Robot spray gun trajectory setting method in copper plate spraying operation

A technology in robot and operation, which is applied in the field of robot spray gun track setting, can solve problems such as complicated locks, and achieve the effects of reducing spraying costs, improving spray head efficiency, and improving coating uniformity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The setting method of robot spray gun trajectory in the copper plate spraying operation of the present invention comprises the following steps:

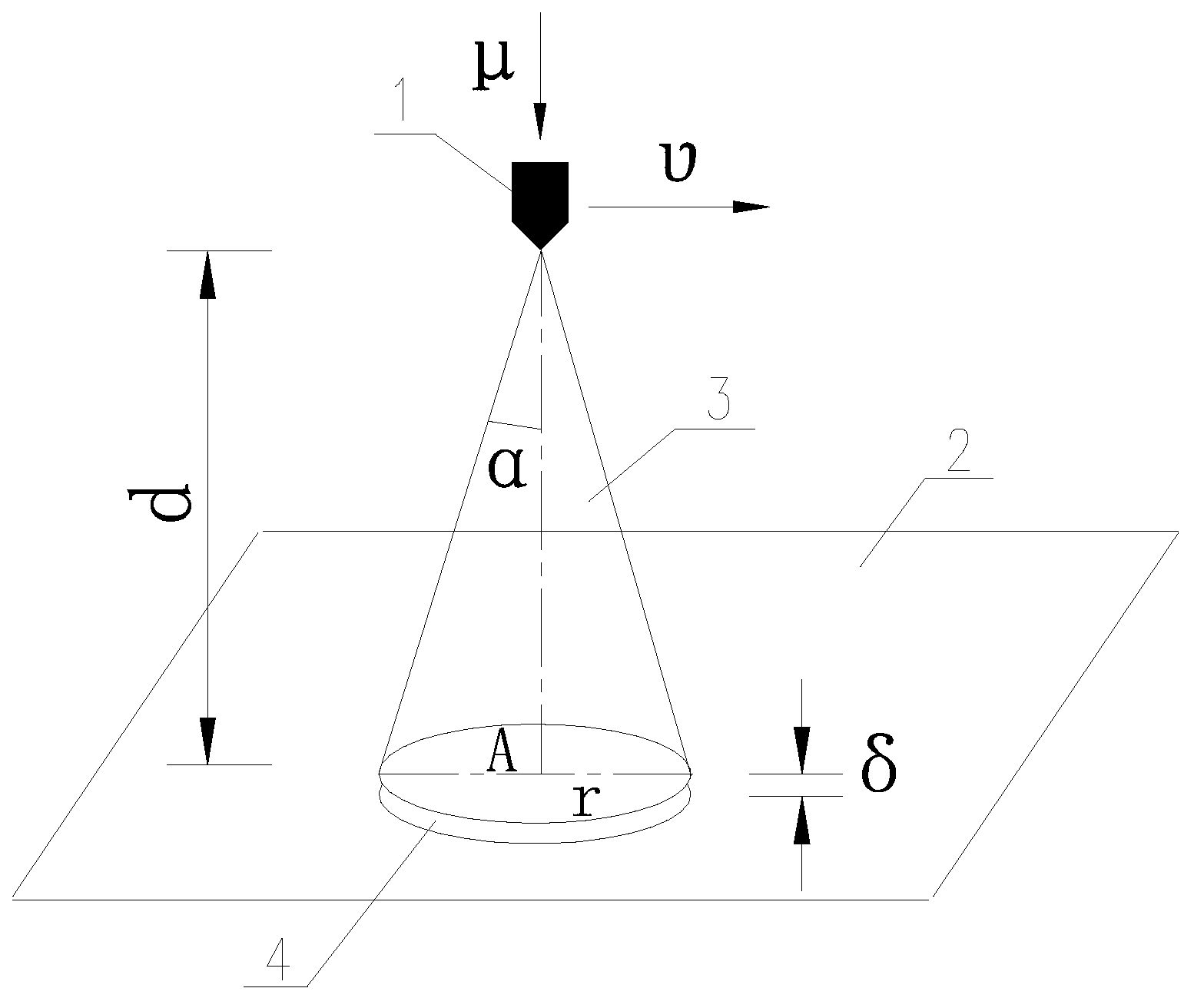

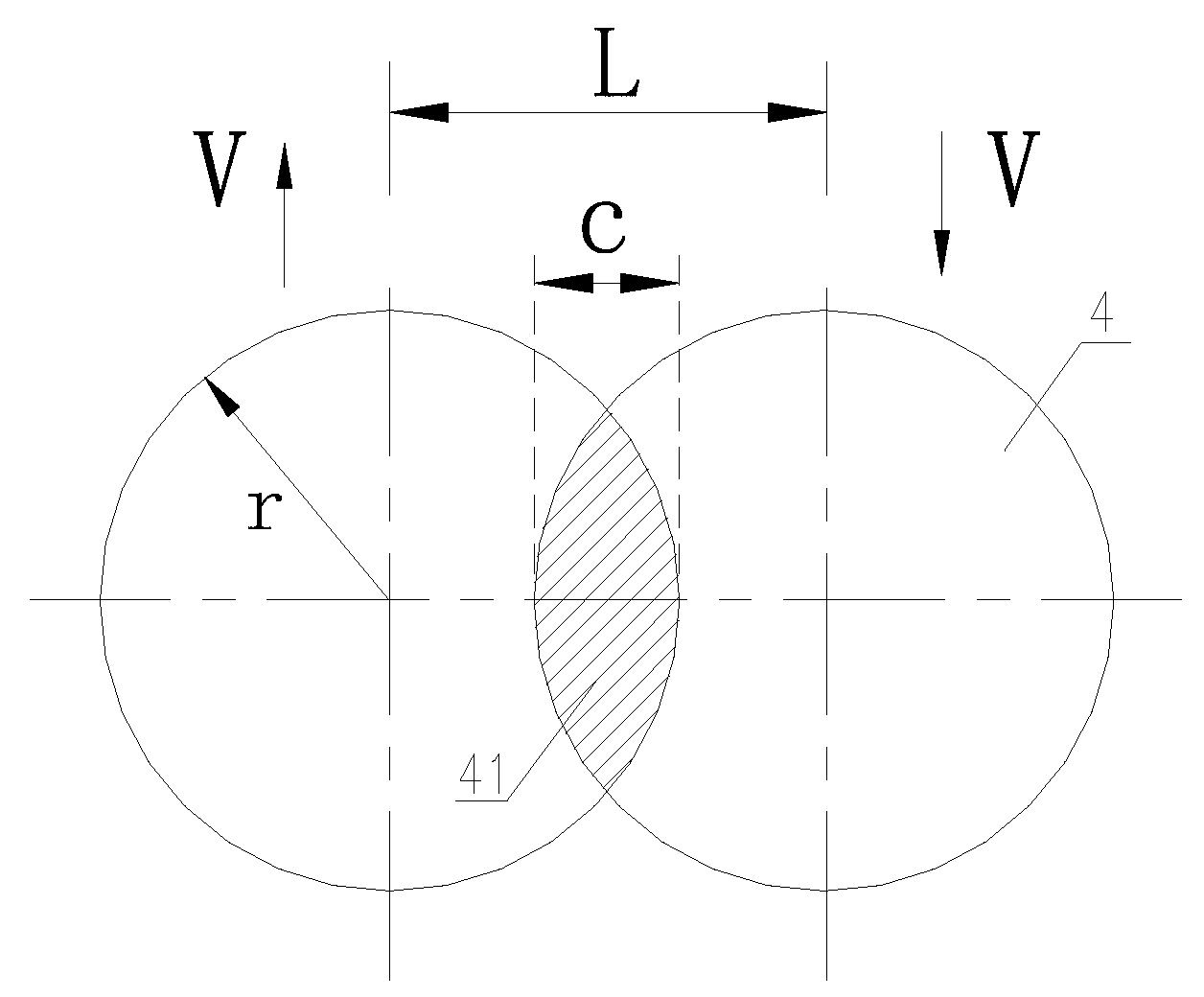

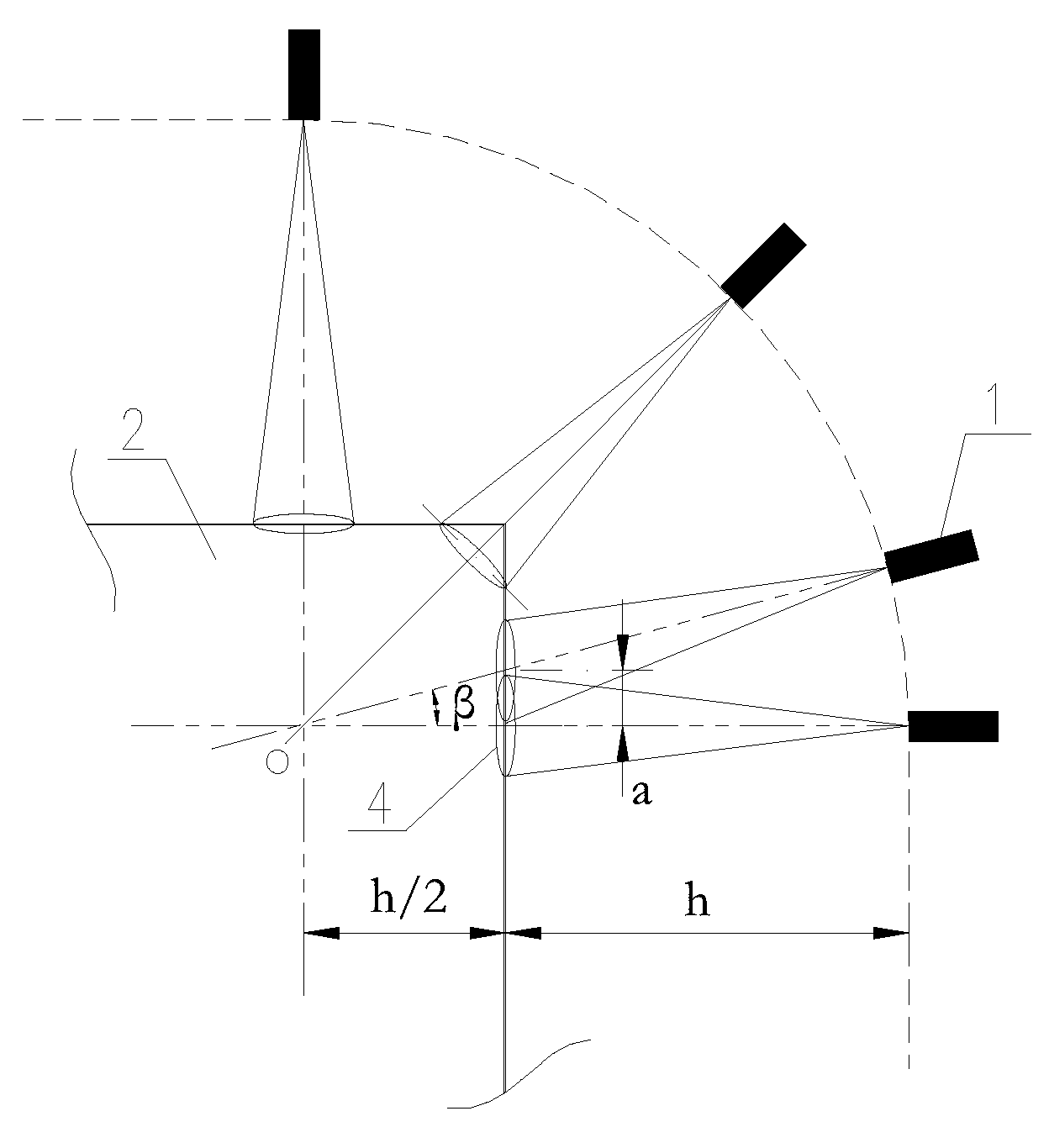

[0015] Step 1, such as figure 1 As shown, in the spraying area of the spraying gun, the geometric model of the spraying process of the robot spraying gun 1 is a spraying cone 3, that is, the spraying medium from the spraying gun 1 to the surface of the copper plate 2 forms a cone. The distance from the surface of the copper plate 2 is d, the moving speed of the spray gun 1 is υ, the spraying angle is α, and the spraying area is a circular area 4 with a conical bottom surface, then the area of the circular area is A=πr 2 , where r is the radius of the circle, radius r = d*tanα, to obtain a coating with a thickness of δ, in order to determine the thickness distribution model of the spray deposition, the robot conducts a single linear reciprocating spray on the copper plate for experimental research, in a specific Under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com