Patents

Literature

174results about How to "Increase height difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

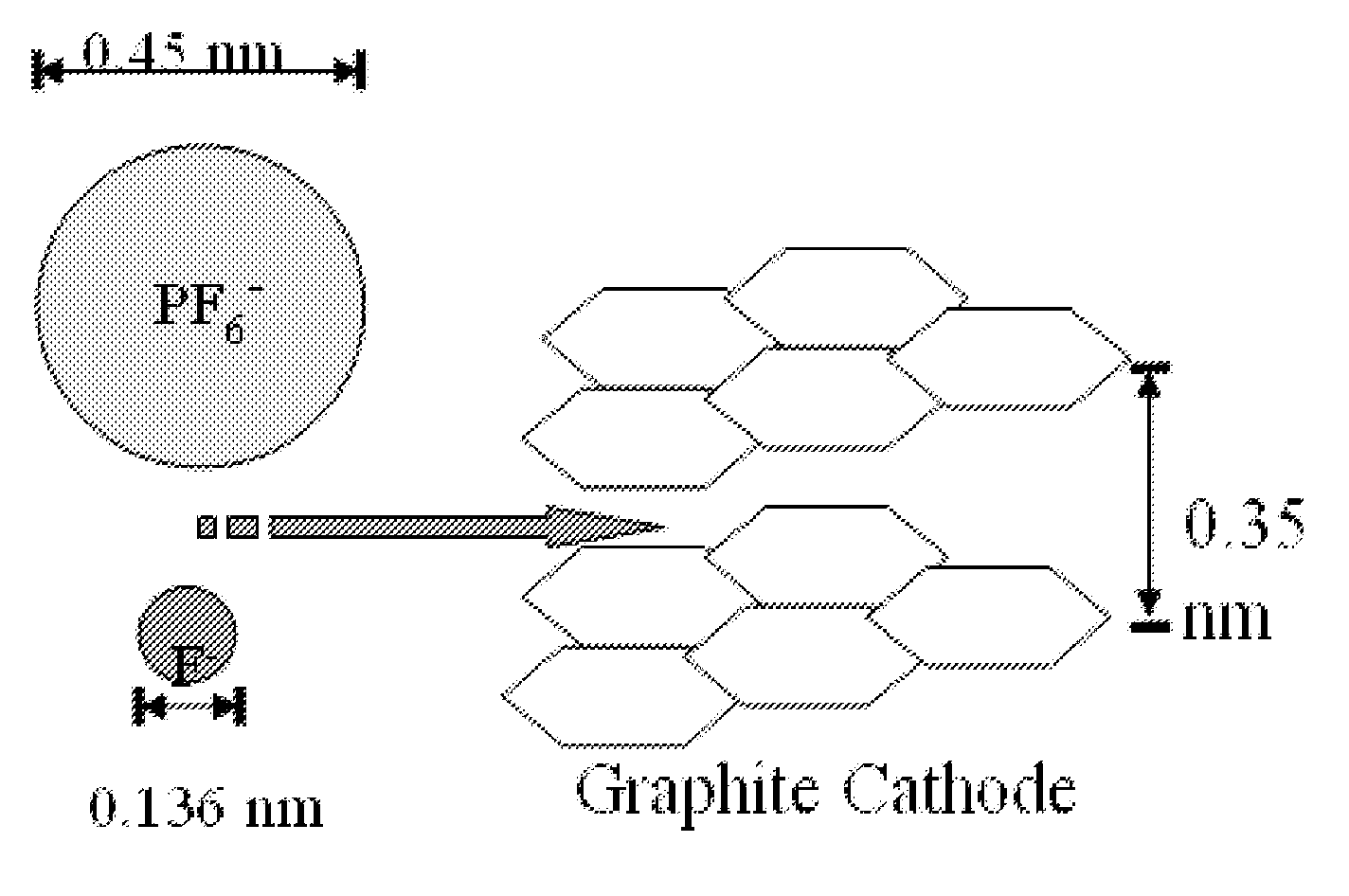

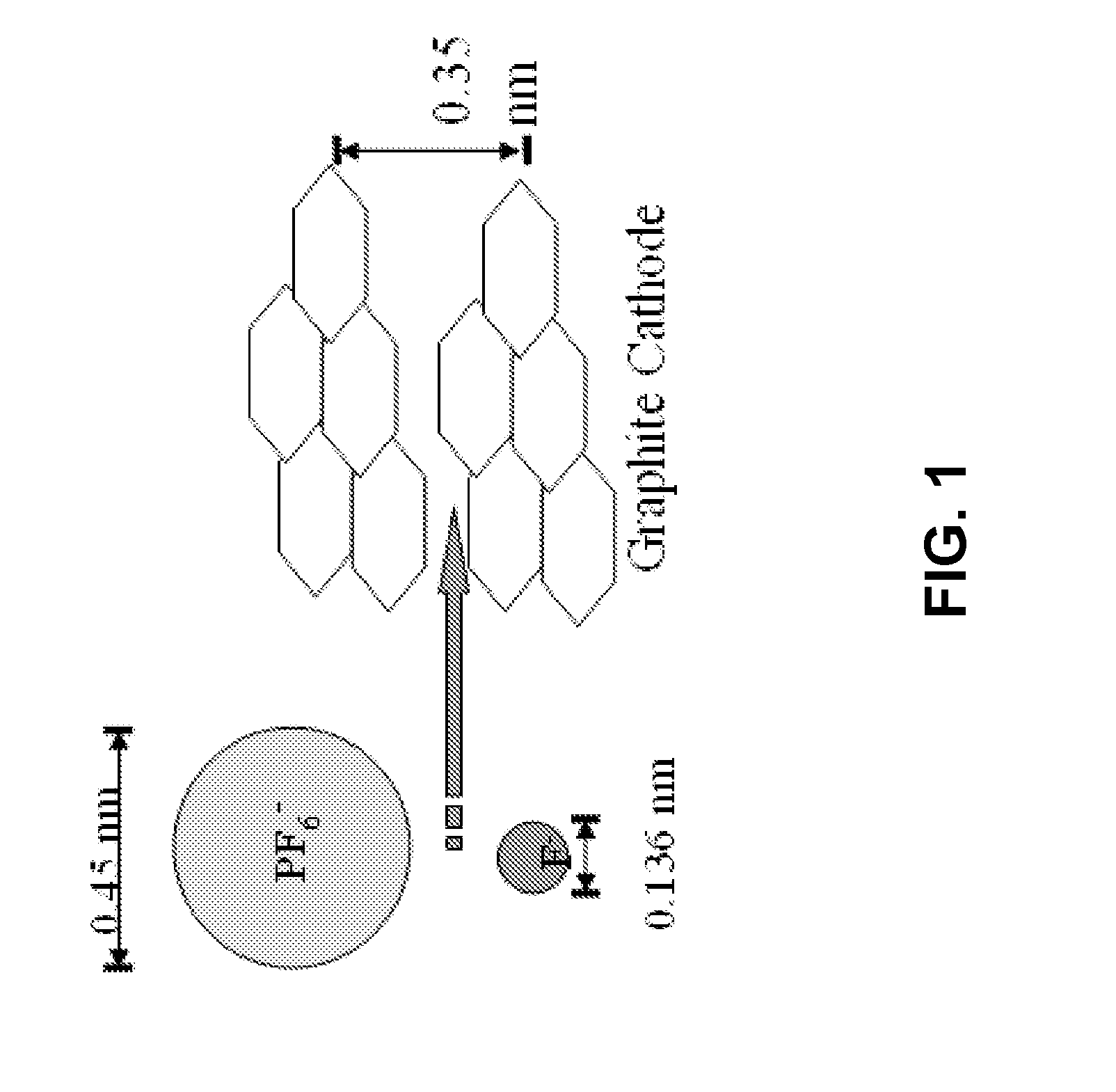

High Voltage and High Specific Capacity Dual Intercalating Electrode Li-Ion Batteries

ActiveUS20060269834A1High voltageHigh energyElectrode carriers/collectorsOrganic electrolyte cellsPresent methodElectrode pair

The present invention provides high capacity and high voltage Li-ion batteries that have a carbonaceous cathode and a nonaqueous electrolyte solution comprising LiF salt and an anion receptor that binds the fluoride ion. The batteries can comprise dual intercalating electrode Li ion batteries. Methods of the present invention use a cathode and electrode pair, wherein each of the electrodes reversibly intercalate ions provided by a LiF salt to make a high voltage and high specific capacity dual intercalating electrode Li-ion battery. The present methods and systems provide high-capacity batteries particularly useful in powering devices where minimizing battery mass is important.

Owner:CALIFORNIA INST OF TECH

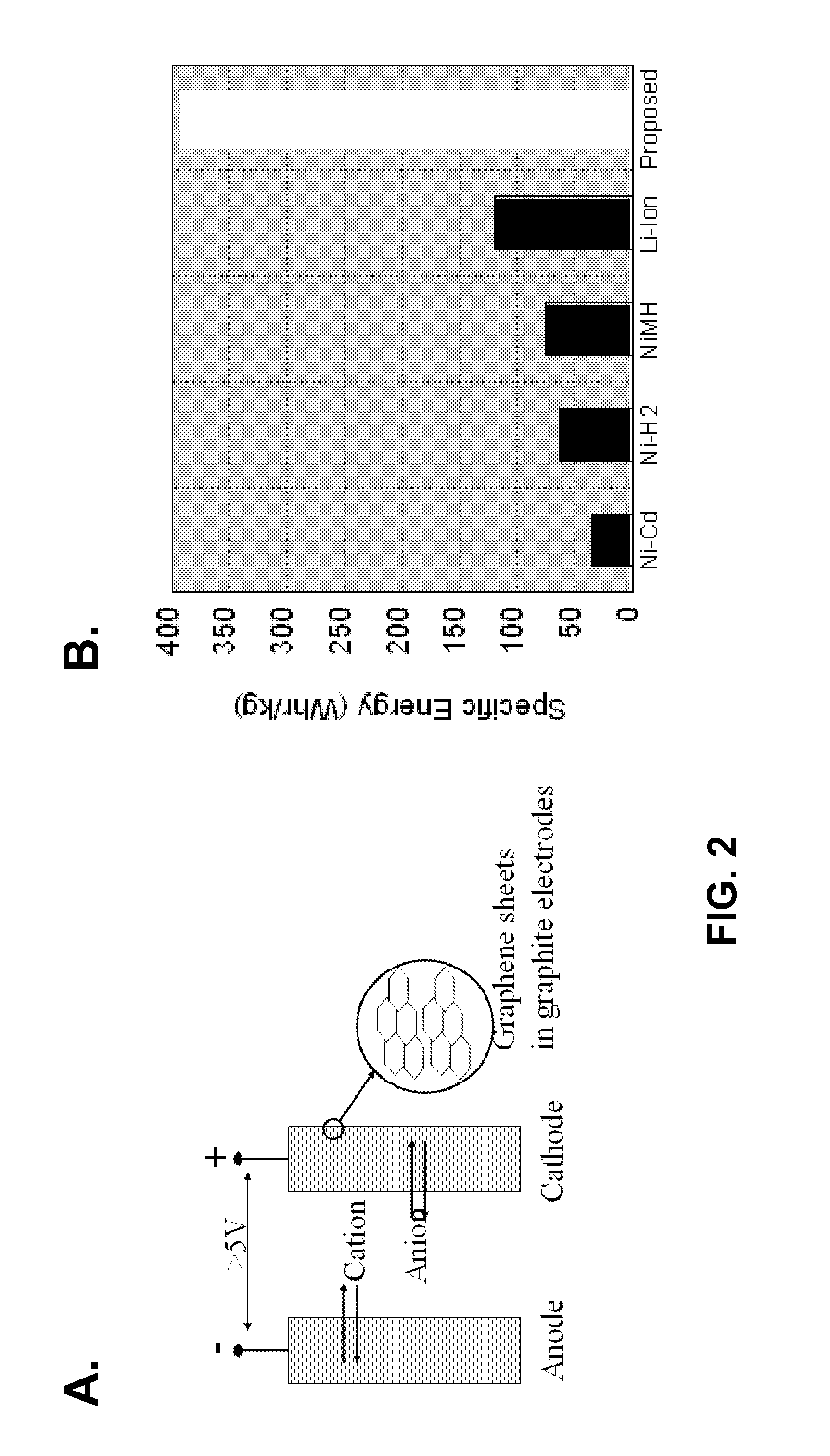

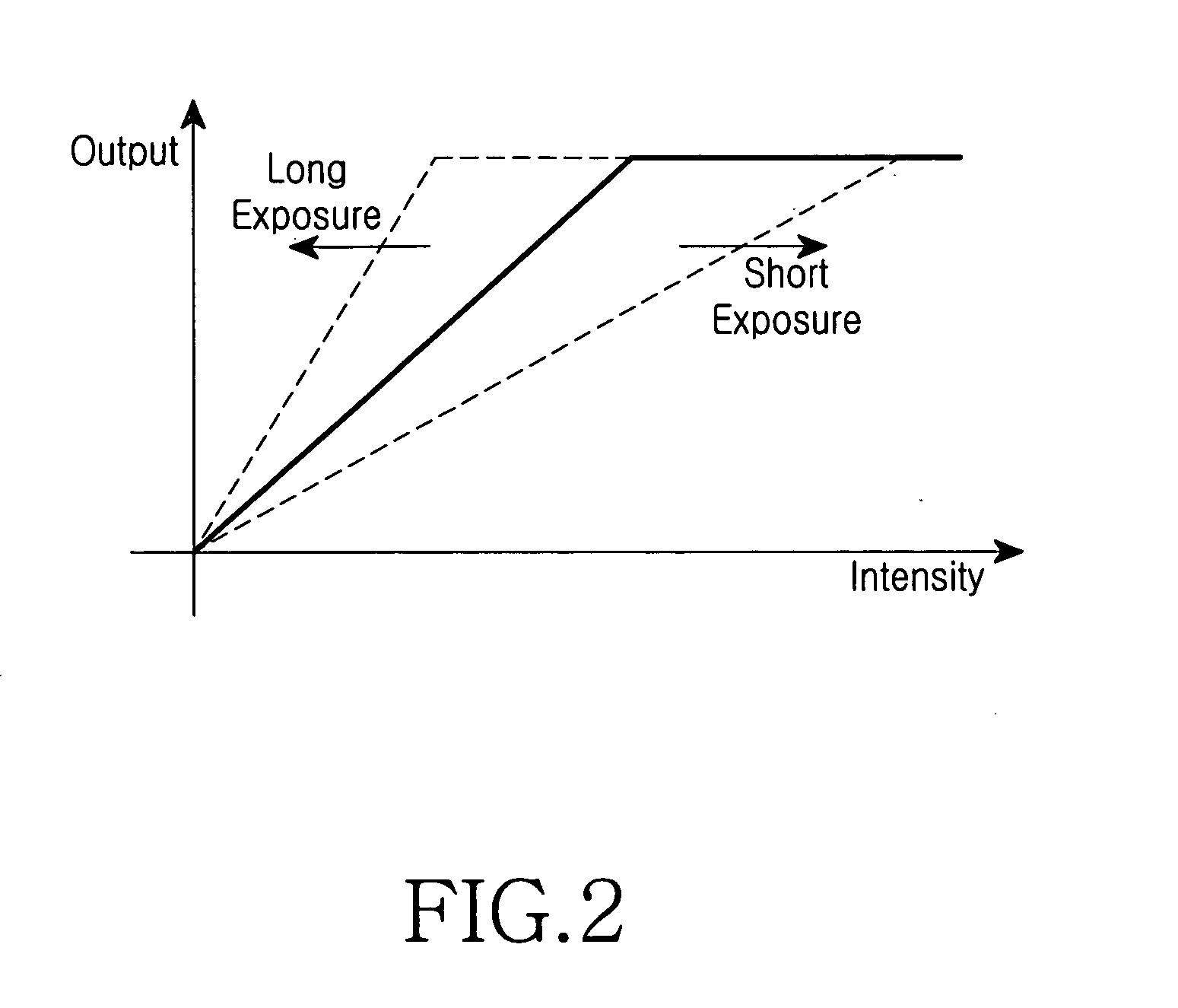

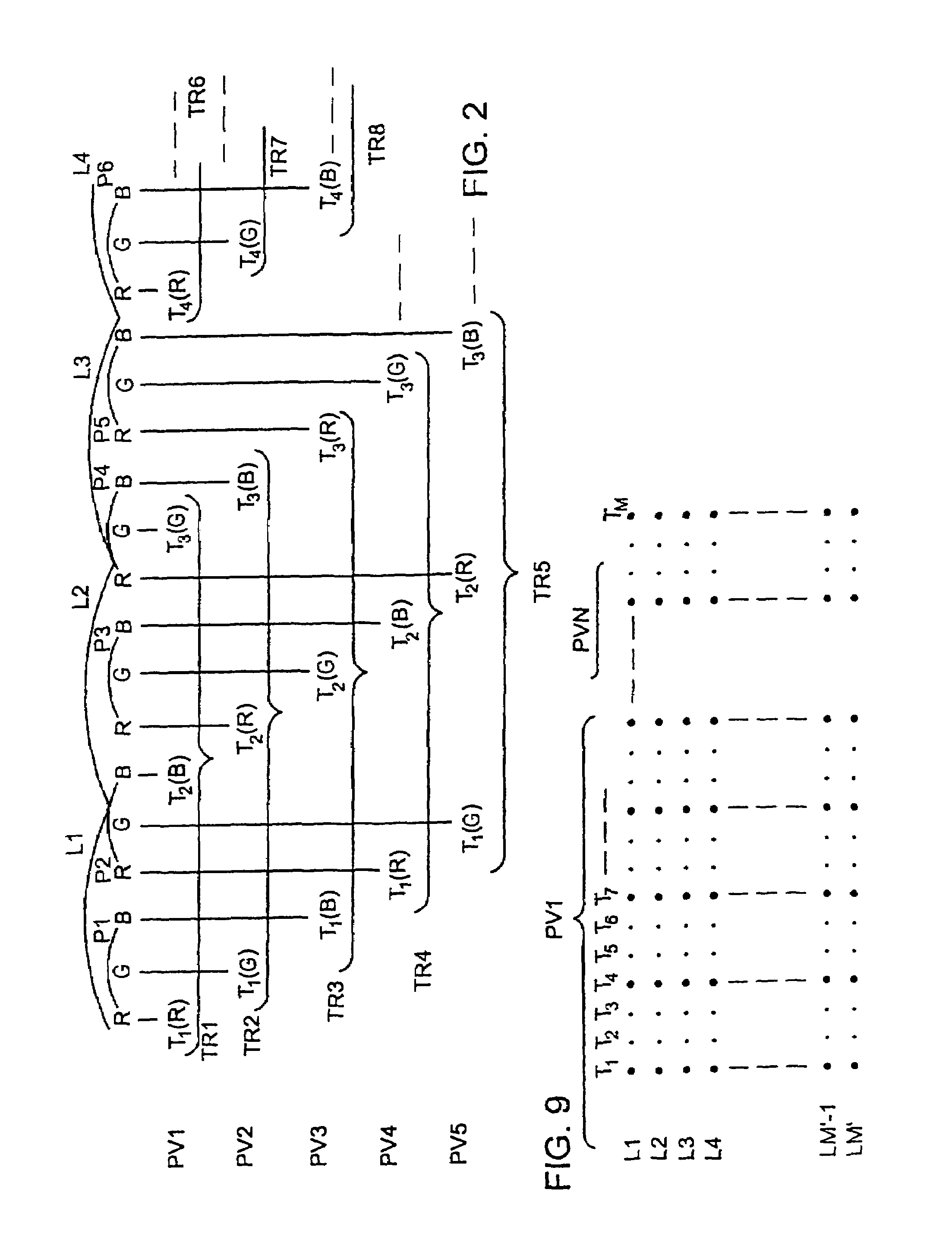

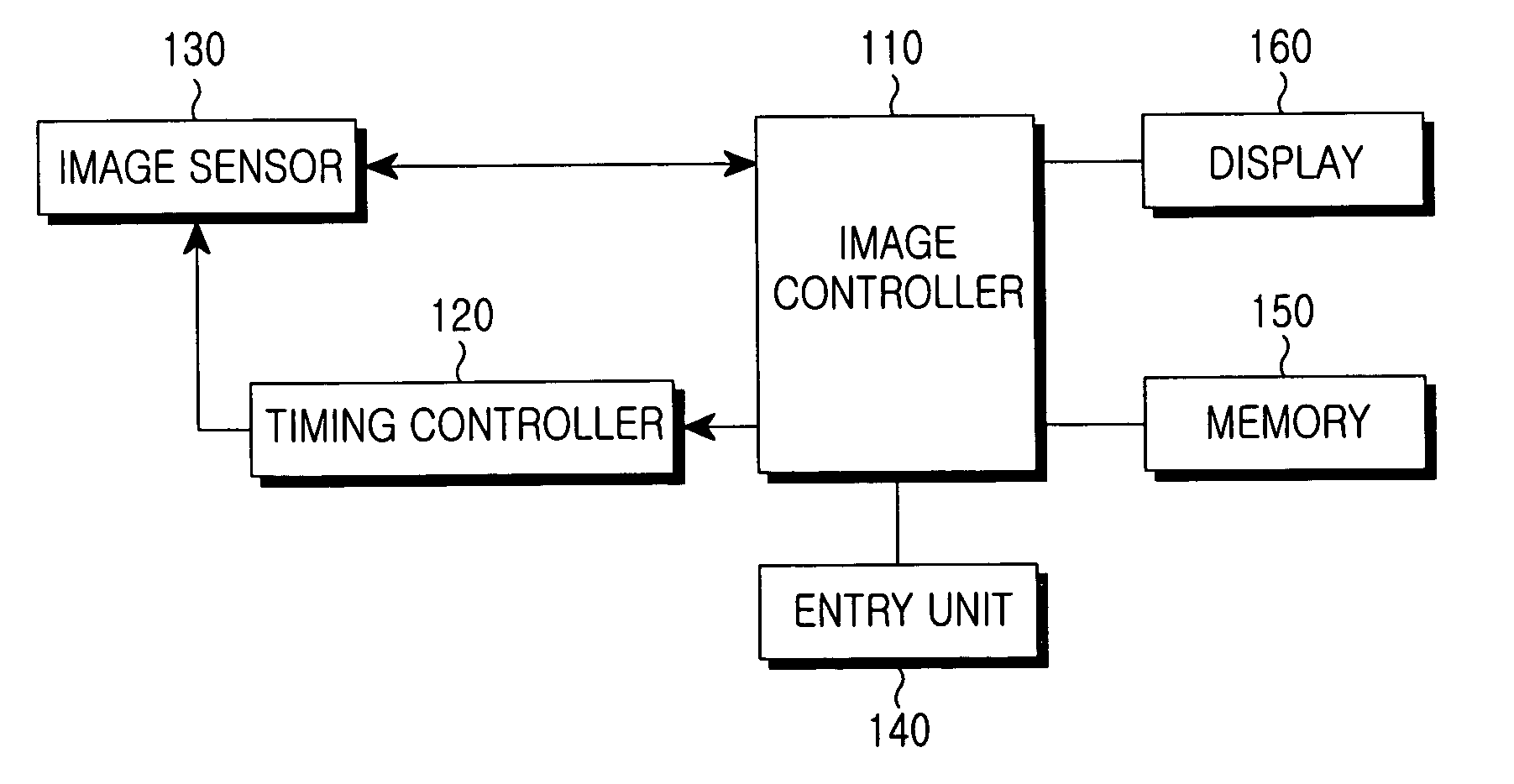

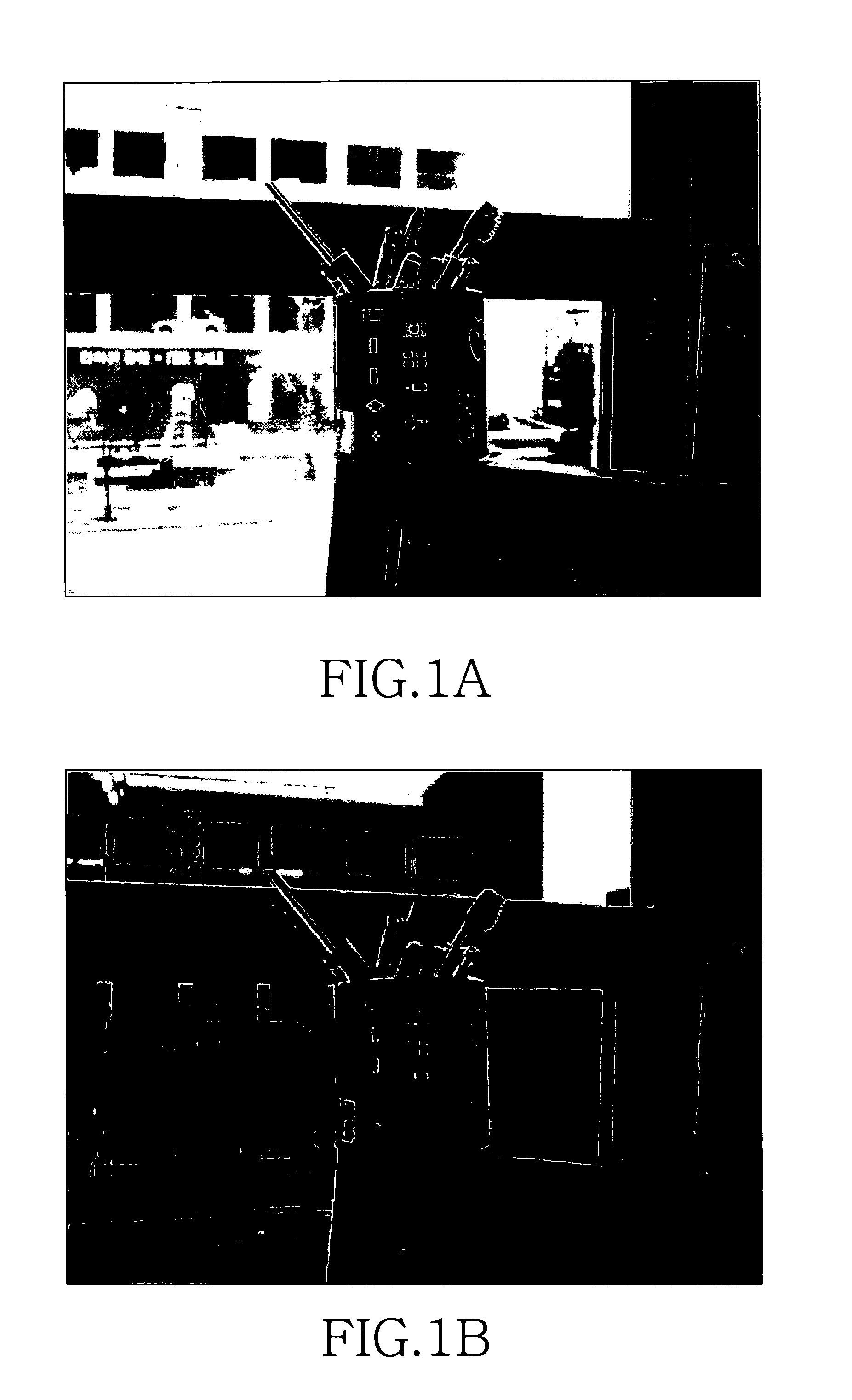

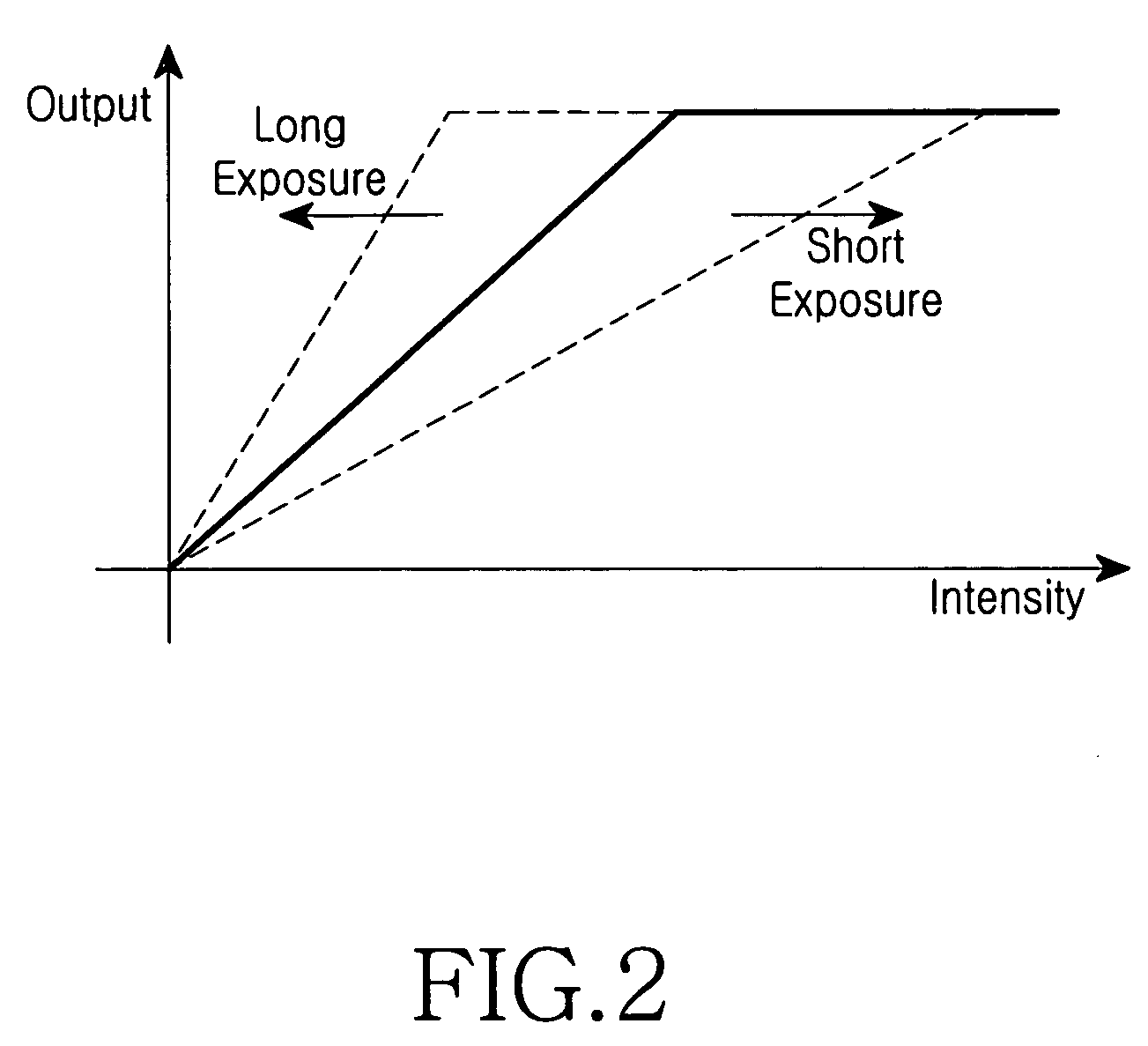

Apparatus and method for improving the quality of a picture having a high illumination difference

InactiveUS20050046708A1Increase weightReduce weightTelevision system detailsCharacter and pattern recognitionIlluminanceReconstruction method

An apparatus and image reconstruction method for use in an apparatus including a digital camera are provided. The apparatus and method include driving an image sensor during a short exposure time in an image reconstruction mode, driving the image sensor during a relatively-long exposure time in the image reconstruction mode, and acquiring first and second frame images having different illumination degrees; assigning substantially identical image data of the first and second frame images to local images each having a predetermined size; calculating local variance values of image data of each of the local areas; comparing a local variance value of the first frame image with a local variance value of the second frame images, assigning a high weight to one local image having a high local variance value, and assigning a low weight to the other local image having a low local variance value; applying the determined weights to image data of individual local areas of the first and second frame images, performing image reconstruction, and displaying a reconstructed image.

