Patents

Literature

114results about How to "Reduce spraying costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene-modified resin powder coating and production process thereof

InactiveCN104194585AIncrease profitReduce pollutionFireproof paintsPolyurea/polyurethane coatingsWeather resistanceGraphene

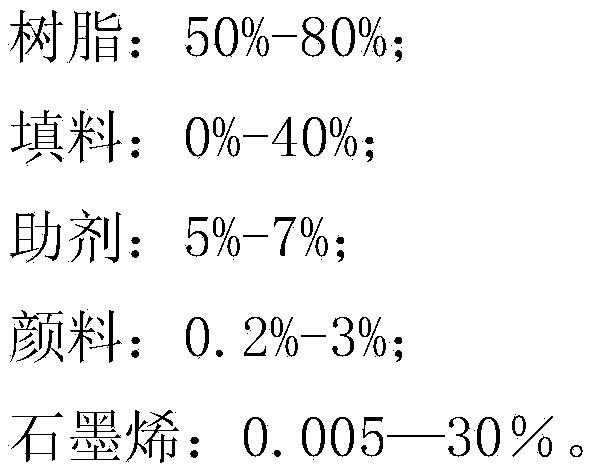

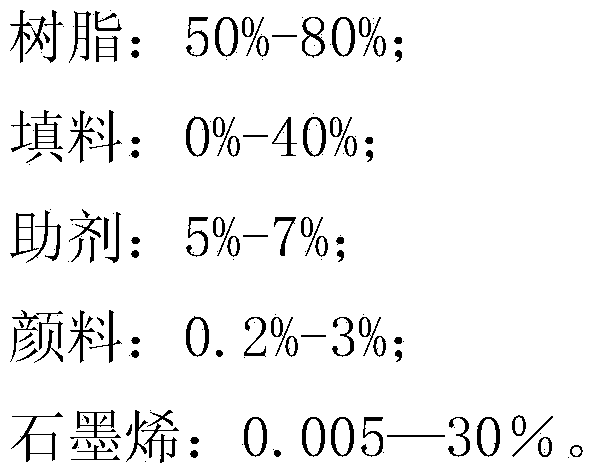

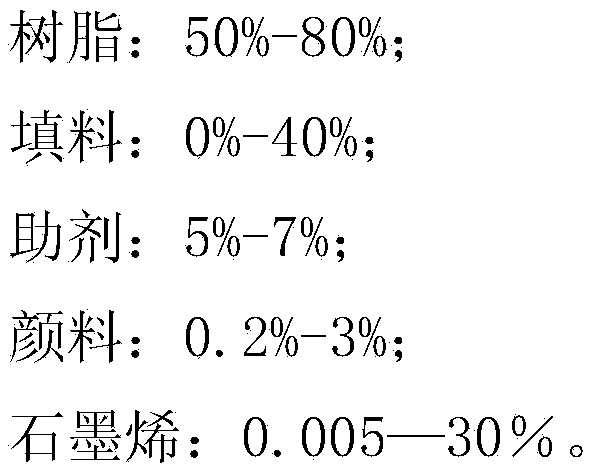

The invention relates to graphene-modified resin powder coating and a production process thereof. The graphene-modified resin powder coating comprises the following components in percentage by weight: 50-80 percent of resin, 0-40 percent of filler, 5-7 percent of an auxiliary agent, 0.2-3 percent of pigment and 0.005-30 percent of graphene. According to the graphene-modified resin powder coating provided by the invention, a proper amount of graphene is added in the traditional resin powder coating, so that the mechanical property, the conductivity, thermal conductivity, flame resistance, corrosion resistance and weather resistance of the resin powder coating are greatly improved; the graphene-modified resin powder coating has a broad market prospect.

Owner:周诚

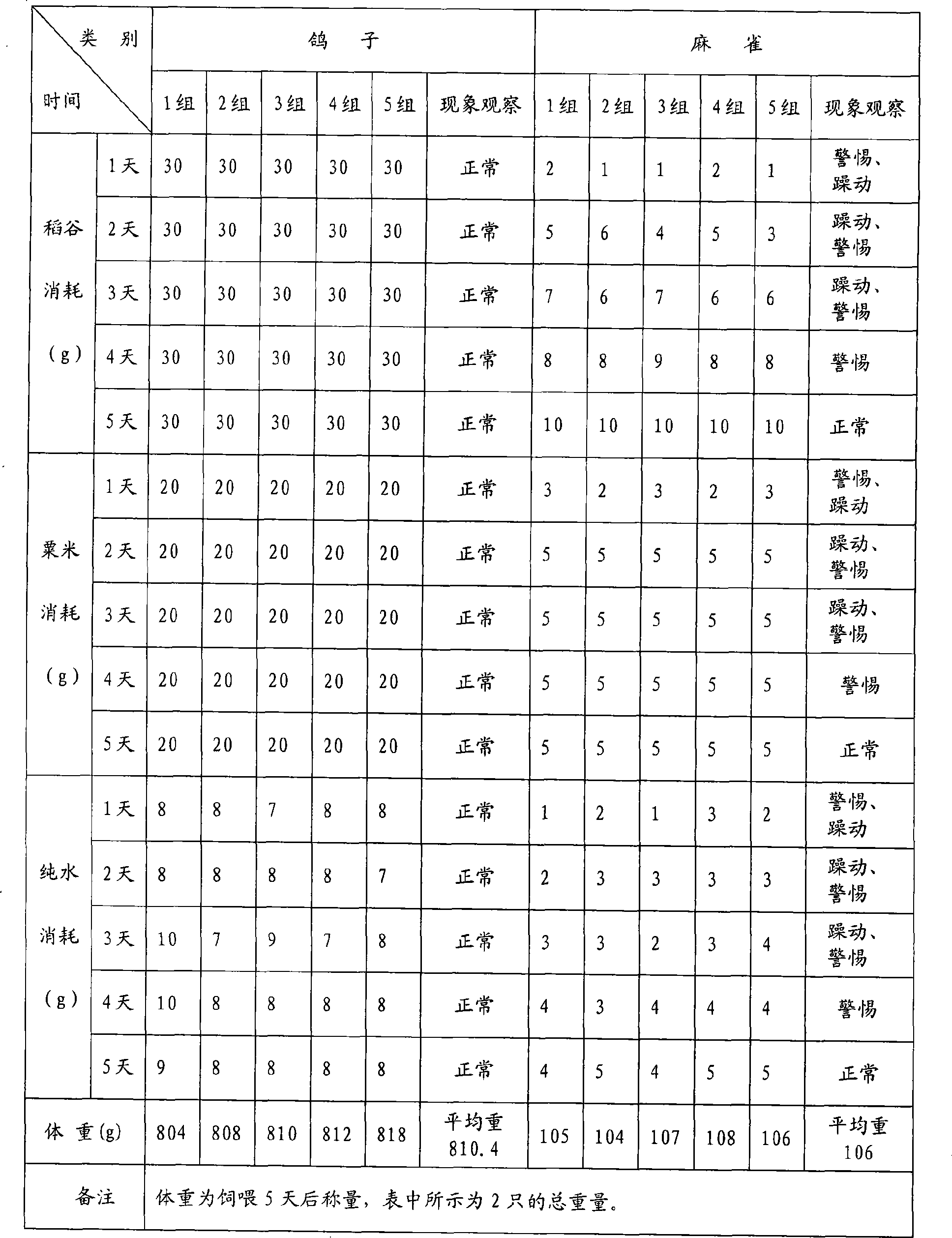

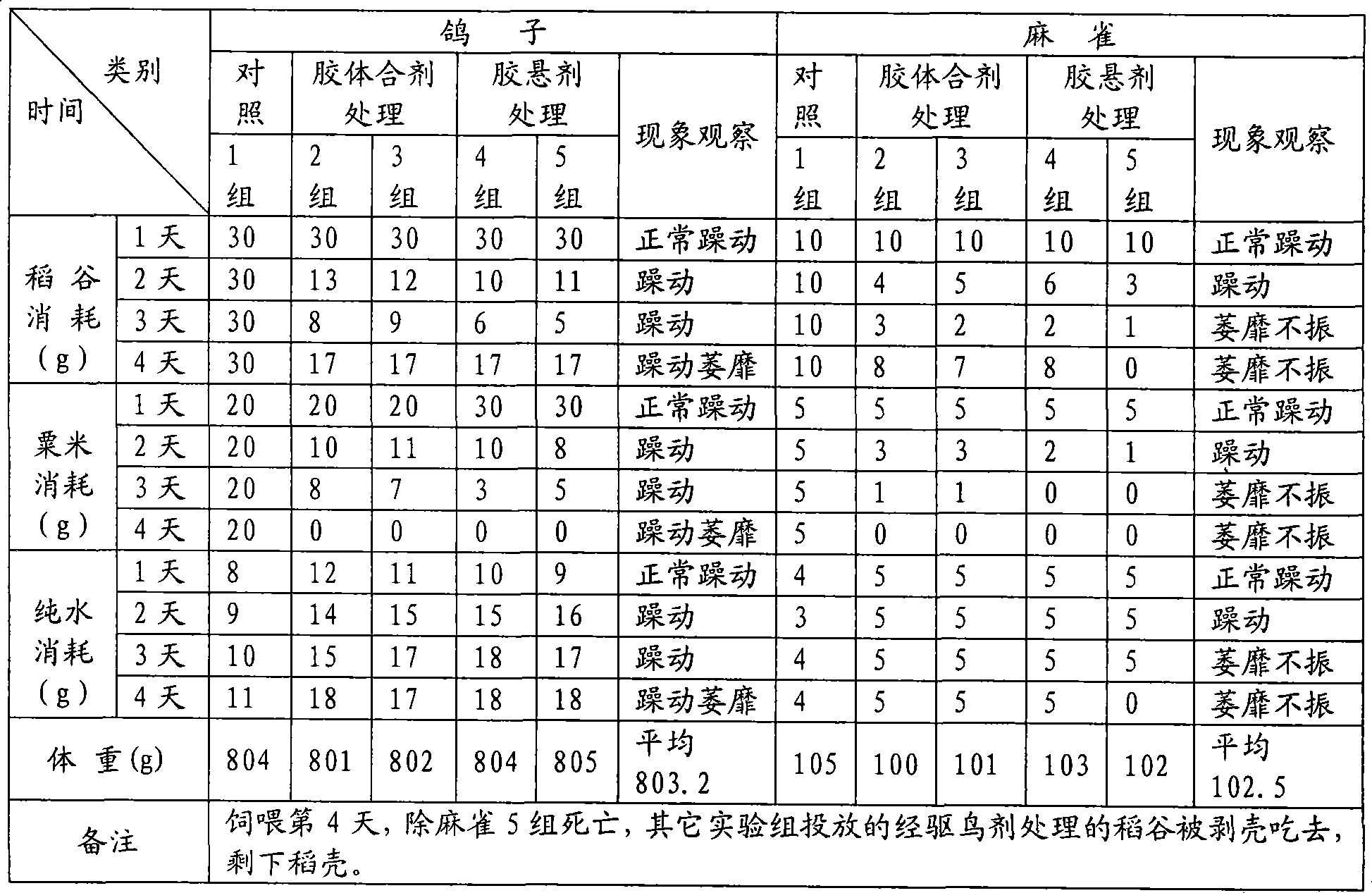

Bird driving composition and colloid mixture thereof, suspending agent and preparation method thereof

A driving-bird composite contains the following materials by different weight percentage: the driving-bird spice is selected from: 1 to 50 percent of methyl ortho-aminobenzoate, one or two of the 0.1-5 percent of heartleaf houttuynia herb essential oil or 10-21 percent of muskiness T; an antioxidant is selected from one or two of the 0.02-0.5 percent of 2, 6-BHT and sodium ascorbate, and the rest is control-released carriers. The driving-bird colloid mixture is made of the driving-bird composite, and the control-released carrier contains organic base or inorganic base, unsaturated fatty acid, antiseptic, emulsification, stabilizing agent, anti-freeze agent and the like. The driving-bird SC is made of the driving-bird composite, and the control-released carrier contains michael essien alkenyl succinic acid ester of starch sodium or Beta-cyclodextrin, antiseptic, emulsification, stabilizing agent, anti-freeze agent and the like. The invention utilizes the odor of the driving-bird spice for leading the bird-trigeminal to generate anaphylactic reaction and the bird-physiology to generate anorexia after pecking by means of diluting the sprayer, the driving-bird composite has the advantages of convenient usage and good effect of driving, and is harmless to the birds and the plant, thus belonging to the environment friendly biological agent products.

Owner:HUANGSHAN SHUANGBAO TECH APPLIED

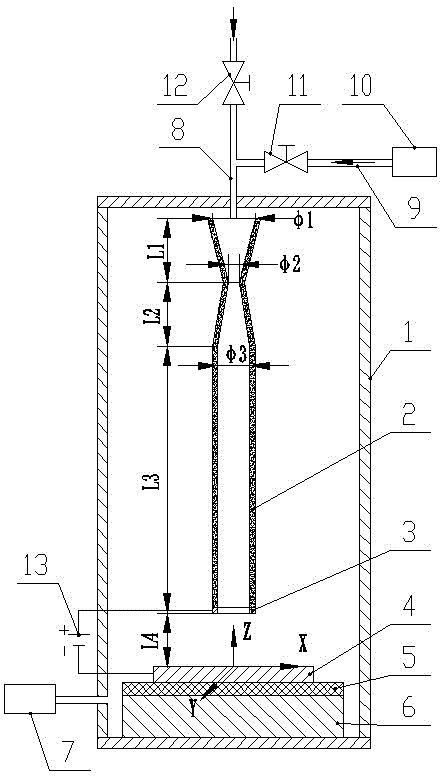

Nano metal particle cold spraying technique

InactiveCN102747363AReduce spraying costsPracticalPressure inorganic powder coatingMetal particleElectric field

The invention discloses a nano metal particle cold spraying technique which sequentially comprises the following steps: (1) arranging a metal ring electrode at the end face of a jet pipe outlet end, wherein the internal diameter of the ring electrode is equal to that of the wall of the jet pipe; (2) putting the ring electrode and a metal matrix in a vacuum environment, wherein the distance between the ring electrode and the surface of the metal matrix is 5-50mm; (3) connecting an adjustable direct-current stabilized voltage supply to the metal matrix and the ring electrode, wherein the ring electrode is connected to the positive pole of the power supply, and the metal matrix is connected to the negative pole of the power supply; and (4) inputting gas with certain pressure and nano metal particles into the jet pipe from the jet pipe inlet, so that the positively charged metal particles impact the negatively-charged metal matrix surface to deposit and form a nano coating on the metal matrix surface. The invention integrates advantages of vacuum cold spraying and electric field assisted cold spraying, selects proper technological parameters, and can implement nano metal particle spraying operation under the working conditions of normal temperature and pressure.

Owner:HENAN POLYTECHNIC UNIV

Nano composite pesticides new formulation and preparation method thereof

InactiveCN101288397AReduce spraying costsImprove adhesionBiocideAnimal repellantsSodium laurateUltimate tensile strength

The invention discloses a new dosage form of nanometer compound pesticide and a preparation method thereof, which is prepared by adopting modified nanometer TiO2, chitosan and technical product of pesticides as the raw materials, wherein, the modified nanometer TiO2 has improved mechanical property which is modified through sodium laurate. By utilizing the property of film build of chitosan, the chitosan and the technical product of pesticides react fully, a layer of film is formed on the surface of a spraying object, the film can reduce loss of liquid medicine, ensure more pesticide to be attached on crops, facilitate penetration of systemic pesticide and increase the safety for the operators of spraying and environment; the added modified nanometer TiO2 helps the film have certain intension and tenacity, thus achieving slow release and long effect of pesticide; meanwhile, by utilizing the antibacterial property of chitosan and nanometer TiO2, the effects of antibacterial property and getting rid of pests of pesticide are increased. The nanometer compound pesticide is a new dosage form of pesticide with the characters of long effect, safety, innocuity, economy and convenience.

