Patents

Literature

261results about How to "Improve compaction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt spreading device for building

InactiveCN109112932AFor subsequent perfusionImprove compaction efficiencyRoads maintainenceEngineeringCantilever

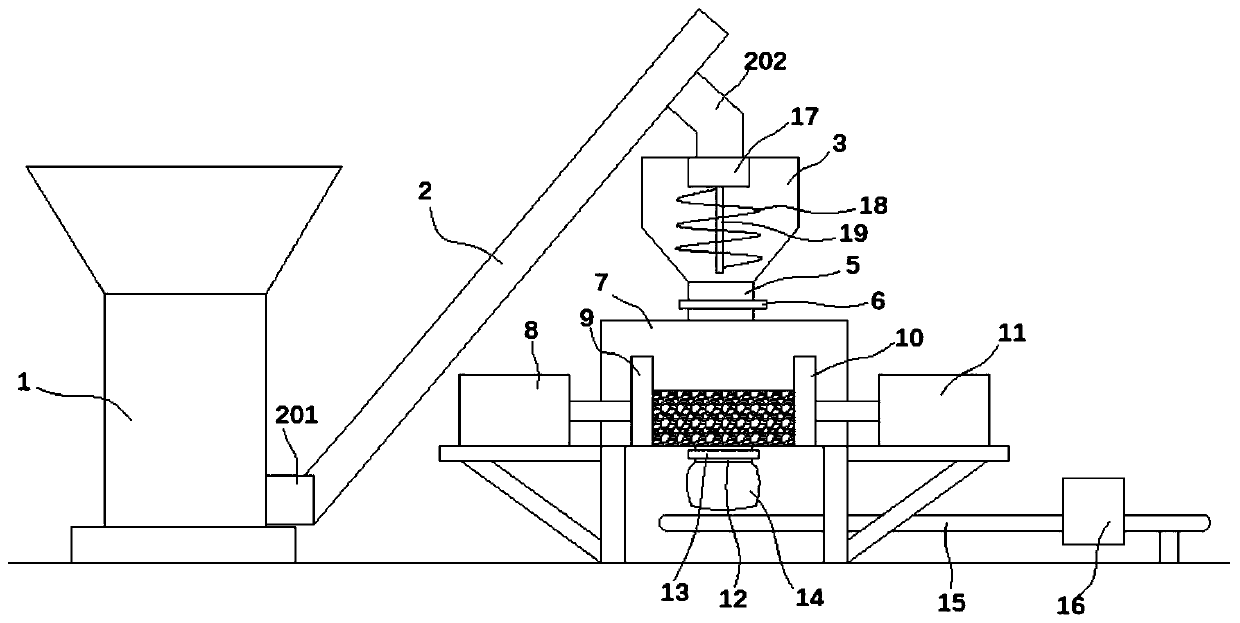

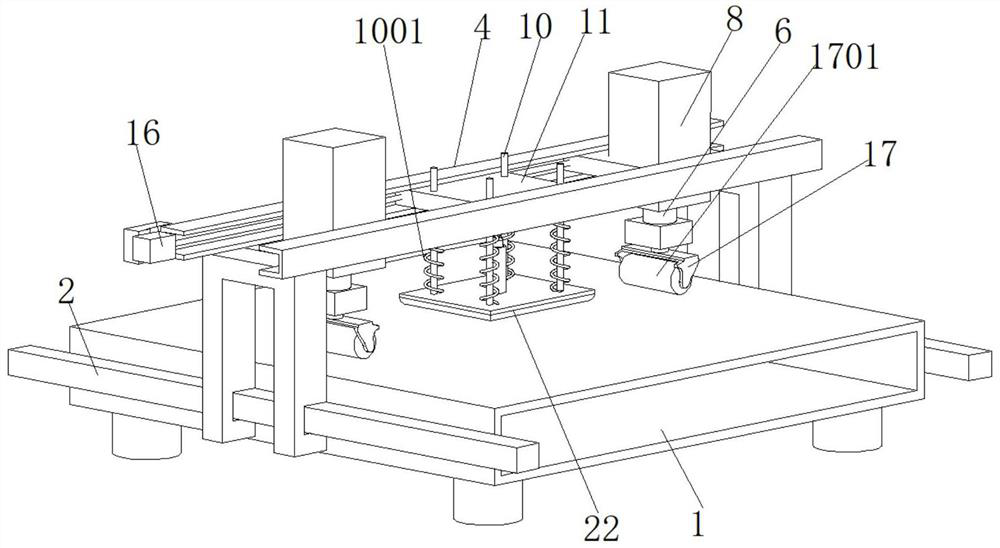

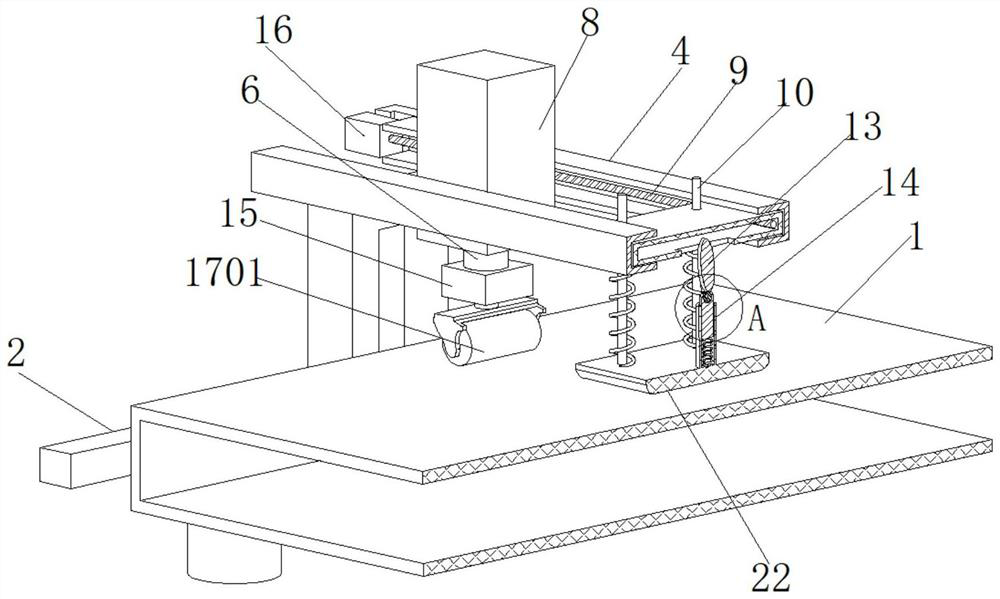

The invention discloses an asphalt spreading device for a building. The asphalt spreading device comprises a vehicle body, a drilling mechanism, a stirring and emptying mechanism and a compaction mechanism, wherein the drilling mechanism is arranged at the front end of the vehicle body and comprises a front cantilever and a drilling cylinder; the stirring and emptying mechanism comprises a stirring cylinder and a discharge pipe; the compaction mechanism is arranged below the vehicle body and comprises a compaction roller and a reciprocating drive mechanism; a control box is arranged on the vehicle body; a vehicle power supply and a switch control panel are arranged in the control box. According to the asphalt spreading device disclosed by the invention, through the drilling cylinder and aprecession drilling mechanism consisting of a thread rod, a prismatic rod and a rotary drum, flat cutting of the edge of a to-be-repaired pit is realized, follow-up asphalt grouting is facilitated, and the cutting efficiency is higher than that of a road cutting machine; through a compaction roller and the reciprocating drive mechanism, the compaction roller compacts the grouted asphalt back and forth without moving the vehicle body, thus the compaction efficiency is relatively high.