Owner:SAMSUNG ELECTRONICS CO LTD

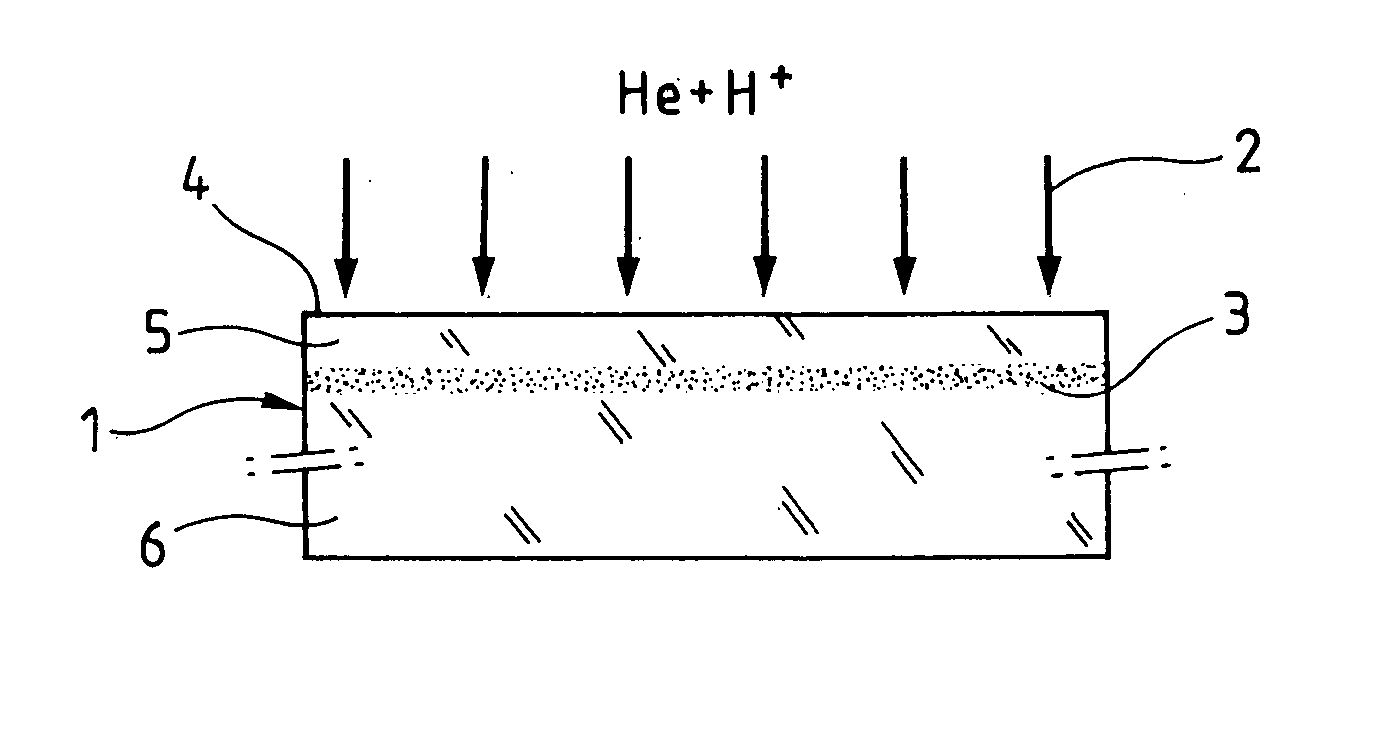

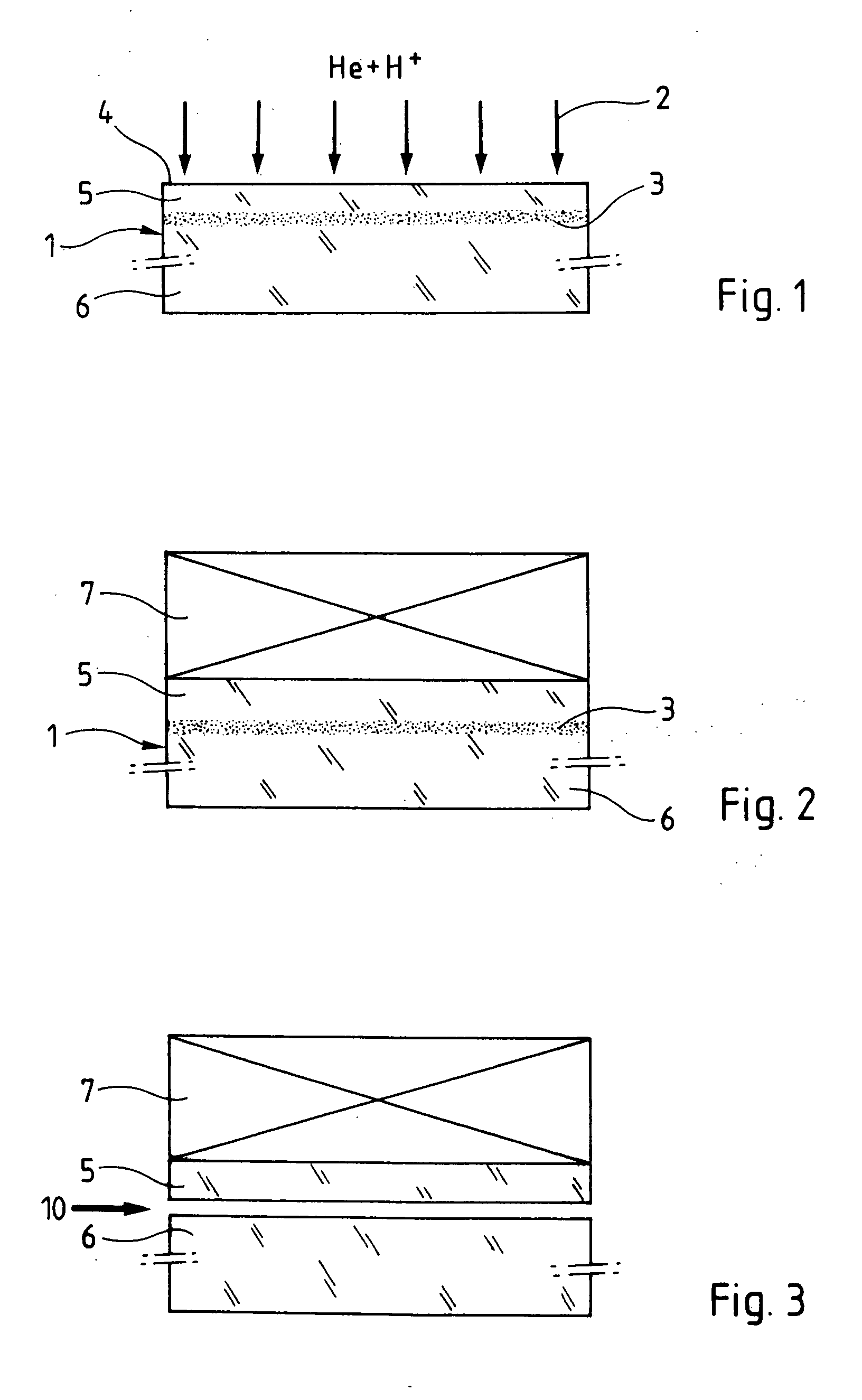

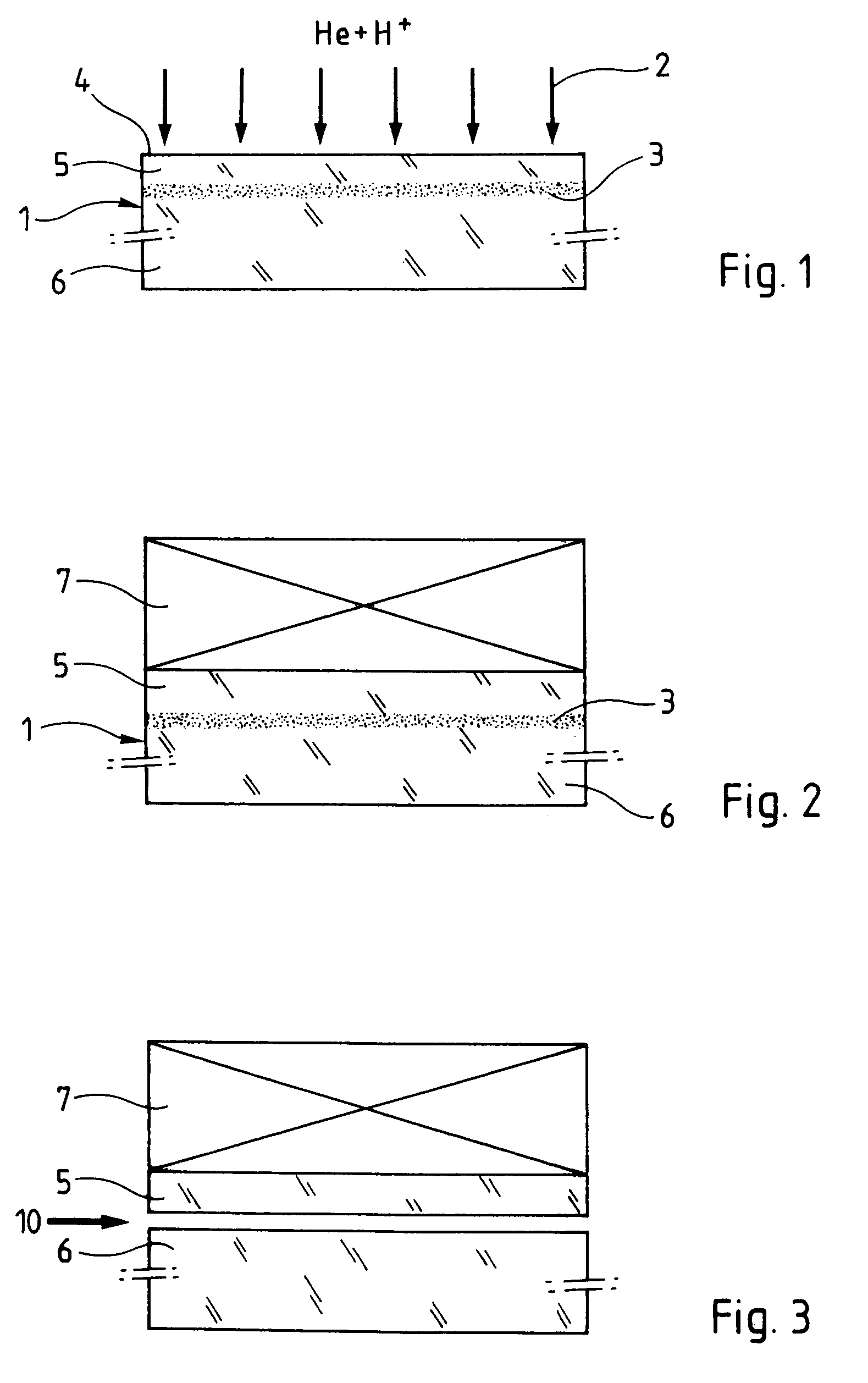

Method of catastrophic transfer of a thin film after co-implantation

ActiveUS20050148163A1Reduce roughnessHigh mechanical stressSemiconductor/solid-state device manufacturingCo implantationAtomic physics

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

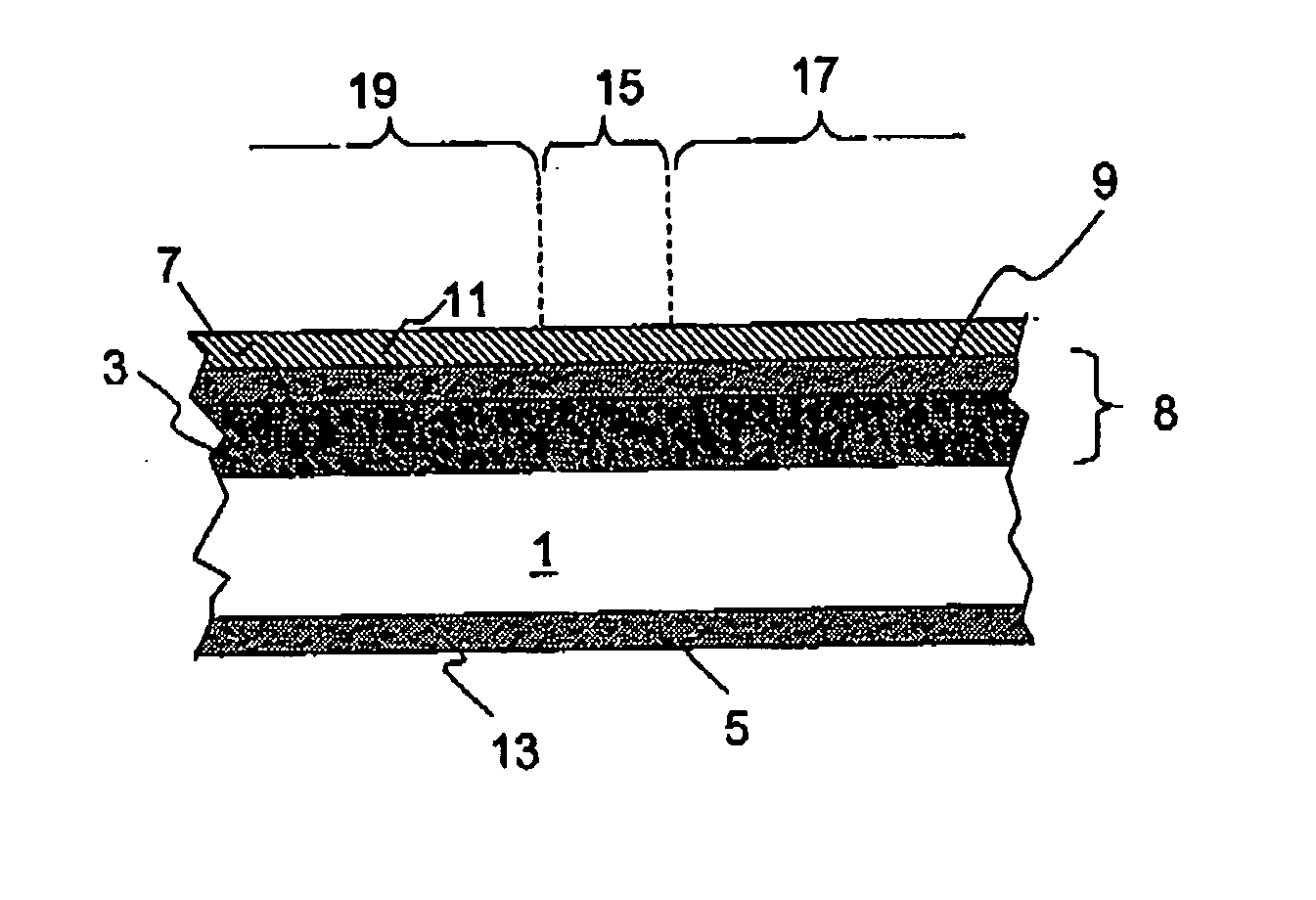

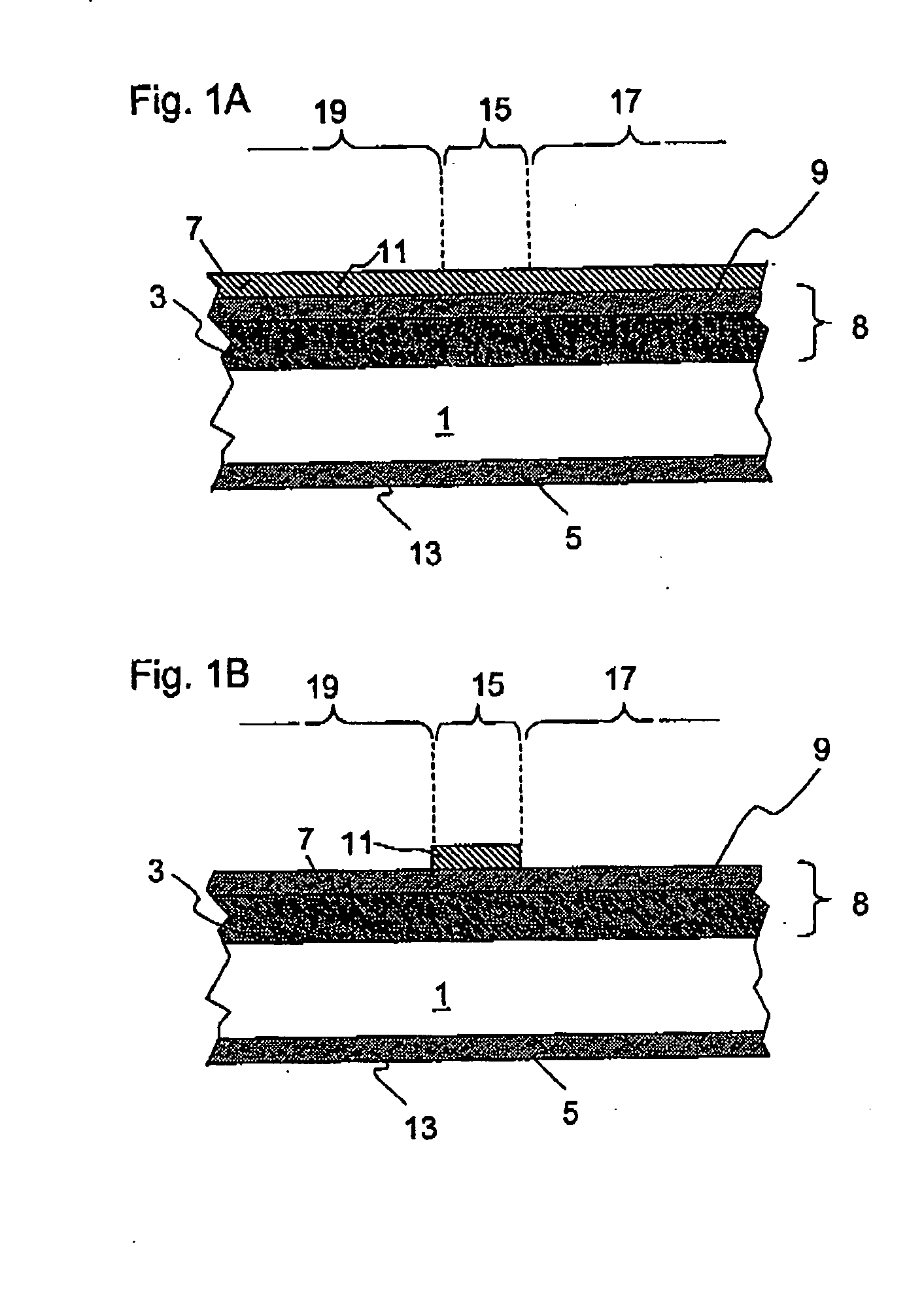

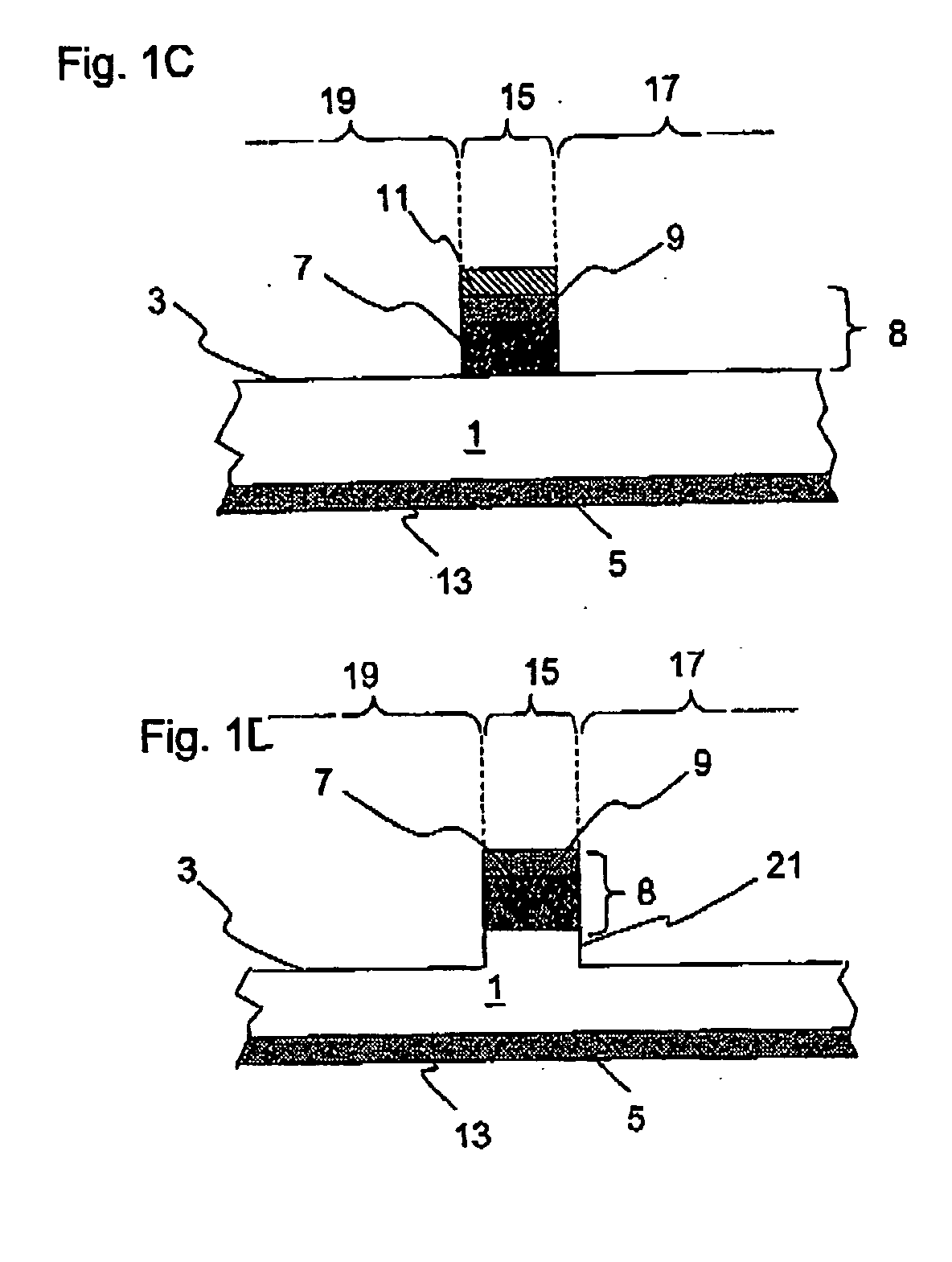

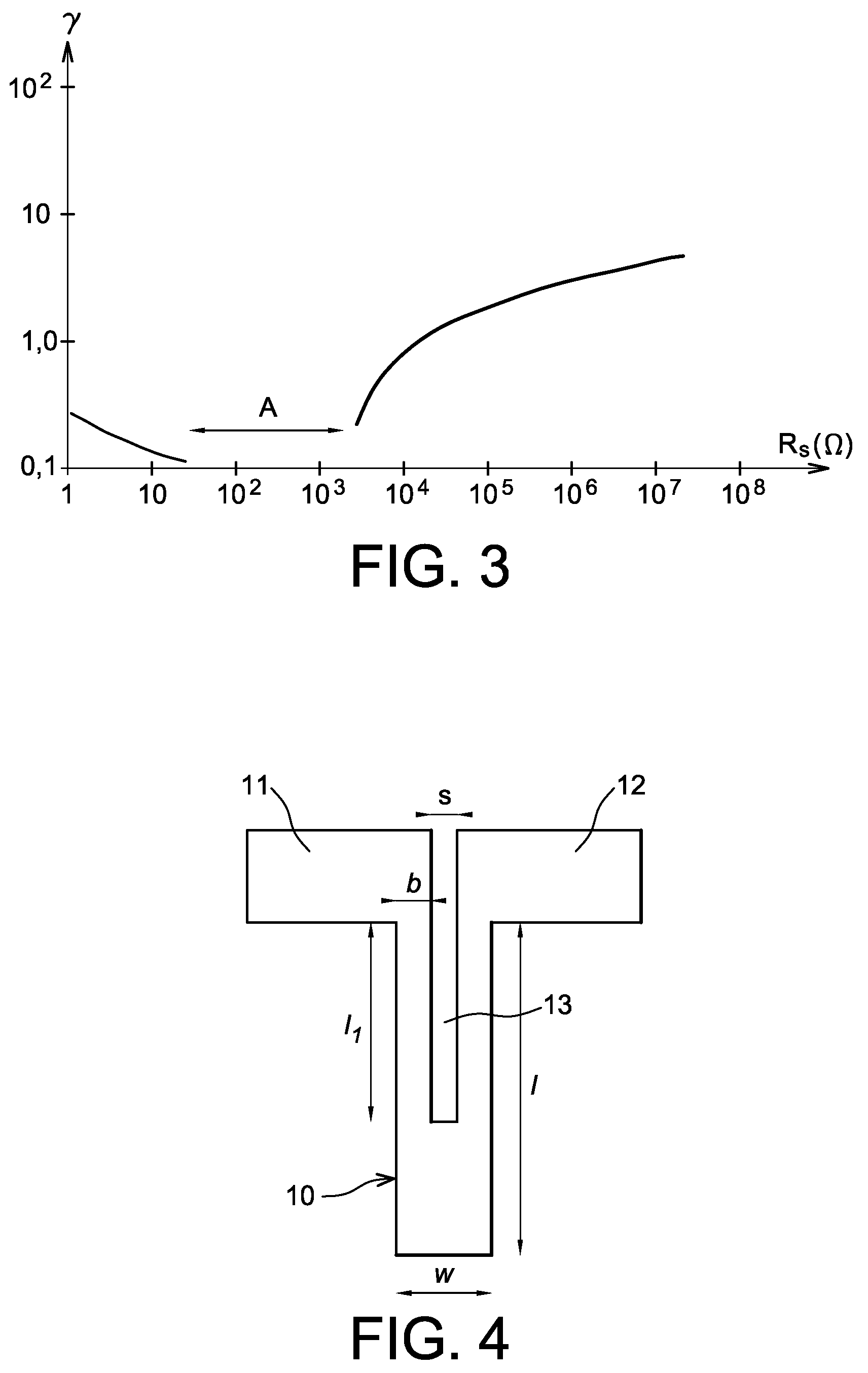

Optical device, and process for producing it

InactiveUS20050058423A1Increase height differenceReduce decreaseCoupling light guidesCoatingsIon exchangeChemistry

A process for producing an optical device by means of ion exchange is provided. The method includes: coating at least one first region of a substrate with a coating having a first layer of exchange atoms in neutral or ionic form; removing substrate material from at least one second region that adjoins the first region; and exchanging substrate ions with exchange ions from the first layer.

Owner:SCHOTT AG

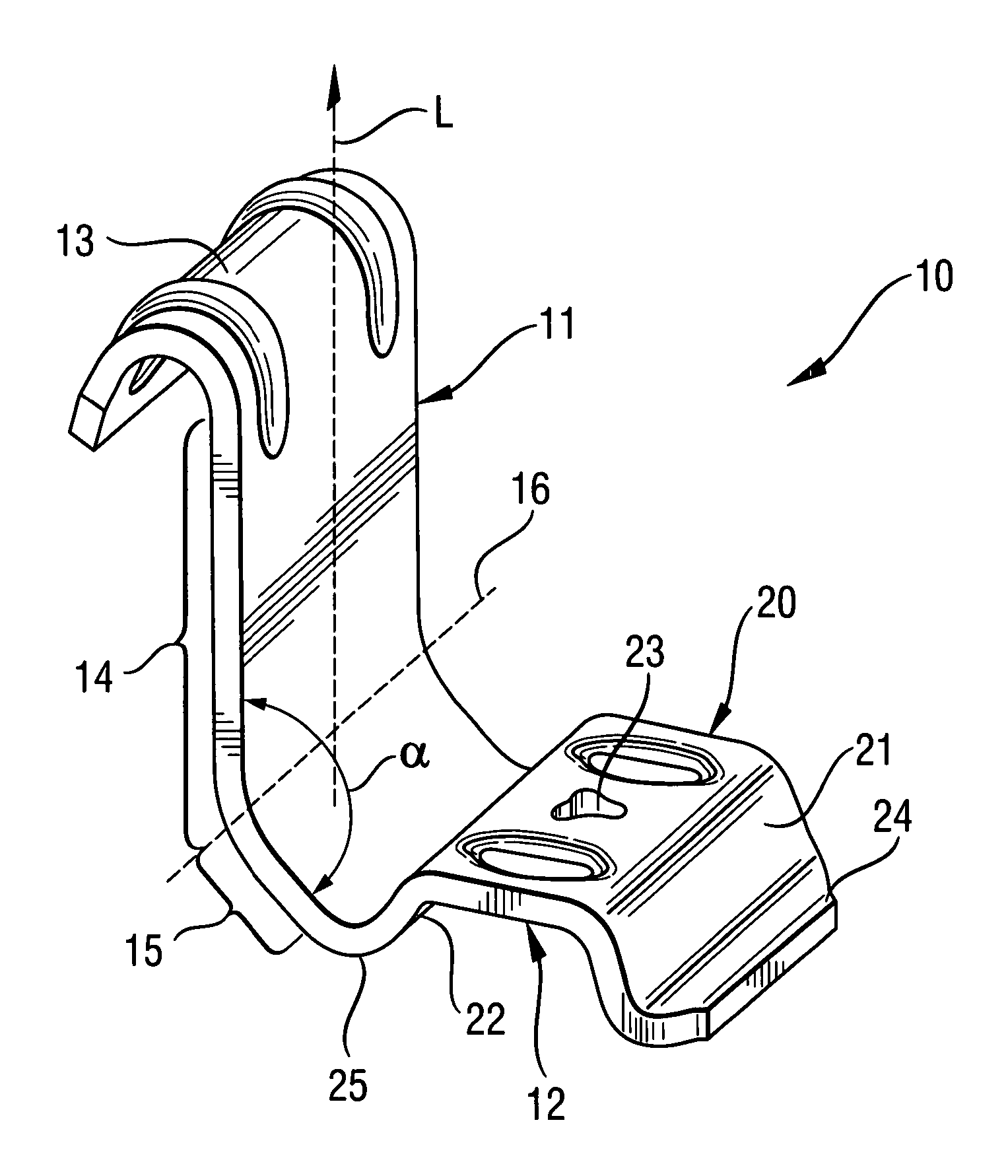

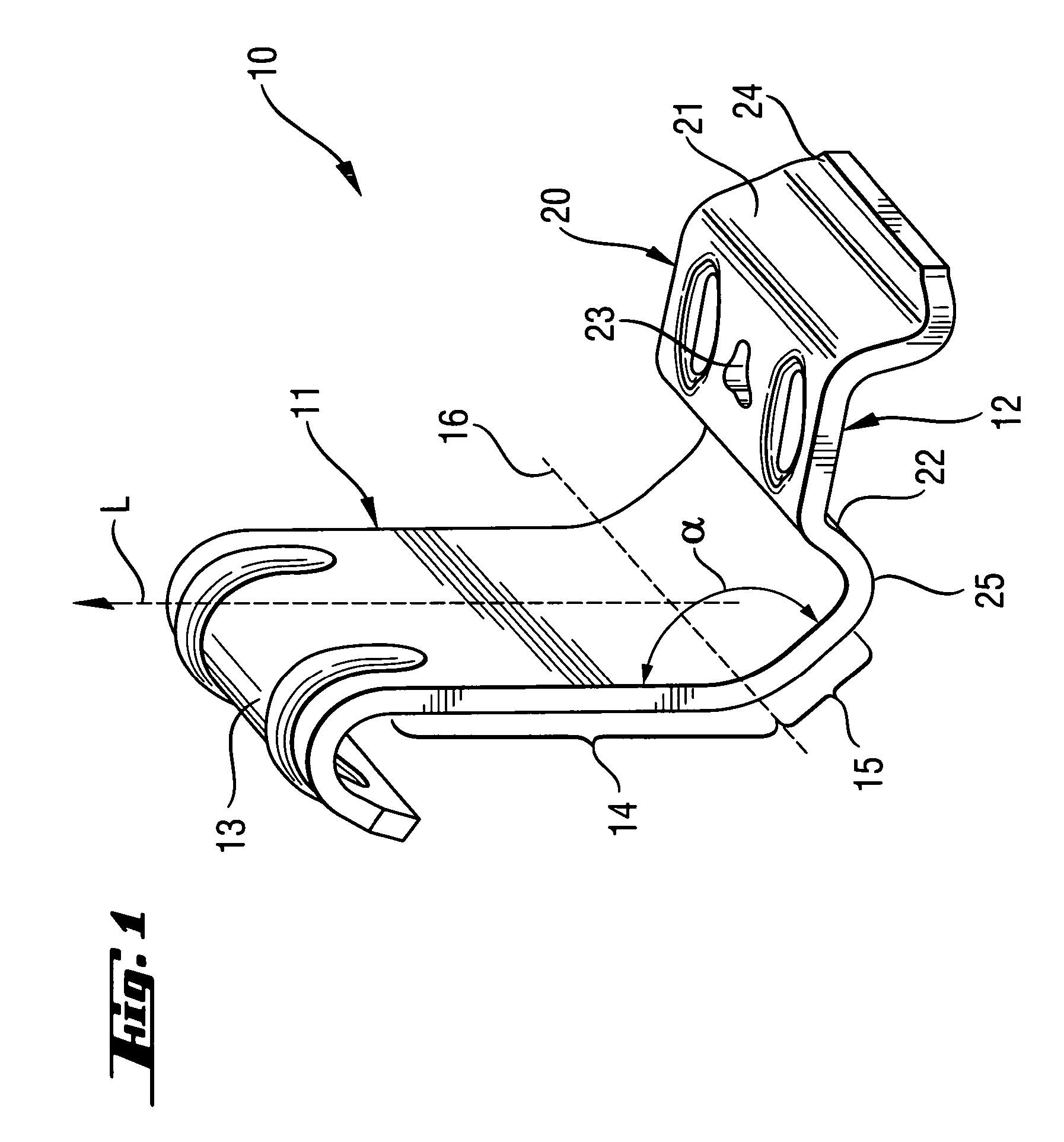

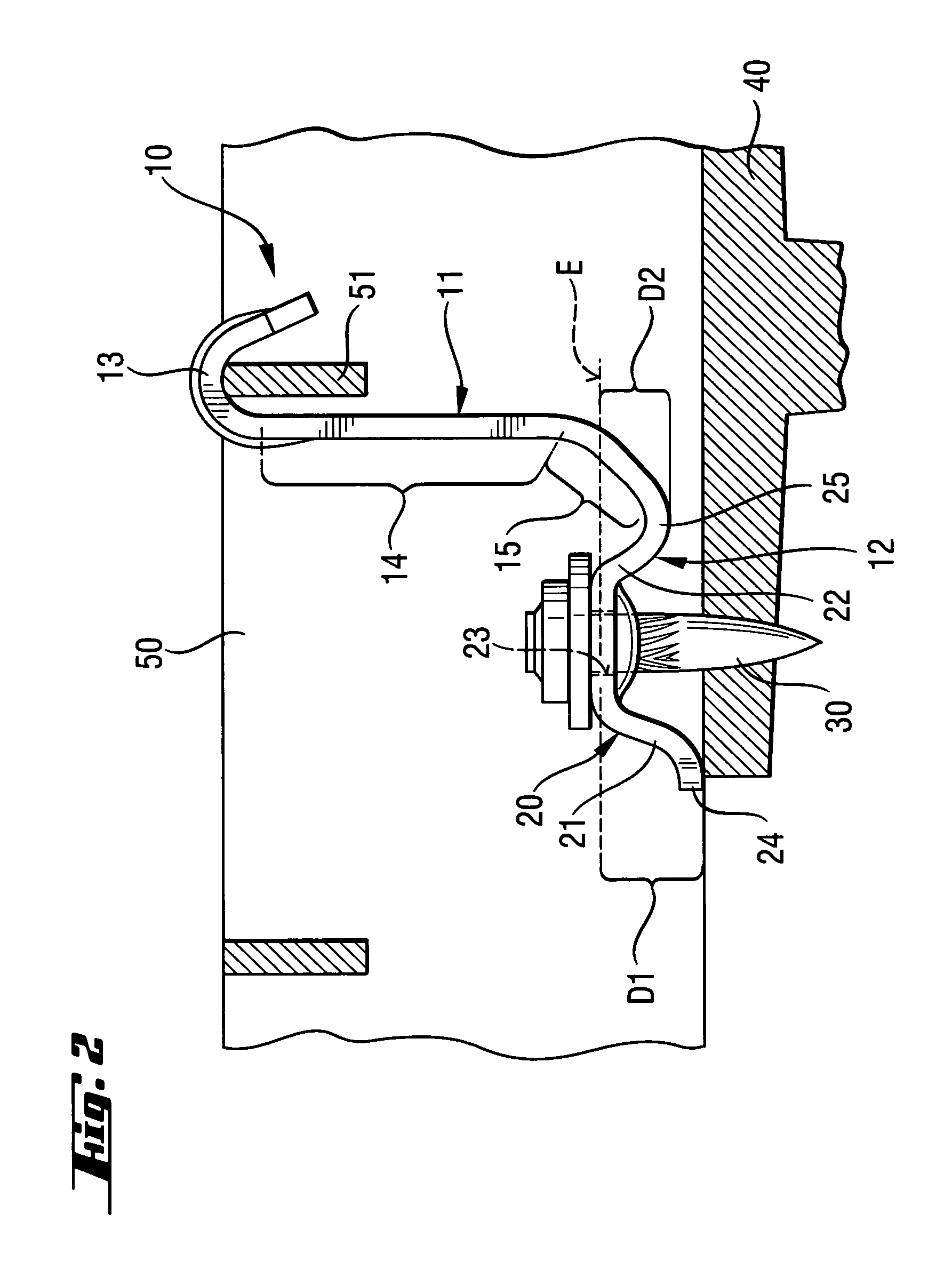

Grid-holding element

ActiveUS7789365B2Certain tolerance rangeEasy to fixCandle holdersLighting support devicesEngineeringSaddle shape