Owner:GUIZHOU UNIV

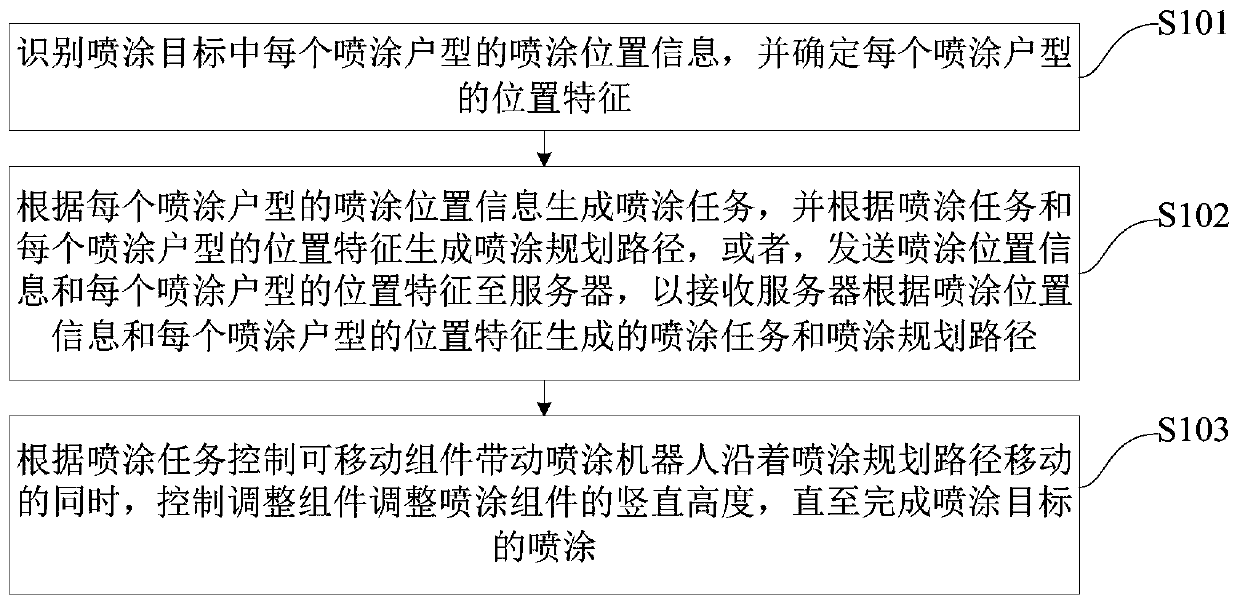

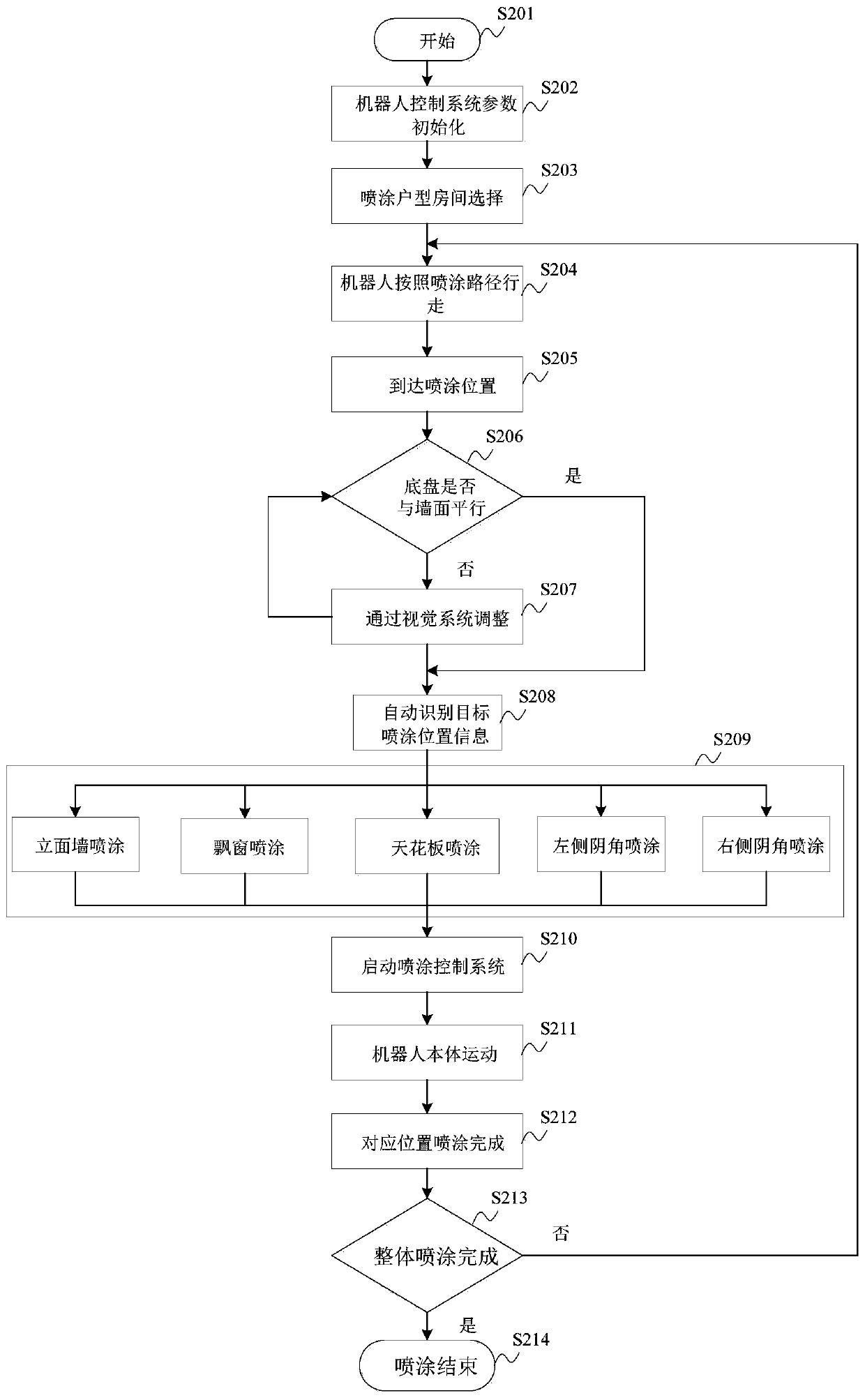

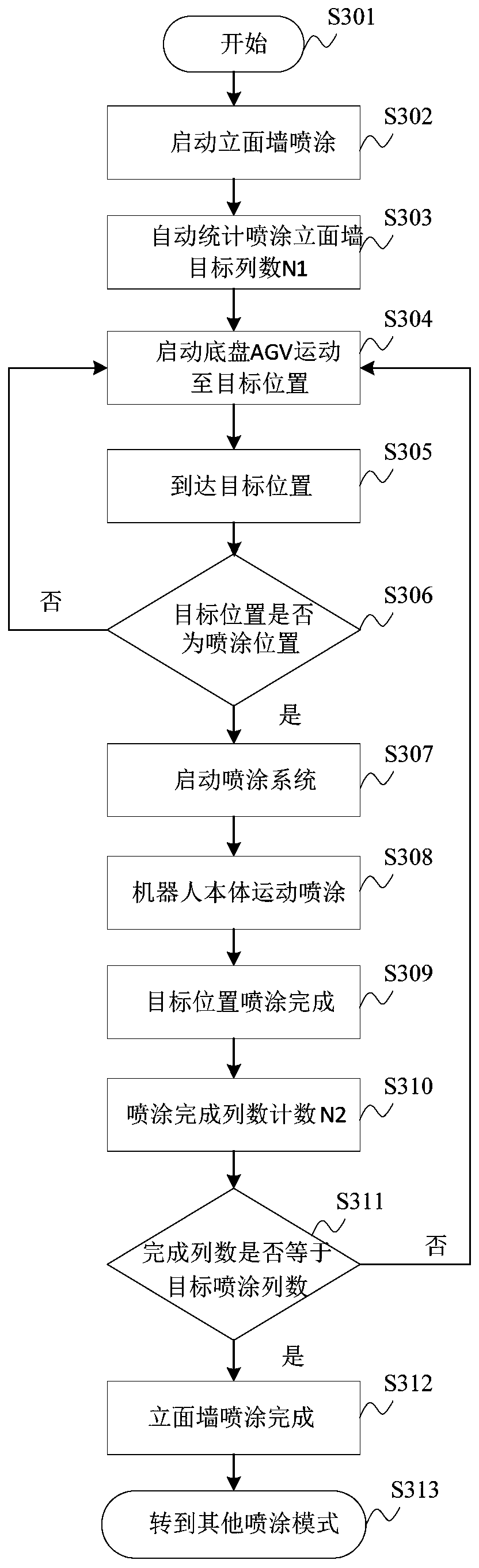

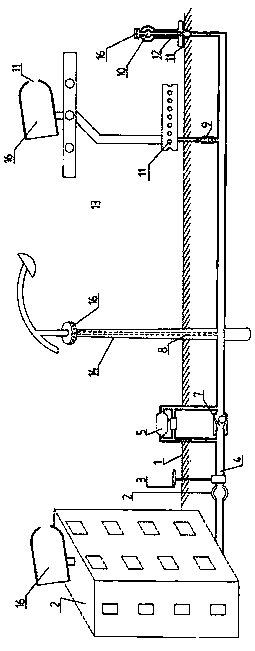

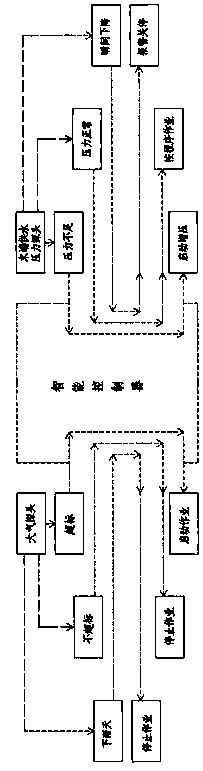

Control method and device of spraying robot and spraying robot with control device

InactiveCN110700523ARealize intelligent sprayingImprove spraying efficiencyBuilding constructionsControl engineeringProcess engineering

The invention discloses a control method and device of a spraying robot and the spraying robot with the control device. The control method comprises the steps that spraying position information of each spraying house type in a spraying target is recognized, and the position feature of each spraying house type is determined; spraying tasks are generated, and each planned spraying path is generatedaccording to the corresponding spraying task and the position feature of the corresponding spraying house type, or the spraying tasks and the planned spraying paths which are generated by a server according to the spraying position information and the position features of the spraying house types are received; and a movable assembly is controlled to drive the spraying robot to move along the planned spraying paths according to the spraying tasks, and an adjusting assembly is controlled to adjust the vertical height of a spraying assembly until the spraying operation of the spraying target is accomplished. As a result, the problems that due to the fact that the spraying process is manually operated, the spraying cost is high, the spraying efficiency is low, the spraying practicability is poor, and the spraying requirement cannot be effectively met are solved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

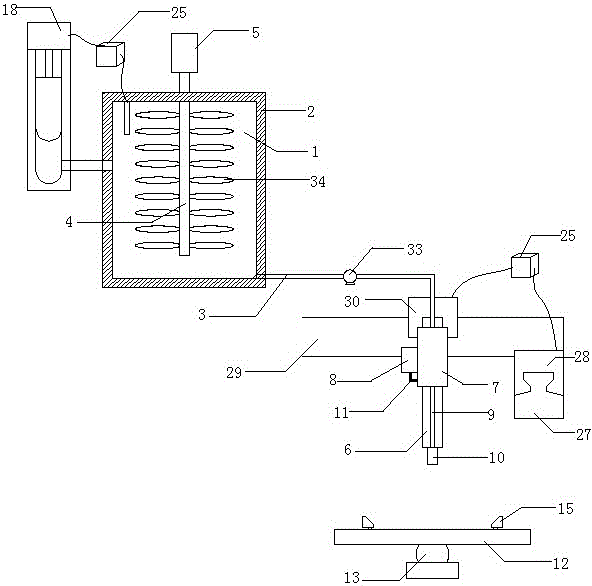

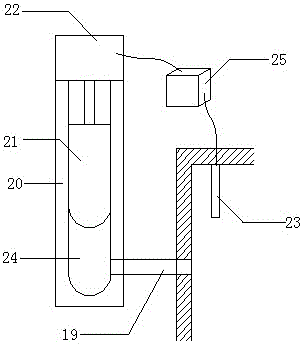

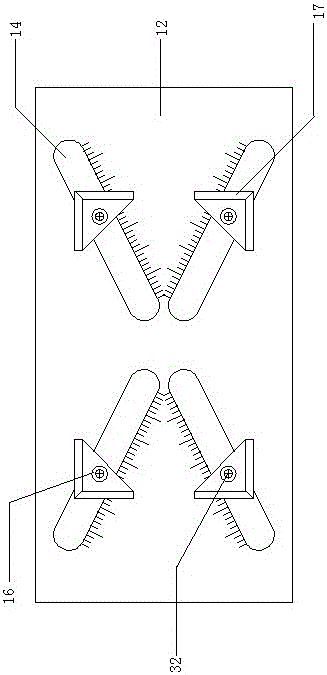

Polyurethane black material spraying equipment

ActiveCN105728236AAll-round sprayingSpray evenlySpray nozzlesLiquid spraying apparatusEngineeringPressurized spray

The invention provides polyurethane black material spraying equipment. The polyurethane black material spraying equipment comprises a black material extracting part, a black material spraying part and a plate clamping part, wherein the black material extracting part comprises a black material storage barrel and a black material stirring device; a cooling sandwich layer is arranged on the lateral wall of the black storage barrel, and a black material extracting pipe is connected to the bottom of the black material storage barrel; the black material stirring device comprises a stirring shaft and a stirring motor; the black material spraying part comprises a spraying gun, a to-be-sprayed black material storage tank and a pressurizing spraying device; the plate clamping device comprises a clamp plate and a universal ball. The polyurethane black material spraying equipment has the advantages that omnibearing and even spraying of the plate can be achieved, the storage quality of polyurethane black materials during storage and use can be guaranteed, and spraying quality and effect are further guaranteed; the polyurethane black material spraying equipment is efficient in spraying and capable of lowering spraying cost favorably.

Owner:上海林馨科技有限公司

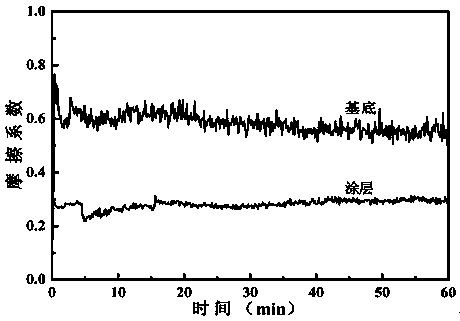

Low-pressure cold spraying copper-based self-lubrication coating and preparation method thereof

ActiveCN108486565AImprove the lubrication effectImprove wear resistancePressure inorganic powder coatingGraphiteCopper

The invention discloses a low-pressure cold spraying copper-based self-lubrication coating which comprises the following raw materials by weight percentage: 10-30% of copper-coated graphite, 8-12% ofaluminum oxide and the balance of copper. The invention further discloses preparation of the coating on the surface of stainless steel 304 by a low-pressure cold spraying technology. The coating is uniform in texture, is well combined with a substrate and has excellent mechanical properties and lubrication and antiwear performance. In addition, a preparation technology of the coating is green, environmentally friendly, convenient to operate and good in controllability; and the coating as a lubrication component in an oil-less or oil-lack environment has wide application prospects and an important practical value.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Protection method of spraying metal for coating edge, corner and seam of steel component

The present invention discloses a protective method for metal spraying of edges, angles and welds of painted steel members. In the pre-treatment procedure of a painted steel member, an operation step of metal spraying is additionally performed on edges, angles and welds of the member after rust removal of the steel member surface by ball throwing or sand blasting, or after phosphorization or inactivation of the steel member surface, a metal coating 5-50 micrometers thick is produced on the member surface. The present invention has the advantage that the technology has simple operation, low spraying cost, prominent protective effect and excellent practical value.

Owner:XUZHOU ZENITH COATING

Silicon-titanium alloy film coat of air preheater tube and electrostatic spraying process thereof

InactiveCN101792262AHigh densityUniform coatingLiquid spraying plantsSteel tubeTemperature resistance

The invention relates to a silicon-titanium alloy film coat of an air preheater tube and an electrostatic spraying process thereof, and belongs to the electrostatic spraying technology of an environment-friendly, energy-saving and efficient silicon-titanium alloy film air preheater tube. Main components of the coat comprise SiO2, NiO, B2O3, TiO2, Pb2O3, NaO2 and K2O. A preparation method for the coat comprises the following steps: mixing and crushing common silicon-titanium alloy power and K2O to charge the powder, spraying the mixture to an air preheater steel tube under the high pressure of 30 to 120KV by using a positioning gun, heating and cooling the steel tube, and cushioning a high-temperature pad to obtain the coat. The process can realize automatic powder spraying, does not need manpower, obtains workpieces with unlimited lengths, and has the characteristics of environmental protection, energy conservation and high efficiency; due to the addition of K2O, the atomization is stable, the film is coated uniformly, the mass density is high and the thickness is controllable; the manpower and spraying cost are saved, and the service life is prolonged; and the prepared coat is superior to that in a common enamel process and a plastic powder electrostatic spraying process on the aspects of mechanical strength, adhesive force, high temperature resistance, abrasion resistance, acid and alkali corrosion resistance, ageing resistance and the like.