Owner:郑州靓岛建筑设计有限公司

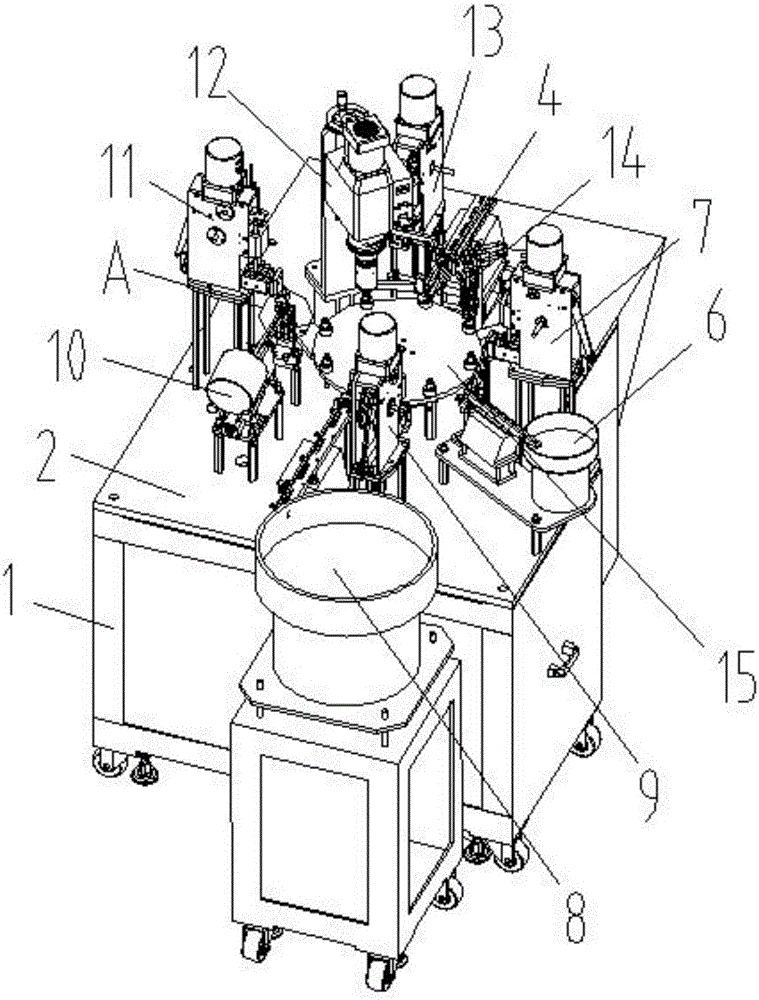

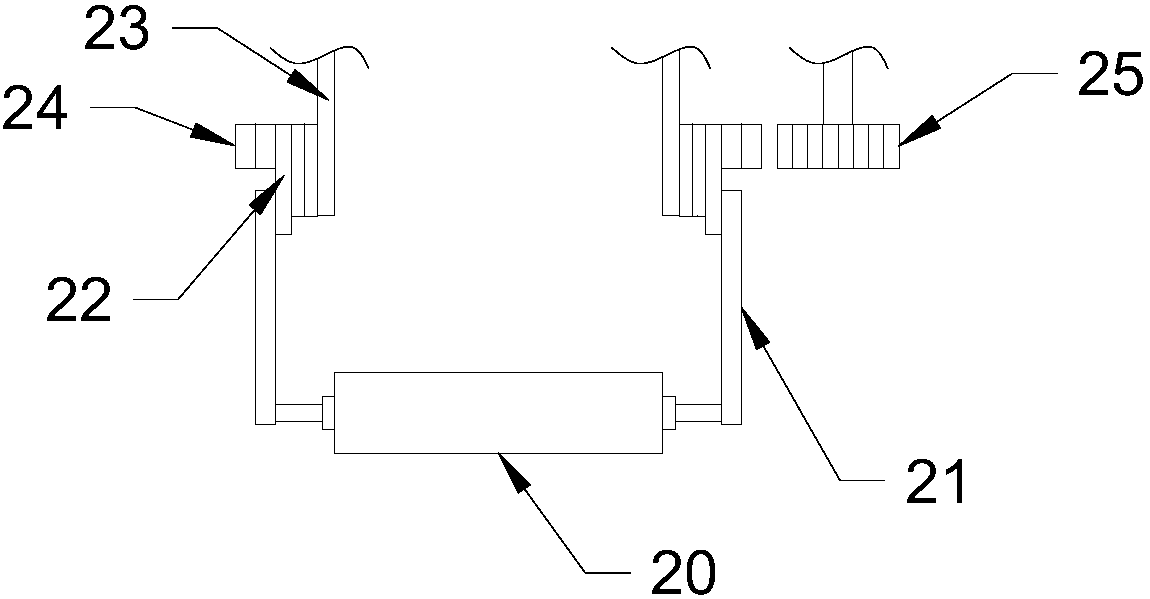

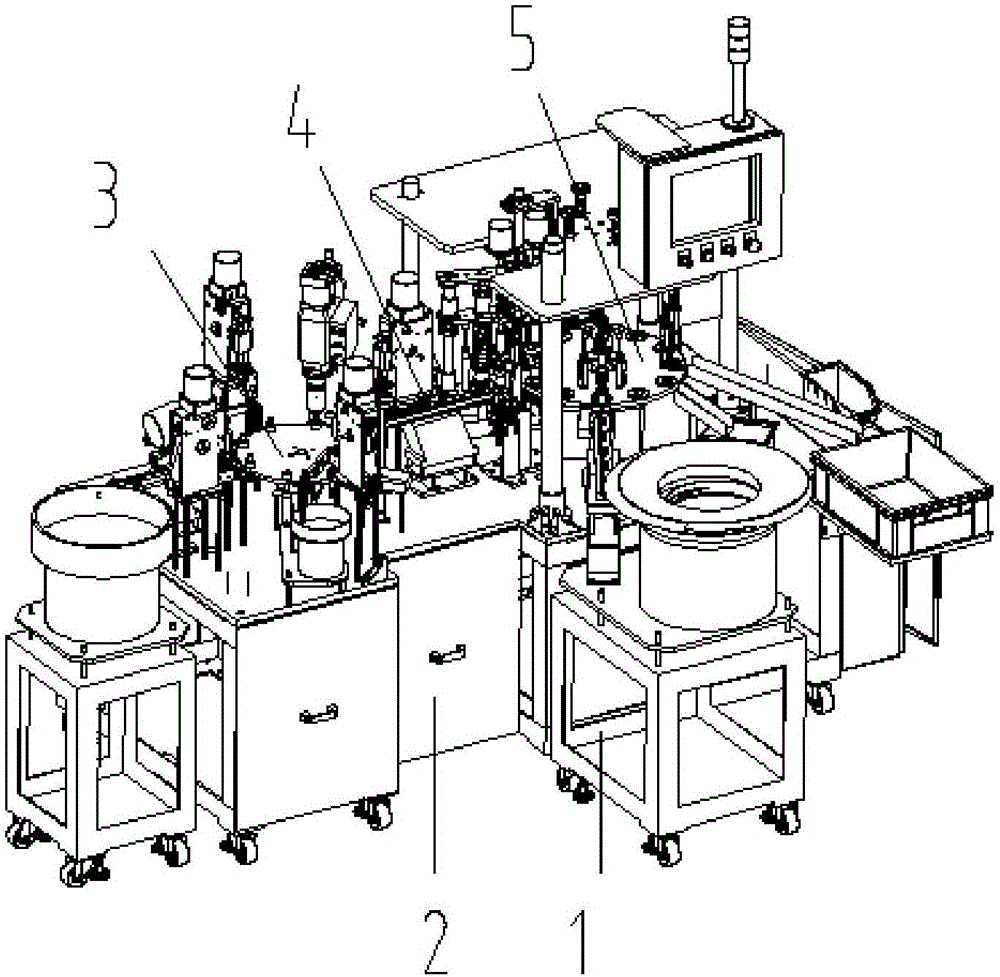

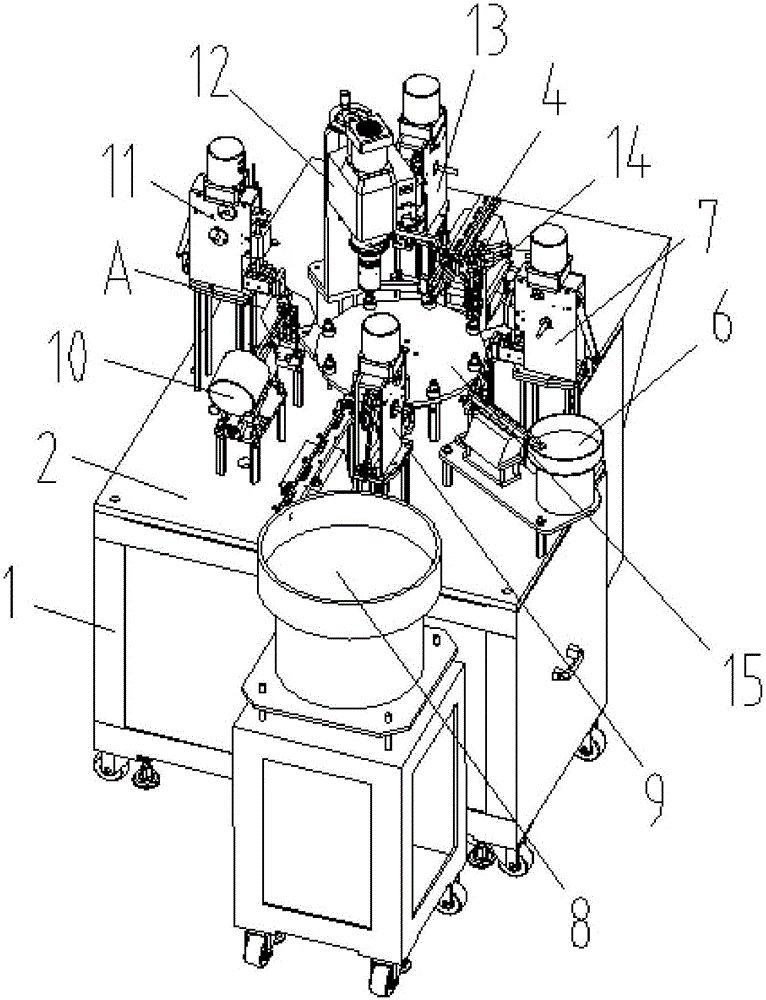

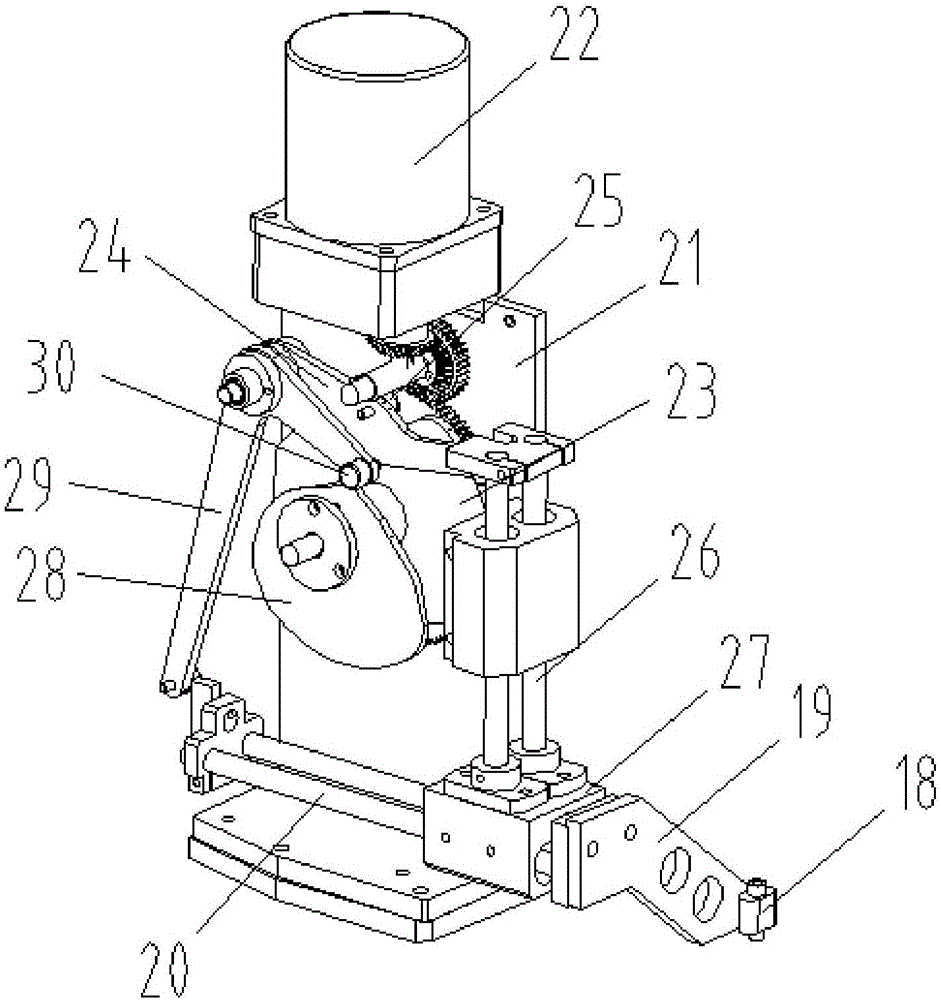

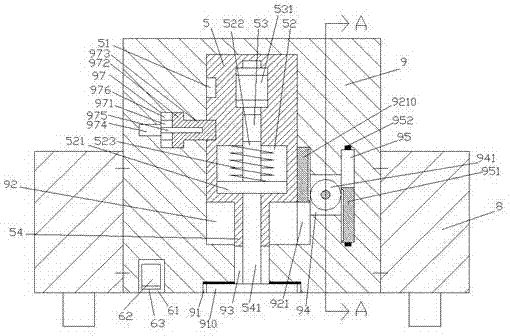

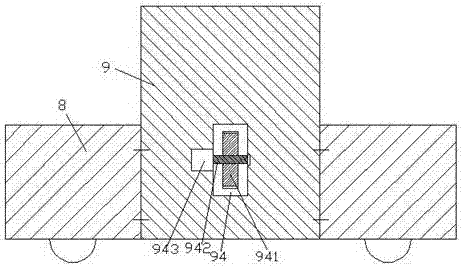

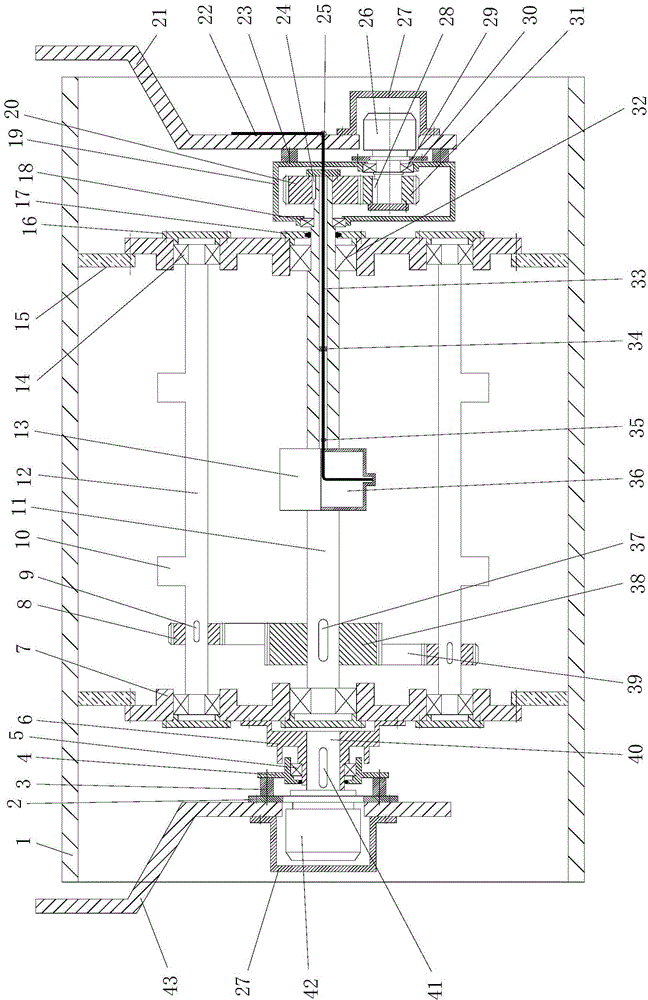

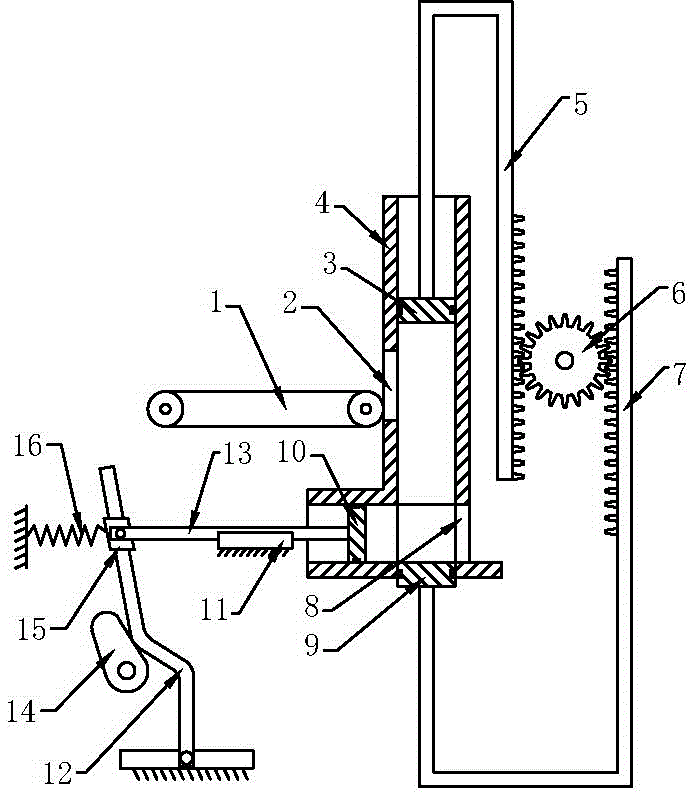

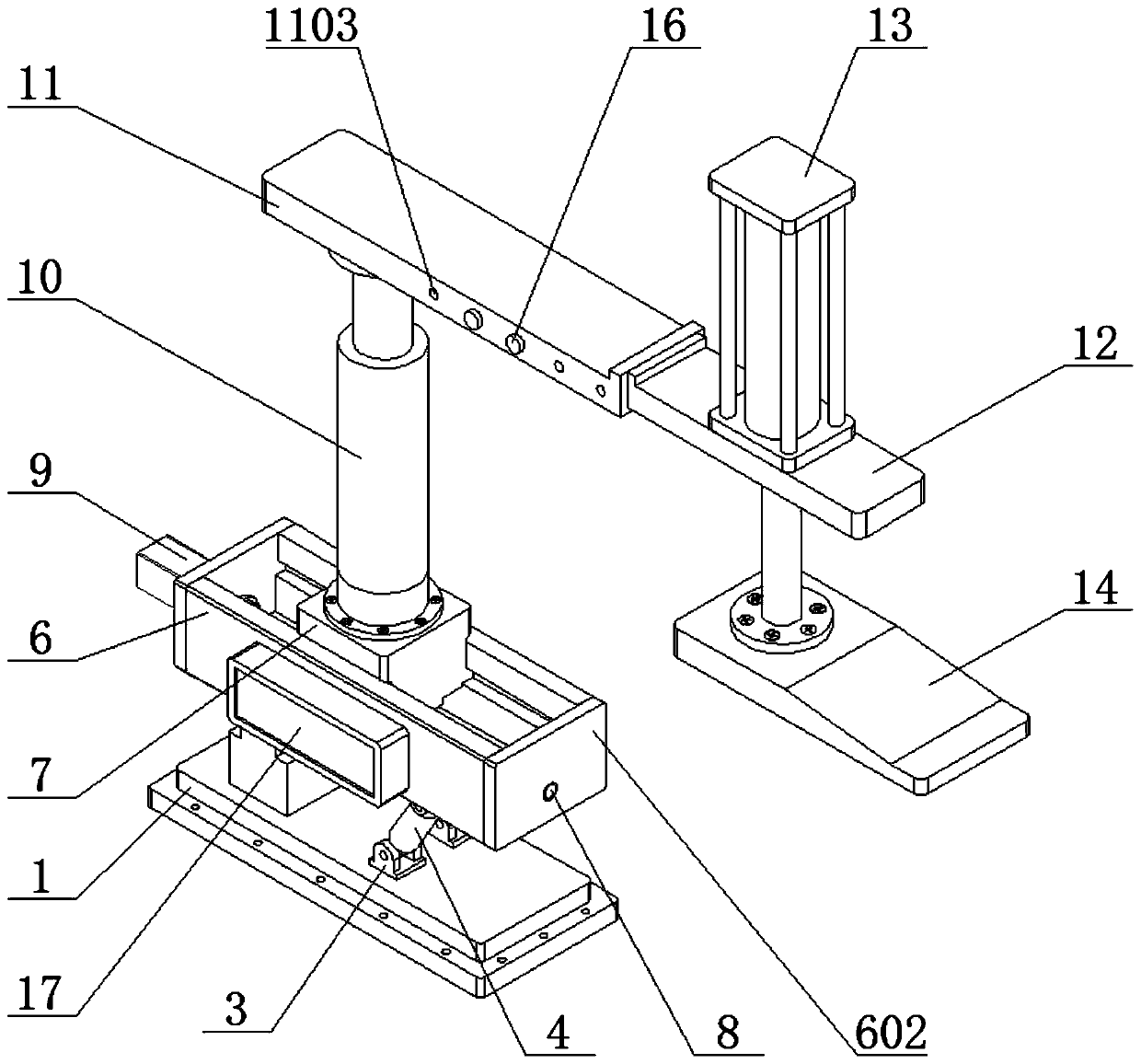

Automatic shaft sleeve assembly machine

InactiveCN106514197AImprove installation efficiencyRealize integrated automatic continuous operationMetal working apparatusDistribution controlEngineering

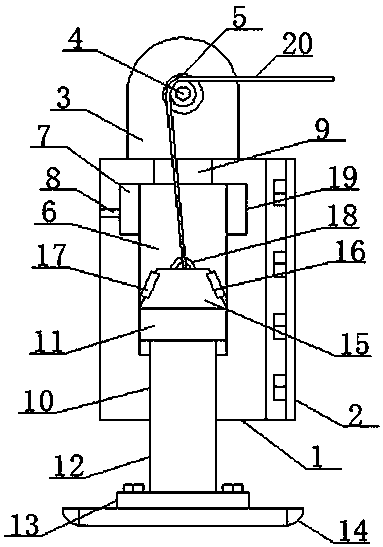

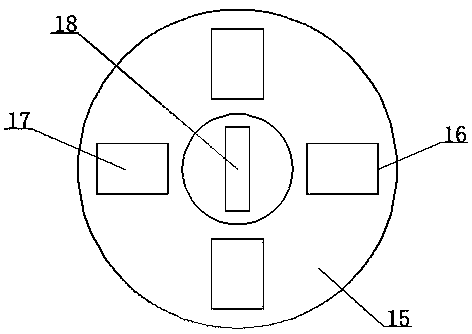

The invention relates to an automatic shaft sleeve assembly machine which comprises a rack and a power distribution control cabinet. The rack is provided with a shaft sleeve mounting rotary disc which is connected to a shaft sleeve mounting motor and uniformly provided with loading holes matched with shafts. A shaft feeding device, a shaft sleeve feeding device, a screw feeding device, a shaft sleeve pressing device and a shaft sleeve discharging device which are matched with the loading holes and connected to the power distribution control cabinet are sequentially arranged outside the shaft sleeve mounting rotary disc. According to the automatic shaft sleeve assembly machine, the shaft sleeve mounting rotary disc is arranged and uniformly provided with the loading holes matched with the shafts, the shaft feeding device, the shaft sleeve feeding device, the screw feeding device, the shaft sleeve pressing device and the shaft sleeve discharging device are sequentially arranged outside the shaft sleeve mounting rotary disc, integrated automatic continuous operation of shaft sleeves and screws is achieved, the shaft sleeve mounting efficiency is greatly improved, and meanwhile, the equipment utilization rate is increased.