Owner:HILTI AG

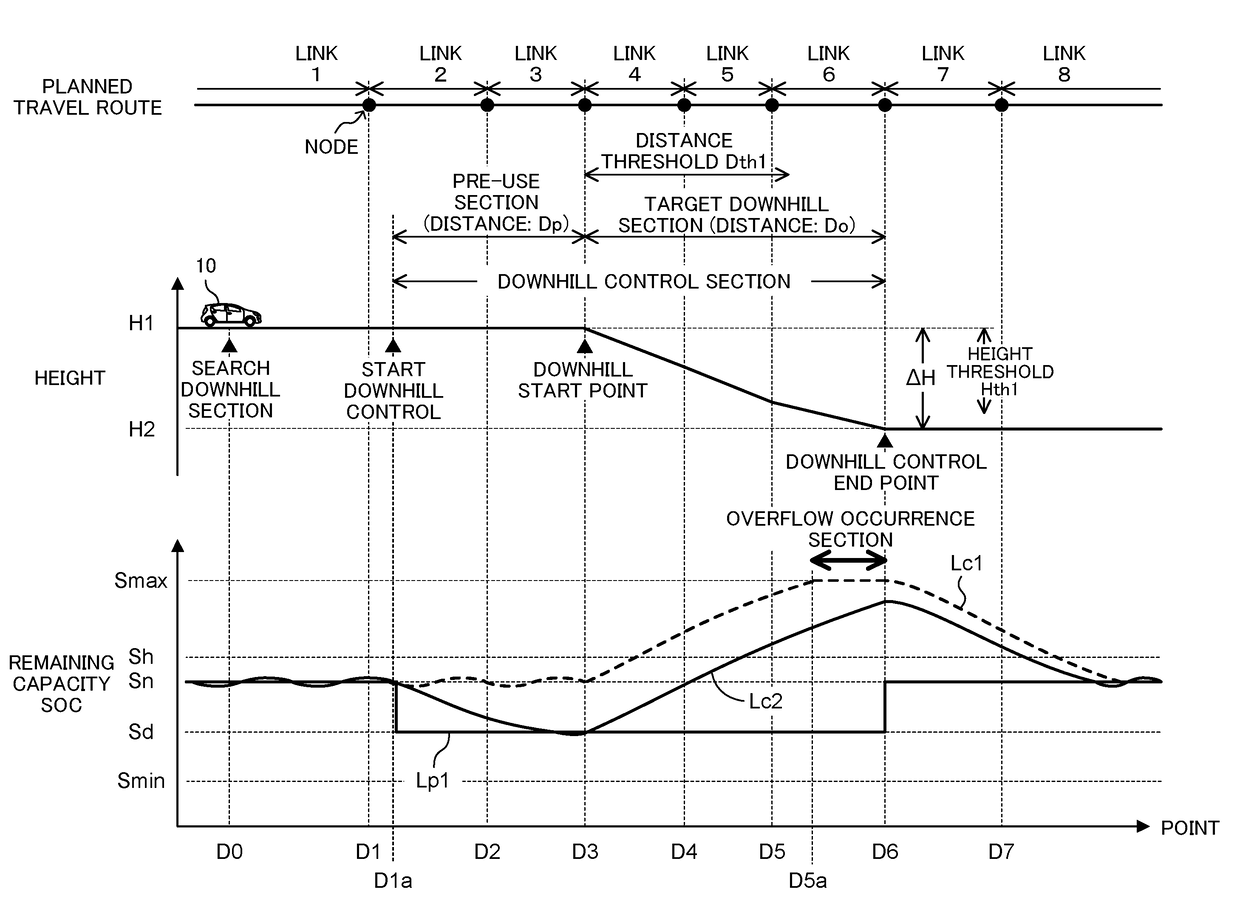

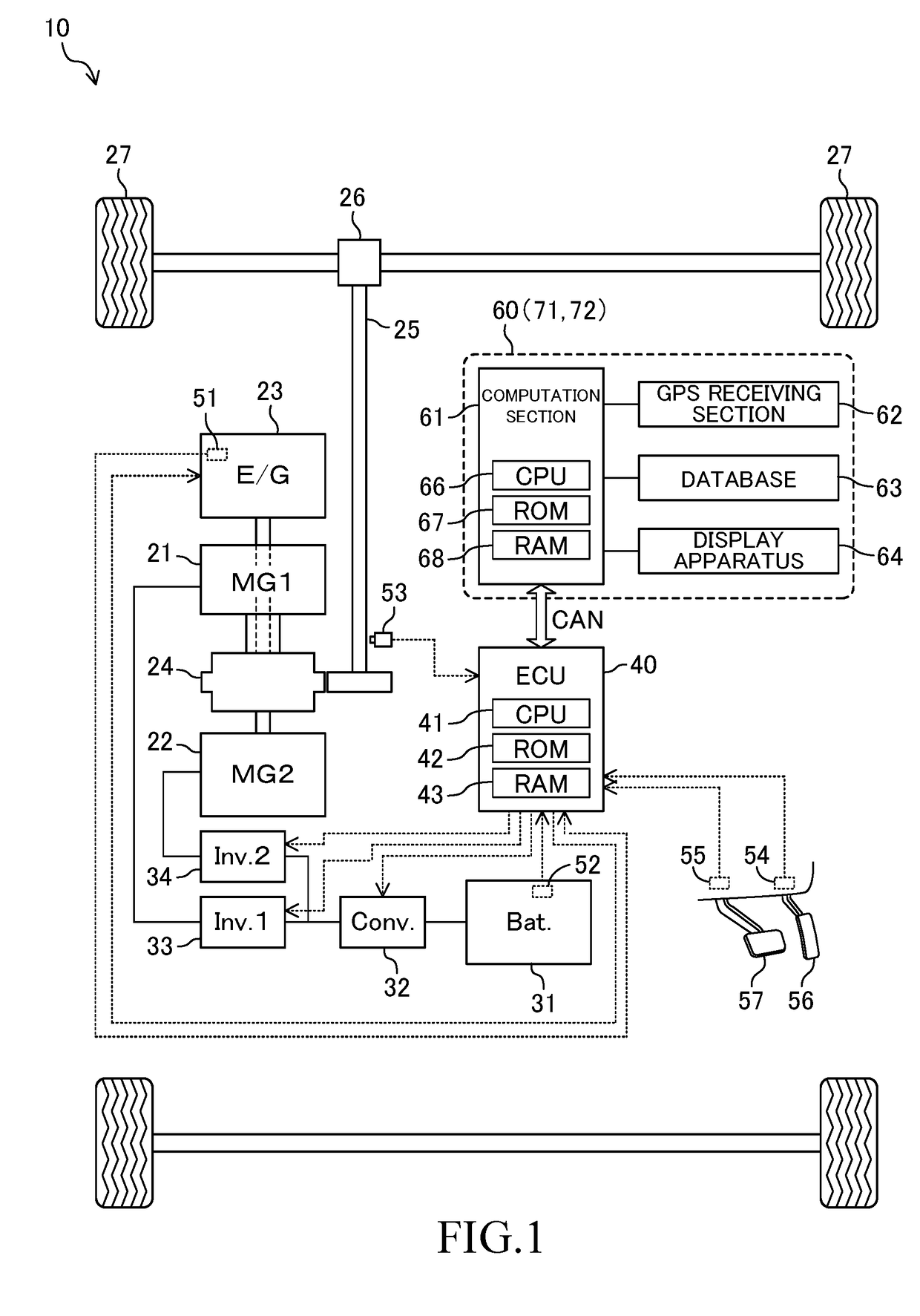

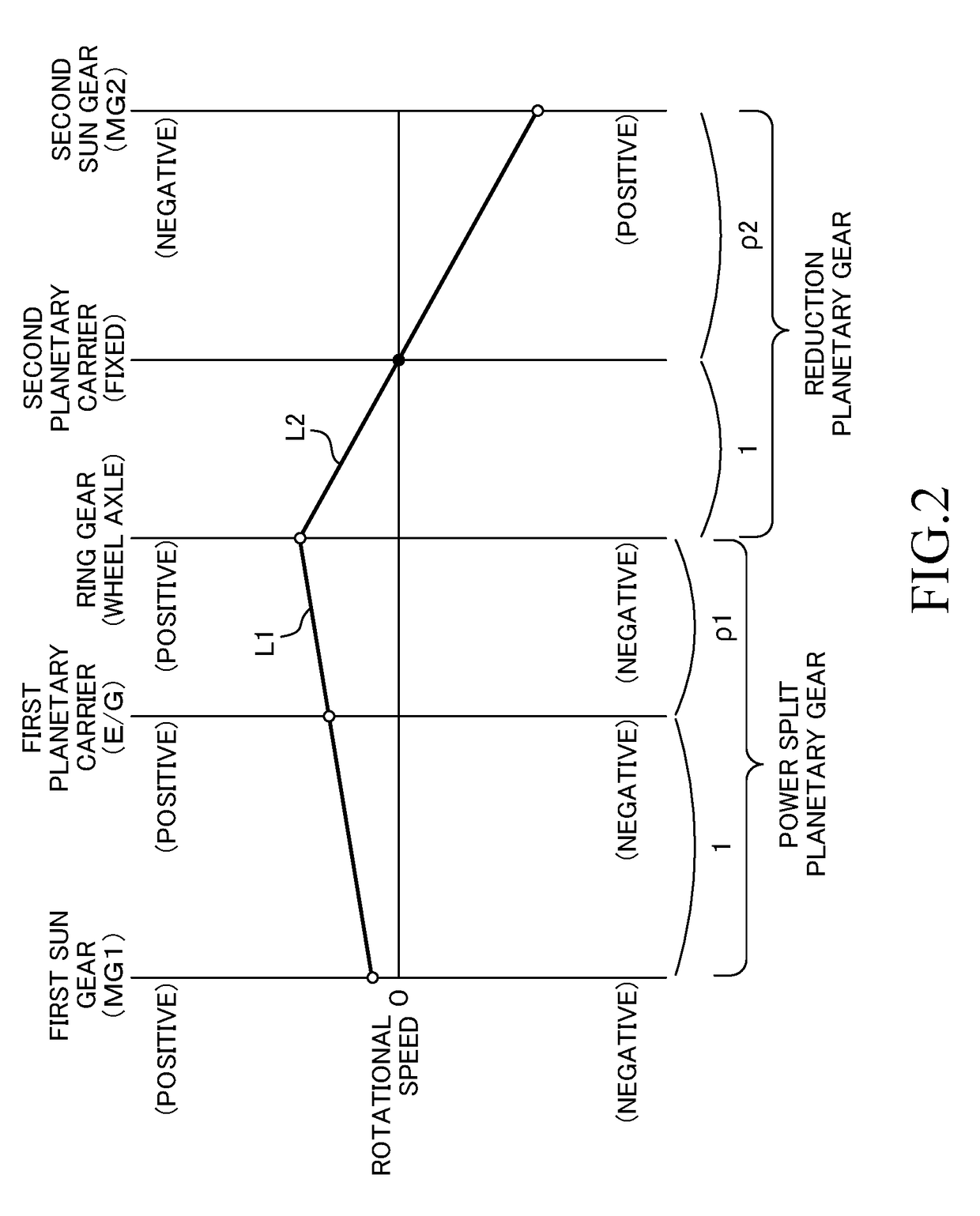

Hybrid vehicle control apparatus

ActiveUS20170088117A1Increases height difference thresholdReliable extractionHybrid vehiclesElectrodynamic brake systemsAerodynamic dragRegenerative brake

A control apparatus for a hybrid vehicle including an internal combustion engine, a motor, and a storage battery and which charges the storage battery with electric power generated as a result of regenerative braking and electric power generated by using an output of the engine. When a planned travel route includes a downhill section whose height difference is greater than a predetermined height difference threshold, the controller executes a downhill control operation that decreases the target remaining capacity of the storage battery. The controller increases the height difference threshold as the estimated average speed of the vehicle during travel in the downhill section increases, to thereby restrain the execution of the downhill control for a downhill section in which an increase in the remaining capacity is not expected due to a large air resistance acting on the vehicle.

Owner:TOYOTA JIDOSHA KK

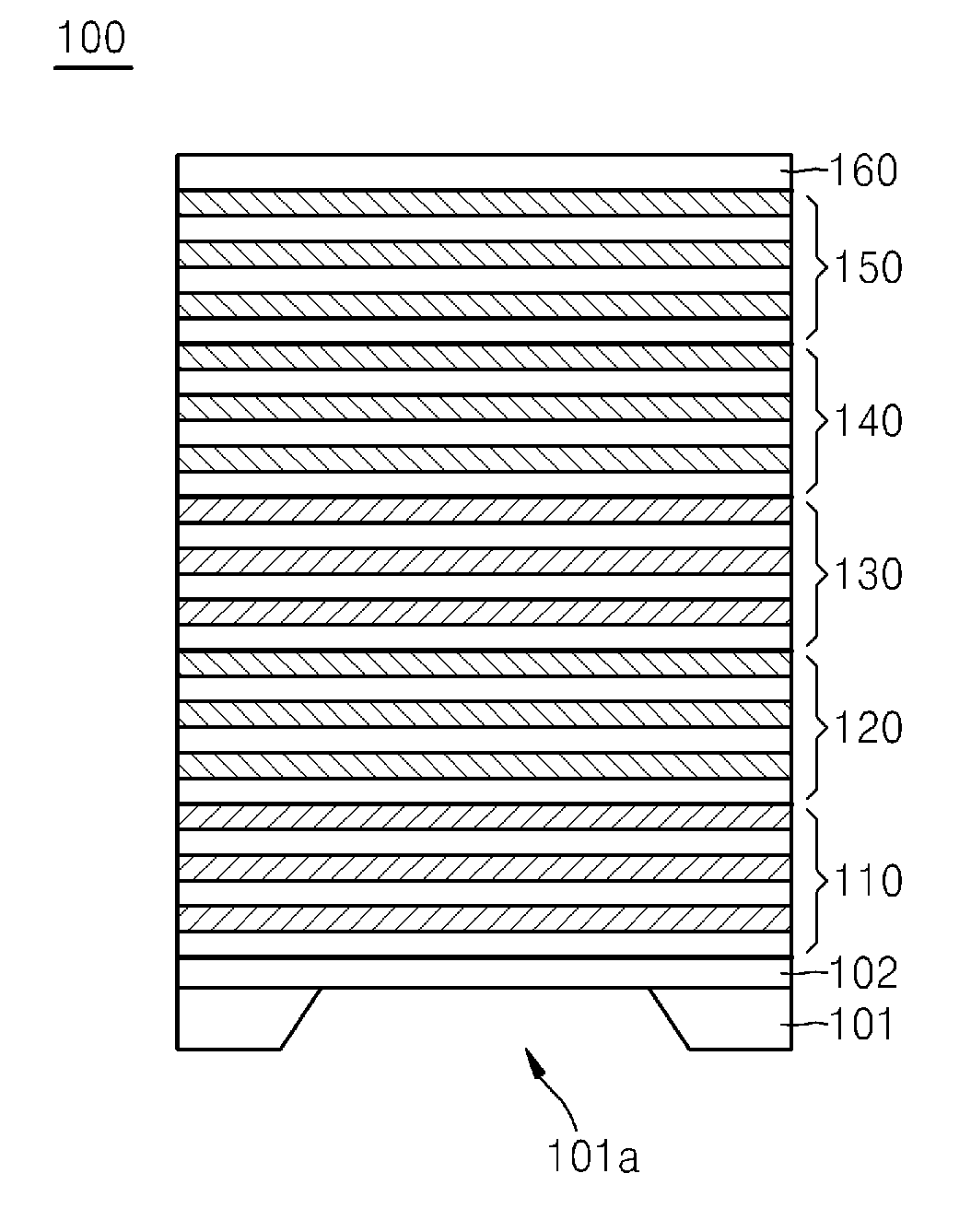

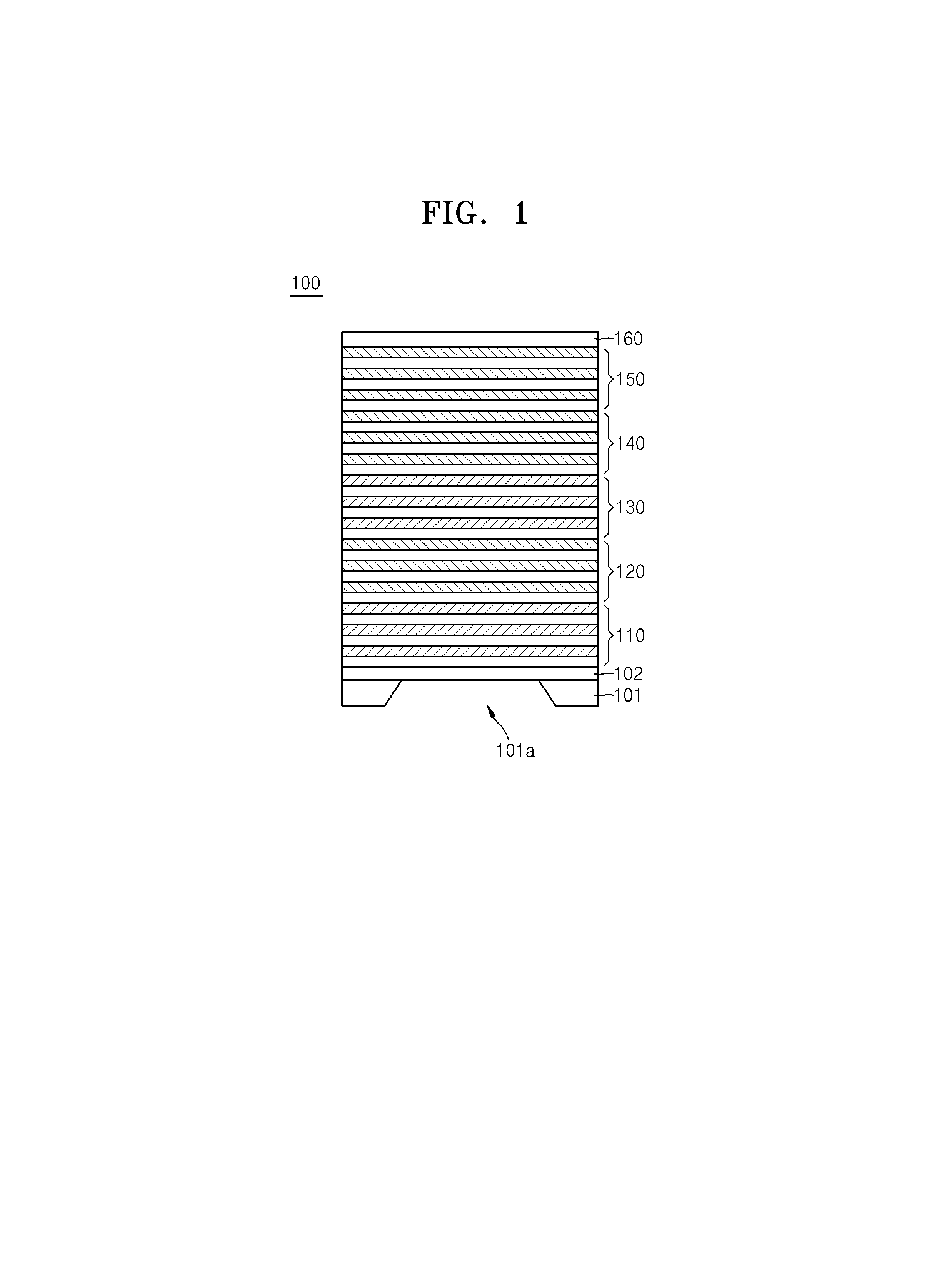

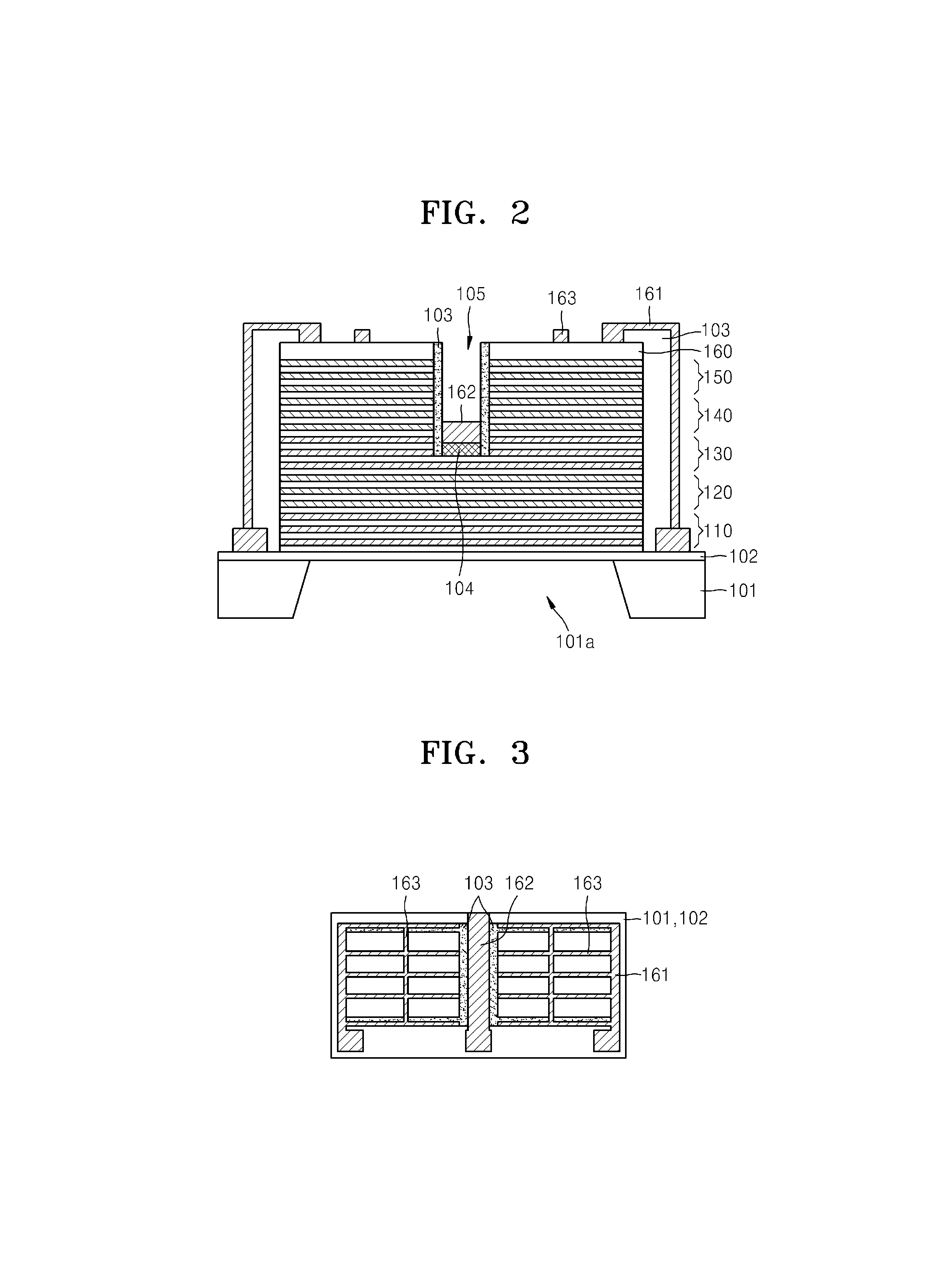

Transmissive image modulator including stacked diode structure having multi absorption modes

ActiveUS20130175500A1Reduce the driving voltageIncrease height differenceCooking-vessel materialsCooking-vessel lids/coversDopantElectricity

A transmissive light modulator including a first reflection layer; a first active layer, arranged on the first reflection layer and including a plurality of quantum well layers and a plurality of barrier layers; a second reflection layer arranged on the first active layer; a second active layer, arranged on the second reflection layer and including a plurality of quantum well layers and a plurality of barrier layers; and a third reflection layer arranged on the second active layer, wherein the first reflection layer and the third reflection layer are each doped with a first type dopant, and the second reflection layer is doped with a second type dopant, which is electrically opposite to the first type dopant.

Owner:SAMSUNG ELECTRONICS CO LTD +1

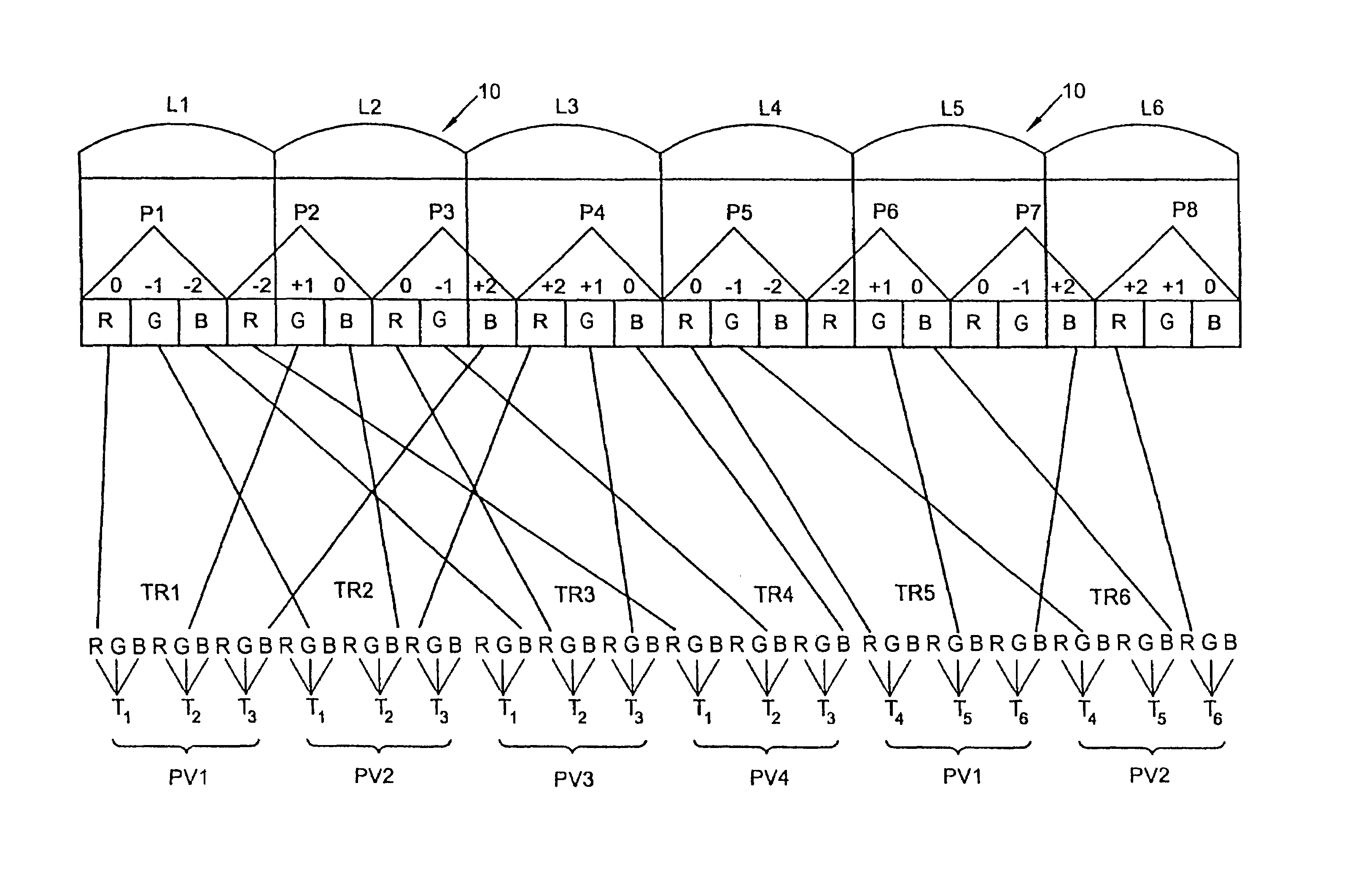

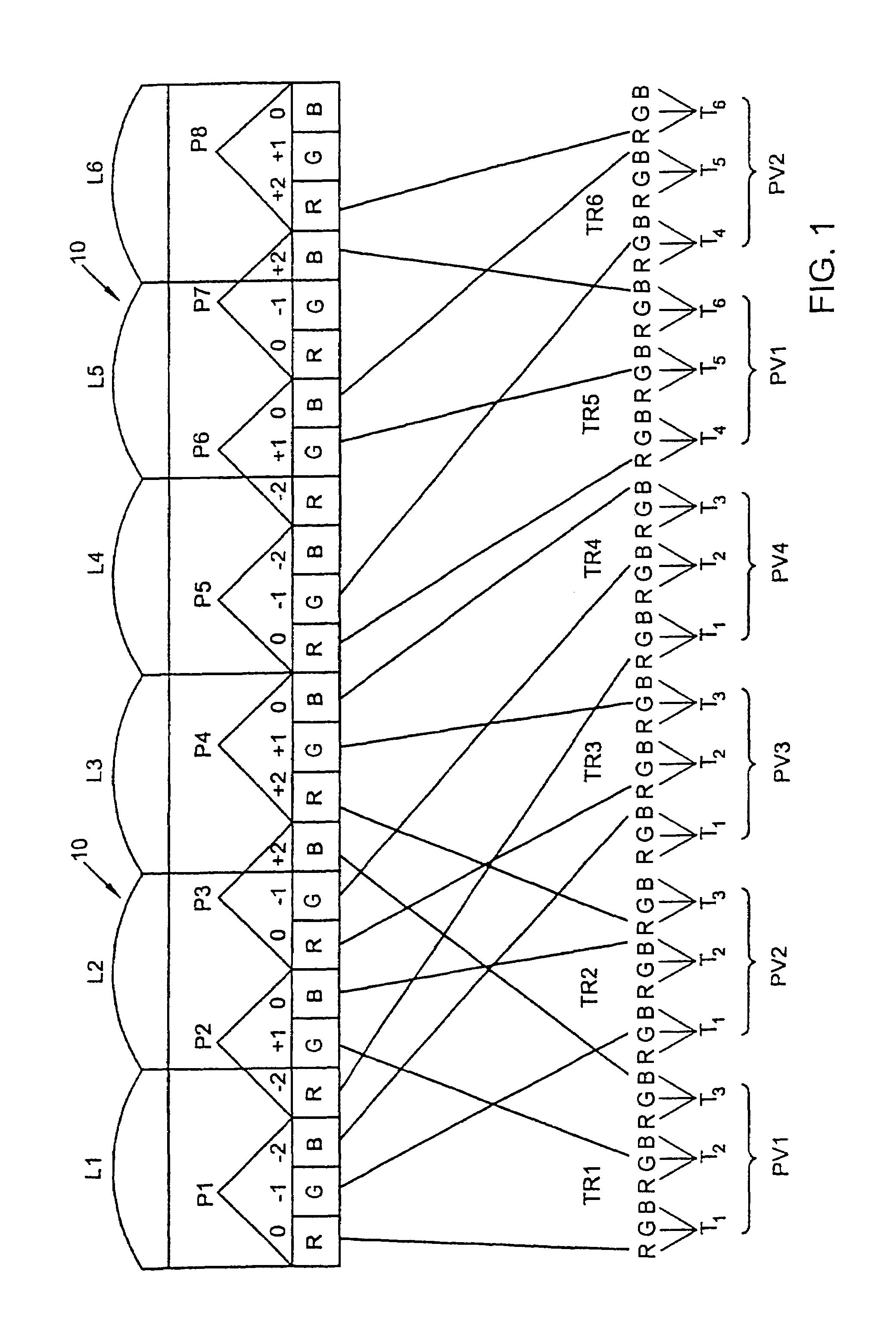

Method for autostereoscopic display

InactiveUS6972744B1Improve finenessImprove perceptionCathode-ray tube indicatorsImage data processingAutostereogramViewpoints

The invention relates to a method of autostereoscopically displaying an N-viewpoint image on a screen having display pixels disposed in rows and columns, each display pixel presenting p>1 color points, corresponding to first, second, . . . , and pth color components, in which method the pixels of an autostereoscopic image to be displayed are displayed by distributing in space the p color points of each pixel amongst the color points of corresponding color components in p different display pixels, the method of the invention starting from a “high definition” autostereoscopic image presenting at least as many pixels having p color points as the N viewpoint image has color points to generate a said autostereoscopic image to be displayed in which each pixel is a color point of the corresponding color component of p different pixels in the high definition autostereoscopic image.