Owner:济南屹林科技有限公司

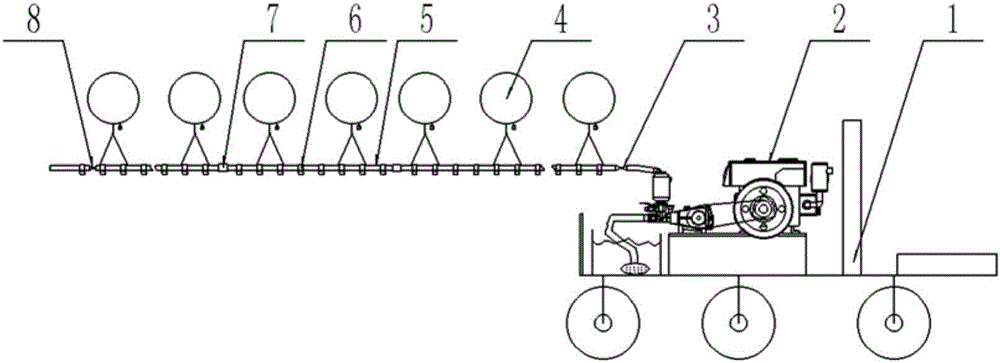

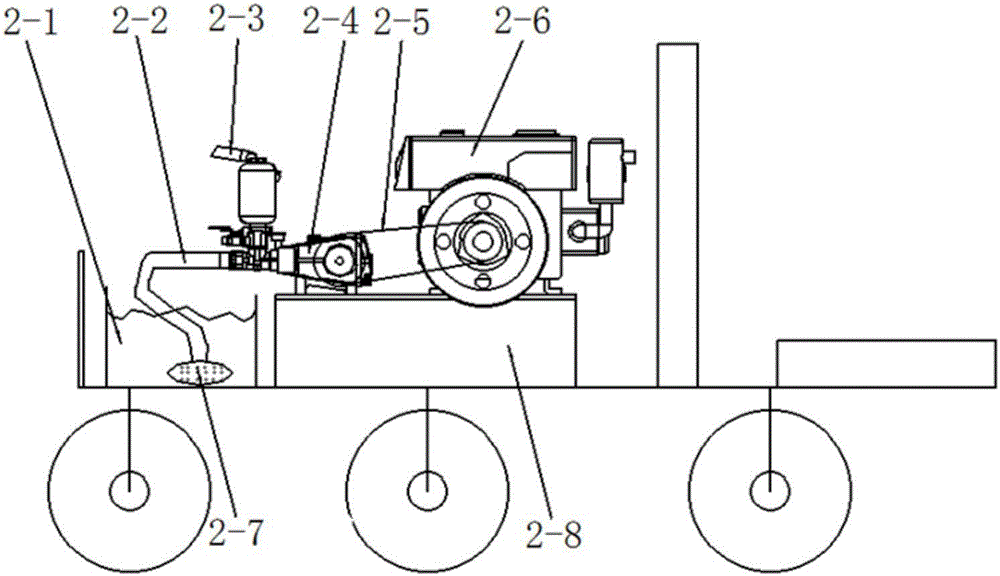

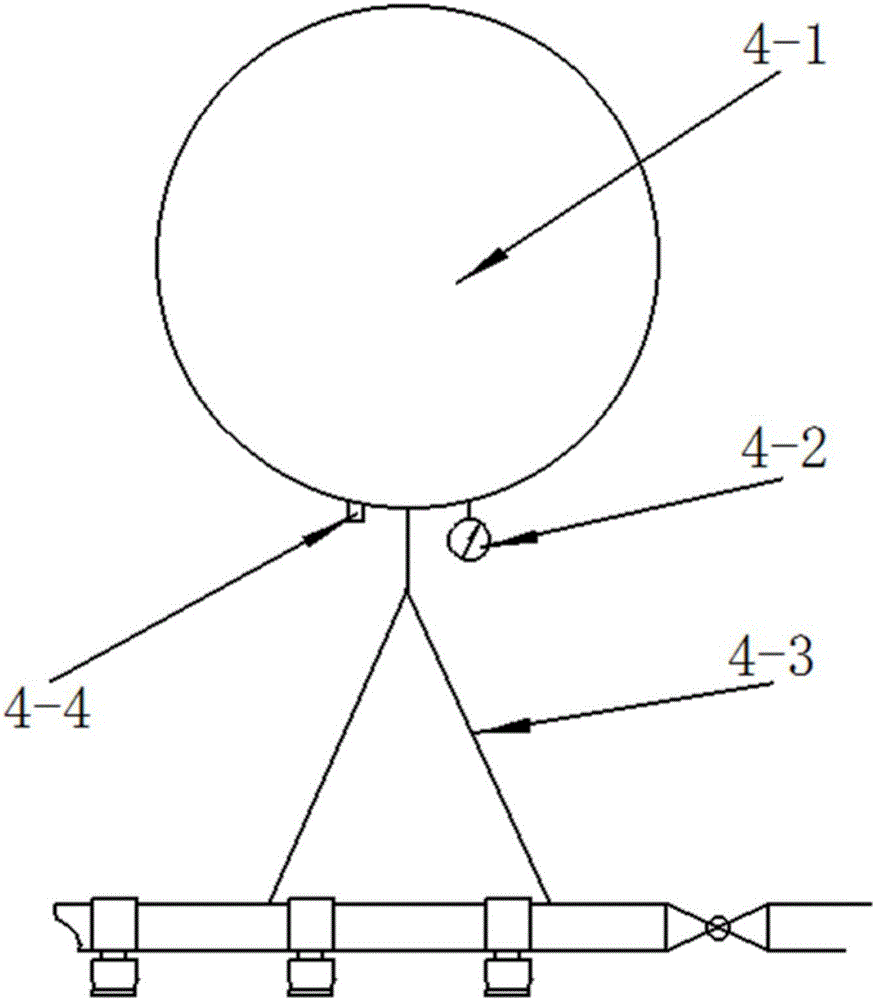

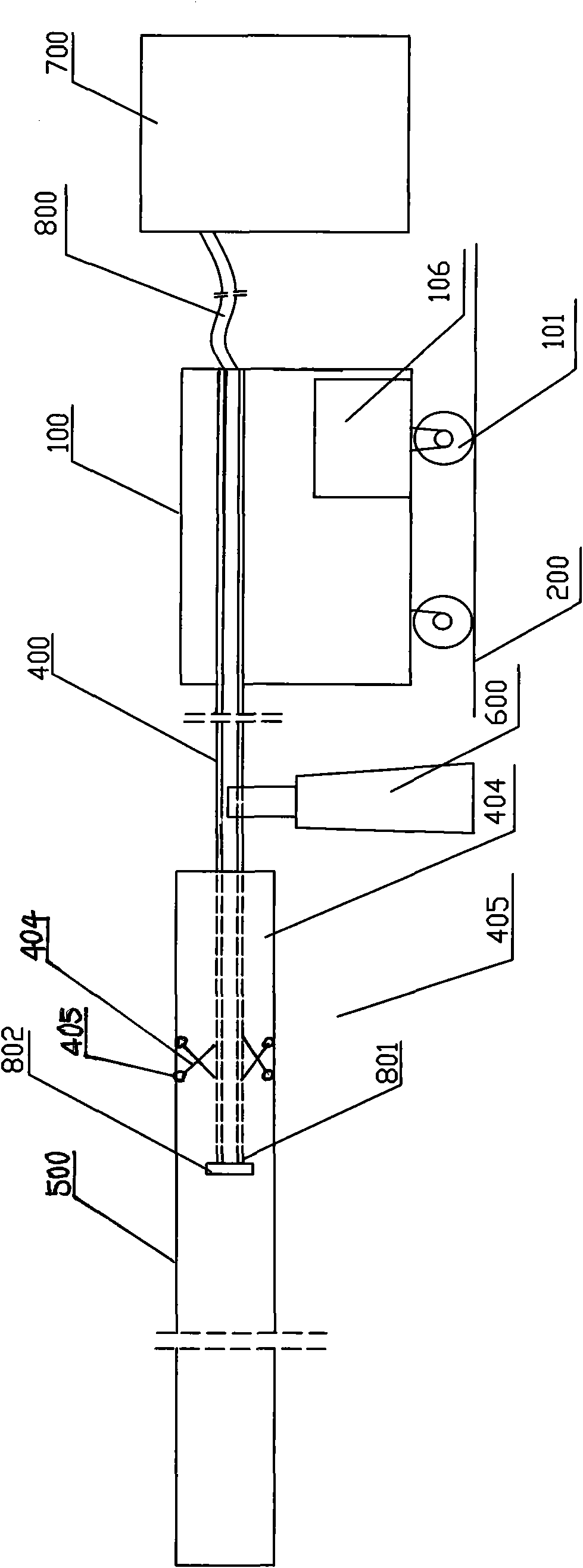

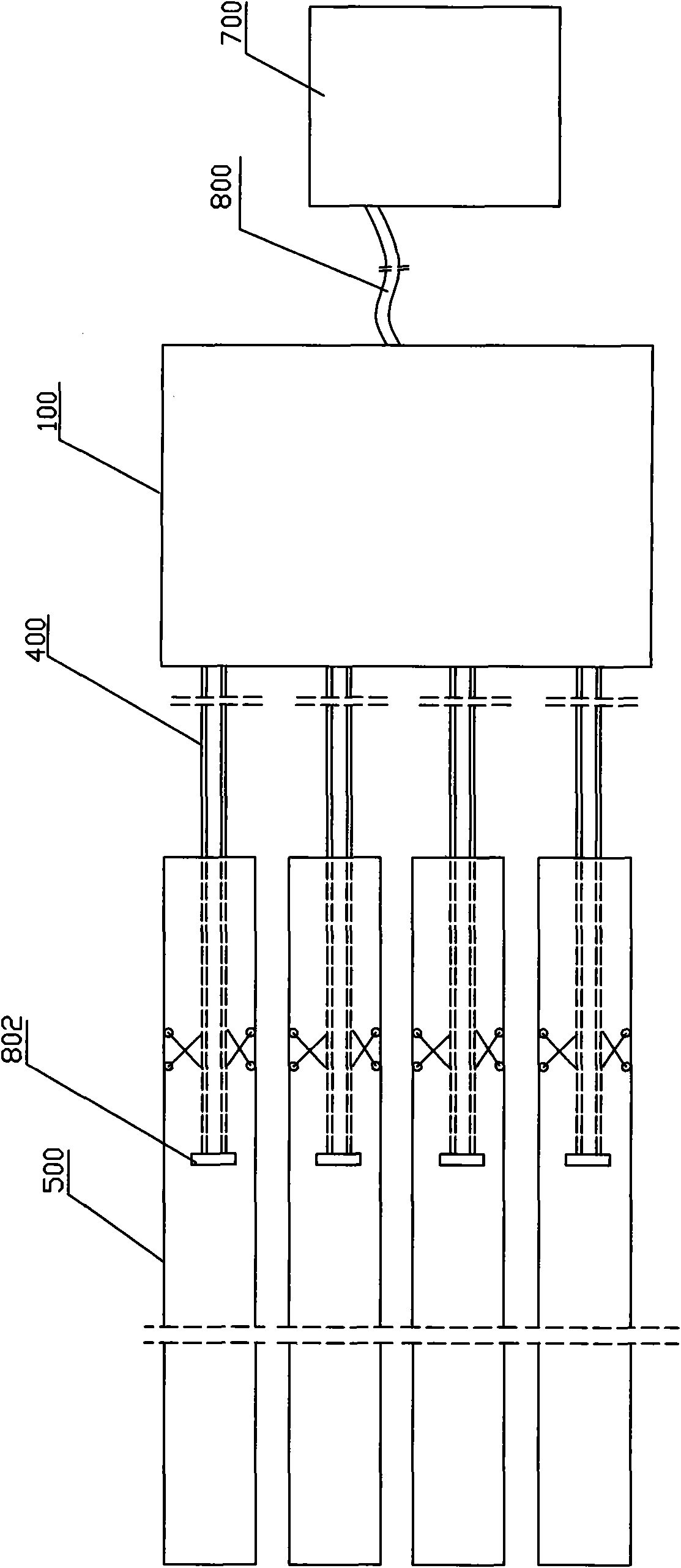

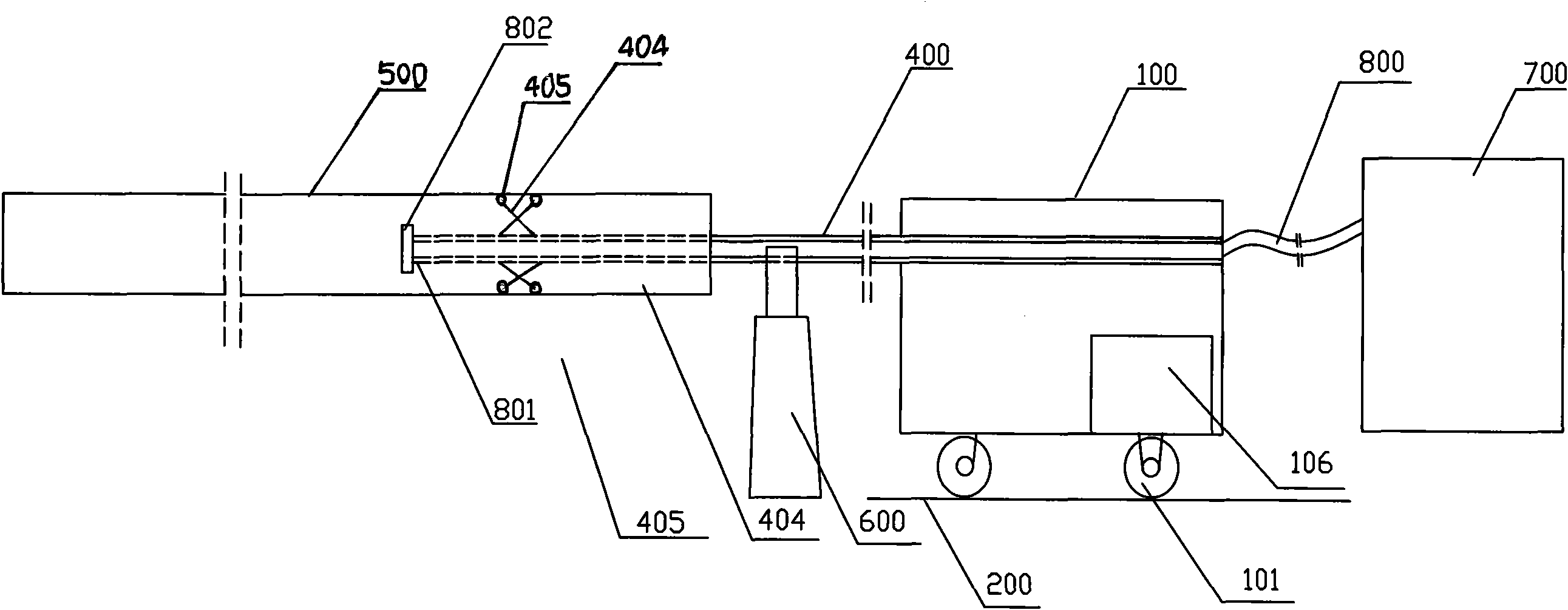

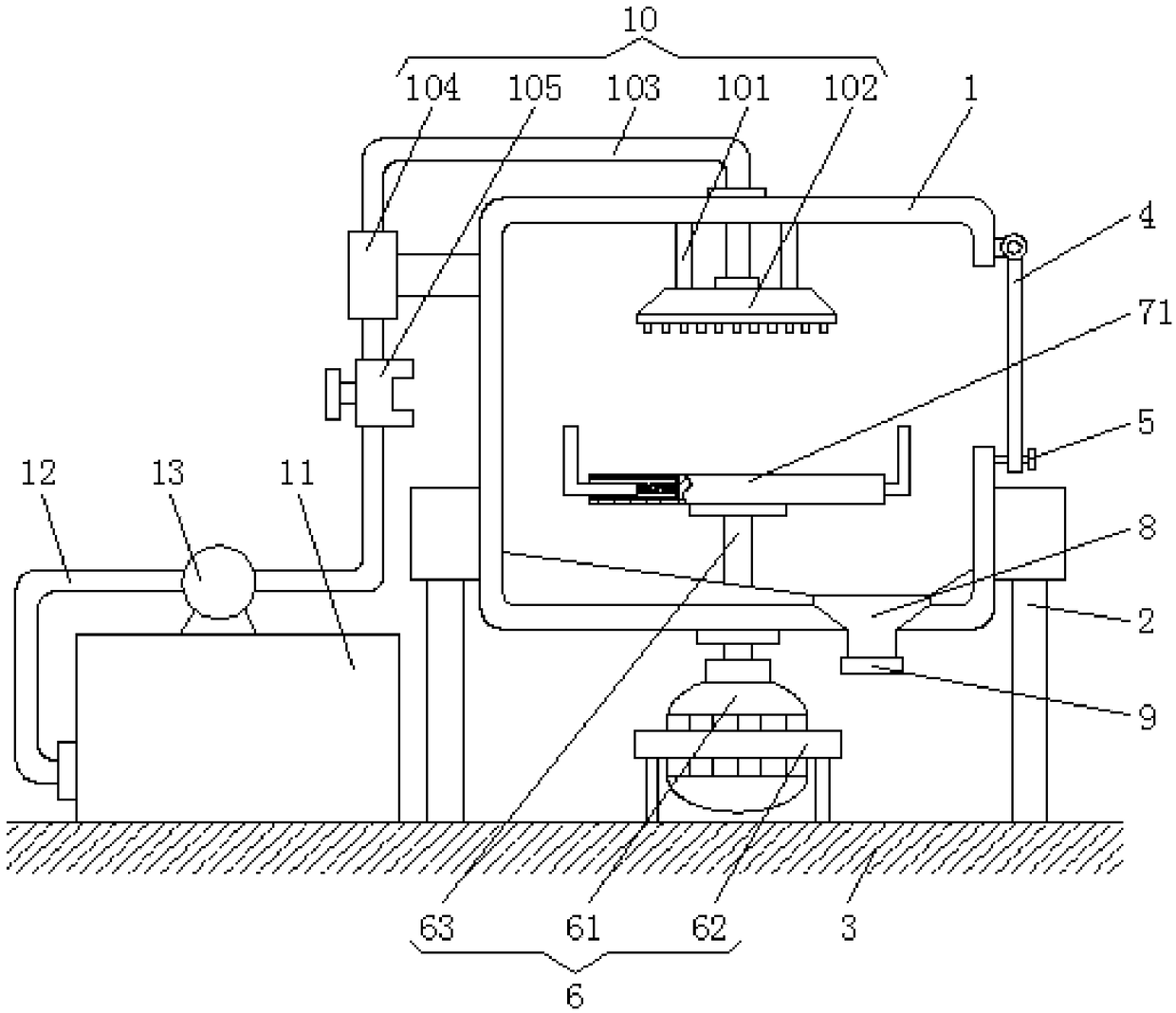

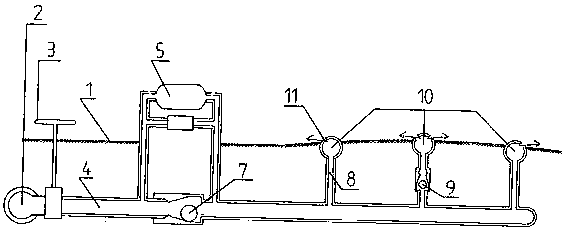

Balloon suspending-type pesticide application system

PendingCN106614472APrevent inflowLarge capacityInsect catchers and killersAgricultural scienceAgricultural pesticides

The invention provides a balloon suspending-type pesticide application system, and belongs to the technical field of agricultural pesticide application. The system comprises a walking device (1), a balloon suspending device (4), a pesticide conveying device (5) and a pesticide spraying power device (2). By means of the system, the damage of pesticides to the human body is eliminated, and the system has the advantages of being convenient to operate, saving labor and time, being high in efficiency, low in pesticide application cost and the like, and is capable of being applied to pesticide application in field and worthy of being widely popularized.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Nickel-plating boron carbide/aluminum composite coating as well as preparation method and application

InactiveCN101684210AIncrease contentGood electron radiation absorption propertiesMolten spray coatingLiquid/solution decomposition chemical coatingElectron radiationBoron carbide

The invention provides a nickel-plating boron carbide / aluminum composite coating, comprising the components of 54-79 percent by weight of nickel-plating boron carbide particles and 21-46 percent by weight of aluminum powder. The invention also provides a preparation method, which comprises the steps of mixing the nickel-plating boron carbide particles and the aluminum powder through pre-treating the nickel-plating boron carbide particles and carrying out chemical nickel-plating surface modification to obtain the nickel-plating boron carbide / aluminum composite coating; and the invention furtherrelates to the application of the nickel-plating boron carbide / aluminum composite coating sprayed on a matrix and used as a space protective coating layer to manufacture a novel space protective material with the nickel-plating boron carbide / aluminum composite coating. The invention has the advantages that a coating layer with the high boron carbide content is prepared by means of normal flame spraying or plasma spraying through carrying out surface modification treatment on the boron carbide particles, therefore, the spraying cost is greatly reduced, and the nickel-plating boron carbide / aluminum composite coating has light characteristic and favorable electron radiation absorption performance.