Owner:柳州市凯仕达汽车配件有限公司

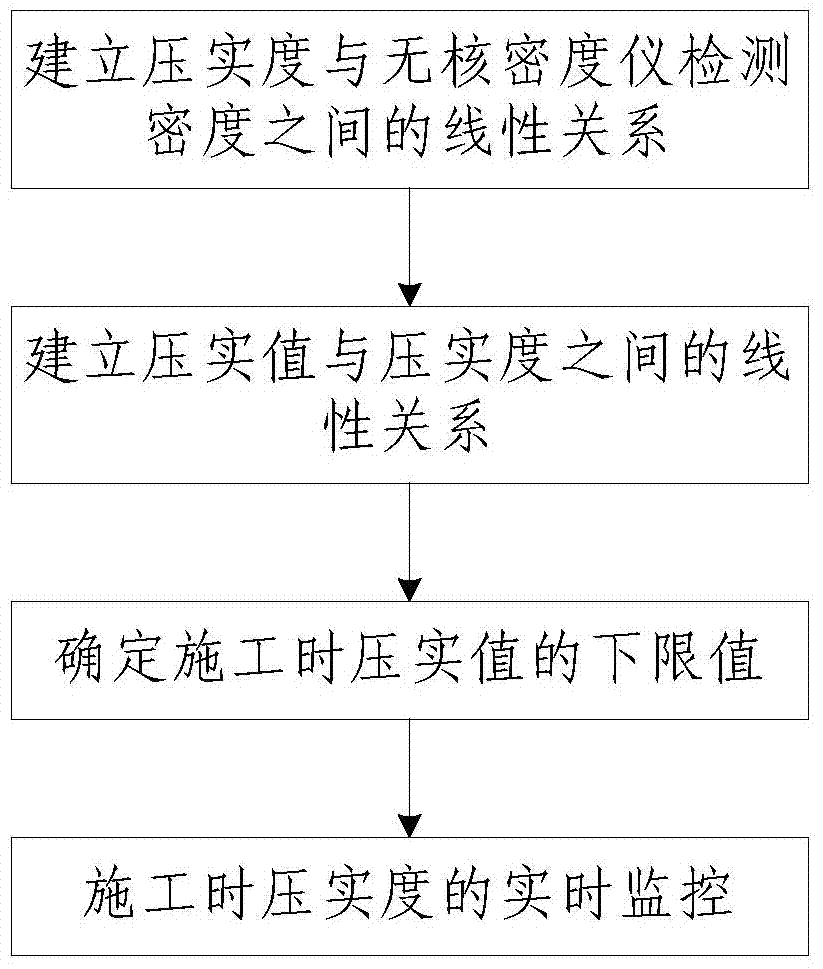

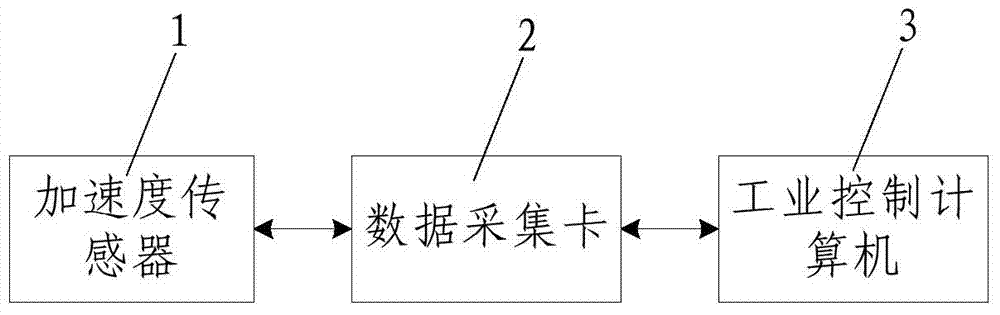

Real-time asphalt road compactness monitoring method

InactiveCN103487351ASimple monitoring methodNovel and reasonable designRoads maintainenceProgramme control in sequence/logic controllersLower limitEngineering

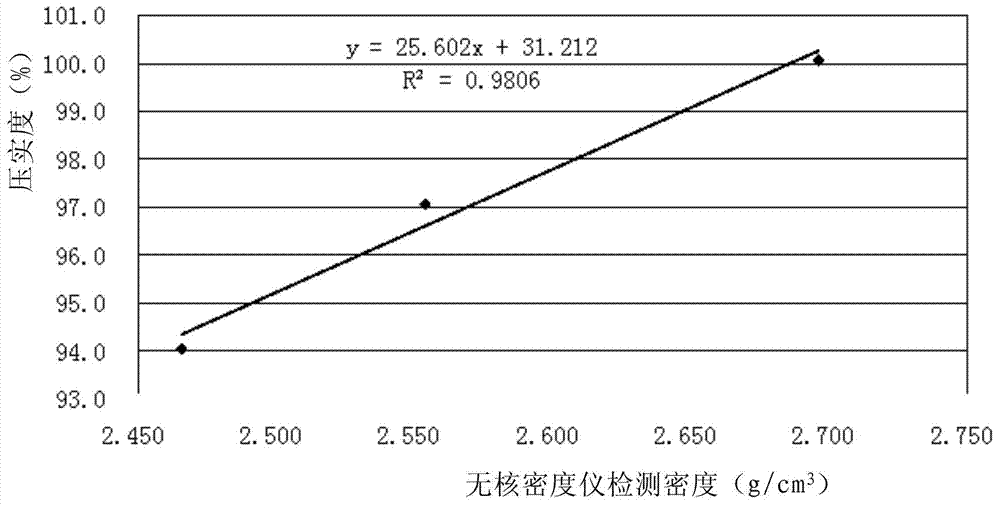

The invention discloses a real-time asphalt road compactness monitoring method which comprises the steps of (1) establishing a linear relation between compactness and detection density of a non-nuclear density gauge; (2) establishing a linear relation between a compaction value and the compactness; (3) according to the lower compactness limit requirement of a construction site and according to the linear relation between the compaction value and the compactness, established in the step (2), determining the lower limit of the compaction value; (4) monitoring the compactness in construction in real time, enabling an vibratory roller operator to control a vibratory roller through observing the compacted or uncompacted information displayed on an industrial control computer, continuously rolling when in uncompaction, and stopping rolling when in compaction. The real-time asphalt road compactness monitoring method is novel and reasonable in design, convenient to realize, capable of improving the compaction quality and efficiency of an asphalt road and avoiding damage to the road, relatively high in compactness detection accuracy, low in realization cost, strong in practicability, and high in popularization and application values.

Owner:CHANGAN UNIV +1

Soil chemical stabilizer formula and application

InactiveCN101684409AImprove compaction efficiencyImproved resistance to water immersionRoadwaysWallsWater contentChemistry

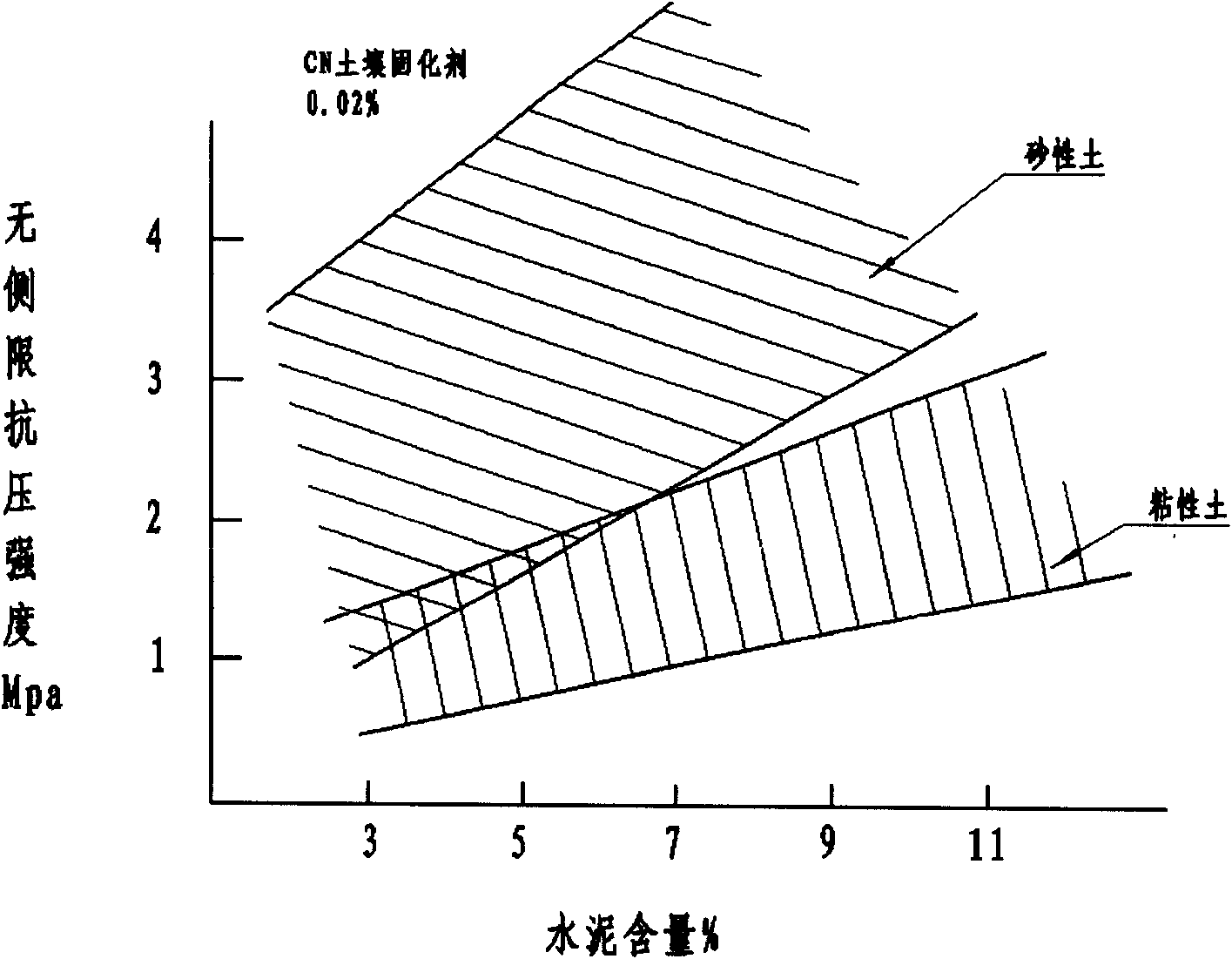

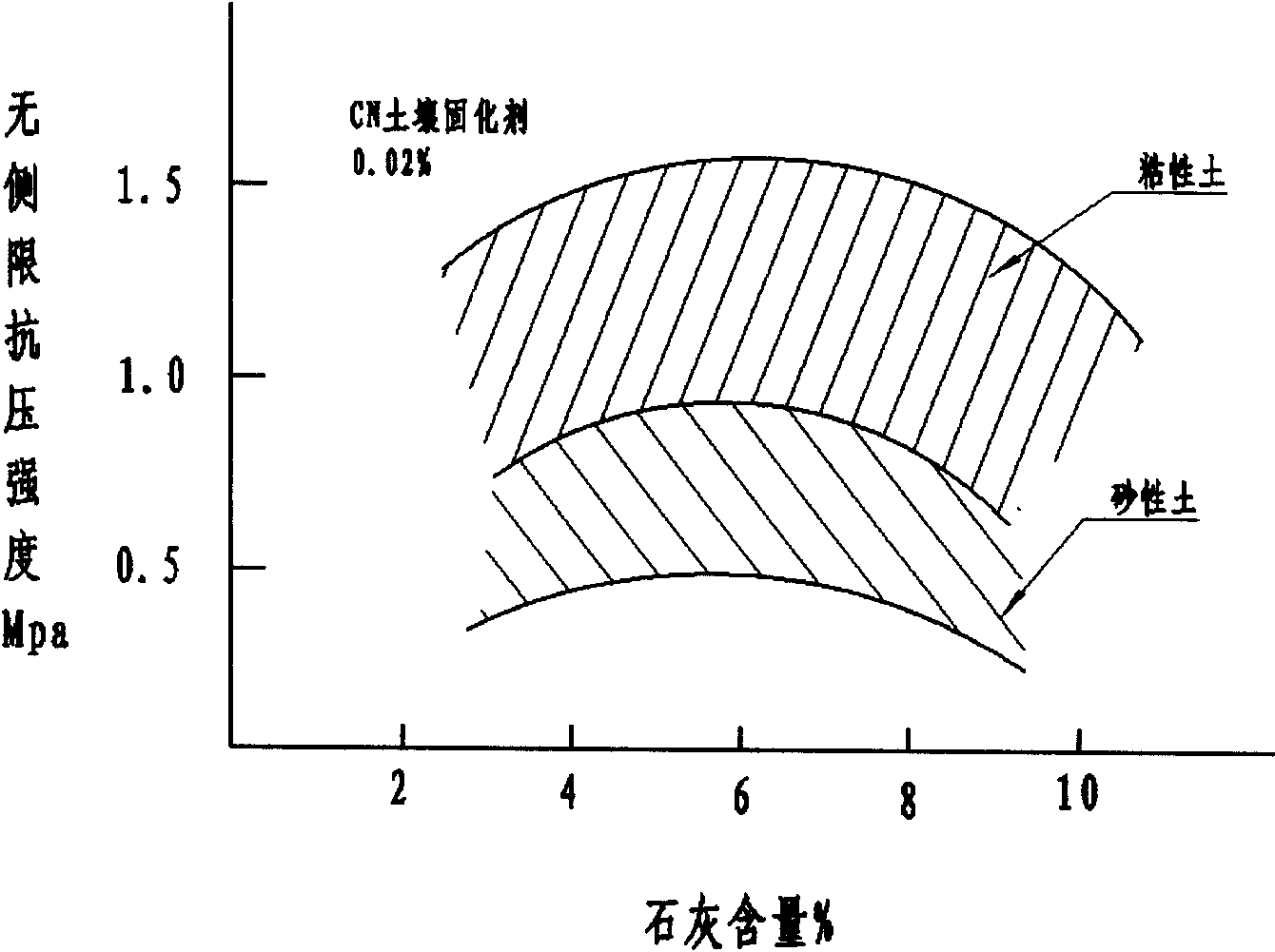

The invention discloses a soil chemical stabilizer formula and an application. The formula is characterized by comprising raw material components in parts by weight: 70-93 parts of sulfuric acid, 3-30parts of rosin oil, 1-6 parts of wetting agent, 0.5-1.7 parts of dispersing agent and 0.3-1.5 parts of thickening agent. Soil and the soil chemical stabilizer are stirred evenly for compaction and maintenance under the condition of the optimum water content, wherein the addition amount of the soil chemical stabilizer accounts for 0.01-0.04% of the soil; the soil chemical stabilizer can be used independently, while a little of concrete or lime needs to be added in many cases; the construction of the stabilizer adopts traditional equipment, and the construction method is the same as the conventional process. The soil chemical stabilizer has the characteristics of low cost, excellent performance and environmental friendly materials, and can be widely applied in the fields, such as subgrade construction, water conservancy construction, country roads, temporary sites, low cost road pavements, wall building and brick making and the like.

