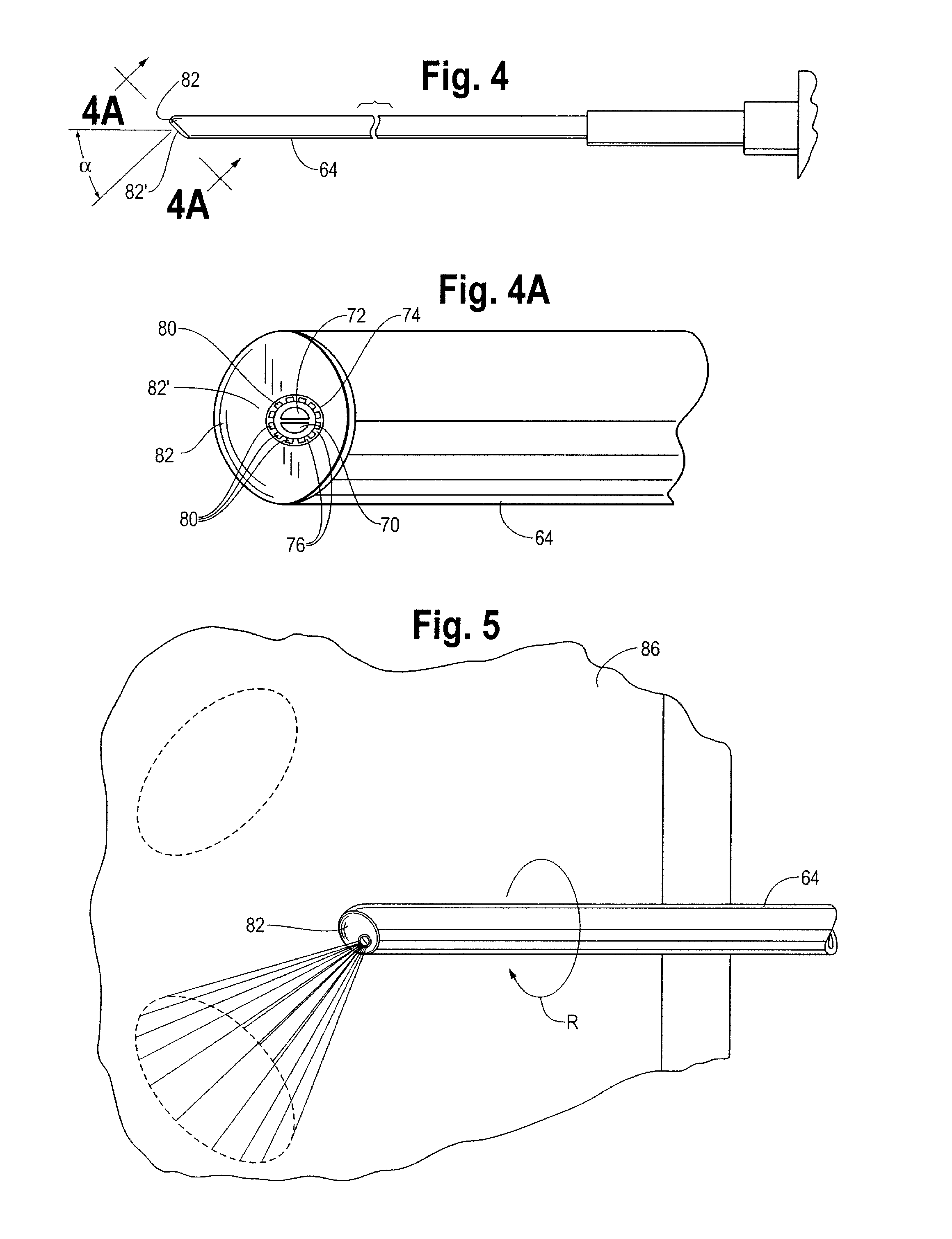

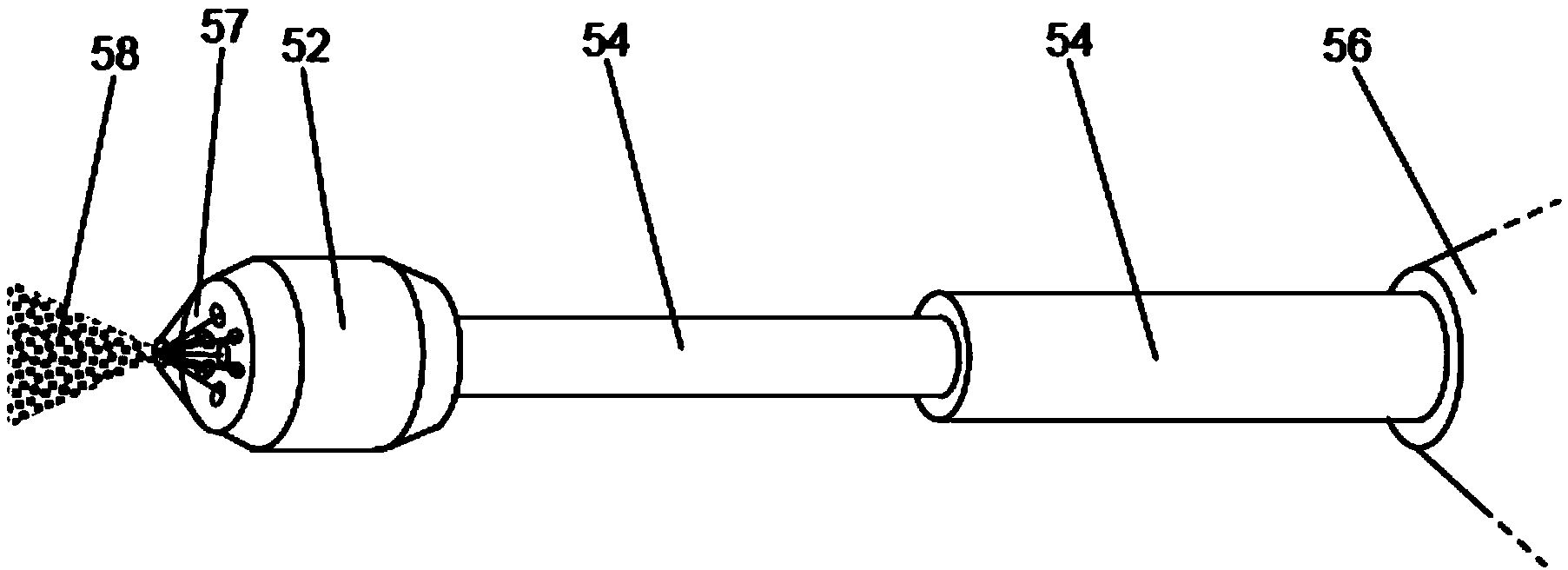

Tissue sealing system and apparatus

A laparoscopic tissue sealant spray apparatus and system having a laparoscopic tissue sealant spray assembly combined with a trocar assembly, the tissue sealant spray assembly having an elongate delivery tube. A spray outlet at a distal end of the elongate delivery tube may be rounded or angled. A ring member provided at the distal end of the elongate delivery tube directs a spray cone toward a portion of a target tissue site, and the spray cone may be repositioned to a different portion of the target tissue site by rotation of the elongate delivery tube. The trocar assembly includes a vent opening that connects to a venting valve member that provides a vent path which passively opens upon operation of the tissue sealant spray assembly, avoiding excessive pressure build-up within a body cavity.

Owner:BAXTER INT INC +1

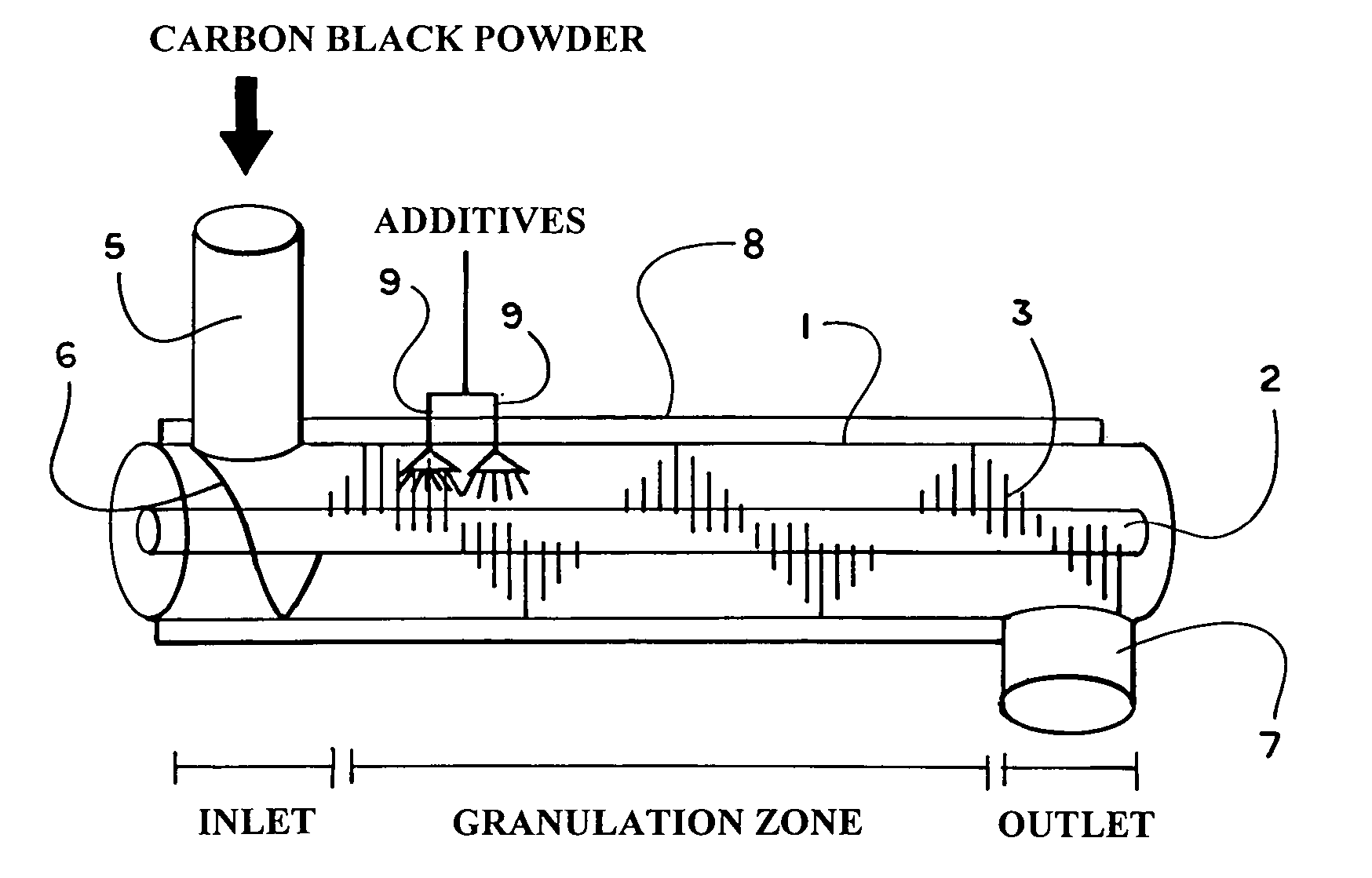

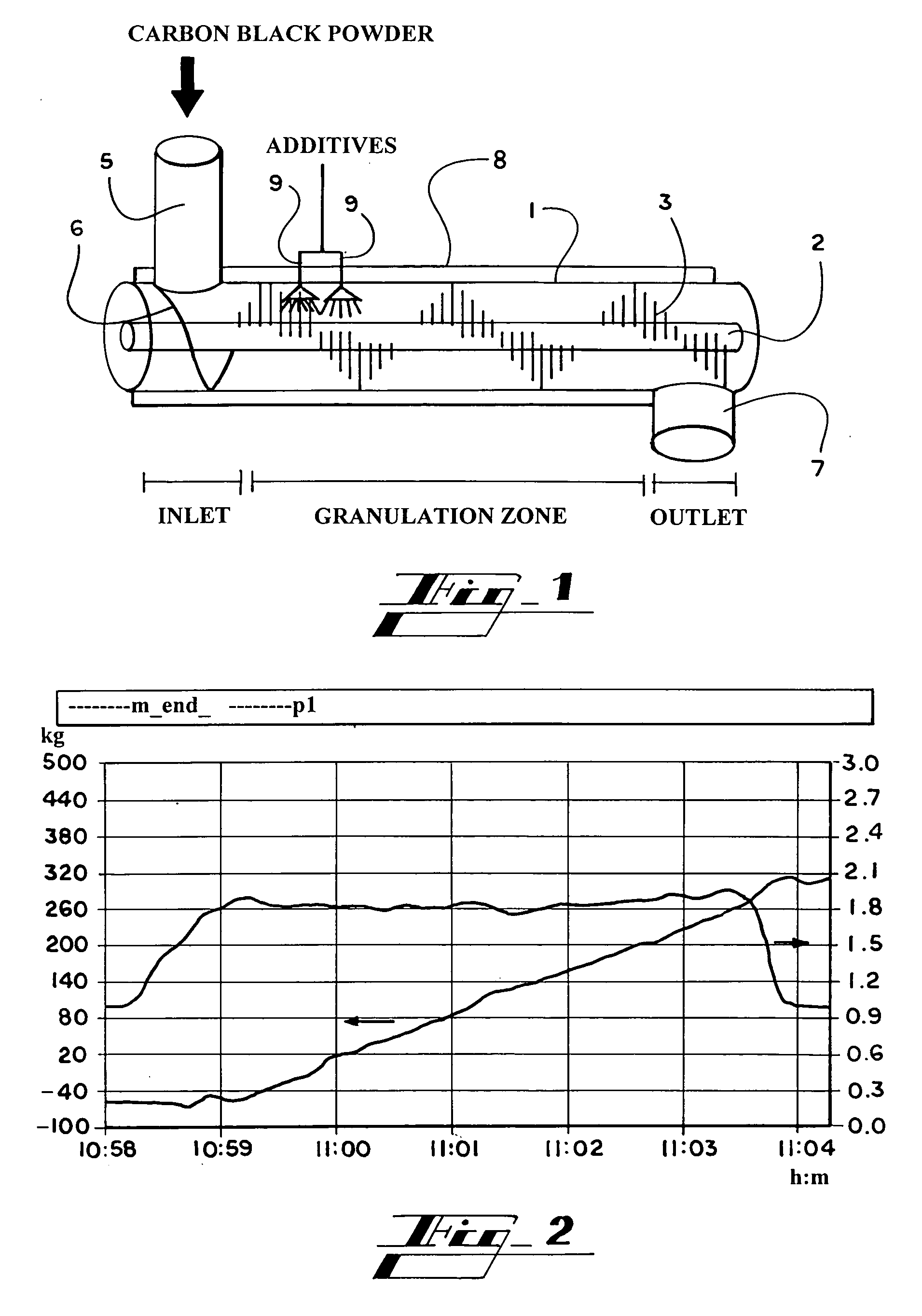

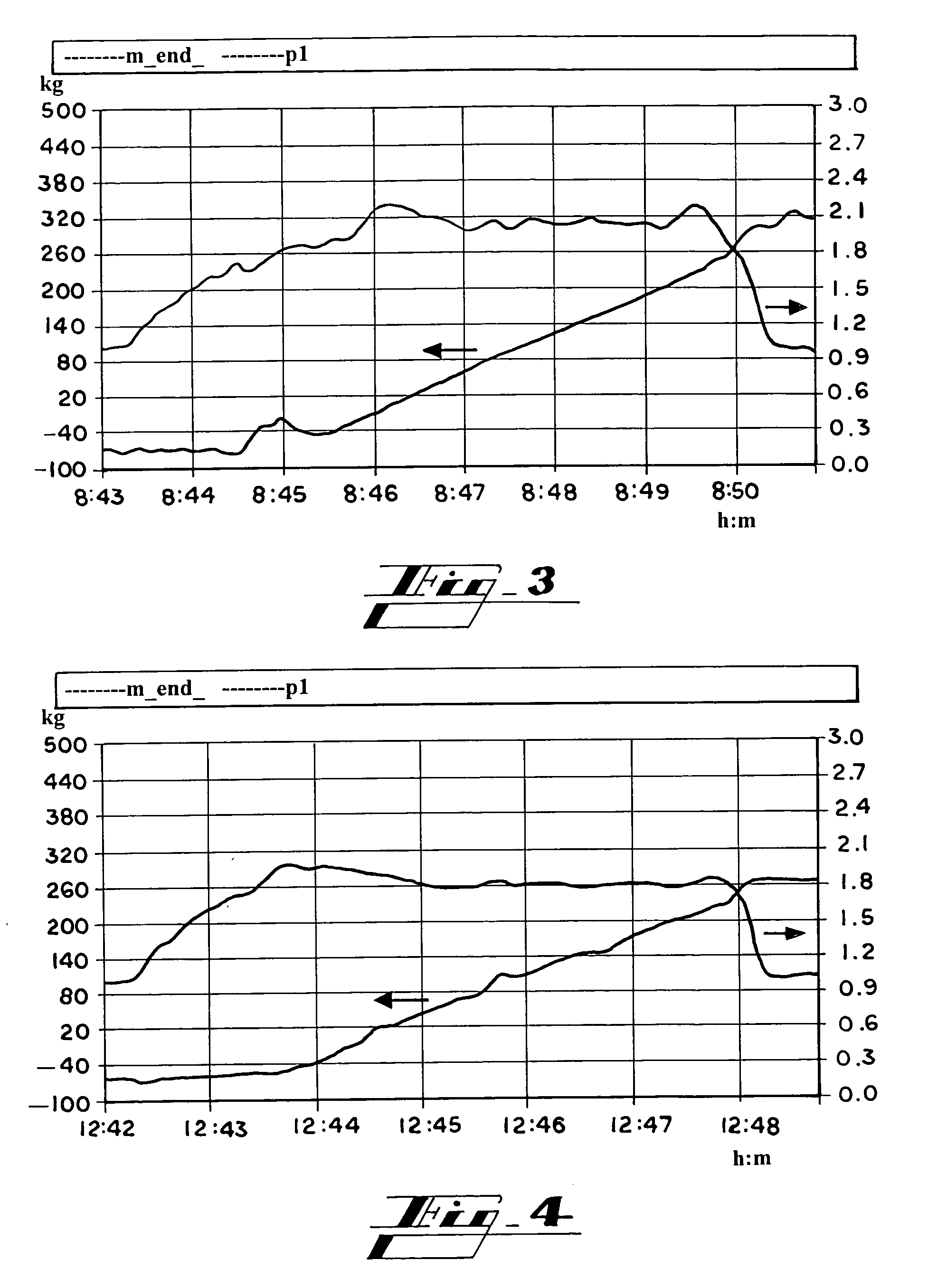

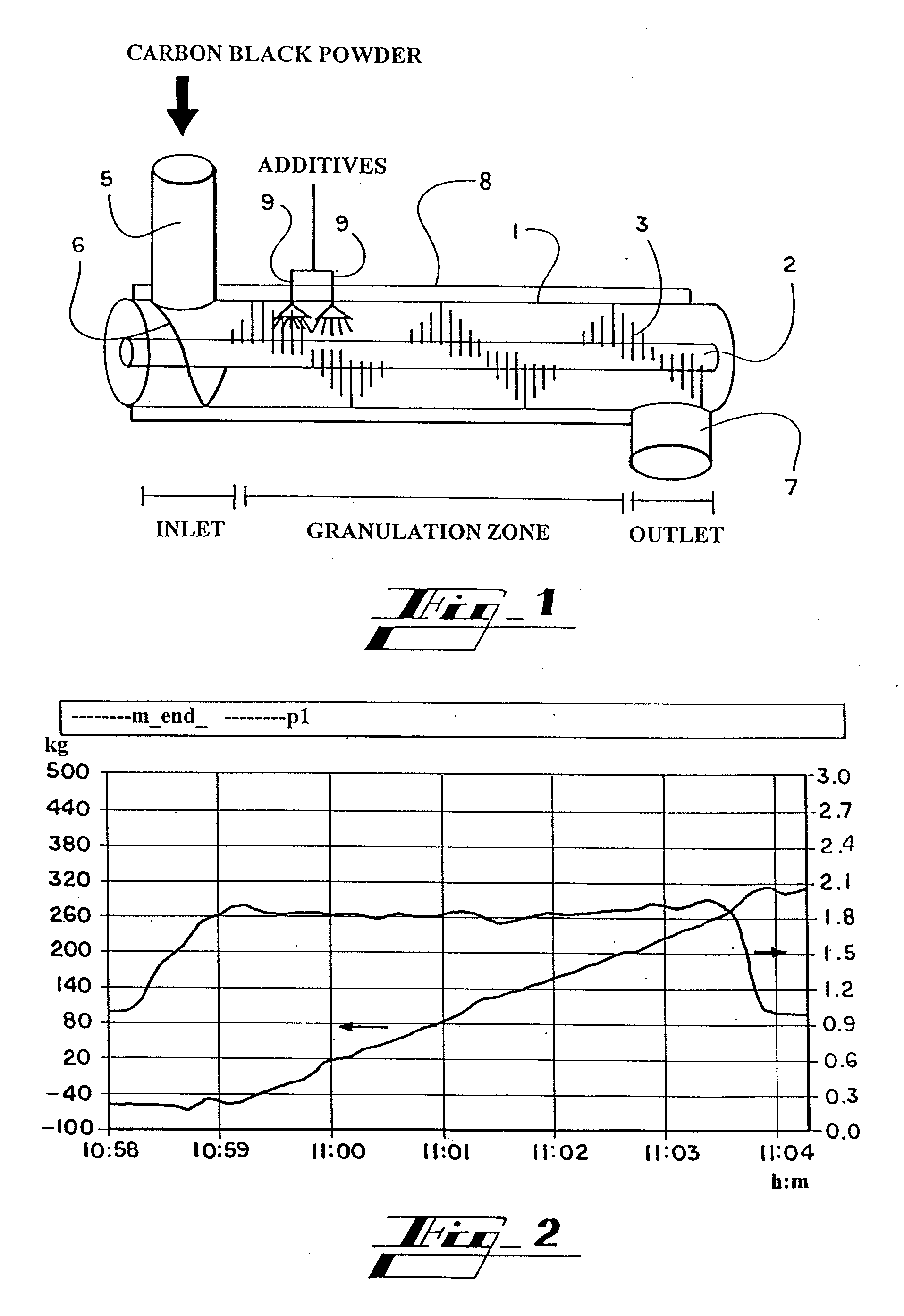

Carbon black pellets

A method for producing carbon black pellets in a ring layer mixing granulator where the feed amount of unpelletized carbon black is kept constant and the water is dispensed via two nozzle holders positioned as close as possible to the inlet, each with two nozzles, where the spray cones make an angle between 10 and 90° to the direction of flow of the carbon black, at a pressure of 3-5 bar measured at the nozzles. Carbon black pellets are disclosed with an oil absorption number greater than 100 ml / 100 g and an oil absorption number of the pressed carbon black greater than 78 ml / 100 g, where the pellet fraction with a diameter greater than 2.5 mm is less than 3.5 wt %, the pellet fraction with a diameter of 0.71-1.0 mm is greater than 22 wt %, and the individual pellet hardness of the fraction with the 0.71-1.0 mm diameter is between 7.0 and 25.0 g. Also disclosed are carbon black pellets with an oil absorption number less than 90 ml / 100 g, and an oil absorption number of the pressed carbon black less than 78 ml / 100 g, where the pellet fraction with a diameter of 0.71-1.0 mm is less than 30 wt % and the individual pellet hardness of the fraction with the 0.71-1.0 mm diameter is between 7.0 and 25.0 g. The carbon black pellets can be used in polymer and rubber mixtures, paints, dyes or pigments.

Owner:EVONIK DEGUSSA GMBH

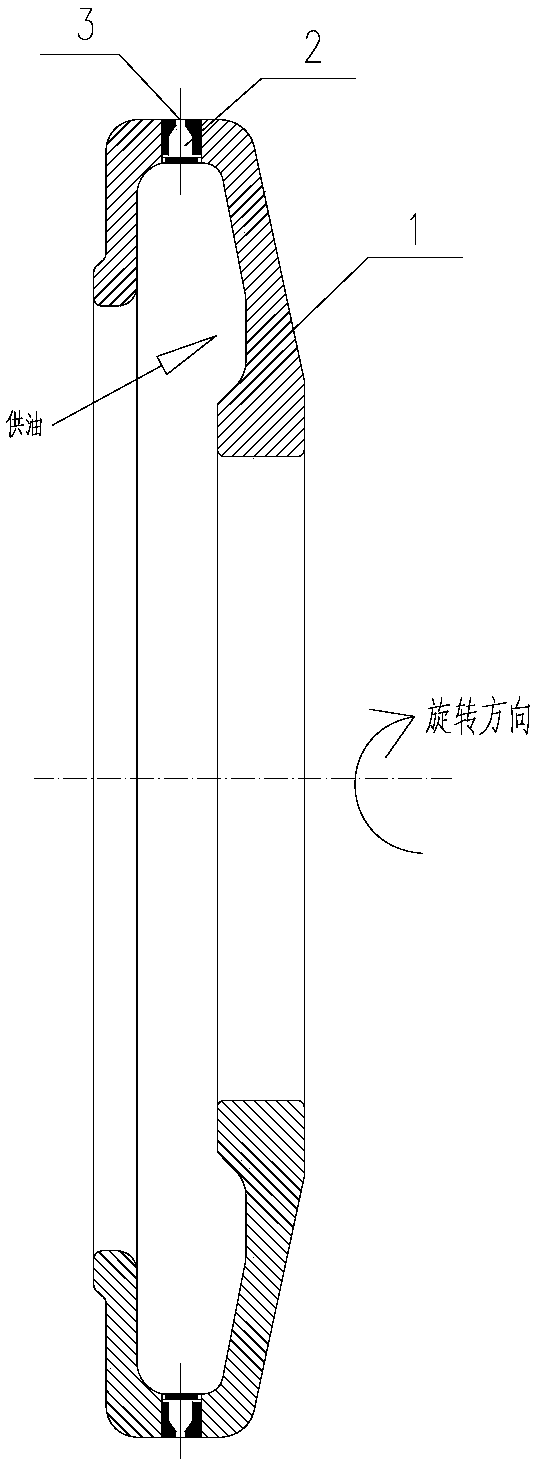

Nozzle for direct-injection engine

InactiveCN101737218AReduces tendency to fluctuate randomlyAvoid tip jettingFuel injection apparatusMachines/enginesInjection pressureSpray cone

The invention relates to a nozzle for a direct-injection engine in the technical field of automobile engines, which comprises a shell, a valve rod, an oil-injection hole, an oil supply hole and oil ways, wherein the oil-injection hole and the oil supply hole are arranged at both ends of the shell respectively; the oil way is positioned in the shell, and both ends of the oil ways are connected with the oil supply hole and the oil-injection hole respectively; one end of the valve rod is arranged inside one side of the shell close to the oil supply hole and is positioned at the center of a plurality of oil ways. The nozzle enables fuel to generate swirl, can ensure the large spray cone angle (namely dispersibility) under the low injection pressure and high backpressure, and simultaneously, avoid undesirable tip injection of atomization, so that the atomization performance of the nozzle is improved.