Owner:ALIOSCOPY +1

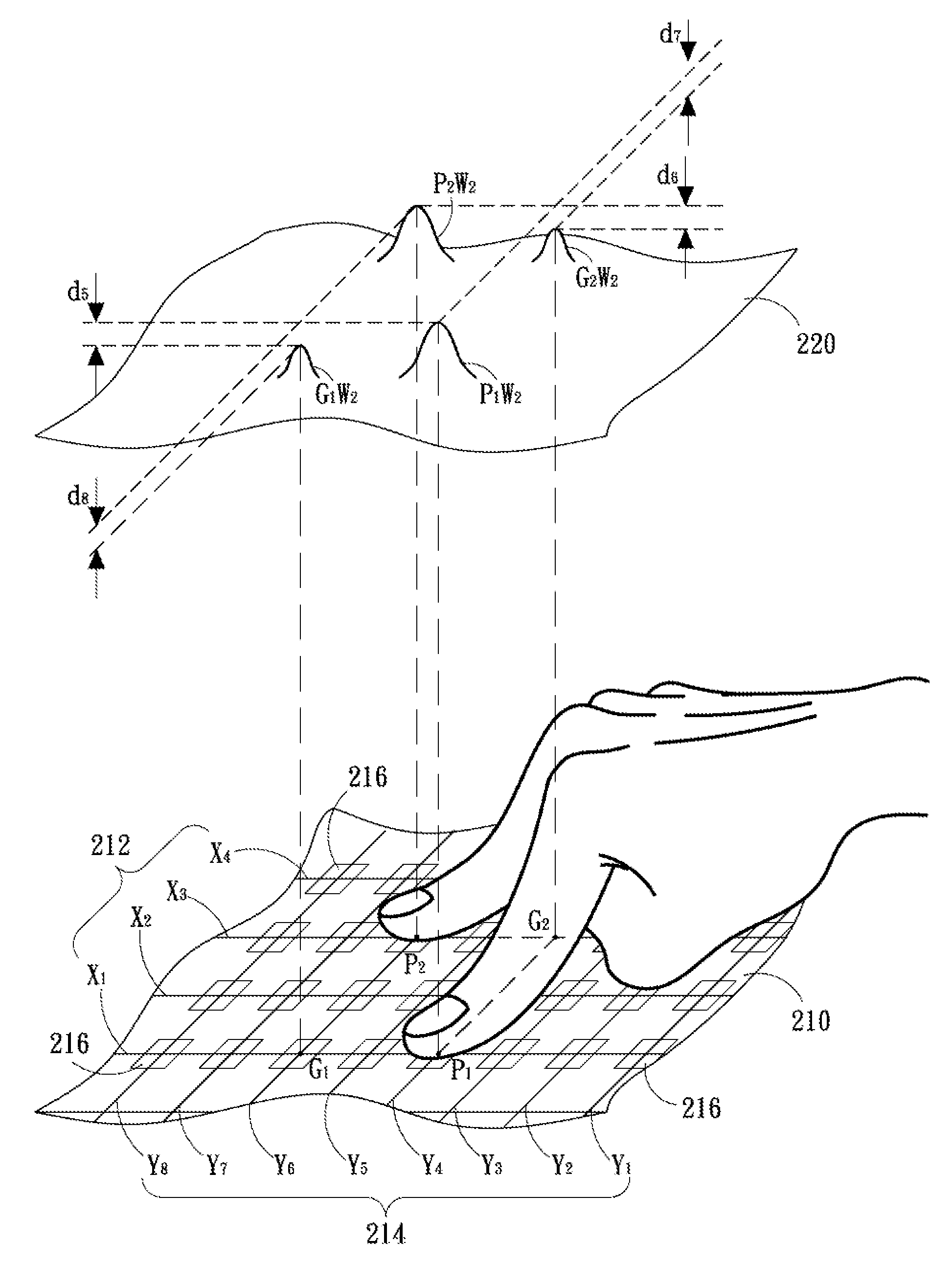

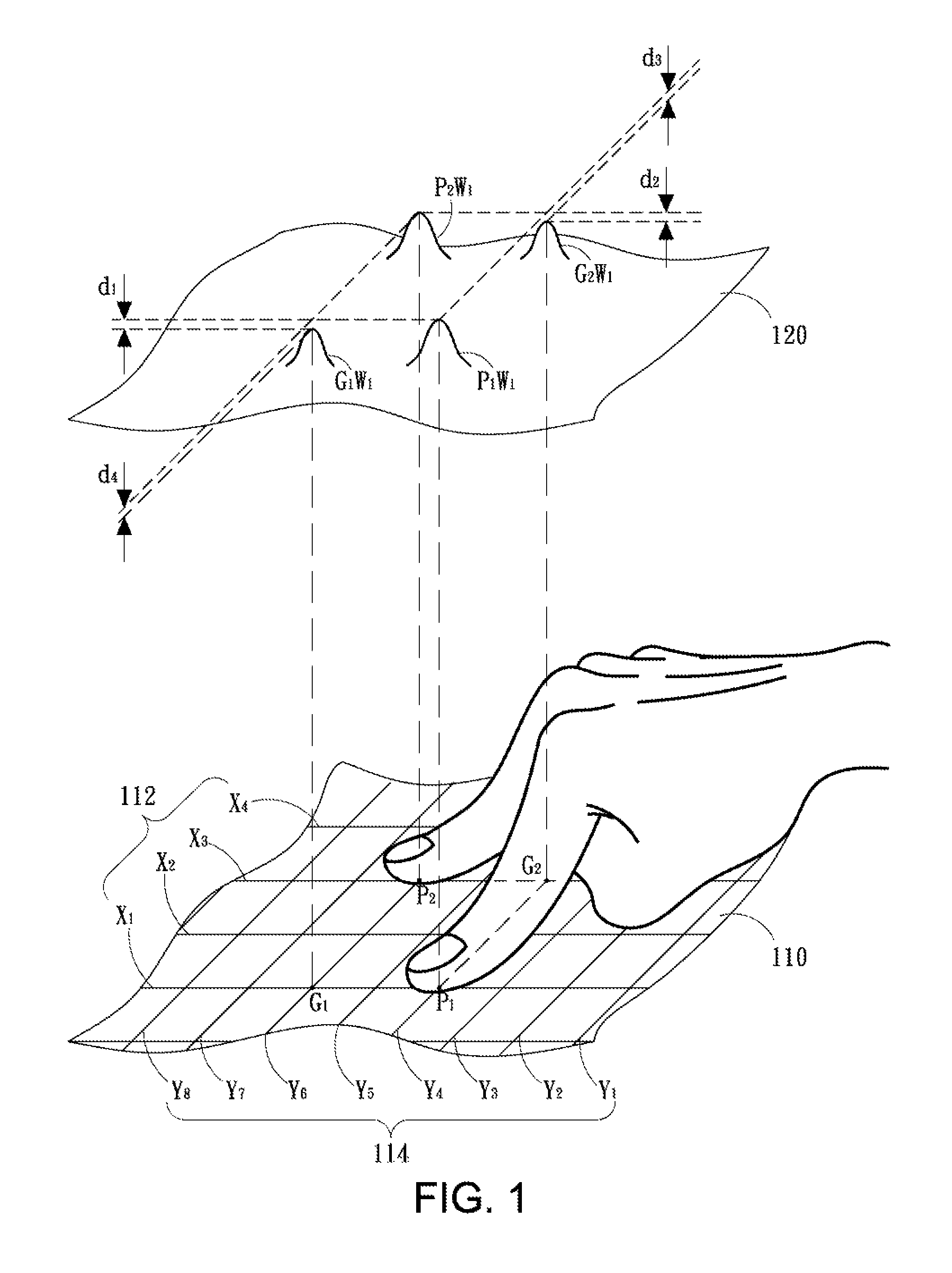

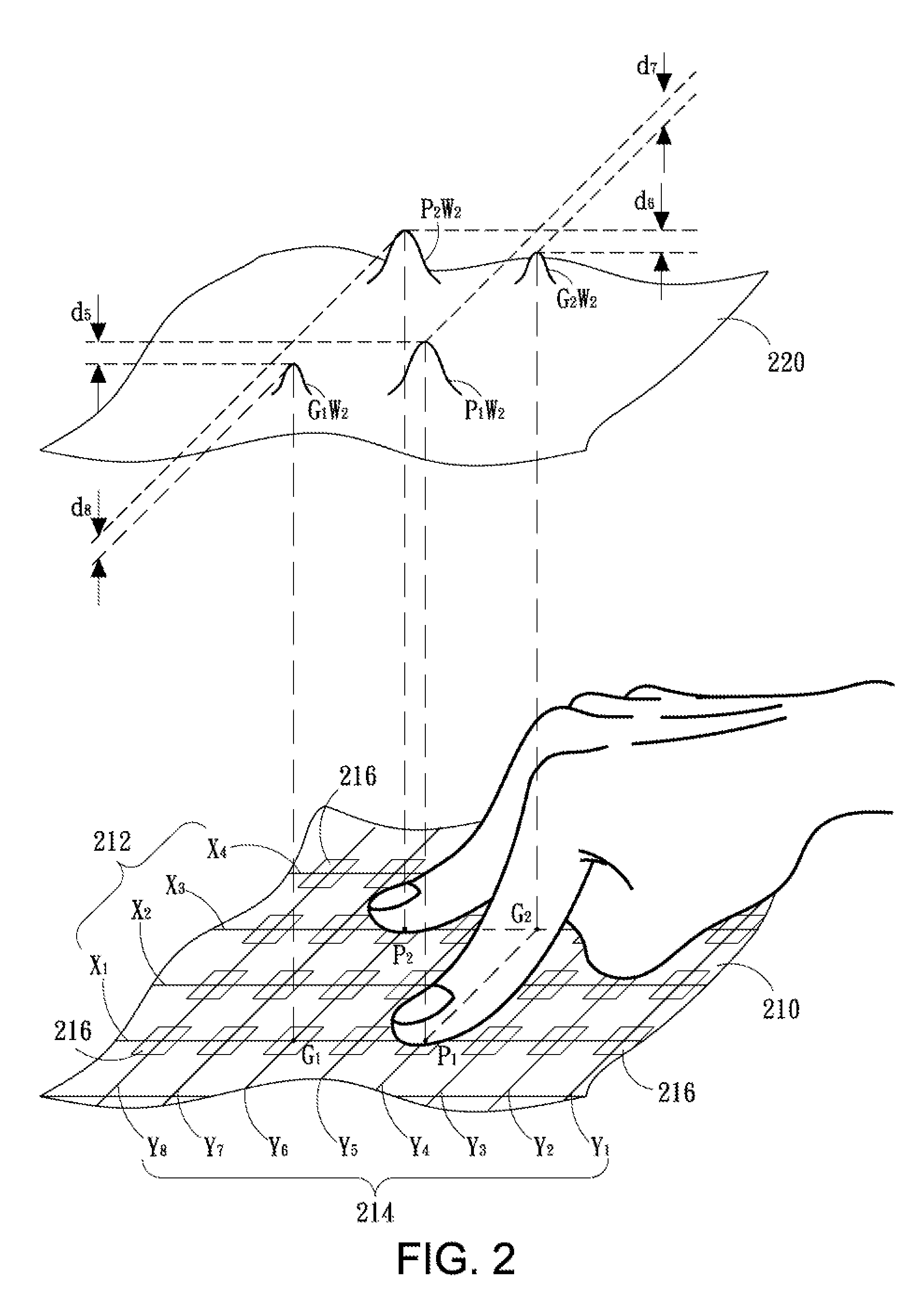

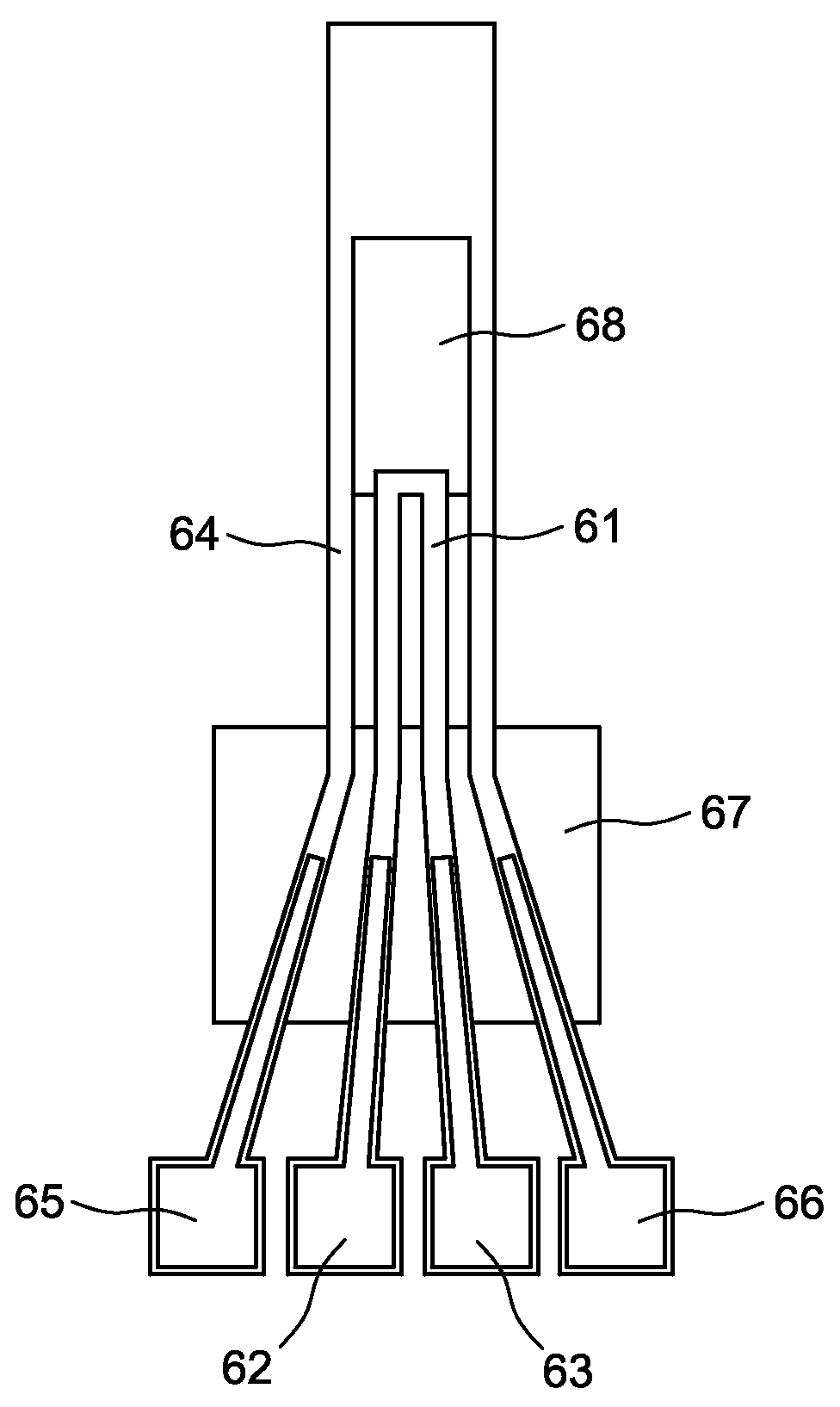

Method and device for capacitive sensing

ActiveUS20100007629A1Increase height differenceInput/output processes for data processingCapacitanceElectrical conductor

This invention discloses a capacitive sensing device. The device includes a plurality of first conductive lines electrically isolated from each other; a plurality of second conductive lines electrically isolated from each other and electrically isolated from and stacked with the first conductive lines to form a plurality of intersecting points; and a plurality of electrical conductors electrically isolated from each other and correspondingly crossing the first and the second conductive lines and being around the intersecting points, wherein the first and second conductive lines and the electrical conductors are electrically isolated from each other. By doing so, when an electrical signal is driven to any first conductive line, the first conductive line is capacitively coupled to the second conductive lines with which it intersects, and the electrical conductors crossing the first conductive line are respectively capacitively coupled to the first conductive line and the second conductive lines which intersect with the first conductive line to provide a higher compound capacitance.

Owner:EGALAX EMPIA TECH INC

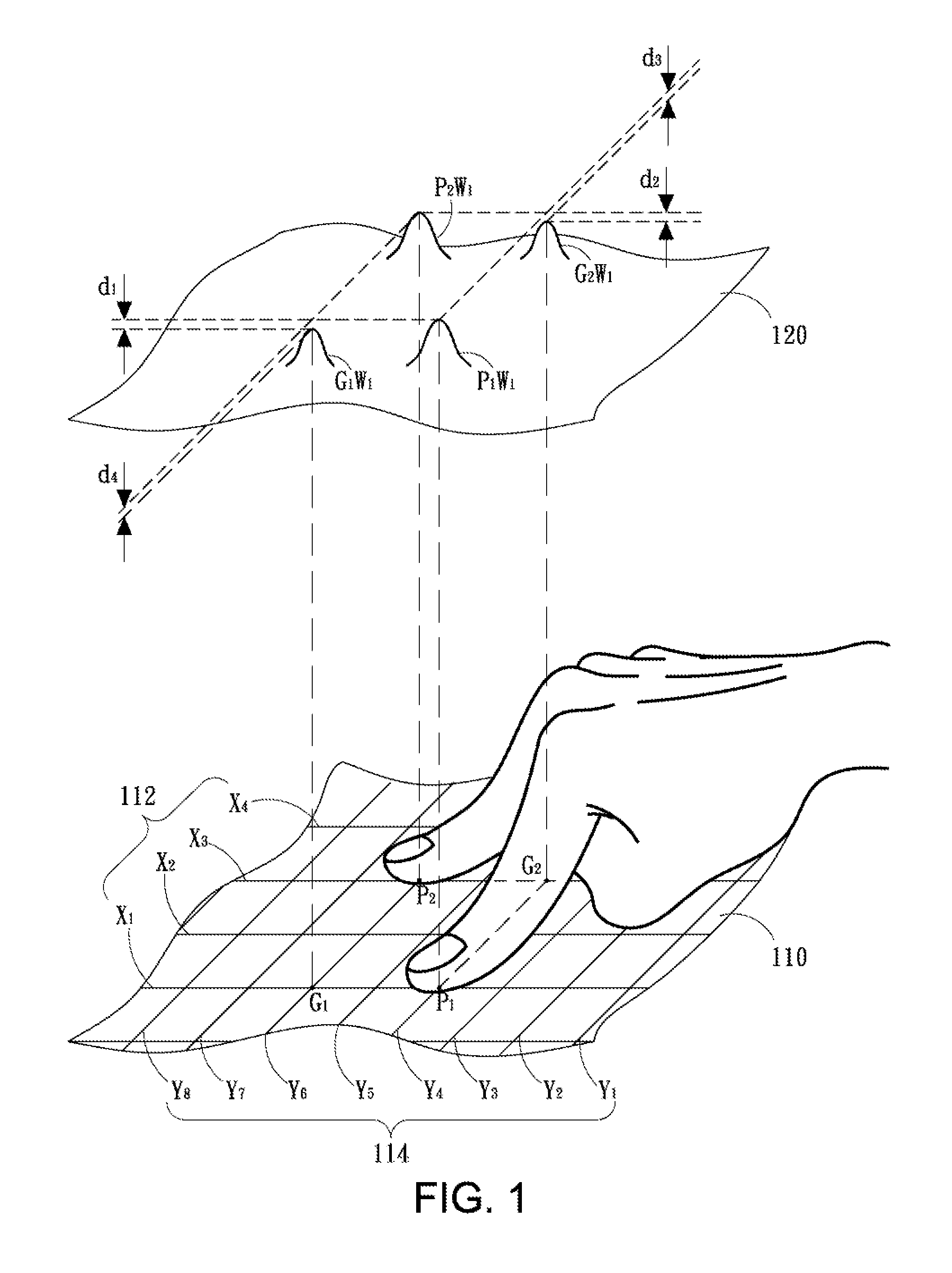

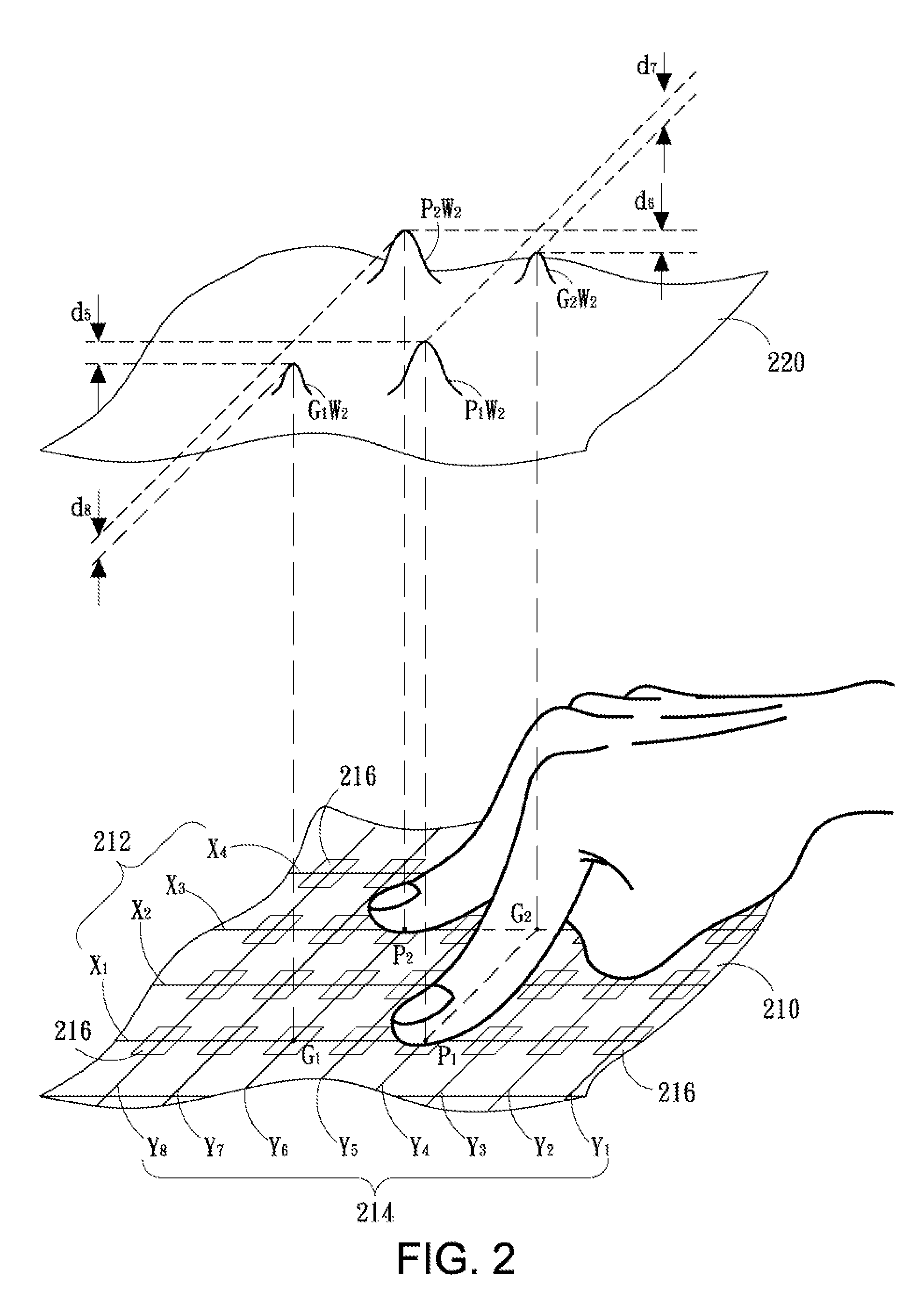

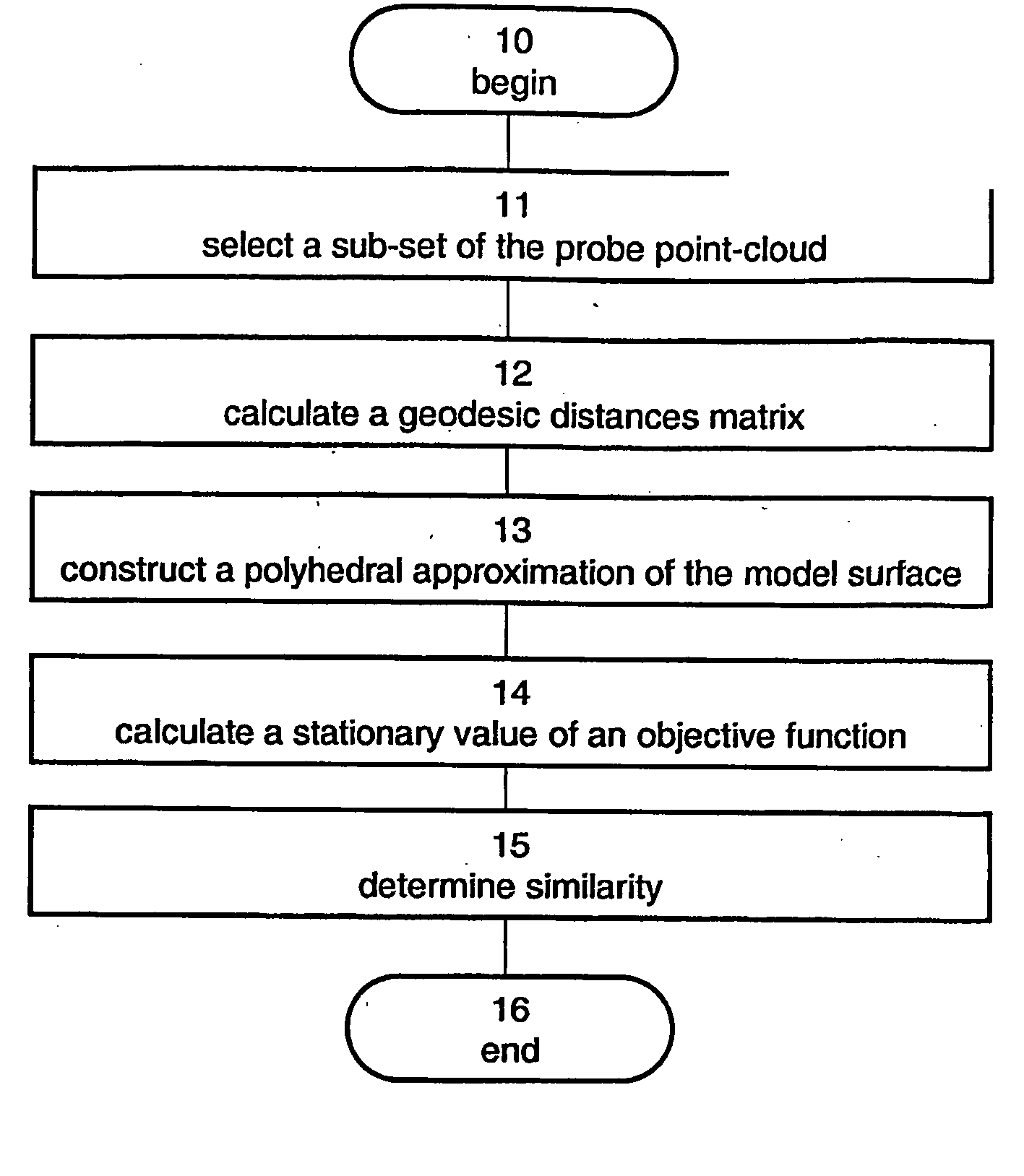

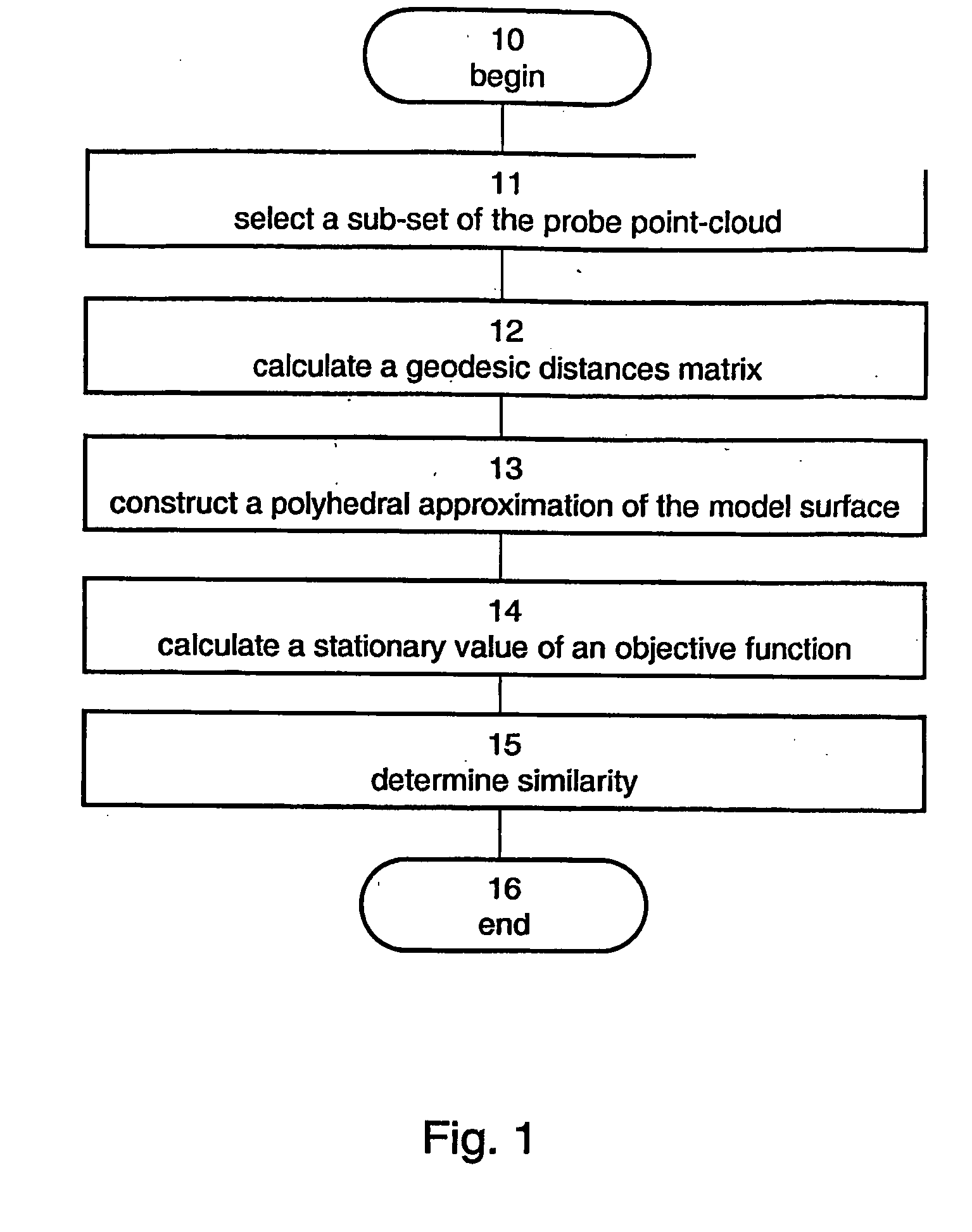

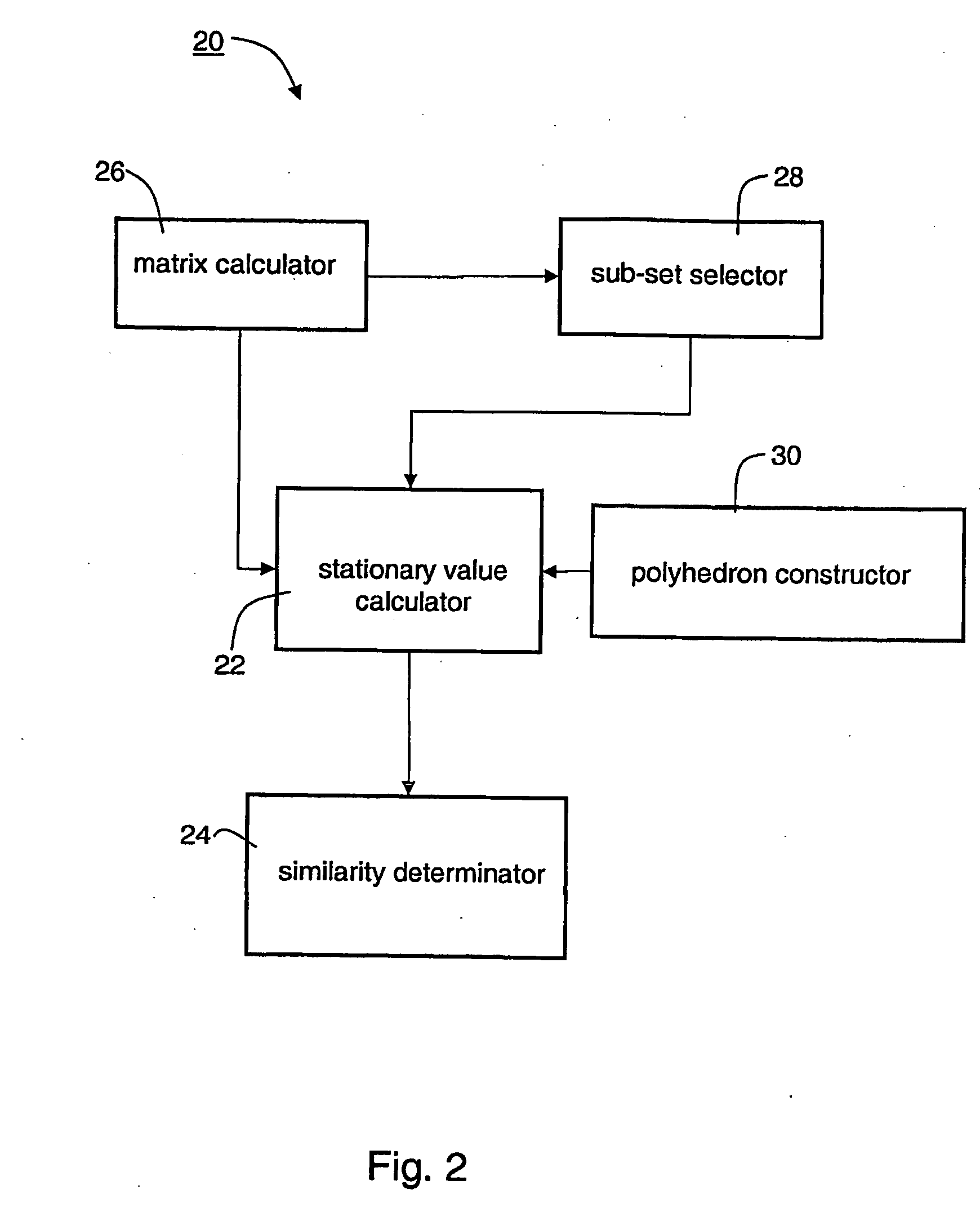

Method And Apparatus For Determining Similarity Between Surfaces

ActiveUS20090028442A1Increase height differenceThree-dimensional object recognitionPlanar modelEnvironmental geology

A method for determining similarity between a non-planar probe surface and a non-planar model surface is disclosed. The method comprises calculating an extremal value of an objective function describing embedding of the probe surface into an embedding space having a non-constant sectional curvature; and determining similarity between the probe surface and the model surface based on the extremal value.

Owner:TECHNION RES & DEV FOUND LTD +1

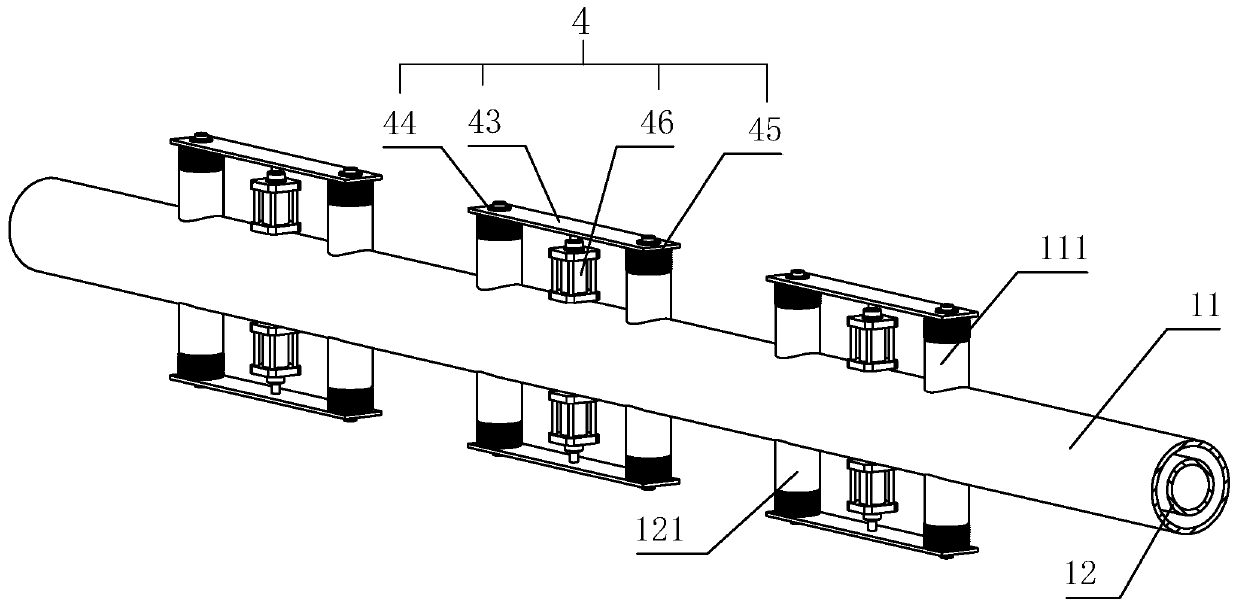

Method and device for capacitive sensing

ActiveUS20100007630A1Increase height differenceInput/output processes for data processingCapacitive couplingCapacitance

This invention discloses a capacitive sensing device. The device includes a plurality of first conductive lines electrically isolated from each other; a plurality of second conductive lines electrically isolated from each other and electrically isolated from and stacked with the first conductive lines to form a plurality of intersecting points; and a plurality of electrical conductors electrically isolated from each other and correspondingly crossing the first and the second conductive lines and being around the intersecting points, wherein the first and second conductive lines and the electrical conductors are electrically isolated from each other. By doing so, when an electrical signal is driven to any first conductive lines, the first conductive lines is capacitively coupled to the second conductive lines with which it intersects, and the electrical conductors crossing the first conductive lines are respectively capacitively coupled to the first conductive lines and the second conductive lines which intersect with the first conductive lines to provide a higher compound capacitance.