Owner:孙建国

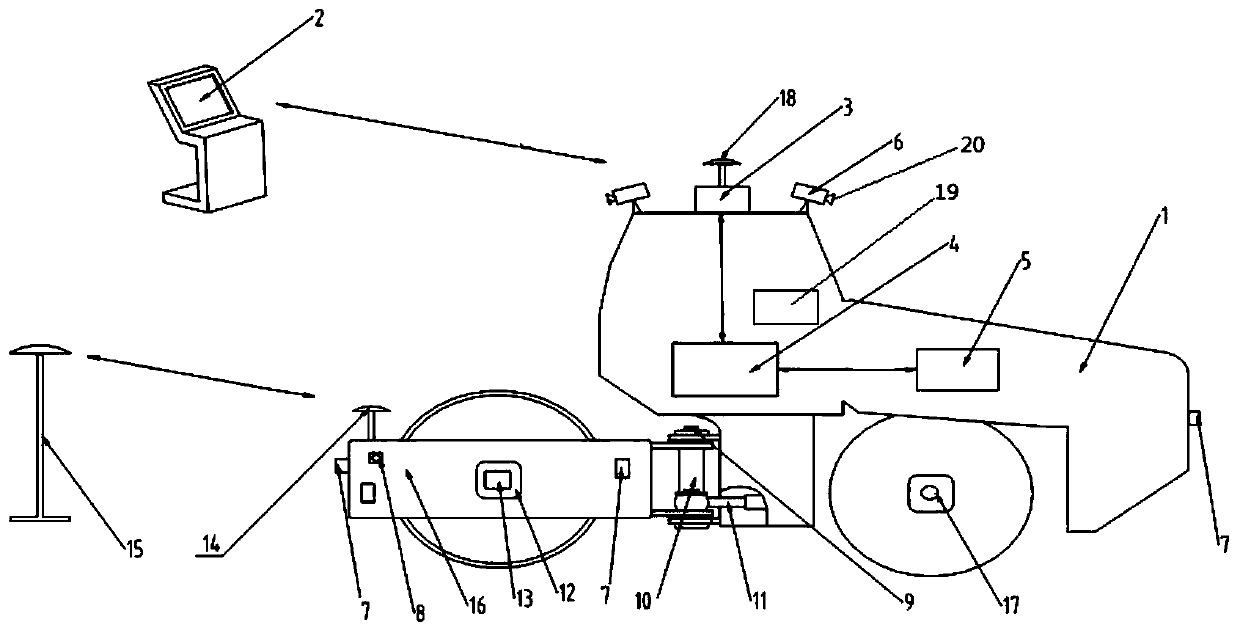

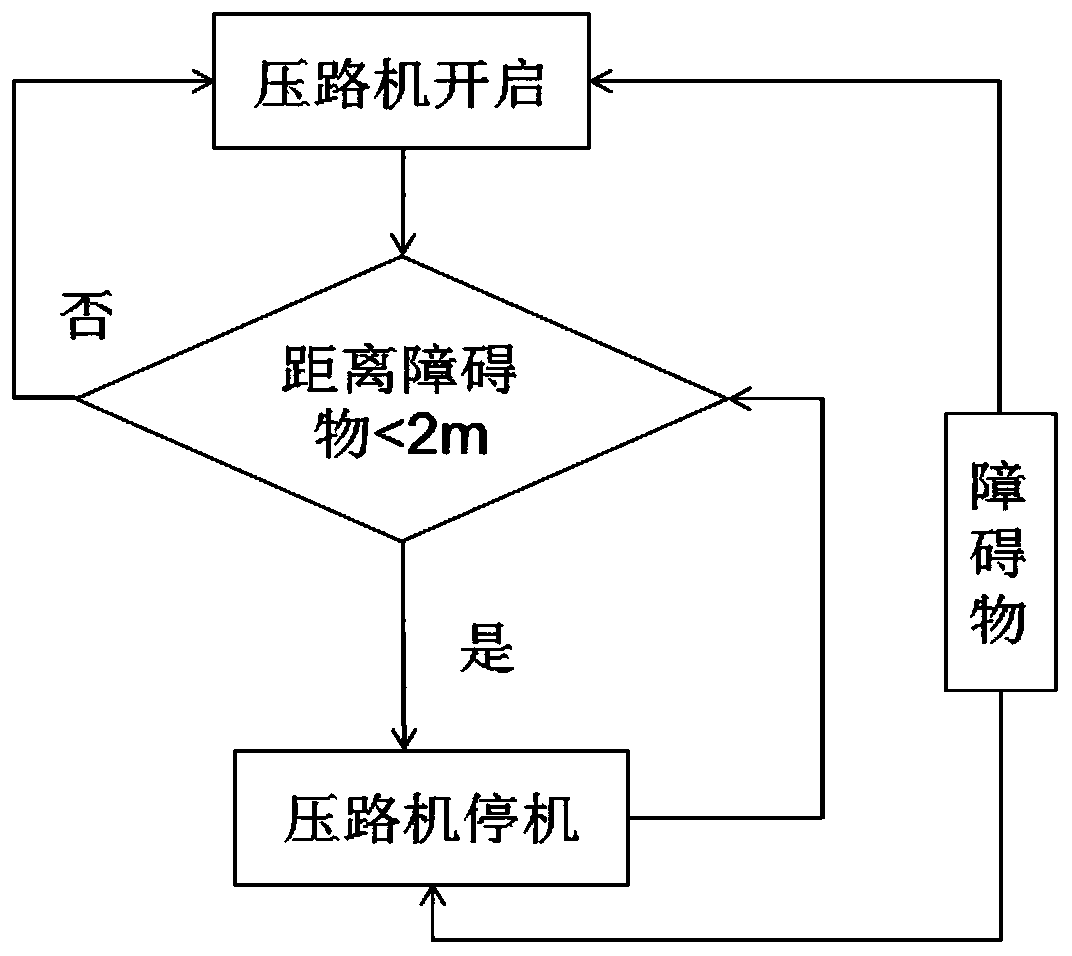

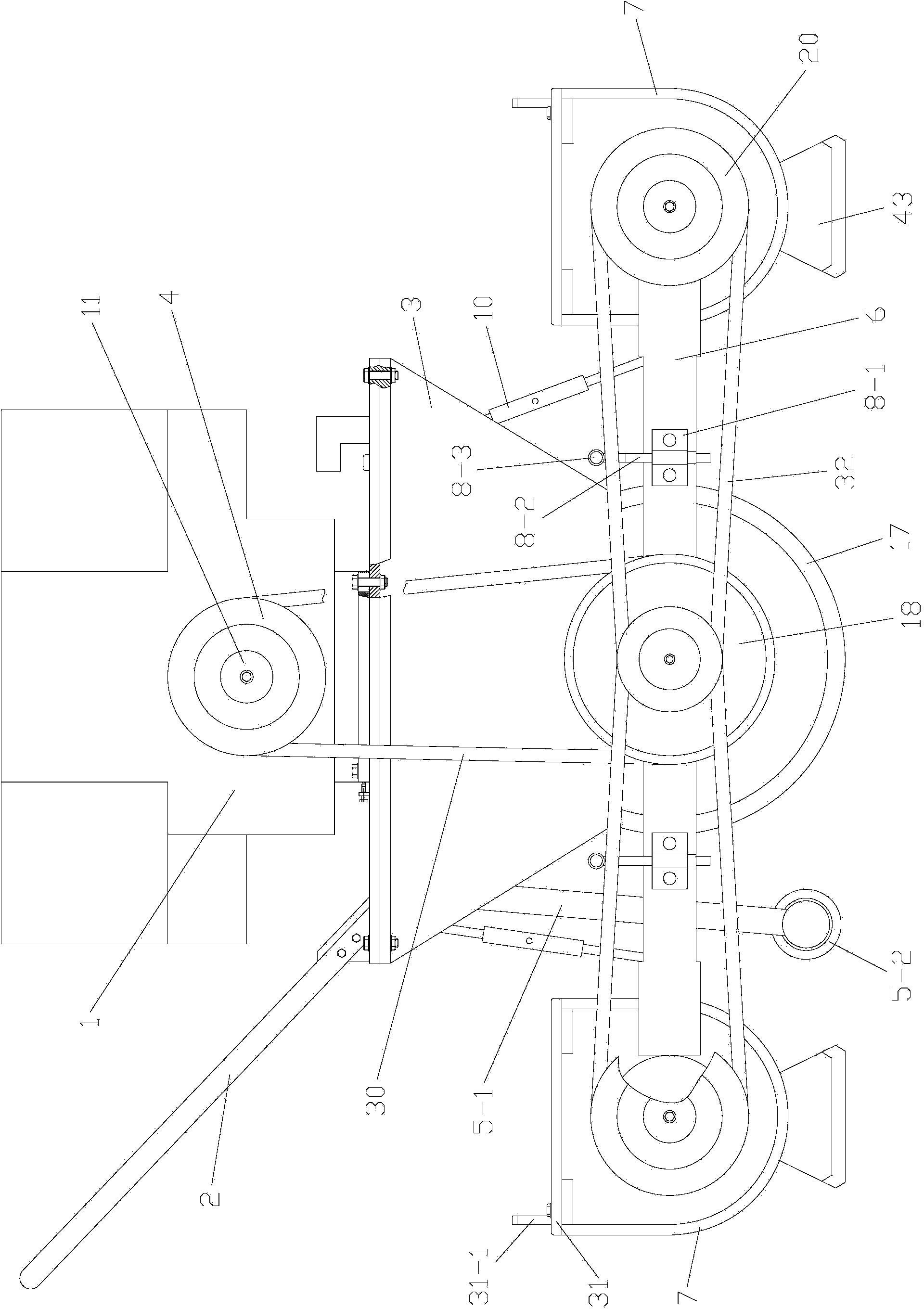

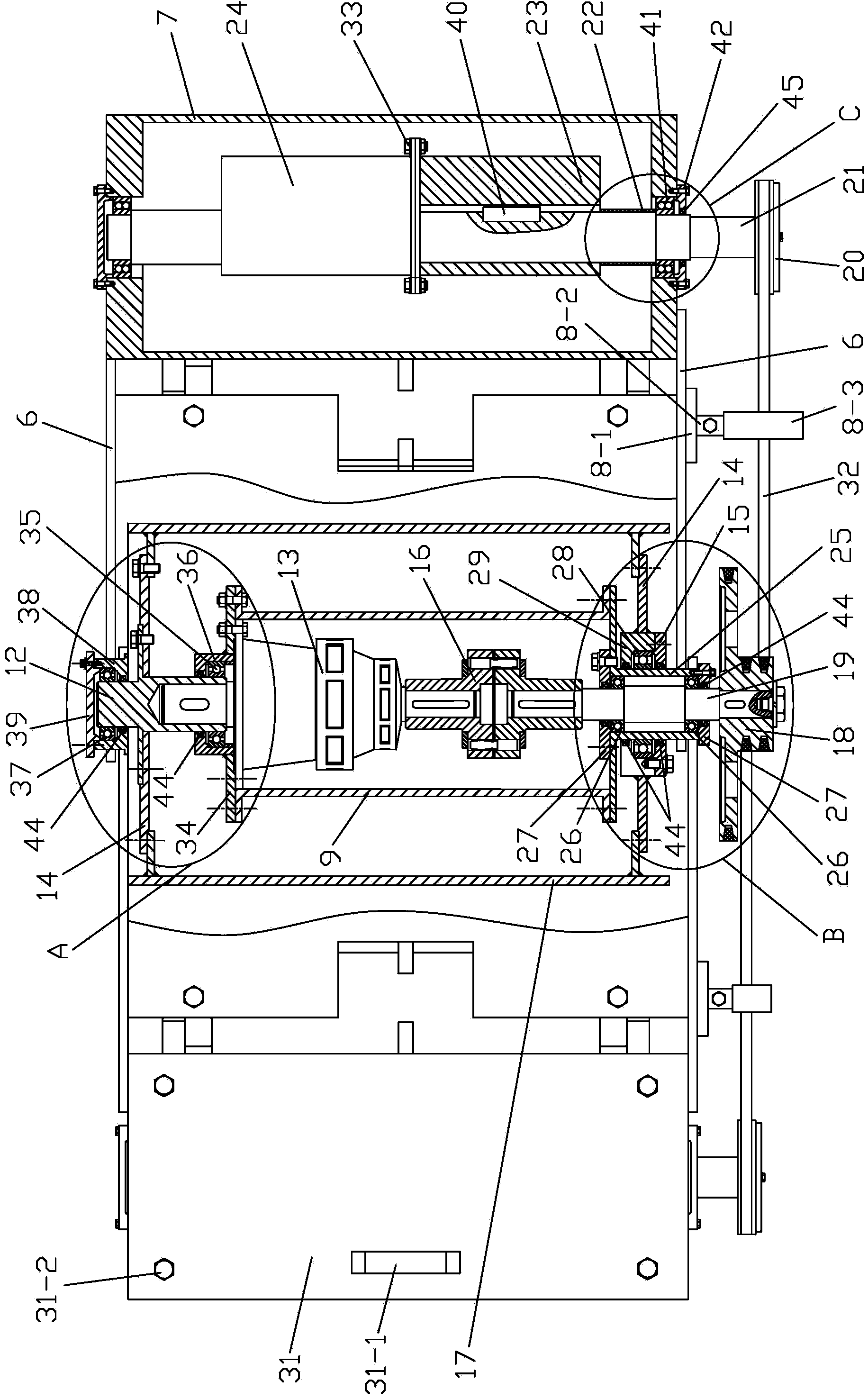

Autonomous operation intelligent road roller system

ActiveCN110331639AReduce harmReduce or get rid of dependenceSatellite radio beaconingMaterial testing goodsManagement planningEngineering

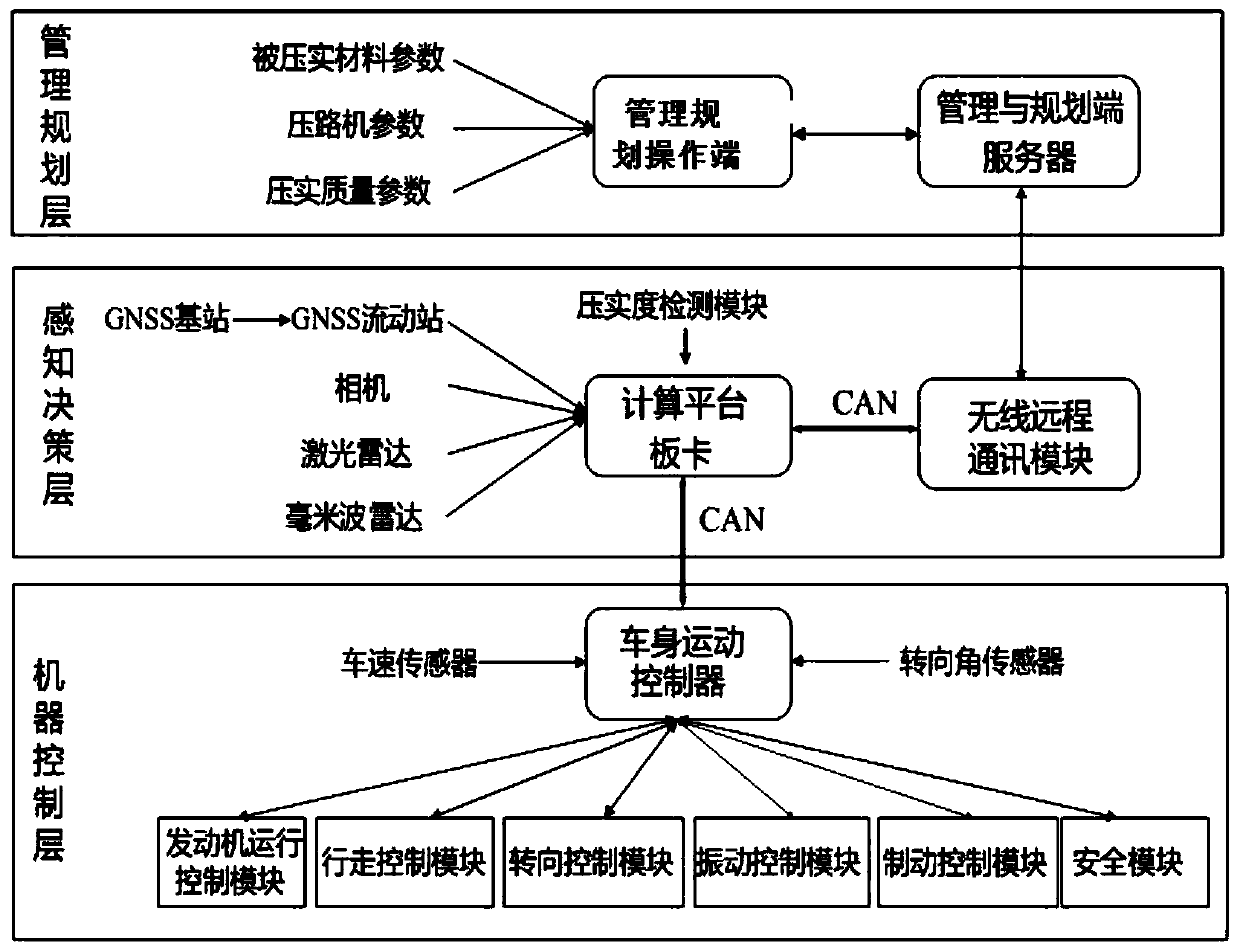

The invention discloses an autonomous operation intelligent road roller system comprising a road roller body, a machine control layer for controlling the motion of the road roller body, a perceive decision layer and a management planning layer; a carrier phase differential technology GNSS is adopted to realize high-precision positioning and course measurement; the vehicle body is provided with a millimeter wave radar for detecting obstacles in the periphery of the vehicle body; the vehicle body is provided with a laser radar and a camera used for high-precision map construction and side slopedetection of a rolling area, so that a management planning end can carry out rolling operation planning; an onboard compaction degree online detection technology is adopted to realize full-coverage online detection of the compaction degree, and a basis is provided for frequency modulation amplitude modulation; an expert system and a big data system are internally arranged in the management planning end, rolling planning can be autonomously performed according to the characteristics of the construction site compacted material, the parameters of the road roller, the compaction degree informationand the high-precision map, and cluster compaction data sharing and collaborative operation is realized; the vibration energy output can be adjusted in real time by the road roller according to the compaction progress, and the compaction quality and efficiency are effectively improved.

