Manufacturing method and system of integrated antenna-containing shell

A manufacturing method and antenna shell technology, applied to antennas, manufacturing tools, antenna supports/mounting devices suitable for movable objects, etc., can solve problems such as high process costs, increased product costs, and defective products, and achieve improvement Production efficiency and yield rate, reduction of spraying cost, effect of height difference improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

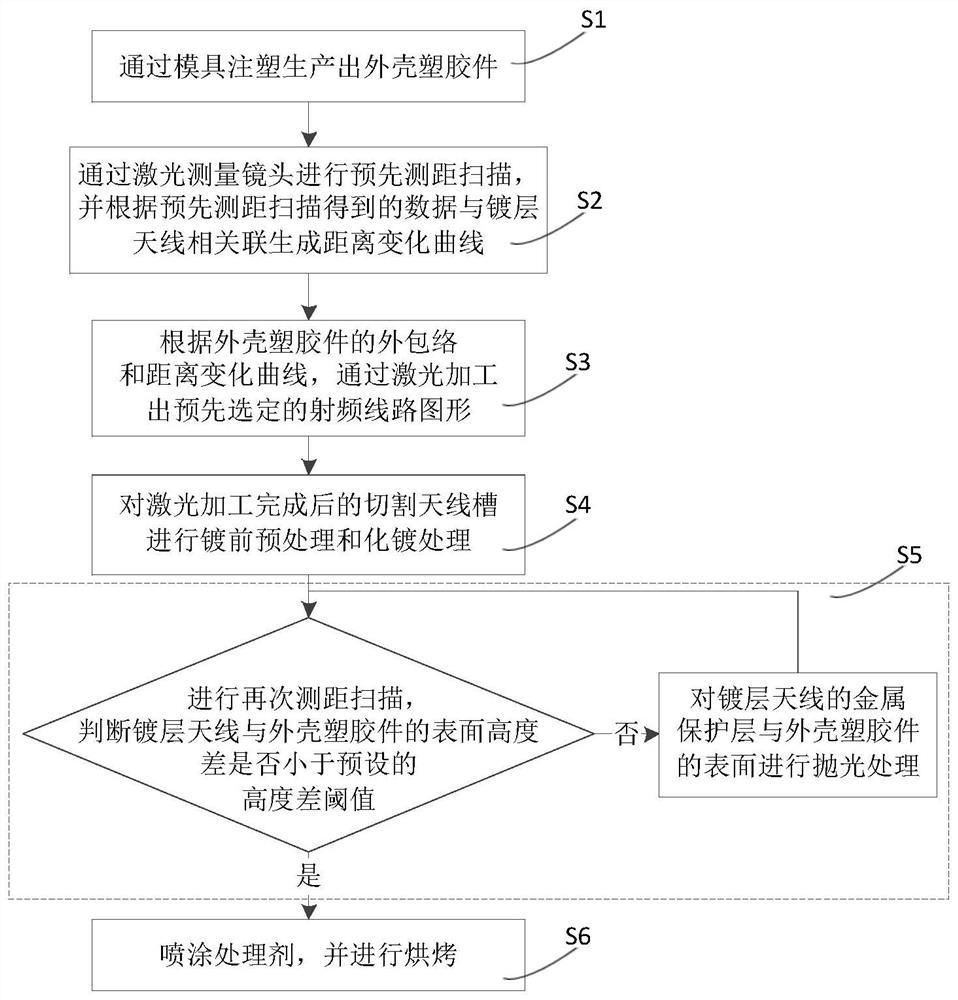

[0058] Such as figure 1 with figure 2 As shown, this example provides a manufacturing method for an integrated antenna housing, including the following steps:

[0059] Step S1, producing the shell plastic part 1 through mold injection;

[0060] Step S2, performing a pre-ranging scan through the laser measuring lens 10, emitting a ranging laser 5, and correlating the data obtained by the pre-ranging scan with the coating antenna to generate a distance change curve;

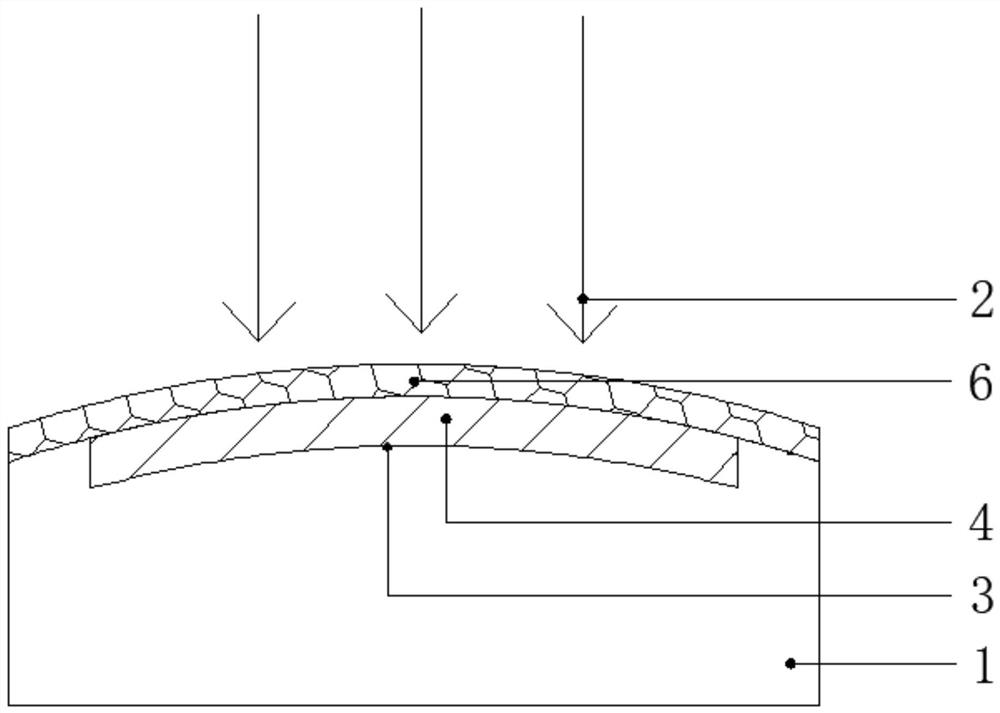

[0061] Step S3, according to the outer envelope and distance change curve of the shell plastic part 1, process the pre-selected radio frequency circuit pattern 3 by laser, that is, emit the cutting laser 2 through the laser cutting lens 11, and in the process of laser processing, pass the laser The measurement lens 10 performs a second distance measurement scan, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com