Owner:EGALAX EMPIA TECH INC

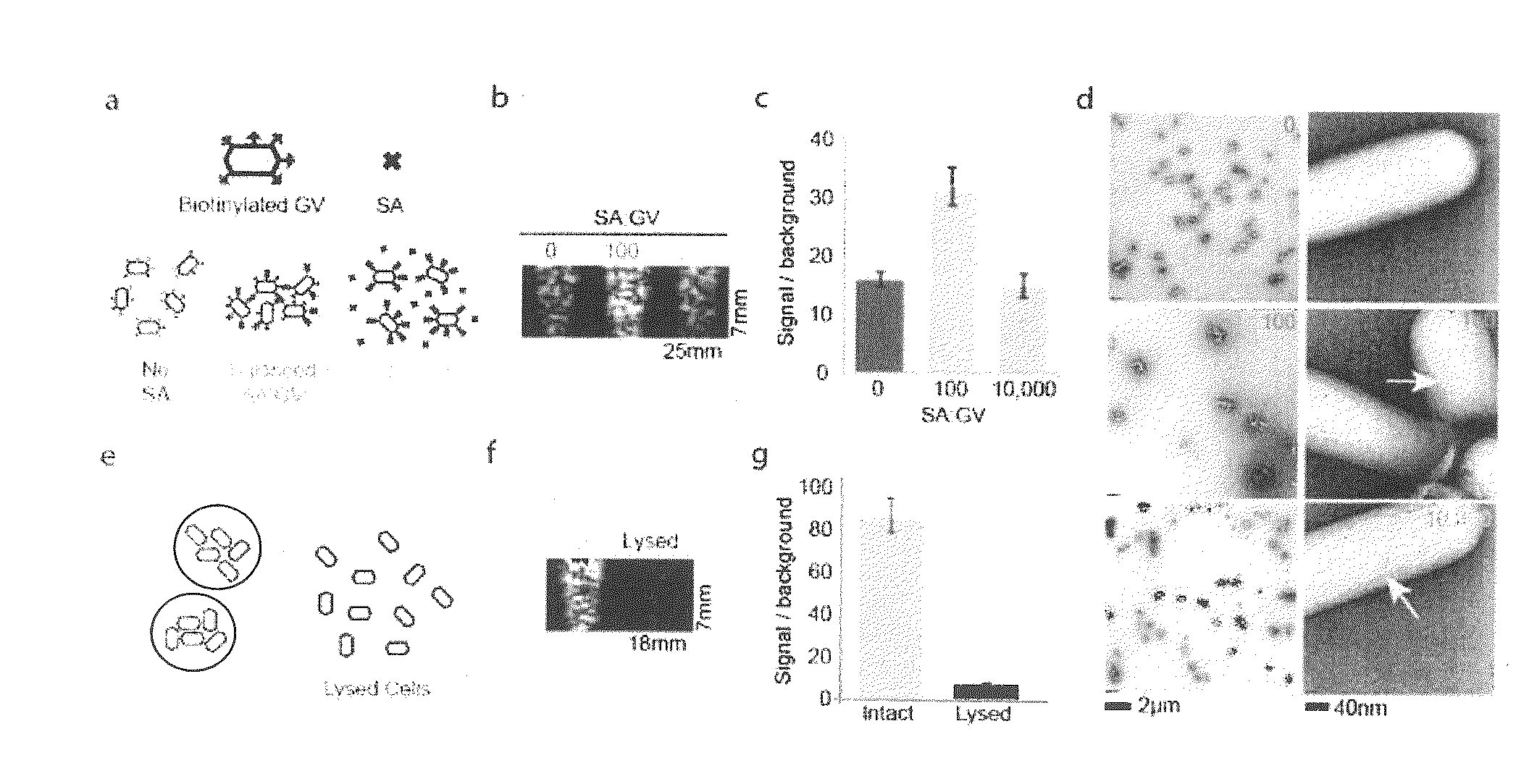

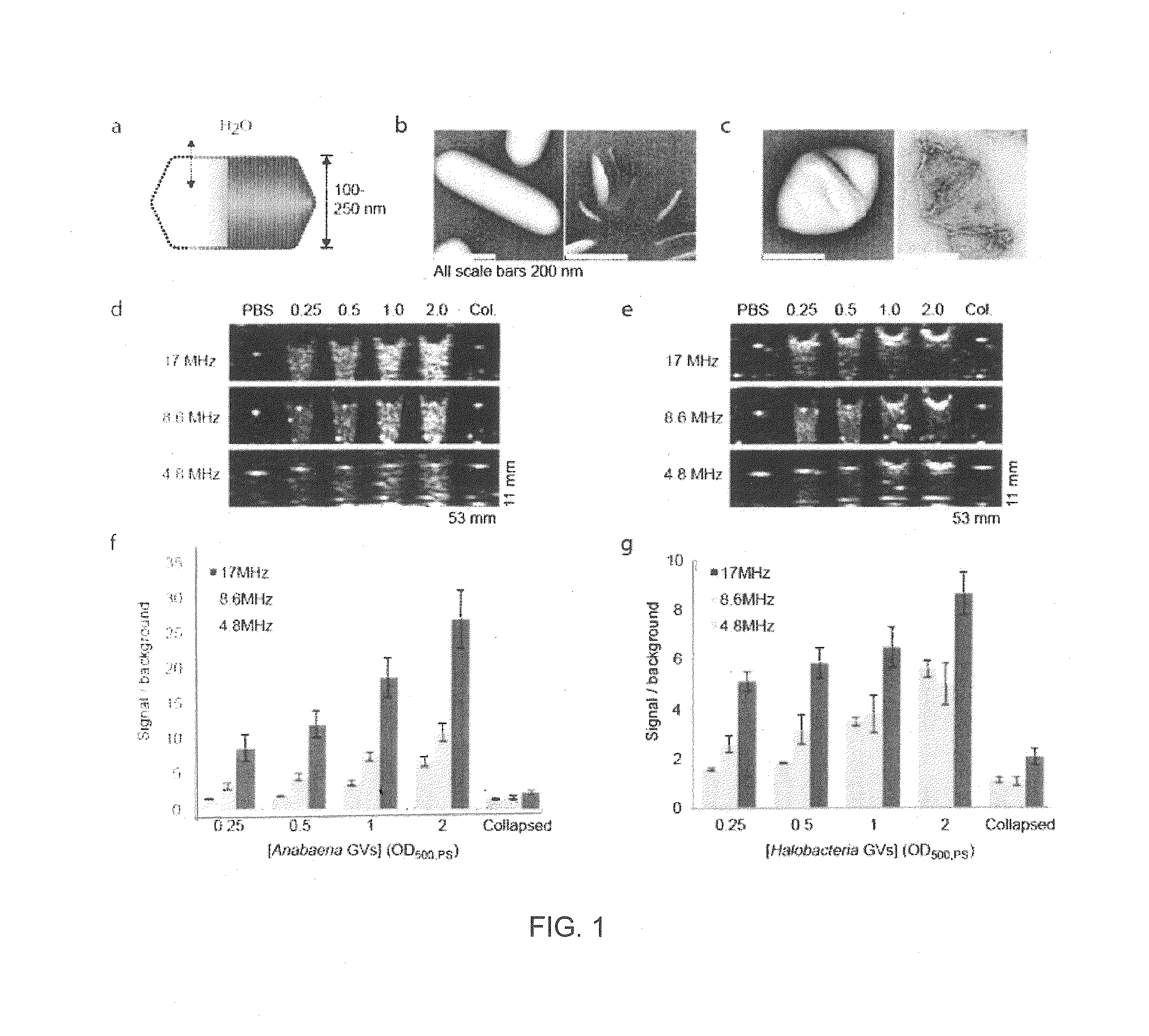

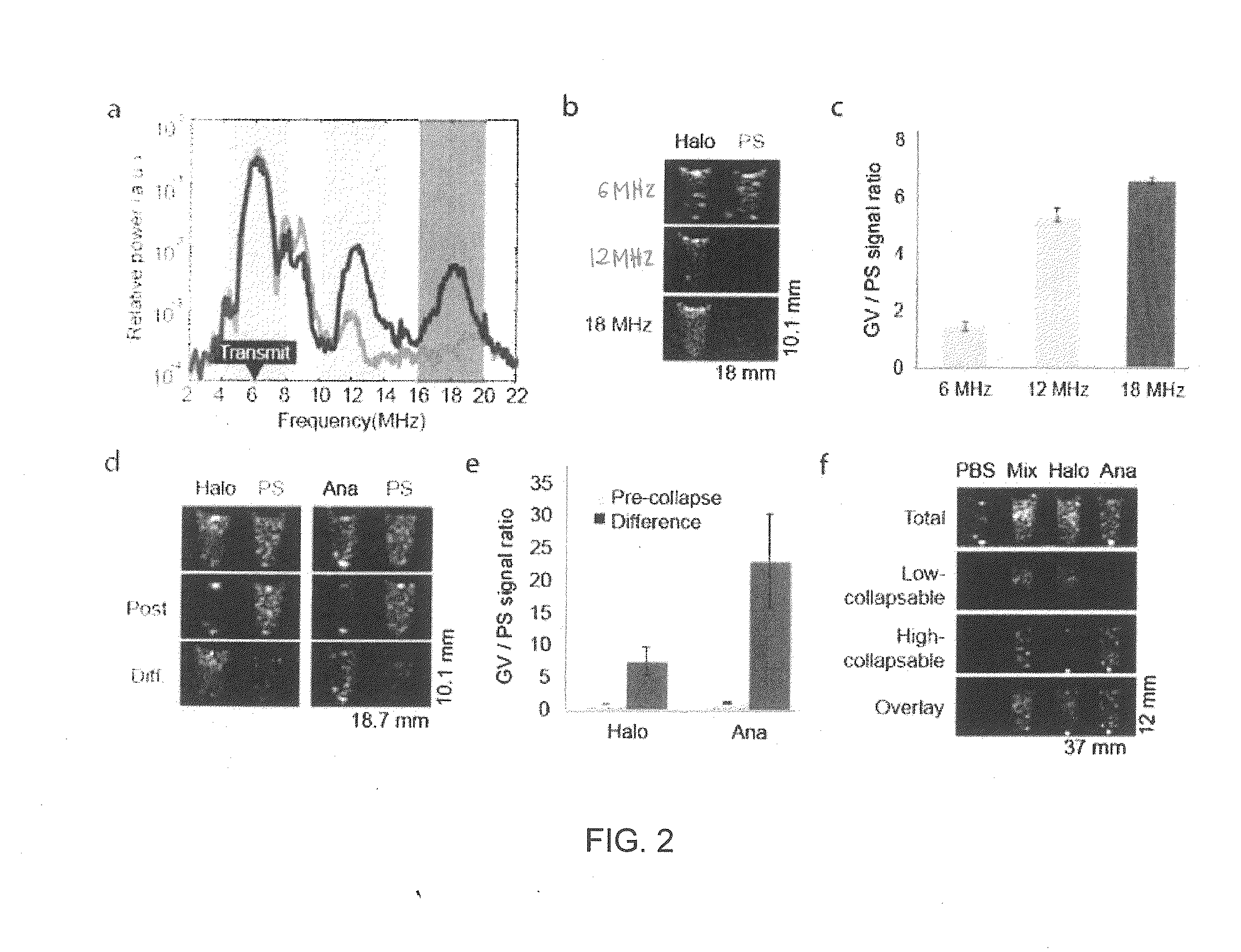

Gas vesicle ultrasound contrast agents and methods of using the same

InactiveUS20140288421A1Superior spatial and temporal resolutionLow costOrgan movement/changes detectionEchographic/ultrasound-imaging preparationsUltrasound imagingUltrasound contrast media

Provided are ultrasound imaging methods that include administering to a subject a contrast agent that includes a plurality of collapsible gas vesicles, obtaining ultrasound data of a target site of interest, and analyzing the ultrasound data to produce an ultrasound image of the target site. Ultrasound contrast agents are also provided. The subject methods and contrast agents find use in ultrasound imaging applications.

Owner:RGT UNIV OF CALIFORNIA

Method of catastrophic transfer of a thin film after co-implantation

ActiveUS7772087B2Reduce roughnessHigh mechanical stressSemiconductor/solid-state device manufacturingCo implantationAtomic physics

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

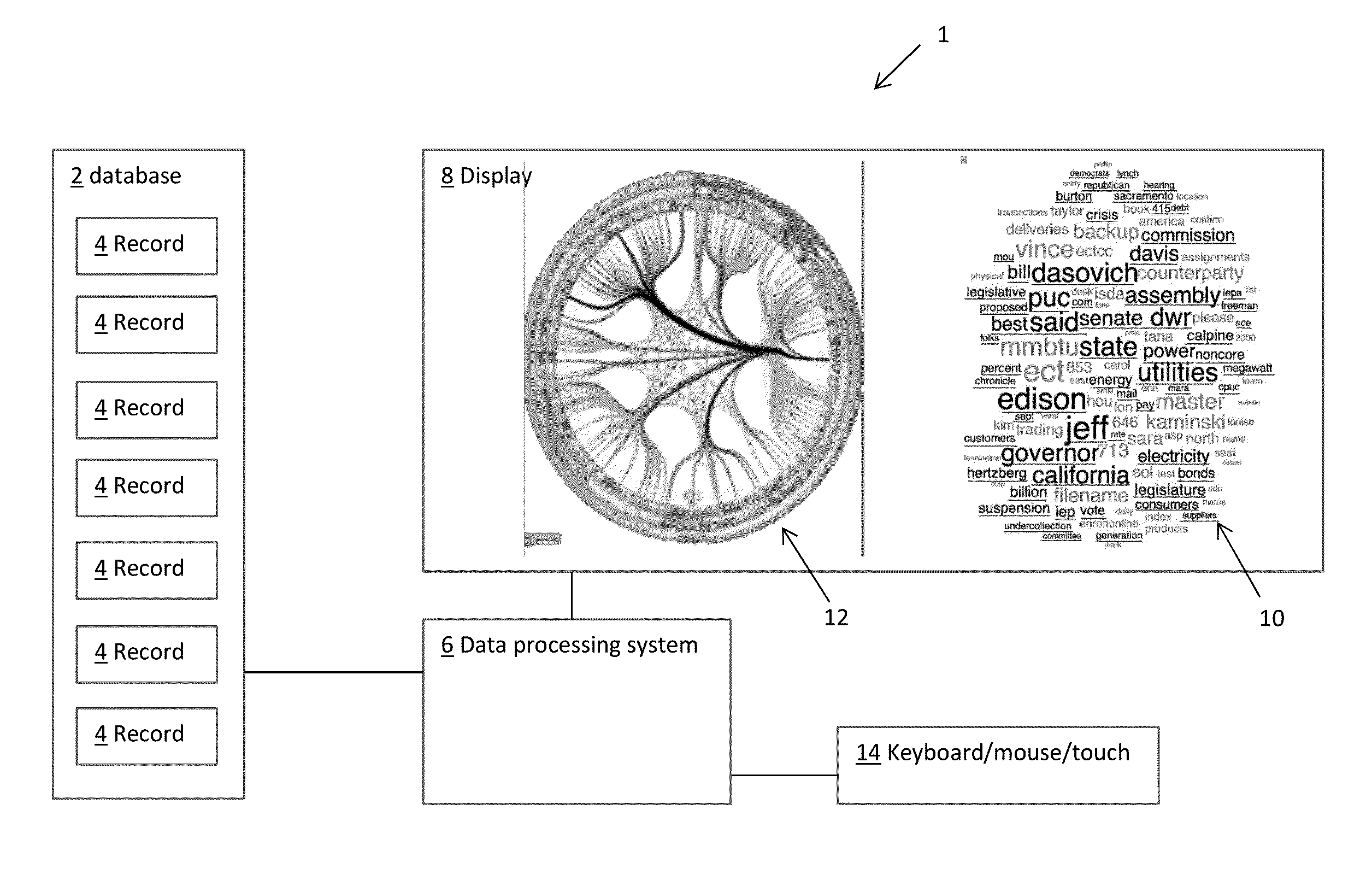

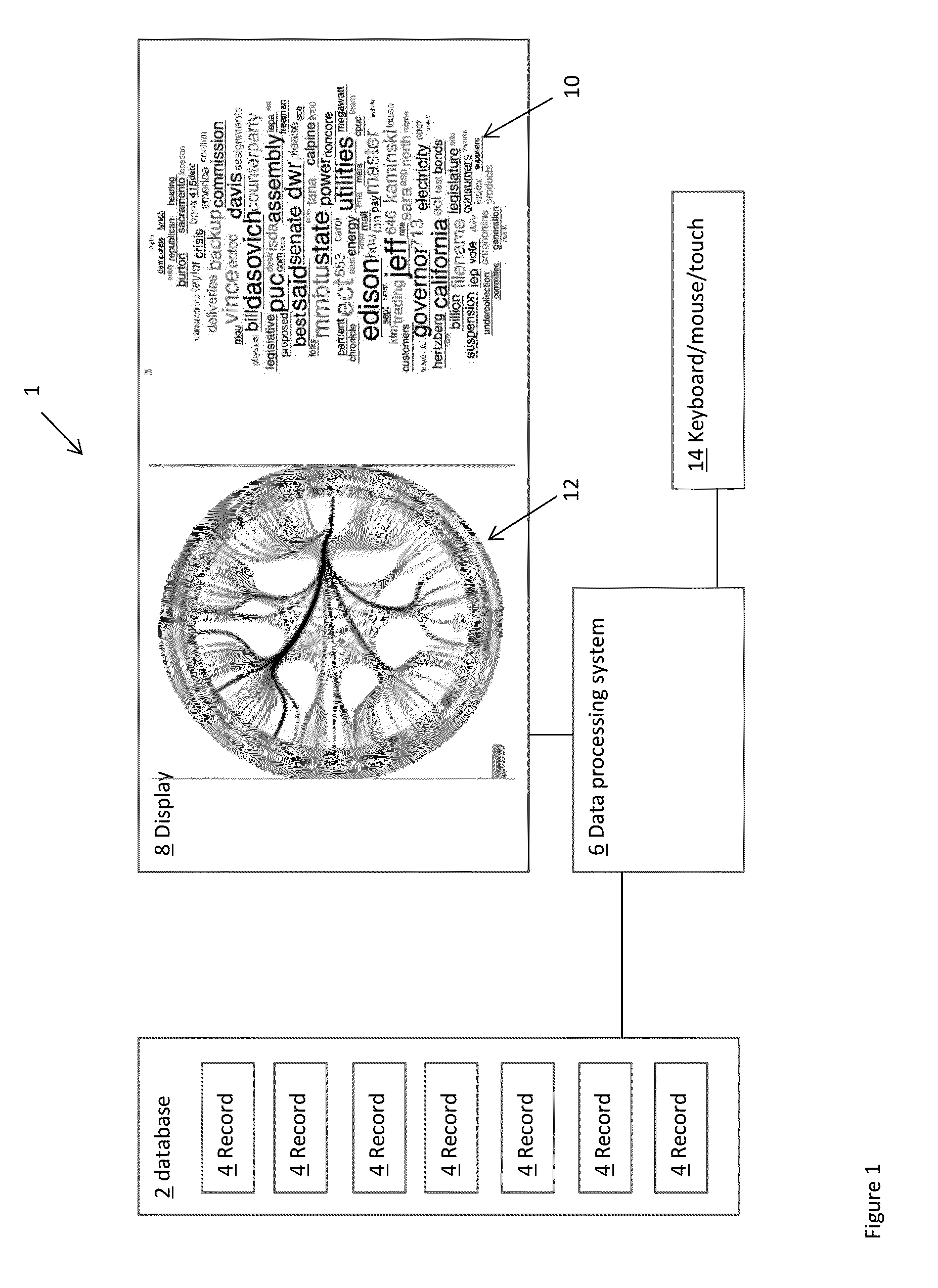

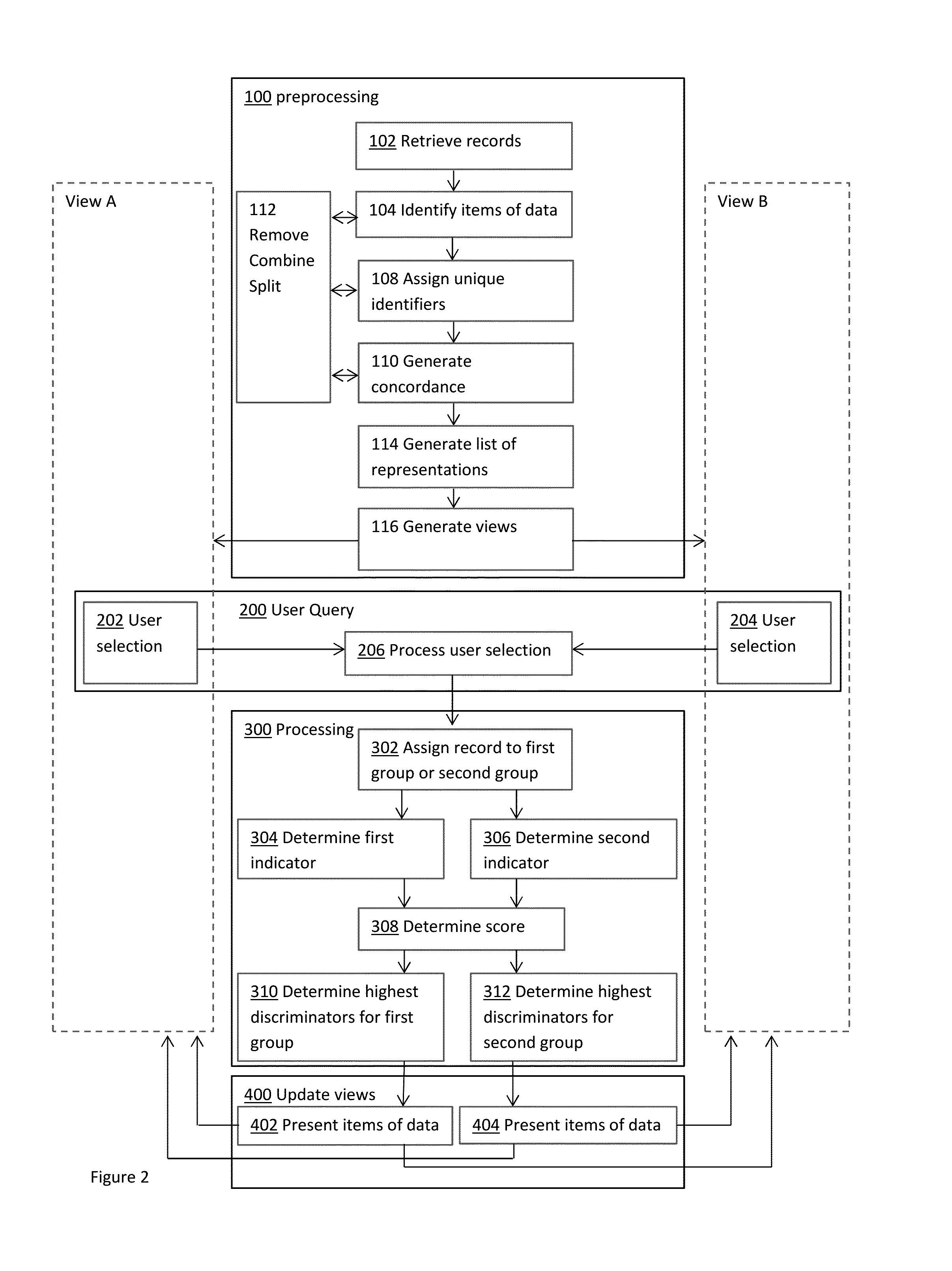

Computer implemented method and device for ranking items of data

ActiveUS20150347558A1Improve query efficiencyEliminate needDigital data processing detailsRelational databasesData storingData mining

A computer implemented method of ranking items of data stored in a database comprising a plurality of records, wherein each record is associated with one or more items of data. The method includes generating a concordance of the items of data associated with the records in the database. Each record is assigned to a first group of records or to a second group of records. For each item of data a first indicator is determined representative of its occurrences in the records of the first group. For each item of data a second indicator is determined representative of its occurrences in the records of the second group. For each item of data a score is determined representative of a discriminative power of that item of data on the basis of the first and second indicator of that item of data.

Owner:SYNERSCOPE

Method and device for capacitive sensing

ActiveUS8531429B2Increase height differenceTransmission systemsInput/output processes for data processingCapacitanceElectrical conductor

The disclosed capacitive sensing device has first conductive lines, second conductive lines and electrical conductors. The first conductive lines are electrically isolated from each other, the second conductive lines are electrically isolated from each other and electrically isolated from and stacked with the first conductive lines to form numerous intersecting points, and the electrical conductors are electrically isolated from each other and correspondingly crossing the first and the second conductive lines and being around the intersecting points. Herein, the electrical conductors are electrically isolated from the first and second conductive lines. When an electrical signal is driven to a first conductive line, the first conductive line is capacitively coupled to the second conductive lines which intersecting mutually, and the electrical conductors crossing the first conductive line are respectively capacitively coupled to the first conductive line and the mutually intersecting second conductive lines to provide a higher compound capacitance.

Owner:EGALAX EMPIA TECH INC

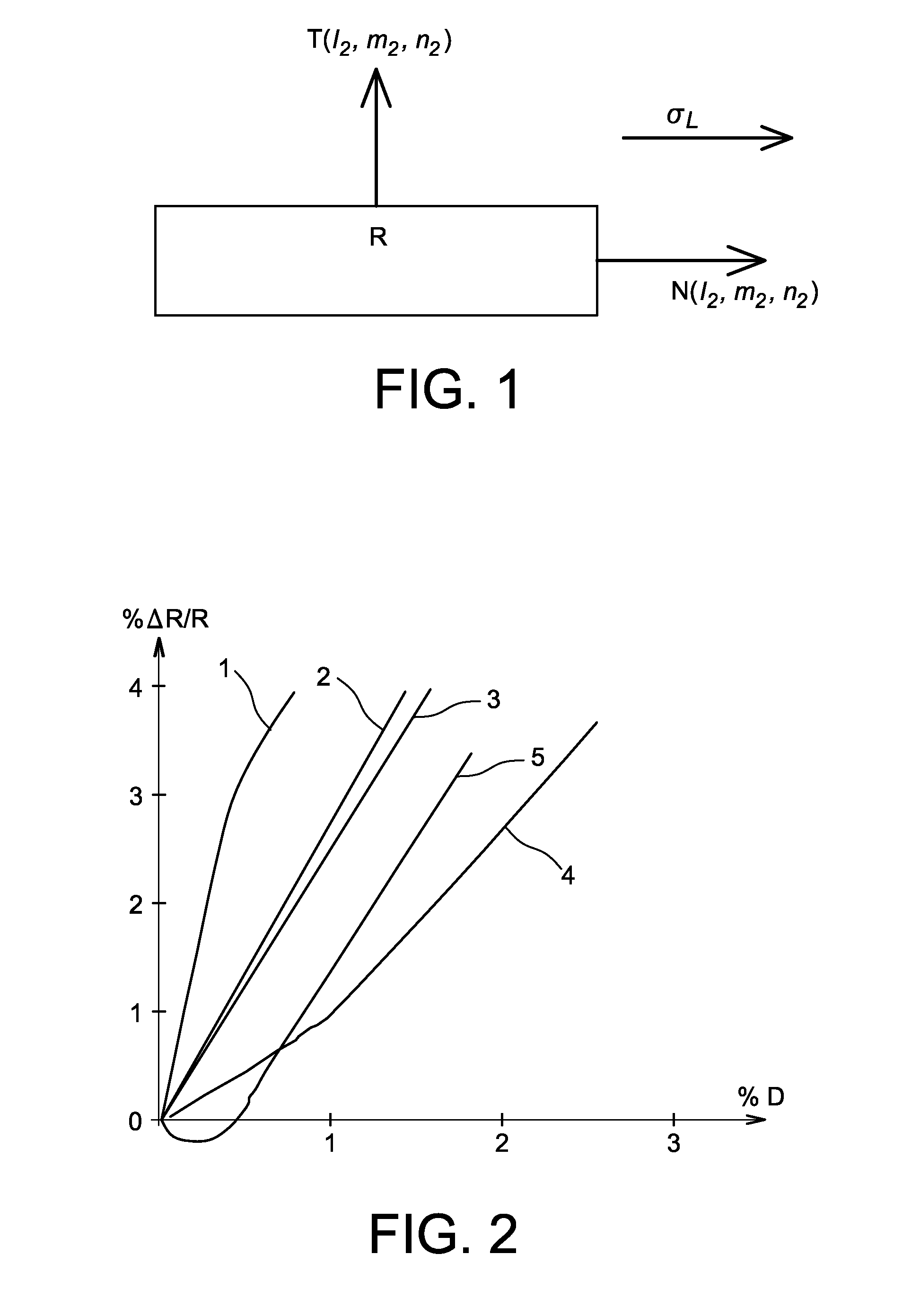

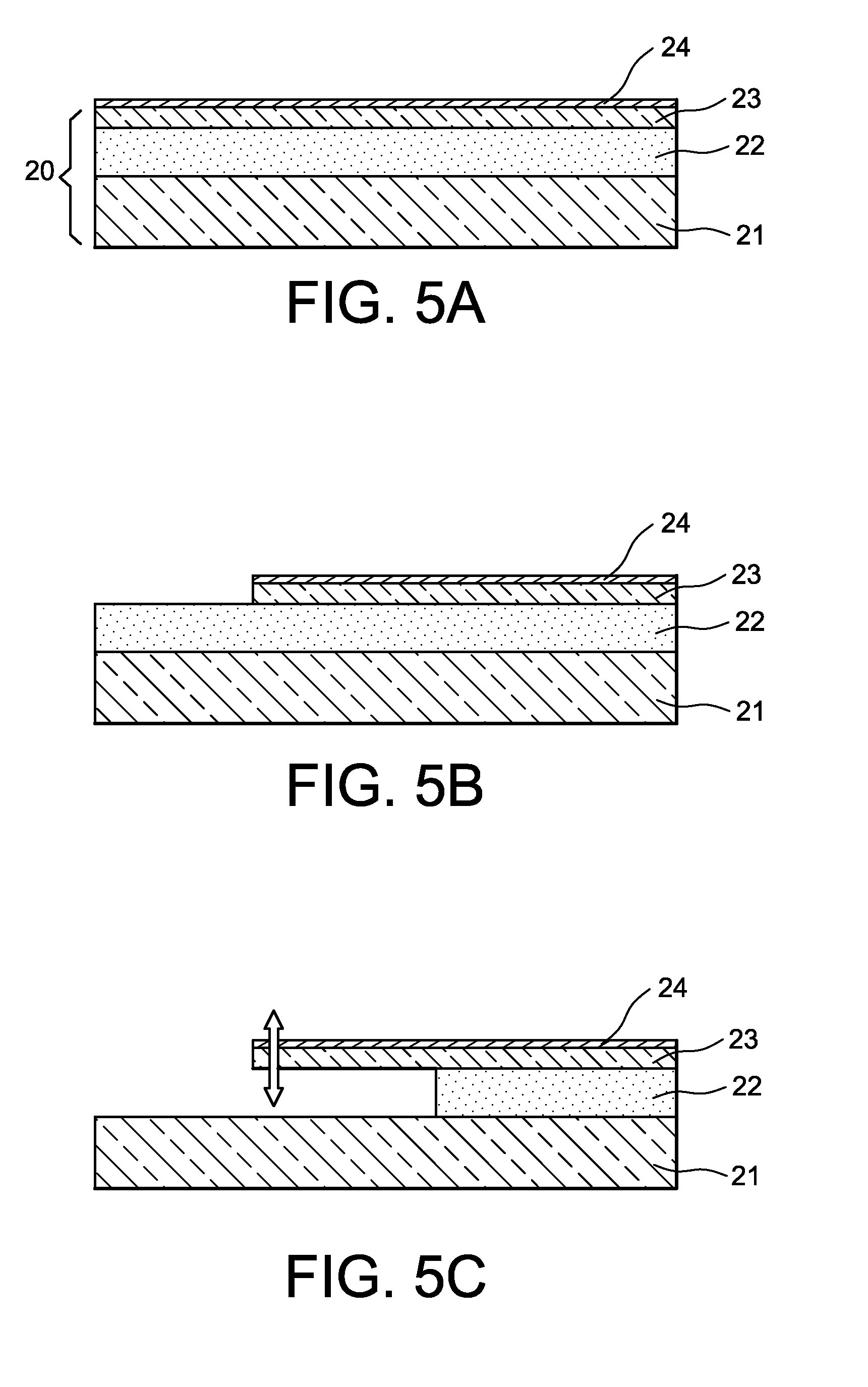

NEMS comprising alsi alloy based transduction means

ActiveUS20120272742A1High sensitivityReduce sizeMaterial analysis using sonic/ultrasonic/infrasonic wavesAcceleration measurementAlloyEngineering

The invention relates to a nano electro- mechanical system (NEMS) formed on a substrate (21) and comprising at least one fixed part associated with the substrate and at least one movable part (23) in relation to the substrate, said system comprising transduction means (24) capable of exciting the movable part to confer on it a movement and / or to detect a movement of movable part, the transduction means comprising at least one electrically conductive material. The electrically conductive material is made of an AlSi alloy based deposition, said deposition being supported at least in part by the movable part of the system.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

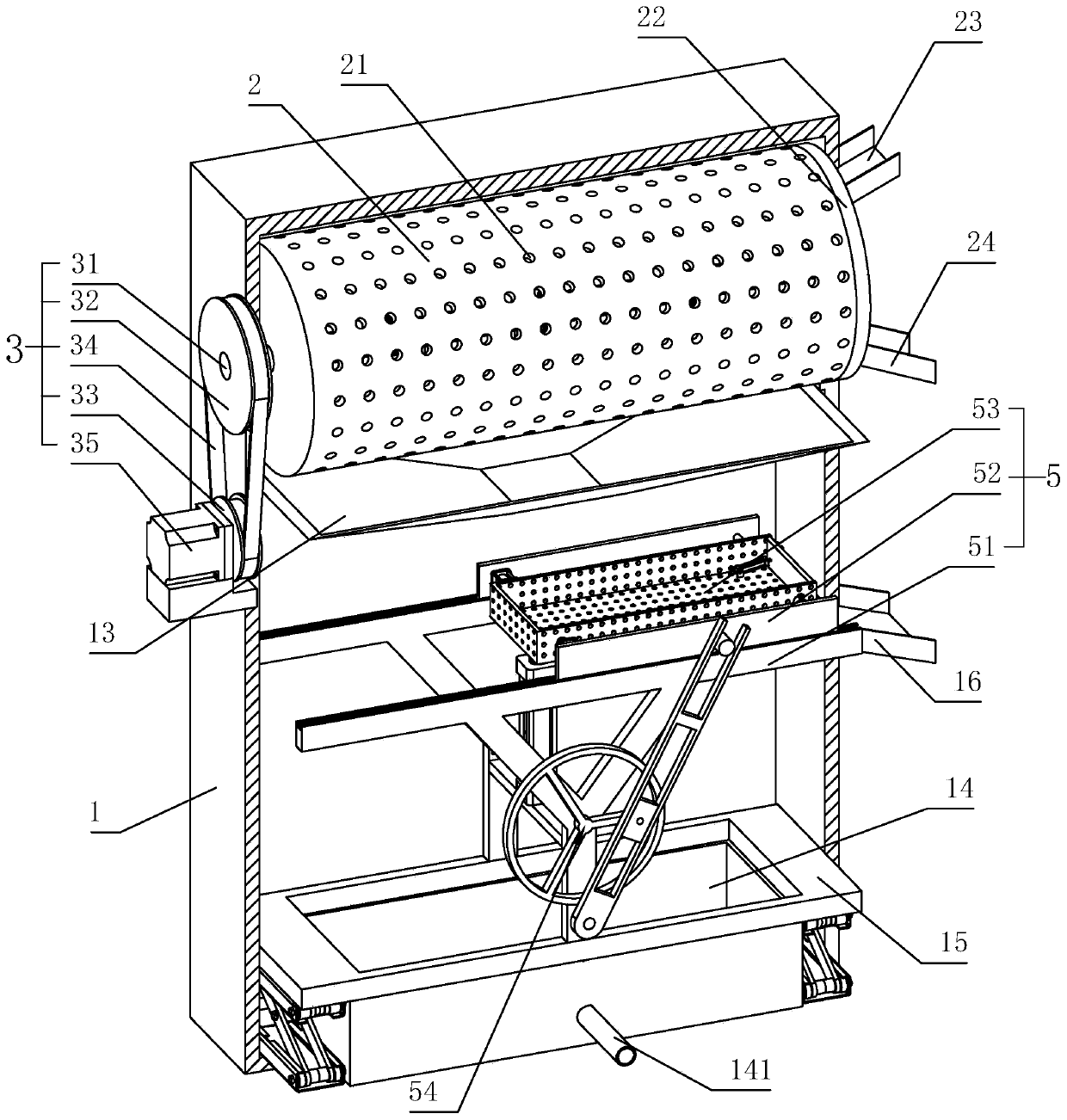

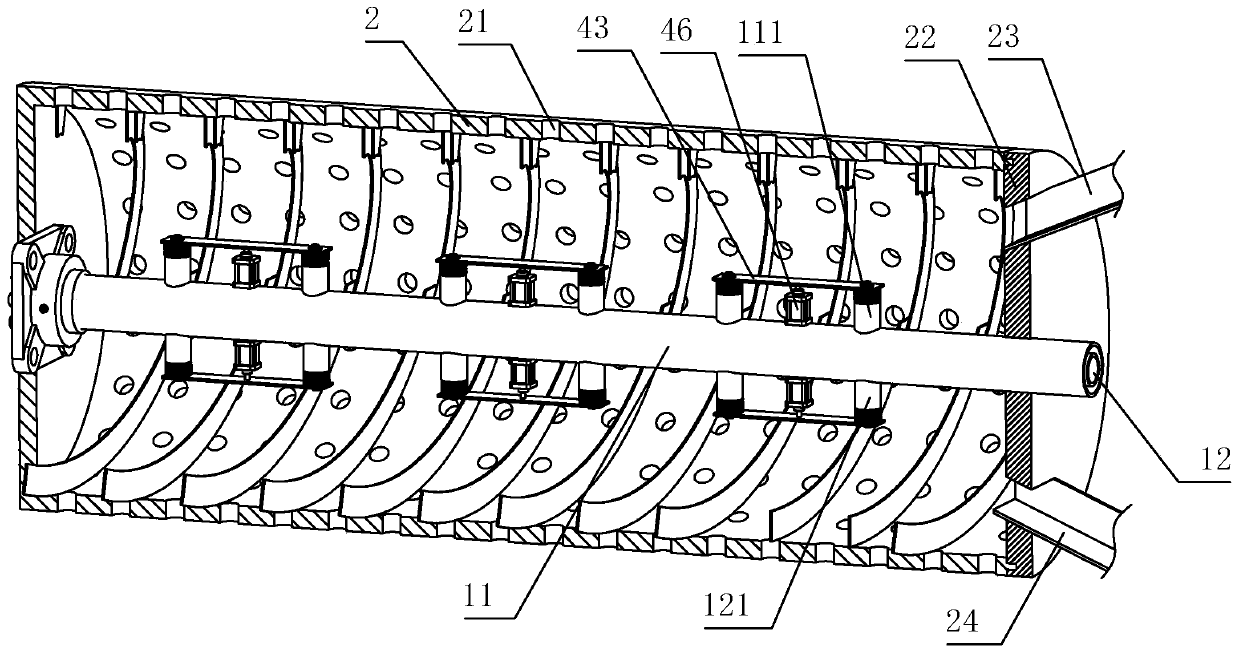

Sand and stone separator

The invention relates to a sand and stone separator. The sand and stone separator comprises a shell, a roller rotationally connected to the shell and provided with an opening in one end, a first driving assembly for driving the roller to rotate and a sealing plate fixedly connected to the shell and rotationally connected to the end, provided with the opening, of the roller, the sealing plate is provided with a feeding hopper and a stone discharging hopper located below the feeding hopper, first screening holes for only allowing sand to pass through are formed in the side wall of the roller, spiral material pushing blades are arranged on the inner side wall of the roller, the shell is provided with a flow guide groove located below the roller, a sand dewatering mechanism located below the flow guide groove and a paste water collecting groove located below the sand dewatering mechanism, the sand dewatering mechanism comprises supporting frames located on the two sides of the paste watercollecting groove correspondingly, sliding pieces connected to the supporting frames in a sliding mode in the horizontal direction, screening grooves formed in the sliding pieces and second driving assemblies for driving the sliding pieces to move back and forth, and second screening holes for only allowing cement paste water to pass through are formed in the screening grooves. The sand and stoneseparator has the effect of increasing the separation rate of the sand, the stone and the cement paste water.