Owner:CHANGAN UNIV

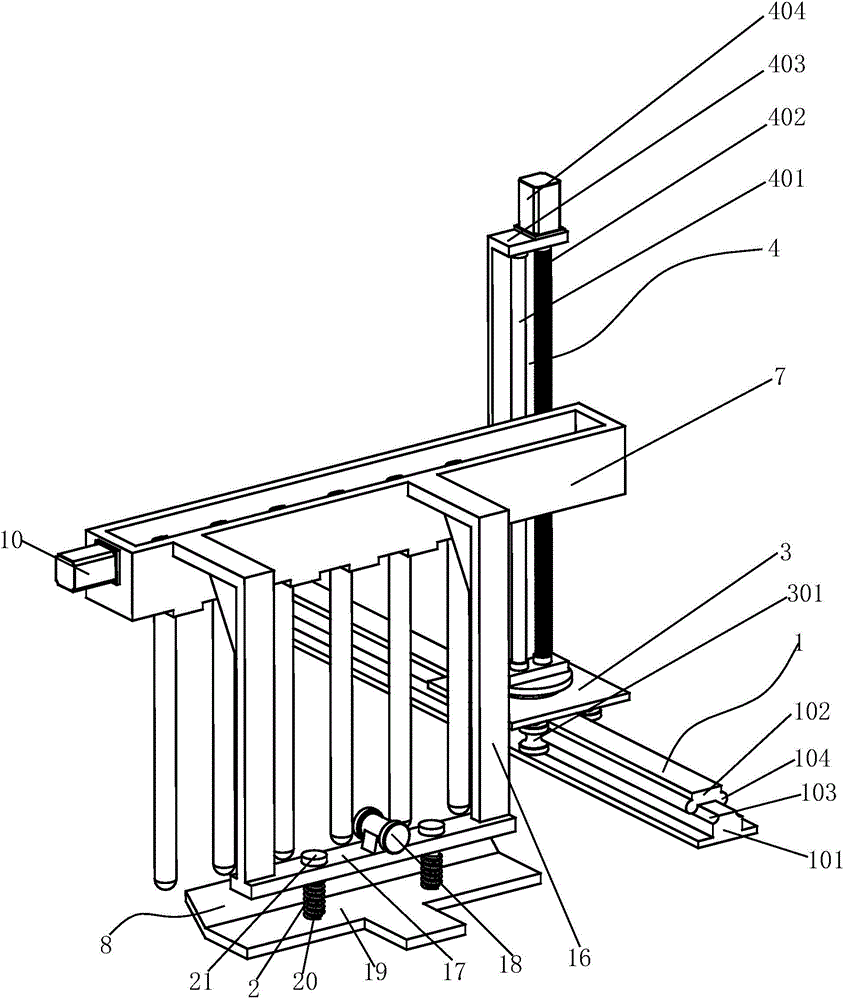

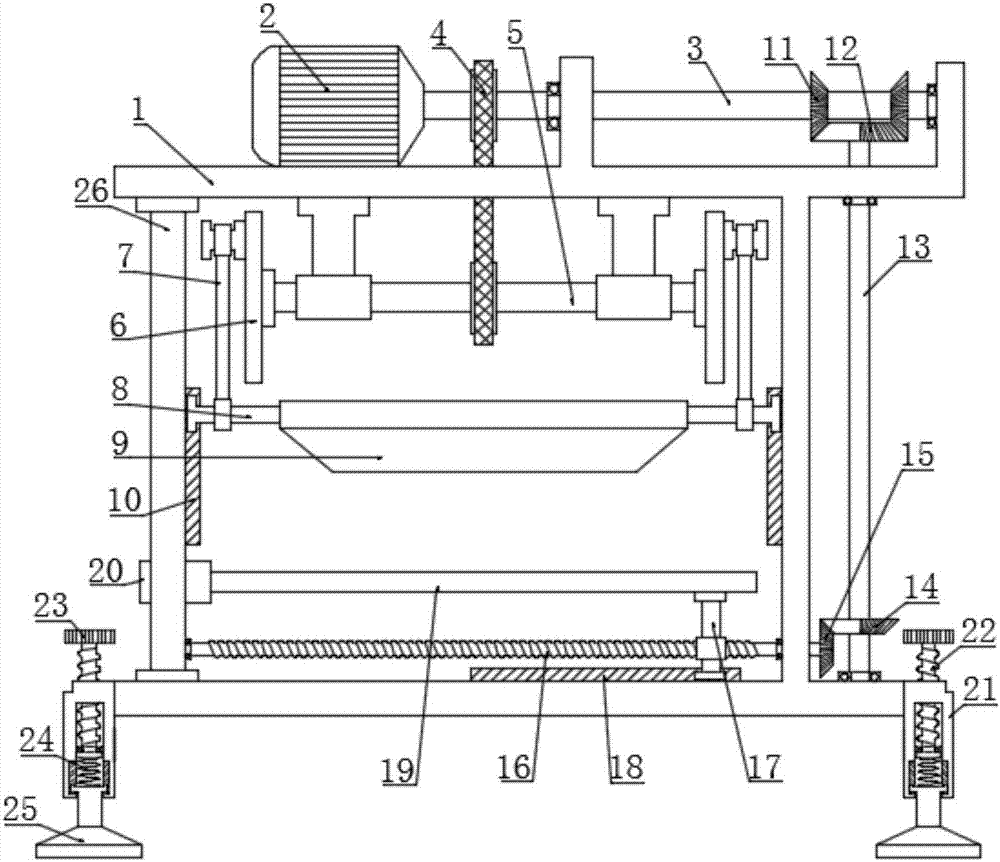

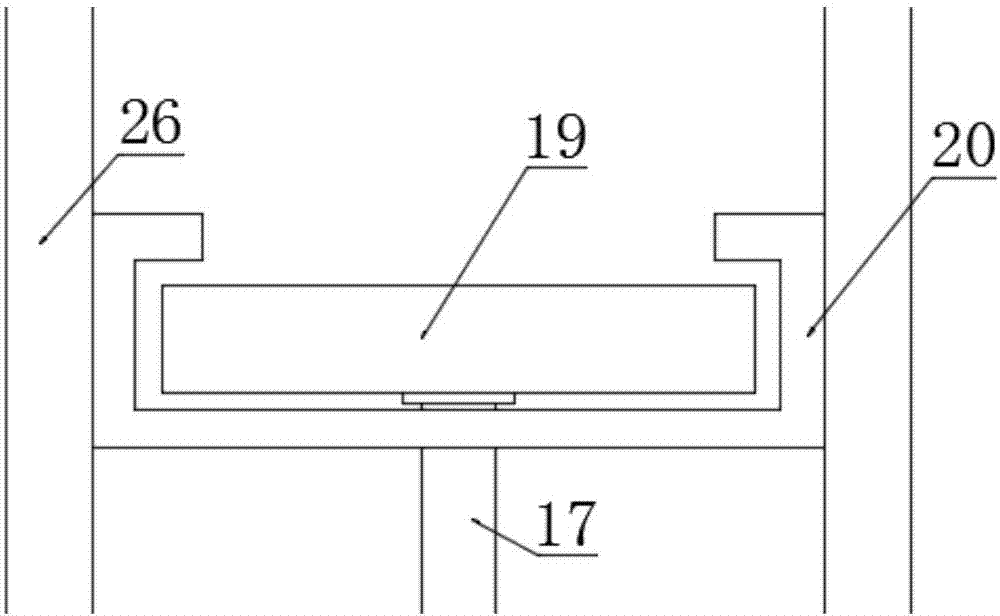

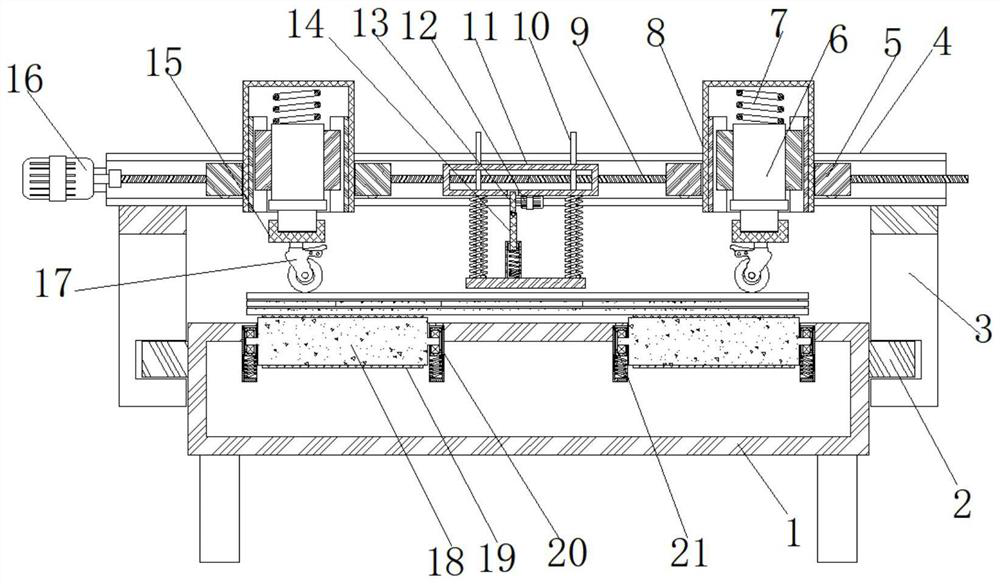

Concrete vibrating leveling device

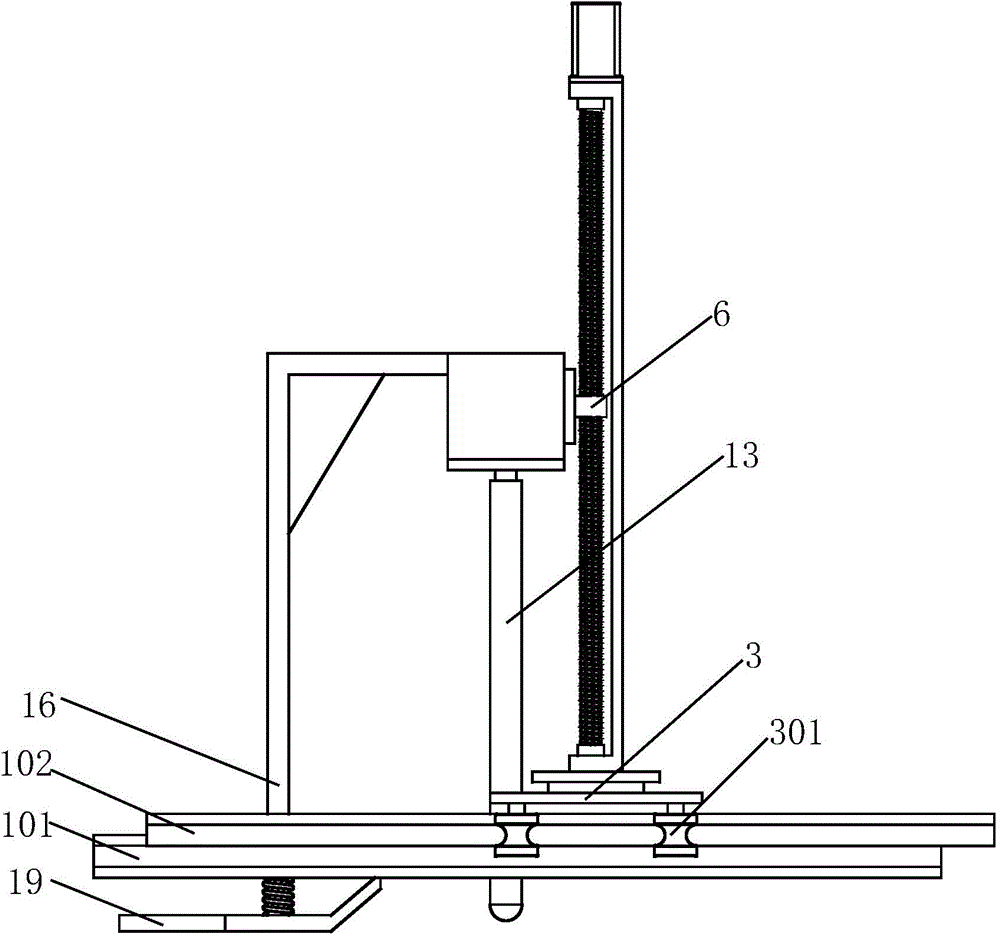

InactiveCN104453241AImprove compaction efficiencyIncrease height differenceBuilding material handlingSlide plateEngineering

The invention relates to a concrete vibrating leveling device which comprises a spliced rail. A sliding plate is arranged on the spliced rail, the lower end face of the sliding plate is provided with at least two rollers correspondingly clamped to the spliced rail, the upper end face of the sliding plate is fixedly provided with a positioning lifting frame, the positioning lifting frame comprises a guide rod and a lead screw, the upper end of the guide rod and the upper end of the lead screw are each fixedly provided with an upper end cap, the upper end caps are fixedly provided with a first motor, a shaft of the first motor is connected with the lead screw, the guide rod is provided with a left sliding sleeve, the lead screw is provided with a right sliding sleeve, a cam box is arranged in front of the left sliding sleeve and the right sliding sleeve, a second motor is fixed to the cam box, a shaft of the second motor is connected with transverse rods transversely arranged in the cam box, the transverse rods correspond to through holes and are each sleeved with an ejector rod cam, and vibration bars are arranged in the through holes in a penetrating mode. According to the device, concrete is tamped through the vibration bars by means of the ejector rod cams fixed to the transverse rods, tamping efficiency of the vibration bars is improved, and the aim that vibration and tamping of the vibration bars are carried out at the same is achieved.