Owner:SHANGHAI JIAO TONG UNIV

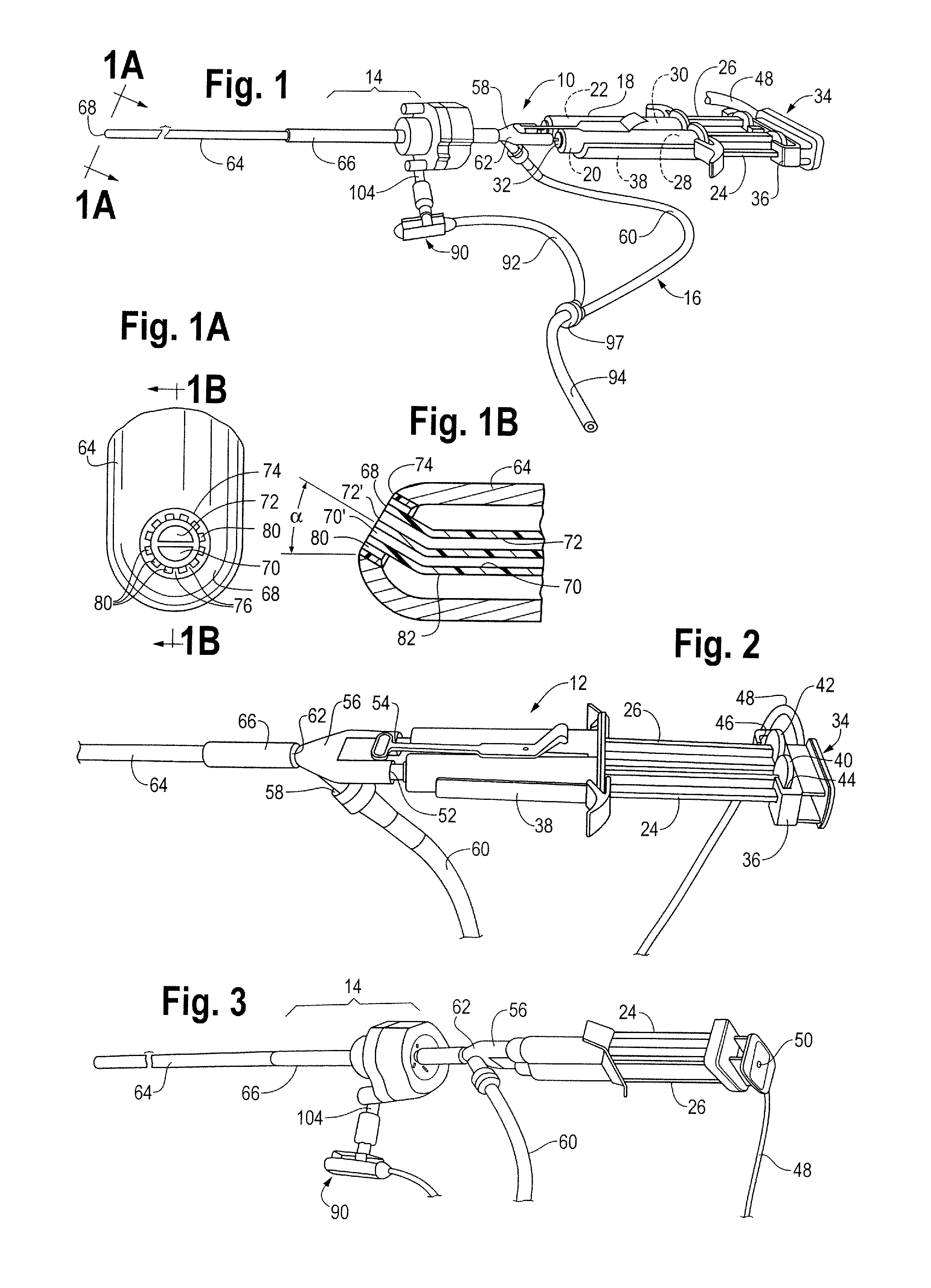

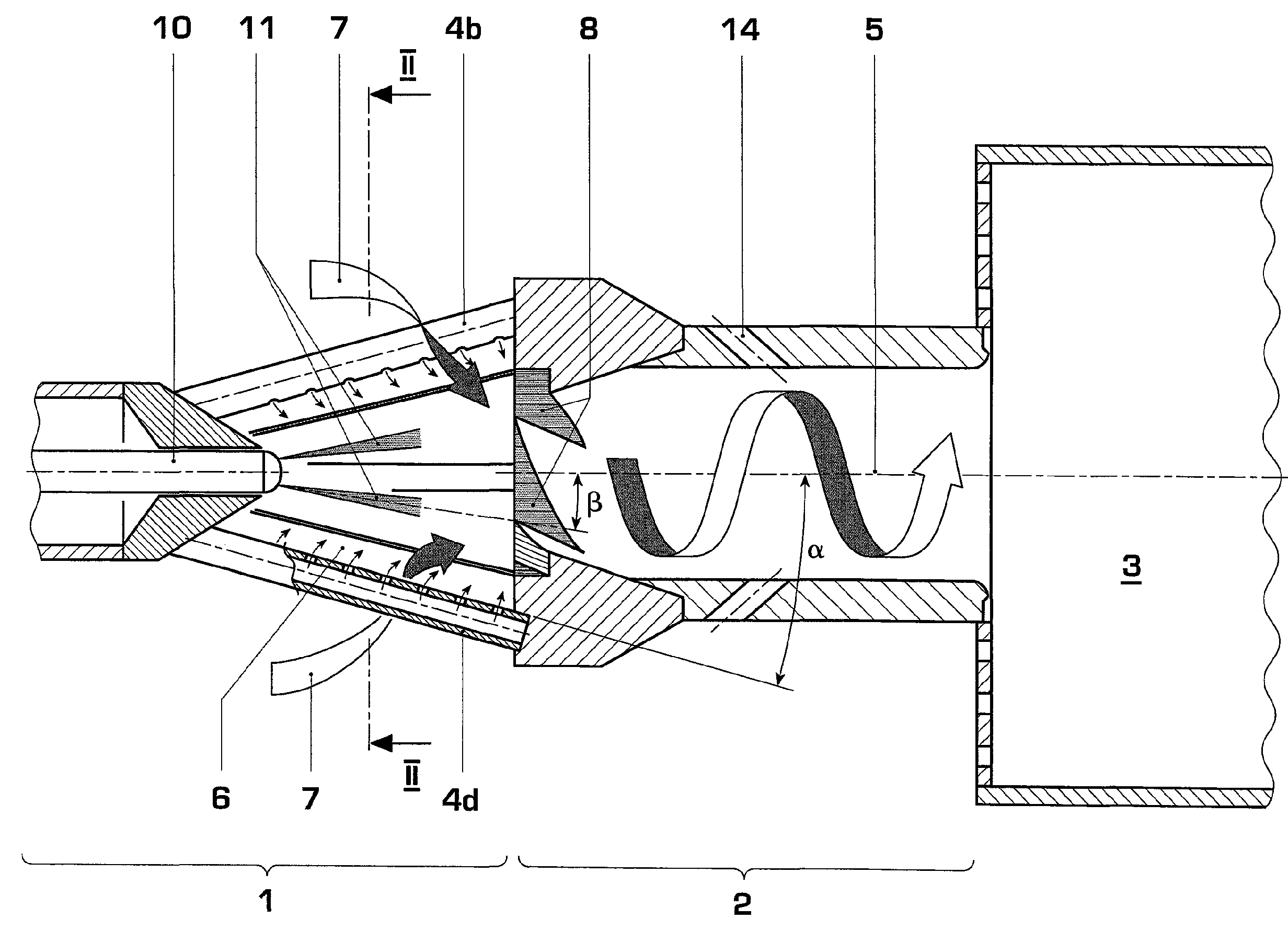

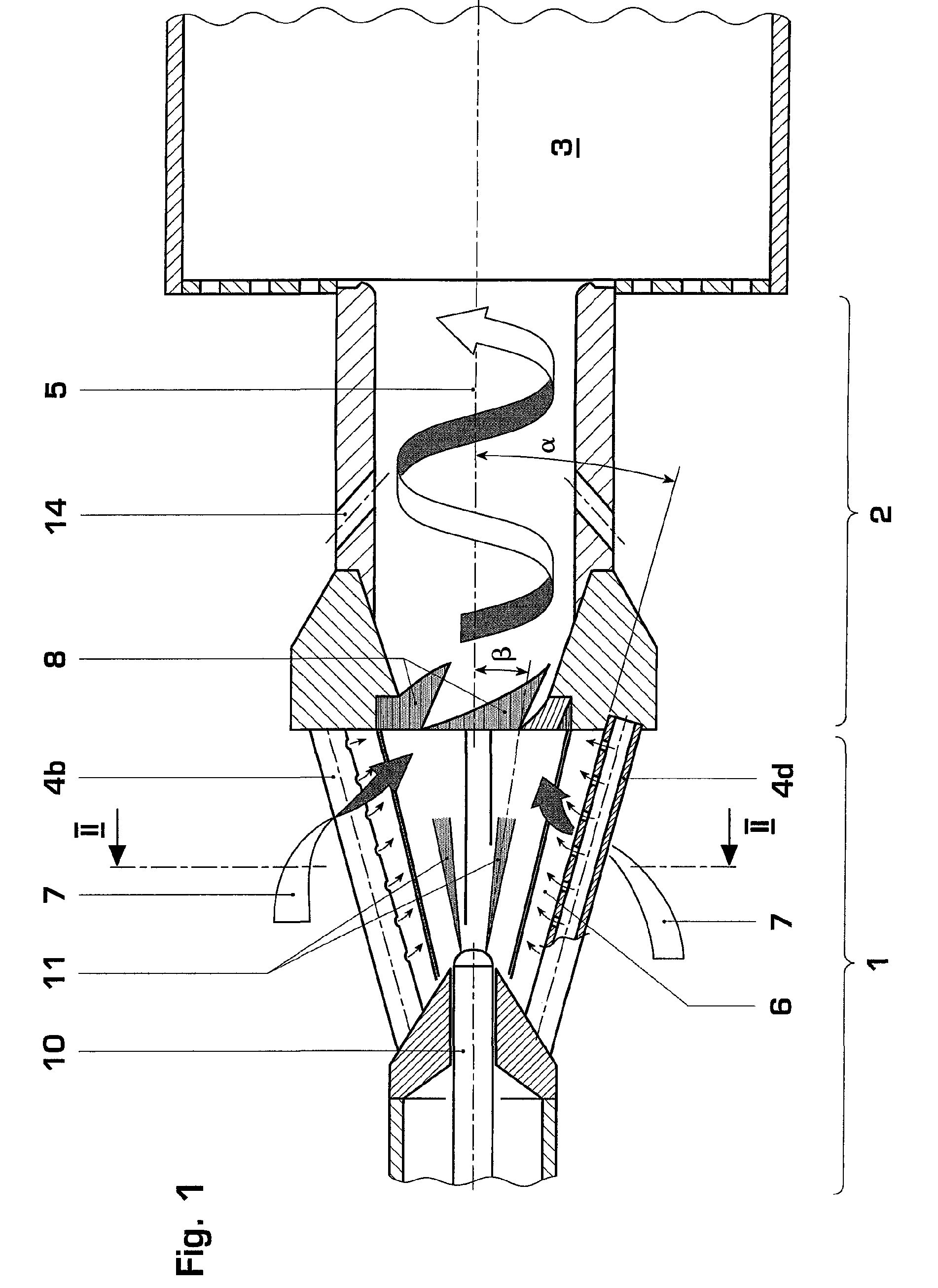

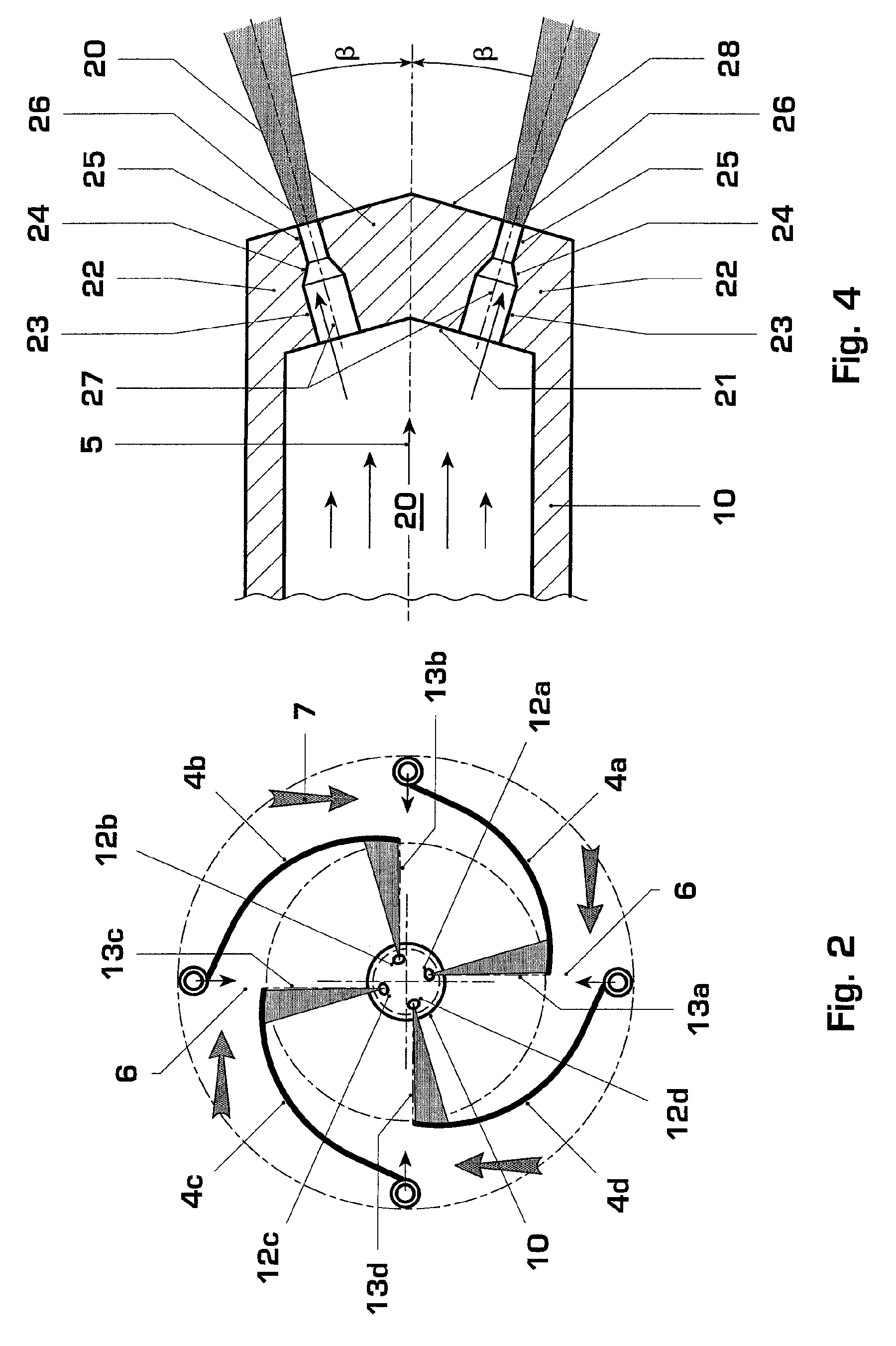

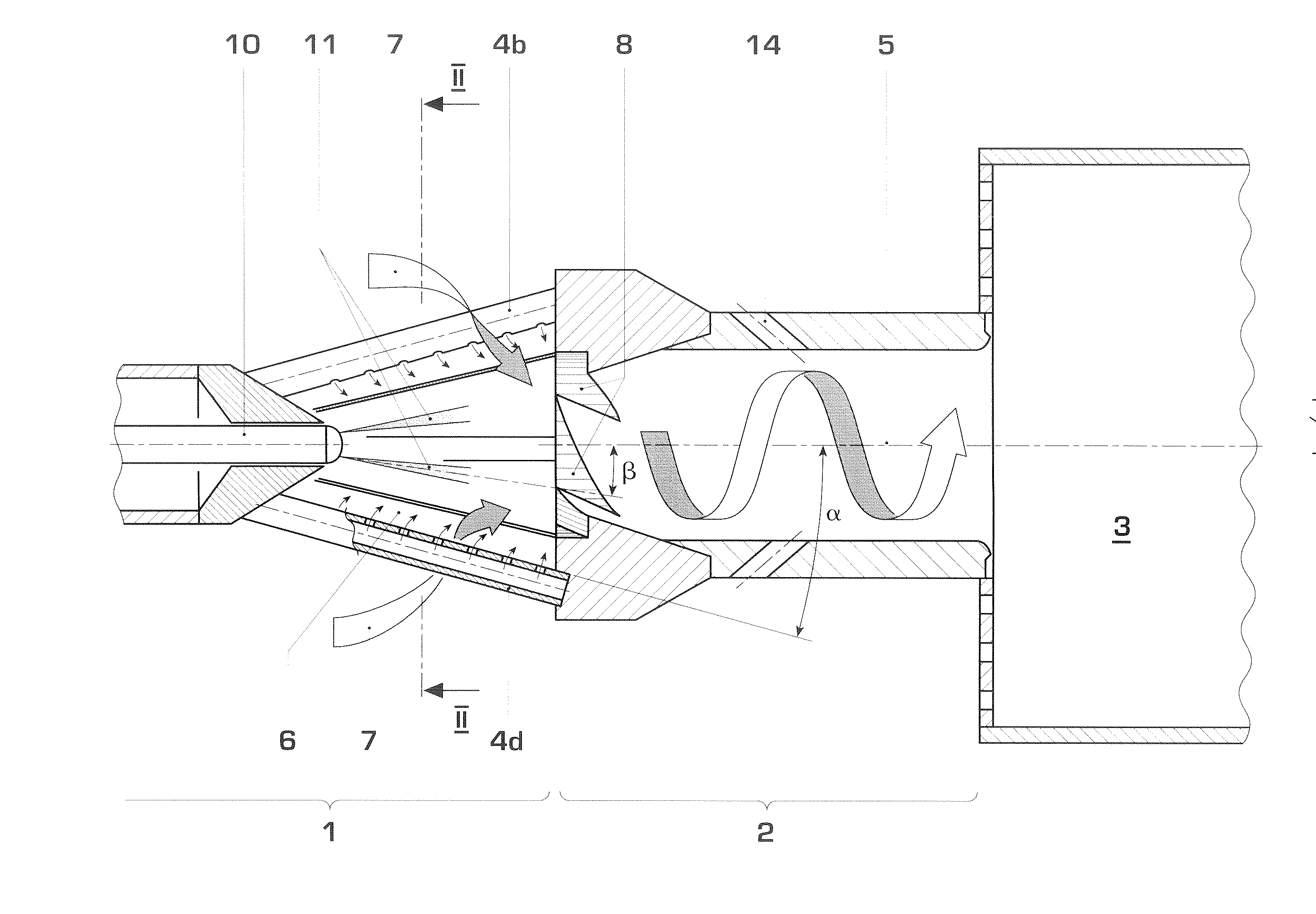

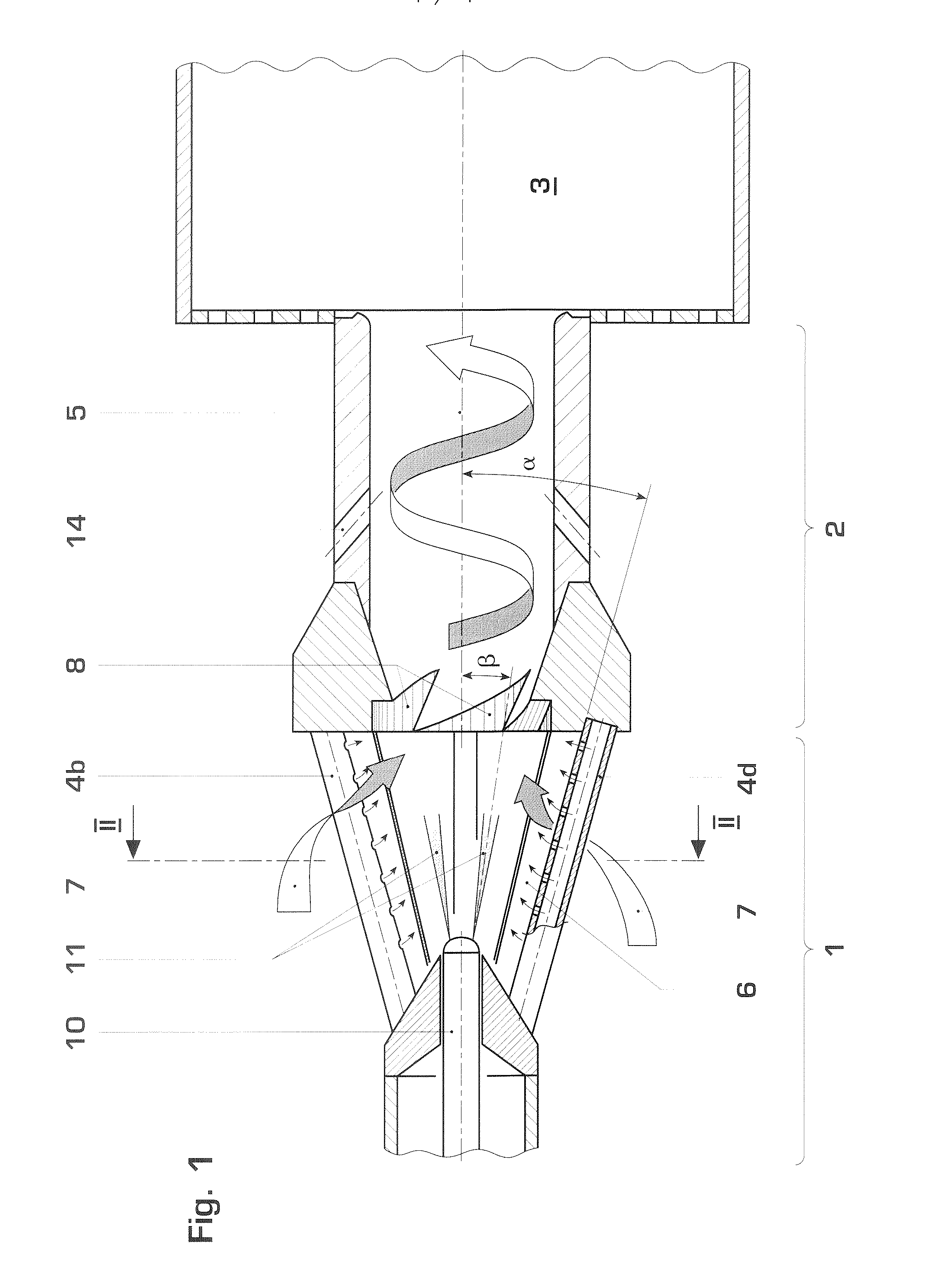

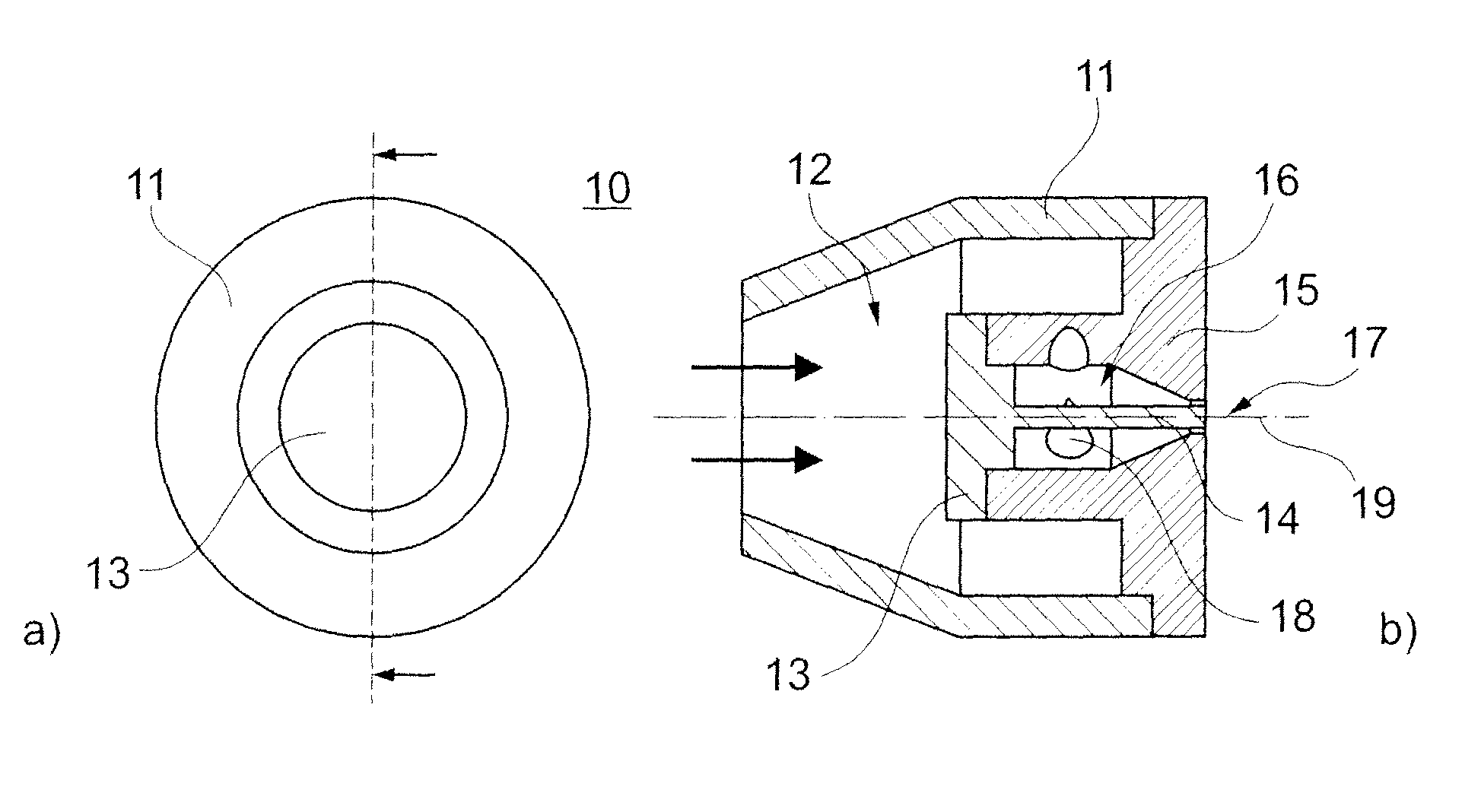

Burner for a gas turbine

A premix burner, for example for a gas turbine, having a conical swirl generator (1) and a cylindrical mixing section (2) which follows it in the direction of flow, includes a high-pressure atomizer nozzle (10) with one or more fuel feed passages. The high-pressure atomizer nozzle (10) includes at least two outlet passages, through which liquid fuel enters the swirl generator (1), these passages being arranged off-center with respect to the longitudinal axis of the nozzle and being configured in such a way that the spray cone (11) of the fuel is oriented at an angle (β) with respect to the longitudinal axis of the swirl generator (1) which is smaller than the cone half-angle (α) of the swirl generator (1). The outlet passages in particular have an internal geometry with a conically narrowed section.

Owner:ANSALDO ENERGIA SWITZERLAND AG

Atomizer anti-drift method and anti-drift atomizer

InactiveCN101628265APrevent drift effectsStrong penetrating powerSpray nozzlesSpray discharge apparatusSpray coneFluid pipe

The invention relates to a structure and a design method of an atomizer applied to agricultural equipment for plant protection, in particular to an anti-drift method of an atomizer applied to miniature motorized agricultural equipment for plant protection and an anti-drift electrostatic atomizer. The anti-drift method of the atomizer comprises the following steps: a. arranging the atomizer which can enable liquid medicine to atomize and spray; b. sleeving an air flow pipe coaxially at the periphery of a fluid pipe of the atomizer and encircling an air flow nozzle at the front end of the air flow pipe at the periphery of a liquid medicine nozzle of the atomizer and using a cyclone device to rotate the air flow before the air low reaches the air flow nozzle; and c. enabling the spray cone angle of the air flow to be larger than the atomization cone angle formed in atomization of the liquid and enabling the spray pressure of the air flow to be larger than the spray pressure of the liquid. The anti-drift method of the atomizer can prevent drift of fogdrops and enhance the atomization application effect. The atomizer has simple structure, small size and good atomization application effect and can prevent drift of fogdrops.

Owner:JIANGSU UNIV

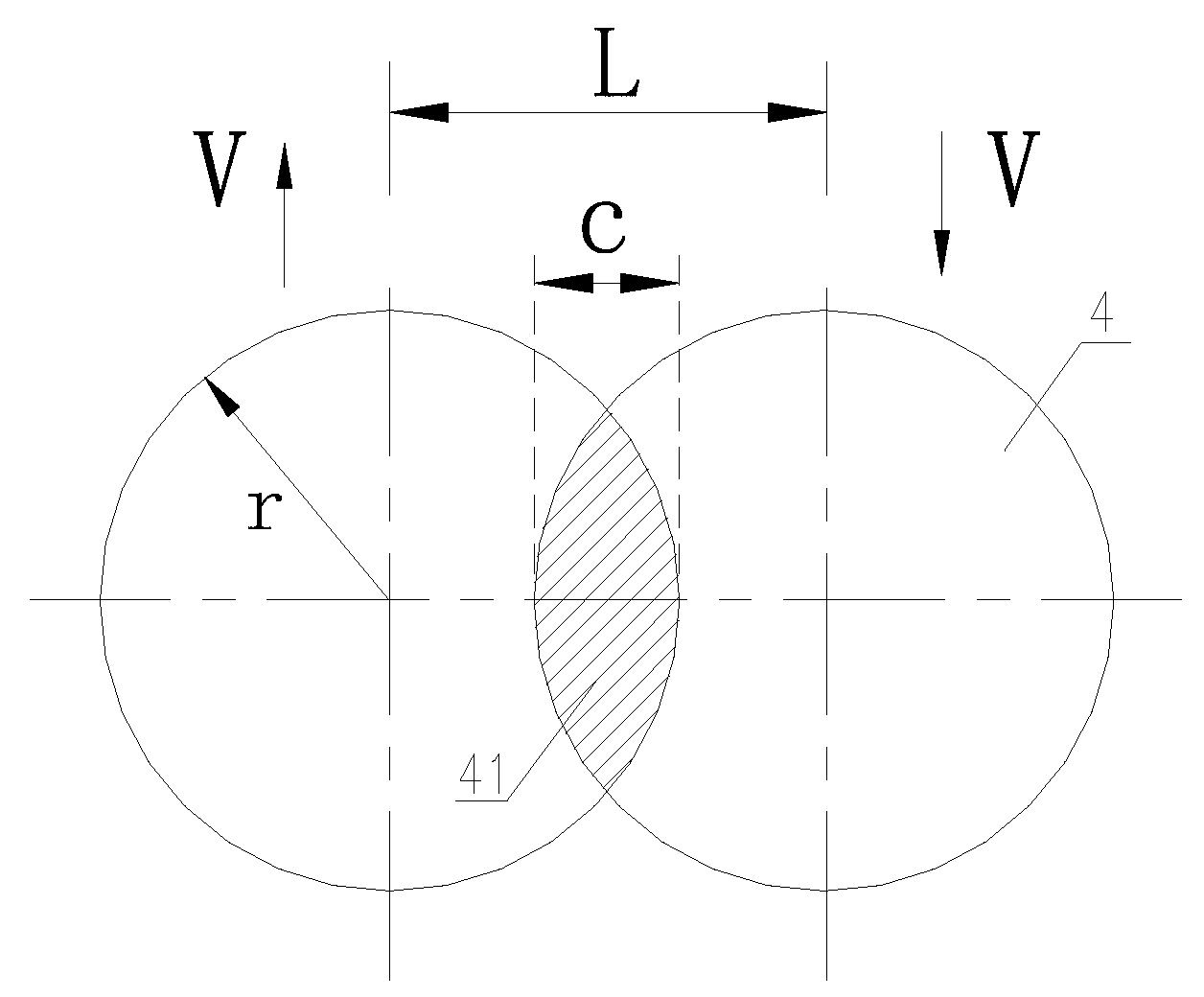

Robot spray gun trajectory setting method in copper plate spraying operation

ActiveCN103838172AAchieve optimization goalsImprove uniformityProgramme control in sequence/logic controllersSpray coneTrajectory database

The invention discloses a robot spray gun trajectory setting method in copper plate spraying operation. The method comprises the steps that a spray gun spraying area is set, wherein the geometric model of the area is a spraying cone; spraying mediums and related parameters of a spray gun are set; the area and the radius of the spraying area and the thickness of a coating are acquired; the stacking range of the spraying area is calculated; according to a spraying angle of the spray gun and the distance between the spray guns of all spraying areas, the stacking distance between adjacent spraying areas is acquired; for a copper plate corner angle, the spray gun is always vertical to an arc face of the copper plate corner angle; in adjacent spraying areas, the spray gun rotates an angle of beta by taking the axis of the corner angle arc face as the circle center; a robot spray gun trajectory database is established and related parameters of the spray gun trajectories of the database are programmed into a spray gun trajectory subprogram; and the trajectory of the spray gun runs according to the setting of the subprogram. According to the method, through the acquired robot spray gun trajectory, an optimization target of the robot spraying operation is realized; the uniformity and the quality of the coating are effectively improved; the spraying cost is reduced; and the spraying efficiency is improved.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

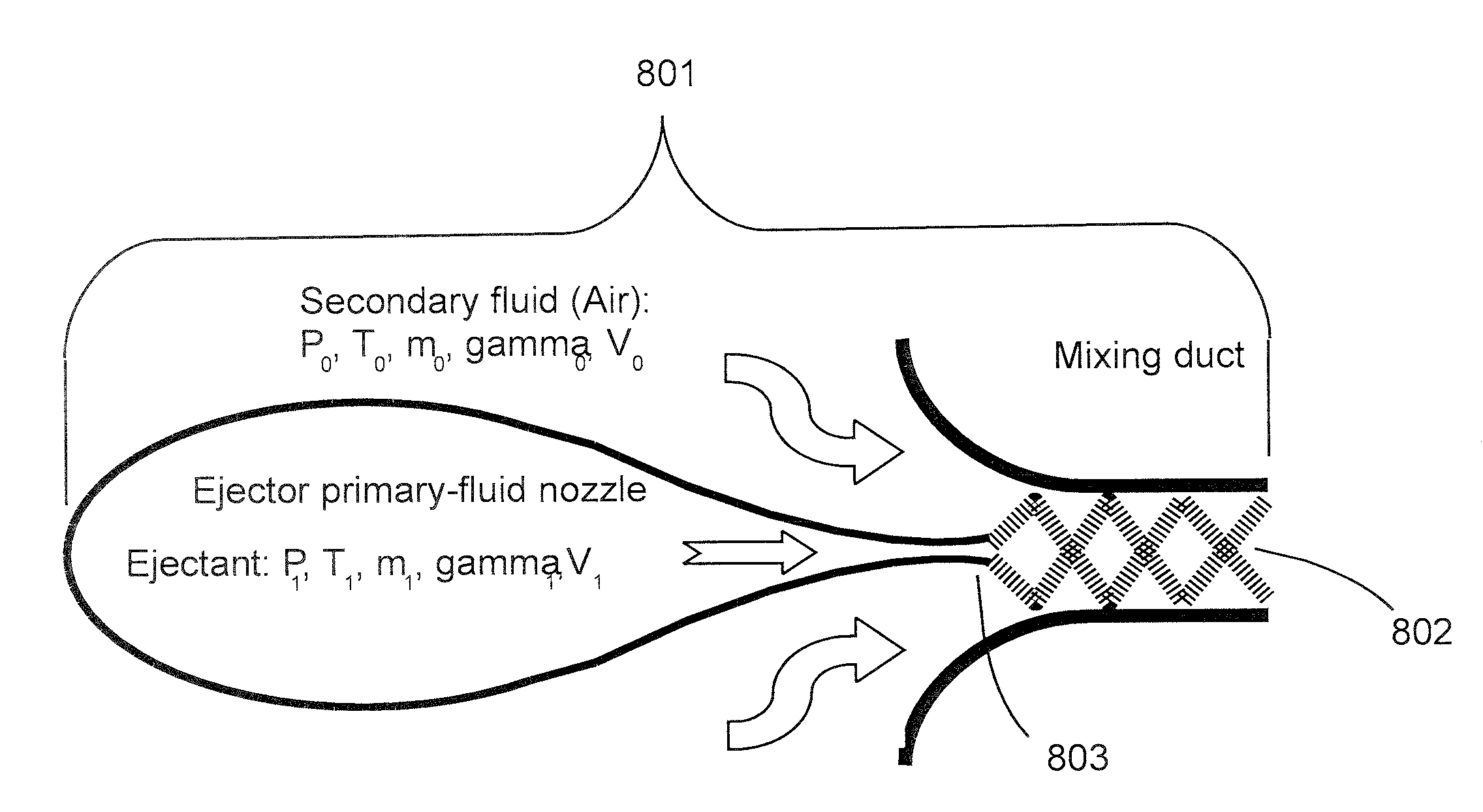

Hypermixing Fluid Ejector

The present invention provides a hypermixing fluid ejector. The ejector includes a reservoir containing a primary fluid and an ejector nozzle with a trailing-edge array of rectilinear orifices. The primary fluid is ejected through these orifices to entrain a secondary fluid, thereby creating a mixed fluid flow. A dividing line is defined on the trailing surface of the nozzle that is orthogonal to the linear axis of the ejector, and the orifices alternate above and below this dividing line in an abutting, offset manner. The orifices are geometrically inclined to produce spray cones that are convergent relative to this dividing line, resulting in convergent helical hypermixing of the primary fluid with the secondary fluid.

Owner:GROSSI FABIO G

Carbon black pellets

A method for producing carbon black pellets in a ring layer mixing granulator where the feed amount of unpelletized carbon black is kept constant and the water is dispensed via two nozzle holders positioned as close as possible to the inlet, each with two nozzles, where the spray cones make an angle between 10 and 90° to the direction of flow of the carbon black, at a pressure of 3-5 bar measured at the nozzles. Carbon black pellets are disclosed with an oil absorption number greater than 100 ml / 100 g and an oil absorption number of the pressed carbon black greater than 78 ml / 100 g, where the pellet fraction with a diameter greater than 2.5 mm is less than 3.5 wt %, the pellet fraction with a diameter of 0.71-1.0 mm is greater than 22 wt %, and the individual pellet hardness of the fraction with the 0.71-1.0 mm diameter is between 7.0 and 25.0 g. Also disclosed are carbon black pellets with an oil absorption number less than 90 ml / 100 g, and an oil absorption number of the pressed carbon black less than 78 ml / 100 g, where the pellet fraction with a diameter of 0.71-1.0 mm is less than 30 wt % and the individual pellet hardness of the fraction with the 0.71-1.0 mm diameter is between 7.0 and 25.0 g. The carbon black pellets can be used in polymer and rubber mixtures, paints, dyes or pigments.