Owner:杭州金鼎实业有限公司

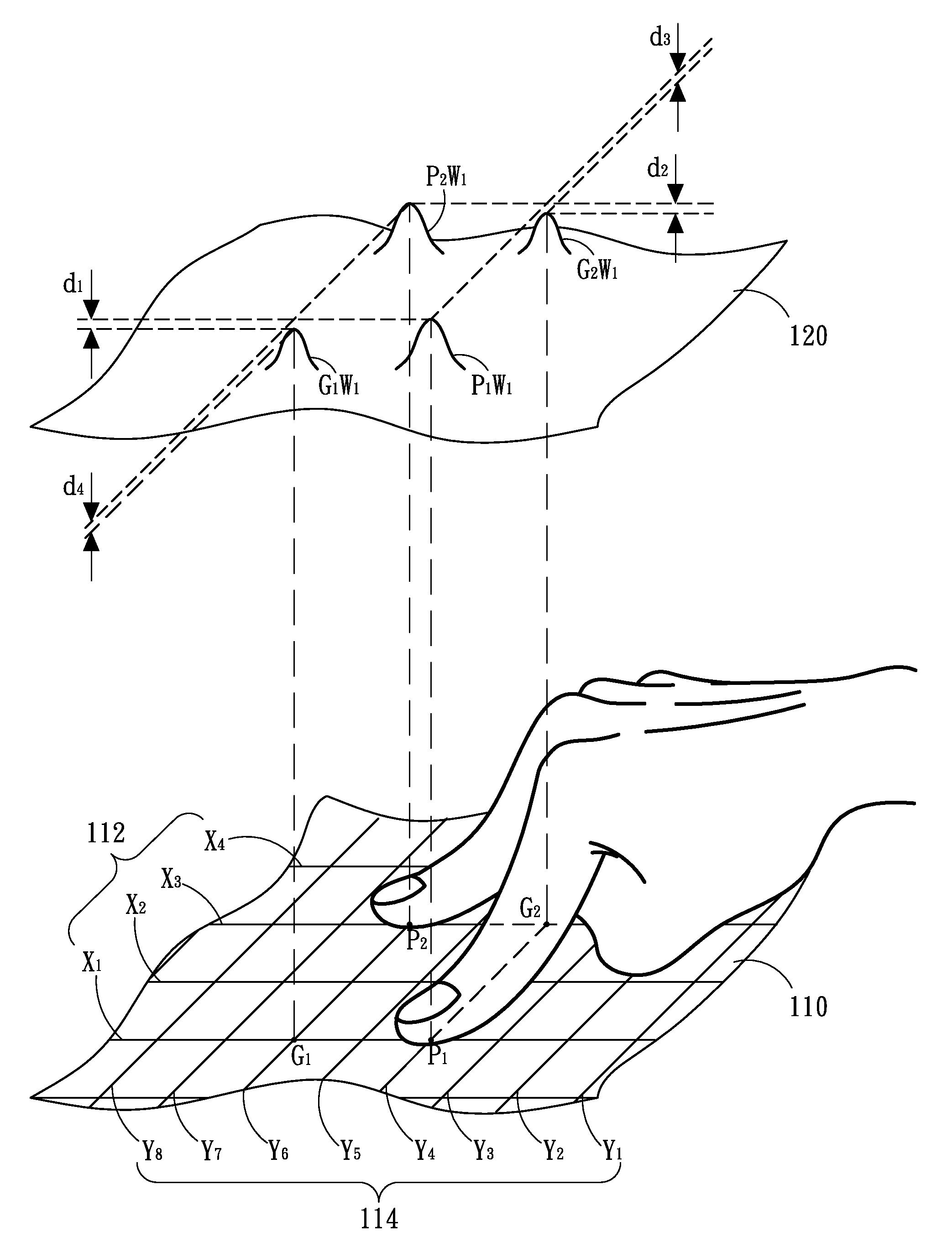

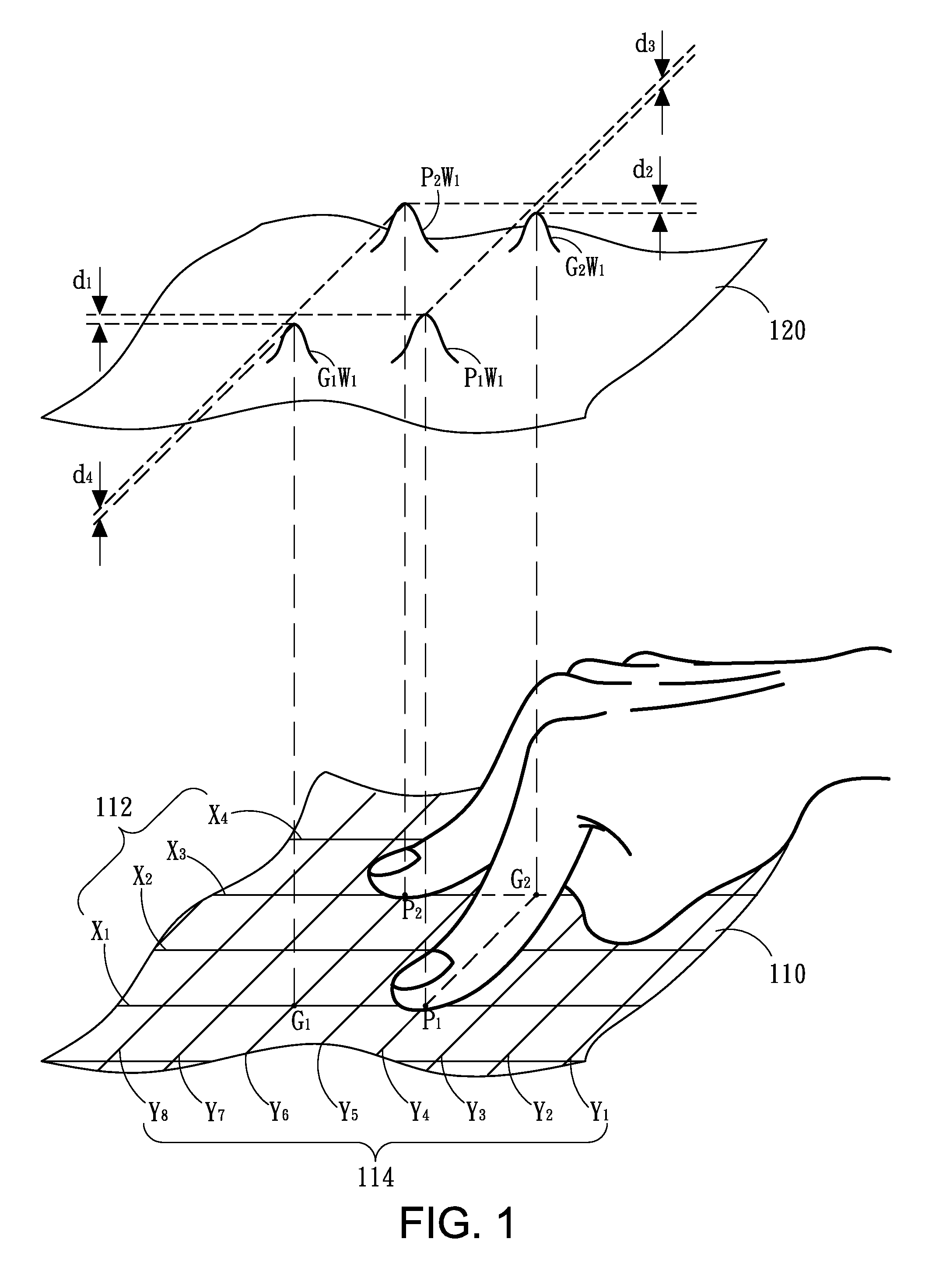

Apparatus and method for improving the quality of a picture having a high illumination difference

InactiveUS7450782B2Improve picture qualityIncrease height differenceTelevision system detailsCharacter and pattern recognitionIlluminanceReconstruction method

An apparatus and image reconstruction method for use in an apparatus including a digital camera are provided. The apparatus and method include driving an image sensor during a short exposure time in an image reconstruction mode, driving the image sensor during a relatively-long exposure time in the image reconstruction mode, and acquiring first and second frame images having different illumination degrees; assigning substantially identical image data of the first and second frame images to local images each having a predetermined size; calculating local variance values of image data of each of the local areas; comparing a local variance value of the first frame image with a local variance value of the second frame images, assigning a high weight to one local image having a high local variance value, and assigning a low weight to the other local image having a low local variance value; applying the determined weights to image data of individual local areas of the first and second frame images, performing image reconstruction, and displaying a reconstructed image.

Owner:SAMSUNG ELECTRONICS CO LTD

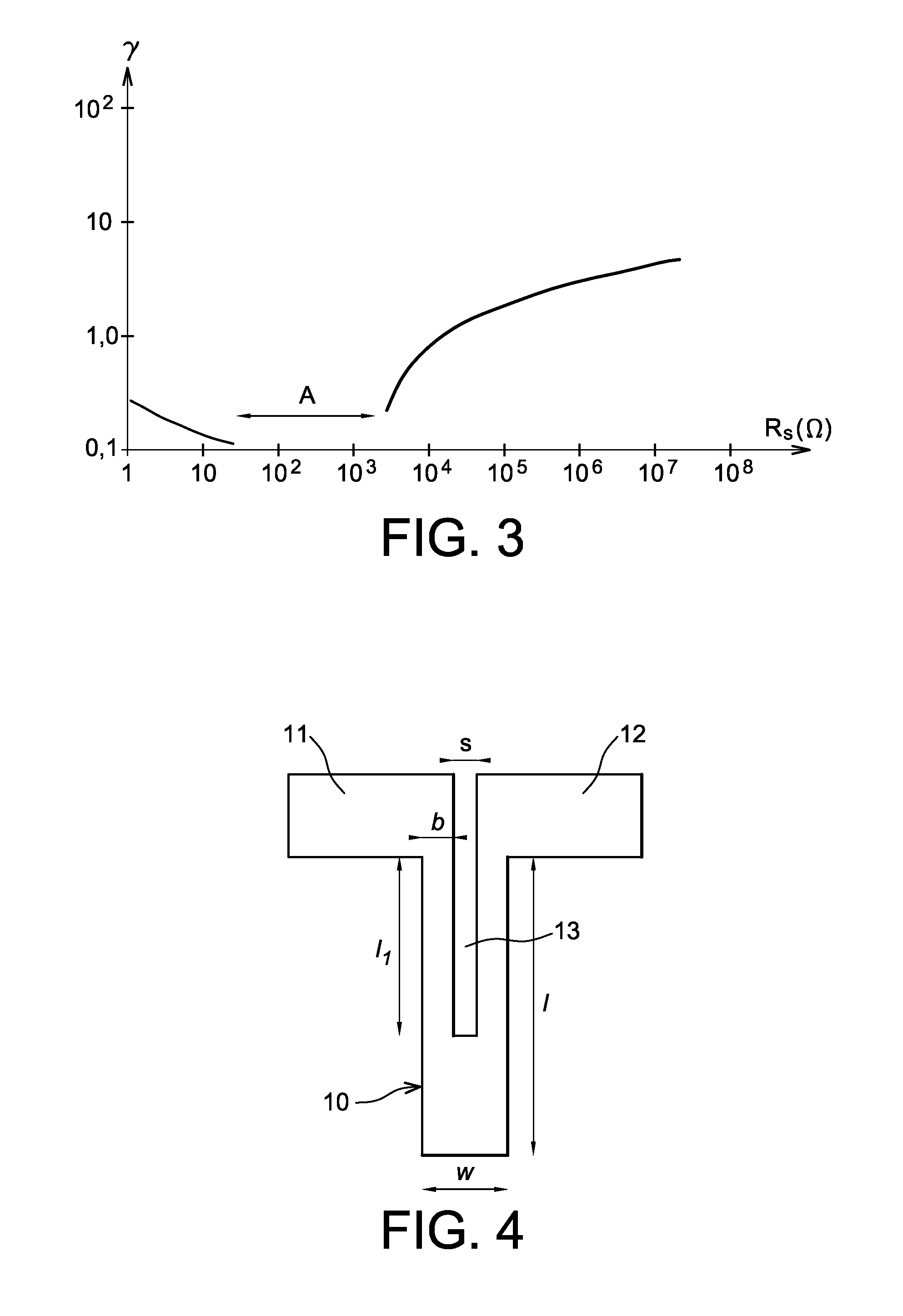

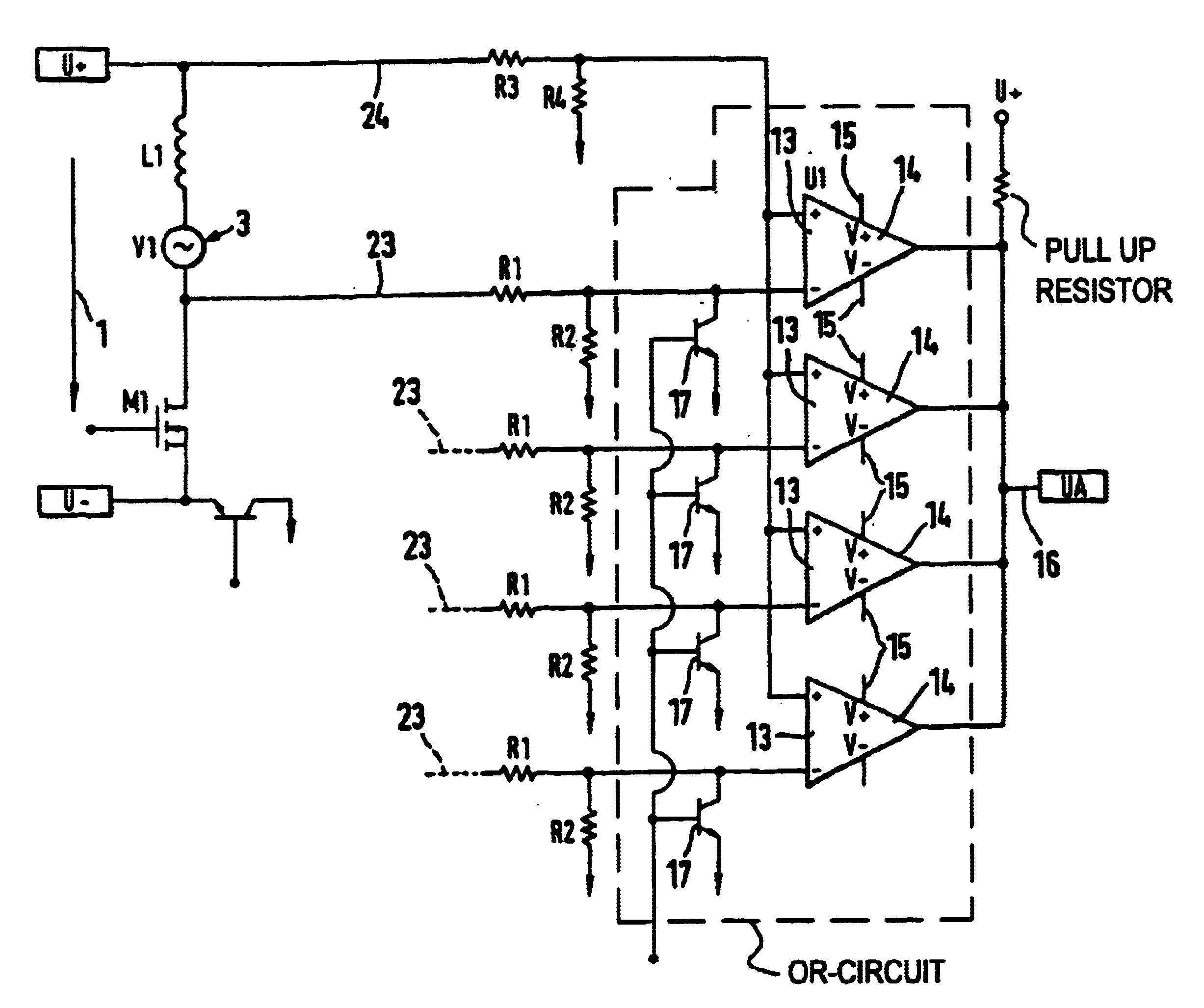

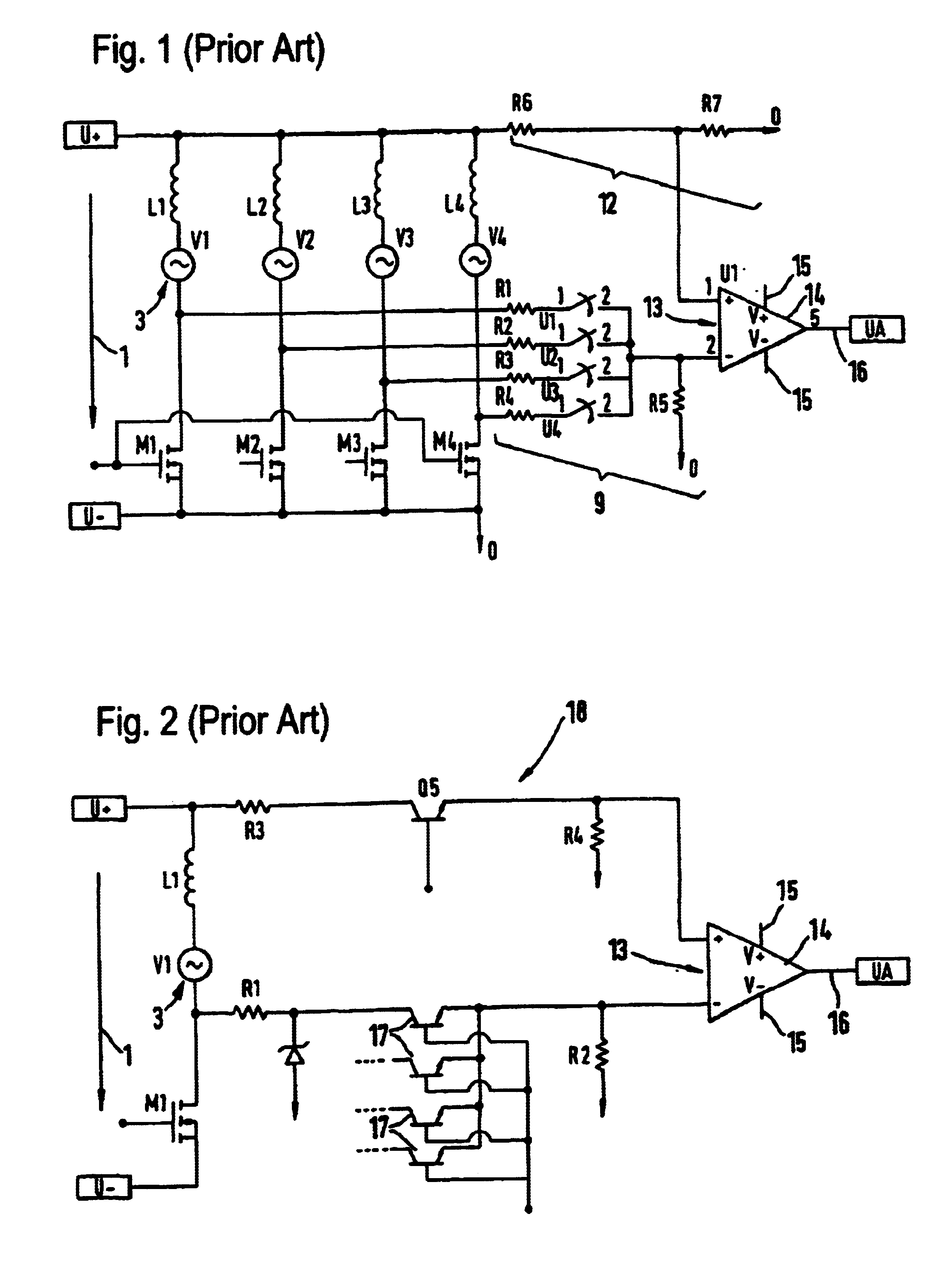

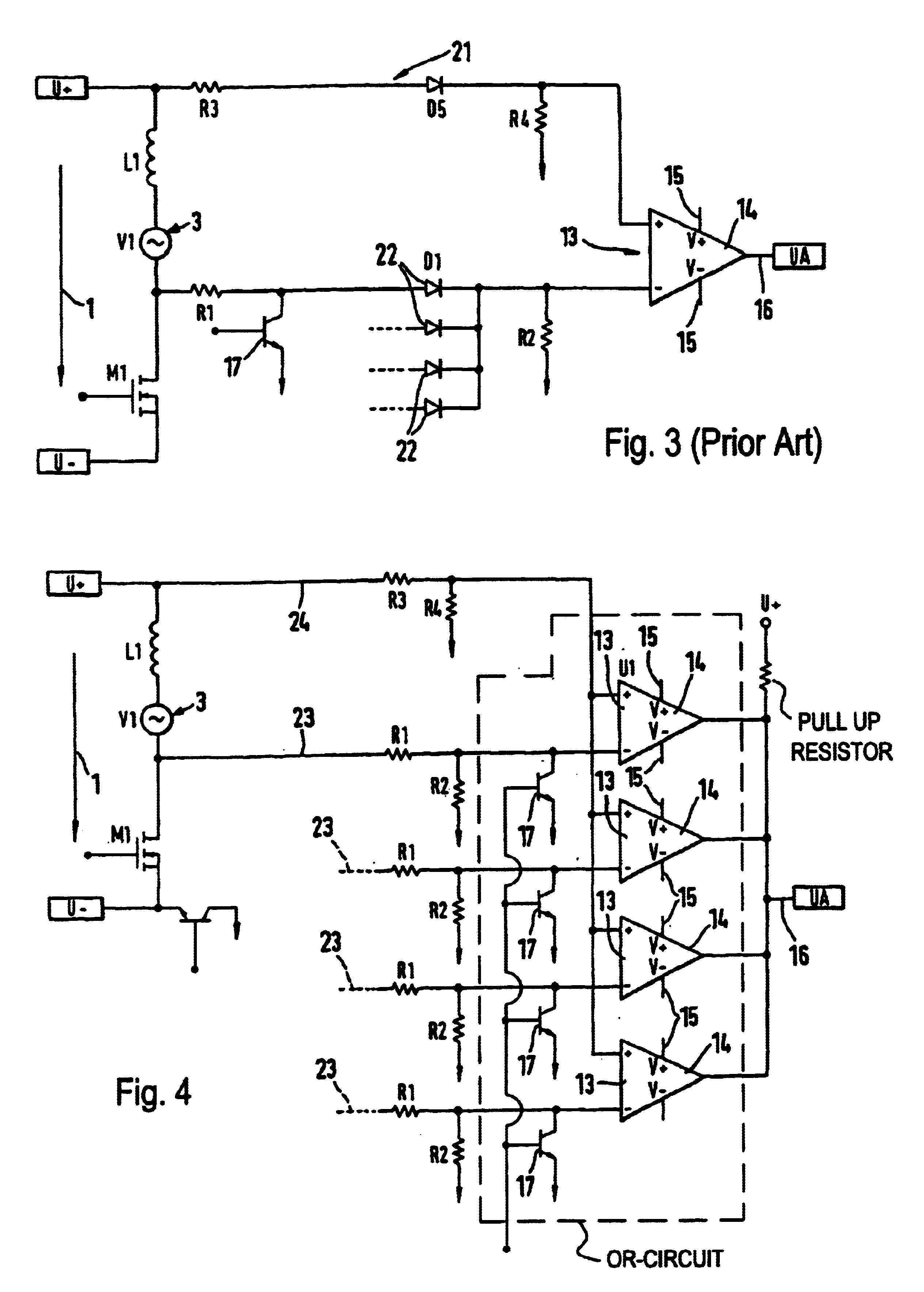

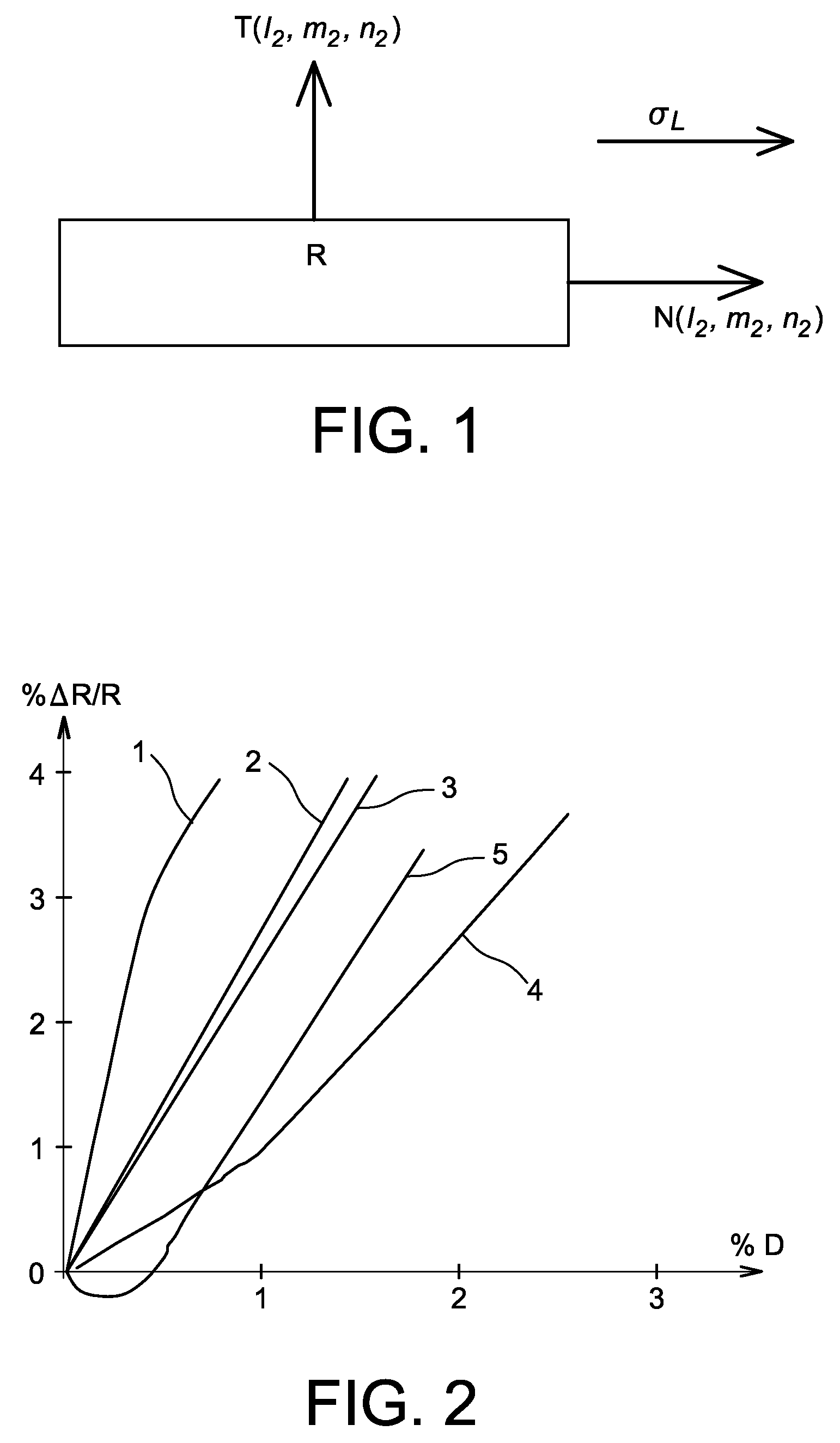

Device for position determination in sensorless motors

InactiveUS6859000B2Avoid disadvantagesSimple designCommutation monitoringSynchronous motors startersElectrical resistance and conductanceEngineering

A device for position determination in a sensorless direct current motor has a plurality of inductivities arranged in corresponding phases and inducing alternating voltages in a motor windings, a plurality of resistances located in phase branches to be evaluated for a position determination of a rotor position of the sensorless direct current motor, and a plurality of comparator components each associated with the corresponding phase branch to be evaluated.

Owner:ROBERT BOSCH GMBH

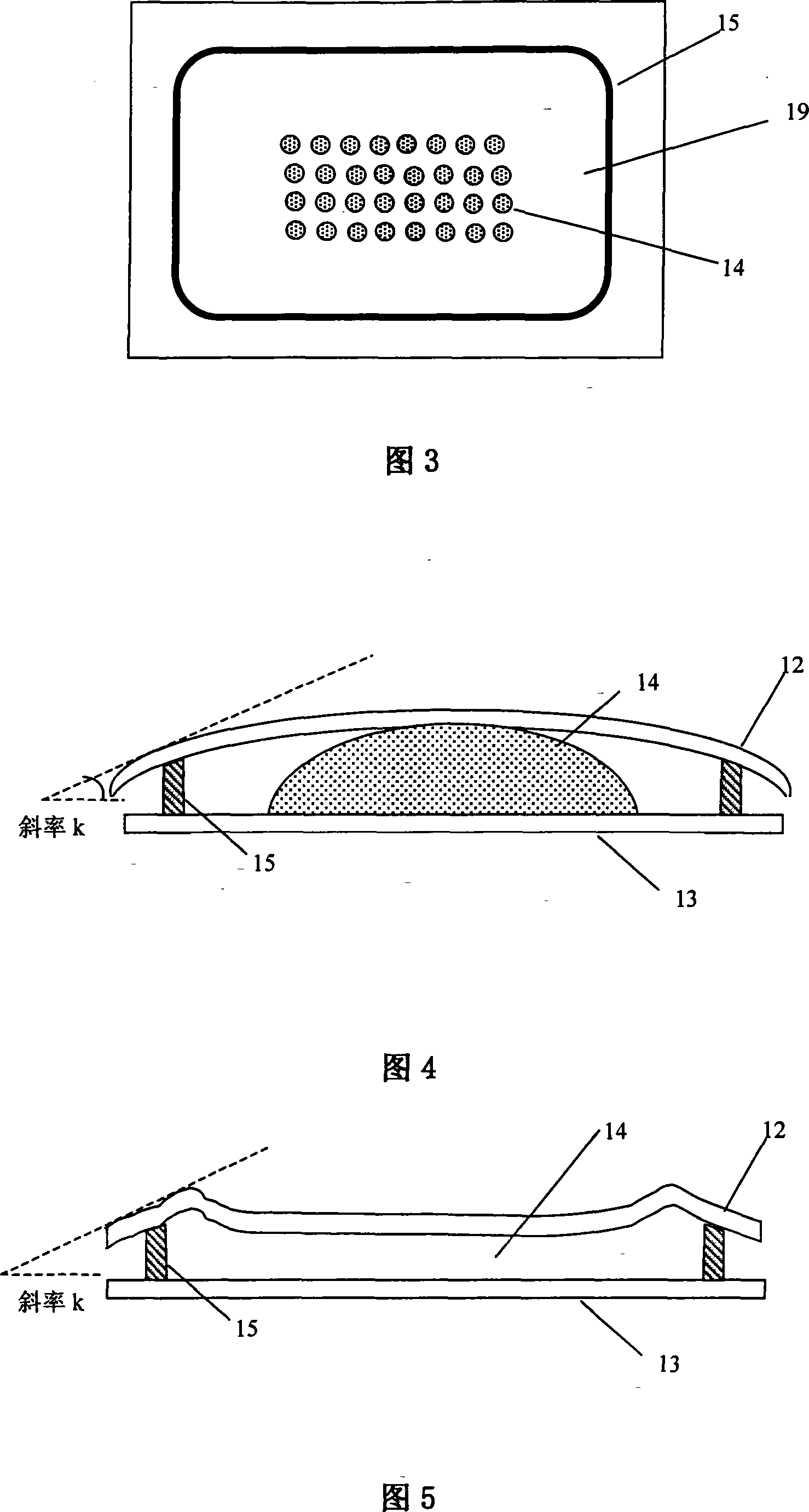

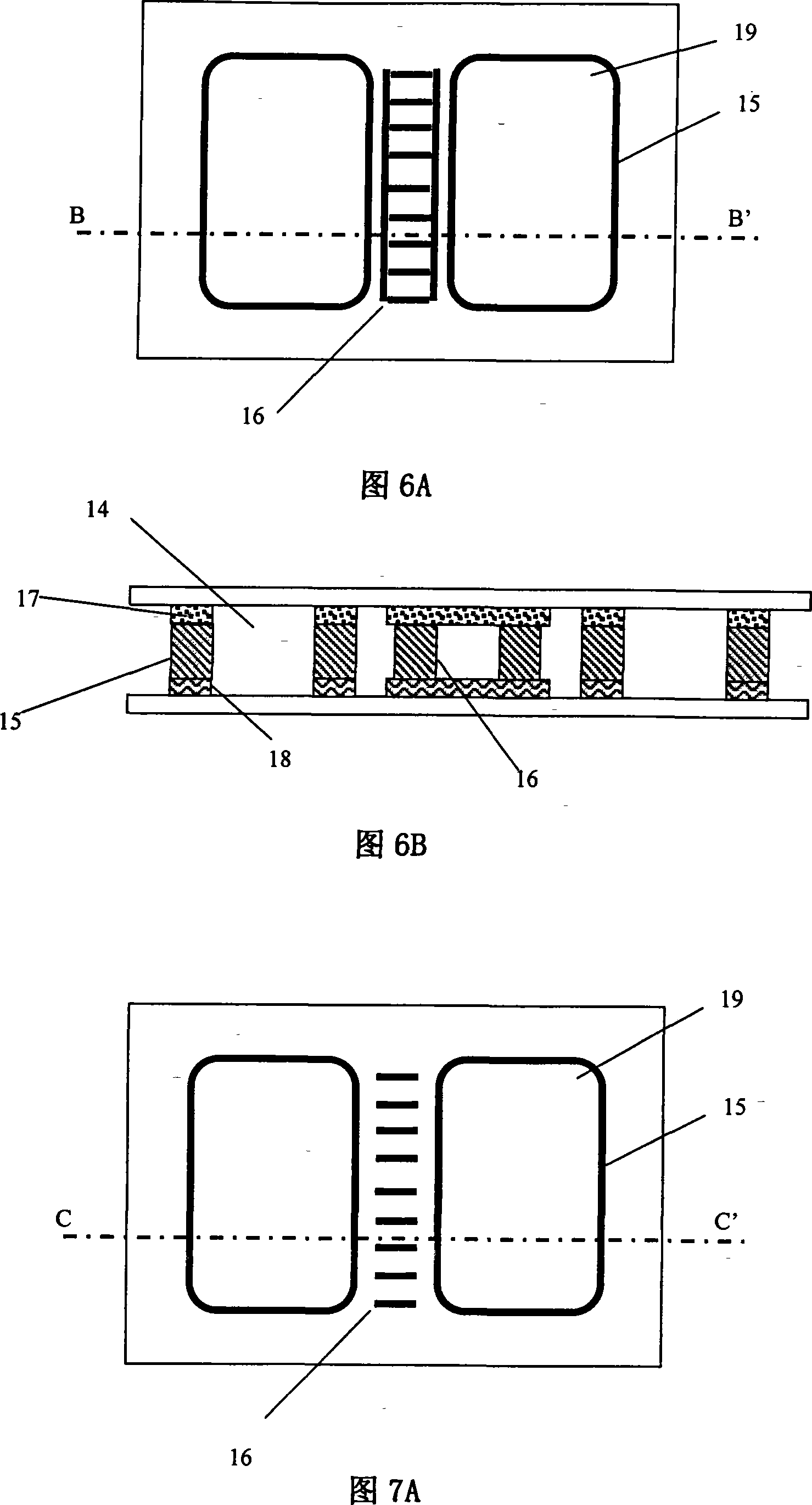

LCD device

InactiveCN101236334AReduces slight tilt issuesReduced freedom of deformationNon-linear opticsLiquid-crystal displayEngineering

The present invention discloses a liquid crystal displace device comprising a first substrate and a second substrate, which are opposite to each other; a plurality of pixel regions are formed on the first substrate and the second substrate; the circumference of the pixel regions is coated by a first frame-sealing glue which combines the first substrate with the second substrate together; the region sealed by the first frame-sealing glue is filled with a liquid crystal layer; a second frame-sealing glue for supporting is arranged between two adjacent pieces of the first frame-sealing glue, wherein, a first manufacture layer is formed on the first substrate which is arranged on the position corresponding to the first frame-sealing glue, or a second manufacture is formed on the second substrate which is arranged on the position corresponding to the first frame-sealing glue; the liquid crystal displace device with the structure is capable of reducing the occurrence that the substrate positioned on the first frame-sealing glue is slightly oblique caused by the inherent problem of an ODF process, thereby optimizing the circumferential case thickness.