Owner:HARBIN INST OF TECH

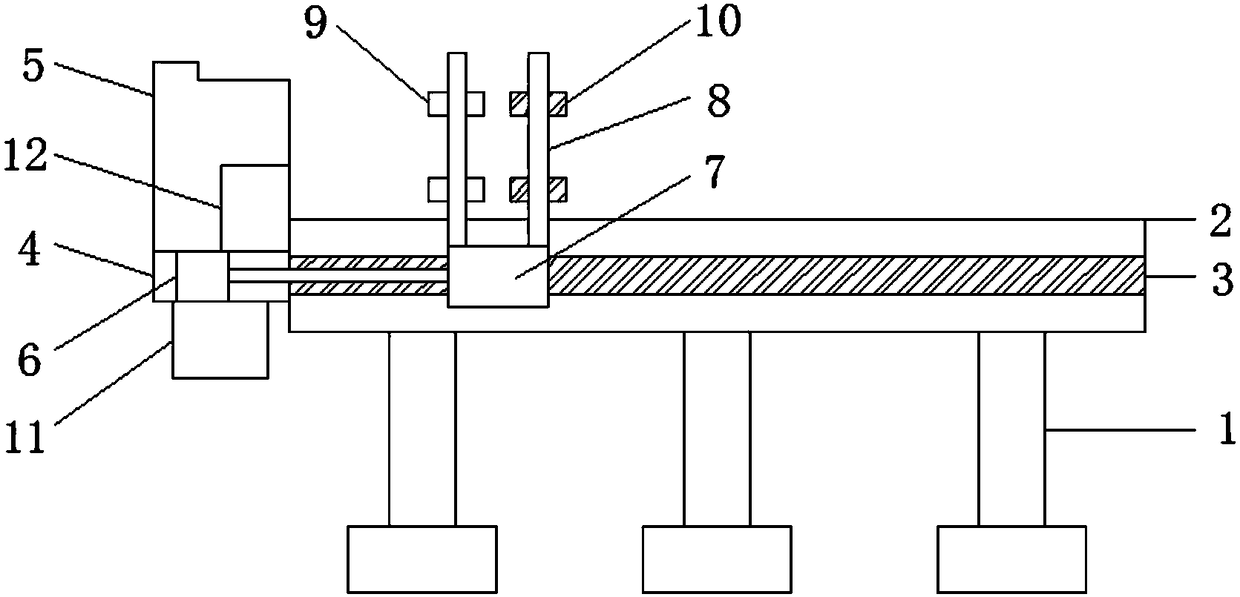

Paint spraying machine for inner wall of steel pipe

The invention relates to a paint spraying machine for the inner wall of a steel pipe. The machine comprises a trolley, four groups of hollow straight pipes and paint nozzles, wherein the hollow straight pipes are fixed on the trolley and extend forward; the paint nozzles are arranged on the front end of the hollow straight pipes; a paint conveying pipe is arranged in the hollow straight pipe; one end of the paint conveying pipe is communicated with a high-pressure airless spraying paint spraying machine, while the other end is communicated with the paint nozzles. The paint spraying machine for the inner wall of the steel pipe, which is used in spraying the inner wall of the steel pipe, has the advantages of no pollution, low cost and convenient operation.

Owner:SHANGHAI HUNENG ANTI CORROSION & HEAT INSULATION ENG

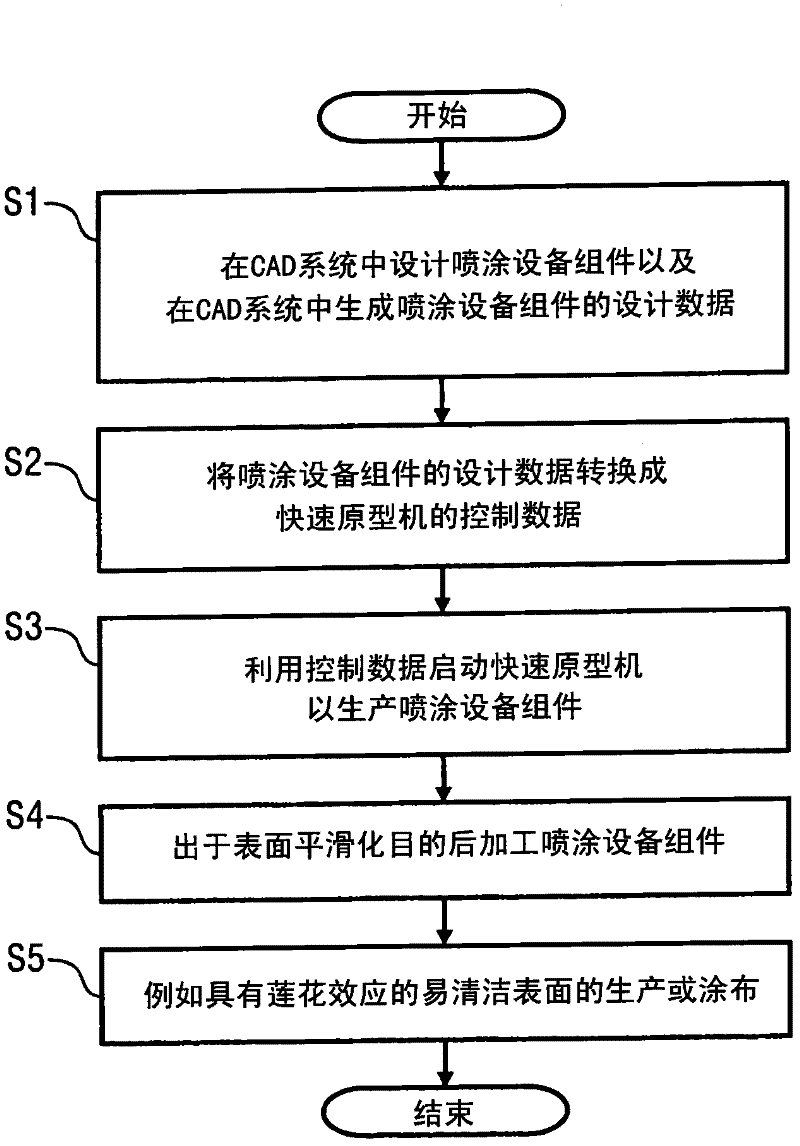

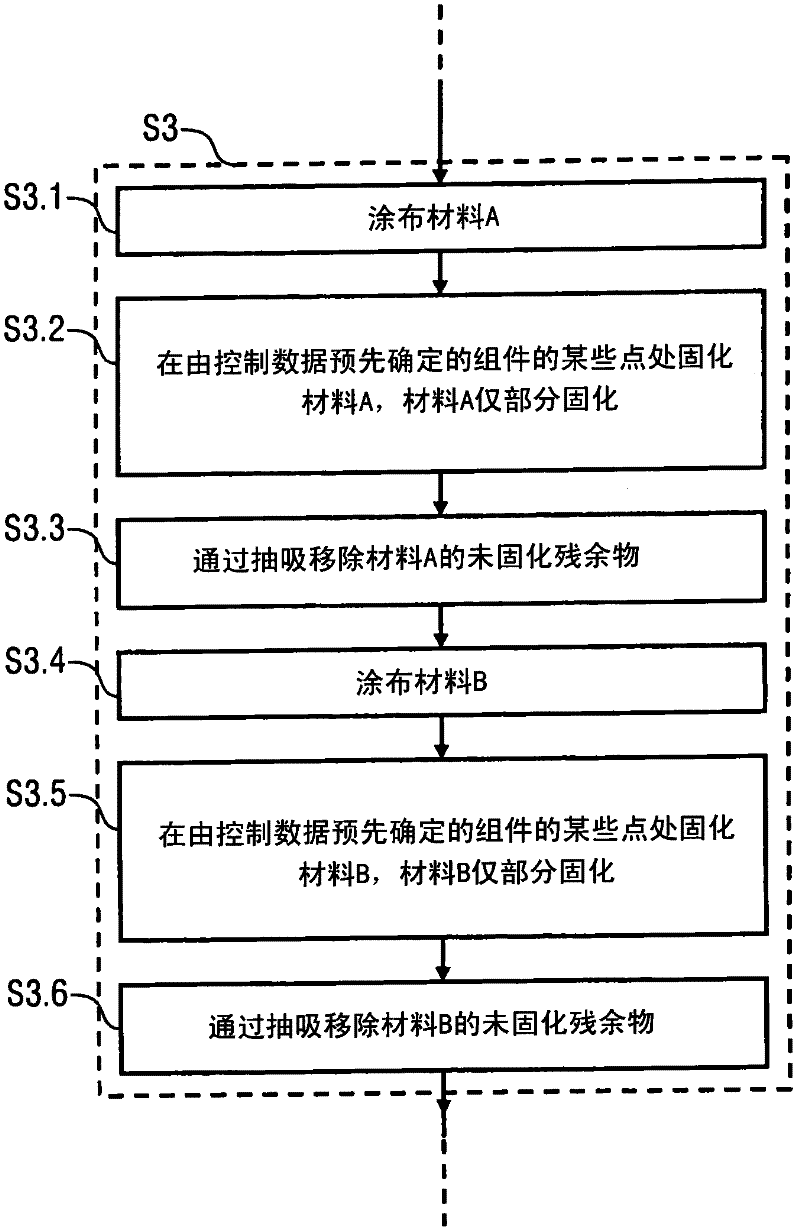

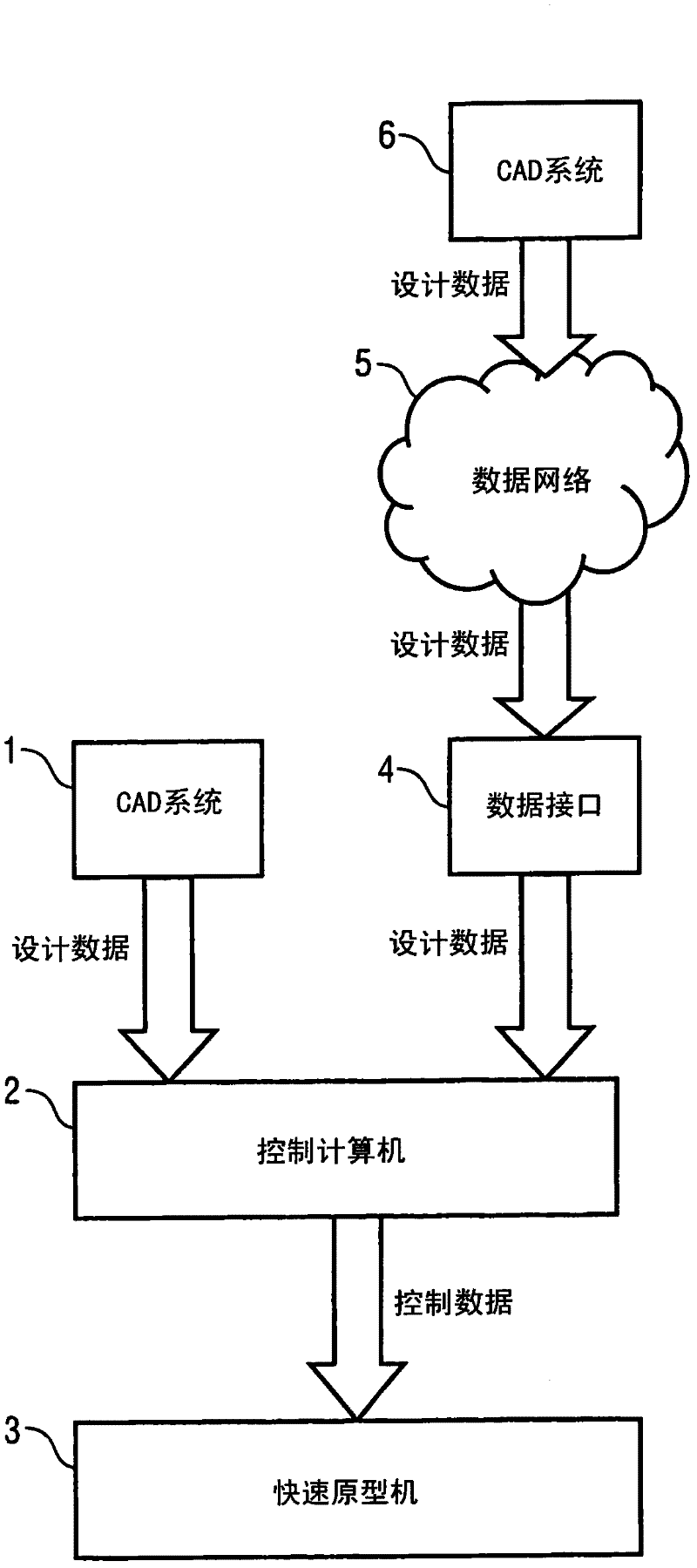

Production method for a paint plant component and corresponding paint plant component

InactiveCN102186652AReduce weightLow mass densityAdditive manufacturing apparatusMovable spraying apparatusRapid prototypingPlant Components

The invention relates to a production method for producing a paint plant component, in particular for producing a component of a colour changer, a colour valve, or a spray device. According to the invention, the paint plant component is produced in a rapid prototyping method. The invention also relates to a paint plant component that is produced accordingly.

Owner:DUERR SYST GMBH

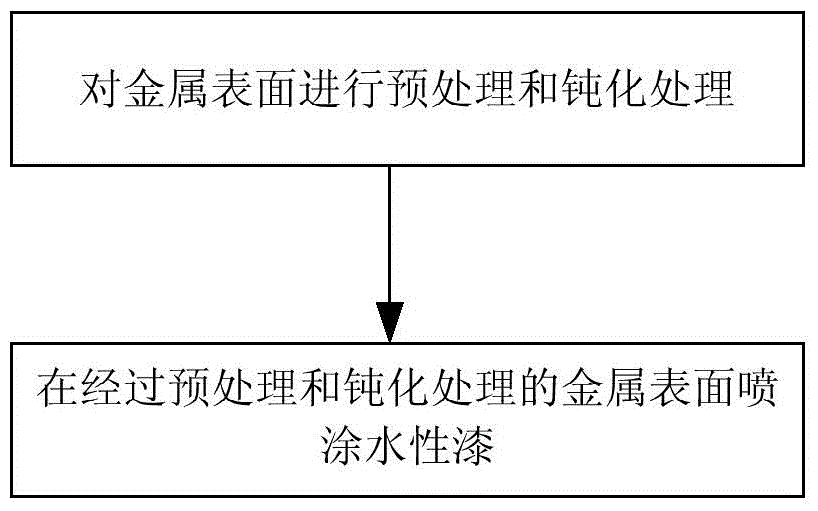

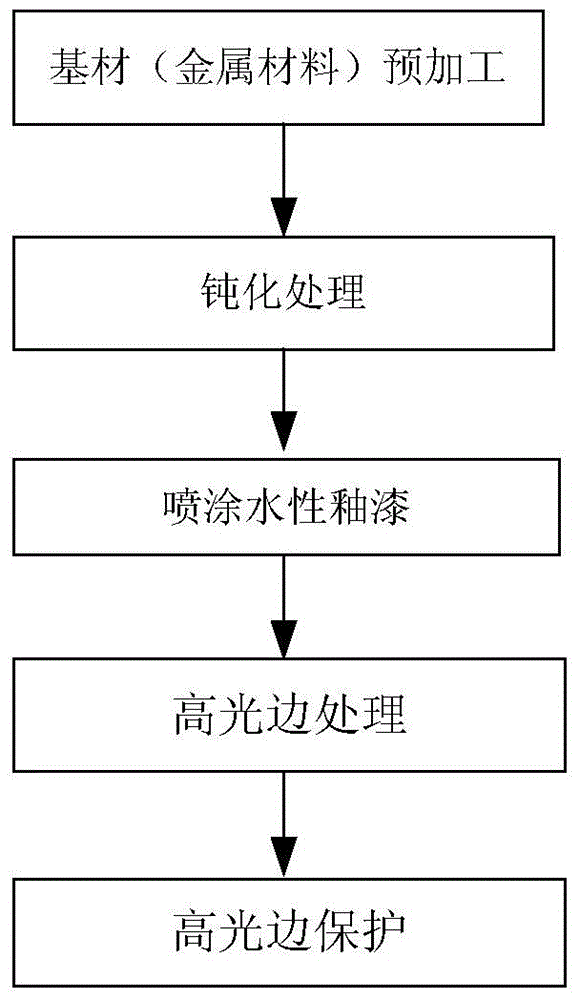

Metal spraying process and mobile phone shell

InactiveCN105149184ASimple spraying processReduce spraying costsPretreated surfacesCoatingsLacquerCommunication device

The invention relates to the technical field of communication devices, in particular to a metal spraying process and a mobile phone shell. The metal spraying process comprises pretreatment and passivating treatment of the surface of metal, and water paint is sprayed on the pretreated and passivated surface of the metal. Meanwhile, the invention further provides a mobile phone adopting the spraying process. According to the metal spraying process and the mobile phone shell, the water paint is sprayed on the pretreated and passivated surface of the metal, the spraying process is simplified, the spraying cost is lowered, and the good spraying effect and environment protection performance are achieved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