Owner:EVONIK CARBON BLACK GMBH

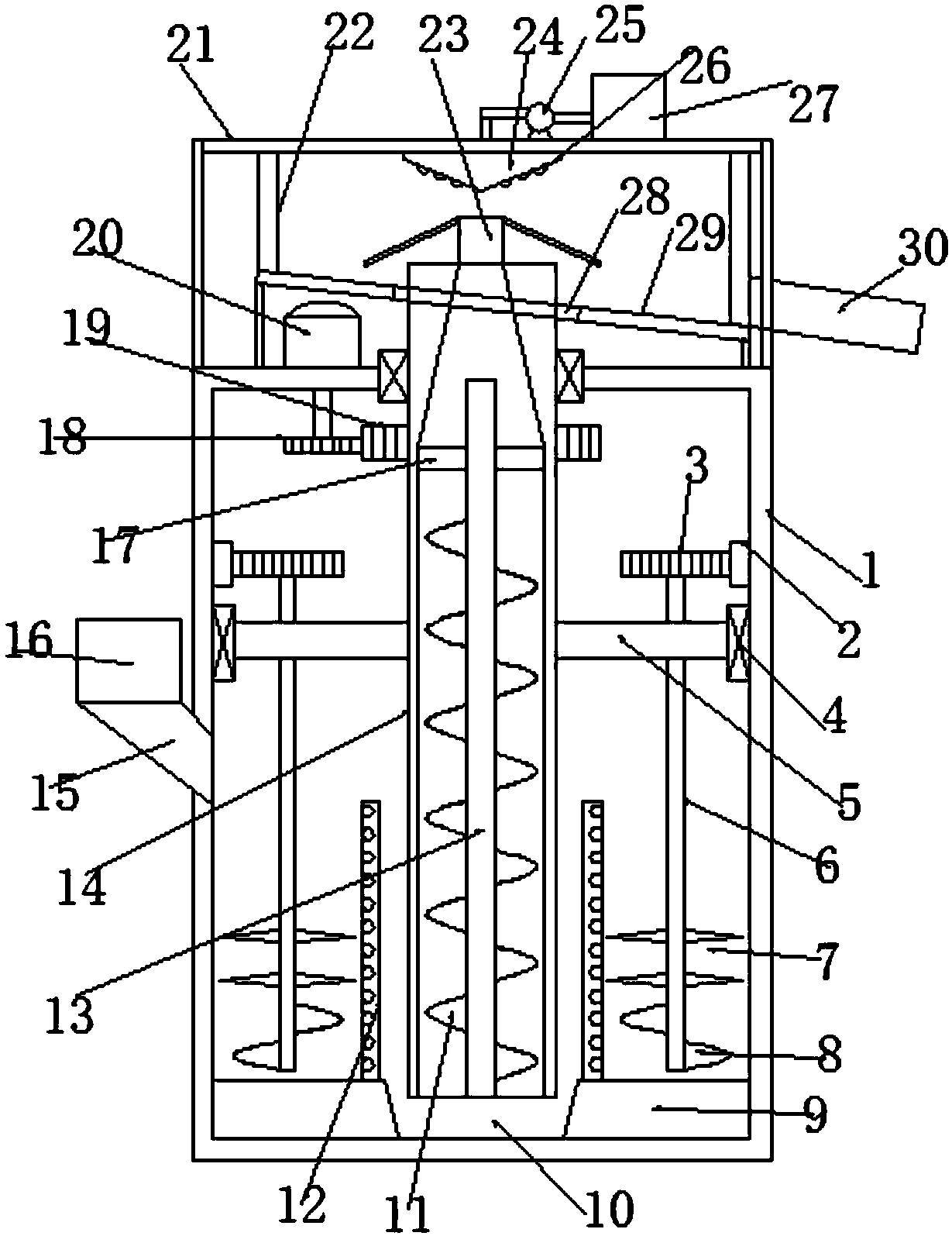

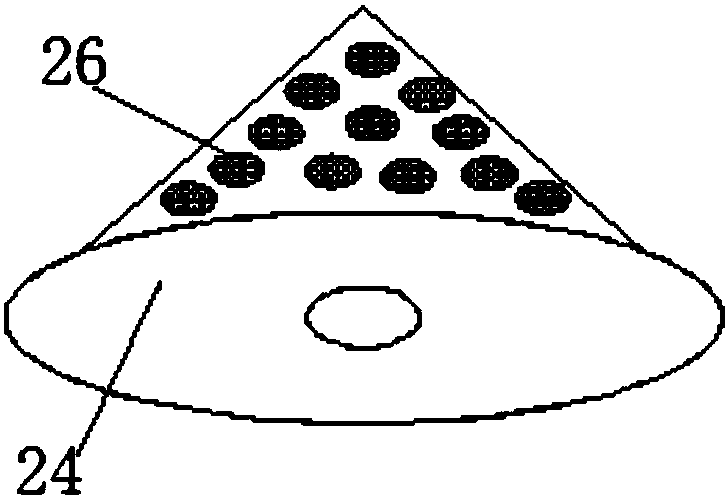

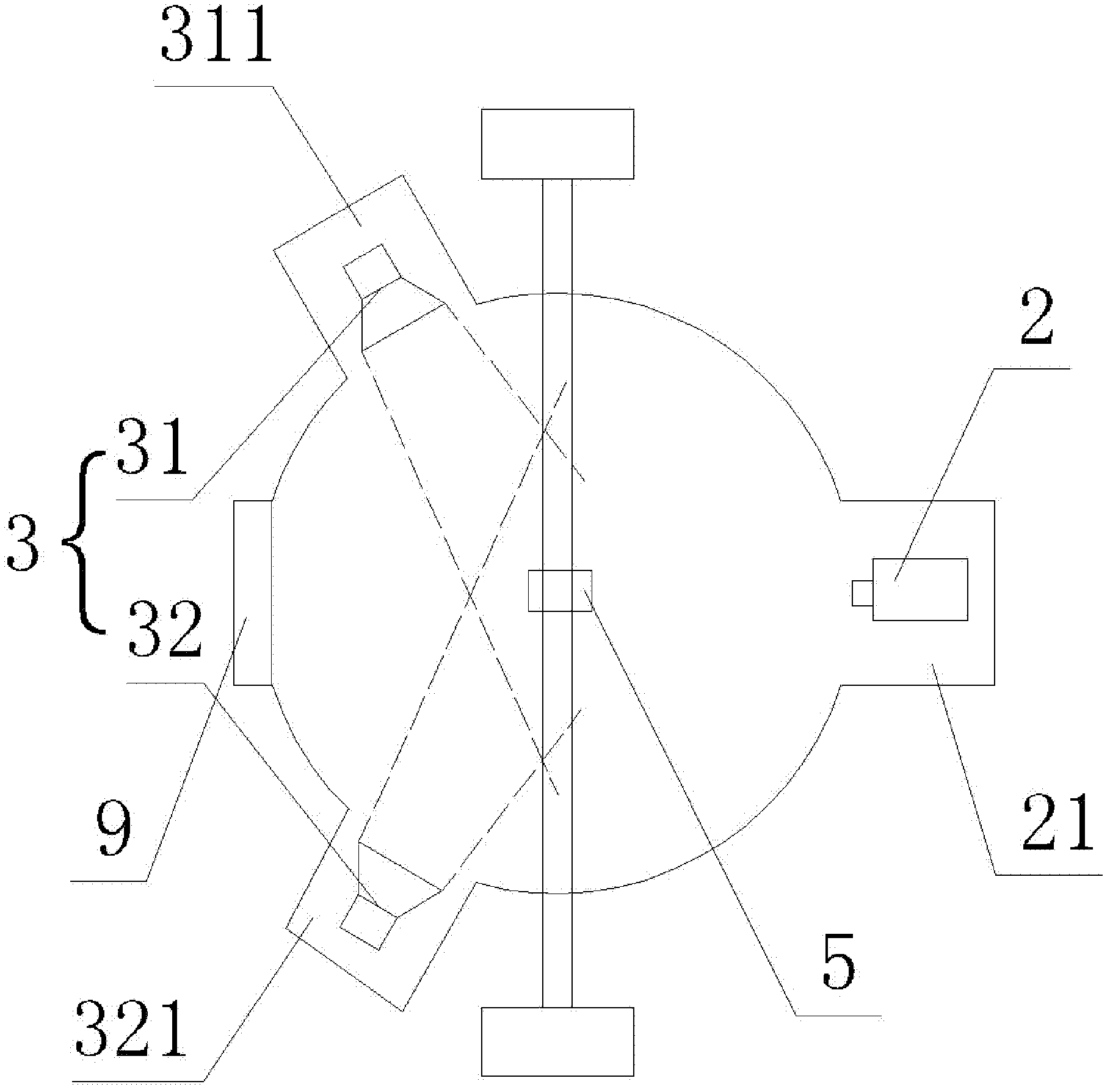

Inner cycle collision mixed type soil repair device

InactiveCN108114971AGuaranteed volumeImprove discretenessContaminated soil reclamationGrain treatmentsHybrid typeSpray cone

The invention discloses an inner cycle collision mixed type soil repair device which comprises a processing box, wherein the processing box is a cylindrical barrel, wherein a lifting barrel is arranged at the middle position of the upper end of the processing box in a penetrating manner, a rotating bearing matched with the lifting barrel is arranged at the upper end of the processing box, a supporting ring is arranged in the bottom of the processing box, a material collecting box is arranged in the middle position of the supporting ring, the lower end of the lifting barrel stretches into the material colleting groove, and a lifting shaft is arranged in the axis position in the lifting barrel. By crushing materials circumferentially and screening the materials through a filter barrel, the sizes of the materials are qualified when the materials are repaired, so that the materials are in full contact with a repair solution in the later period; the materials then upwell along the lifting barrel through lifting blades and collide with a material spraying cone which sprays the repair solution, so that the dispersion degree of the materials is enhanced; the materials are in contact with the repair solution sprayed from the nozzle conveniently, so that the repair effect is improved and the practicality is high.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

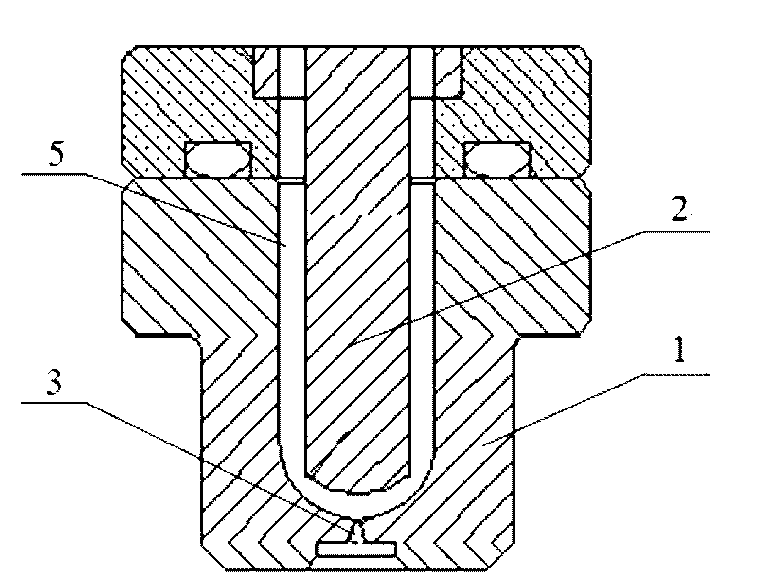

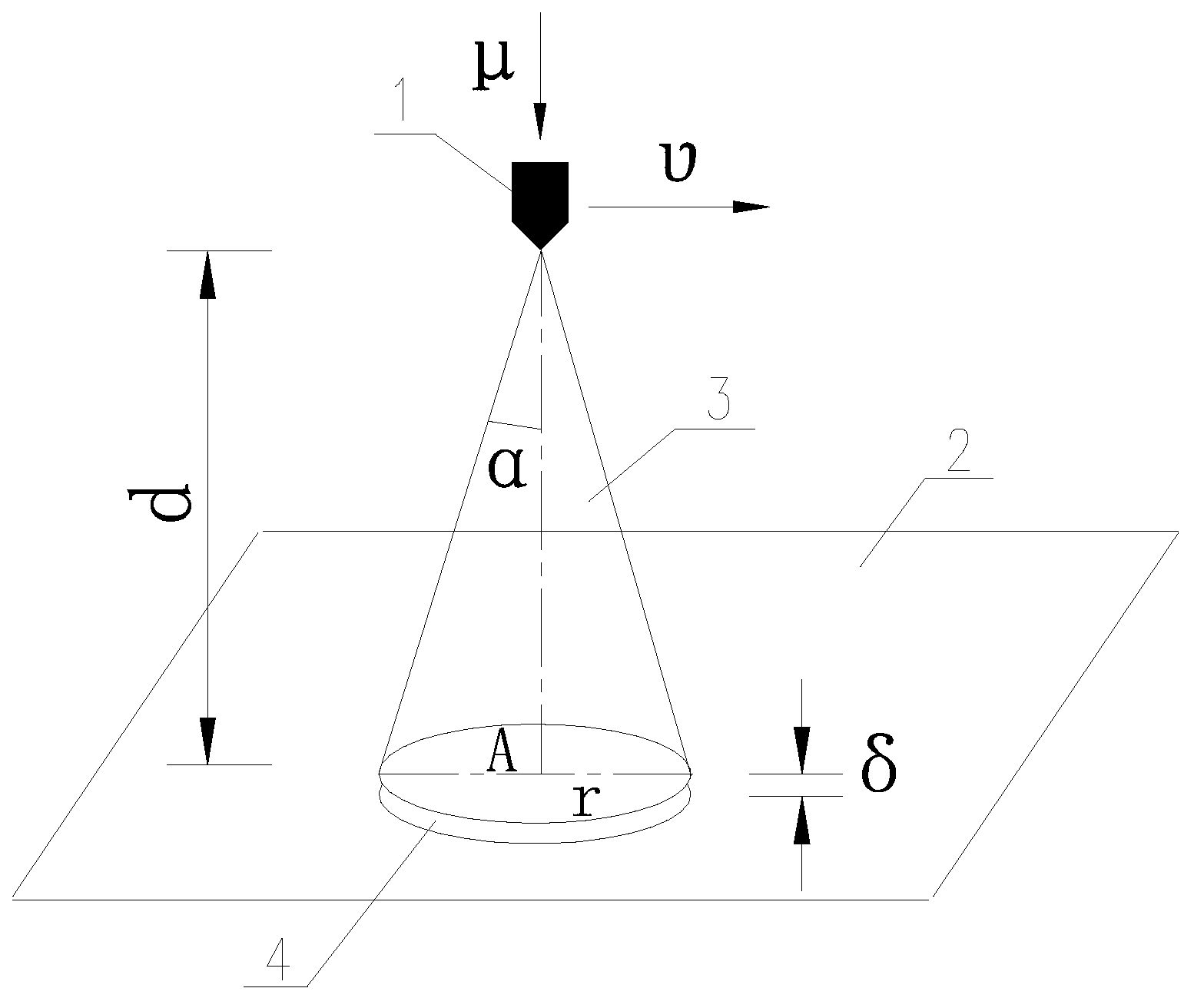

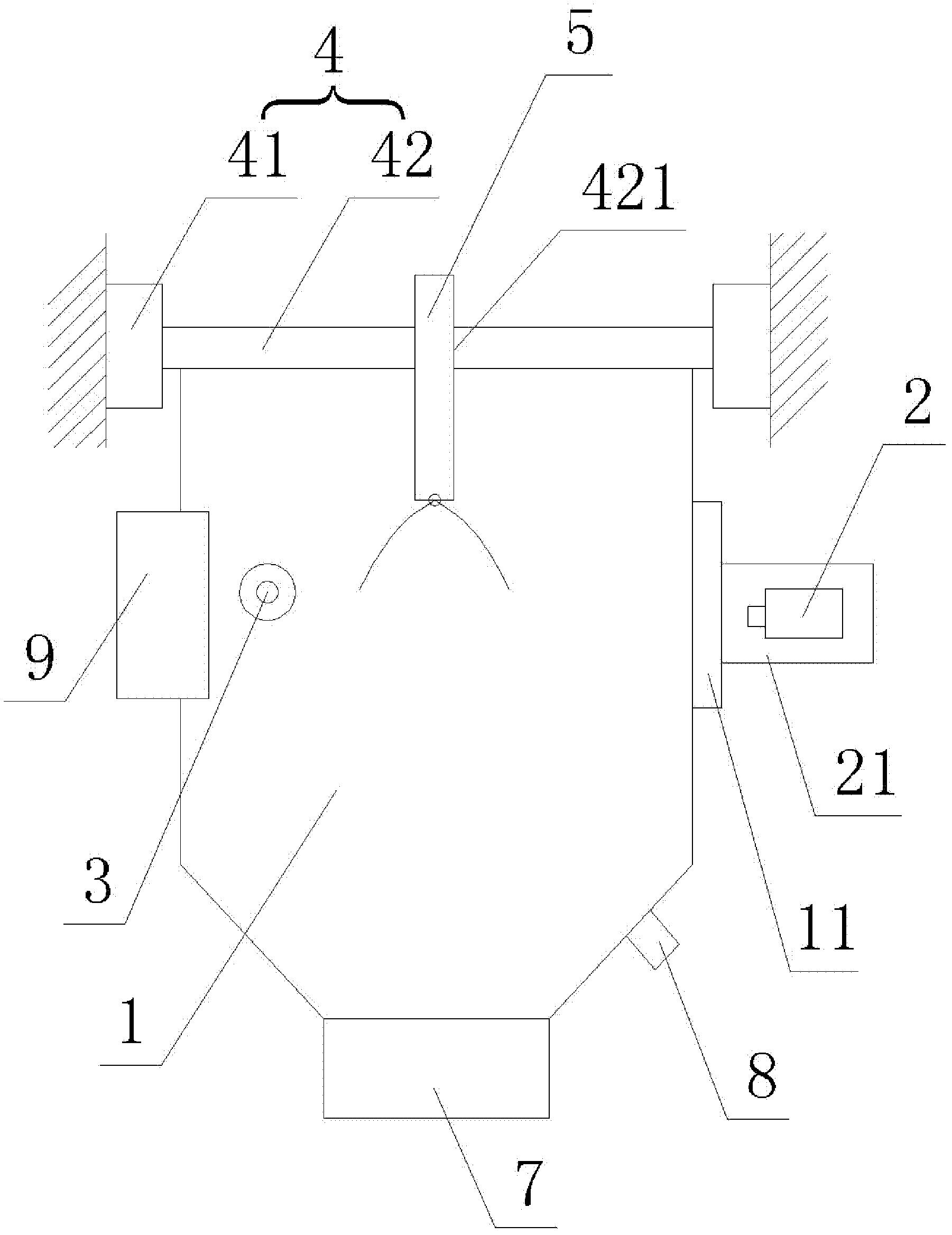

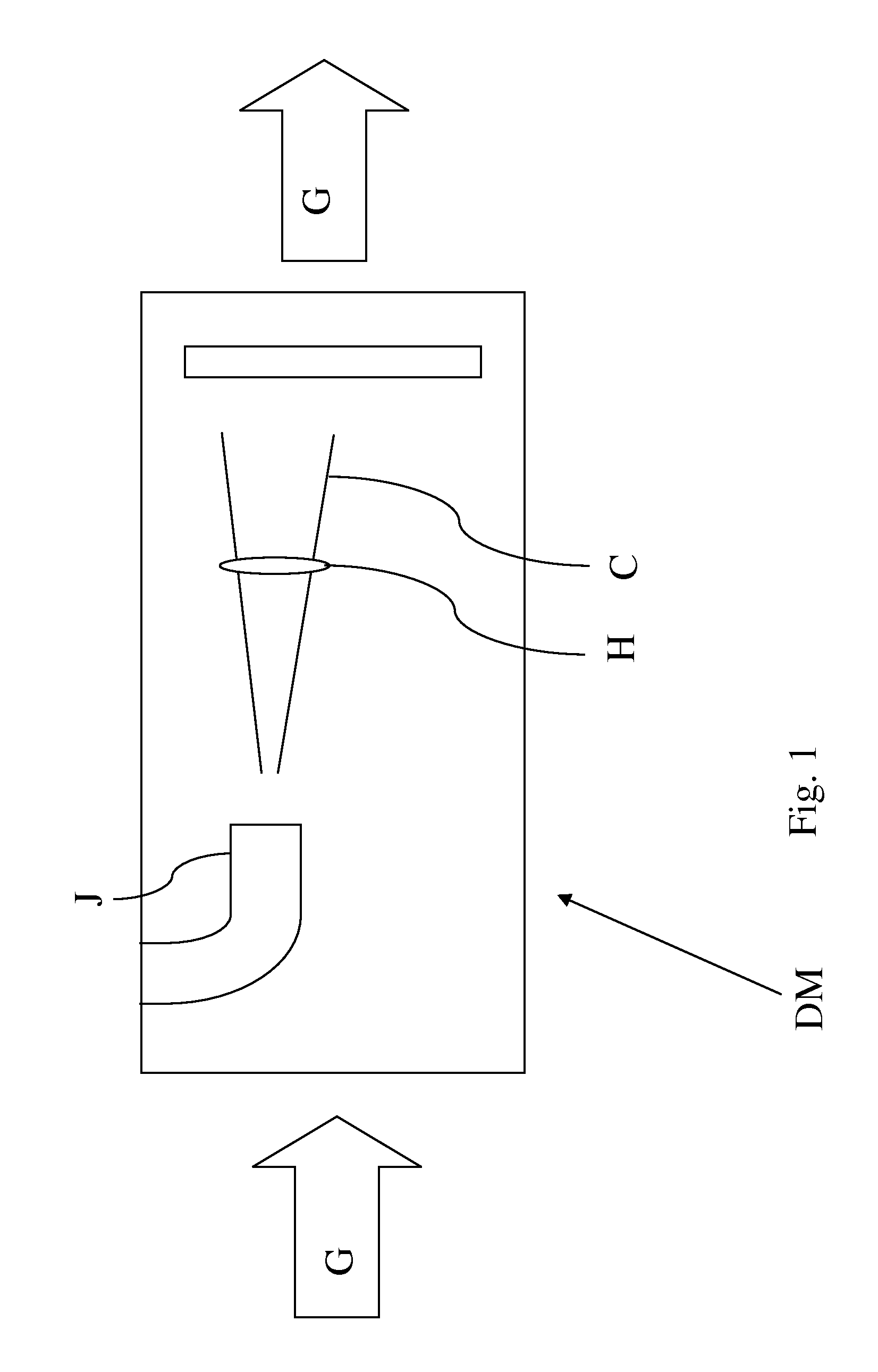

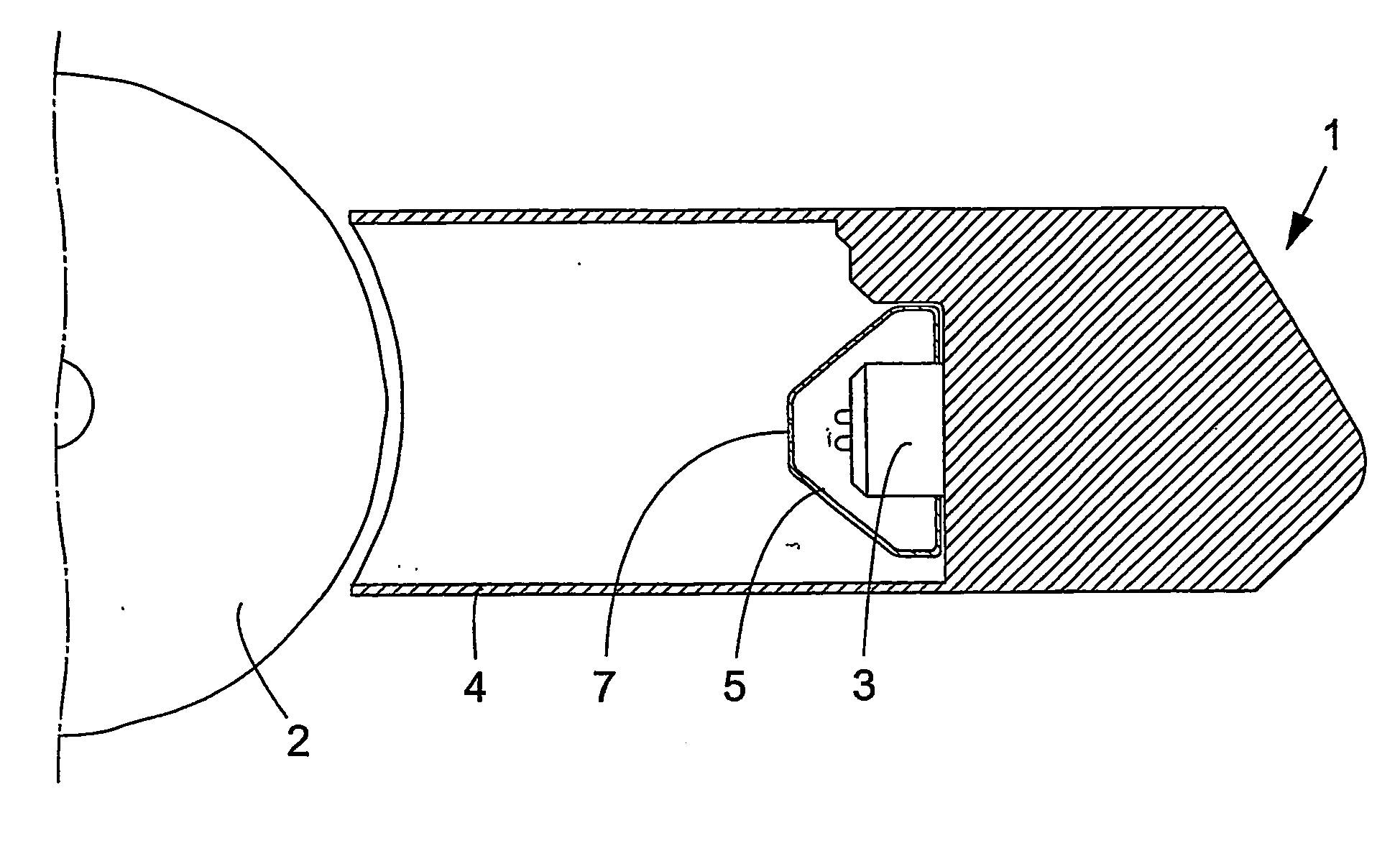

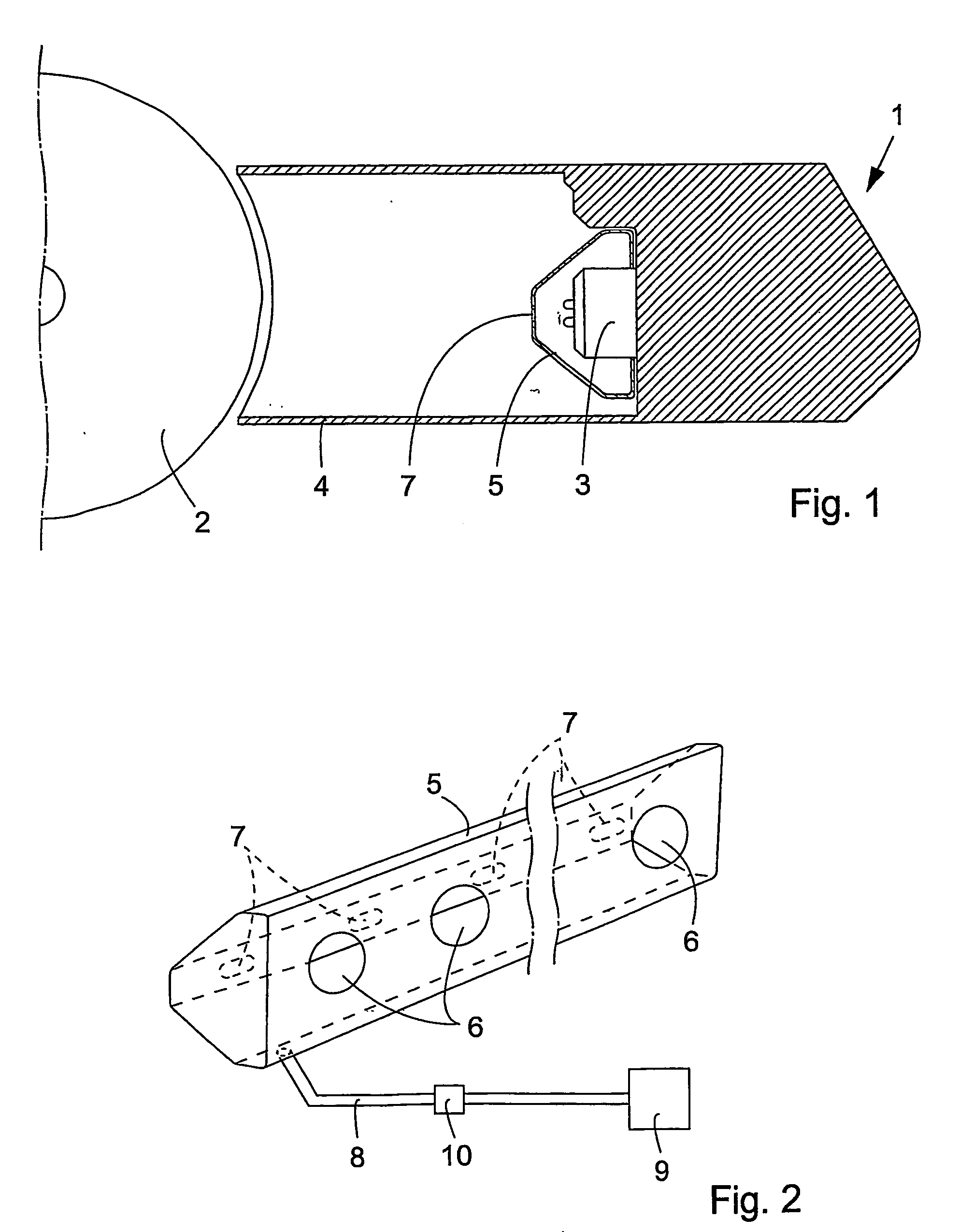

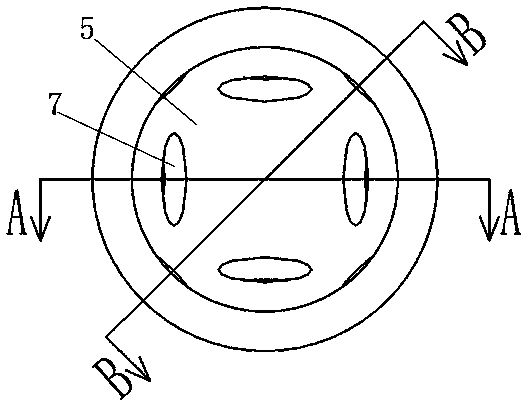

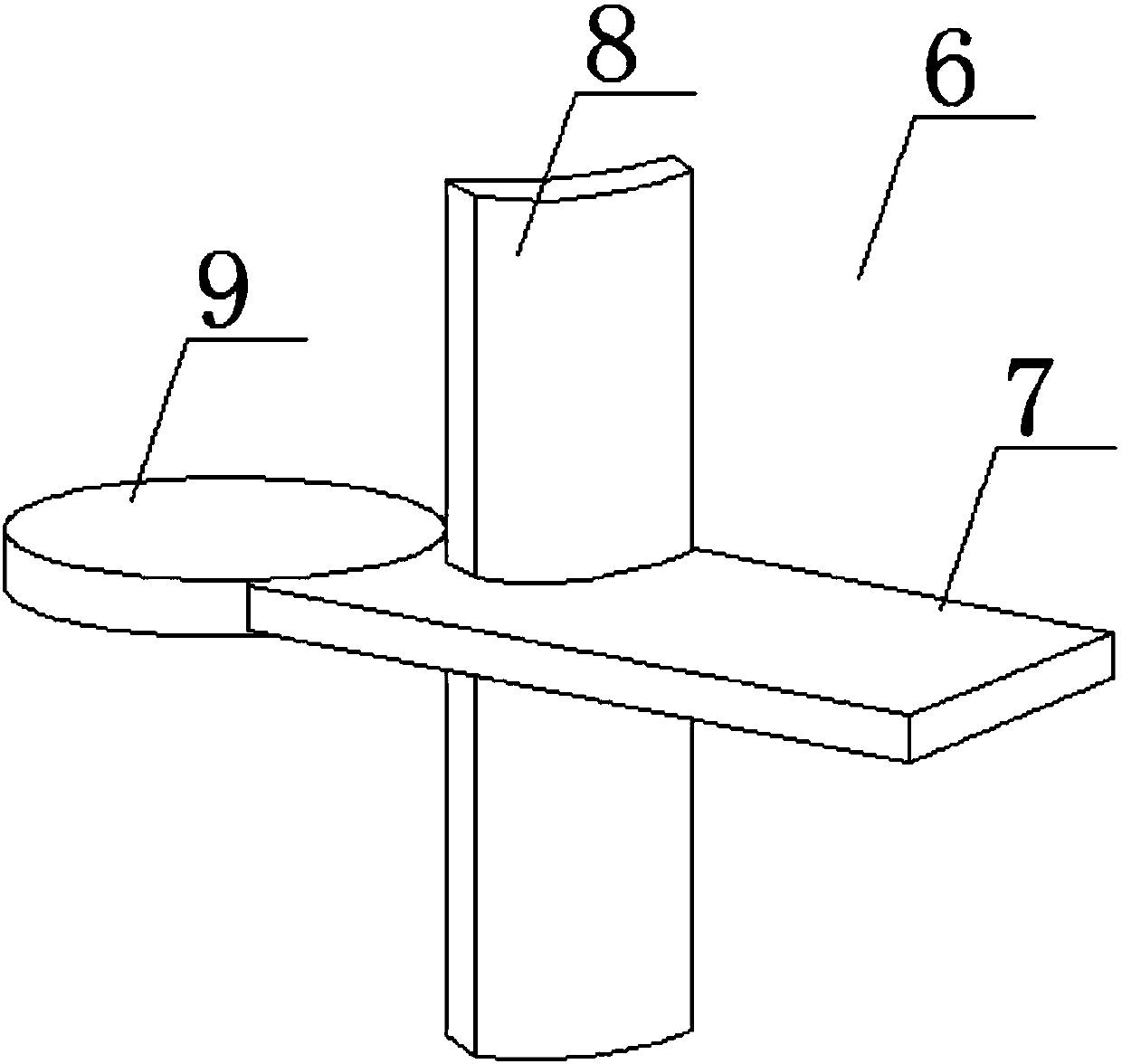

Device for measuring spray cone angle

ActiveCN102506765AClear boundariesHigh precisionGas-turbine engine testingUsing optical meansSpray conePhysics

The invention provides a device for measuring a spray cone angle, comprising a spraying room (1), a camera (2) and a spot light (3), wherein the spraying room (1) is internally provided with a nozzle (5); the camera (2) is used for photographing the spray cone angle of the nozzle (5); and the spot light (3) is mounted on the side wall of the spraying room (1). According to the device, by reasonably arranging the position of the spot light and adjusting the brightness of the spot light, the boundary of conical spraying is clearer, so that the accuracy of the measurement is greatly improved.