Owner:上海广电光电子有限公司

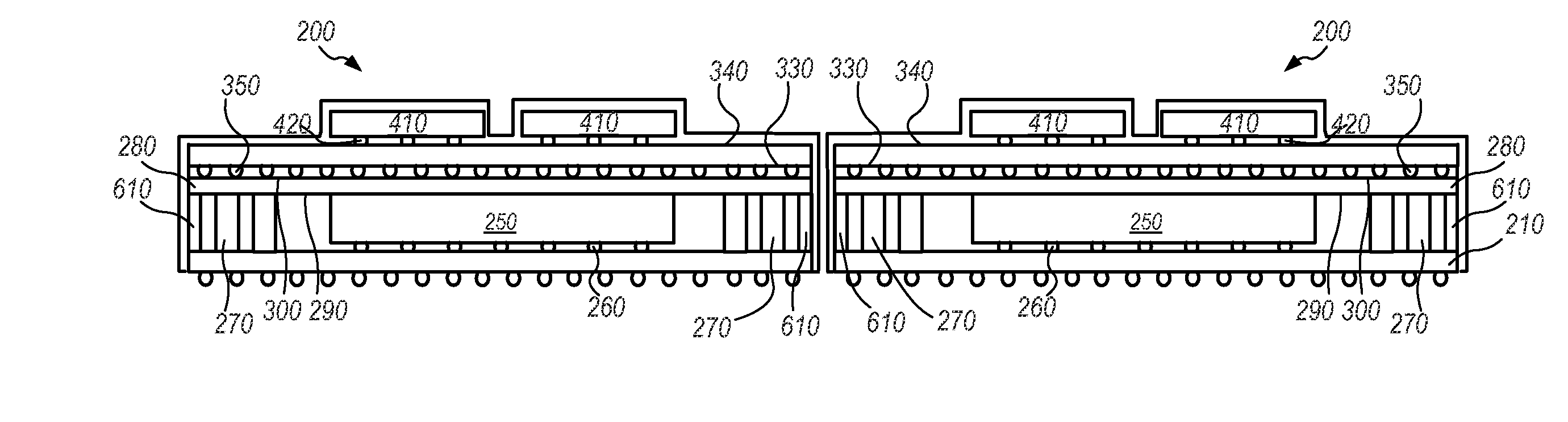

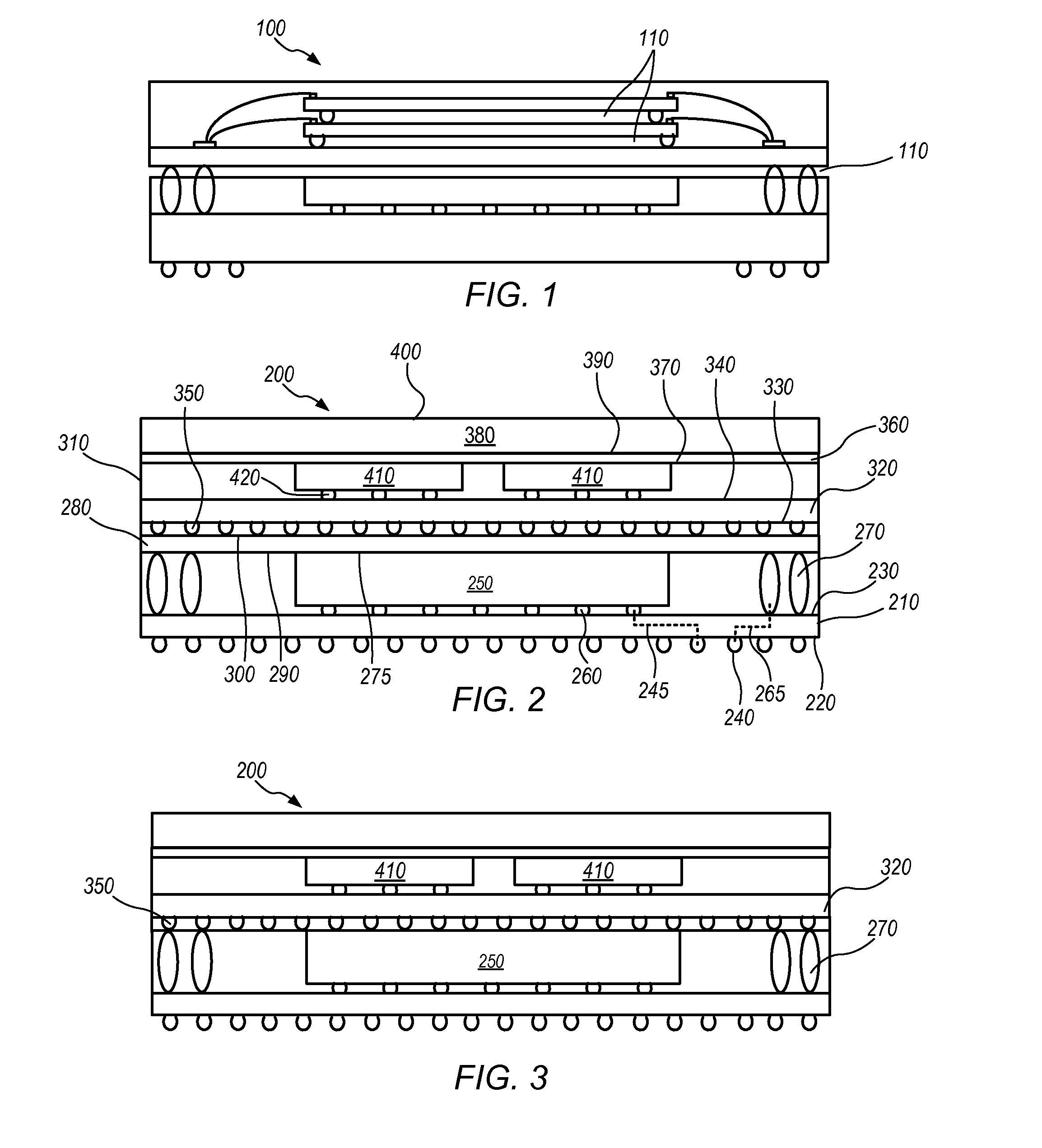

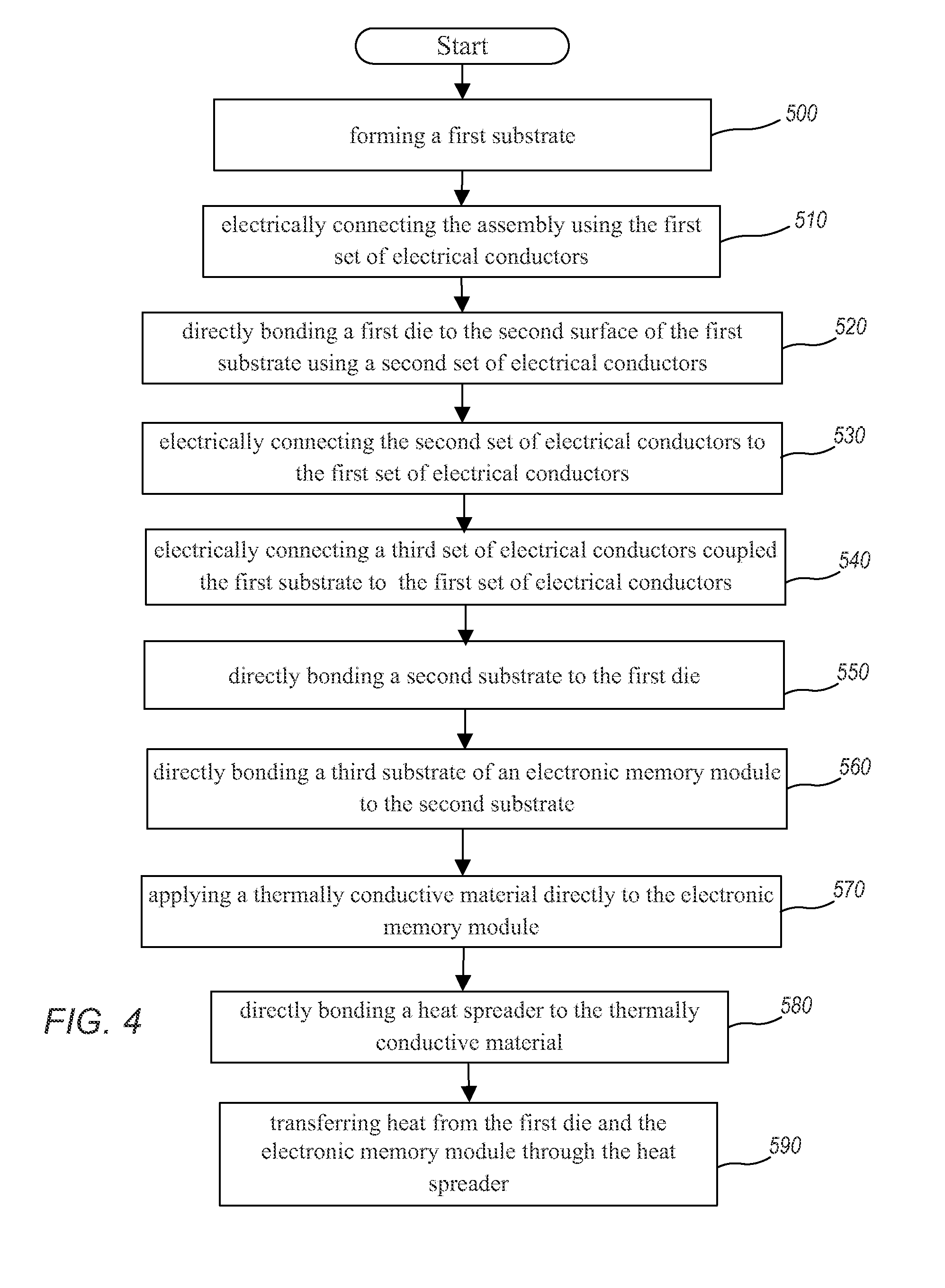

EMI shielded wafer level fan-out pop package

ActiveUS20150303149A1Improve shielding effectEnhance reflectanceSemiconductor/solid-state device detailsSolid-state devicesElectricityElectrical conductor

In some embodiments, a semiconductor device package assembly may include a first substrate. The first substrate may include a first set of electrical conductors which electrically connect the assembly. In some embodiments, the assembly may include at least one electrical conductor coupled to the first substrate such that at least one of the electrical conductors exposes through a perimeter surface of the semiconductor device package assembly. In some embodiments, the assembly may include a first die electrically connected to a second surface of the first substrate using a second set of electrical conductors. The assembly may include an electronic memory module coupled to the first die. In some embodiments, the assembly may include a shield applied to an upper surface of the assembly and electrically coupled to at least one of the exposed electrical conductors. The shield may inhibit, during use, electromagnetic interference.

Owner:APPLE INC

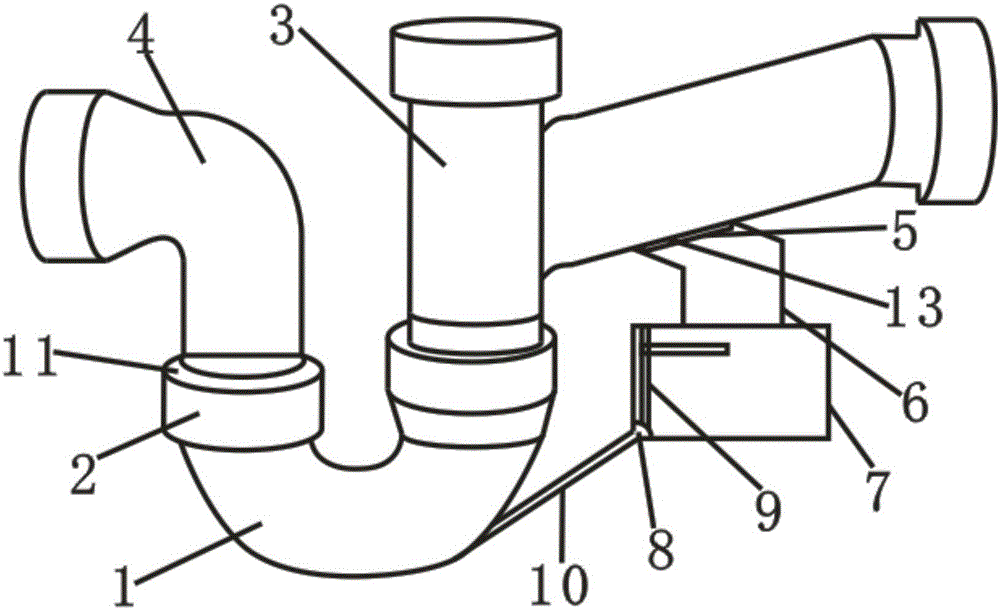

U-shaped anti-clogging sewer pipe

The invention discloses a U-shaped anti-clogging sewer pipe. The U-shaped anti-clogging sewer pipe comprises a U-shaped pipe, wherein water inlet pipes and a water outlet pipe are connected to two ends of the U-shaped pipe through connectors; the water inlet pipes are of inverted Y-shaped structures, and the number of the water inlet pipes is two; one water inlet pipe is directly connected with the U-shaped pipe, and the other water inlet pipe is fixedly connected with the water inlet pipe; a permeating hole is etched in the bottom of the inclined water inlet pipe; an elbow is arranged on the permeating hole; a back flushing water tank is connected to the tail end of the elbow; a water outlet is formed in the side face of the bottom of the back flushing water tank; a floating rod type piston is arranged inside the back flushing water tank; switching of the water outlet is controlled by the floating rod type piston; besides, the water outlet is connected with the bottom of the U-shaped pipe through an inclined pipe. For the whole device, back flushing on the bottom of the U-shaped pipe is performed by adopting a full-automatic matching structure, thereby preventing U-shaped pipe clogging due to sundry stacking, and improving the sewage discharging capacity; the U-shaped anti-clogging sewer pipe is particularly suitable for a small-caliber U-shaped pipe and sewer pipes with small single-pass water flow.

Owner:WUHU HUIYU TRADING CO LTD

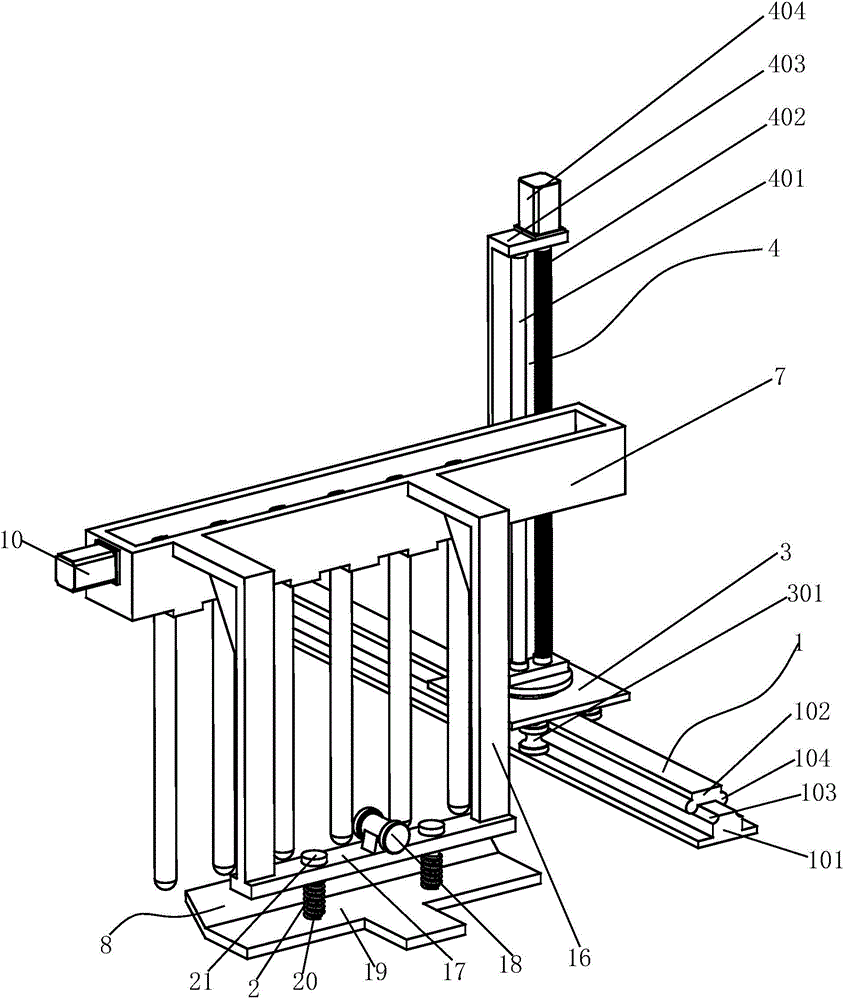

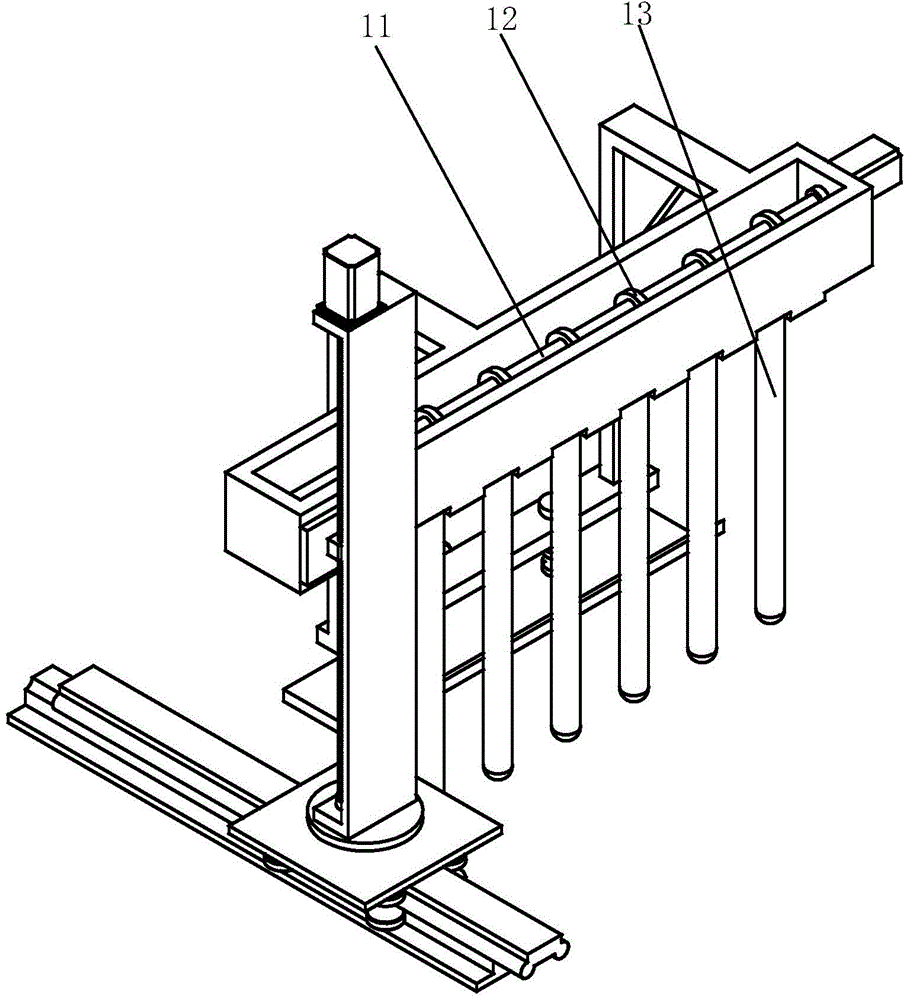

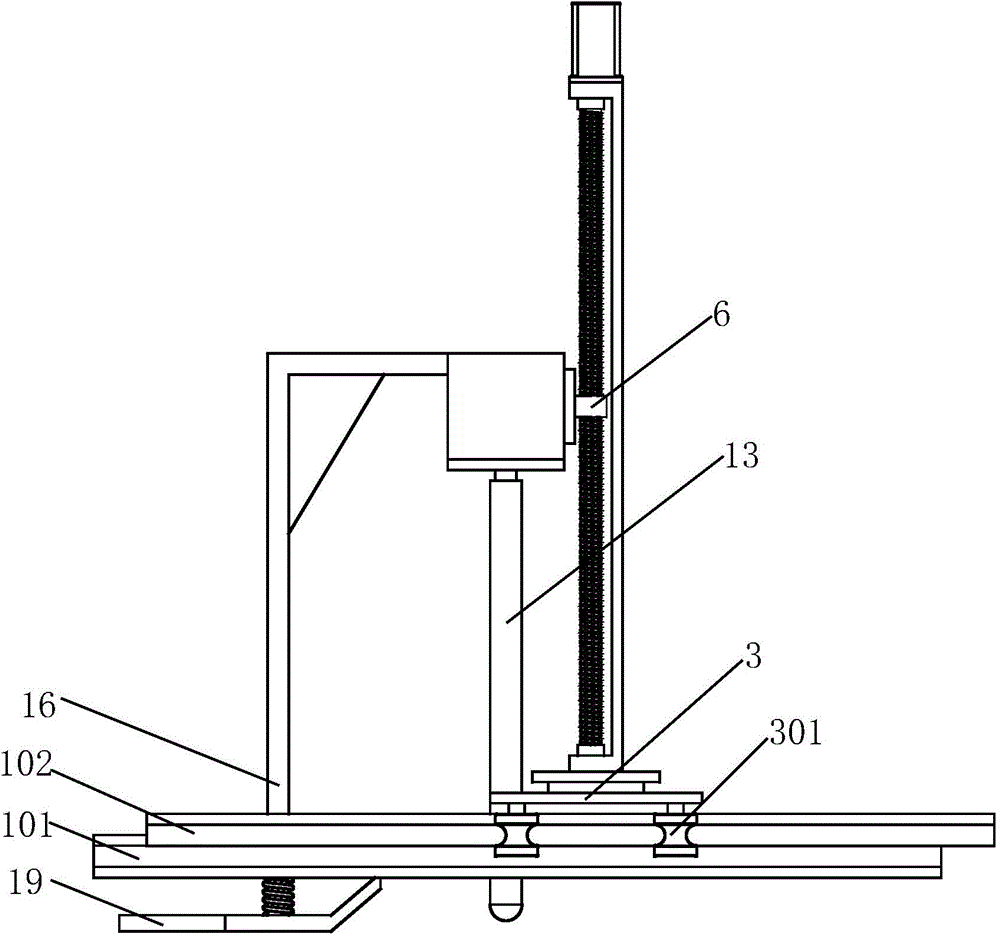

Concrete vibrating leveling device

InactiveCN104453241AImprove compaction efficiencyIncrease height differenceBuilding material handlingSlide plateEngineering

The invention relates to a concrete vibrating leveling device which comprises a spliced rail. A sliding plate is arranged on the spliced rail, the lower end face of the sliding plate is provided with at least two rollers correspondingly clamped to the spliced rail, the upper end face of the sliding plate is fixedly provided with a positioning lifting frame, the positioning lifting frame comprises a guide rod and a lead screw, the upper end of the guide rod and the upper end of the lead screw are each fixedly provided with an upper end cap, the upper end caps are fixedly provided with a first motor, a shaft of the first motor is connected with the lead screw, the guide rod is provided with a left sliding sleeve, the lead screw is provided with a right sliding sleeve, a cam box is arranged in front of the left sliding sleeve and the right sliding sleeve, a second motor is fixed to the cam box, a shaft of the second motor is connected with transverse rods transversely arranged in the cam box, the transverse rods correspond to through holes and are each sleeved with an ejector rod cam, and vibration bars are arranged in the through holes in a penetrating mode. According to the device, concrete is tamped through the vibration bars by means of the ejector rod cams fixed to the transverse rods, tamping efficiency of the vibration bars is improved, and the aim that vibration and tamping of the vibration bars are carried out at the same is achieved.

