Nano metal particle cold spraying technique

A metal particle and cold spraying technology, applied in the surface field, achieves the effect of strong practicability, simple spraying equipment, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

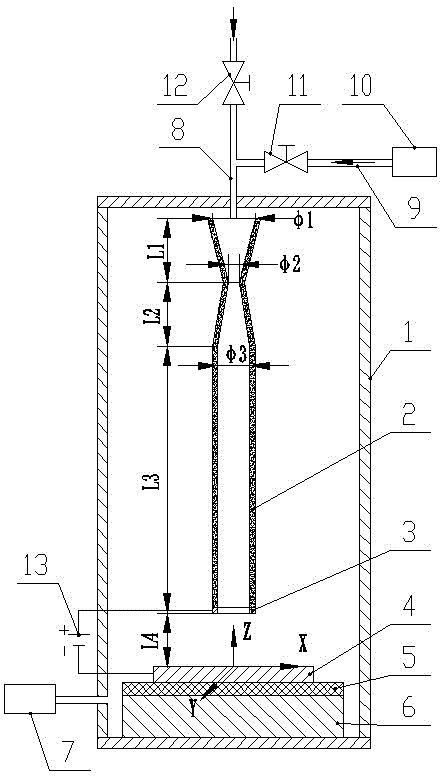

[0027] The spraying equipment that the present invention adopts is as figure 1 As shown, the vacuum spraying chamber 1 is included, and the vacuum spraying chamber 1 is provided with a workbench 6 and a ceramic Laval nozzle 2 that can be adjusted and moved in three-dimensional directions. The nozzle 2 is located above the workbench 6 and is perpendicular to the surface of the workbench 6. , the lower part of the vacuum spraying chamber 1 is connected with a vacuum pump 7 for vacuuming, the upper end of the spray pipe 2 is connected with an air inlet pipe 8, and the air inlet pipe 8 is connected with a powder feeding pipe 9 and a powder feeding device 10, and the powder feeding pipe 9 is provided with a powder feeding pipe The valve 11 is provided with an intake valve 12 on the intake pipe 8 .

[0028] A kind of nanoscale metal particle cold spraying process of the present invention adopts the following steps in sequence:

[0029] (1) Glue a circle of metal ring electrode 3 on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com