Owner:CHINA AVIATION POWER MACHINE INST

System for preventing the urea crystal formation within an exhaust gas after treatment system

System for preventing the urea crystal formation within the ATS, the exhaust ATS comprising a dosing module having dosage means for producing a spray of urea-based reducing agent defining a spray cone downstream of the dosage means, the device comprising an electric heating element, suitable to be connected to an electrical energy source, arranged in order to operatively fall within the spray cone.

Owner:FPT MOTORENFORSCHUNG

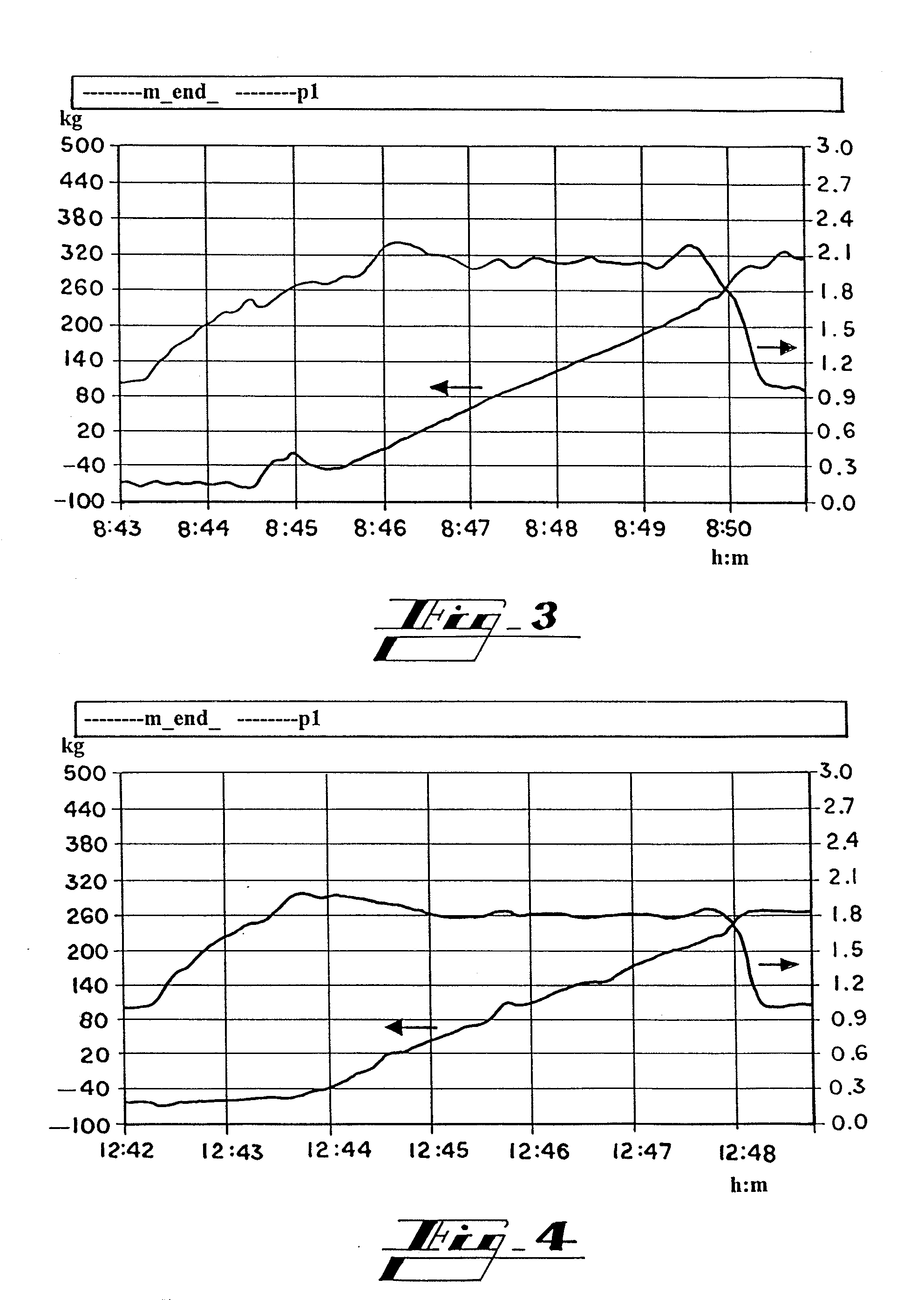

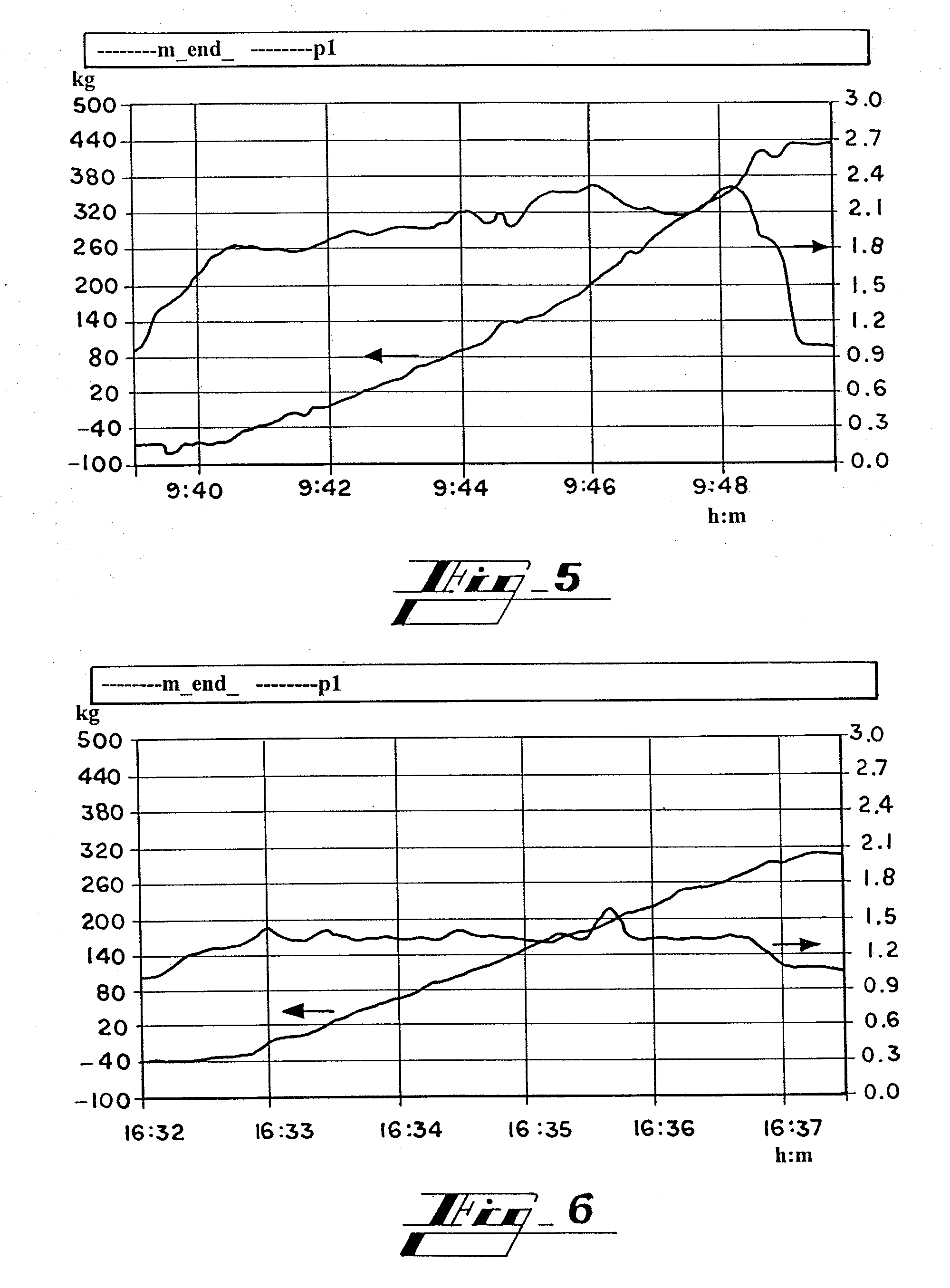

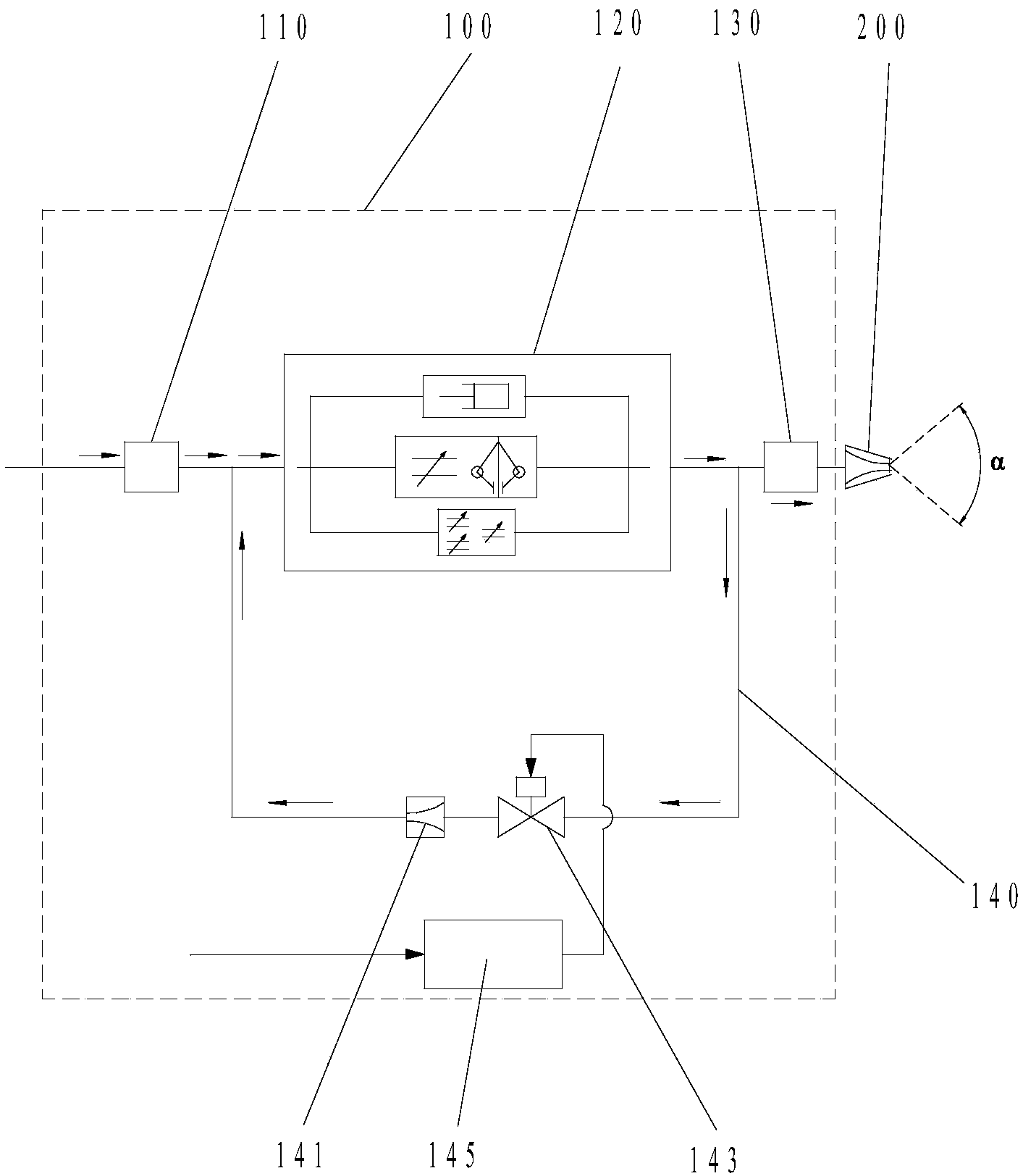

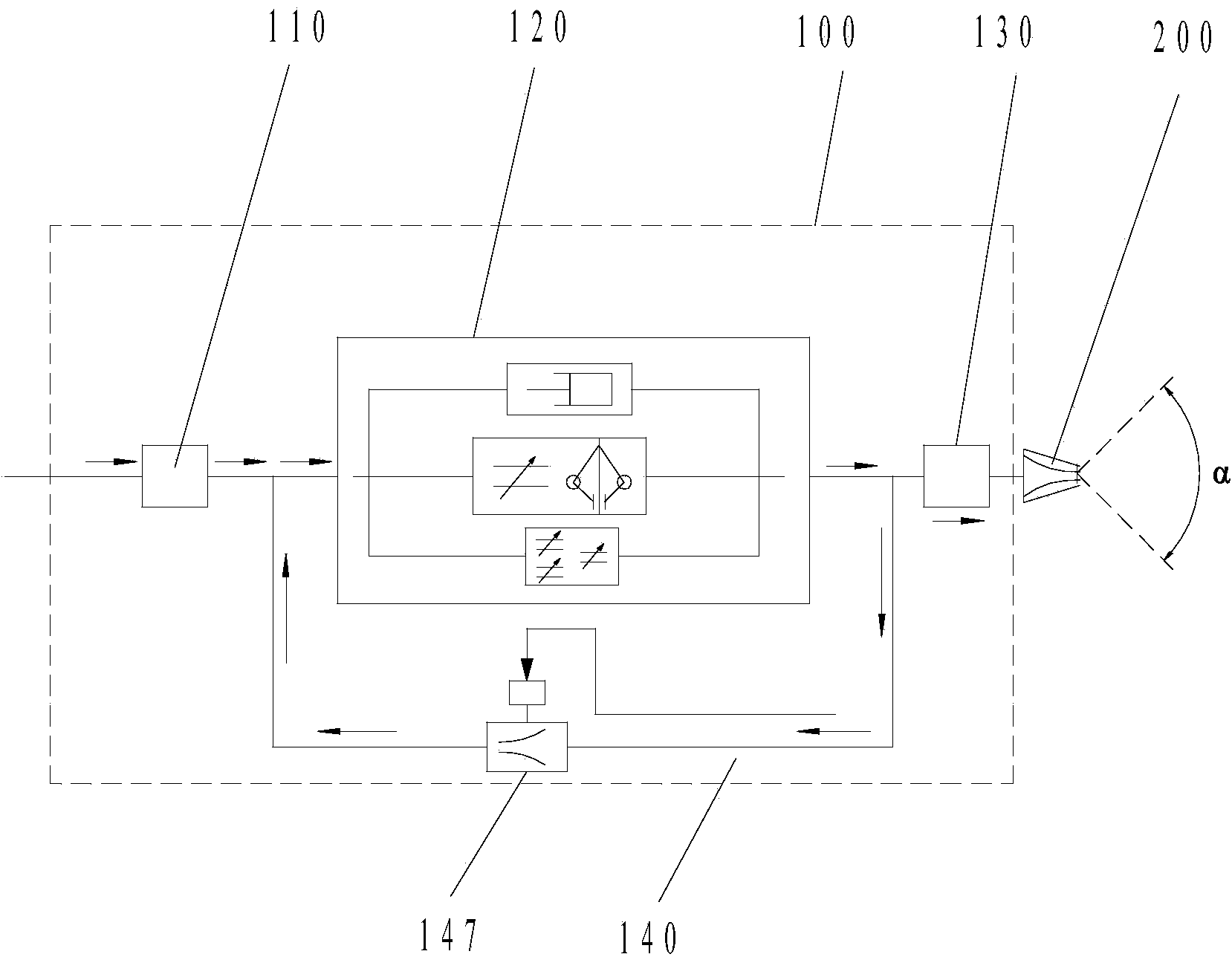

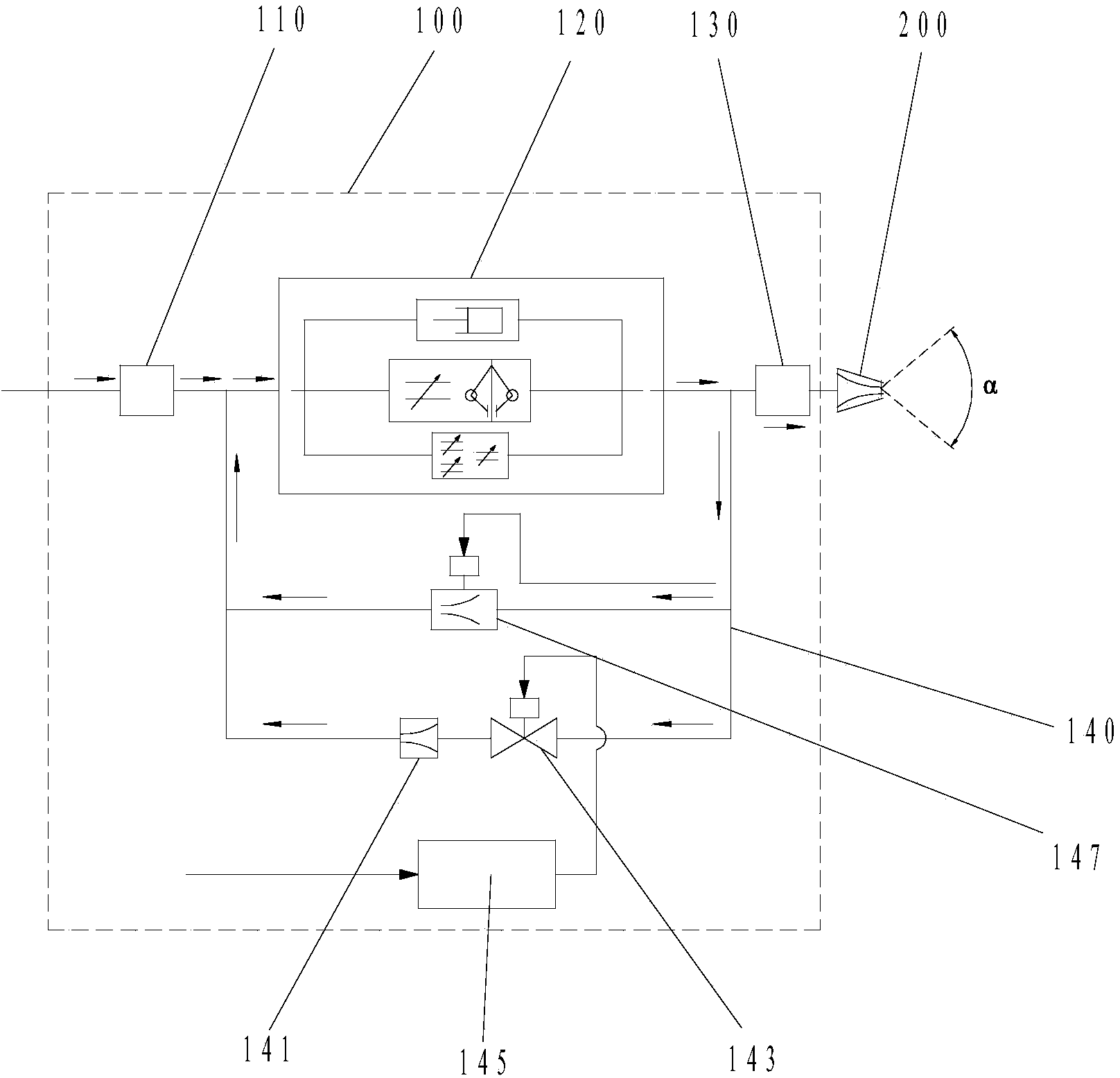

Start fuel supply control method and system for micro gas turbine

ActiveCN103967622ASatisfy oil supplyMeet needsTurbine/propulsion engine ignitionTurbine/propulsion engine startersSpray coneCombustion chamber

The invention discloses a start fuel supply control method and system for a micro gas turbine, and is used for fuel supply control in the start process of the micro gas turbine. The micro gas turbine adopts a centrifugal atomization fuel nozzle, fuel is supplied to the centrifugal atomization fuel nozzle through a fuel control unit, atomized by the centrifugal atomization fuel nozzle, and ignited for combustion in a combustion chamber; the fuel supply requirements of the micro gas turbine in plain and plateau application scenarios can be met through adjusting the flow amount and / or a spray cone angle of the centrifugal atomization fuel nozzle. According to the method and system, under the condition of not changing technical parameters of the fuel supply control unit, the flow pressure characteristics of the fuel nozzle can be changed, the start fuel flow can be reduced, the gas-fuel ratio of ignition start can be increased, the fuel pressure in front of the nozzle can be increased, the atomization performance is enhanced, and the plateau ignition start performance is enhanced, and thus the fuel supply characteristic requirements of the micro gas turbine in high altitude application can be met and the operation field range of the micro gas turbine is widened.

Owner:CHINA AVIATION POWER MACHINE INST

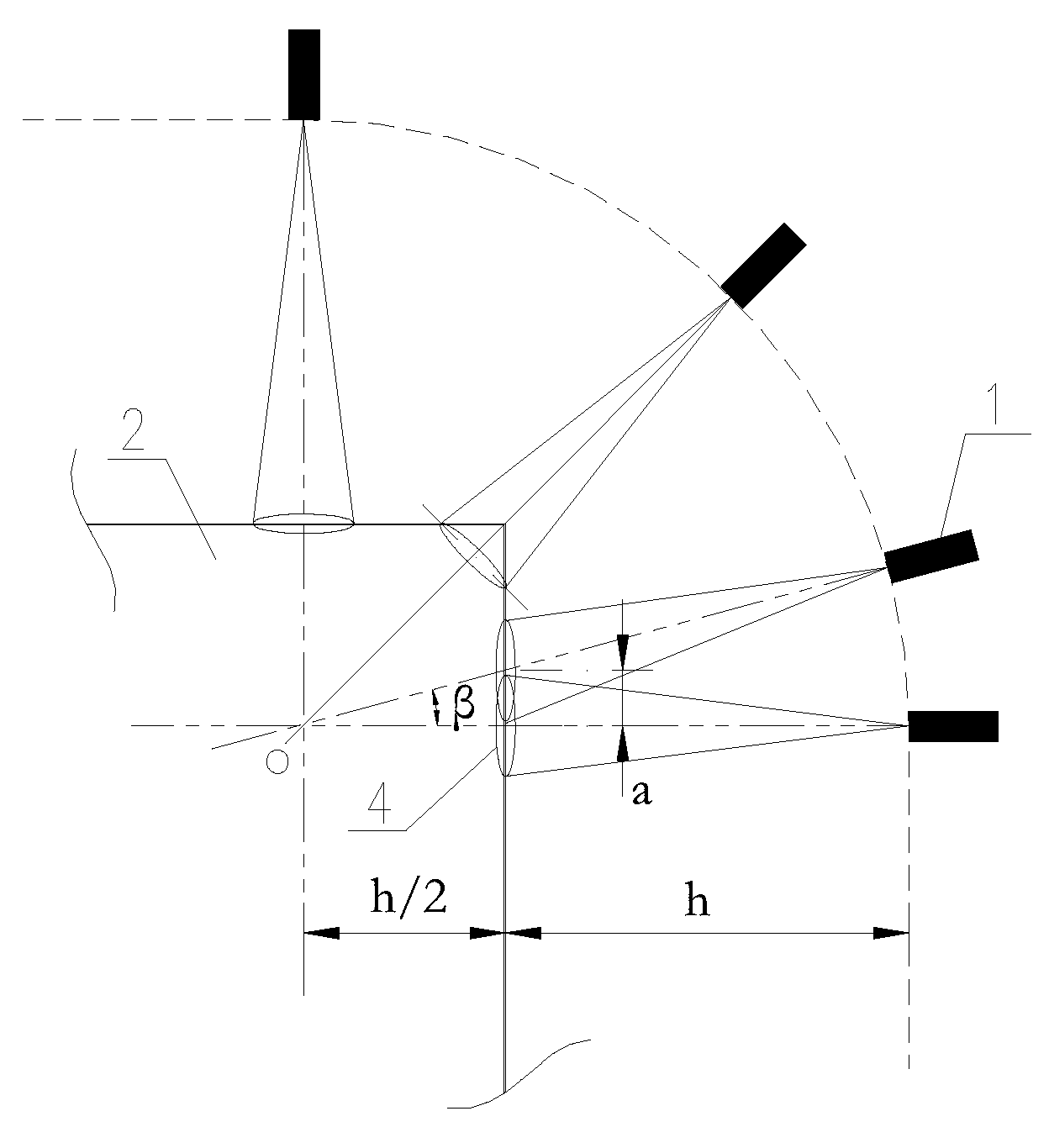

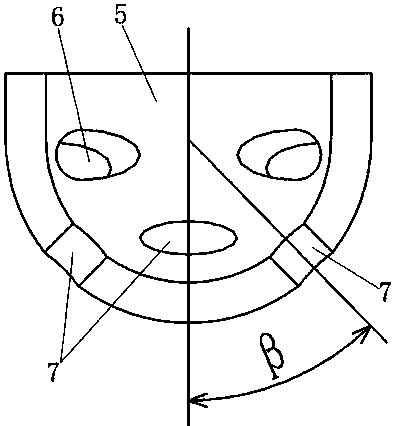

Burner for a Gas Turbine

InactiveUS20070207431A1Reduce turbulenceSmall angleContinuous combustion chamberGaseous fuel burnerCombustorSpray cone

A premix burner, for example for a gas turbine, having a conical swirl generator (1) and a cylindrical mixing section (2) which follows it in the direction of flow, includes a high-pressure atomizer nozzle (10) with one or more fuel feed passages. The high-pressure atomizer nozzle (10) includes at least two outlet passages, through which liquid fuel enters the swirl generator (1), these passages being arranged off-center with respect to the longitudinal axis of the nozzle and being configured in such a way that the spray cone (11) of the fuel is oriented at an angle (β) with respect to the longitudinal axis of the swirl generator (1) which is smaller than the cone half-angle (α) of the swirl generator (1). The outlet passages in particular have an internal geometry with a conically narrowed section.