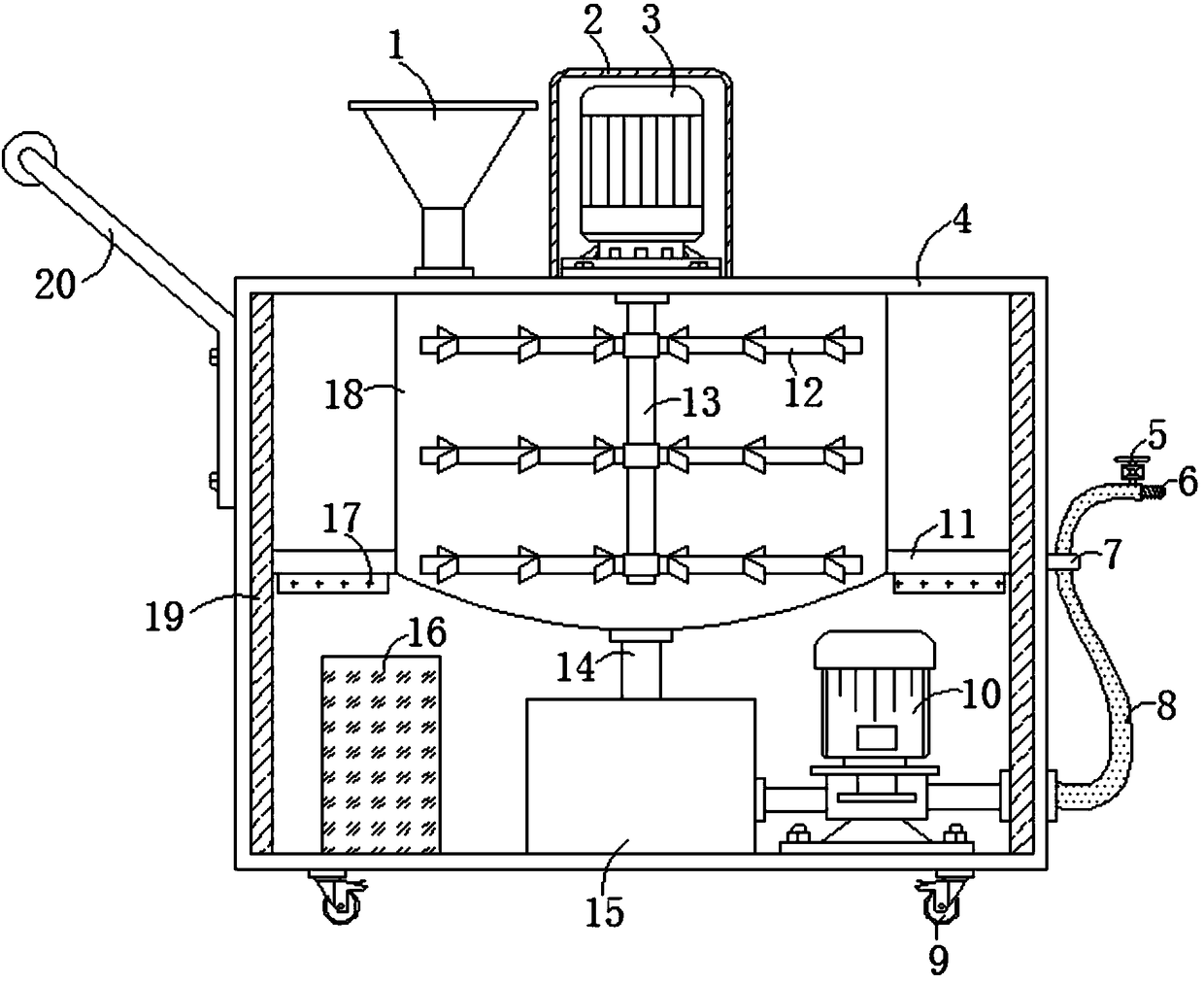

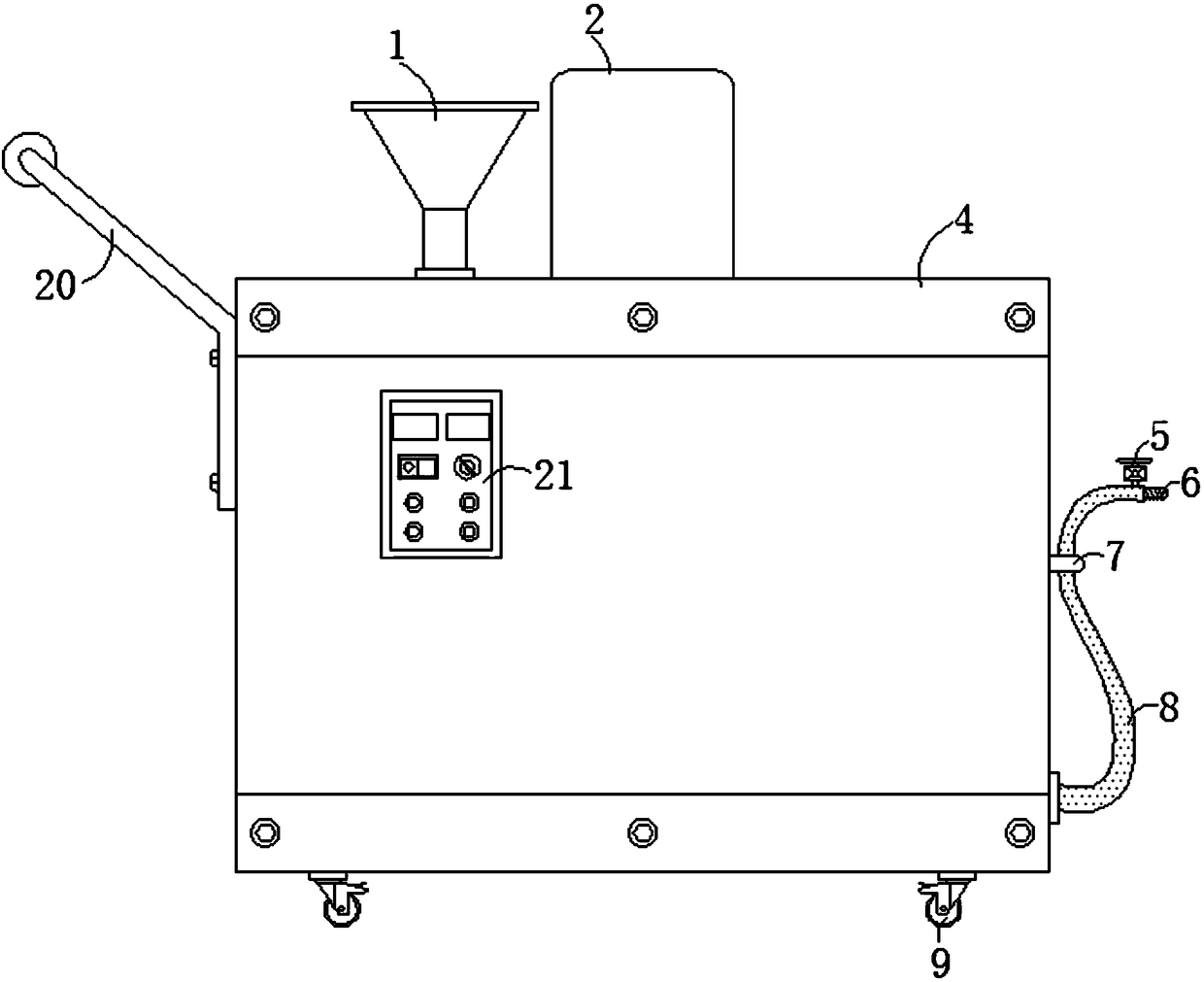

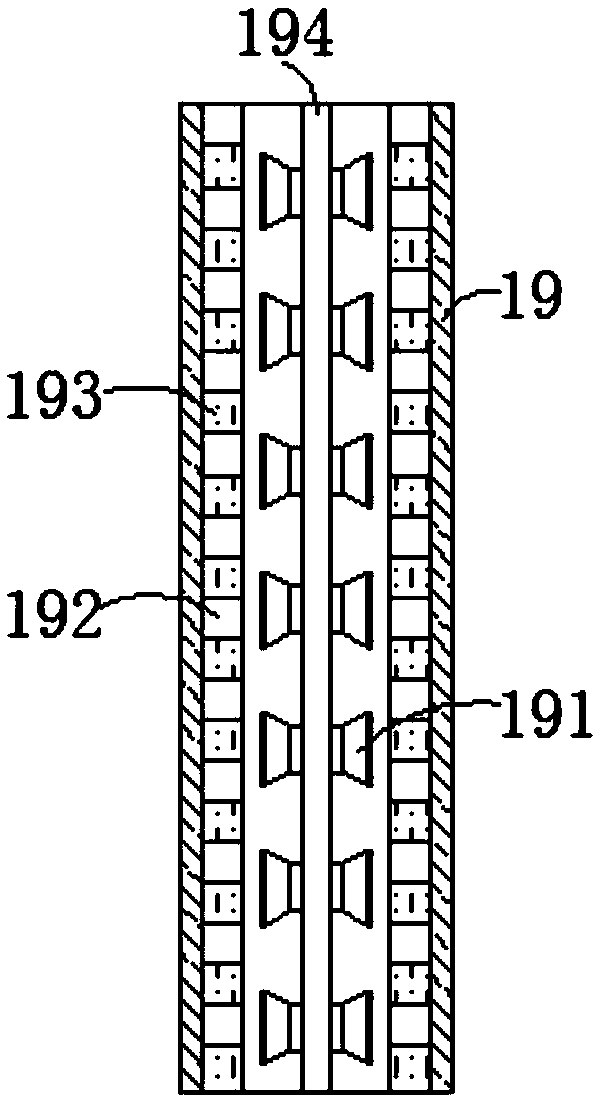

Unshaped refractory material spraying device

InactiveCN108080177AImprove work efficiencyAvoid noise pollutionLiquid spraying apparatusFixed frameWorking environment

The invention discloses an unshaped refractory material spraying device. The unshaped refractory material spraying device comprises a device box body, a fixed frame is installed in the middle inside the device box body, sound insulation boards are arranged at both sides of the inner wall of the device box body, a stirring bin is fixed to the middle of the fixed frame, electrostatic dust removers are symmetrically installed at the portion, closer to the two sides of the bottom of the stirring bin, at the bottom of the fixed frame, a discharging pipe is connected to the middle of the bottom of the stirring bin, a feed storage box is connected to the bottom of the discharging pipe, and a stirring shaft is installed in the middle of the top inside the stirring bin. Through the arrangement of asound insulation machine cover and the sound insulation boards, sound absorption and noise lowering of equipment are achieved, noise pollution is prevented, a healthy and comfortable working environment is easily built for workers, the work efficiency of the workers is improved, the electrostatic dust removers are arranged to adsorb dust, the dust is prevented from being attached to parts to influence cooling of the parts, efficient cooling of the parts is guaranteed, and the spraying cost is greatly lowered.

Owner:浙江康斯迪冶金科技有限公司

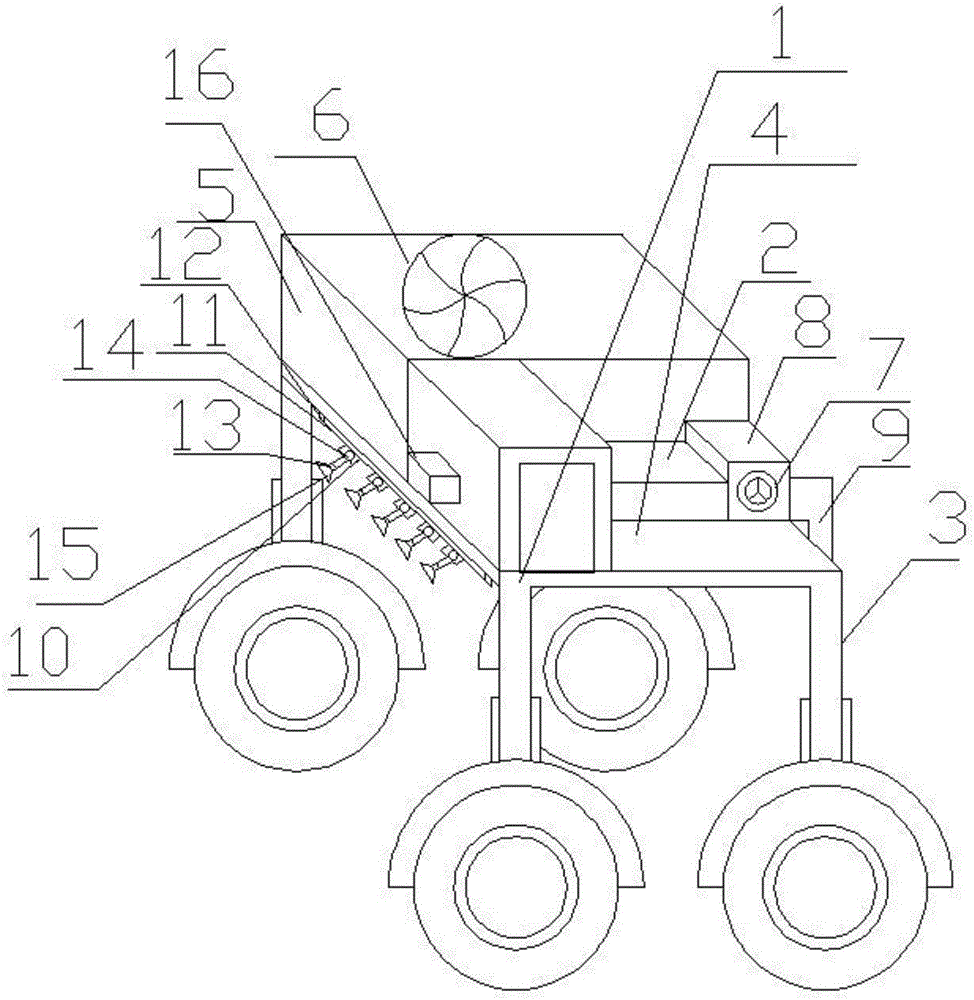

Agricultural mechanical equipment applied to insecticide sprinkling

InactiveCN106386758AGuaranteed SprayingImprove spraying effectInsect catchers and killersAgricultural engineeringMechanical equipment

The invention relates to the technical field of agricultural machinery and especially relates to a piece of agricultural mechanical equipment applied to insecticide sprinkling. The agricultural mechanical equipment applied to the insecticide sprinkling is controlled by a control device, the distance between a bearing table face and the ground can be adjusted, and the equipment is applicable to sprinkling for various types of crops; a tilt angle sensor can be used to measure a tilt angle between the device and the ground, so that a supporting frame of the sprinkling device can be adjusted, and a sprinkling angle can be ensured; and a flow sensor can be used to control an insecticide liquid sprinkling amount of the sprinkling device, so that a utilization rate of an insecticide liquid can be ensured.

Owner:ZHONGSHAN CHENGHAO FRUIT PLANTING SPECIALIZED COOP

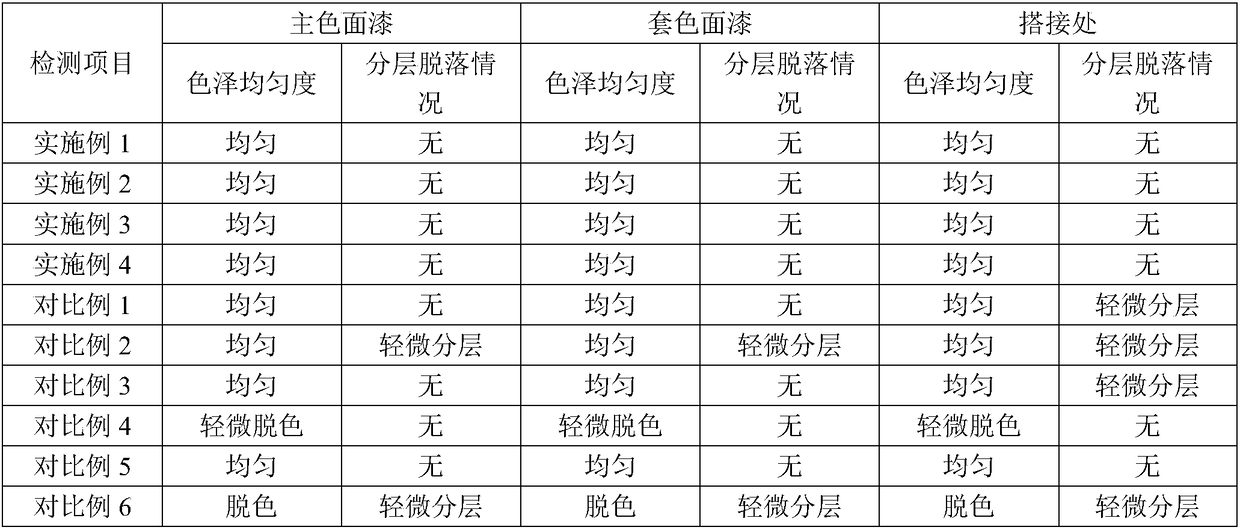

Bicolor spraying technology for semi-trailer body

InactiveCN109225779ARealization of two-color sprayingIncreasing the thicknessPretreated surfacesSpecial surfacesSemi-trailerMaterials science

The invention relates to a bicolor spraying technology for a semi-trailer body, which belongs to the technical field of body spraying, and solves the technology problem of thin spraying layer, poor corrosion resistance and easy delamination at overlap of bicolor semi-trailer body spraying technology in the prior art, the spraying of the semi-trailer body is completed by paint pretreatment, surfacepretreatment of the vehicle body, main color area spraying, color matching area spraying, and varnish spraying, not only the bicolor spraying of the semi-trailer body is achieved, but also through the polishing of a main color area, a color matching area, overlap of the main color area and the color area, the two-layer spraying of main color topcoat and color matching topcoat, the delamination ofthe main color topcoat and the color matching topcoat overlap is reduced, the thickness and corrosion resistance of main color and color-matching surface spraying of car body are improved.

