Electroplating and chemical plating composite protecting process for NdFeB permanent magnet and NdFeB permanent magnet with composite protective layer

An electroless nickel plating layer and permanent magnet technology, applied in the direction of magnetic objects, superimposed layer plating, metal material coating process, etc., can solve the problems of low porosity, slow plating speed, affecting production efficiency, etc. The effect of porosity, corrosion resistance improvement, and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

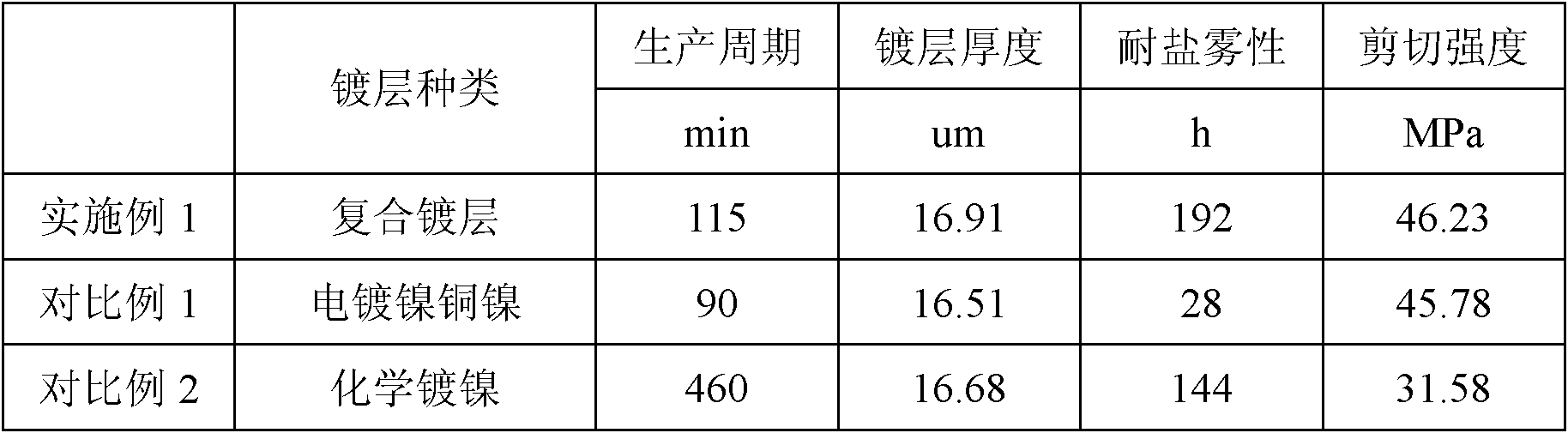

Embodiment 1

[0026] The combined protection process of sintered NdFeB permanent magnet electroplating and electroless plating is carried out according to the following steps:

[0027] 1. First, the sintered NdFeB permanent magnet with a size of 31×31×25mm is treated before electroplating. The process is as follows:

[0028] Ultrasonic degreasing (temperature 60°C, time 5min)-tap water washing-tap water washing-nitric acid pickling (concentration 9%, room temperature, time 10s)-ultrasonic ash removal-nitric acid pickling (concentration 3.5%, room temperature, time 15s)- Ultrasonic ash removal-tap water washing-sulfuric acid surface activation (concentration 6%, room temperature, time 15s)-pure water washing.

[0029] 2. Electroplate the NdFeB permanent magnet,

[0030] a. First, put the magnet into the electroplating solution 1 with a pH value of 4.15 for electroplating. The composition of the plating solution 1 is nickel sulfate: 359.42g / L, nickel chloride: 50.05g / L, boric acid: 46.78g / L;...

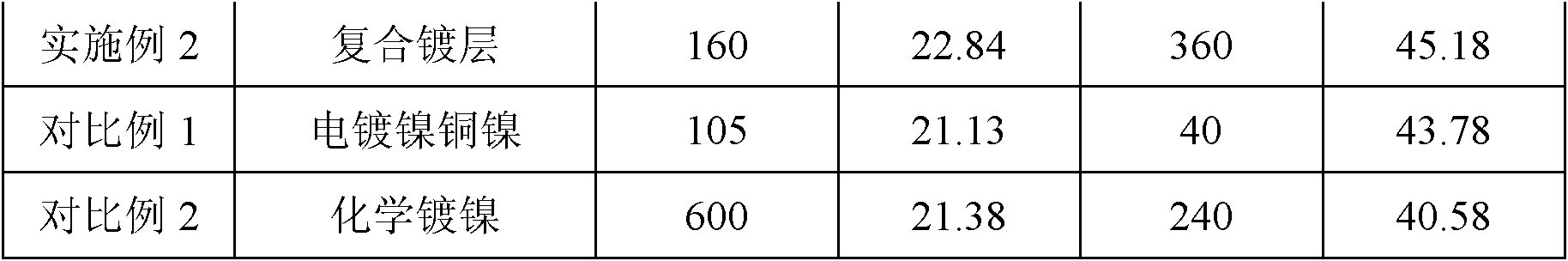

Embodiment 2

[0044] The combined protection process of sintered NdFeB permanent magnet electroplating and electroless plating is carried out according to the following steps:

[0045] 1. First, the sintered NdFeB permanent magnet with a size of 40×27.7×2.4mm is treated before electroplating. The process is as follows:

[0046] Ultrasonic degreasing (temperature 65°C, time 4min) - tap water washing - tap water washing - nitric acid pickling (concentration 8%, room temperature, time 15s) - ultrasonic dedusting - nitric acid pickling (concentration 6%, room temperature, time 5s) - Ultrasonic ash removal-tap water washing-sulfuric acid surface activation (concentration 3%, room temperature, time 20s)-pure water washing.

[0047] 2. Electroplate the NdFeB permanent magnet,

[0048] a. First, put the magnet into the electroplating solution 1 with a pH value of 4.19 for electroplating. The composition of the plating solution 1 is nickel sulfate: 361.42g / L, nickel chloride: 51.05g / L, boric acid: ...

Embodiment 3

[0063] The combined protection process of sintered NdFeB permanent magnet electroplating and electroless plating is carried out according to the following steps:

[0064] 1. First, the sintered NdFeB permanent magnet with a size of 31×31×25mm is treated before electroplating. The process is as follows:

[0065] Ultrasonic degreasing (temperature 70°C, time 3min) - tap water washing - tap water washing - nitric acid pickling (concentration 6%, room temperature, time 20s) - ultrasonic ash removal - nitric acid pickling (concentration 4.5%, room temperature, time 10s) - Ultrasonic ash removal-tap water washing-sulfuric acid surface activation (concentration 9%, room temperature, time 10s)-pure water washing.

[0066] 2. Electroplate the NdFeB permanent magnet,

[0067] Put the magnet into the electroplating solution with a pH value of 4.3 for electroplating. The composition of the plating solution is nickel sulfate: 308.00g / L, nickel chloride: 60.14g / L, boric acid: 52.25g / L; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com