Owner:ANSALDO ENERGIA SWITZERLAND AG

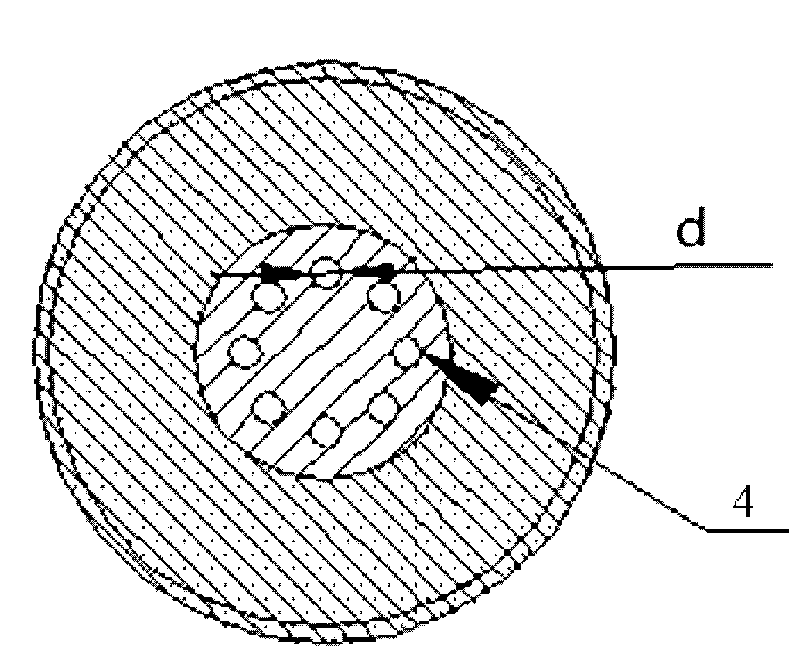

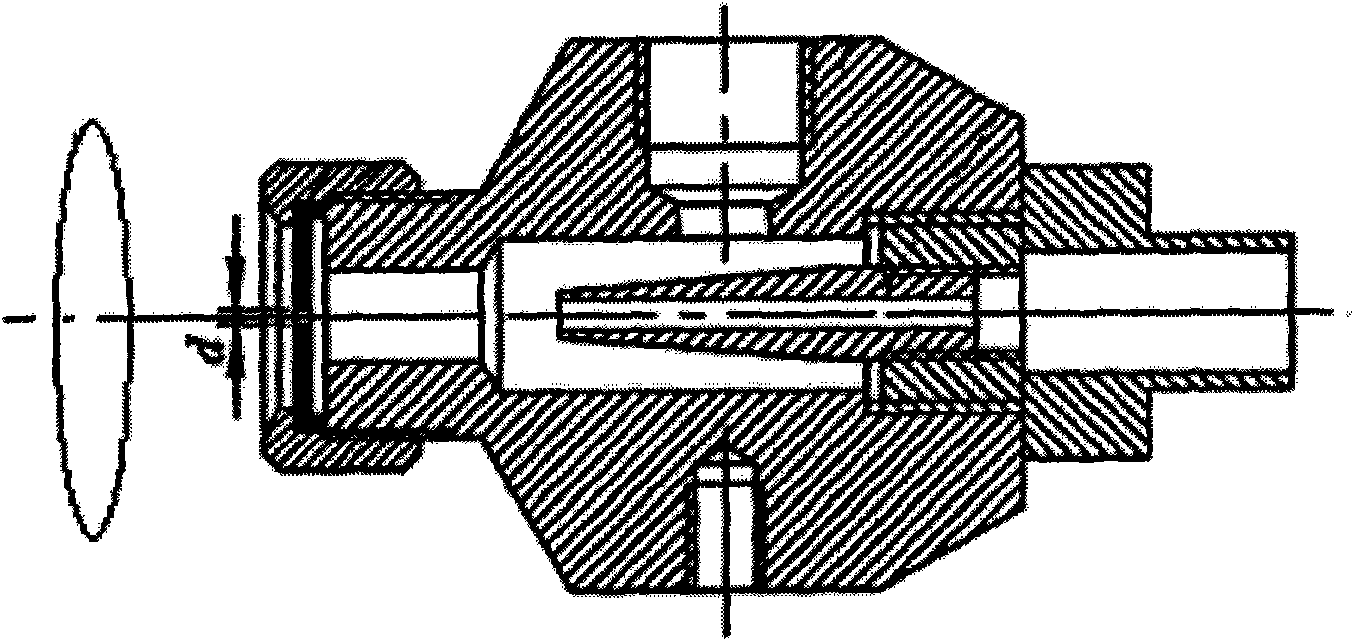

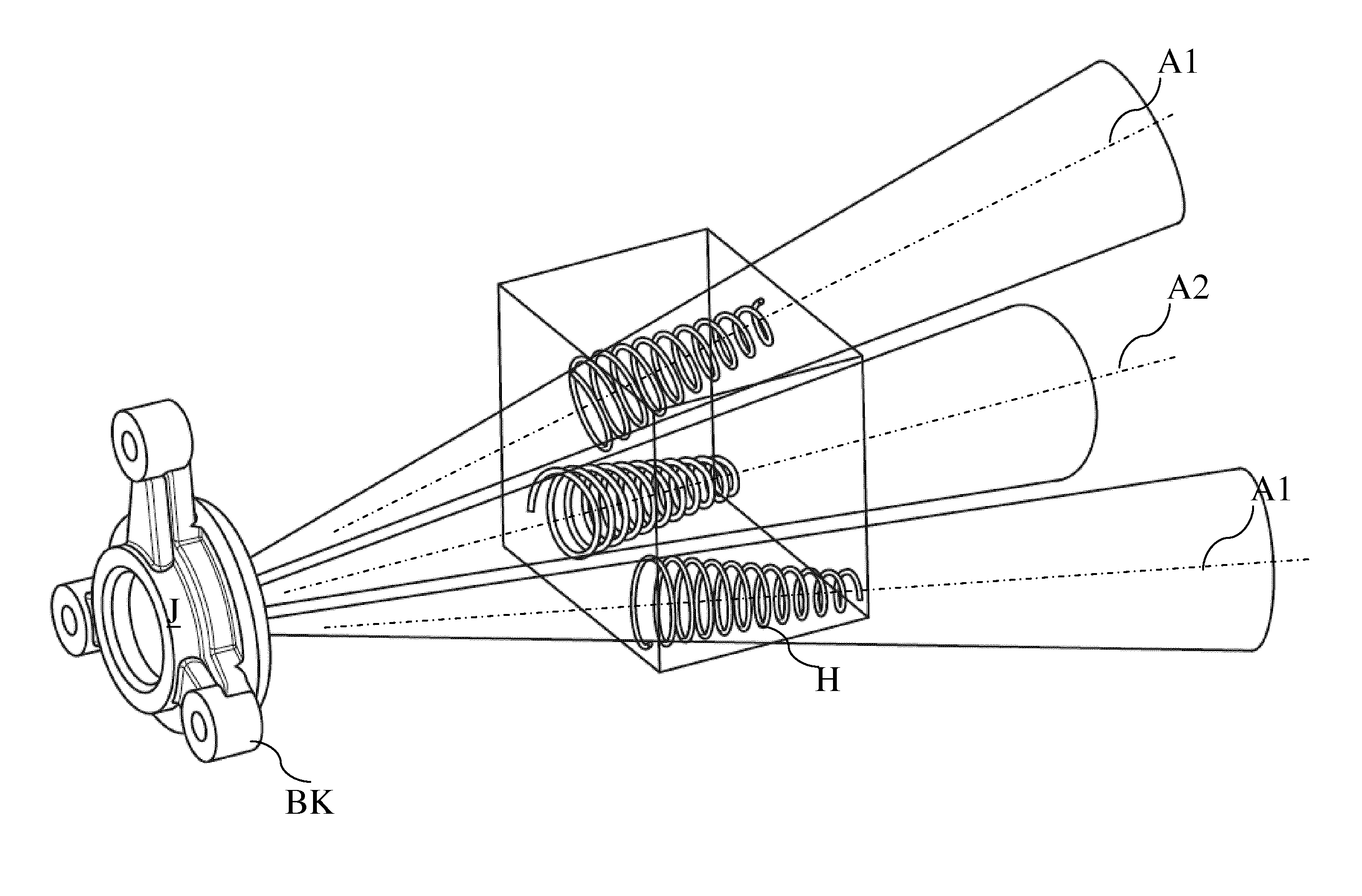

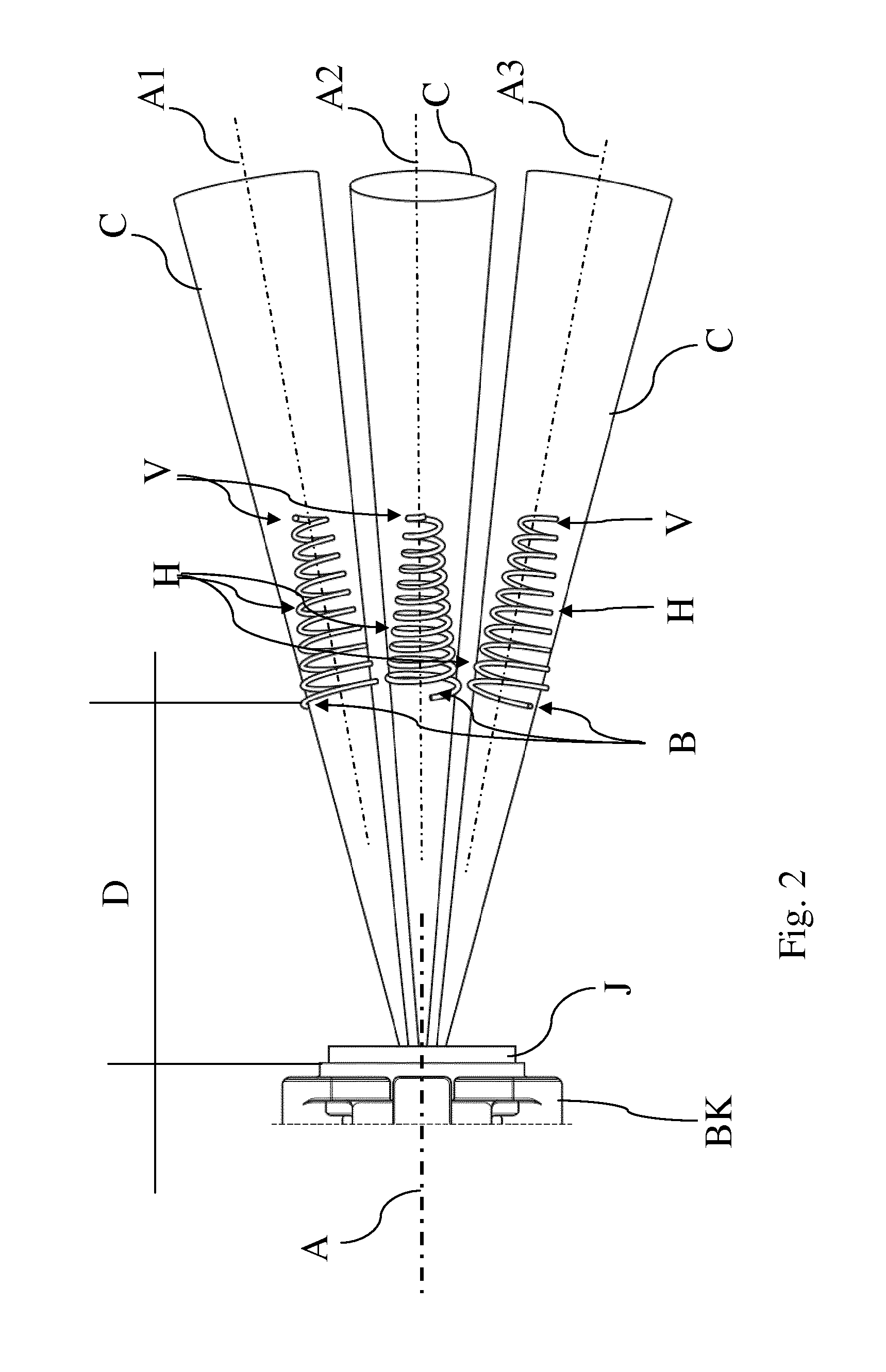

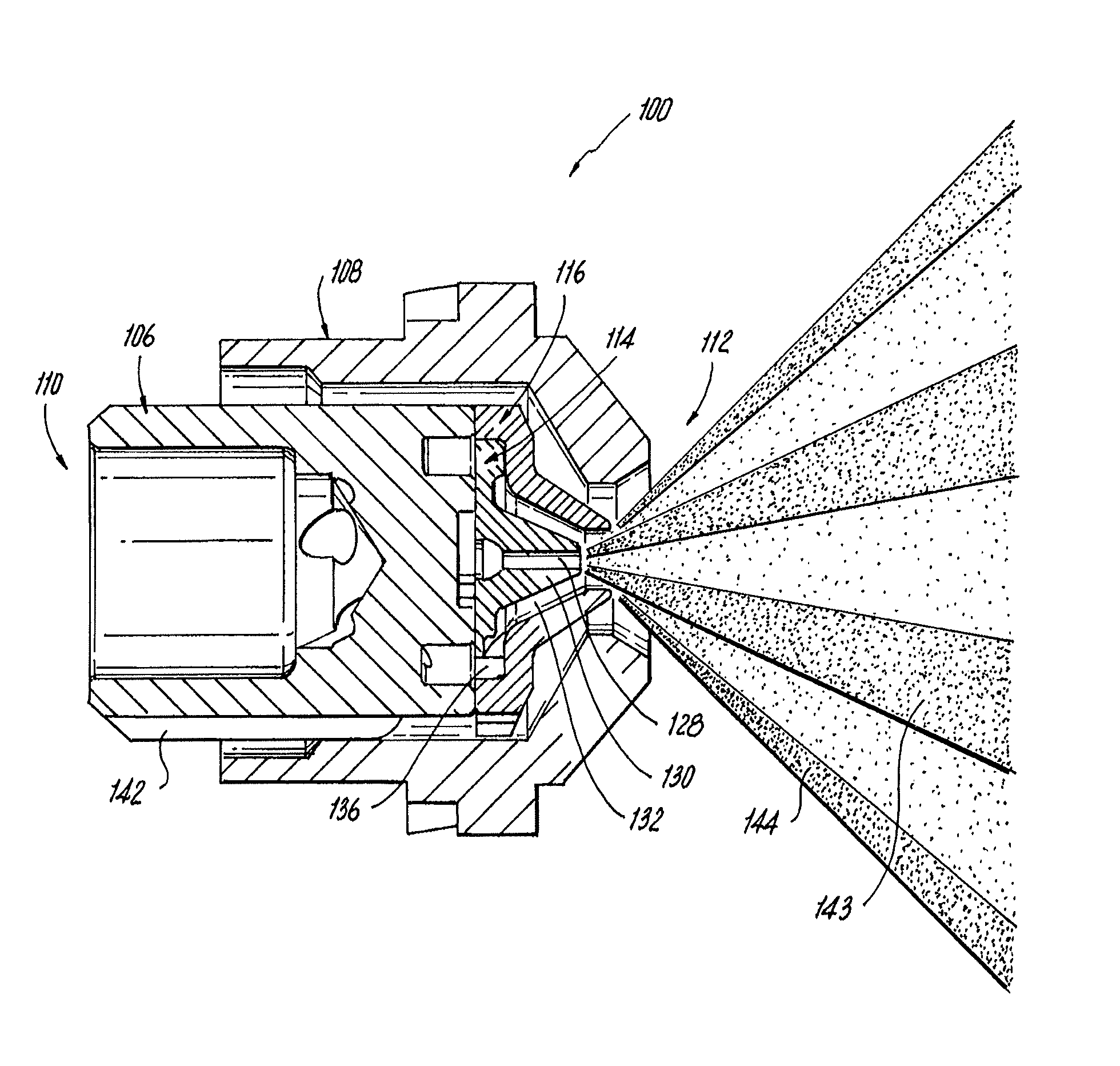

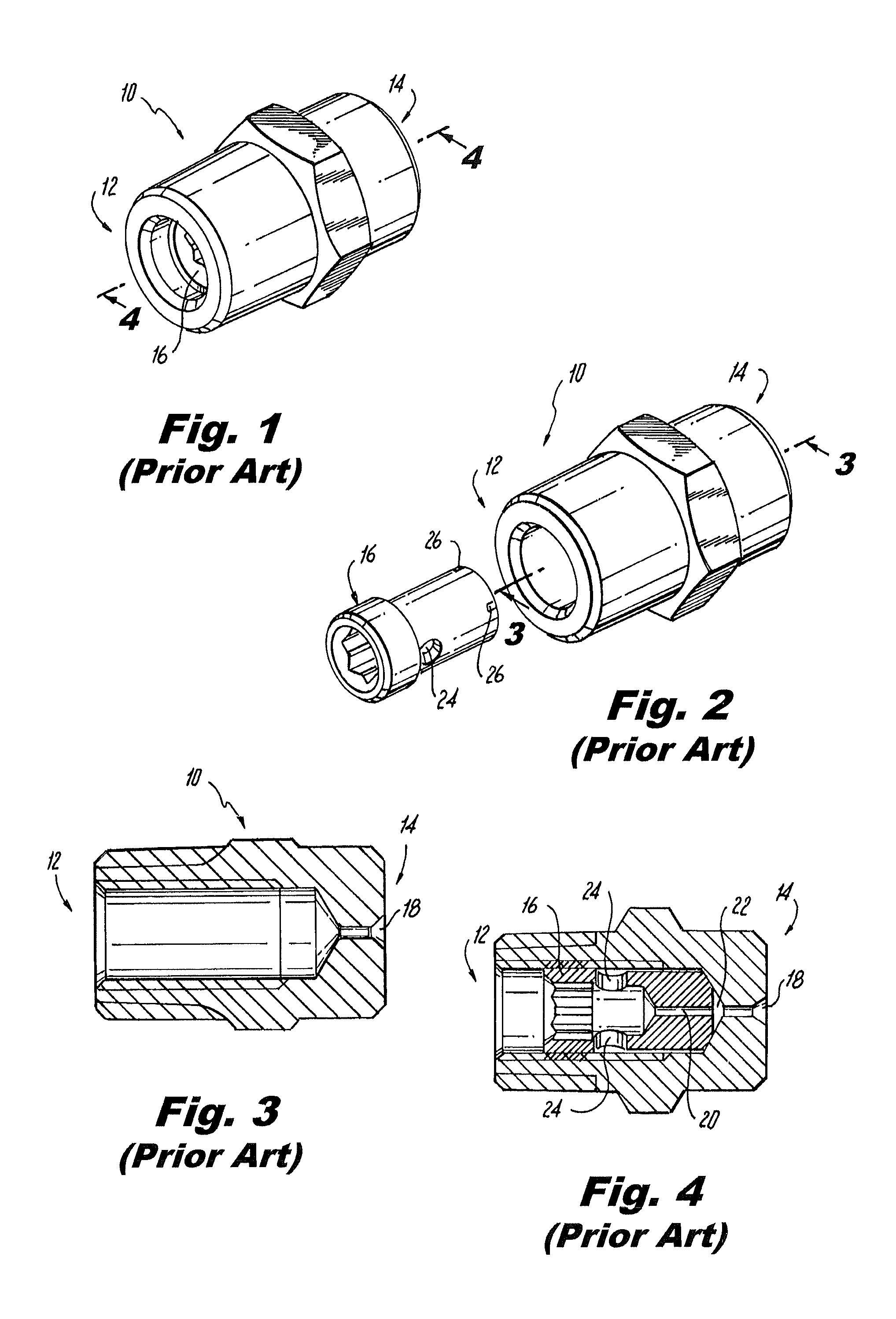

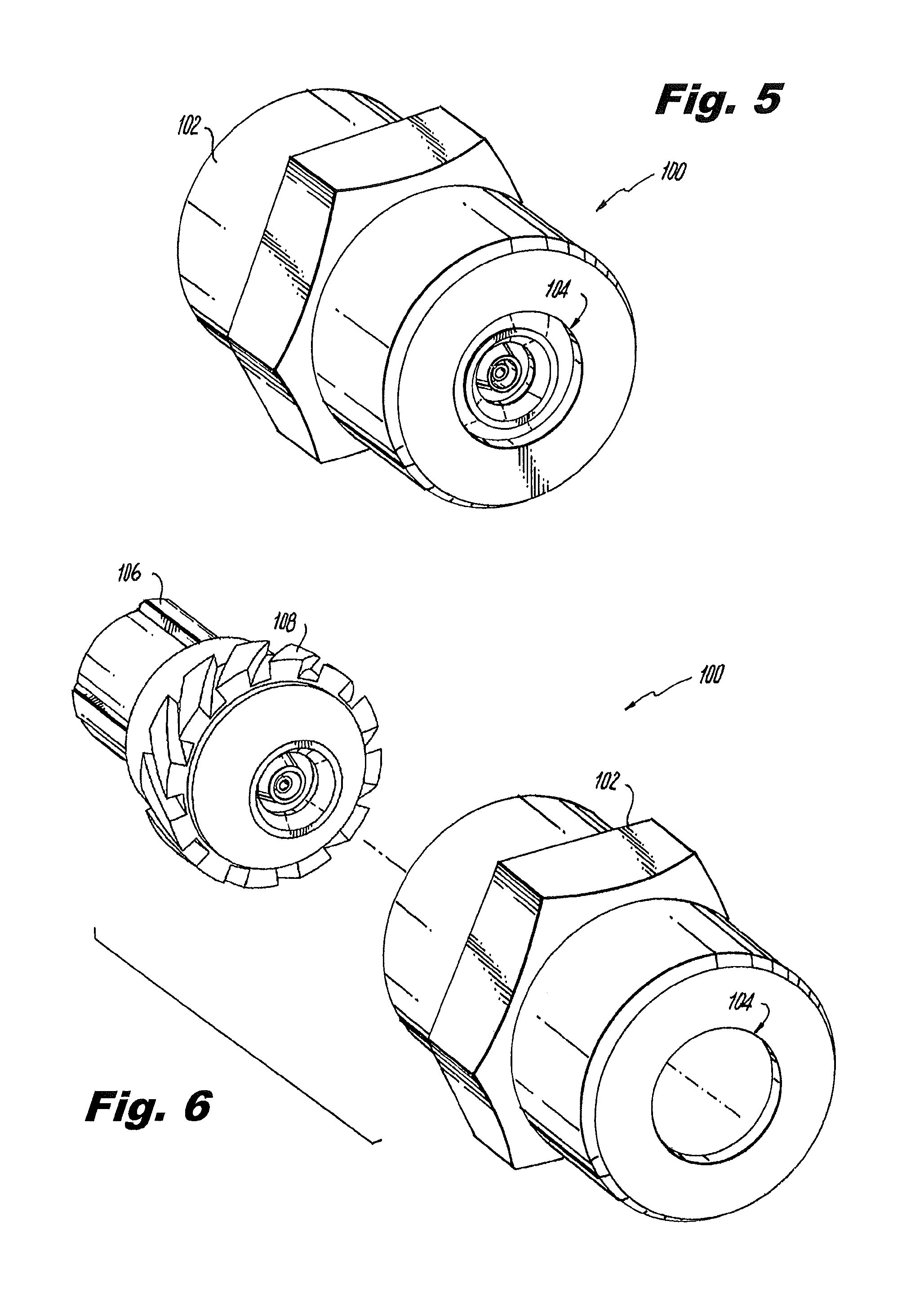

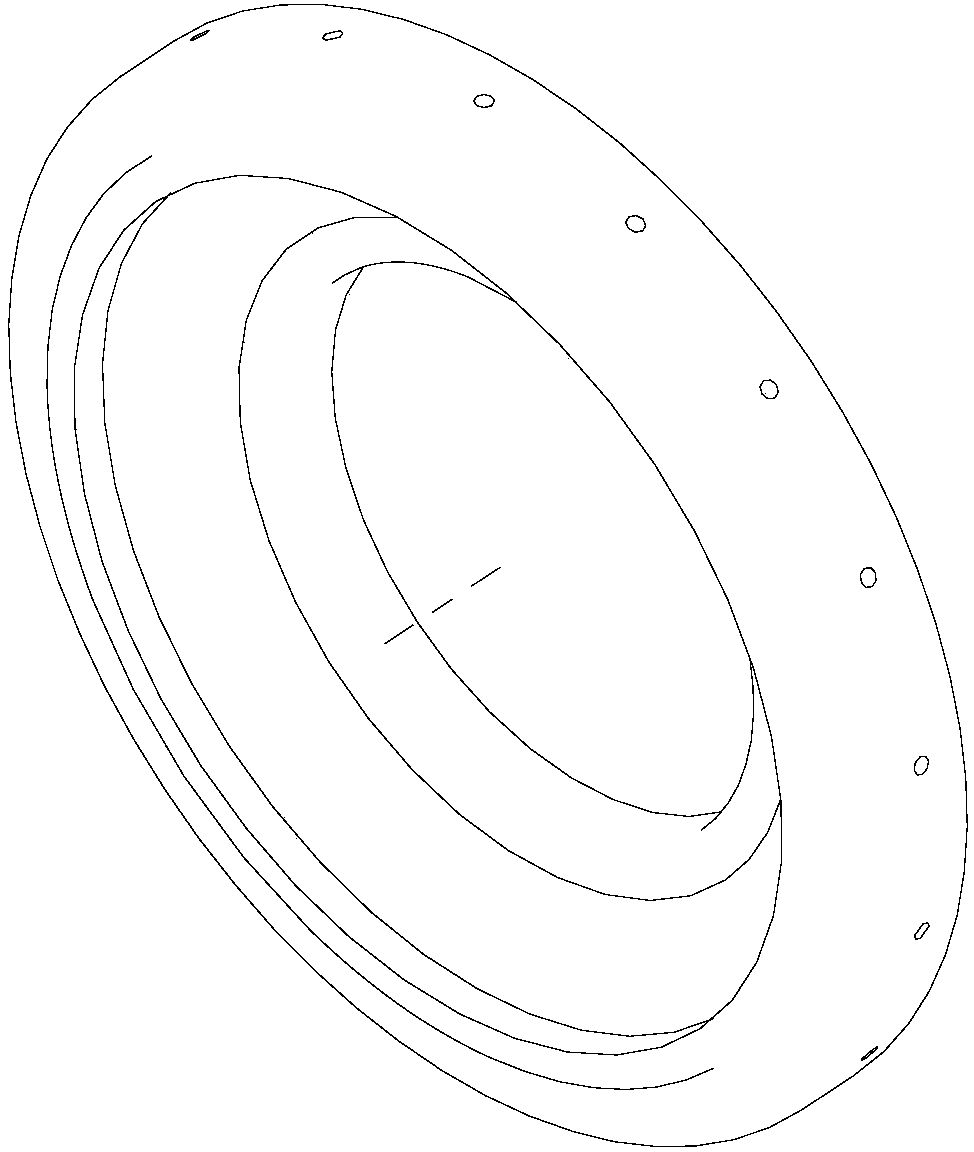

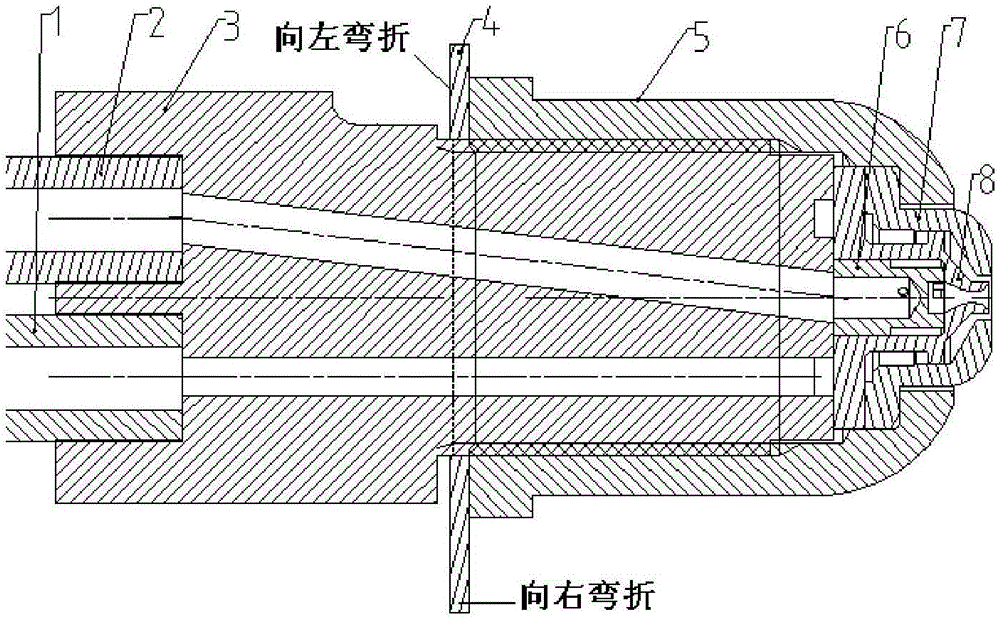

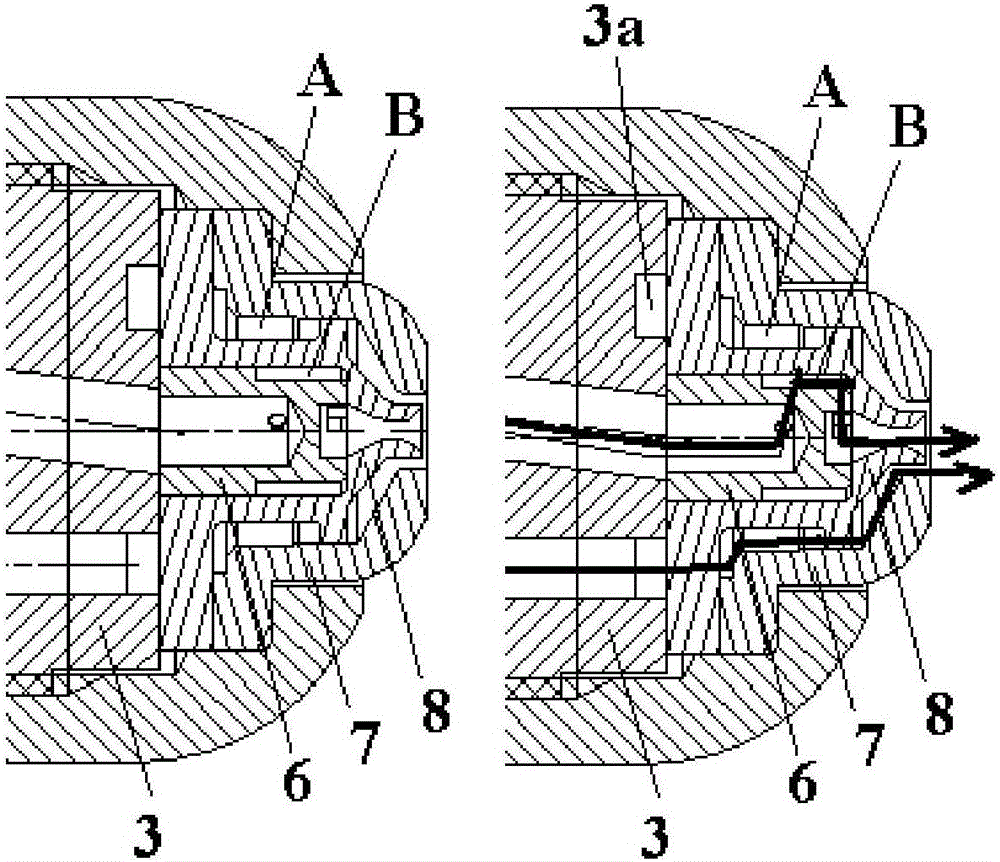

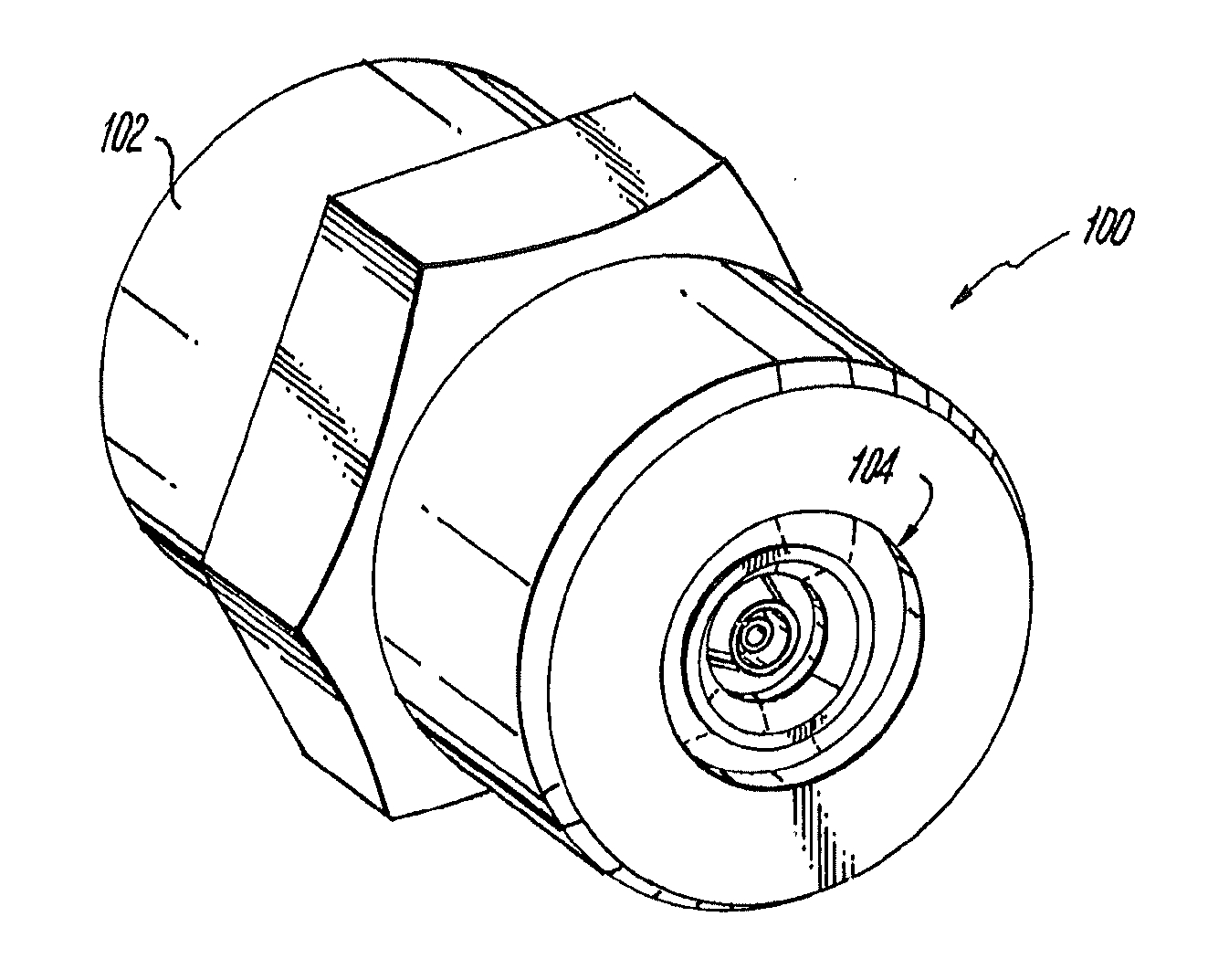

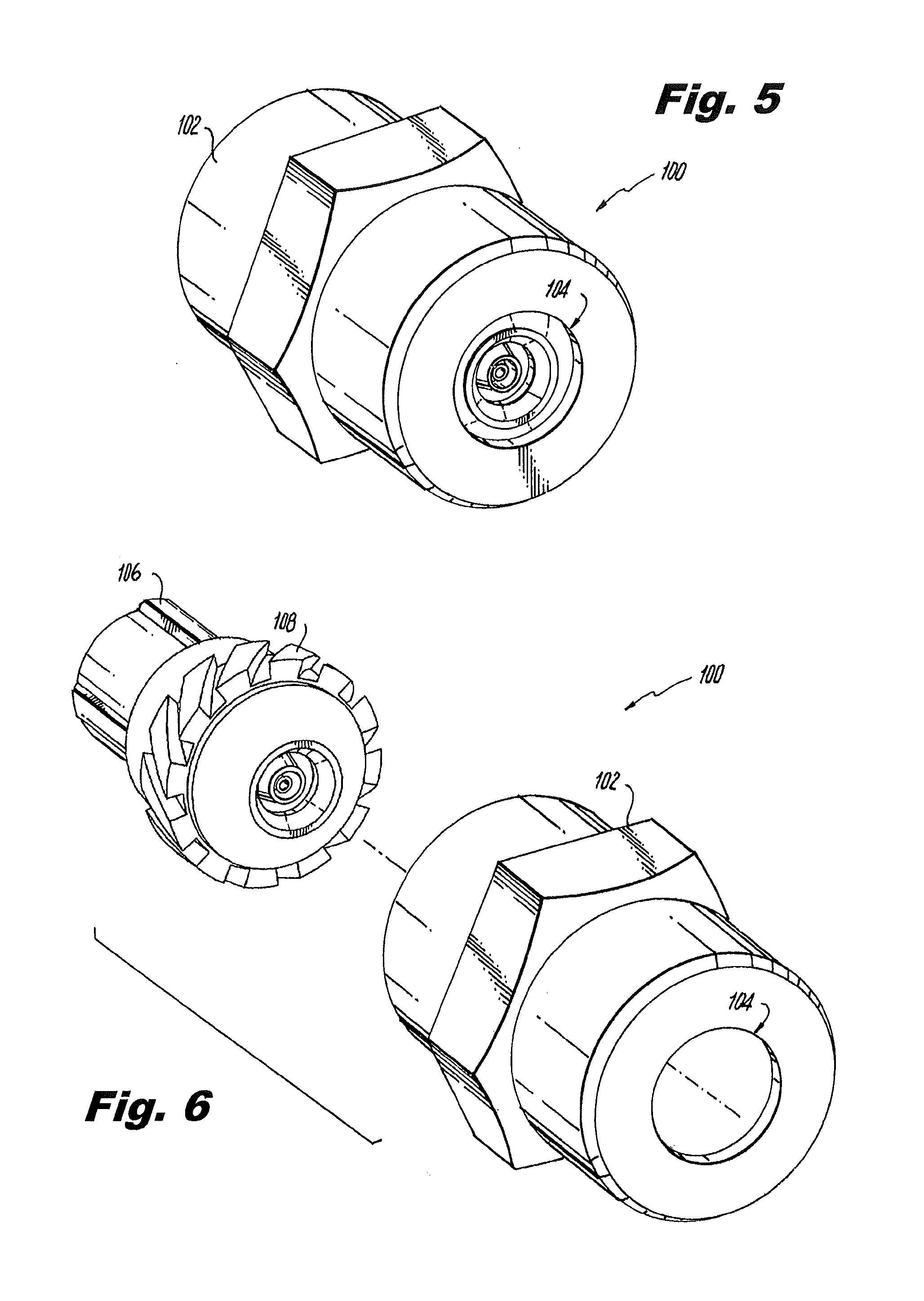

Single circuit multiple spray cone pressure atomizers

An atomizer includes an atomizer body having a liquid inlet and a spray outlet with a liquid flow circuit defined through the inner atomizer body for fluid communication of liquid from the inlet to the spray outlet. The liquid flow circuit branches into a plurality of sub-circuits. Each sub-circuit is configured to produce a spray cone of atomized liquid issuing from the spray outlet such that the spray cone of each sub-circuit has a different cone angle. The sub-circuits are mechanically separated from one another to limit interaction of liquid in the sub-circuits and thereby produce a distinct and stable spray cone from each sub-circuit over a range of liquid flow rates.