Owner:石家庄金多利专用汽车有限公司

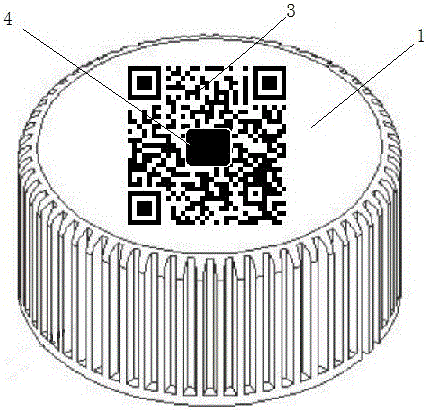

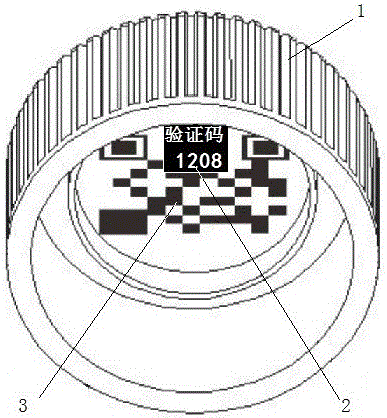

Two-dimensional code bottle cap and manufacturing method thereof

InactiveCN106628579AEasy to produceFast manufacturingContainers for flexible articlesPackaging cigaretteLogistic managementEngineering

The invention provides a two-dimensional code bottle cap and a manufacturing method thereof. An ink-jet printer is used for printing light-color verification codes and deep-color two-dimensional codes on the front face of the transparent bottle cap sequentially. The deep-color two-dimensional codes cover the light-color verification codes for secrecy, and after commodities are sold, a consumer ruinously opens the transparent bottle cap, and reads verification code information from the back face of the transparent bottle cap through naked eyes; two-dimensional codes can be scanned, verification webpage can be opened, verification information is input, and integrals and other awards are obtained. The two-dimensional codes serve as plain codes, multiple purposes of logistics management and the like are obtained, the production process is extremely simple, and the production cost is extremely low.

Owner:KHAINAN YAYUAN ANTI TSOUNTERFEIT TECH RES INST

Spraying device for surface of copper product

InactiveCN110899024AReasonable designImprove spraying effectSpraying apparatusElectric machineEngineering

The invention provides a spraying device for a surface of a copper product. The device comprises a spraying device body, wherein a transmission bin, a spraying liquid storage bin and a workbench are arranged in the spraying device body, sliding grooves are formed on the workbench, a first fixing column and a second fixing column are arranged on two sides respectively, a telescopic rod base plate is arranged on one side of the first fixing column, a moving plate is arranged on the other side of the base, a telescopic rod is arranged at the top of the telescopic rod base plate, one end of the telescopic rod penetrates through the first fixed column to be connected with the movable plate, a clamp is arranged on one side of the movable plate and comprises a fixed clamping plate, a movable clamping plate and a clamp column, a groove is formed in the clamp column, a threaded rod is arranged in the groove, the threaded rod is sleeved with the movable clamping plate, a motor base plate is arranged on one side of the second fixed column, a clamp is arranged on the other side of the second fixed column, and a driving motor is arranged on the motor base plate. The device is advantaged in thatthe clamp and the transmission bin are arranged, a product is clamped and rotates, and the transmission bin drives a spray head to spray back and forth, so spraying is more uniform and comprehensive,and spraying efficiency and quality are improved.

Owner:江西富电优品电器有限公司

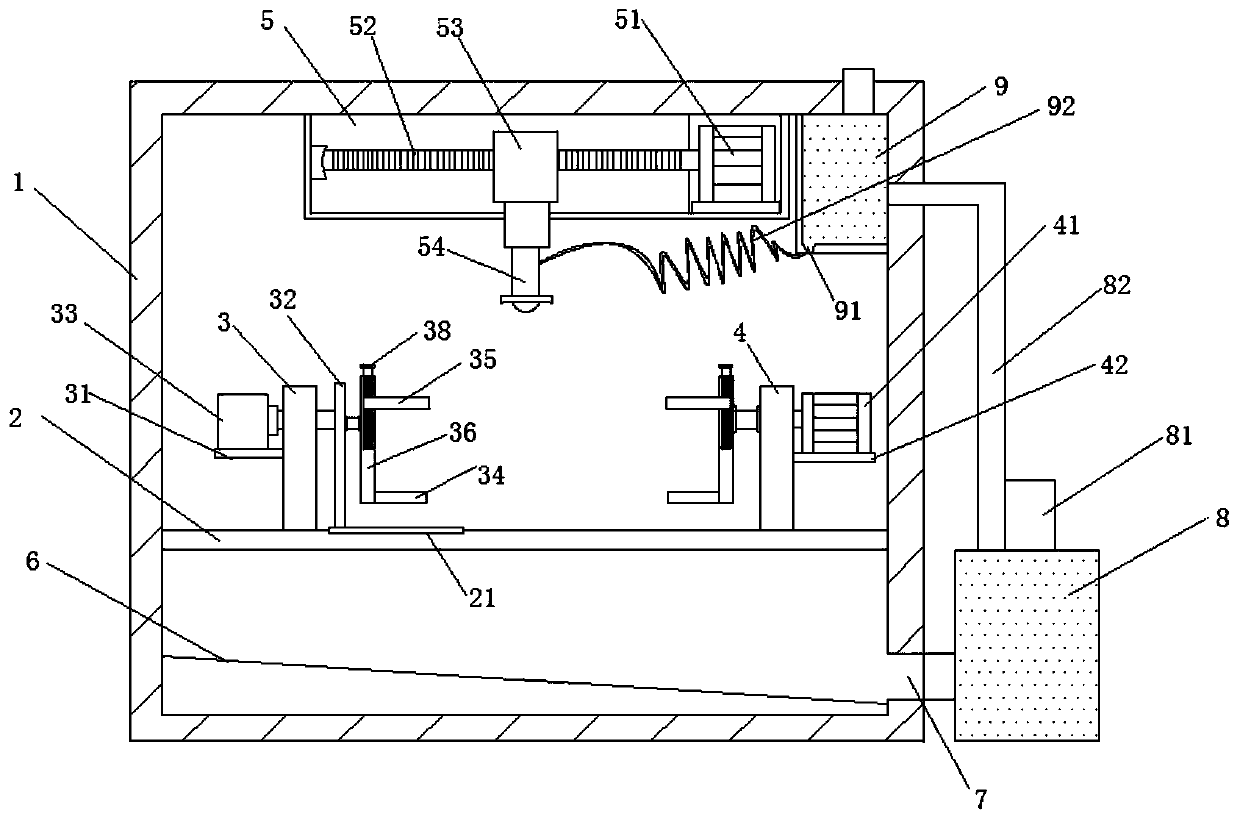

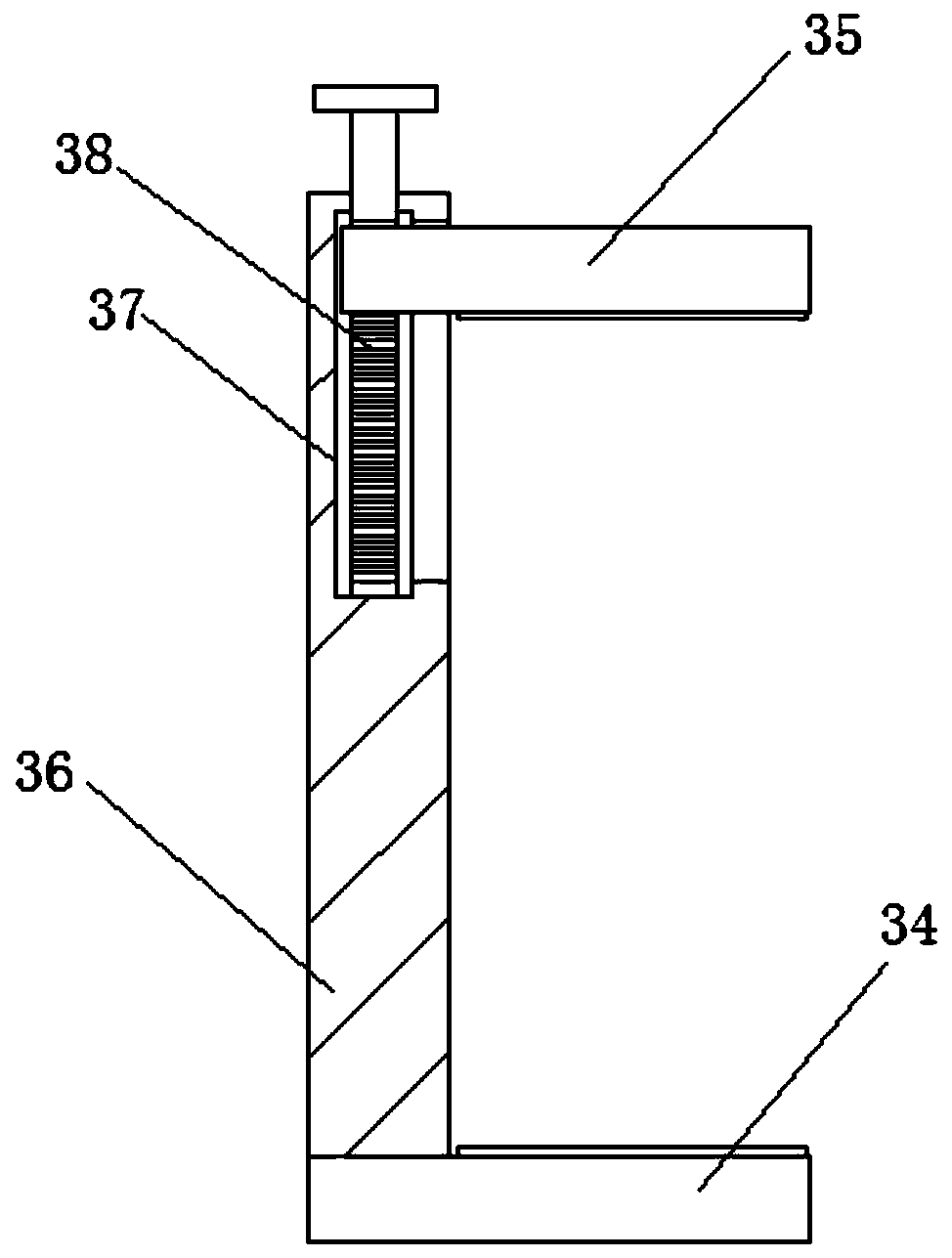

Suspended type article storage frame framework powder spraying equipment

InactiveCN109013145AGuaranteed stabilityImprove creativitySpray boothsPhysical healthAgricultural engineering

The invention relates to the technical field of article storage frame machining equipment and discloses suspended type article storage frame framework powder spraying equipment. The suspended type article storage frame framework powder spraying equipment comprises a powder spraying box, a supporting rod and a foundation; the bottom of the side surface of the powder spraying box is fixedly connected with the top of the foundation through a supporting rod; and a movable cover is fixedly mounted at the top of one side of the powder spraying box. According to the suspended type article storage frame framework powder spraying equipment, by arranging the powder spraying box and a sprinkling device, an article storage frame framework can be placed in a closed environment to perform powder spraying operation, a problem that the smell of a paint spreads is solved, the spraying operation environment is optimized, the physical health of working personnel is guaranteed, and the surrounding environment is protected; and meanwhile, as the styles of article storage frames are different, the dimensions of corresponding frameworks are also different; by arranging a clamping device, the frameworks can be adjusted and fixed according to the dimensions of the frameworks, the stability of the frameworks in the spraying process is guaranteed, and the creativity of the powder spraying device is alsoenhanced.

Owner:江门市安隆五金工艺有限公司

Synergistic slow-release coated fertilizer and preparation method thereof

InactiveCN109574748AIncrease contentIncrease percentageOrganic fertilisersAmmonium salt fertilisersHumic acidChemistry

The invention relates to a preparation method of synergistic slow-release coated fertilizer. The preparation method comprises the following steps of S1, preparation of a first coating material: agitating urea and a 20% to 40% of formaldehyde solution in a reaction tank until the urea is completely dissolved, regulating the pH of a solution to 8 to 9 by using triethanolamine, reacting for 1h to 2hat a normal temperature, regulating the pH to be between 5 to 6.5, heating to 60 DEG C to 80 DEG C while agitating, continuously agitating, and stopping heating until a reaction system approaches a gel state, so as to obtain the first coating material; S2, preparation of a second coating material: uniformly mixing 70% to 99% of humic acid, 0.5% to 1% of activator and 0.5% to 29% of polynucleic acid powder according to percentage by weight, so as to obtain the second coating material; S3, raising the temperature of a urea master batch with a particle size range of 2.0mm to 5.0mm to 60 DEG C to80 DEG C in a revolving drum, spraying the first coating material to the surface of the urea master batch through a sprinkling device, and aeration-drying, so as to complete a first layer of coating;and S4, preheating fertilizer completed in the first layer of coating, preheating to 40 DEG C to 50 DEG C, spray-coating an adhesive (dissolving alginic acid in an alkaline solution) to the surface offluidized fertilizer, and then dispersing the second coating material on the surface of the fertilizer, so as to obtain the synergistic slow-release coated fertilizer.