Owner:NANJING DENGYU MACHINERY EQUIP MFG CO LTD

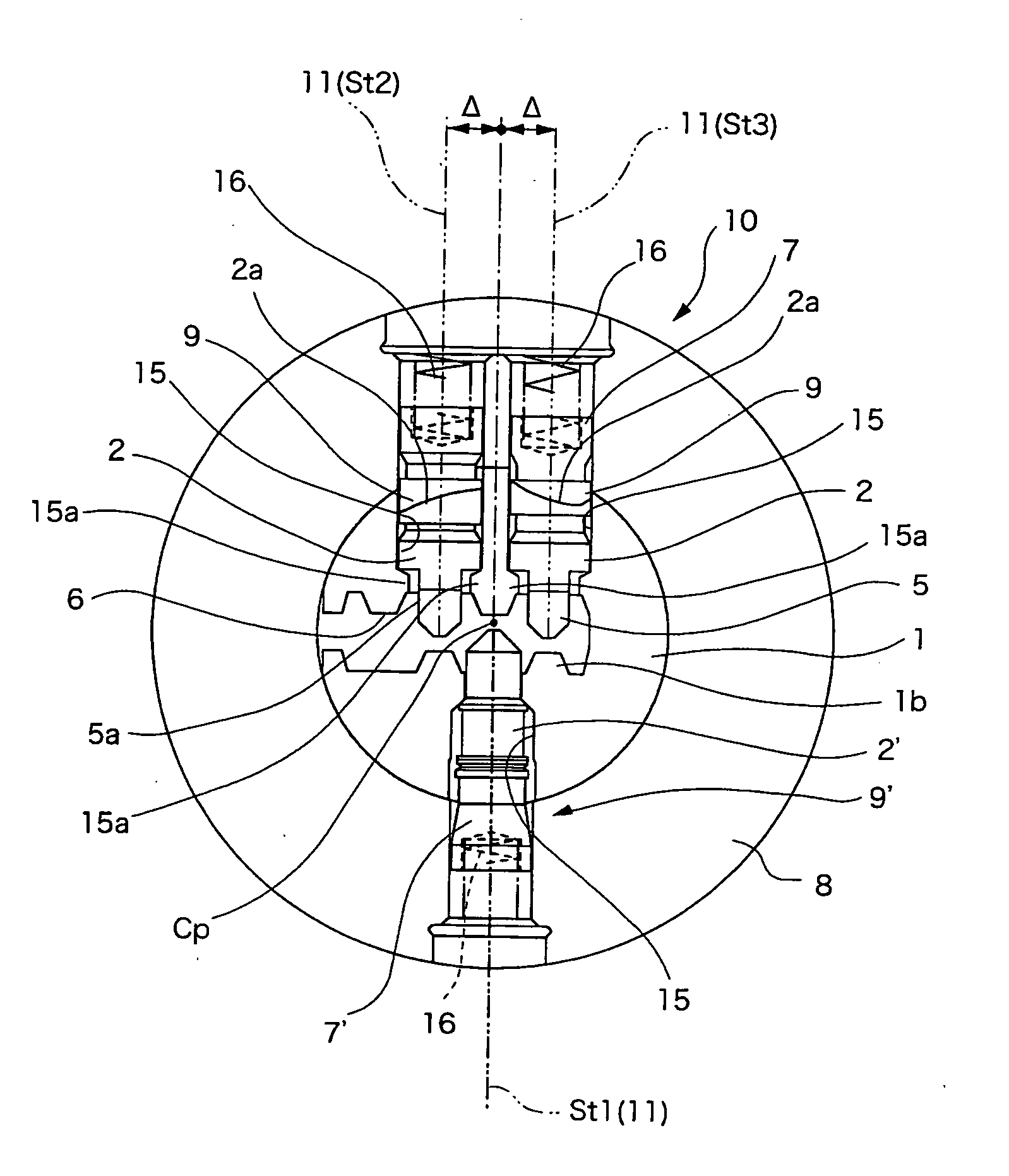

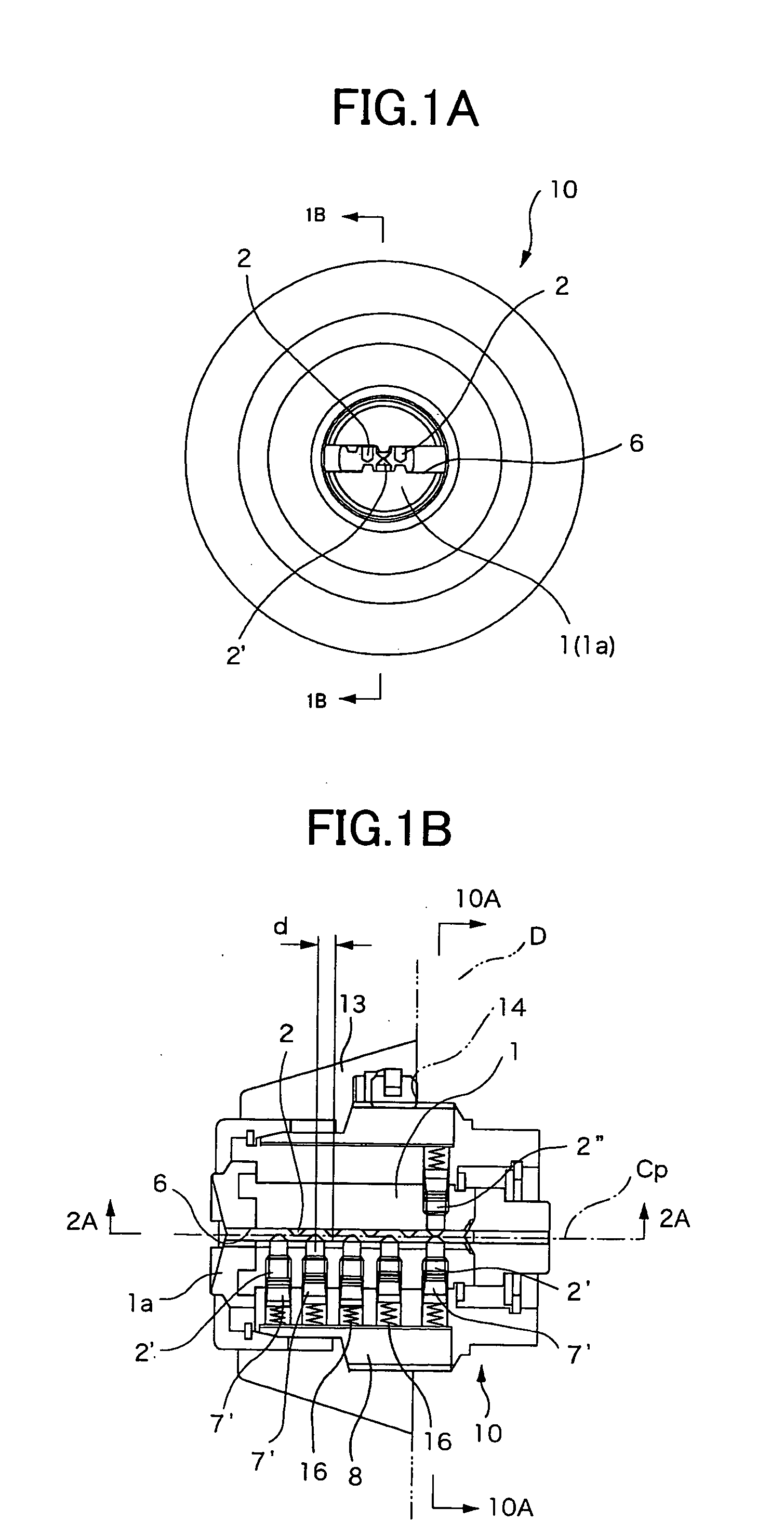

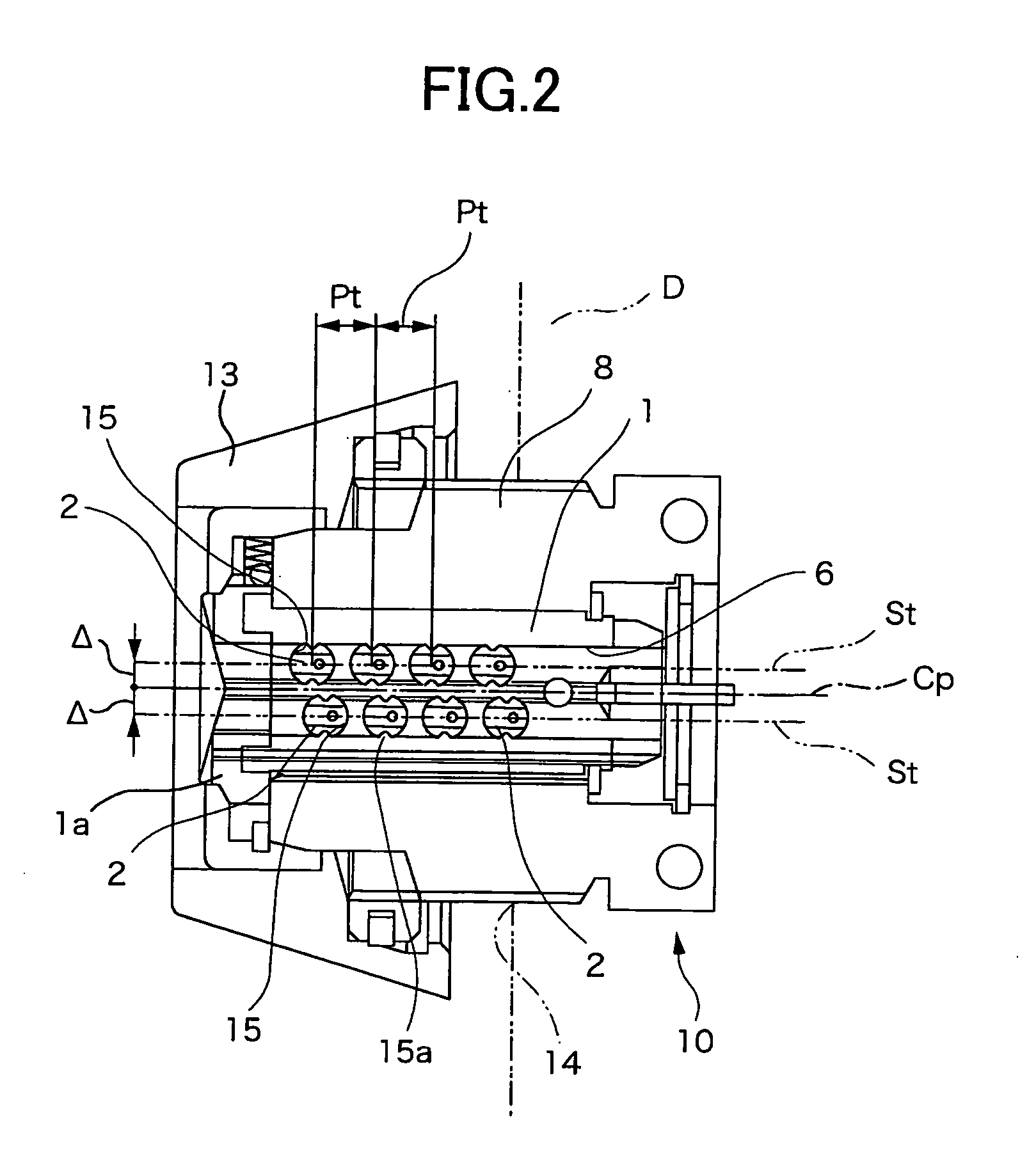

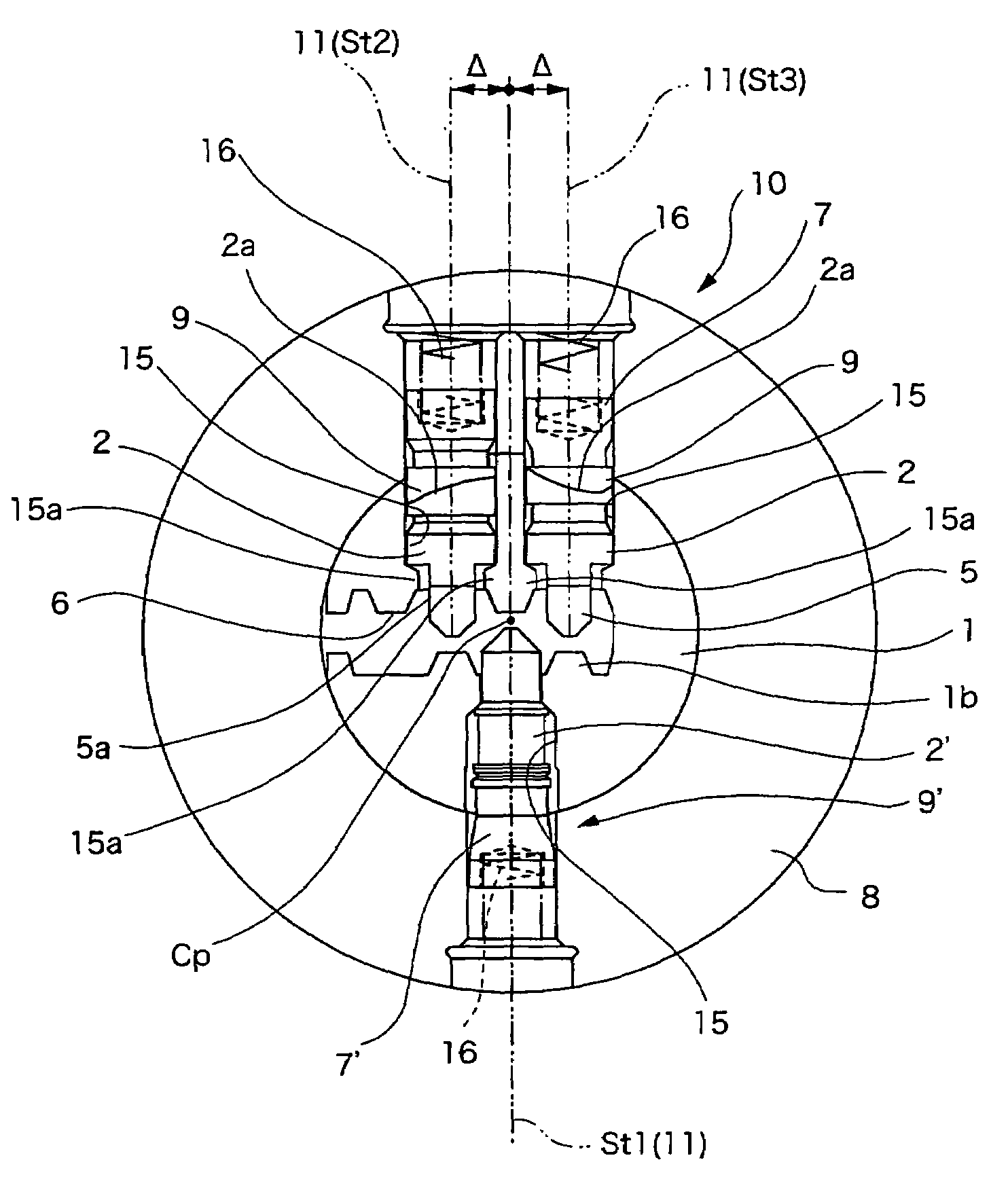

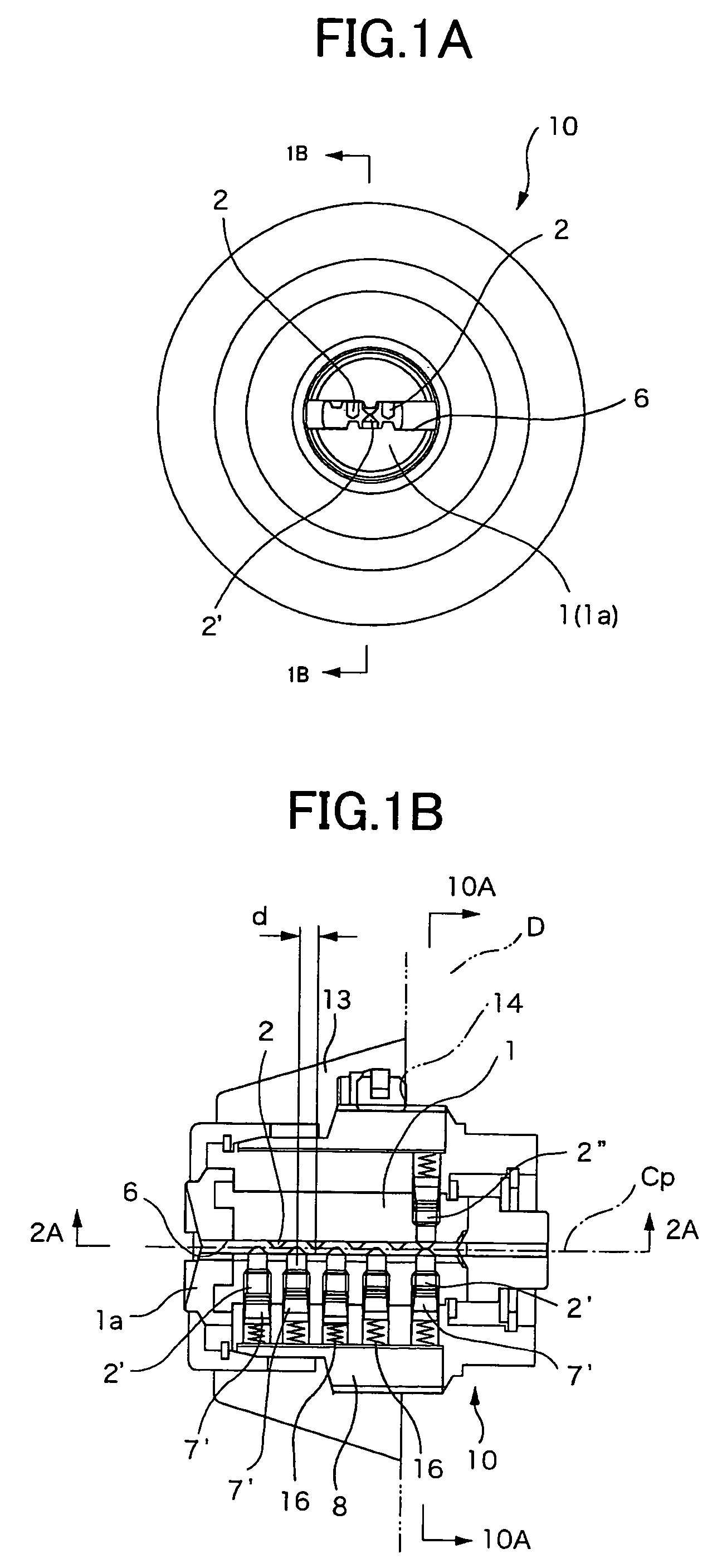

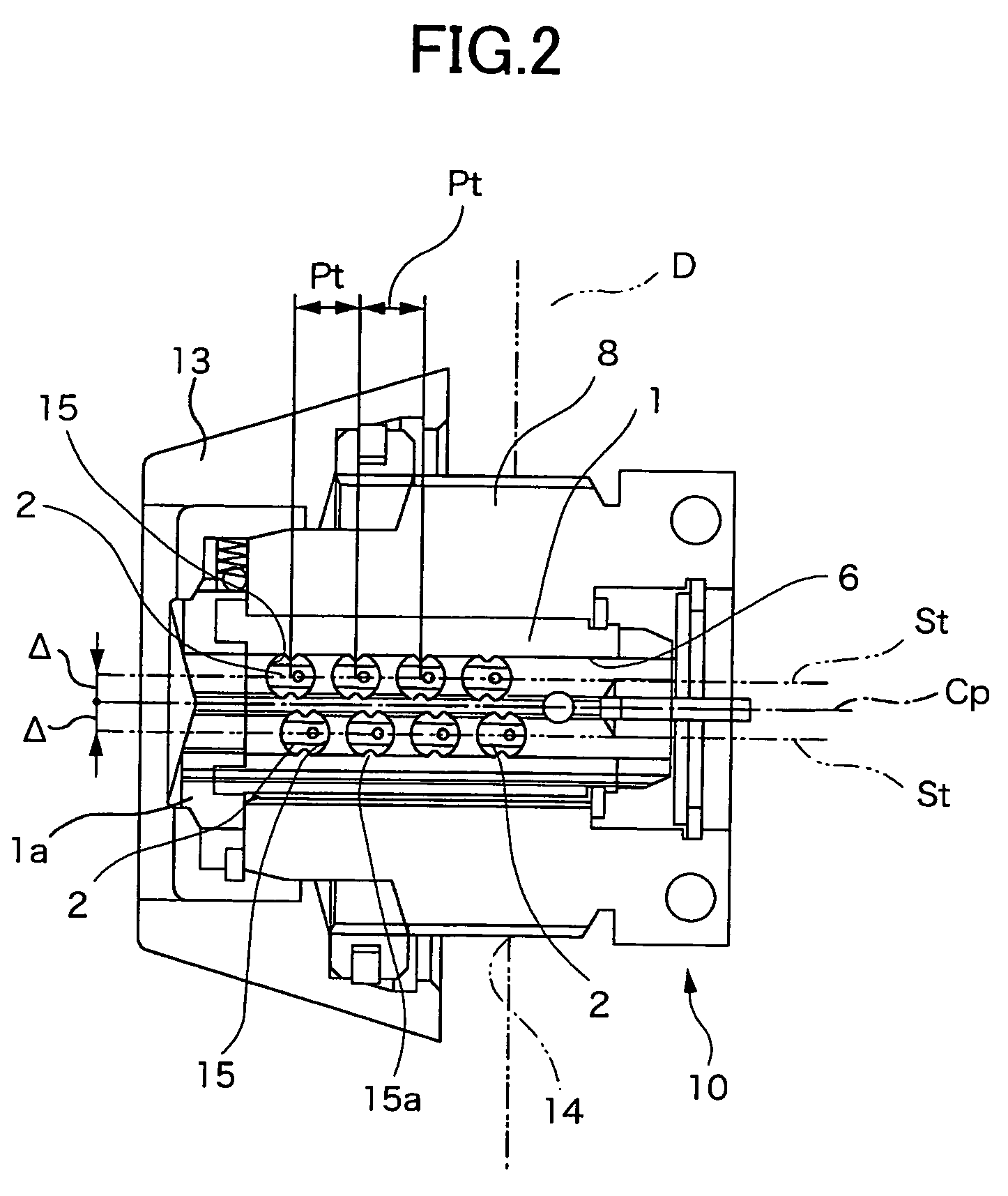

Cylinder lock device

InactiveUS20060042335A1Increase different lock codeIncreasing different locking codeKeysCylinder locksEngineeringConical surface

Tumbler pins 2 are movably housed in a plug 1. A locked / unlocked state is determined by the turning position on the moving direction center axes of the tumbler pins 2. An unlocking key 4 to be inserted into the plug 1 is provided with unlocking code forming recesses 3 for determining the turning positions of the tumbler pins at code decision positions. The tumbler pins 2 are provided at their leading end portions with drive portions 5, which have slope sides of conical faces gradually reduced in diameter toward the leading ends and having rotational centers offset from the moving direction center axes. The side wall faces of the unlocking code forming recesses 3 are formed of conical faces having rotational centers substantially aligned with those of the conical faces forming the slope sides of the drive portions 5. At code decision positions, the slope sides of the drive portions 5 are forced to contact with the side wall faces of the unlocking code forming recesses 3 thereby to determine the turning positions of the tumbler pins2.

Owner:ALPHA

NEMS comprising AlSi alloy based transducer

ActiveUS9016125B2High sensitivityReduce sizeVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransducerConductive materials

A nano electro-mechanical system (NEMS) formed on a substrate is provided including at least one fixed part associated with the substrate and at least one movable part in relation to the substrate, the system including a transduction component configured to excite the movable part to confer on it a movement and / or to detect a movement of the movable part, the transduction component including at least one electrically conductive material. The electrically conductive material is made of an AlSi alloy based deposition, the deposition being supported at least in part by the movable part of the system.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

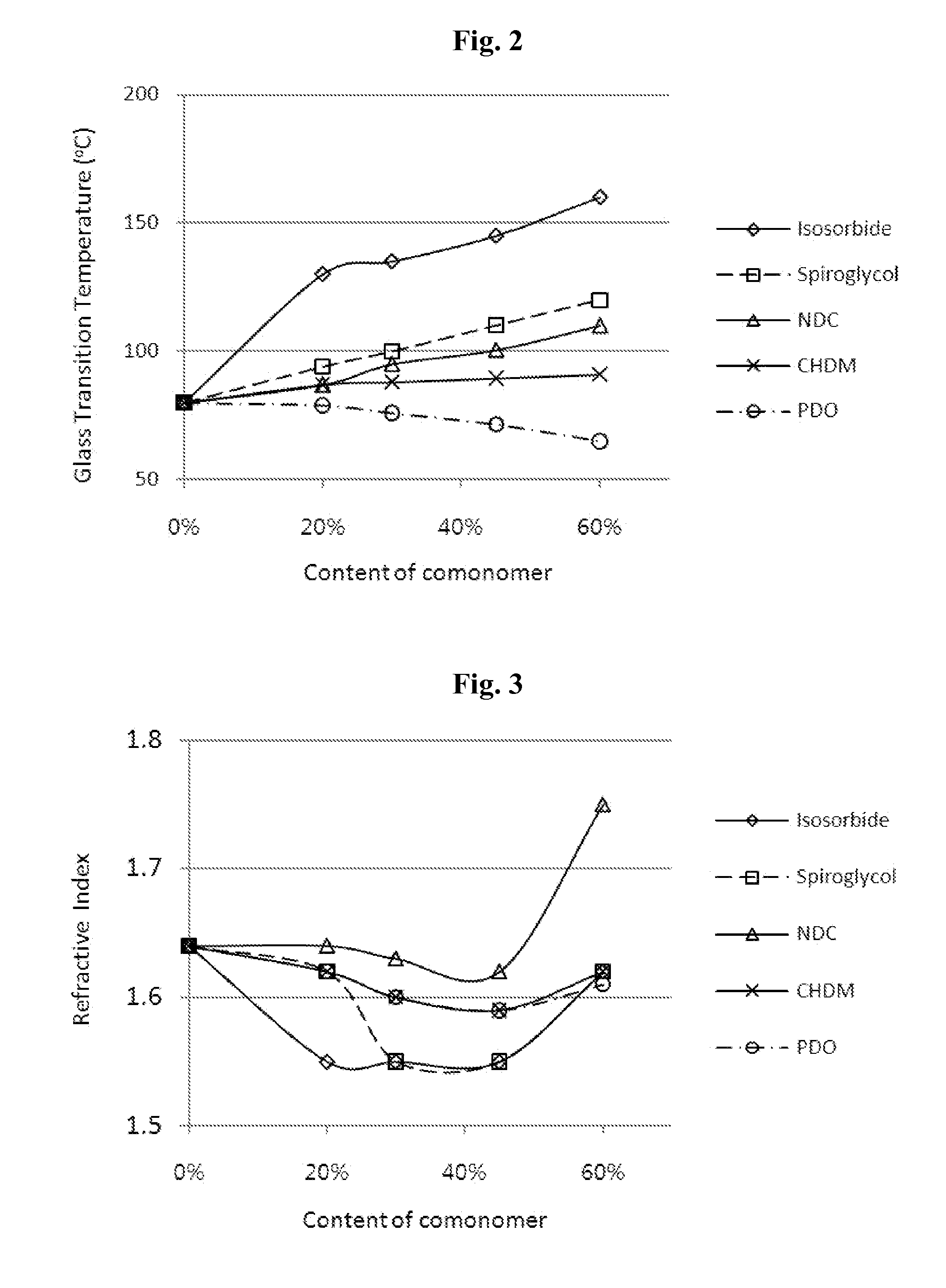

Multilayered optical film, and preparation method thereof

InactiveUS20120207993A1Increase thermal resistanceReduce smogSynthetic resin layered productsElectrical equipmentPolyolAlcohol

A multilayered optical film has a structure in which a first resin layer comprising PEN and a second resin layer comprising PET copolymerized with heterocyclic polyvalent alcohol are alternatively laminated. The multilayered optical film has excellent optical characteristics because of having excellent heat resistance, showing excellent elongation in case of preparation, having low haze, and having a large difference in a refractive index between resin layers.

Owner:SKC CO LTD

Cylinder lock device

InactiveUS7421869B2Increasing different locking codeIncrease height differenceKeysCylinder locksEngineeringConical surface

Tumbler pins 2 are movably housed in a plug 1. A locked / unlocked state is determined by the turning position on the moving direction center axes of the tumbler pins 2. An unlocking key 4 to be inserted into the plug 1 is provided with unlocking code forming recesses 3 for determining the turning positions of the tumbler pins at code decision positions. The tumbler pins 2 are provided at their leading end portions with drive portions 5, which have slope sides of conical faces gradually reduced in diameter toward the leading ends and having rotational centers offset from the moving direction center axes. The side wall faces of the unlocking code forming recesses 3 are formed of conical faces having rotational centers substantially aligned with those of the conical faces forming the slope sides of the drive portions 5. At code decision positions, the slope sides of the drive portions 5 are forced to contact with the side wall faces of the unlocking code forming recesses 3 thereby to determine the turning positions of the tumbler pins 2.

Owner:ALPHA

Fabrication method for printed circuit board with golden finger coated with gold on four surfaces

InactiveCN105704946AImprove height differenceImprove bite erosion normal linesPrinted element electric connection formationEtchingPrinted circuit board

The invention discloses a fabrication method for a printed circuit board with a golden finger coated with gold on four surfaces. The fabrication method comprises the following steps of 1) fabricating a primary outer-layer circuit pattern, and fabricating all circuit patterns containing golden finger lines; 2) carrying out first etching after pattern electroplating; 3) carrying out first solder welding, and partially windowing the golden finger lines; 4) fabricating a secondary outer-layer circuit pattern, covering a dry film except a golden finger region, and electroplating nickel and gold on the golden finger region; 5) carrying out third outer-layer circuit pattern after the dry film is removed; and 6) carrying out second etching, removing the covered film and then carrying out second solder welding. With the adoption of the two-time solder welding process, the height difference existing between a copper surface and a substrate is improved, the problems of nickel permeation caused by unfirm dry film coverage after the fabrication of the primary outer-layer circuit pattern and the secondary outer-layer circuit pattern and copper leakage of the golden finger caused by medicine liquid hidden under the dry film to affect the performance of the circuit board are solved, and the problem that a normal circuit is corroded due to excessive medicine liquid etched during lead etching is further improved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

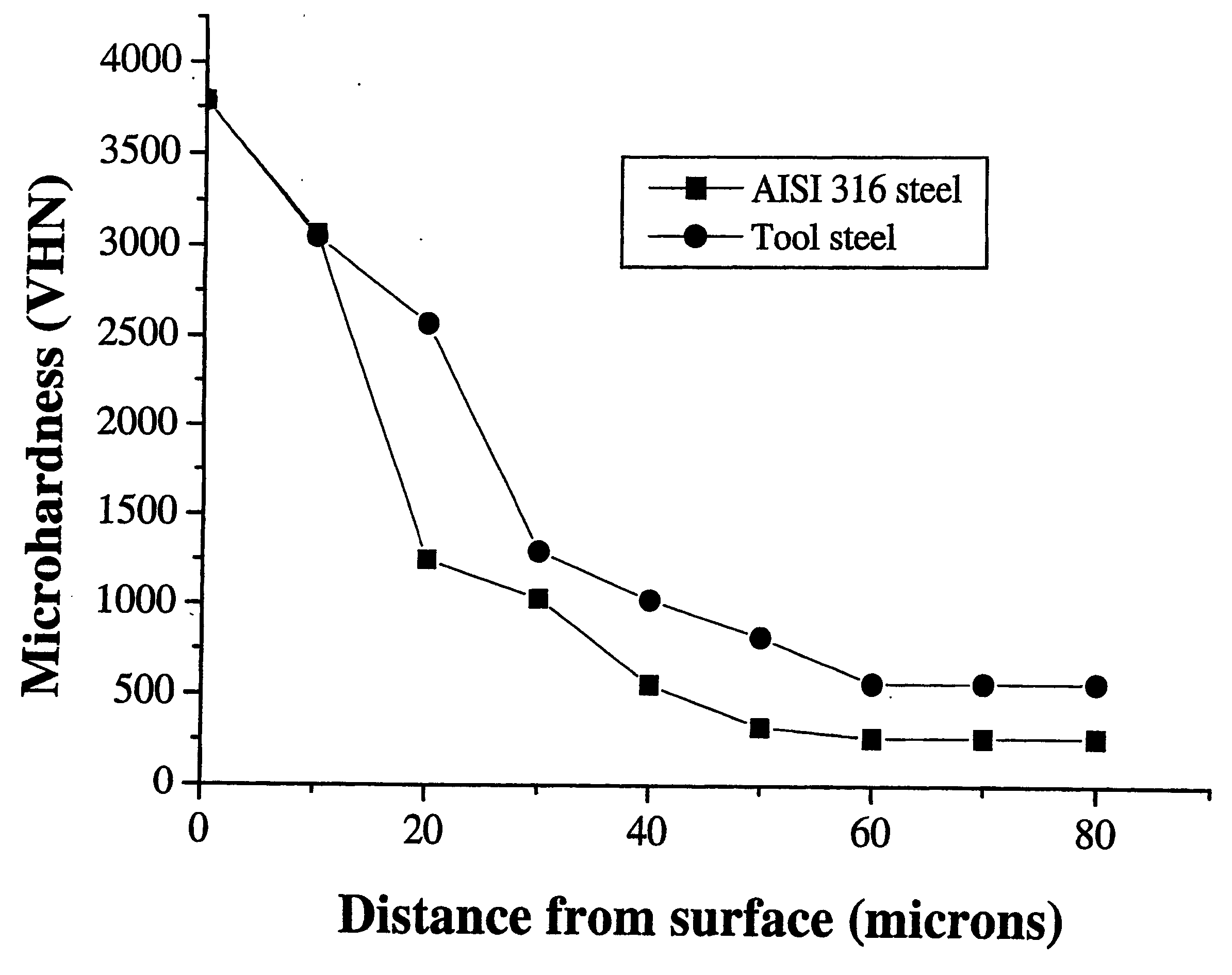

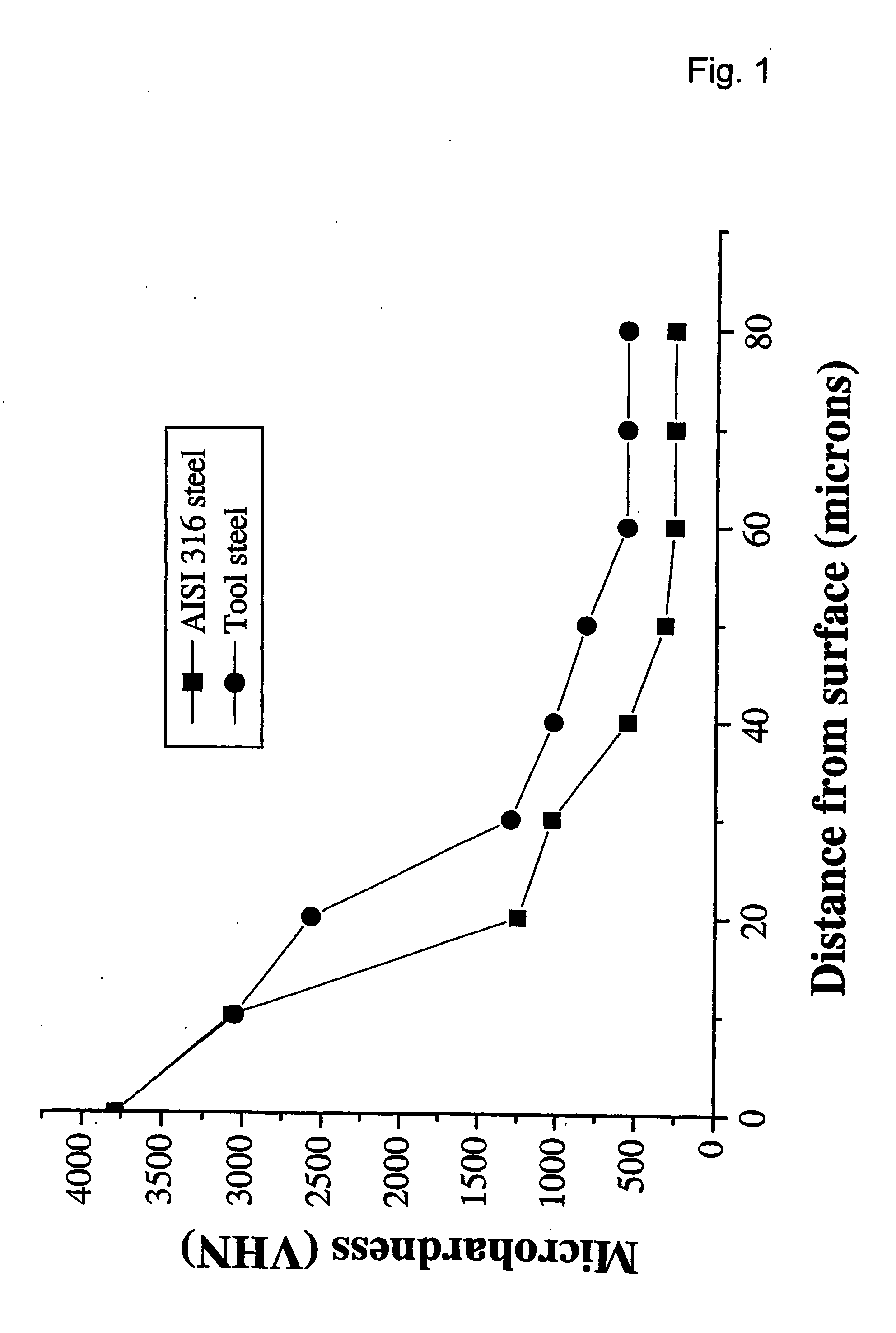

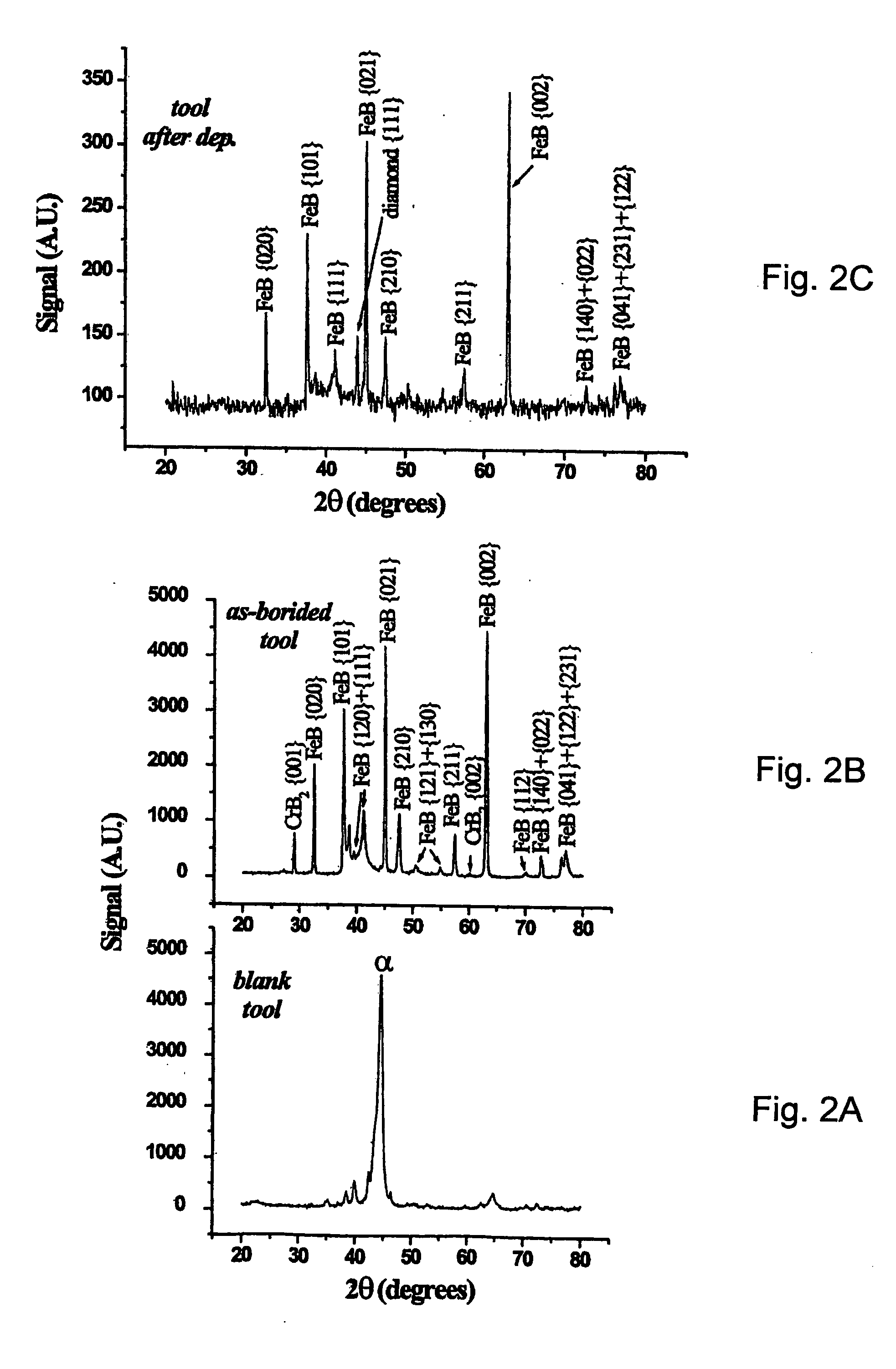

Method of forming a diamond coating on an iron-based substrate and use of such an iron-based substrate for hosting a CVD diamond coating

InactiveUS20050064097A1Reduce adhesionRelease stressSolid state diffusion coatingChemical vapor deposition coatingGas phaseChemical vapor deposition

A method of forming a diamond coating on an iron-based substrate, comprising: providing an iron based substrate with an outer layer which substantially comprises metal borides; and depositing the diamond coating on the outer layer using a process of Chemical Vapor Deposition (CVD). The outer layer may be formed by deposition, by depositing a metal layer which is capable of being boronized followed by boronizing said metal layer, or by boronizing said iron-based substrate. The invention is also related to the use of an iron-based substrate comprising an outer layer with substantially borides for hosting a CVD diamond coating.

Owner:STICHTING VOOR DE TECH WETENSCHAPPEN

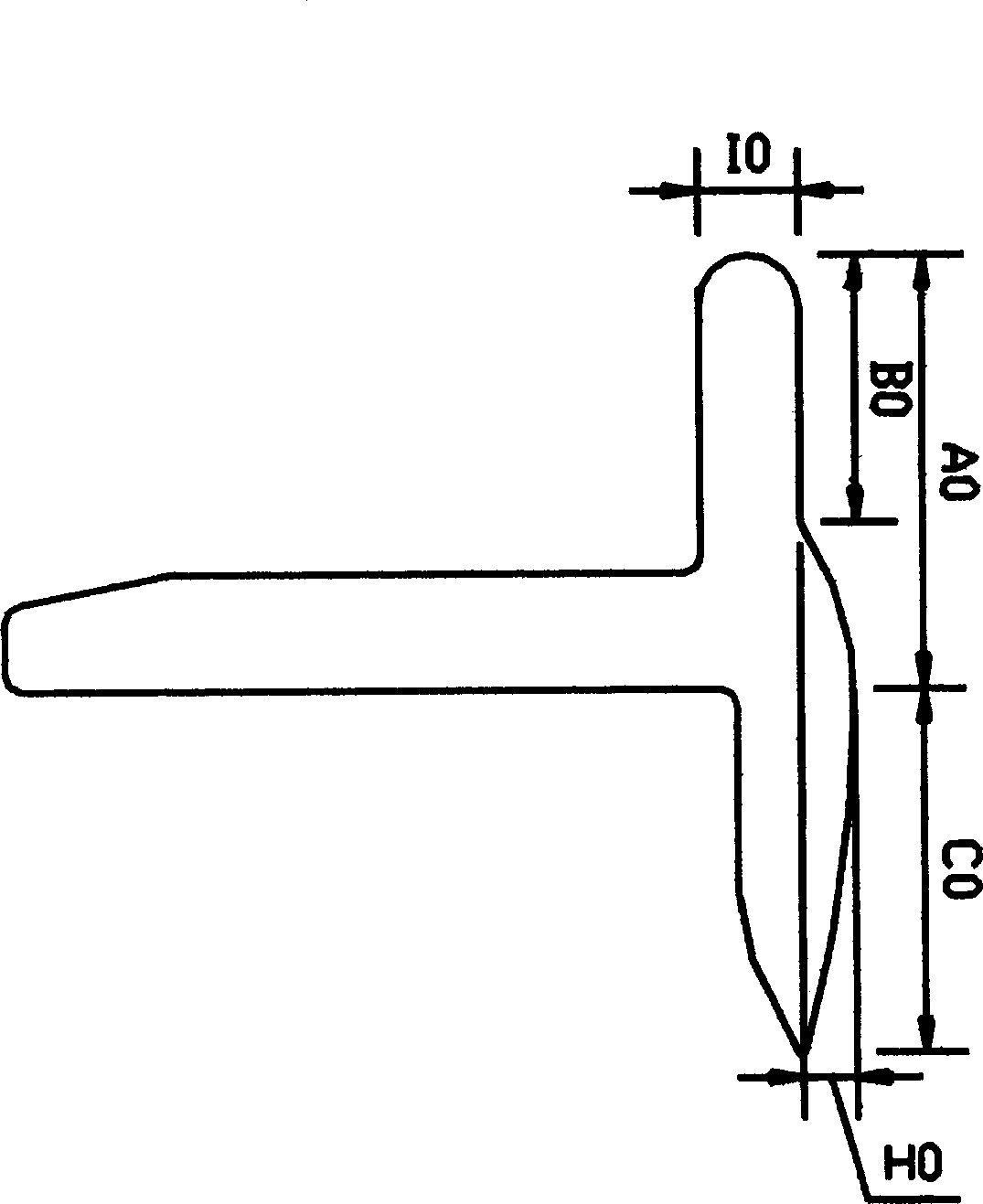

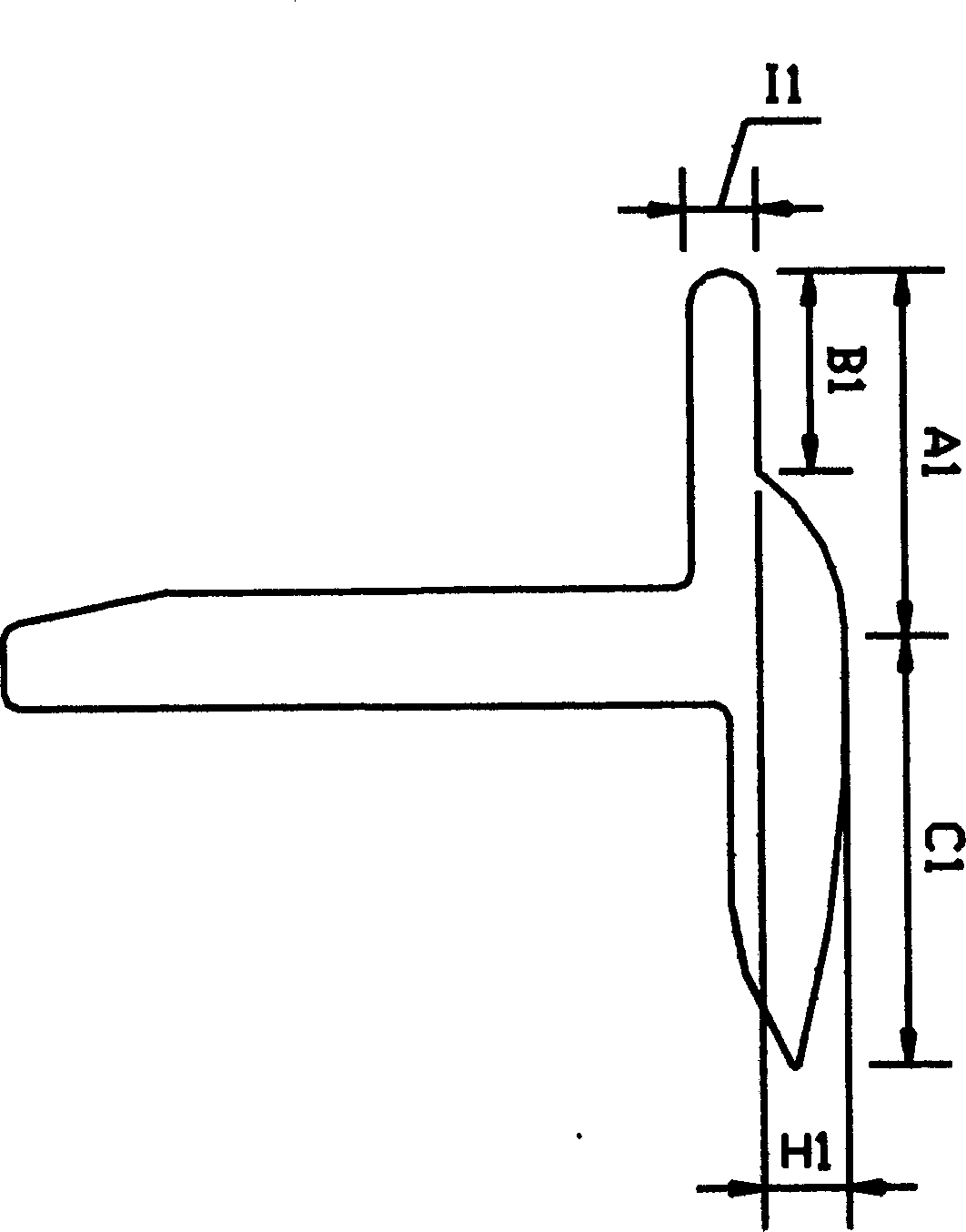

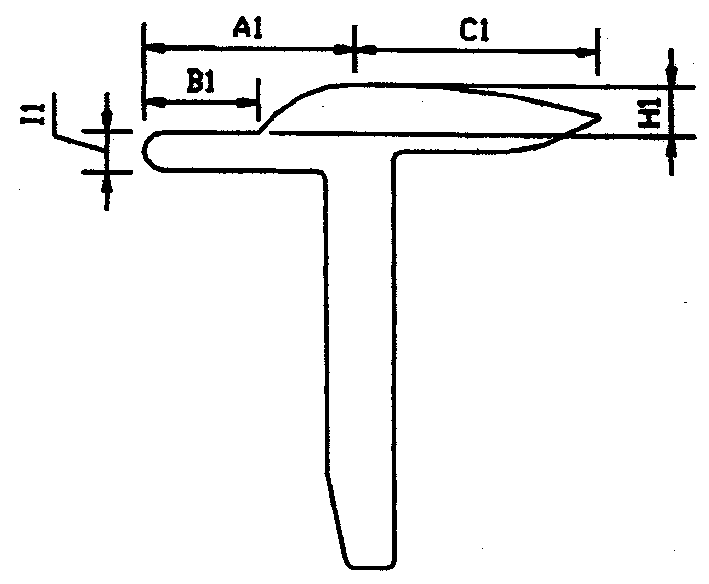

Leather collar under pin and sipnning frame using same

InactiveCN1478933AIncrease the lengthShorten the lengthDrafting machinesContinuous wound-up machinesLeading edgeYarn

A lower pin of apron for spinning machine features that it has a basic T-shaped cross-section, its top surface is composed of a straight line part and a curve part, and said straight line part and curve part has the size relation individually or relatively. Its advantages are simple structure, better control force for drafting yarn, and high quality of yarn.

Owner:汤永学

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com