Owner:COLLINS ENGINE NOZZLES INC

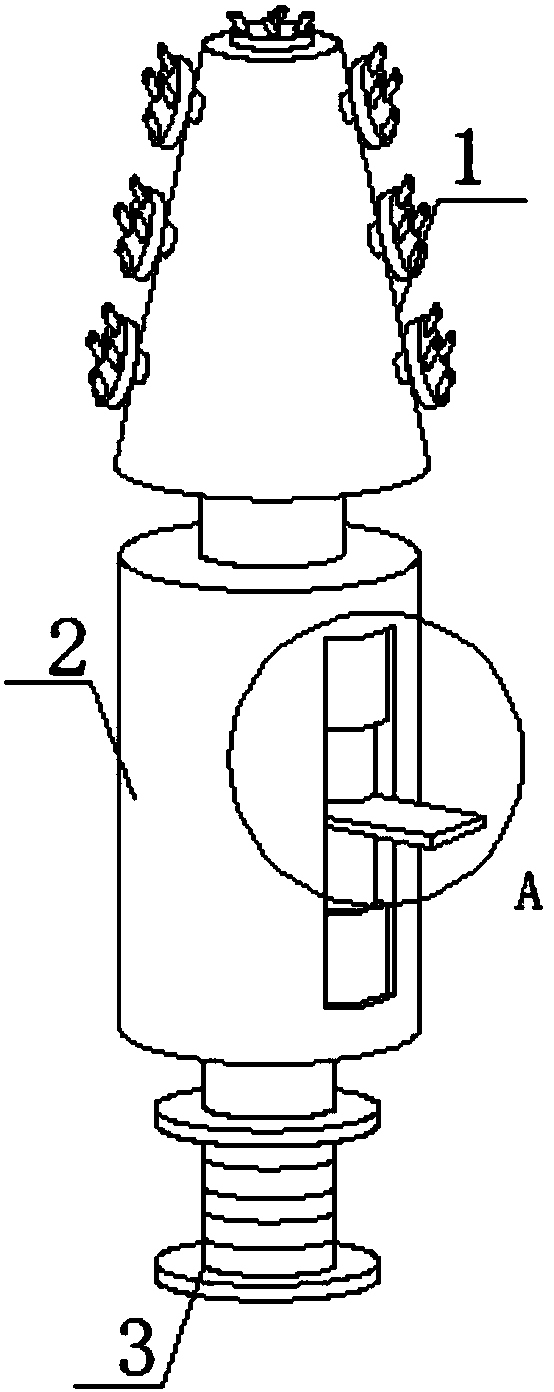

Fuel nozzle testing platform

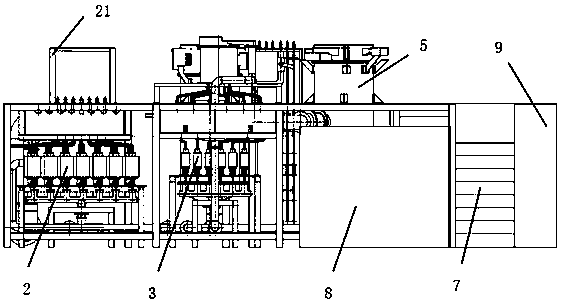

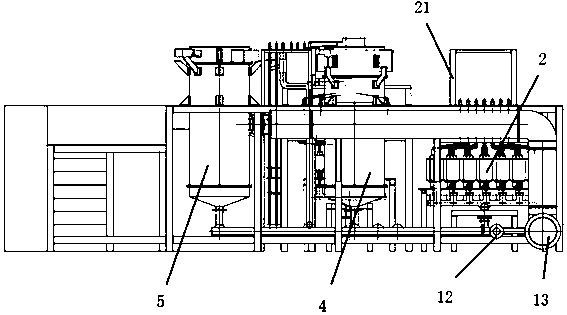

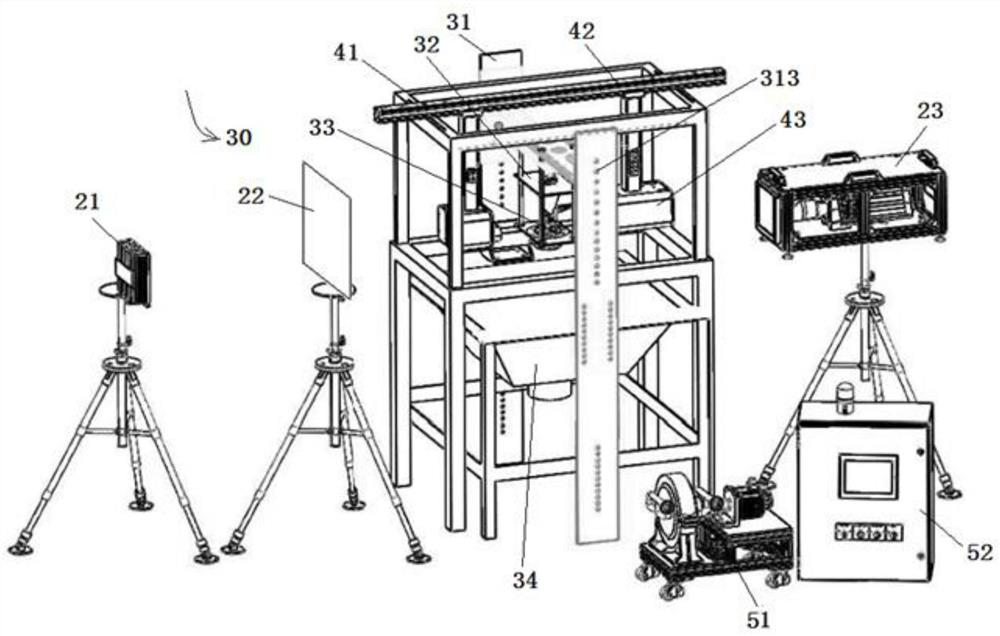

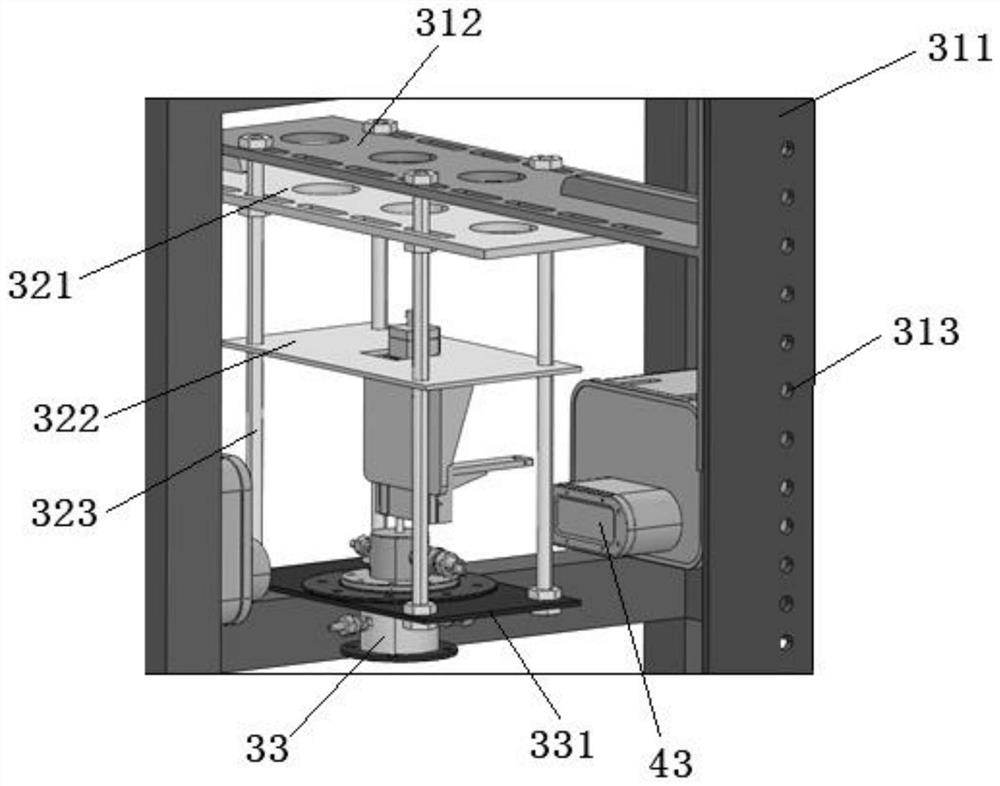

PendingCN109387373ACompact layoutExquisite designGas-turbine engine testingJet-propulsion engine testingAviationSpray cone

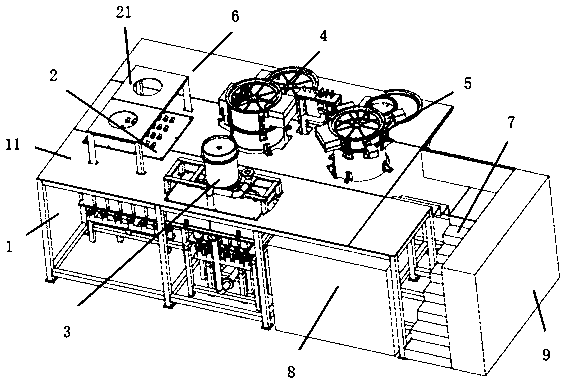

The invention belongs to the technical field of an aeroengine, and discloses a fuel nozzle testing platform. The fuel nozzle testing platform comprises a stand with a floor, a trunk pipe testing device which penetrates through the floor, a maldistribution degree testing device, a spraying cone angle manual measuring device and an automatic measuring device. The trunk pipe testing device and the maldistribution degree testing device are vertically arranged. The spraying cone angle manual measuring device and the automatic measuring device are parallelly arranged next to the long side of the rectangular floor. The trunk pipe testing device, the maldistribution degree testing device, the spraying cone angle manual measuring device and the automatic measuring device form a U-shaped path. The width of the U-shaped path is 700-900mm. The maldistribution degree testing device, the spraying cone angle manual measuring device and the automatic measuring device respectively comprise a testing clamp for mounting a single nozzle clamp or a trunk pipe nozzle clamp. The floor is provided with a plane rack which extends at the long side of the spraying cone angle manual measuring device and is used for placing a changed testing clamp. The side surface of the stand is provided with a lifting mechanism for climbing the floor by an operator.

Owner:中科航空动力(株洲)装备制造研究院有限公司

System for producing alloy containing rare earth metal

ActiveUS20060076719A1Prevent oxidationFacilitates and improves efficiencyQuenching devicesSpray coneRare earth

In order to keep a spray nozzle (3) in a printing press spray beam (1) clean, air with a certain overpressure is supplied to a cover (5; 13; 24) surrounding the spray nozzle (3), the spray cone from the spray nozzle leaving the cover undisturbed through a slot (7; 16; 26) therein.

Owner:SANTOKU CORP

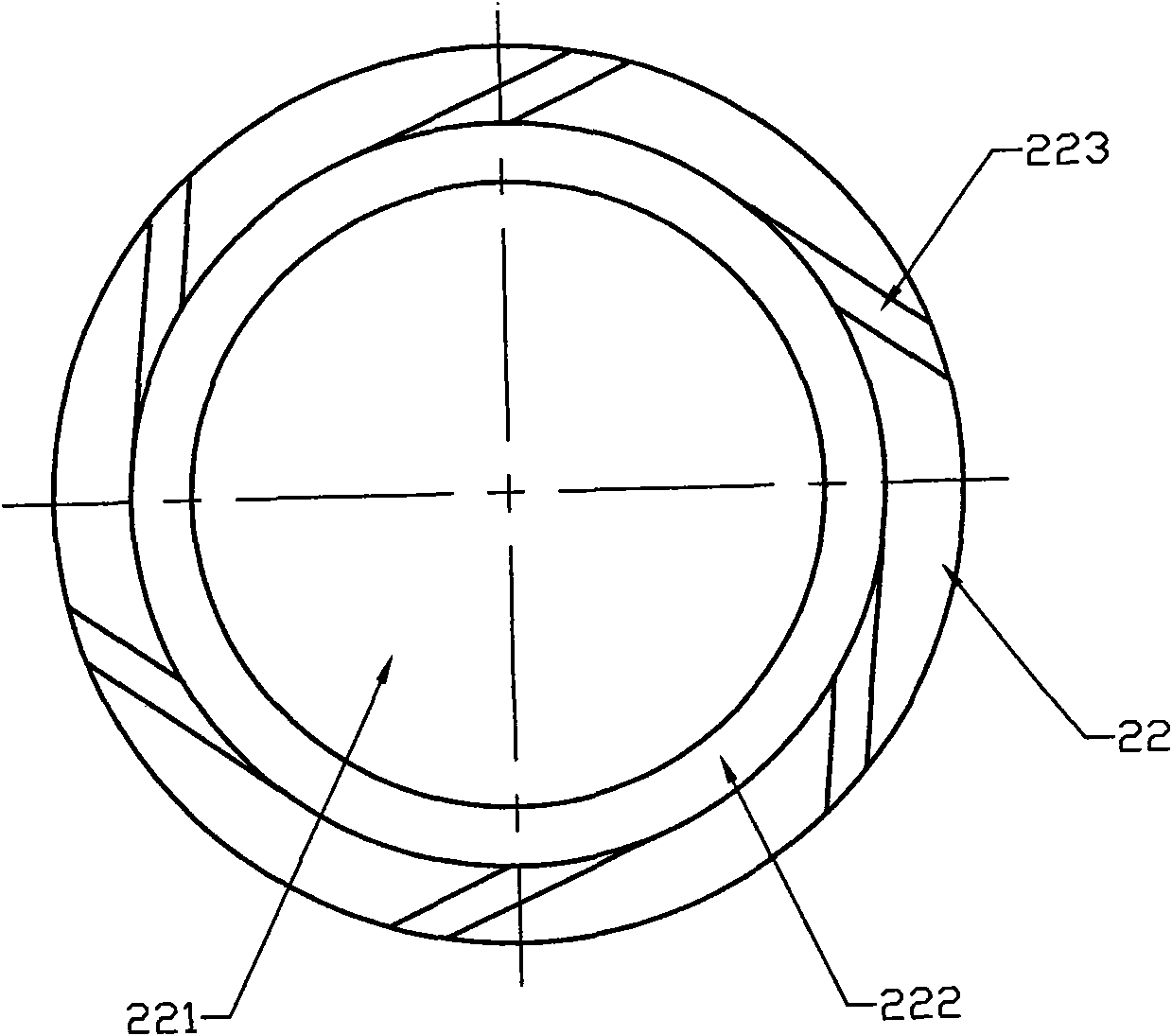

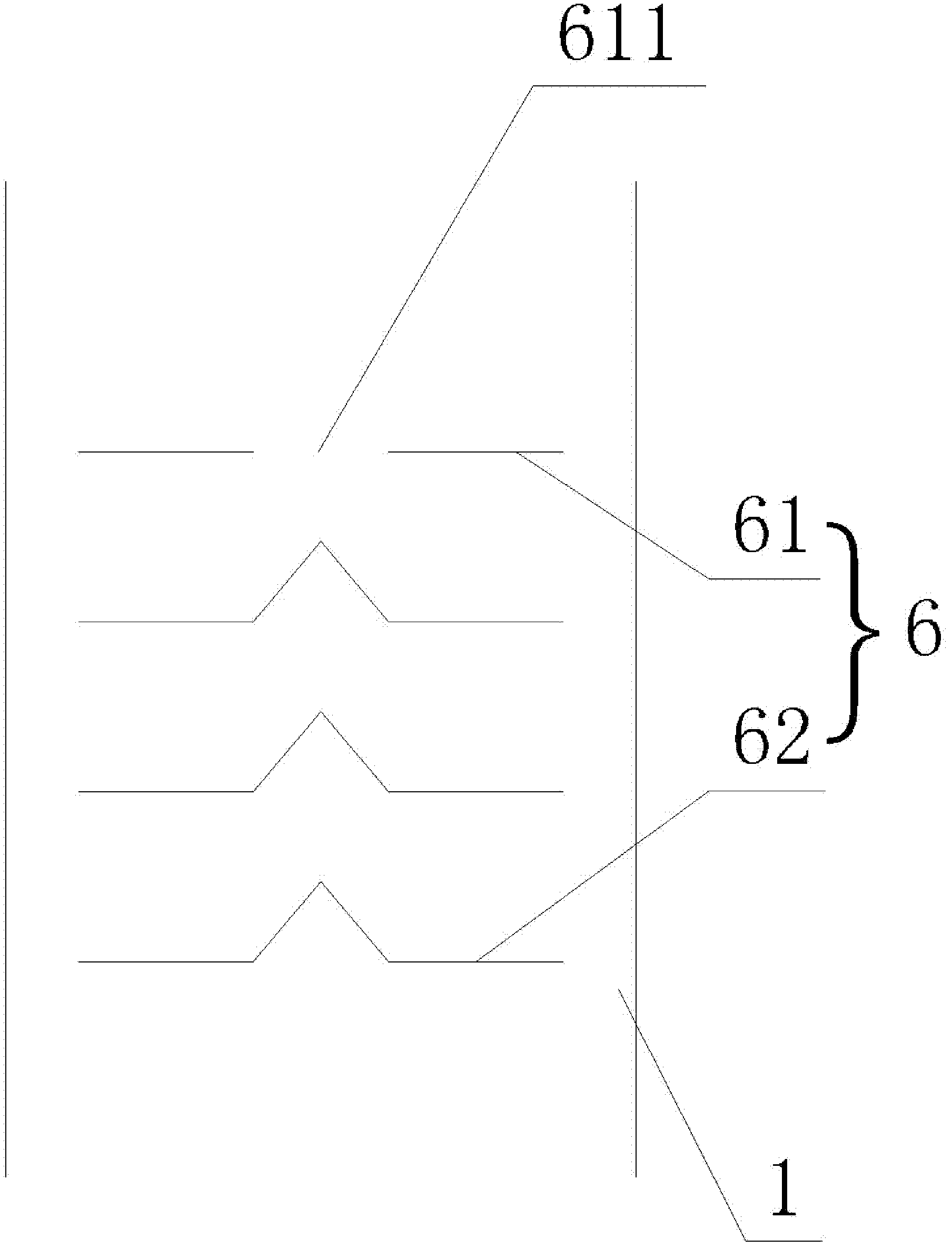

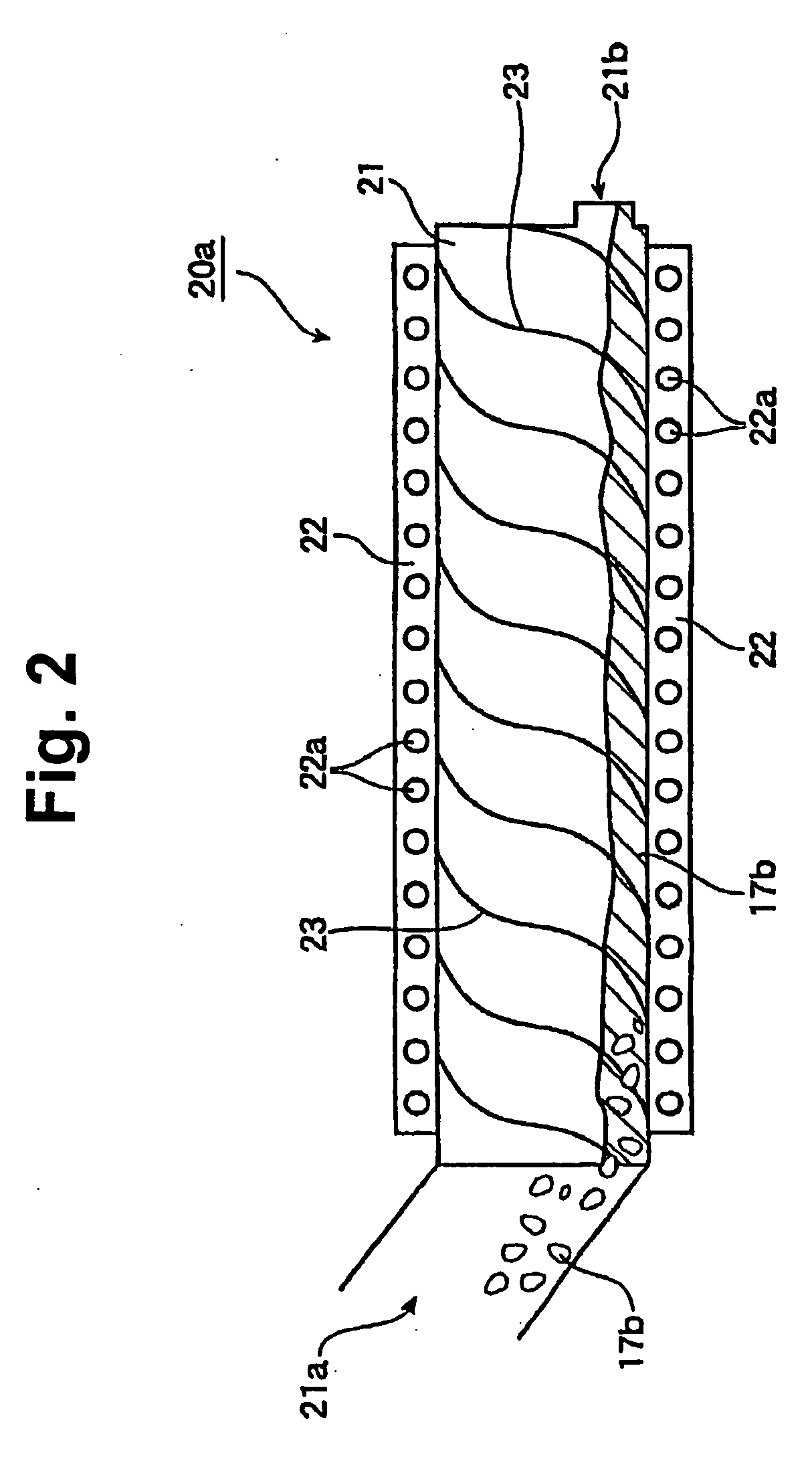

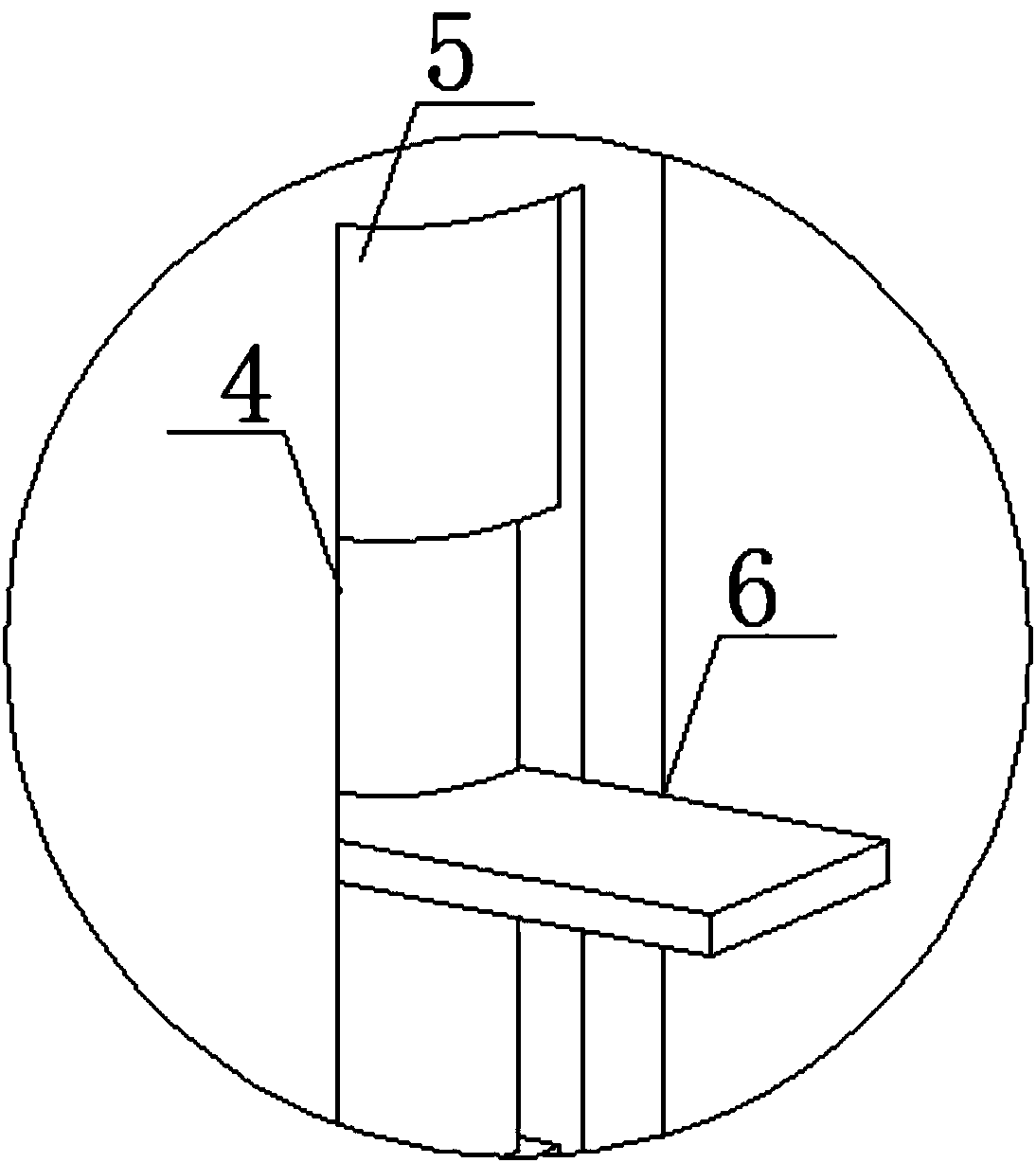

Large extension spray cone-angle slinger ring atomizer structure

ActiveCN108151066AHigh thermal efficiencyExtended dwell timeContinuous combustion chamberAviationCombustion chamber

The invention belongs to the technical field of aero-engine combustor, and particularly relates to a large extension spray cone-angle slinger ring atomizer structure. An effective mean to improve thethermal efficiency of a small turbine engine is to improve the mixing of the head portion of a flame tube. The invention provides a large extension spray cone-angle sling ring atomizer technology, a swirl structure is added at a nozzle of a slinger ring atomizer, and under the action of centrifugal force of the slinger ring atomizer, fuel can leave the slinger ring atomizer in the form of swirlingflow; and on the basis of good atomization, the injection angle of the fuel is increased, the residence time of the fuel in the flame tube is increased, the oil and gas mixing is enhanced and the combustion efficiency is improved. An optimization design of corresponding parameters of various combustion organizations is carried out for the purpose of simple machining and high combustion efficiency, and a simple and efficient slinger ring atomizer structure is obtained.