Owner:河北百禾丰化肥有限公司

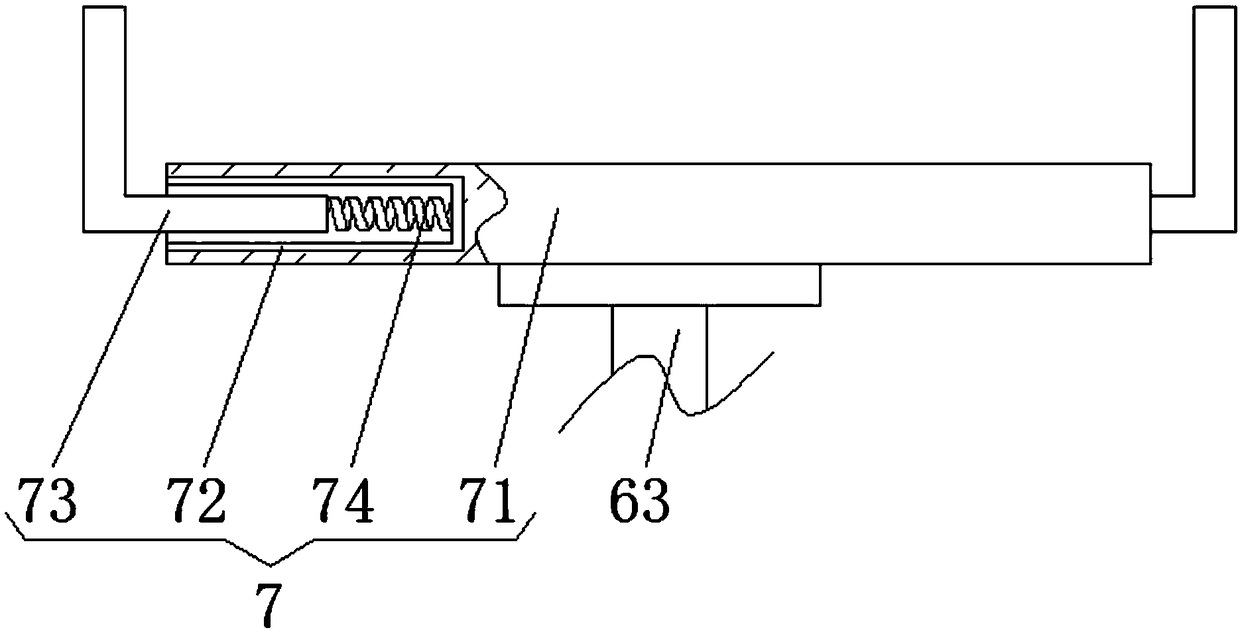

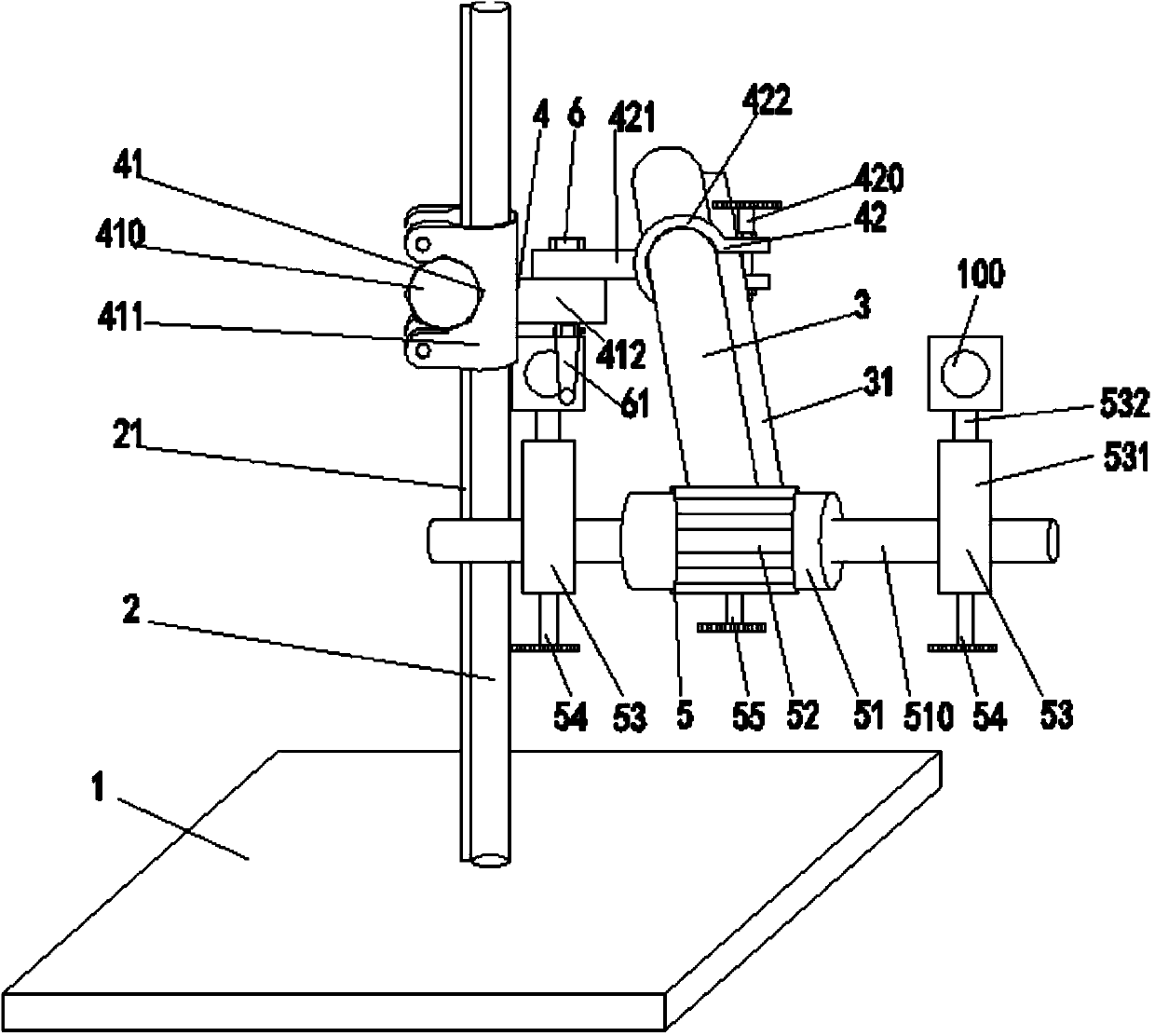

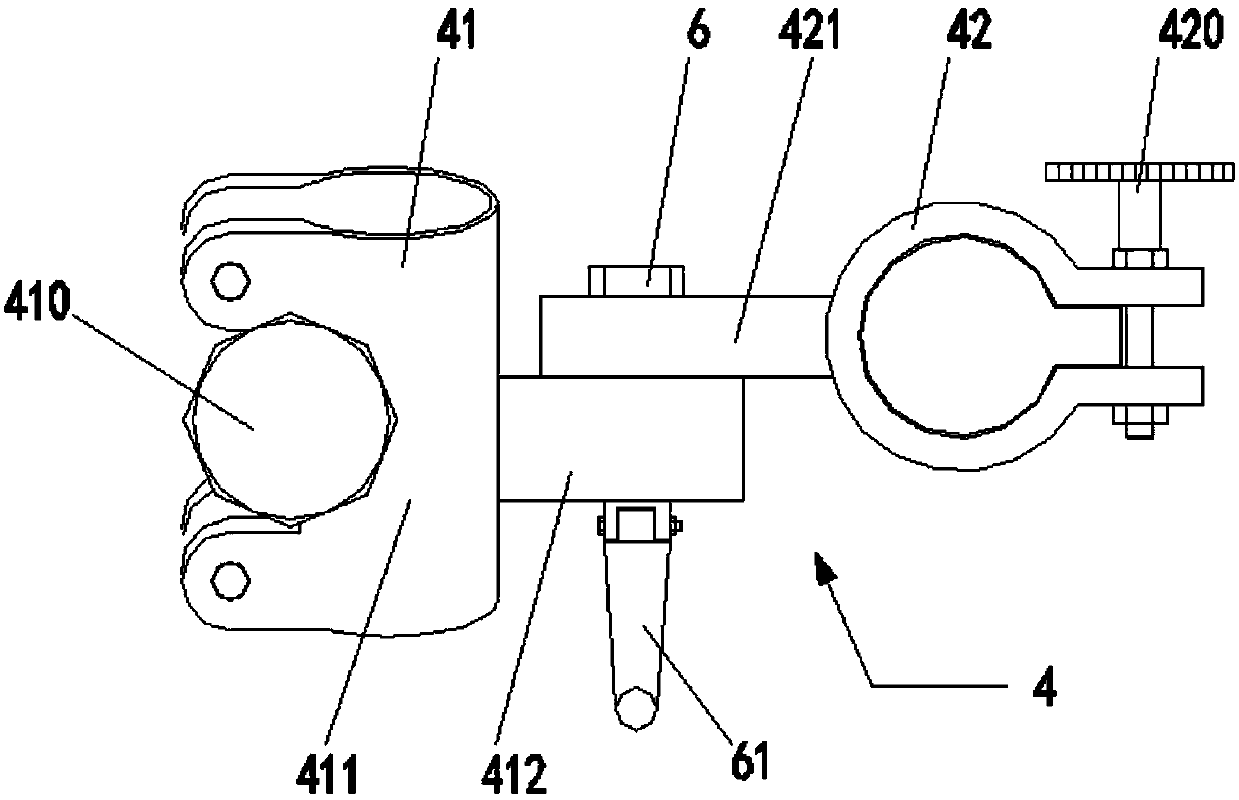

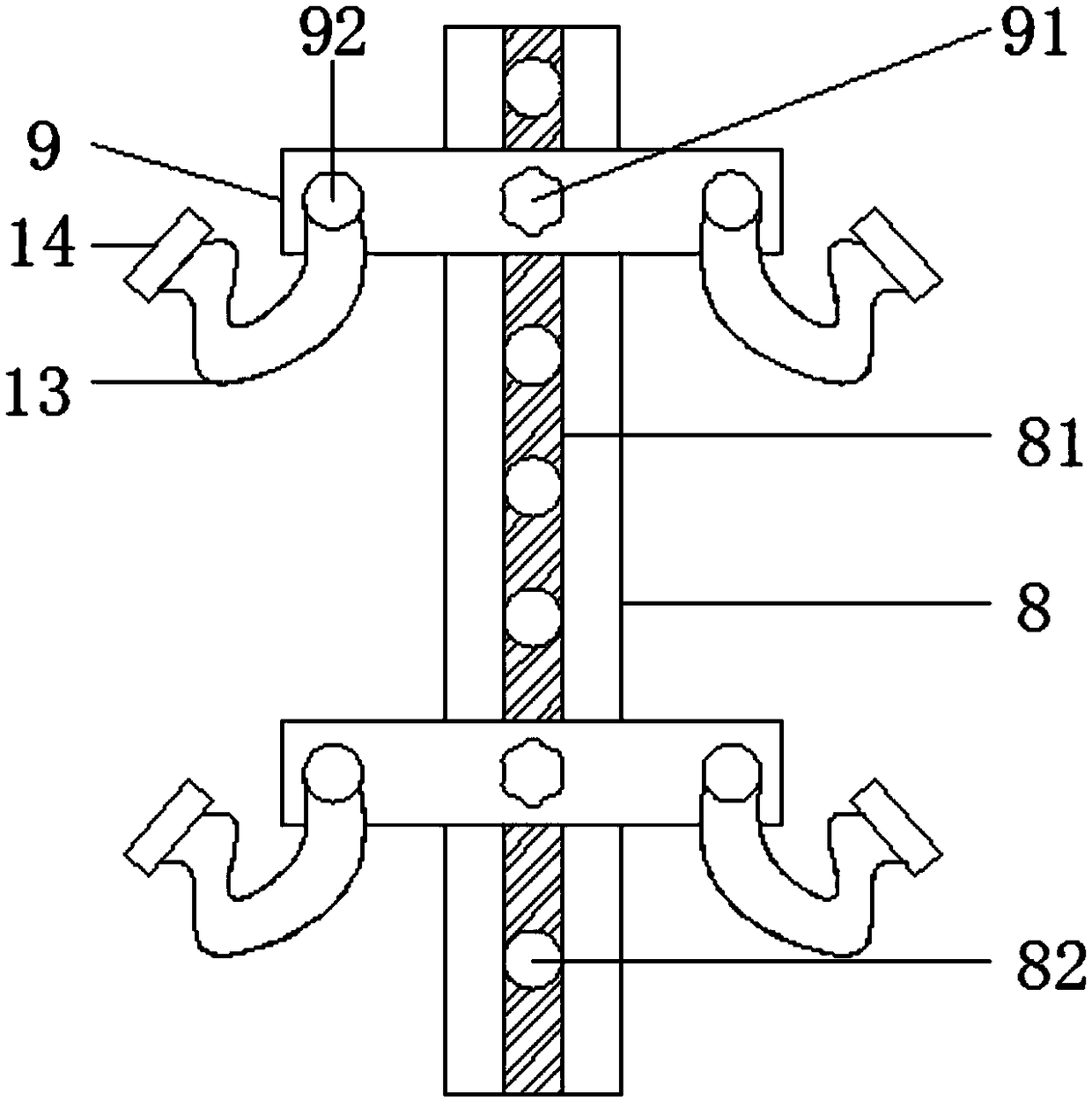

Plasma spraying head fixing frame

ActiveCN104178722ALevel of achievementAchieve vertical movementMolten spray coatingFixed framePlasma sprayed

The invention discloses a plasma spraying head fixing frame which comprises a base or other similar structures with the function of the base, and further comprises two adjusting rods with a certain intersection angle. Moving sliding rails are arranged on the two adjusting rods, the two adjusting rods are connected through a rotatable connecting component, the connecting component is composed of a first connecting sleeve piece capable of achieving the vertical movement and a second connecting sleeve piece mainly achieving the horizontal movement, the first connecting sleeve piece and the second connecting sleeve piece are connected through a rotating shaft, sliding pair components are arranged on the connecting component, the two adjusting rods are sleeved with the sliding pair components respectively, one end of one adjusting rod is further provided with an adjustable connecting component for being fixedly connected with a spraying head, and the spraying head is fixed to an adapter component of the adjustable connecting component. According to the fixing frame, the aim that the spraying direction of the plasma spraying head can be precisely positioned to any direction can be achieved, and the production efficiency of spraying can be greatly improved.

Owner:GUANGDONG GREEN PRECISION COMPONENTS CO LTD

Novel high-temperature-resistant and anti-corrosion ceramic coating and preparation technology

InactiveCN105086803AReduce spraying costsIncrease working temperatureAnti-corrosive paintsPolyurea/polyurethane coatingsCeramic coatingStrong acids

The invention aims to provide a novel high-temperature-resistant and anti-corrosion ceramic coating which can resist strong-acid corrosion at the high temperature, has good wear-resisting property and heat conductivity, low spraying cost and long service life and can be firmly attached to walls of related equipment, and a preparation technology. The novel high-temperature-resistant and anti-corrosion ceramic coating comprises, in parts by weight, 45-50 parts of nano ceramic powder, 10-15 parts of powdery quartz, 10-15 parts of polyurethane resin, 5-8 parts of dodecylene alcohol ester, 3-4.5 parts of powdery calcium carbonate, 3-5 parts of cobalt powder, 2-3 parts of powdery purple clay, 1-2 parts of powdery silicon dioxide, 0.5-1 part of paraffin, 5-8 parts of ethyl acetate, 5-8 parts of n-butyl alcohol and 1-5 parts of powdery vermiculite.

Owner:中国大唐集团科学技术研究总院有限公司

Water-soluble photocatalytic titanium dioxide sol spray and preparation method thereof

InactiveCN109603550AReduce spraying costsReduce pollutionGas treatmentDispersed particle separationEpoxyPhotocatalytic degradation

The invention relates to the technical field of environmental protection, and discloses a water-soluble photocatalytic titanium dioxide sol spray and a preparation method thereof. The water-soluble photocatalytic titanium dioxide sol spray is prepared from the following raw materials in parts by weight: 3-5 parts of titanium tetrachloride, 50-70 parts of epoxy resin, 10-30 parts of absolute ethylalcohol, 4-6 parts of sodium hydroxide solution, and 8-10 parts of hydrogen peroxide. A nano-titanium dioxide sol spray is used as a photocatalyst and supported on the leaf surface of a plant, providing a large surface area, so that the photocatalyst can be supported effectively and the effect of the photocatalyst can be maintained for a long time; in addition, as the leaf stomates of the plant can absorb automobile exhaust gases, the automobile exhaust gas pollution can be reduced more efficiently by virtue of the coupling of absorption by the leaf stomates and photocatalytic degradation. Thetechnical product is a water-soluble photocatalytic titanium dioxide sol and thus can be used in combination with a multifunctional landscaping pesticide-spraying sprinkler of the transport department, and the catalyst spraying cost can be greatly reduced.

Owner:IRONMAN ENVIRONMENTAL TECH CO LTD

Spraying system for axle forging and pressing dies of electric vehicles

InactiveCN108246546AAdjustable spacingShorten the timeSpraying apparatusForging/hammering/pressing machinesHydraulic pumpEngineering

The invention discloses a spraying system for axle forging and pressing dies of electric vehicles, and relates to the technical field of vehicle axle spraying. The tops of multiple sets of support columns are fixedly connected through a transverse plate, sliding grooves are formed in the front and rear end faces of the transverse plate, the left side of the transverse plate is provided with a mounting plate, and the front and rear end faces of the mounting plate are provided with hydraulic devices; matched sliding blocks are installed in inner cavities of the sliding grooves, the top of each sliding block is provided with two mounting rods, two spraying adjustment blocks are arranged on the mounting rod at the left side of the top of each sliding block, and two purging adjustment blocks are arranged on the mounting rod at the right side of the top of each sliding block; the bottom of the mounting plate is provided with a blower, and an inner cavity of a material spraying bottle is provided with a hydraulic pump; through the cooperation of adjustment grooves, adjustment holes and positioning bolts, the distance of the spraying adjustment blocks can be conveniently adjusted, the requirement of spraying the axle forging and pressing dies of different types is met, another device is not needed for replacement, the time is saved, the working efficiency is greatly improved, and meanwhile the spraying cost is reduced.

Owner:GAOYOU NORTH POWER MACHINERY

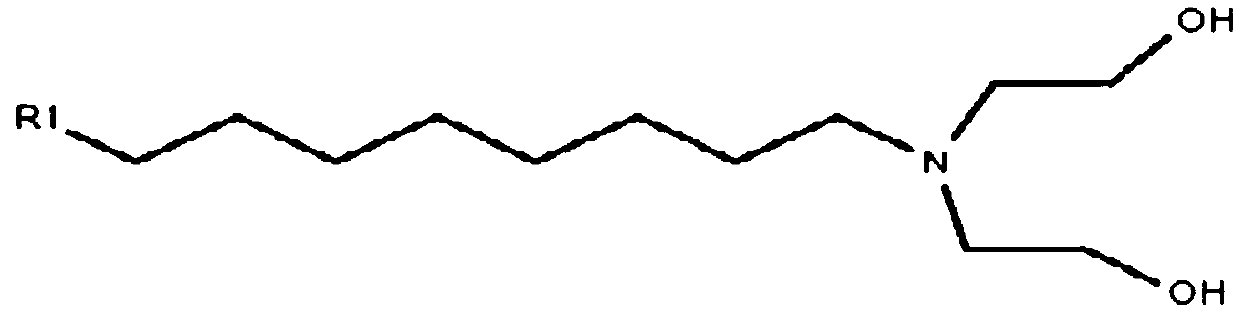

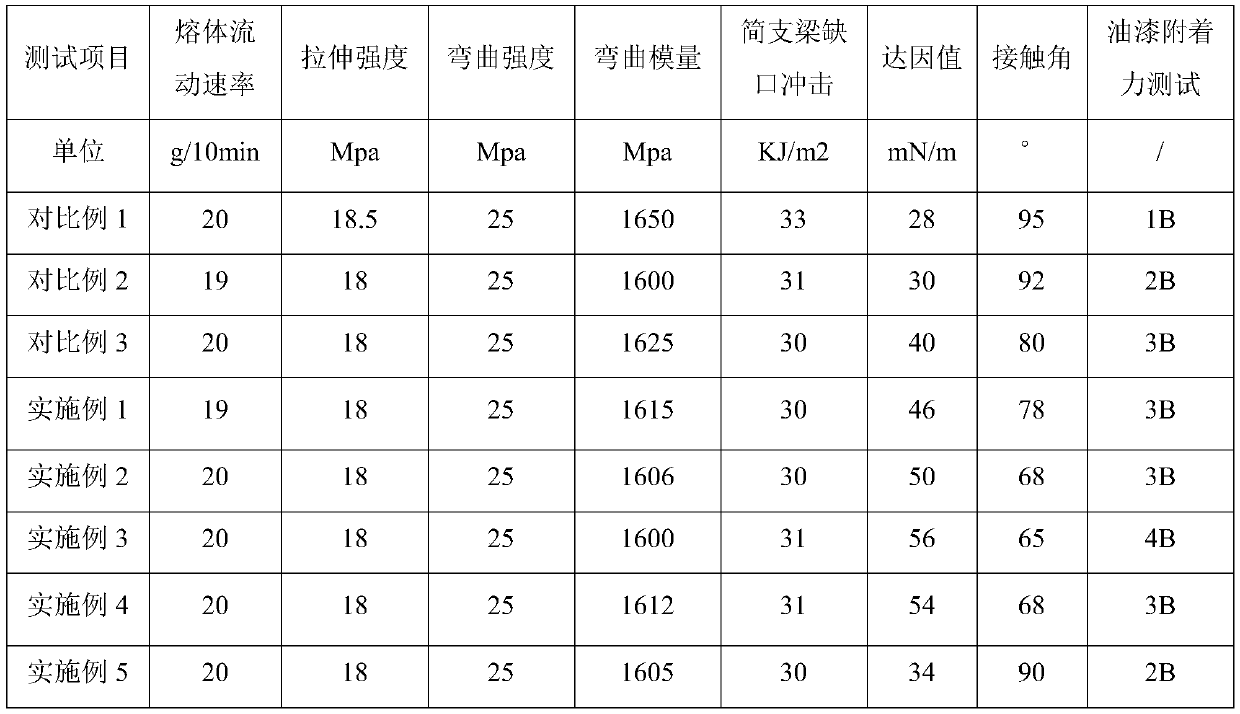

Polypropylene composition with high surface tension and preparation method thereof

The invention discloses a polypropylene composition with high surface tension and a preparation method thereof. The polypropylene composition is prepared from a polypropylene mixture, a polar modifierwith a polar group, a polar modification auxiliary aid, a filler, a flexibilizer and a functional aid, wherein the polar modifier with the polar group is diethanol amine with a long-chain alkyl group, and the polar modification auxiliary agent is at least one of maleic anhydride modified polypropylene, acrylic acid modified polypropylene and polyvinyl alcohol. The polypropylene composition disclosed by the invention has high surface tension and wettability, can obviously improve the spraying property of a polypropylene injection molding part, simplify the spraying process and reduce the spraying cost, can meet the performance requirements of automobile part manufacturers at home and abroad, and has a wide application prospect.