Owner:NANJING DENGYU MACHINERY EQUIP MFG CO LTD

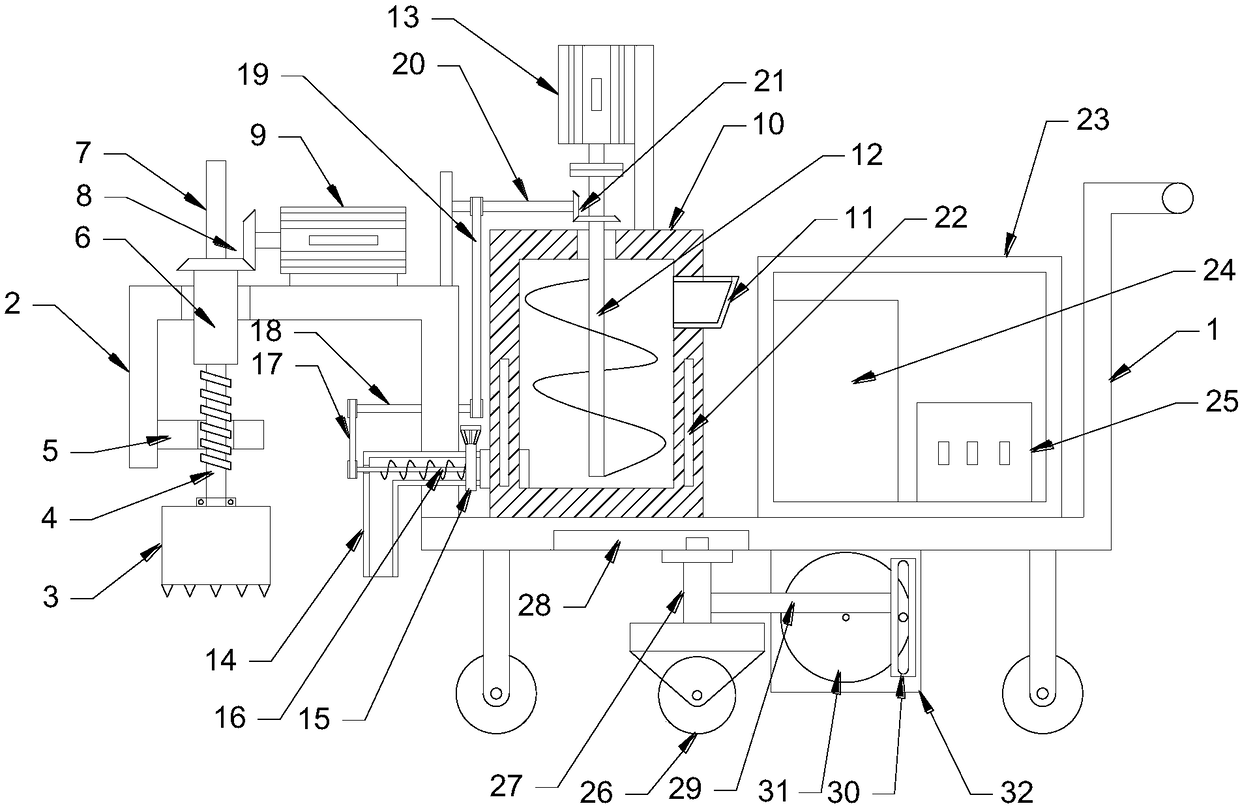

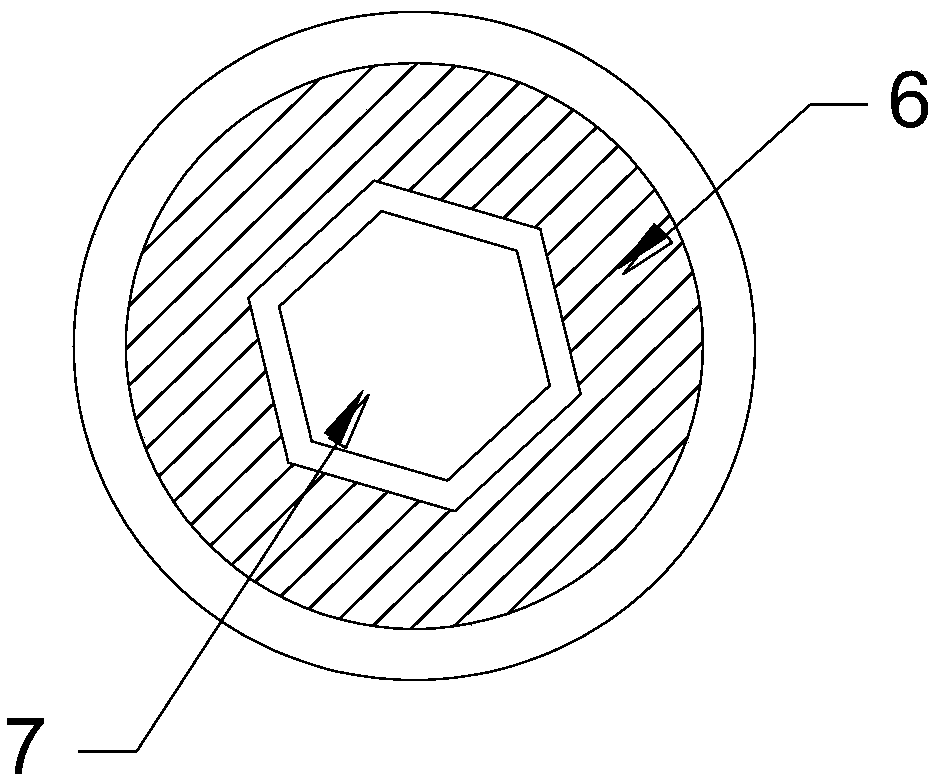

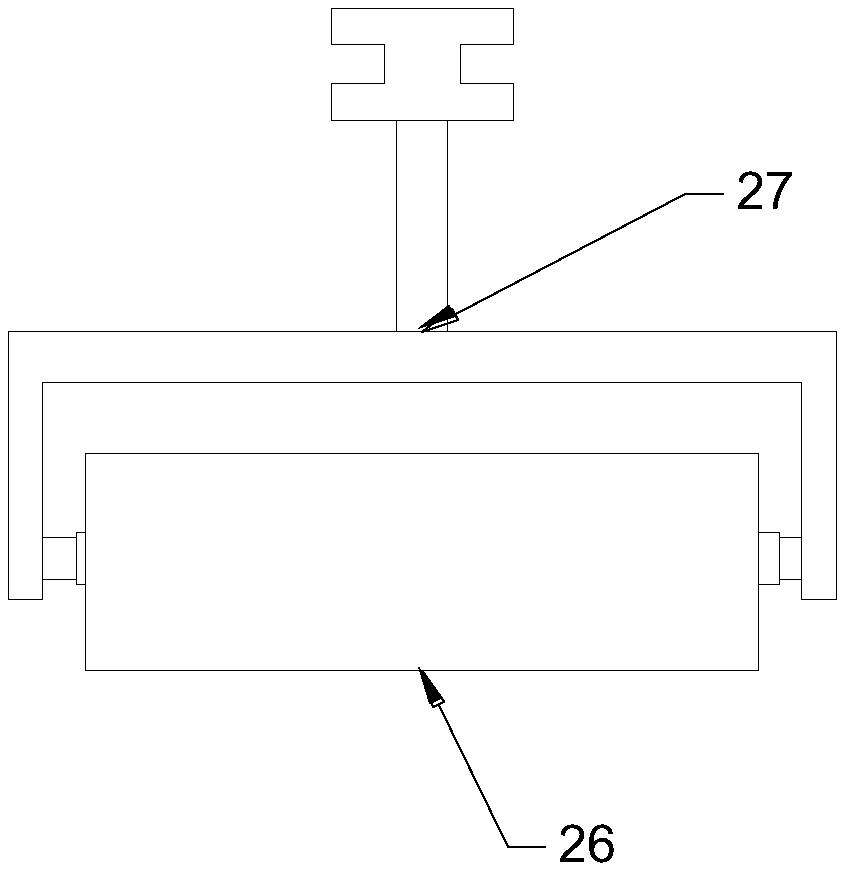

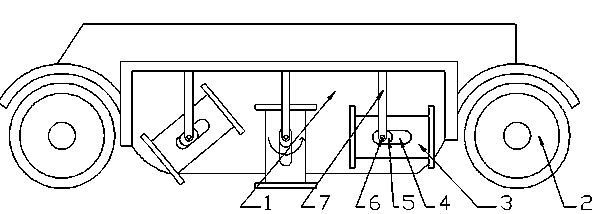

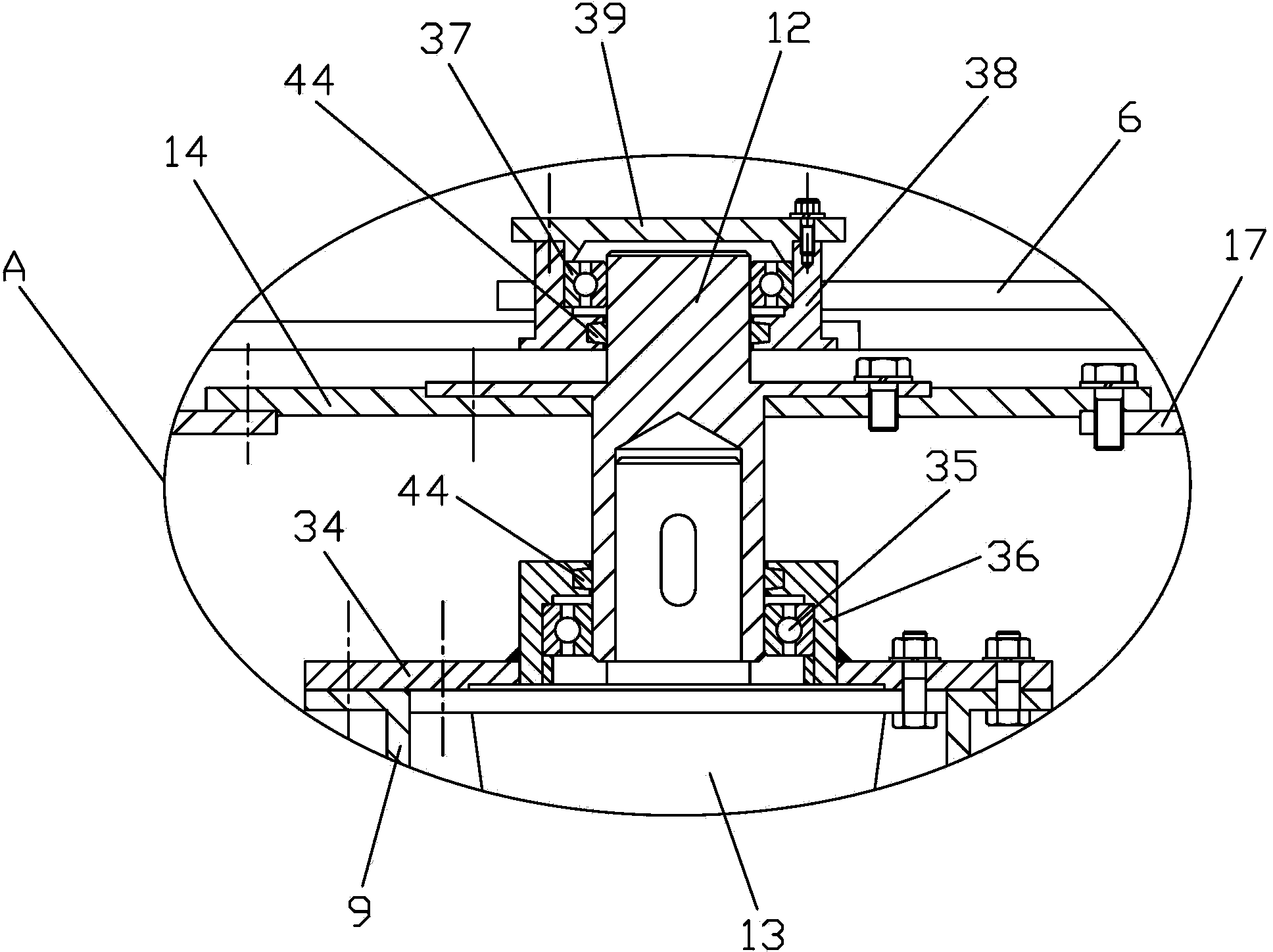

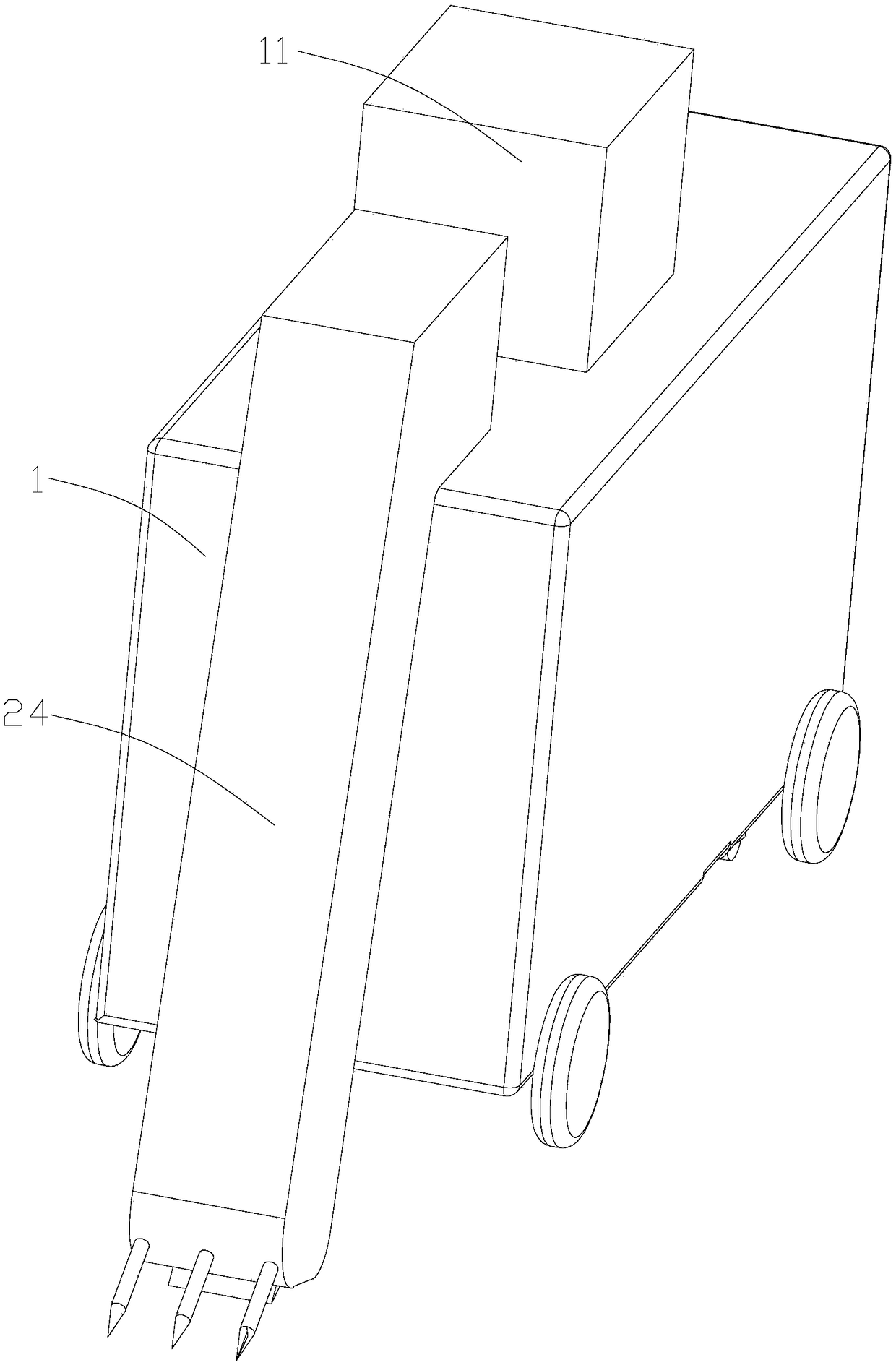

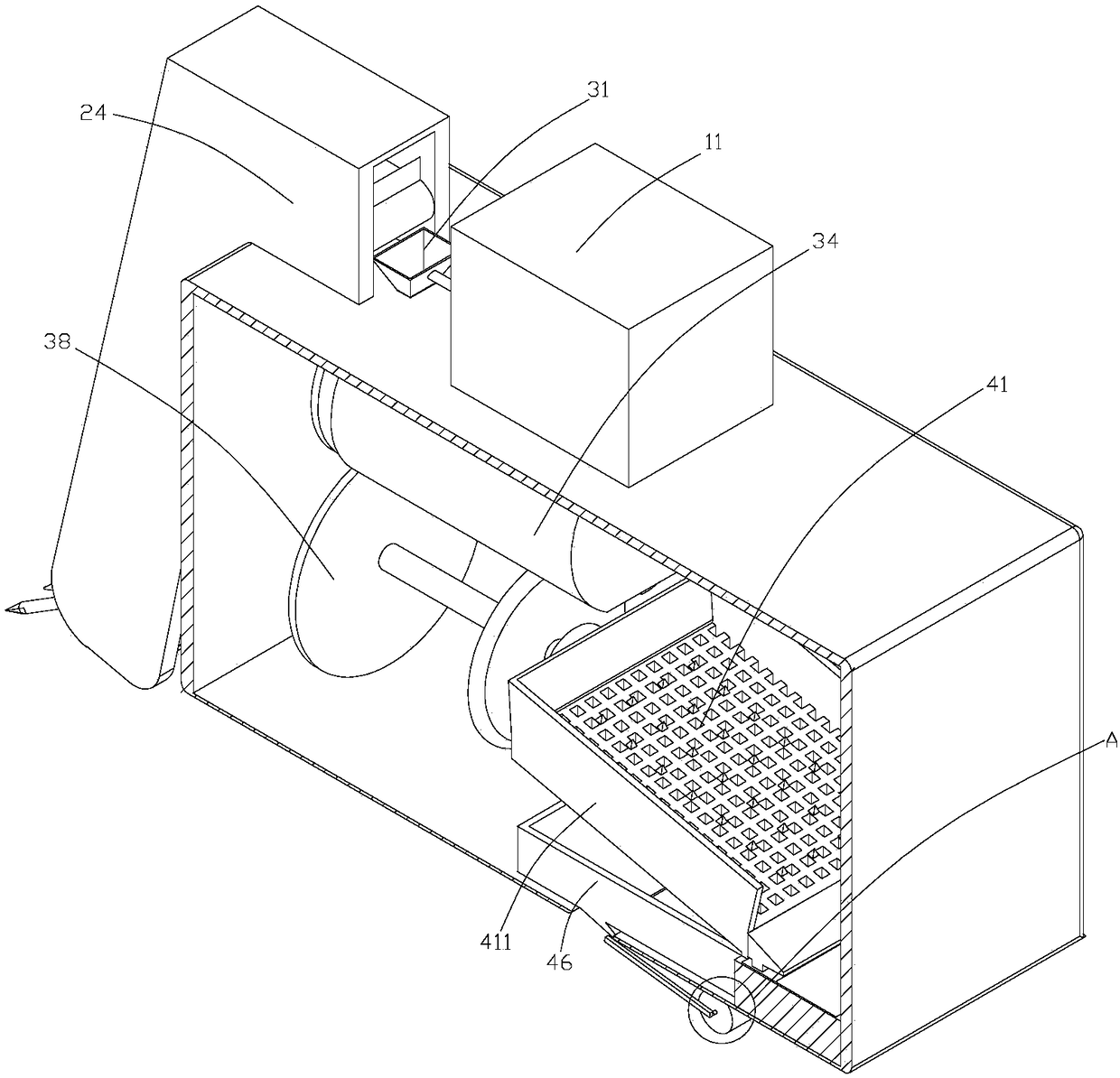

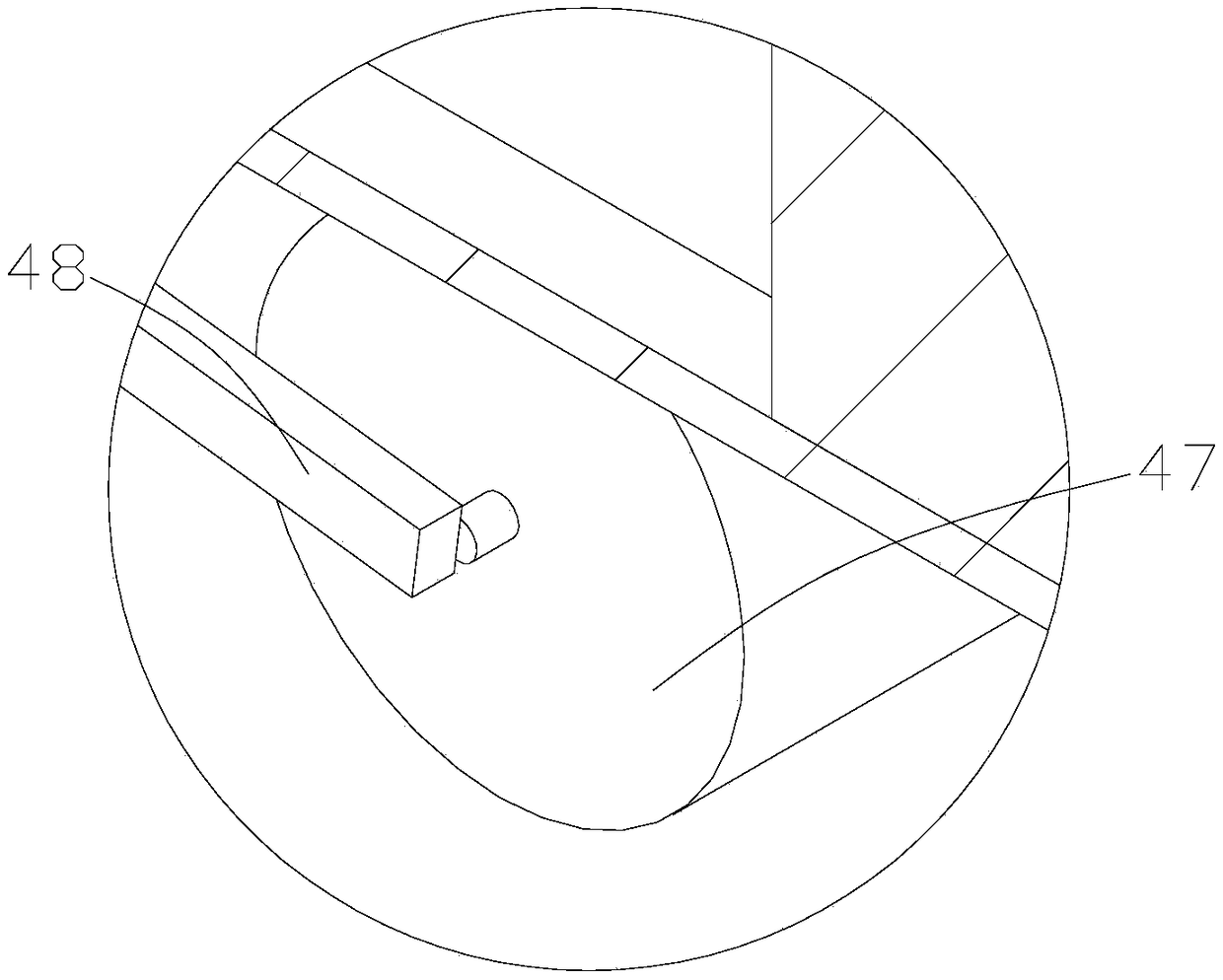

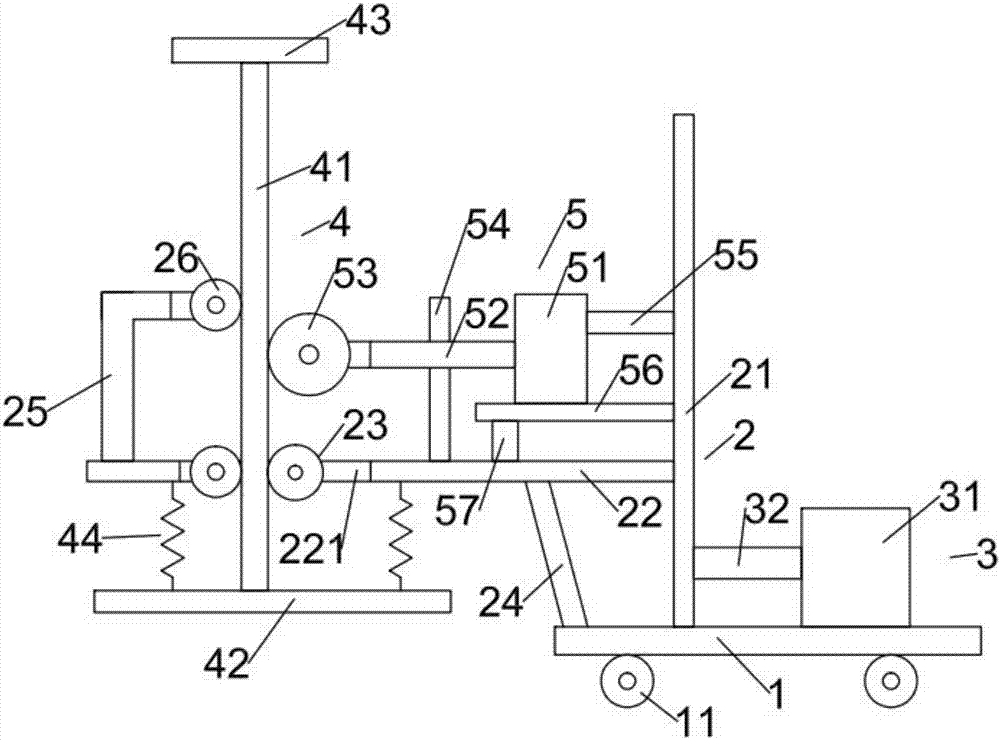

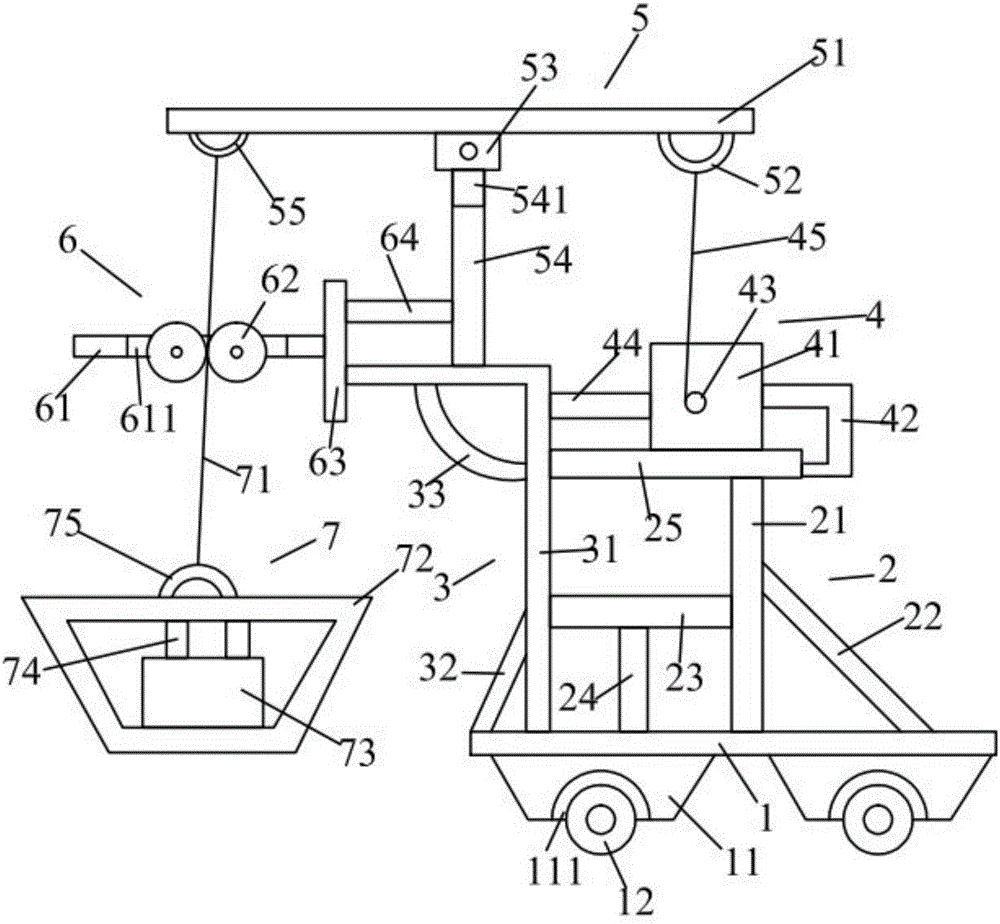

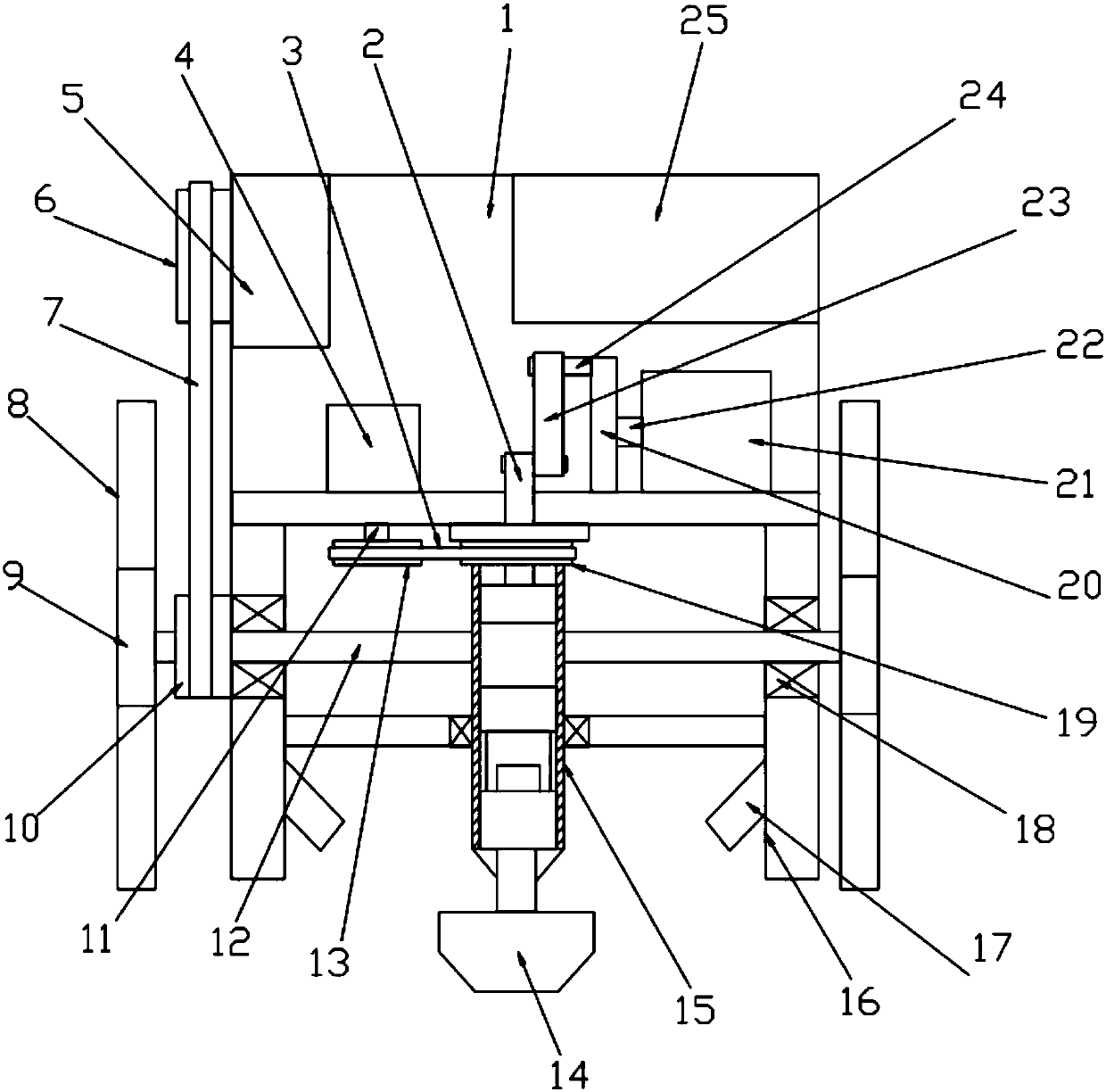

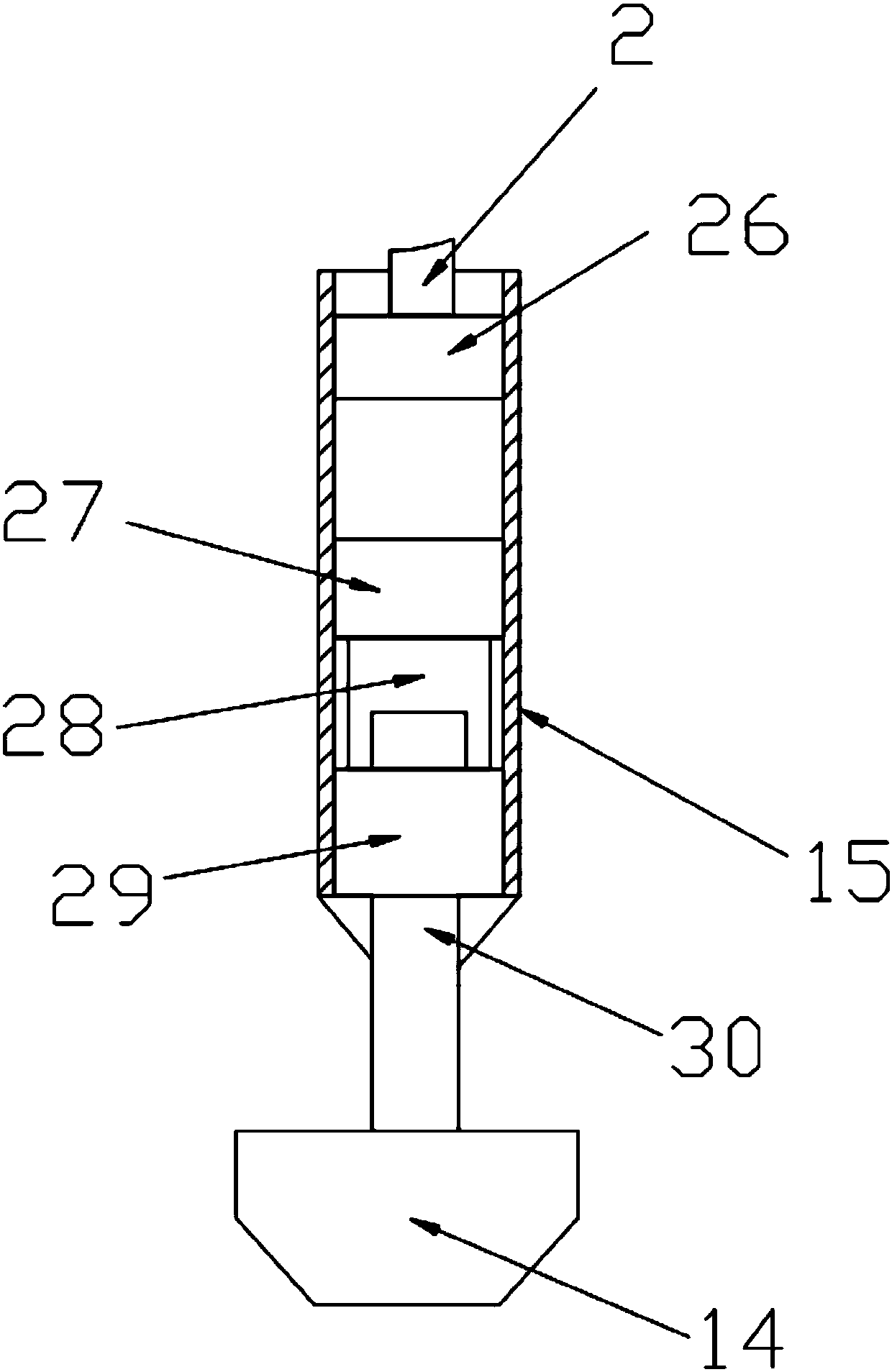

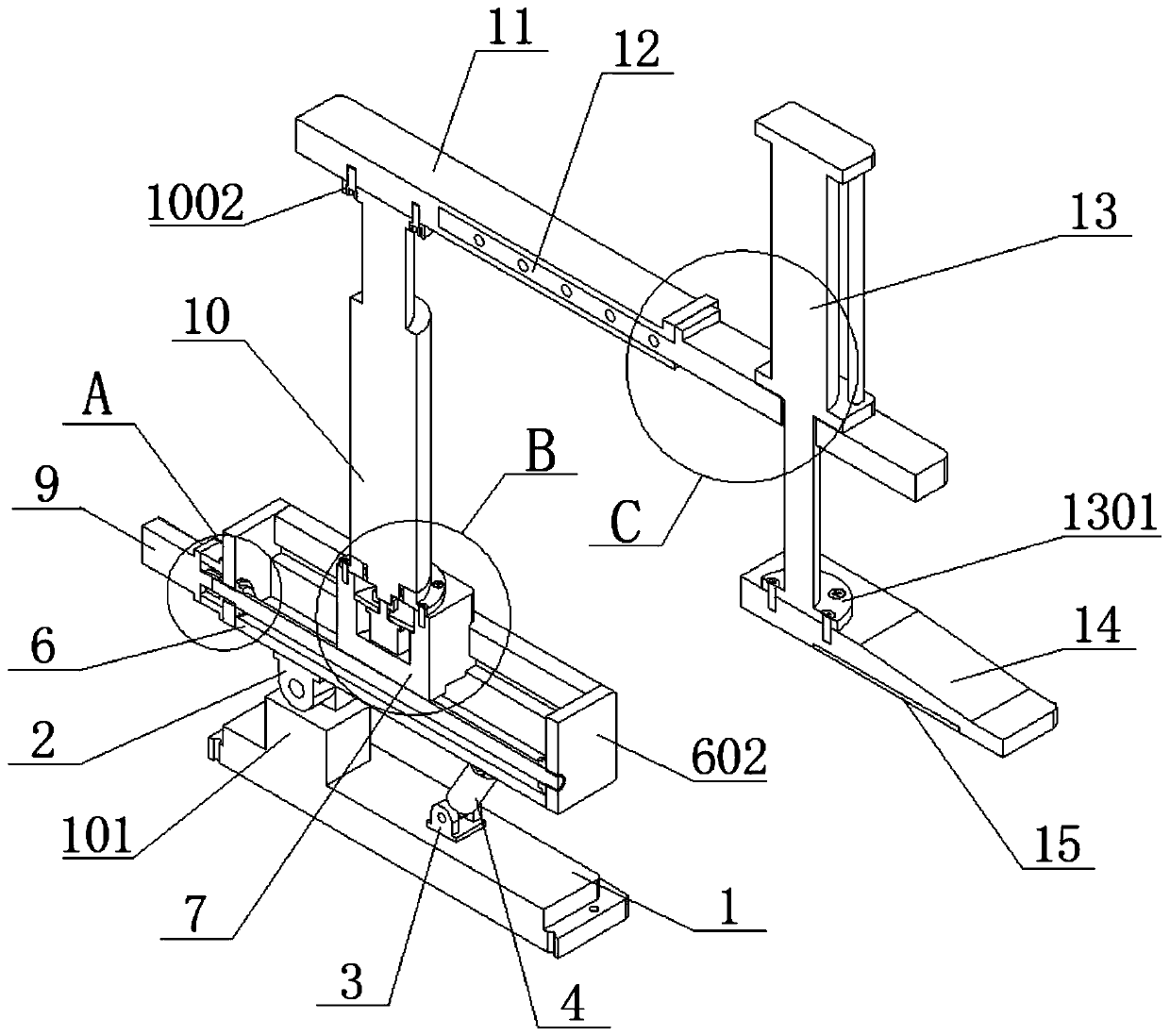

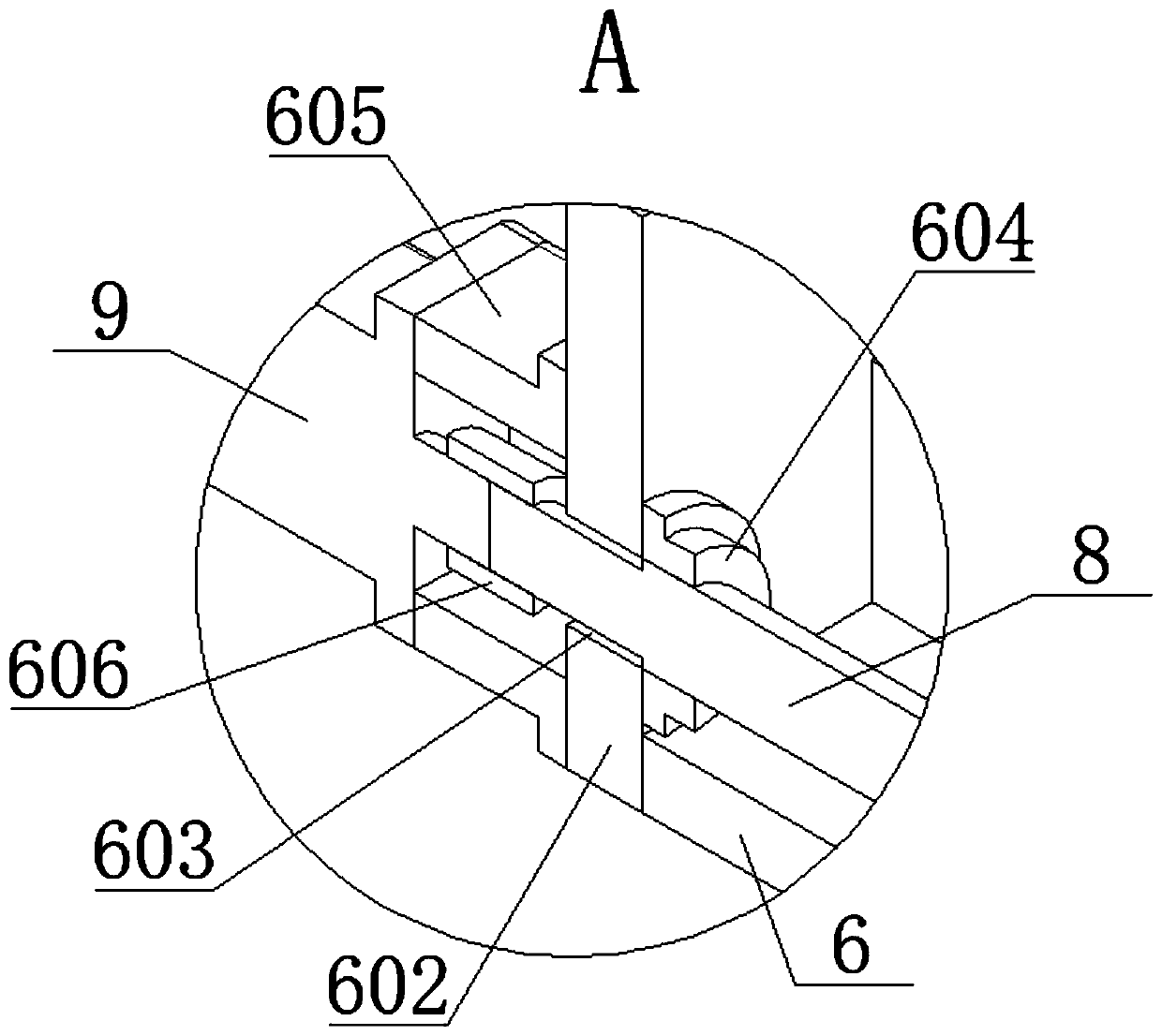

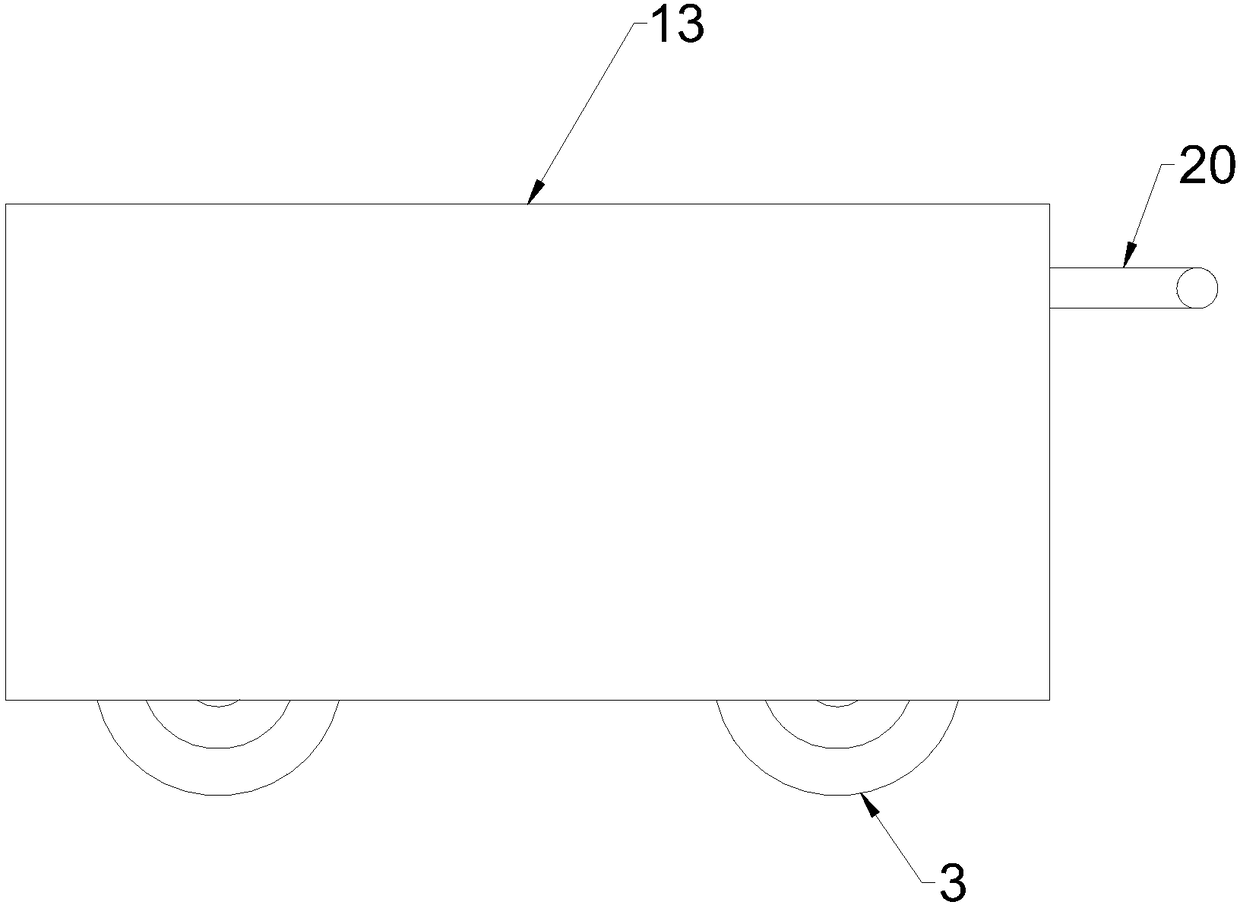

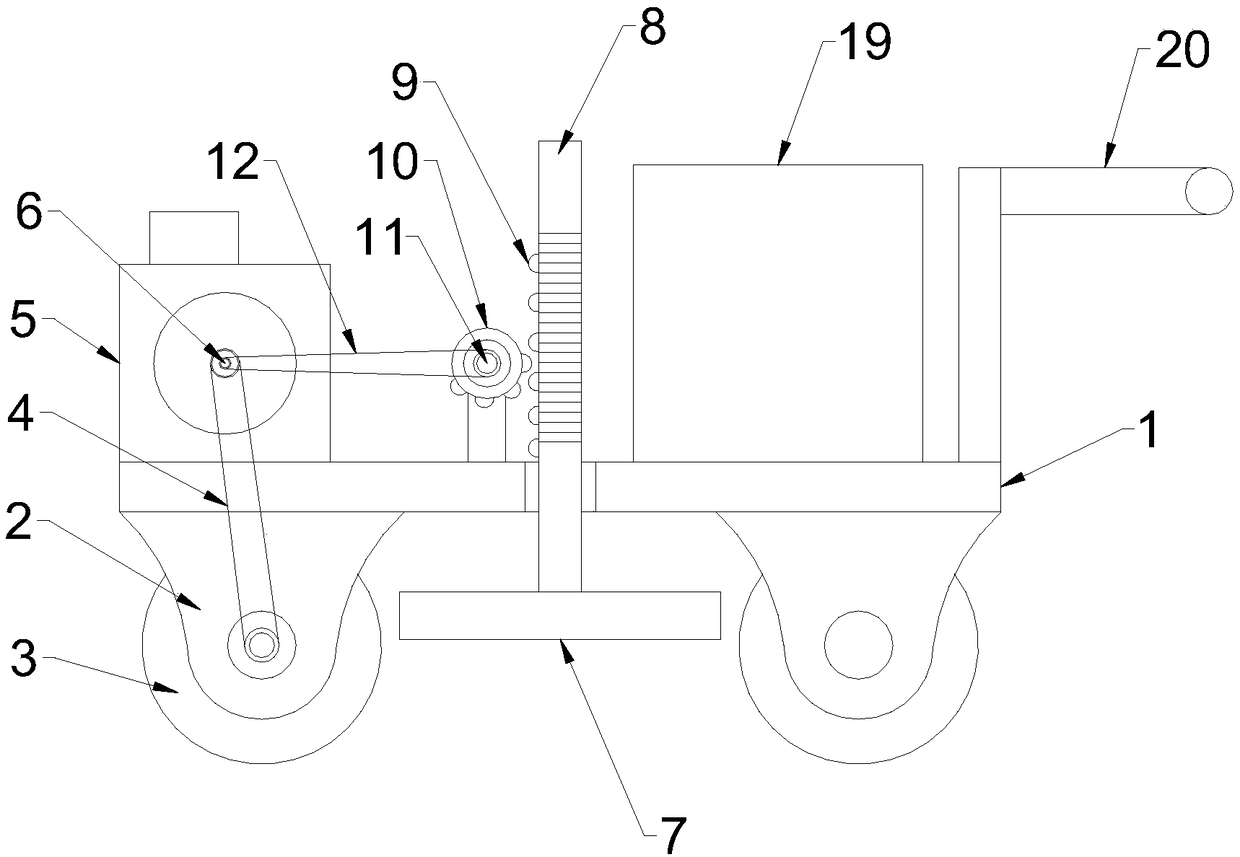

A small road repair device that is easy to operate

InactiveCN109056487AGuaranteed perfusion qualityImprove compaction efficiencyRoads maintainenceEngineeringAsphalt

The invention discloses a small road repairing device convenient for operation, which comprises a vehicle body, a drilling mechanism, a filling mechanism and a compaction mechanism. The drilling mechanism comprises a drill barrel; The filling mechanism comprises a stirring barrel; A material discharge pipe is communicate with that lower part of the stir barrel, and the material discharge