Owner:BEIJING POWER MACHINERY INST

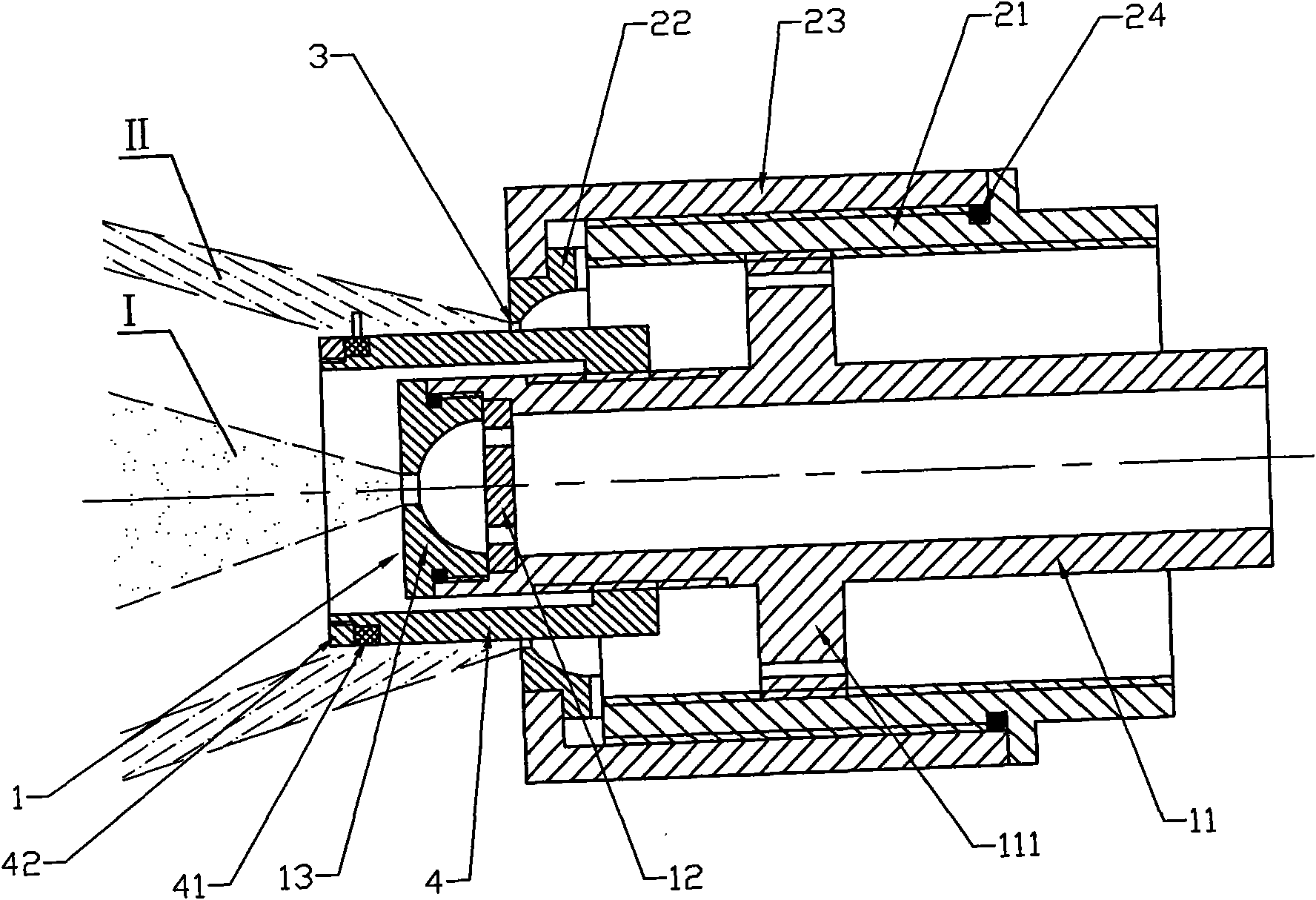

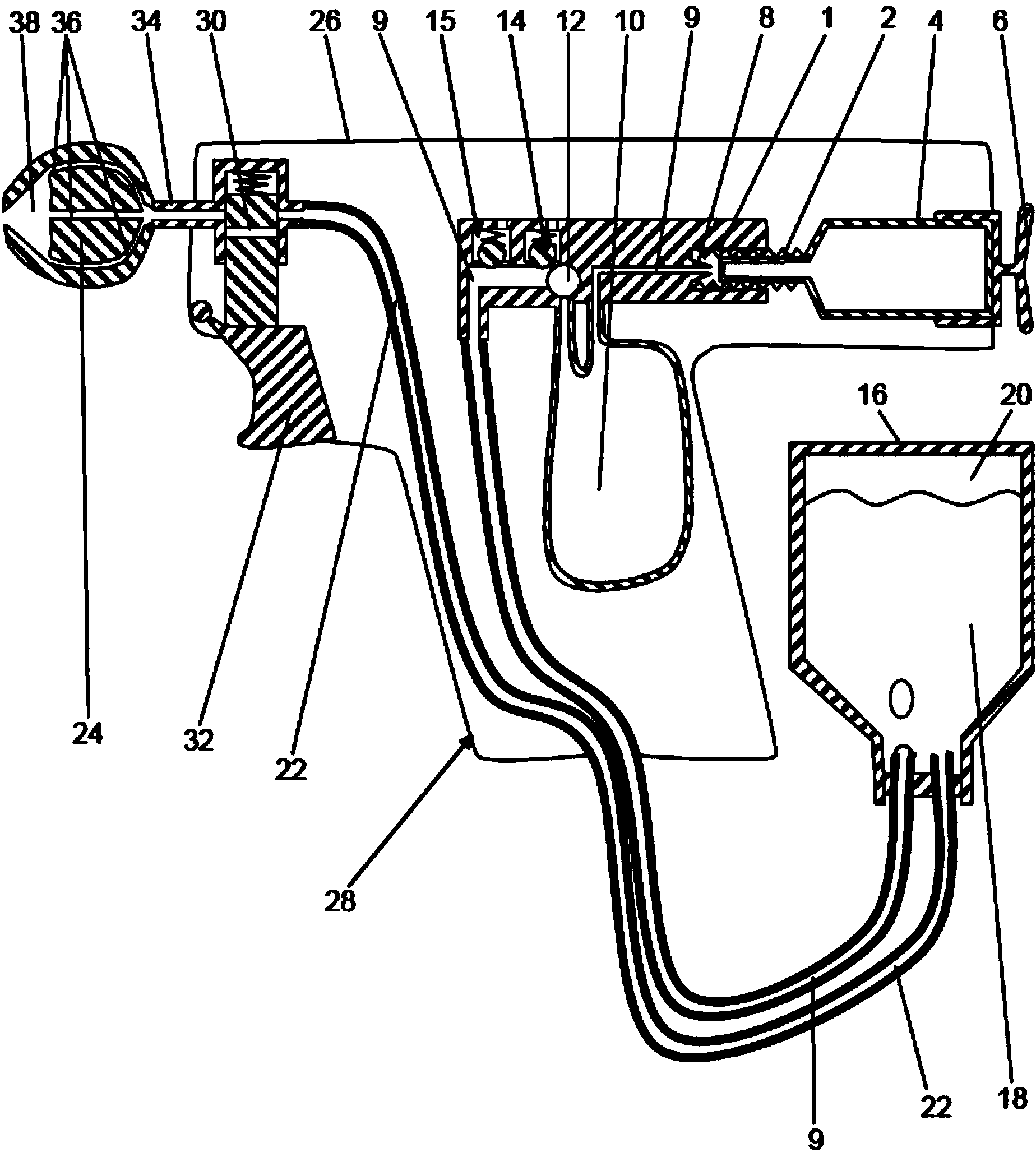

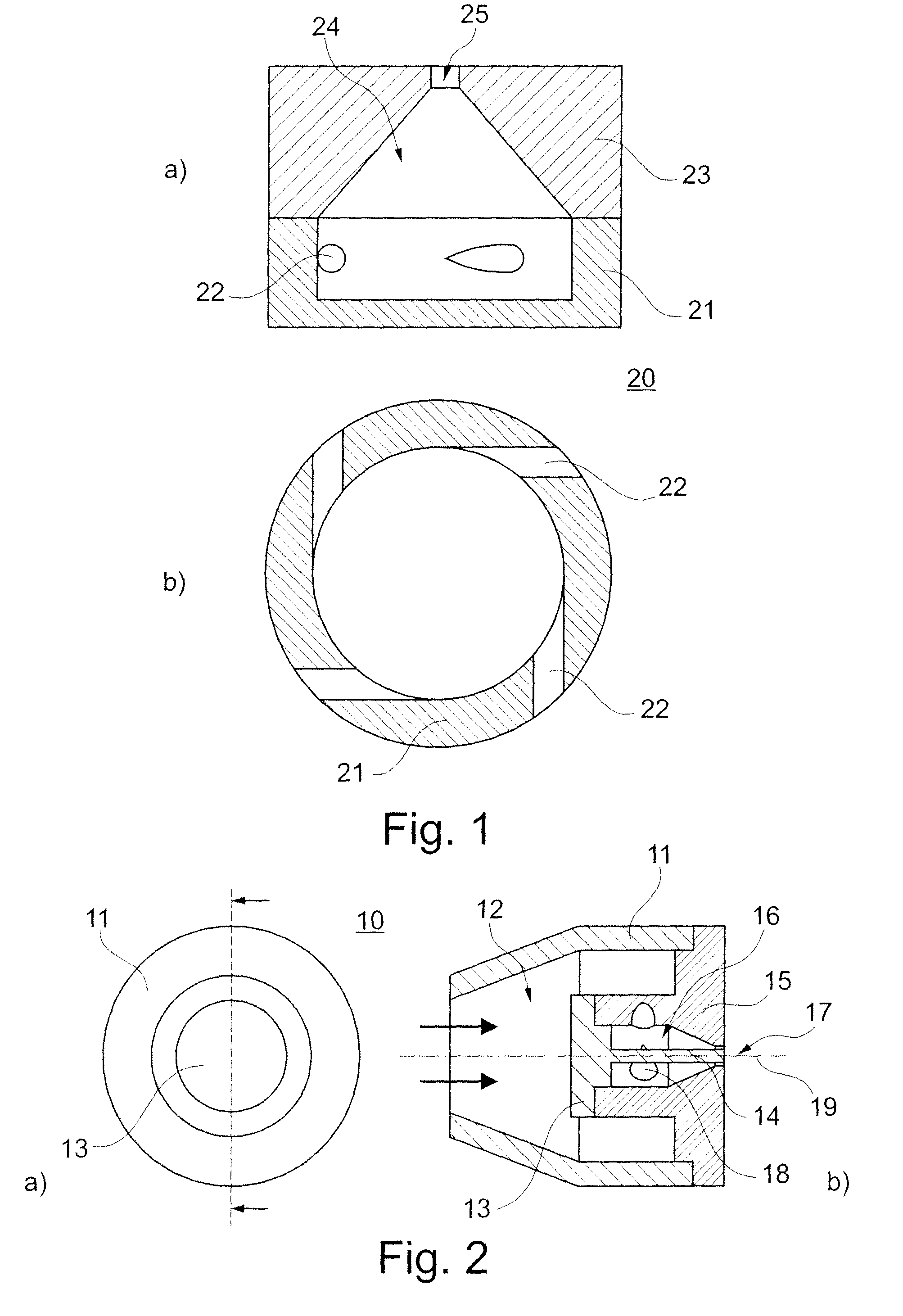

Medical spraying device with nozzle and method for producing a spray cone

The invention relates to a medical spraying device for irrigating a wound, in particular a lavage system, having a liquid resevior for a medical irrigation liquid or a connection for such a liquid reservior and a compressed gas reservior. The compressed gas reservior is connected or connectable via a pressure line to the liquid reservior, such that the irrigation liquid can be pushed by the gas pressure of the compressed gas reservior acting on the irrigation liquid thorugh a nozzle in order to produce a spray cone. The nozzle is proivded with a plurality of opens which are arranged in way with angles.The irrigation liquid away from the opens is jetted in a pulverization space and / or an discharge opening of the nozzle and a spray cone is produced from the pulverization irrigation liquid. The invention also relates to usage of the medical spraying device to produce a spray cone for removing infected organiations, and also relates to a method for producing the spray cone of the medical irrigation liquid.

Owner:HERAEUS MEDICAL

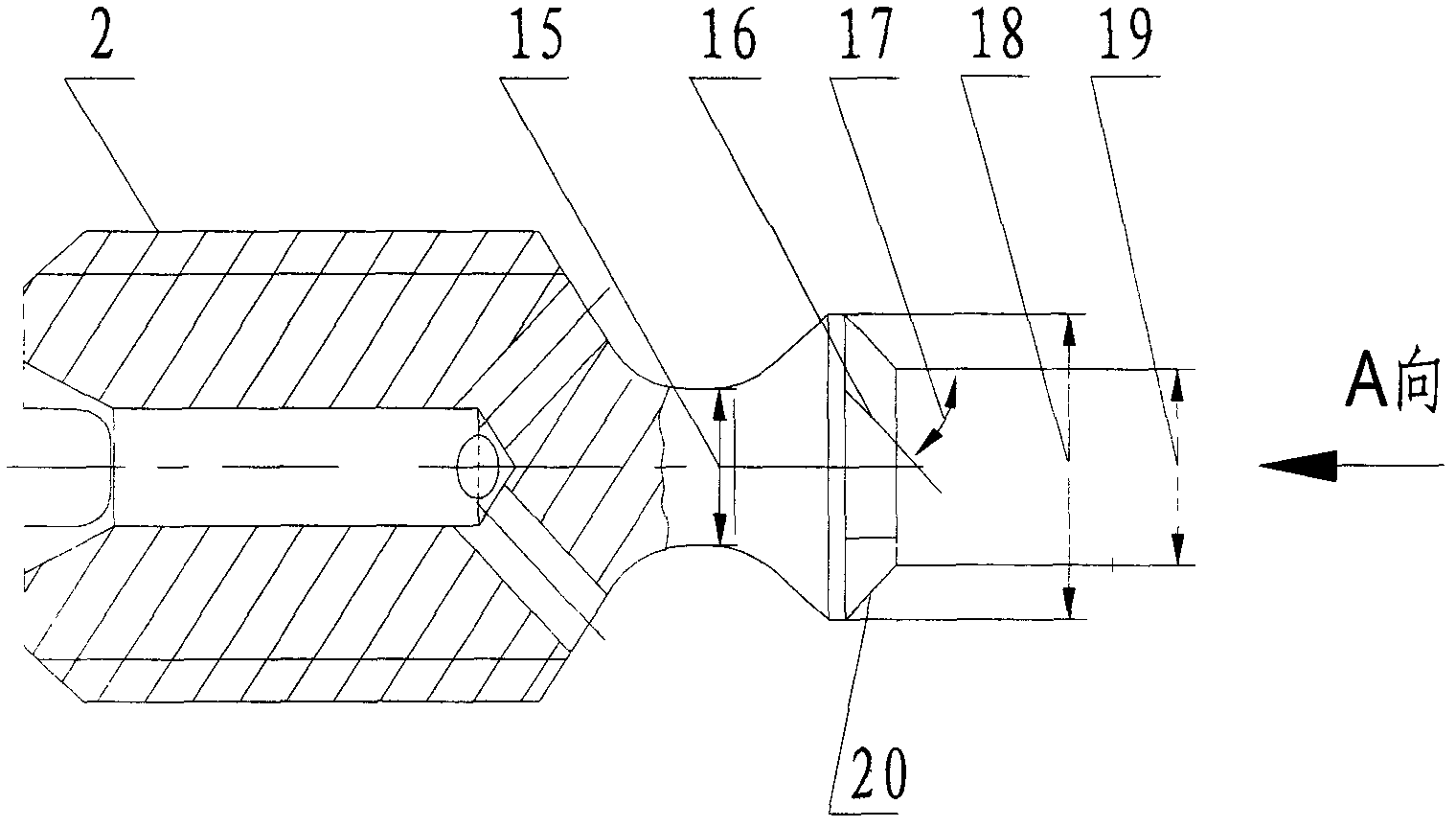

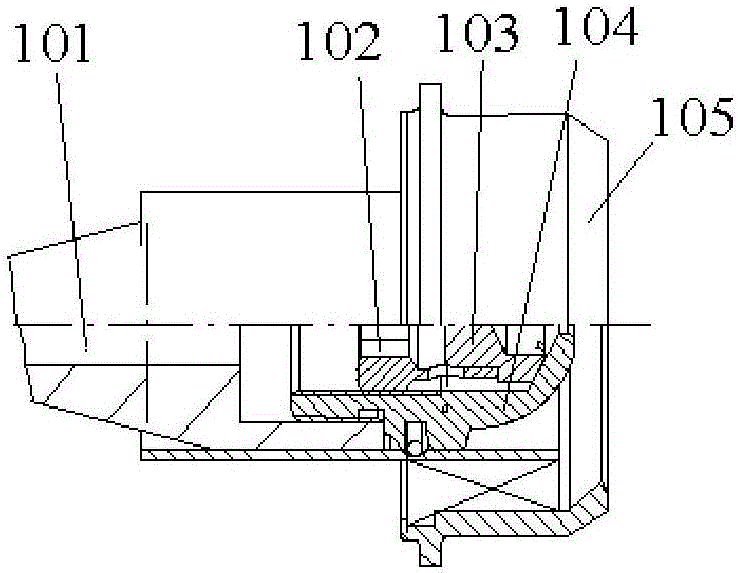

Double-oil-channel centrifugal nozzle structure adopting integrated design of main oil channel and auxiliary oil channel

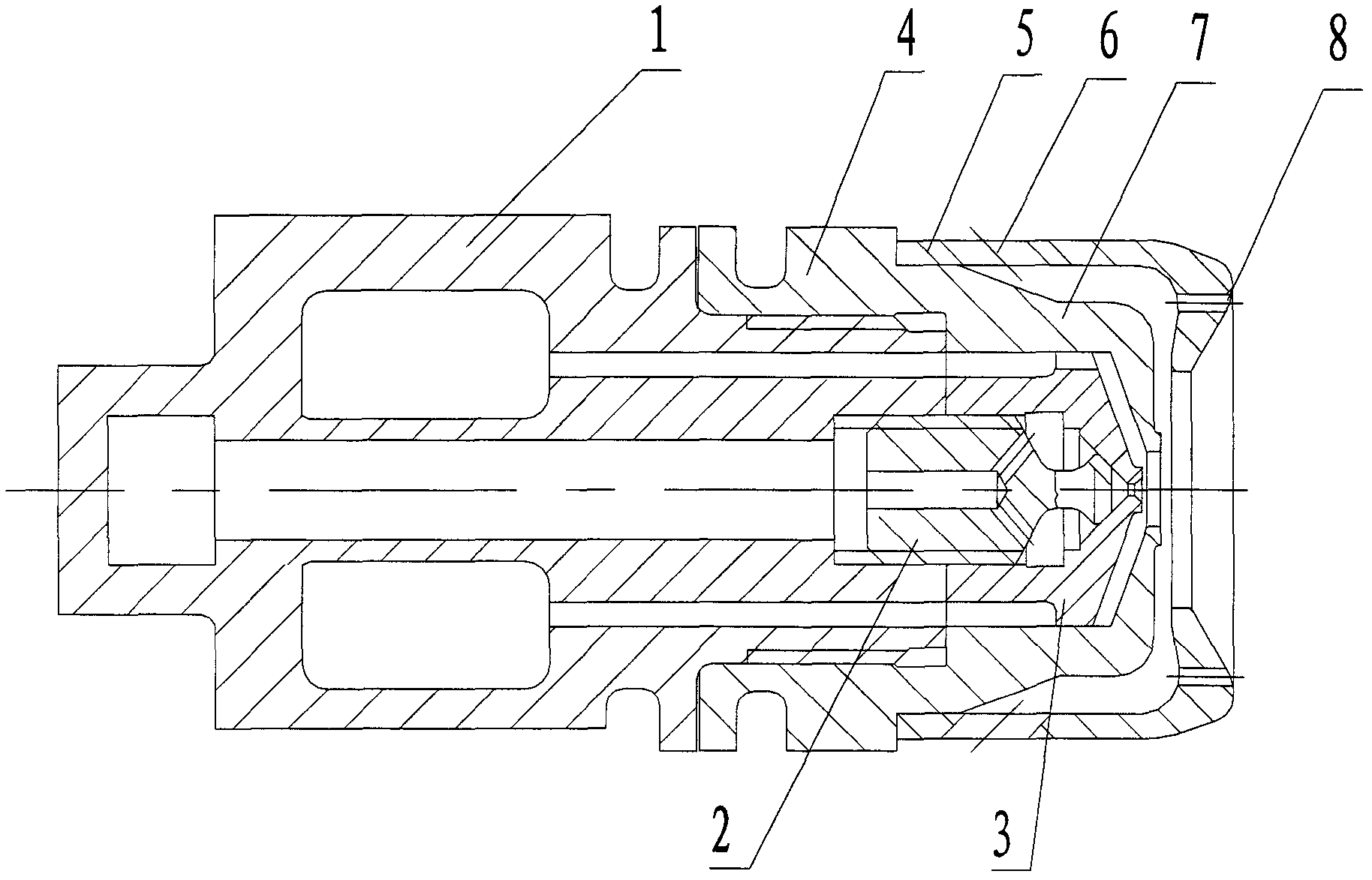

ActiveCN106499559AAchieve sealingSimple structureFuel injection apparatusMachines/enginesSpray coneFuel oil

The invention belongs to the technical field of turbine engines for small missile / unmanned aerial vehicles, and specifically relates to a double-oil-channel centrifugal nozzle structure adopting an integrated design of a main oil channel and an auxiliary oil channel. The double-oil-channel centrifugal nozzle structure comprises a main oil tube, an auxiliary oil tube, a nozzle rod, a locking sheet, a fixing nut, an auxiliary oil channel hydrocyclone, a main oil channel nozzle and an auxiliary oil channel nozzle. The double-oil-channel centrifugal nozzle structure disclosed by the invention and adopting the abovementioned technical scheme is simple and reliable; and test results indicate that the arrangement of an opening point of the main oil channel is reasonable, the double-oil-channel nozzles can meet the requirement of a high-flow adjustment ratio, the spray cone angles of the main oil channel and the auxiliary oil channel are reasonable, and fuel oil atomization of the main oil channel and the auxiliary oil channel in the whole working whole course of an engine meets a use need.

Owner:BEIJING POWER MACHINERY INST

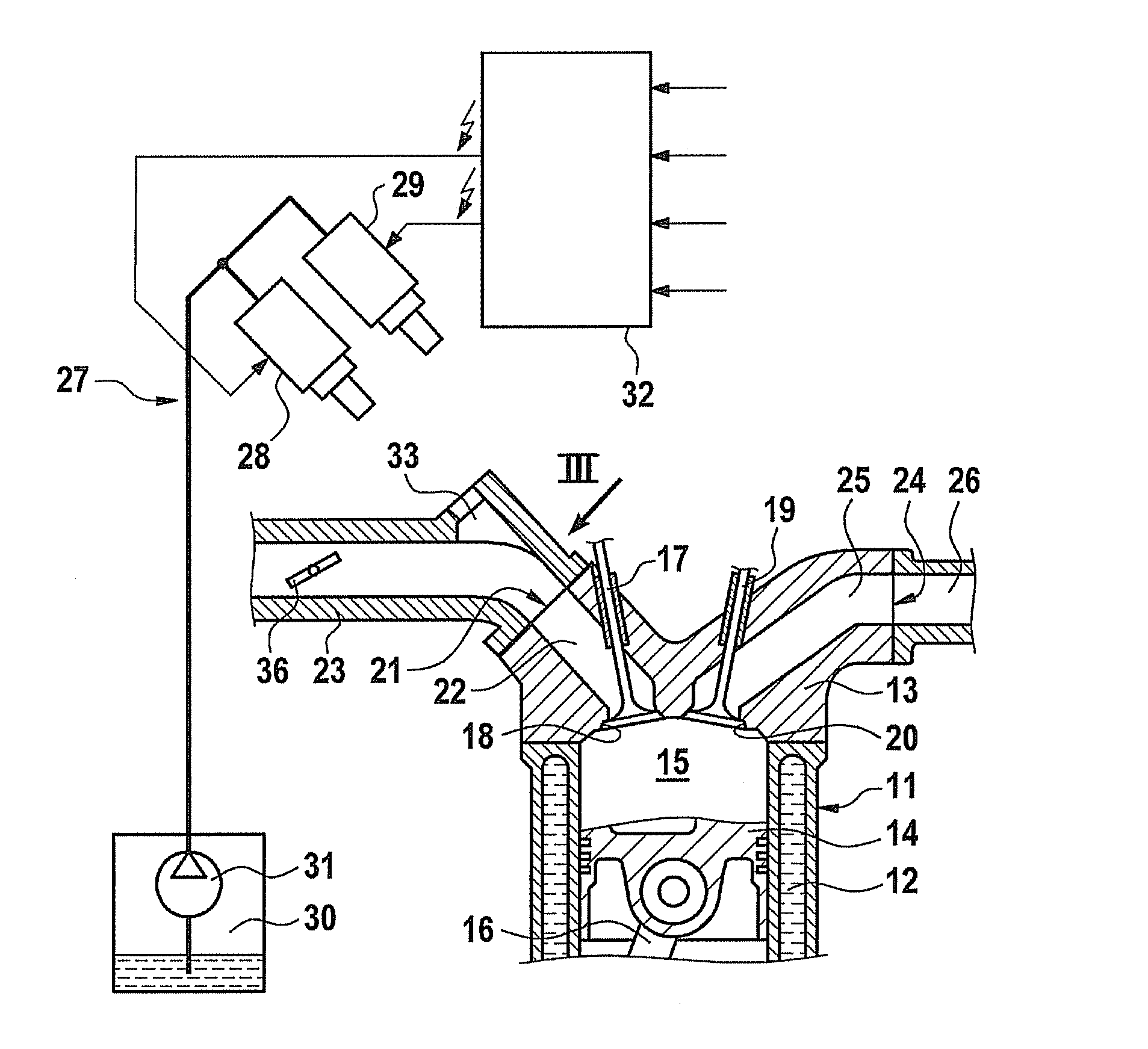

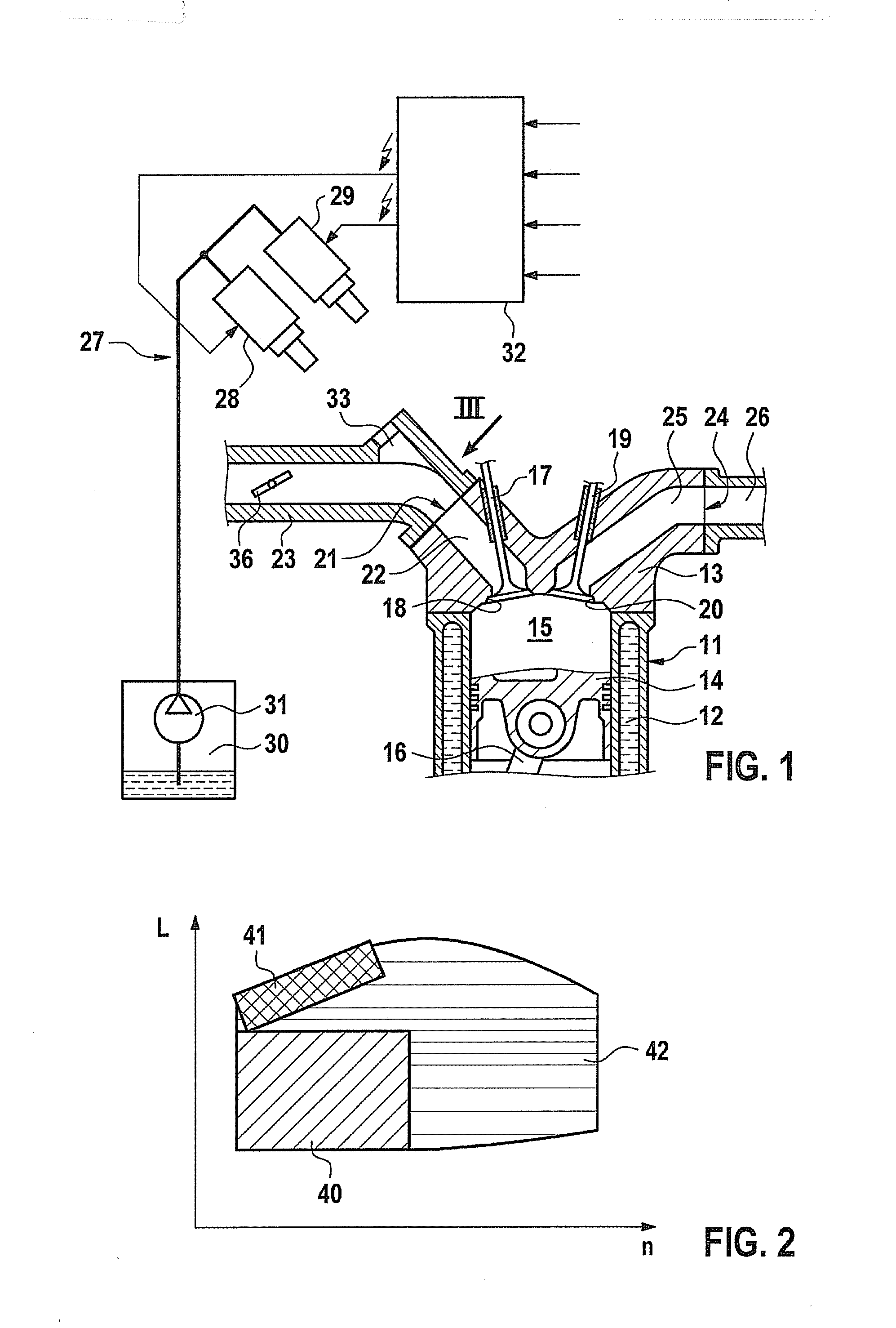

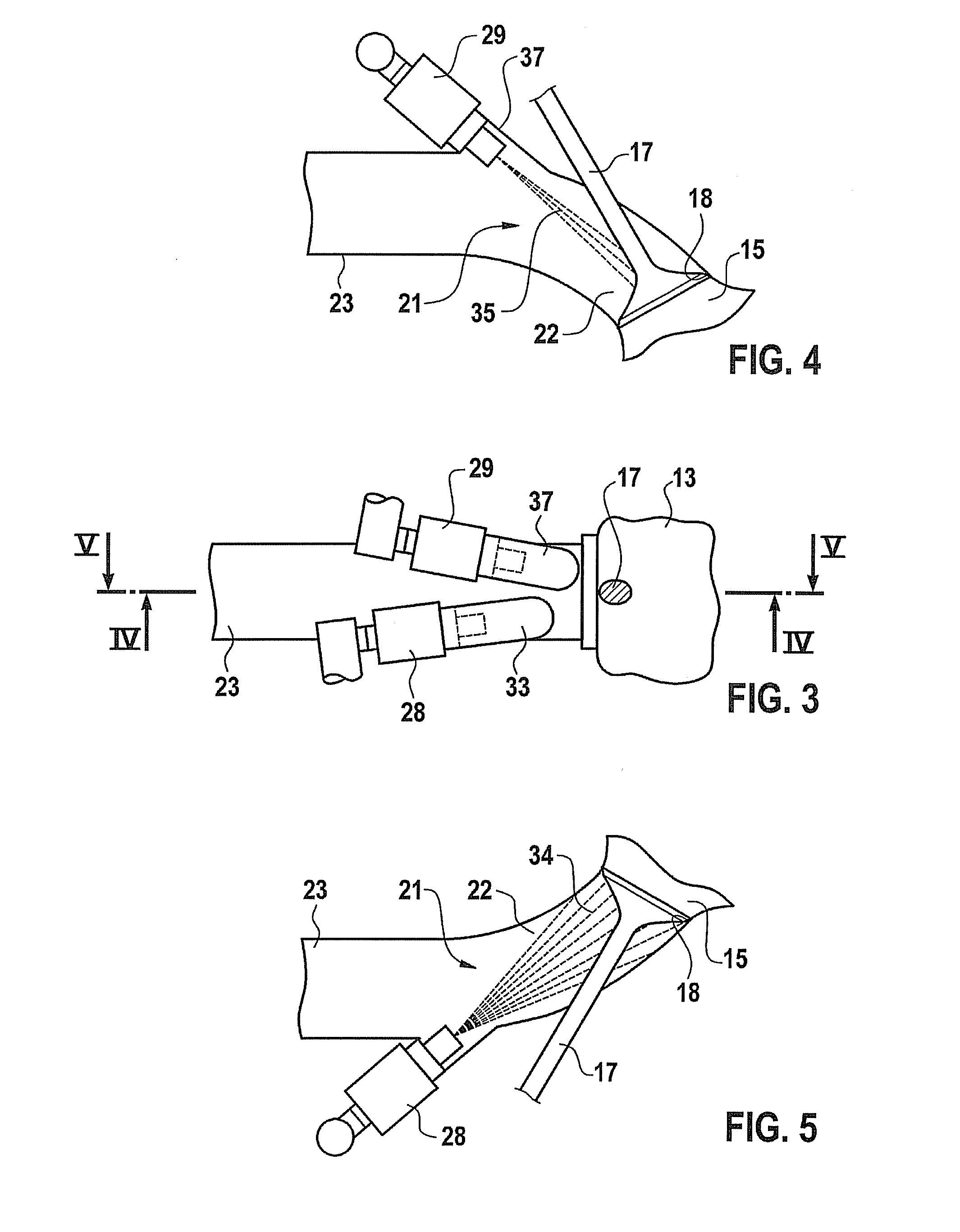

Internal combustion engine

ActiveUS20110283974A1Easy to optimizeReducing sensitivity to knockingLow pressure fuel injectionMachines/enginesSpray coneExternal combustion engine

An internal combustion engine has at least one combustion chamber which may be closed by an intake valve, at least one air intake port which leads to the intake valve, and a fuel injection device which in association with the at least one combustion chamber has a first injector and a second injector for the metered injection of fuel into at least one intake port. To achieve significantly improved mixture preparation and combustion of the fuel-air mixture in the combustion chamber, the two injectors are configured such that the first injector injects a widely divergent spray cone having a large cone angle, and the second injector injects an only slightly divergent spray cone having a much smaller cone angle.