Owner:ORINKO NEW MATERIAL CO LTD

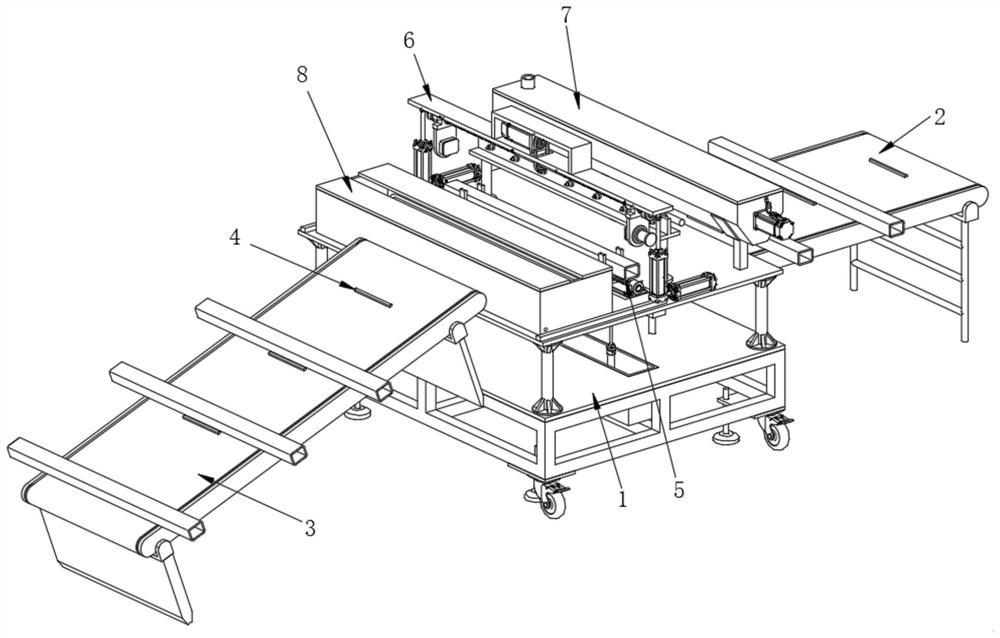

Machining process for aluminum alloy profile

ActiveCN112354729AReduce spraying costsUniform thicknessPretreated surfacesLiquid spraying apparatusMachining processMaterials science

The invention discloses a machining process for an aluminum alloy profile, and relates to the technical field of aluminum alloy profile production. In a spraying link for a corrosion-resistant material in the whole process, the surface of the aluminum alloy profile is subjected to fully-automatic spraying treatment, and therefore the problems that when a spray gun is manually held by a hand to spray the corrosion-resistant material to the aluminum alloy profile, a high labor cost, low working efficiency, high operation requirement on workers, and a need of wearing protective suits additionallyare caused, so that the cost of the surface spraying treatment for the aluminum alloy profile is additionally increased, and the corrosion-resistant material is manually sprayed, the thickness of thecorrosion-resistant material on the surface of the aluminum alloy profile cannot be accurately controlled, so that on one hand, the yield is reduced due to the uneven thickness, and on the other hand, waste of the corrosion-resistant material is caused, and the machining cost is increased, are avoided. Mechanical automation equipment is utilized, the efficiency and the spraying precision in the process of spraying the corrosion-resistant material on the surface of the aluminum alloy profile are greatly increased, and therefore the yield is increased.

Owner:山东鲁昌铝业有限公司

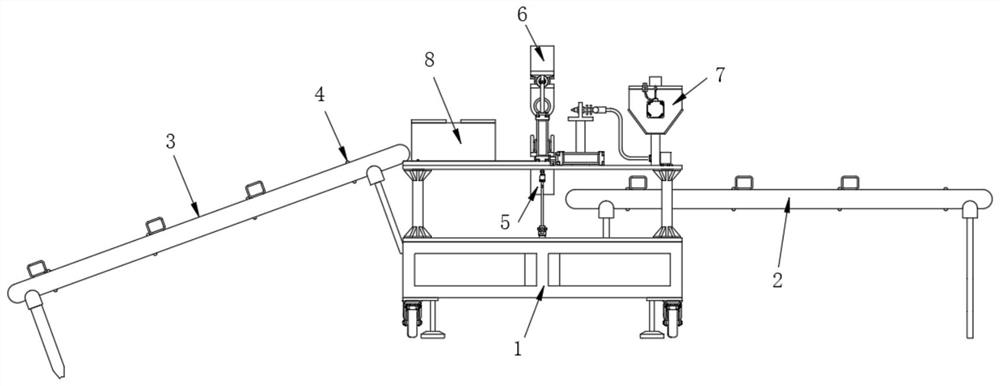

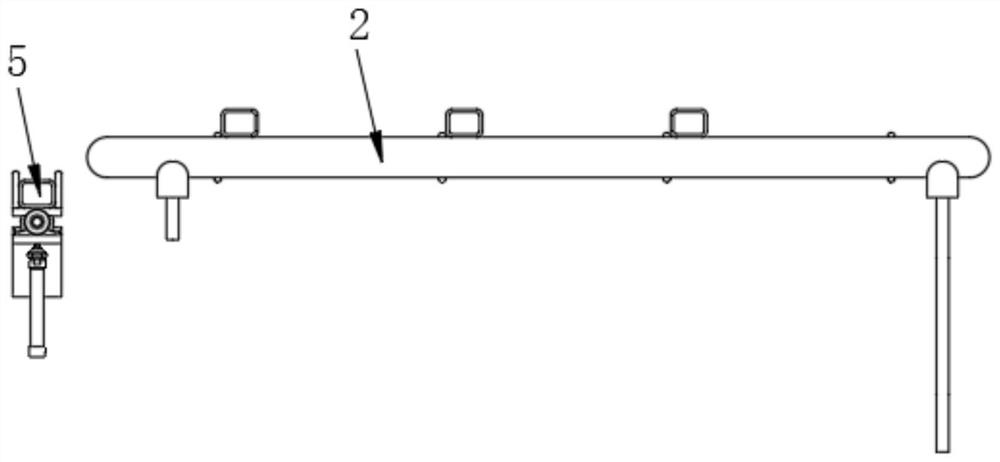

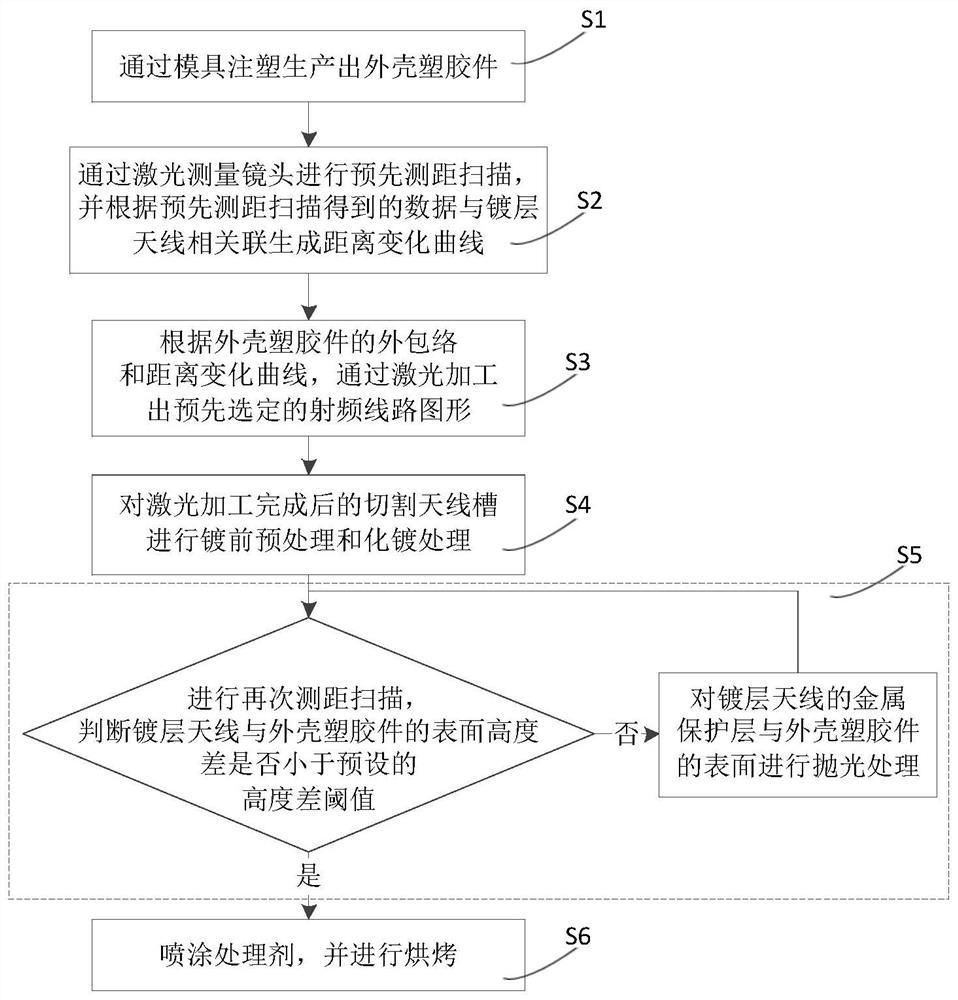

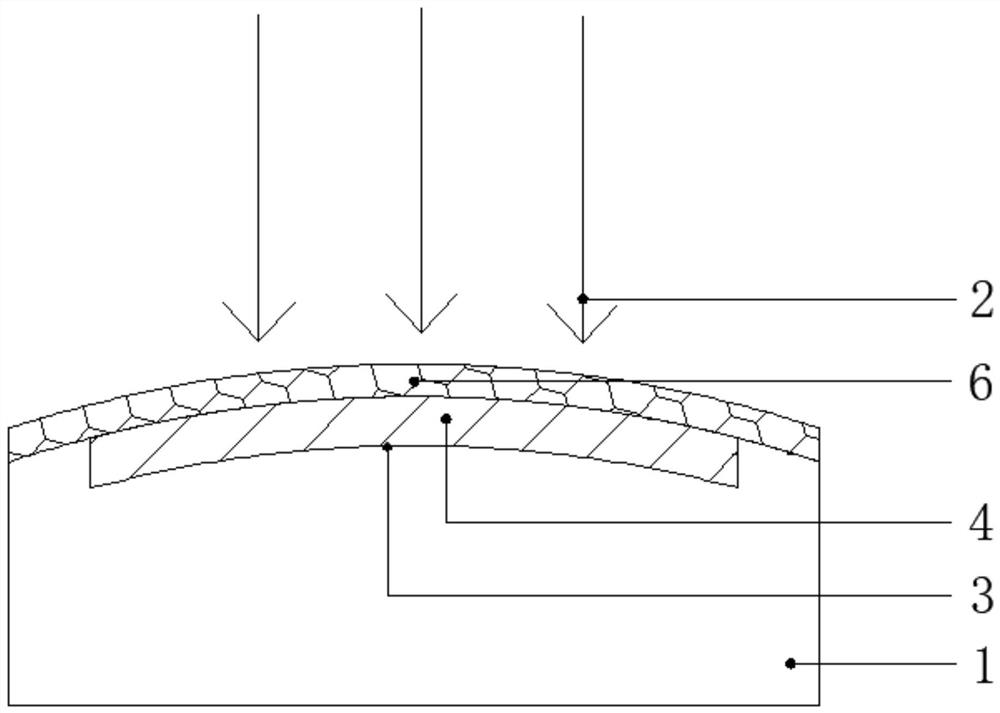

Manufacturing method and system of integrated antenna-containing shell

ActiveCN113889752ASmall surface height differenceSurface height difference improvementAntenna supports/mountingsAntenna adaptation in movable bodiesChemical platingIntegrated antenna

The invention provides a manufacturing method and system for an integrated antenna-containing shell. The manufacturing method comprises the steps that S1, producing a shell plastic part; S2, carrying out pre-ranging scanning through a laser measuring lens, and generating a distance change curve; S3, processing a preselected radio frequency circuit pattern through laser according to the outer envelope of the shell plastic part and the distance change curve; S4, carrying out pre-plating pretreatment and chemical plating treatment on an antenna groove; S5, carrying out distance measurement scanning again until the surface height difference between the coating antenna and the shell plastic part is lower than a preset height difference threshold value; and S6, srapying a treating agent, and carrying out baking. The method and system can adapt to outer enveloping of the shell plastic part, the height difference between the coating antenna and the shell plastic part is greatly improved, repeated dismounting, mounting and polishing of the coating clamp for a product are not needed, the machining technology is greatly simplified, the production cost is effectively reduced, and the production efficiency and the yield are improved.

Owner:SHENZHEN CICENT COMM TECH CO LTD

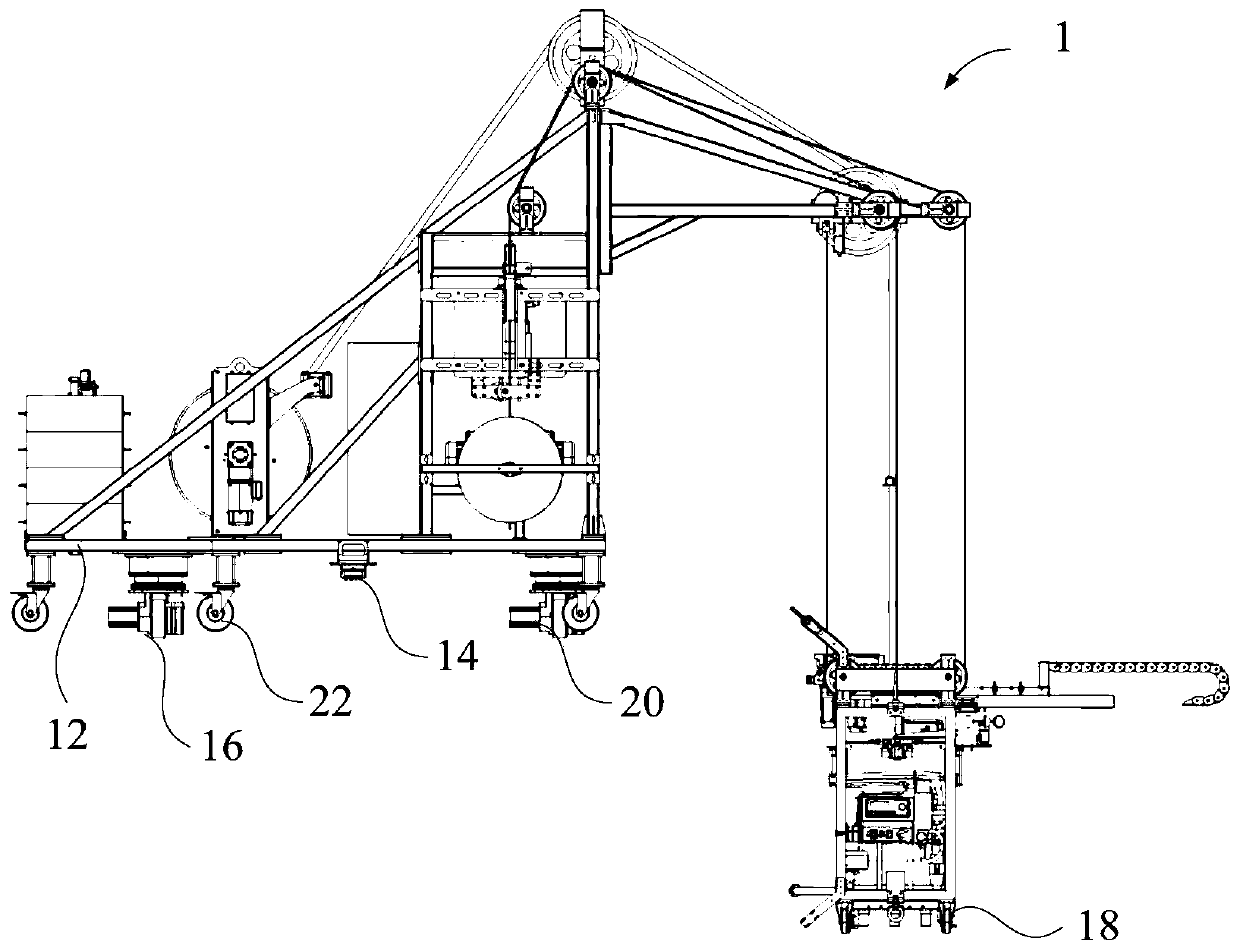

Spraying robot, control method thereof, and storage medium

InactiveCN110453894AReduce manual involvementReduce spraying costsBuilding constructionsSteering wheelAgricultural engineering

The invention provides a spraying robot, a control method thereof, and a computer readable storage medium. The spraying robot comprises a suspension mechanism, a laser sensor, a steering wheel and a control device, the laser sensor is arranged on the suspension mechanism and used for obtaining environment information, the steering wheel is arranged on the suspension mechanism and can control moving of the suspension mechanism, the control device is connected with the laser sensor and the steering wheel and used for controlling moving of the suspension mechanism and constructing map informationaccording to the environment information. The laser sensor arranged on the suspension mechanism can record the environment information in the moving process of the suspension mechanism, thus the control device constructs the map information according to the environment information, the spraying robot can automatically construct the map information, thus the spraying robot can move and / or spray according to the map information, manual participation is reduced, and the spraying cost is effectively lowered.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Sprinkling system fixed to road

PendingCN110130262ATraffic will not affectWill not affect normal drivingRoad cleaningService pipe systemsHorizonEngineering

The invention discloses a sprinkling system fixed to a road. The sprinkling system fixed to the road comprises an underground longitudinal main water supply pipe, a stop valve, a transverse connectingpipe, vertical leading-out pipes and sprinkling holes formed in the pipe walls of longitudinal main sprinkling pipes, wherein the longitudinal main water supply pipe, the stop valve, the transverse connecting pipe, the vertical leading-out pipes and the longitudinal main sprinkling pipes communicate with one another in sequence and are sunken into the horizon plane, the sprinkling holes formed inthe longitudinal main sprinkling pipes are exposed to the ground, the sprinkling holes are formed by directly drilling in the pipe walls of the longitudinal main sprinkling pipes or installing sprinkling heads additionally, sprinkling towards the two sides is carried out through the sprinkling holes when the longitudinal main sprinkling pipes are arranged at a position of a separation yellow lineon the middle part of the road, and the hole diameters and the hole distances of the sprinkling holes are adjusted relying on the self pressure of a water supply system and the height difference between the middle part of the road and the two sides of the road so that sprinkling water can flow to the two sides of the road automatically to cover the whole road surface. The road sprinkling system can perform all-weather operation, no pollution to passing vehicles can be caused, traffic cannot be affected, the situation that dead angles are not sprinkled cannot occur, and long-term benefits areachieved through the one-off investment.

Owner:新乡市达威智能门窗实用技术研究中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com