Owner:ROBERT BOSCH GMBH

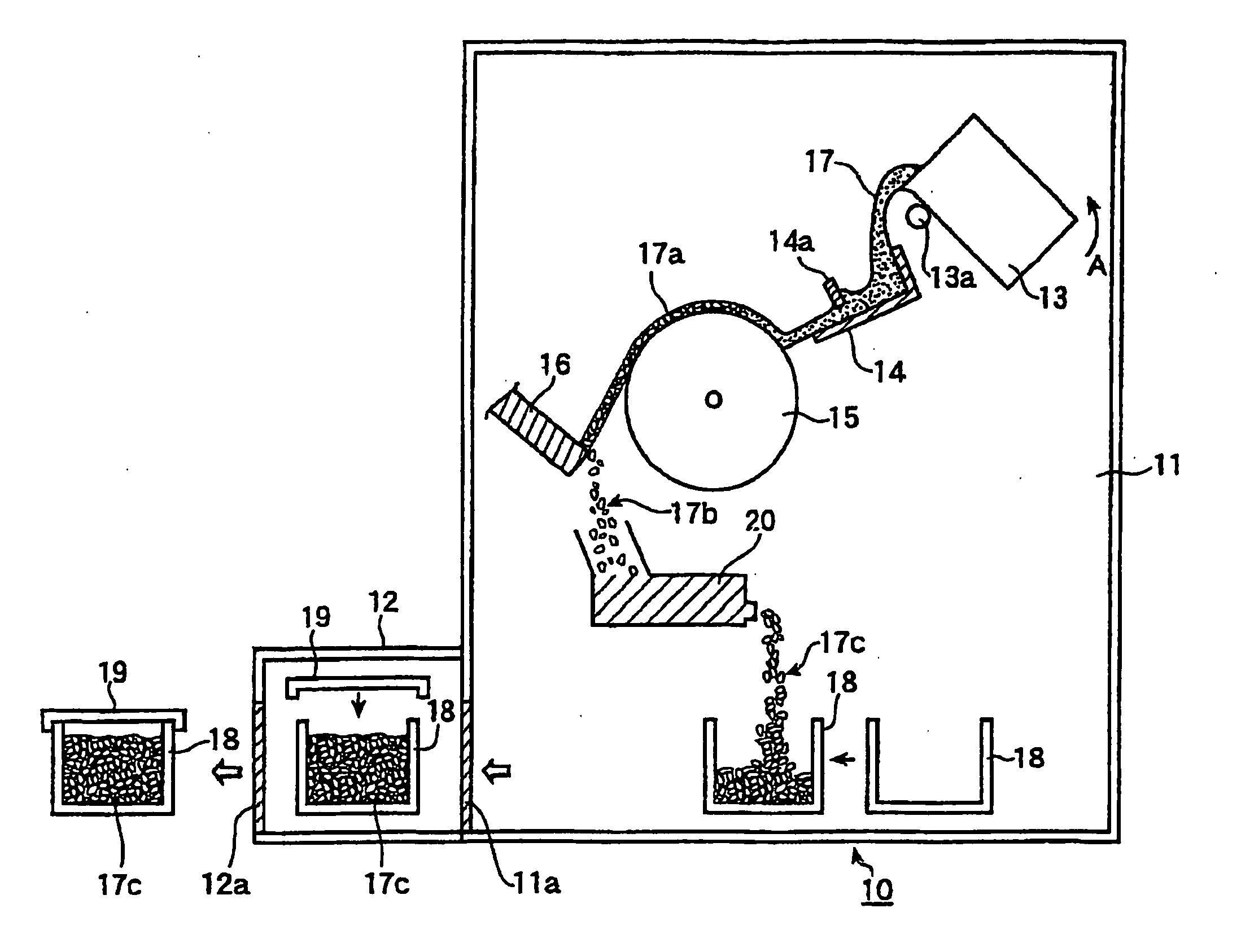

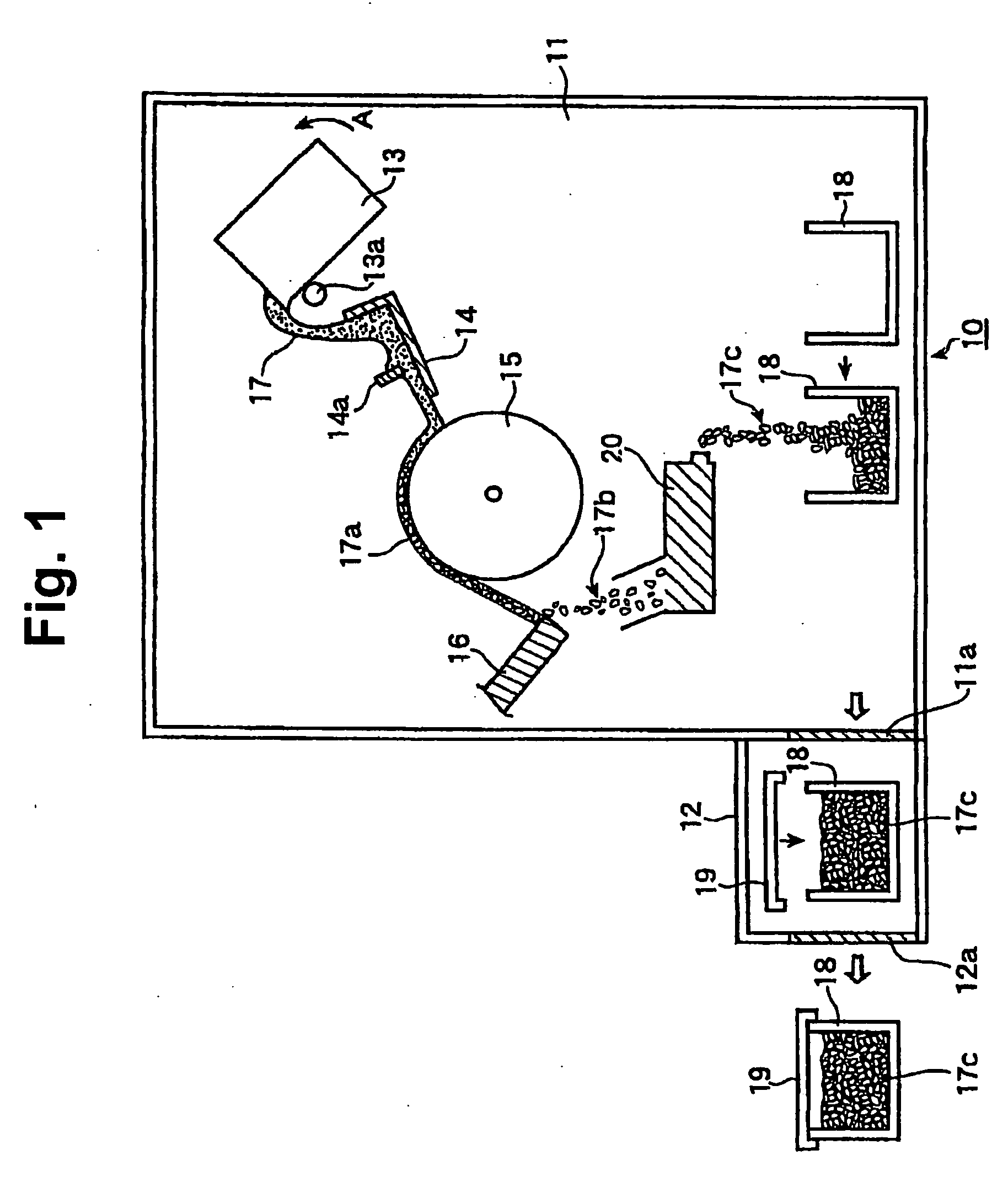

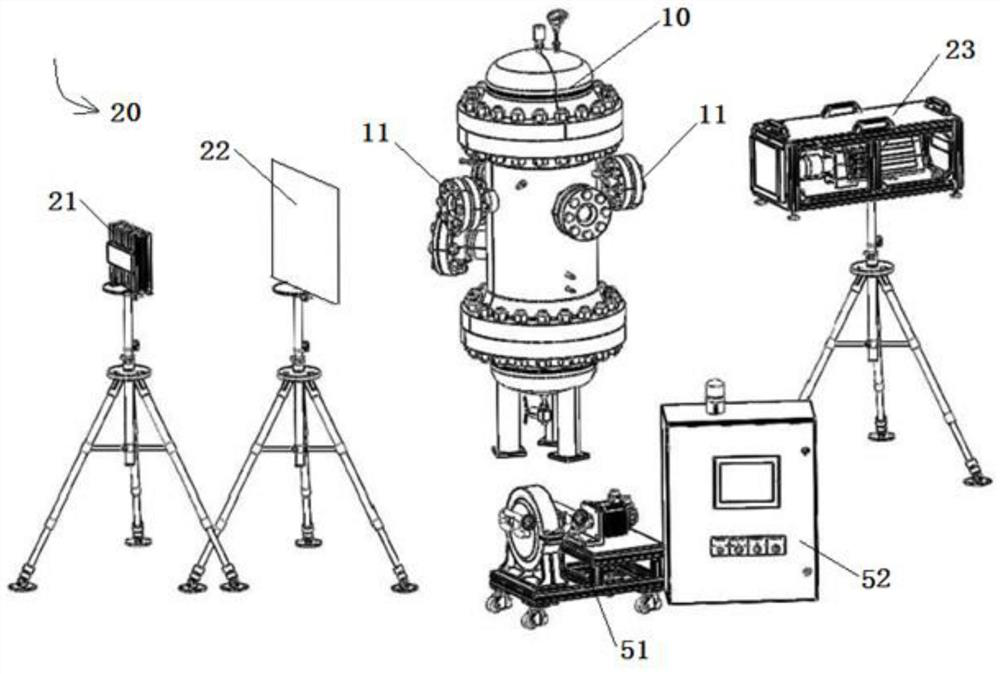

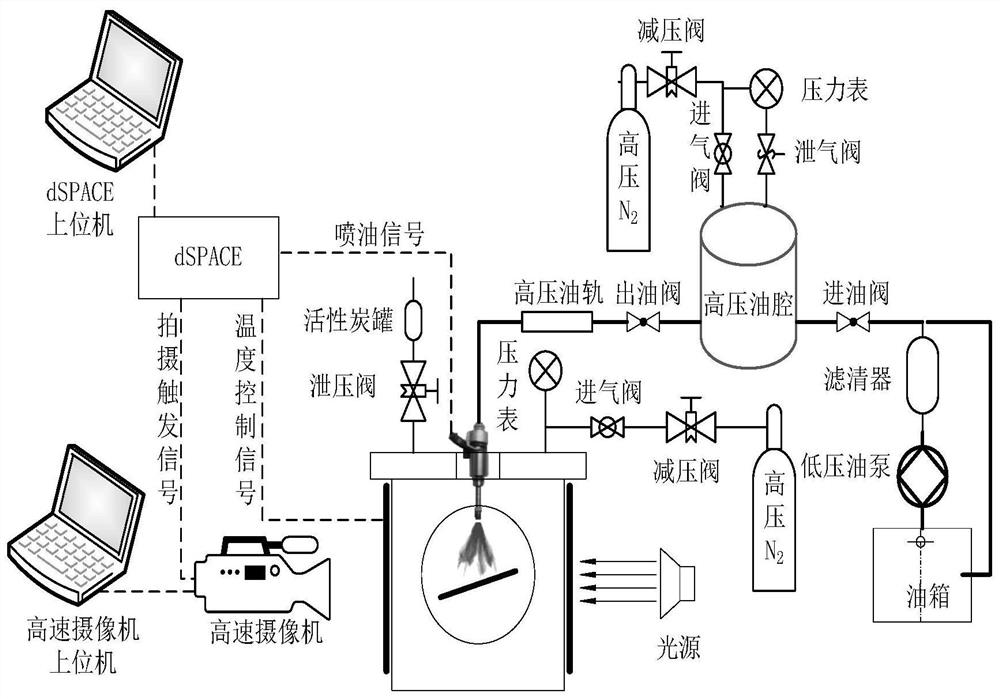

Multifunctional atomization test system

PendingCN114061964AAccurate measurementAvoid corrosionGas-turbine engine testingJet-propulsion engine testingSpray coneEngineering

The invention discloses a multifunctional atomization test system. The system comprises a high-pressure atomization test system, a normal-pressure atomization test system and a propellant supply system; the high-pressure atomization test system comprises a high-pressure atomization cabin and a first spray cone angle measuring device; the normal-pressure atomization test system comprises a normal-pressure spray device, a second spray cone angle measuring device and a spray particle size measuring device; the normal-pressure spray device comprises a nozzle and a nozzle height adjusting frame; the spray particle size measuring device comprises a height lifting frame, a sliding rod and a laser particle analyzer; and the propellant supply system can be used for providing gas-liquid or liquid-liquid two-component propellants for a nozzle in the high-pressure atomization cabin or a nozzle on the nozzle height adjusting frame. With the system adopted, atomization tests in various environments such as a normal-pressure atomization test, a high-back-pressure atomization test and an atomization test under flow pulsation can be carried out, atomization tests of various spraying media can also be carried out, and the spray cone angle and the liquid film breaking length can be accurately measured.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Single circuit multiple spray cone pressure atomizers

An atomizer includes an atomizer body having a liquid inlet and a spray outlet with a liquid flow circuit defined through the inner atomizer body for fluid communication of liquid from the inlet to the spray outlet. The liquid flow circuit branches into a plurality of sub-circuits. Each sub-circuit is configured to produce a spray cone of atomized liquid issuing from the spray outlet such that the spray cone of each sub-circuit has a different cone angle. The sub-circuits are mechanically separated from one another to limit interaction of liquid in the sub-circuits and thereby produce a distinct and stable spray cone from each sub-circuit over a range of liquid flow rates.

Owner:COLLINS ENGINE NOZZLES INC

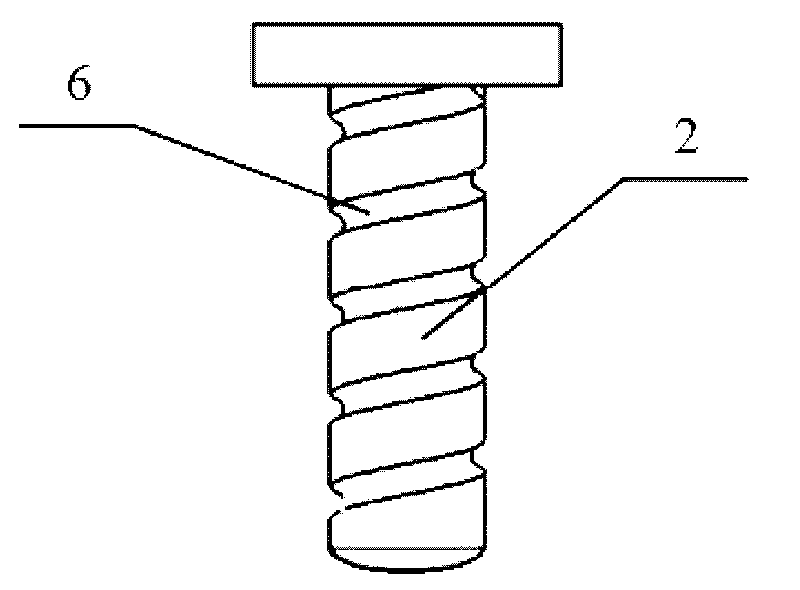

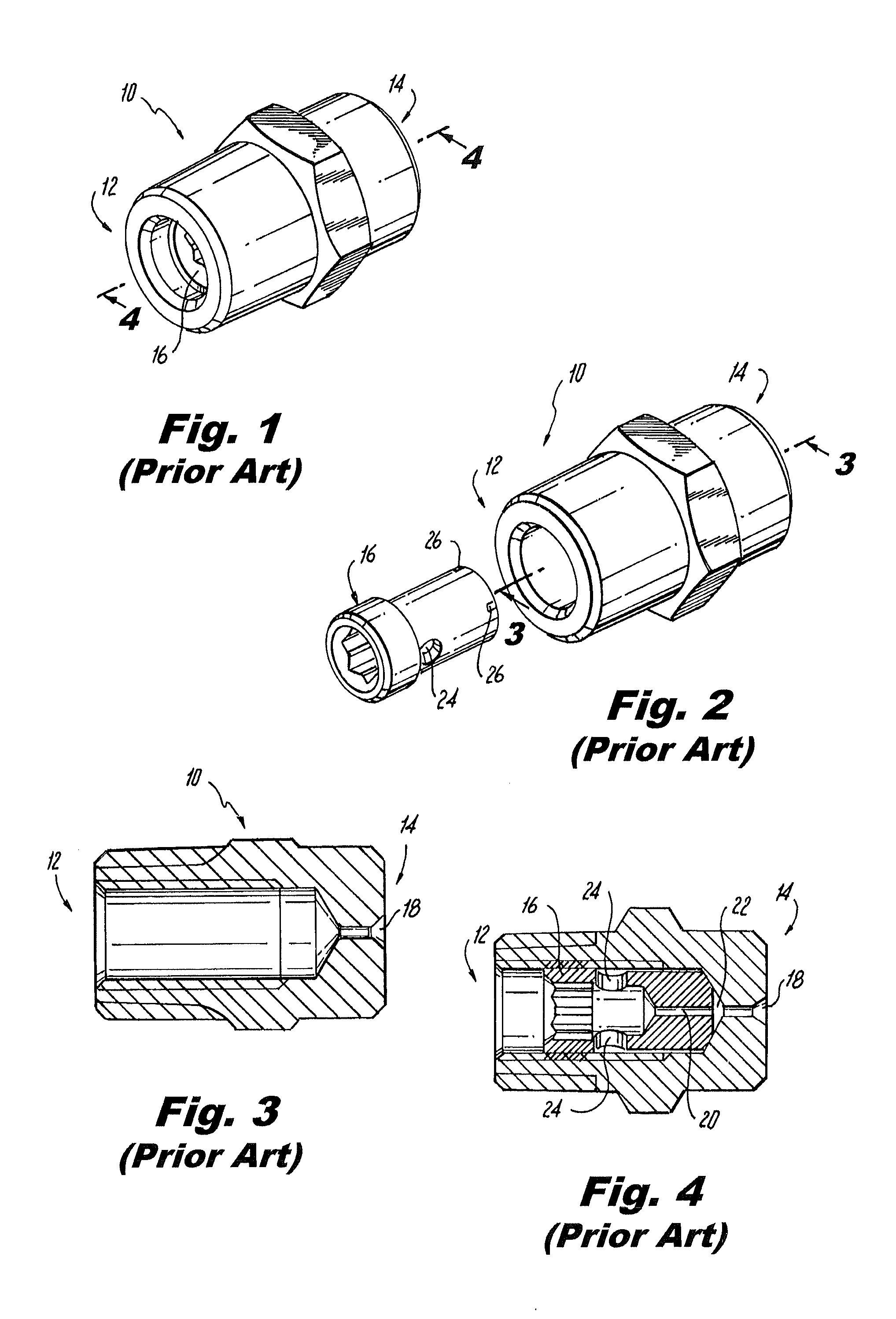

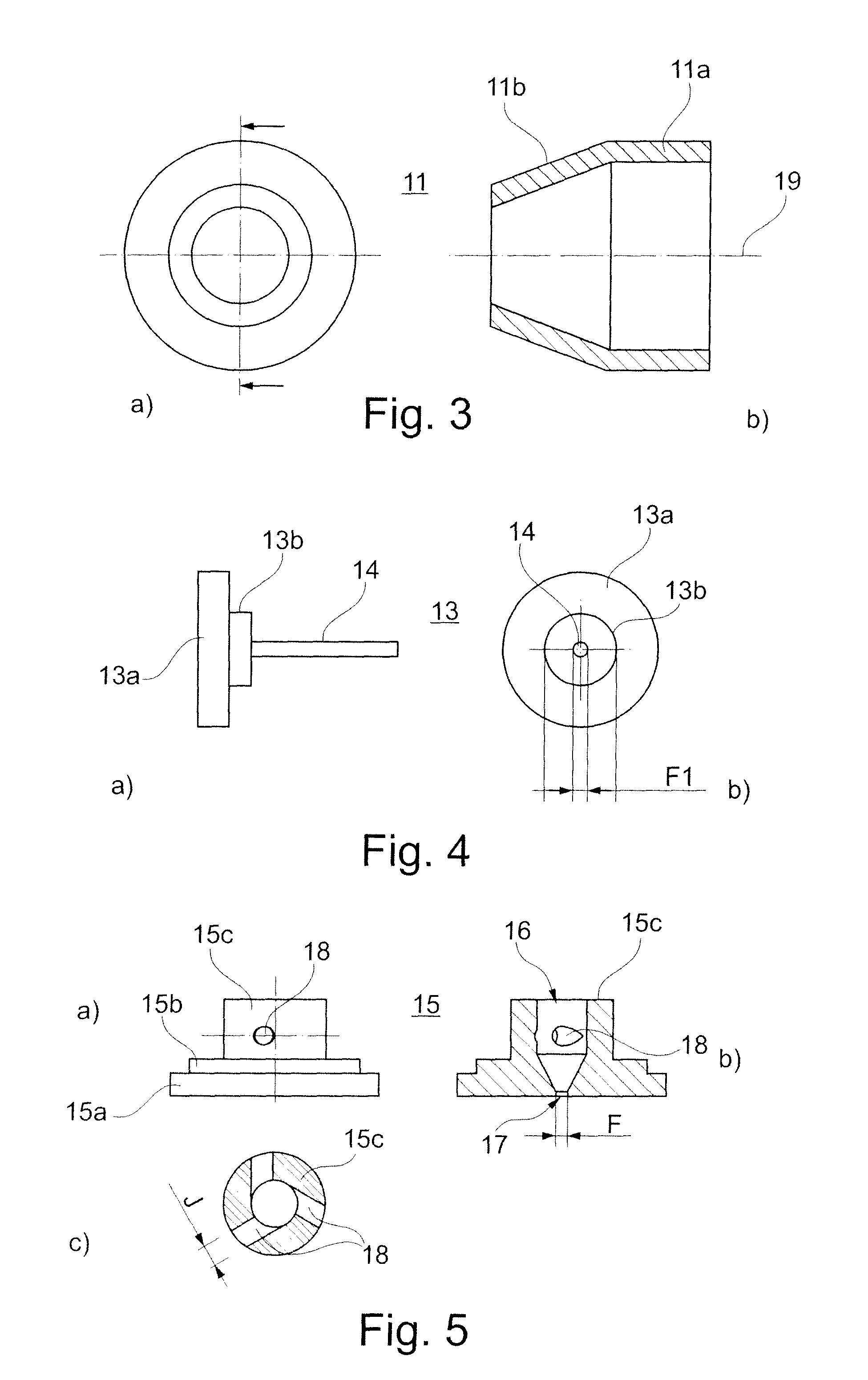

Injection nozzle having constant diameter pin and method for operating the injection nozzle

An injection nozzle (10), especially for injecting liquid fuel, preferably crude oil, into the combustion chamber of a gas turbine, includes an inner chamber (16) which extends along a nozzle axis (19), conically tapers to a concentric nozzle orifice (17), and to which the medium which is to be injected is fed from outside through a plurality of inlet ports (18) which are arranged in a distributed manner around the nozzle axis (19). The inlet ports (18) are oriented perpendicularly to the nozzle axis (19) and each lead tangentially into the inner chamber (16). With such an injection nozzle, an improved spray cone is achieved by the fact that a pin (14), which extends in the axial direction, is concentrically arranged in the inner chamber (16) and passes through the region of the mouths of the inlet ports (18) and extends right into the nozzle orifice (17).

Owner:ANSALDO ENERGIA SWITZERLAND AG

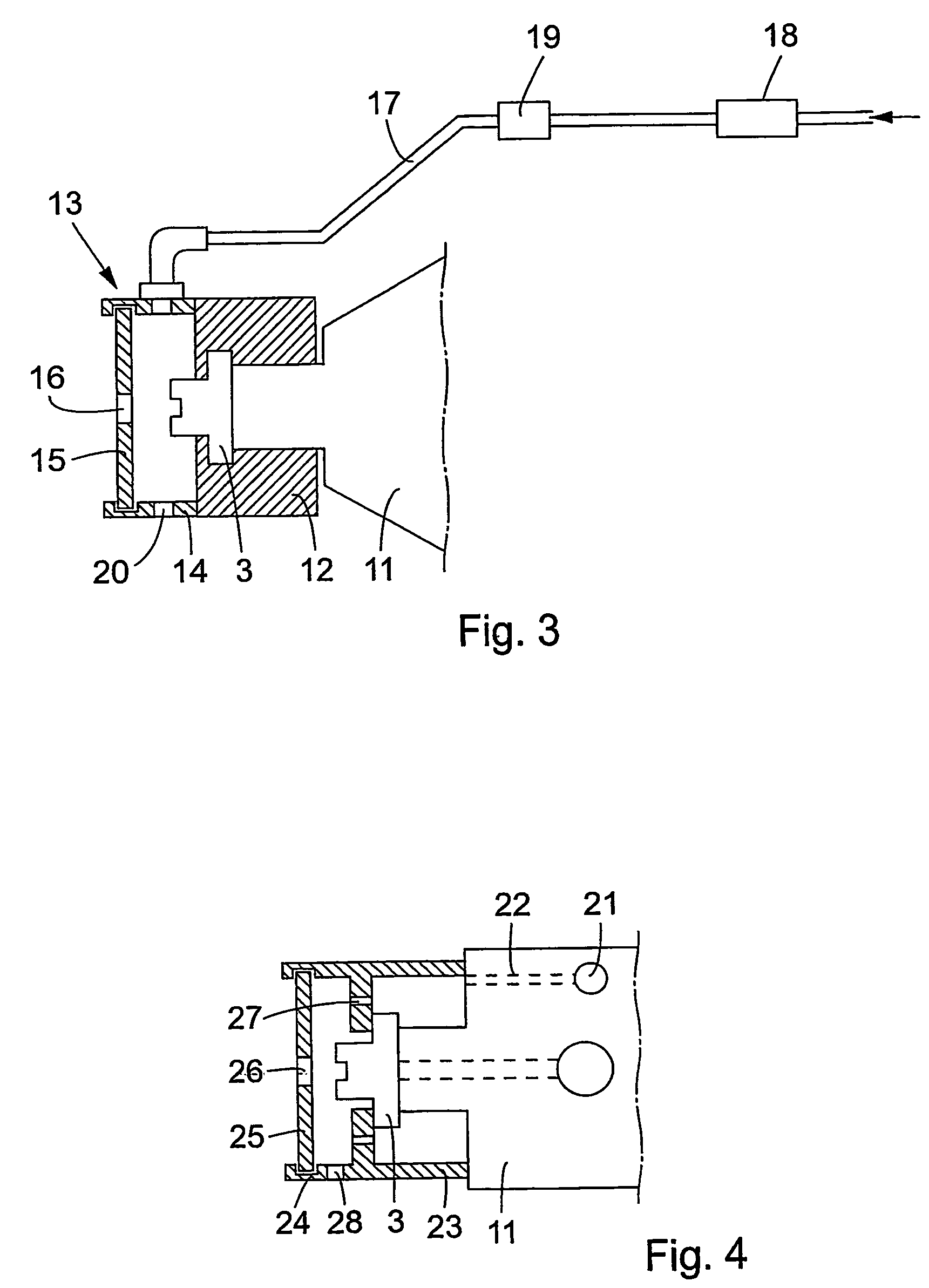

Method and device for keeping a number of spray nozzles in a printing press beam clean

In order to keep a spray nozzle (3) in a printing press spray beam (1) clean, air with a certain overpressure is supplied to a cover (5; 13; 24) surrounding the spray nozzle (3), the spray cone from the spray nozzle leaving the cover undisturbed through a slot (7; 16; 26) therein.

Owner:BALDWIN JIMEK

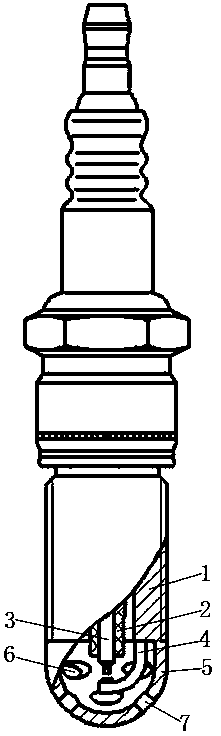

Spark plug with precombustion chamber structure

The invention relates to a spark plug with a precombustion chamber structure. The spark plug includes a tubular metal shell, an insulator fixed in the metal shell, a central hole arranged in the insulator, a central electrode mounted in the central hole and a side electrode connected to the metal shell. A spark plug gap is formed between the central electrode and the side electrode. A precombustion chamber shell is connected to the lower end of the metal shell. A precombustion chamber is defined by the lower ends of the precombustion chamber shell and the metal shell. The spark plug gap is located in the precombustion chamber. The precombustion chamber shell is provided with multiple upper spray holes and multiple lower spray holes. The multiple spray holes are located on the upper side ofthe multiple lower spray holes. The spark plug with the precombustion chamber structure can form up-down stratified jet flames with different spray cone angels during a combustion process of an engine, thereby accelerating the combustion of mixed gas, effectively solving the problem of decrease of burning rate when a gasoline engine adopts a Miller / Atkinson cycle, ensuring the ignition stability,and avoiding carbon deposition blockage.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

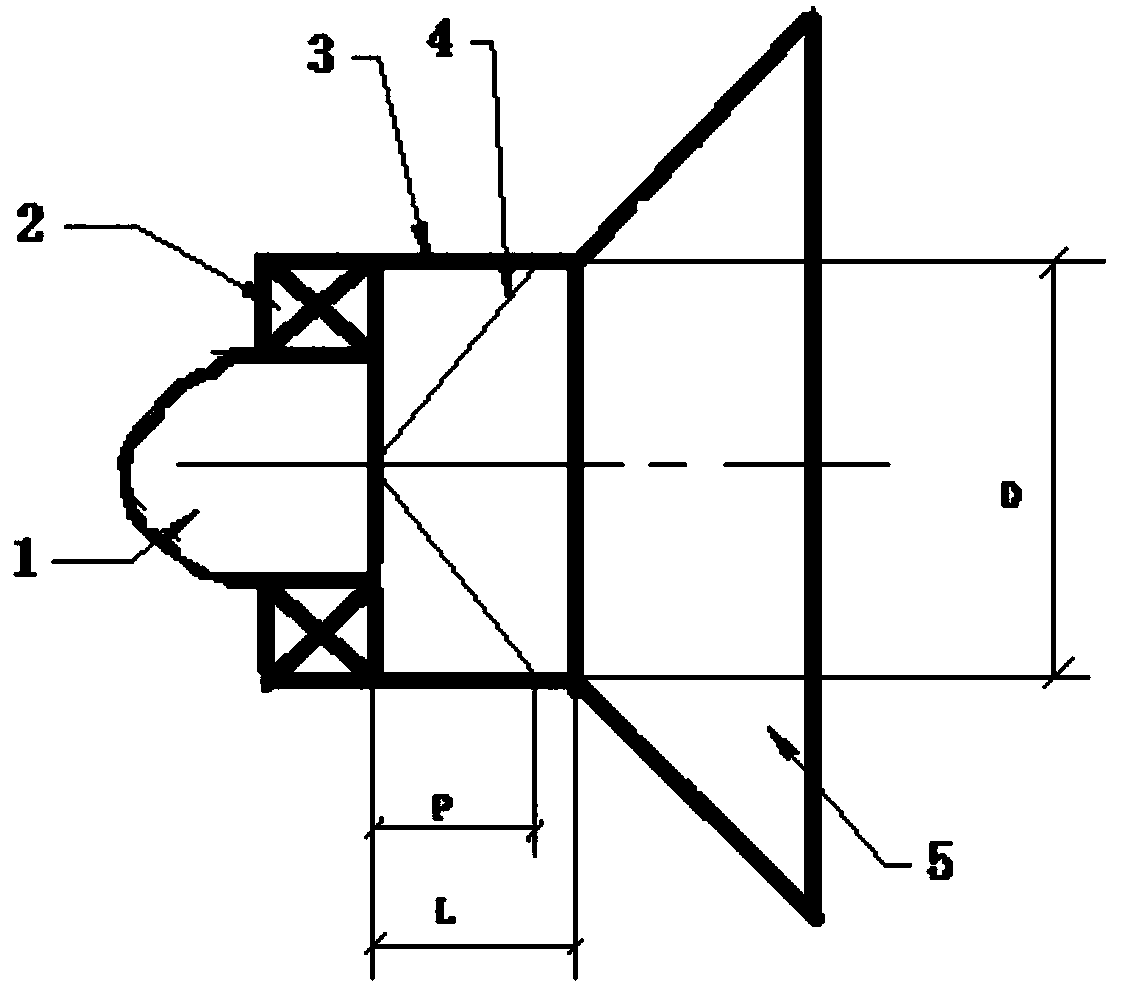

Premixing chamber of aircraft engine flame tube and design method thereof

InactiveCN108119915AImprove performanceReduce exhaust smokeContinuous combustion chamberCycloneSpray cone

The invention provides a premixing chamber of an aircraft engine flame tube and a design method thereof. The premixing chamber is of a cylindrical structure, and the premixing chamber is arranged between a fuel nozzle, a flame tube cyclone outlet and a flame tube head, to achieve oil and gas premixing. The method for designing the premixing chamber of the aircraft engine flame tube comprises the following steps: (1) determining the inner diameter D of the premixing chamber; and (2) determining the axial length L of the premixing chamber; (3) determine the distance P of a main spray cone angleof the fuel nozzle at a droppoint of the wall surface of the premixing chamber; (4) determining that an auxiliary spray cone angle of the fuel nozzle does not collide with the wall surface of the premixing chamber, and flame is directly sprayed into the flame tube. According to the premixing chamber of the aircraft engine flame tube and the design method thereof, the size of the premixing chambercan be accurately designed, the workload in the combustion chamber testing process is reduced, manpower and material resources are saved to the largest extent, and the premixing chamber has an obviouseffect of reducing exhaust smoking of a combustion chamber and improving combustion stability of the combustion chamber.

Owner:TIANJIN CHENGLI AVIATION TECH CO LTD

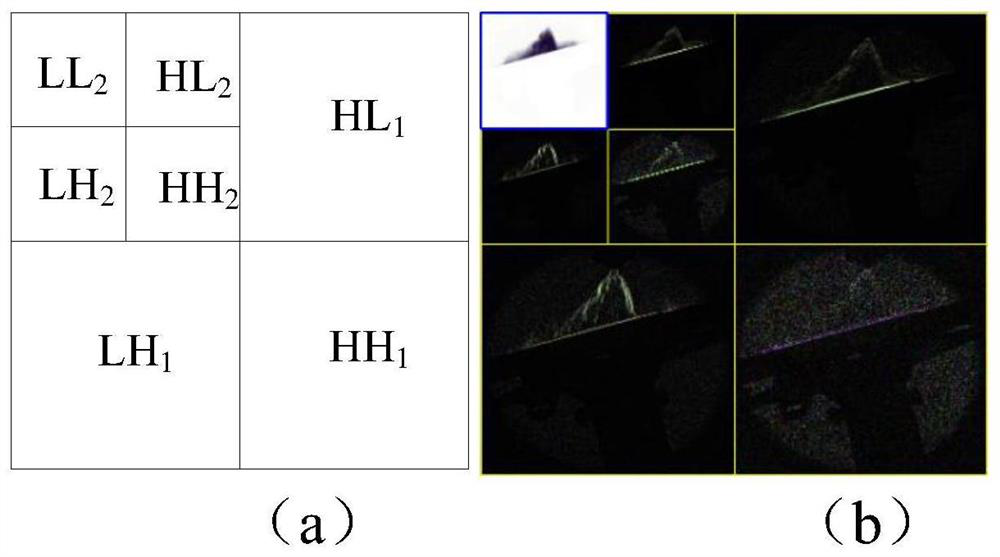

GDI gasoline engine spray wall-impingement parameter automatic extraction method and system based on machine vision

PendingCN112053345AAccurate separationAvoid Extraction ErrorsImage enhancementImage analysisMachine visionSpray cone

The invention discloses a GDI gasoline engine spray wall-impingement parameter automatic extraction method and system based on machine vision. The method comprises the following steps: step 1, background separation; 2, hierarchical binarization based on wavelet transform; 3, extraction of spray wall-impingement parameters: 3.1, extraction of a spray penetration distance L; 3.2, extraction of a spray cone angle theta; 3.3, extraction of a spraying radius r; and 3.4, extraction of a spray height h. The automatically extracted spray wall-impingement parameters can accurately reflect the spray wall-impingement development trend, the parameter values are basically consistent with those in a manual calibration result, the error is small, and the spray wall-impingement parameters can be automatically, rapidly and accurately extracted.

Owner:CHANGCHUN UNIV

Physiological seawater nasal atomization device

The invention discloses a physiological seawater nasal atomization device. The device comprises a spraying cone head, a liquid containing chamber, a handle, a sliding groove, an insertion chamber, a pushing frame, a push plate, inserted sliding plates, a push ring, a rotary cone, side spraying plates, an upper spraying plate, a first motor, a transmission gear ring, a second motor, rotary plates and nozzles. The physiological seawater nasal atomization device has the advantages that when the physiological seawater nasal atomization device is in use, the spraying cone head is inserted into a nostril, a user holds tightly the handle with one hand and lifts the push plate upwards with the other hand, physiological seawater floods into the spraying cone head from the liquid containing chamber,at the same time, the first motor drives the rotary cone to rotate through the transmission gear ring, then, the physiological seawater is sprayed out from the side spraying plates and the upper spraying plate, besides, and when the rotary cone rotates, the side spraying plates and the upper spraying plate synchronously rotate, so that it is ensured that the device sprays the nasal comprehensively and evenly, a cone spraying head sprays the nasal more broadly and comprehensively, and the device sprays the nasal efficiently; the device is small in occupied space and convenient to operate, andall components are flexible in connection.

Owner:YANCHENG QIUHENG MEDICAL DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com