pipe extends to the lower part of the vehicle body and is provided with a manual valve; The compaction mechanism includes a compaction roller. As that drill barrel is fixedly connecte with an upper and lower rotate mechanism composed of a threaded sleeve and a rotating rod, the drill barrel is convenient to drill a hole at a place to be repaired of the road, the asphalt pouring interface is smoothed, and the pour quality is ensured; and the drill barrel is fixed on the upper and lower rotating mechanism composed of the threaded sleeve and the rotating rod. The rotary compaction of the poured asphalt iscarried out by means of a compaction roller which is linked with a rotary ring, so that the compaction efficiency is improved, and the operation is convenient compared with manual compaction.

Owner:孙同娟

Compaction device facilitating carton recycling

The invention discloses a compaction device facilitating carton recycling. The right side of a motor is rotationally connected with a driving shaft, and the driving shaft is rotationally connected with a device body through a bearing. The left portion of the driving shaft is in rolling connection with the upper end of a transmission belt. The lower end of the transmission belt is in rolling connection with a driven shaft. The two sides of the driven shaft are in cup joint with the lower end of a hanging rod. The upper end of the hanging rod is fixedly connected with the device body. The two ends of the driven shaft are fixedly connected with rotation discs. The circumferential eccentric positions of the rotation discs are rotationally connected with the upper ends of connecting rods, and the lower ends of the connecting rods are connected with stand bars. According to the device, the transmission belt is used for driving the driven shaft to rotate so as to drive the rotation discs to rotate, the rotation discs drive a pressing head to move up and down in a reciprocating manner along sliding grooves through the connecting rods to compact cartons; in the carton compaction process, afirst lead screw drives the workbench to intermittently move left and right at intervals; after compaction is finished, the workbench moves leftwards to push the cartons out, then new cartons are placed, the workbench moves rightwards to conduct continuous compaction; and damping devices are used for damping the device body, and damping of springs can be adjusted by unscrewing adjusting wheels.

Owner:盐城富邦包装有限公司

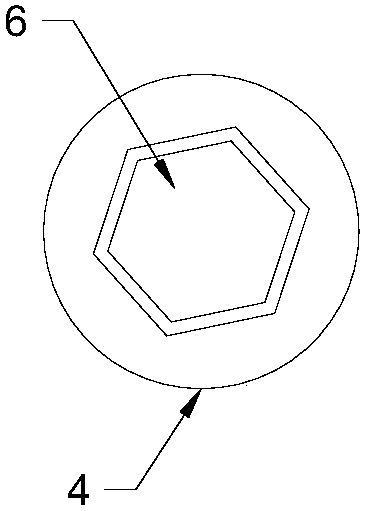

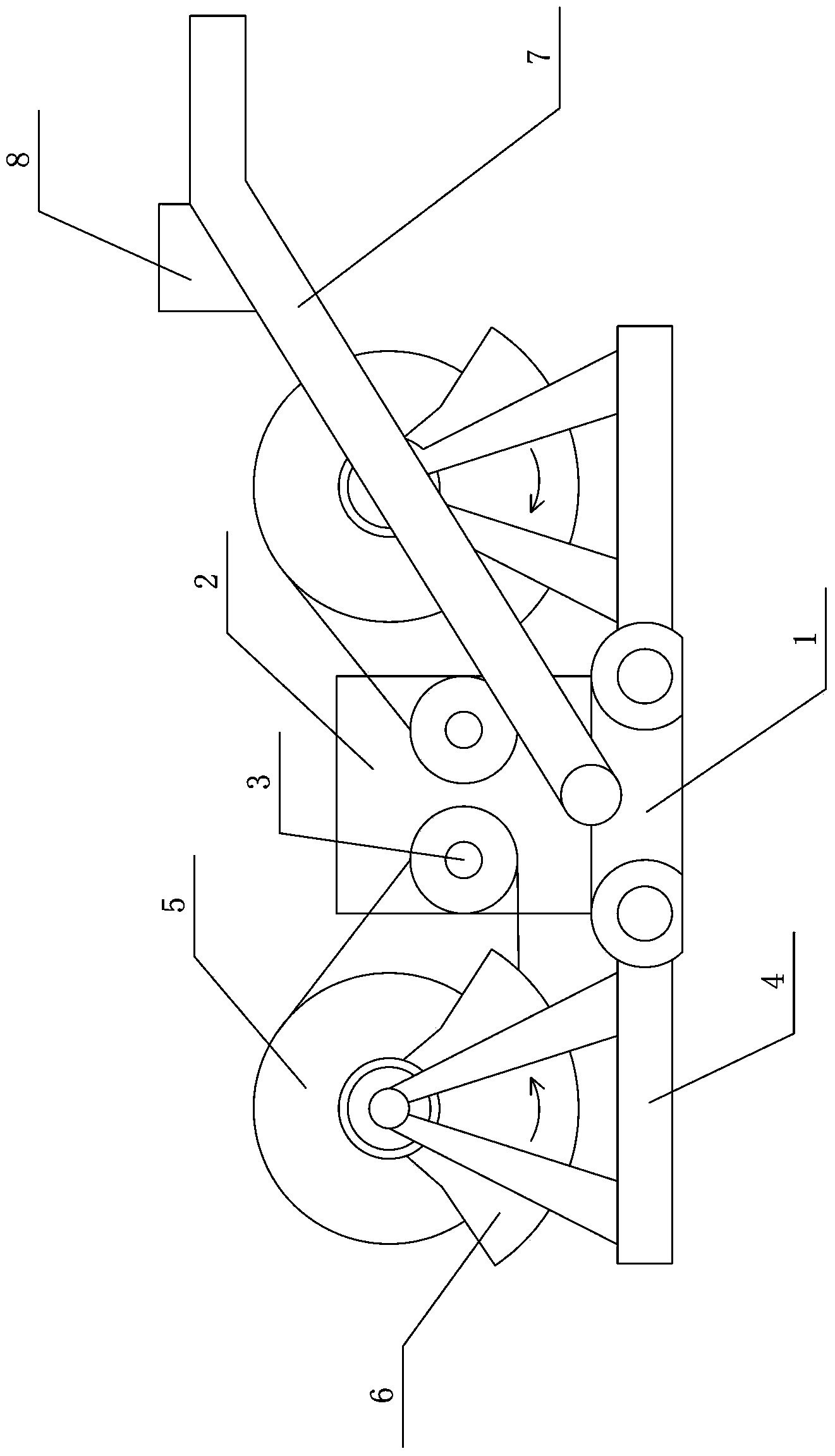

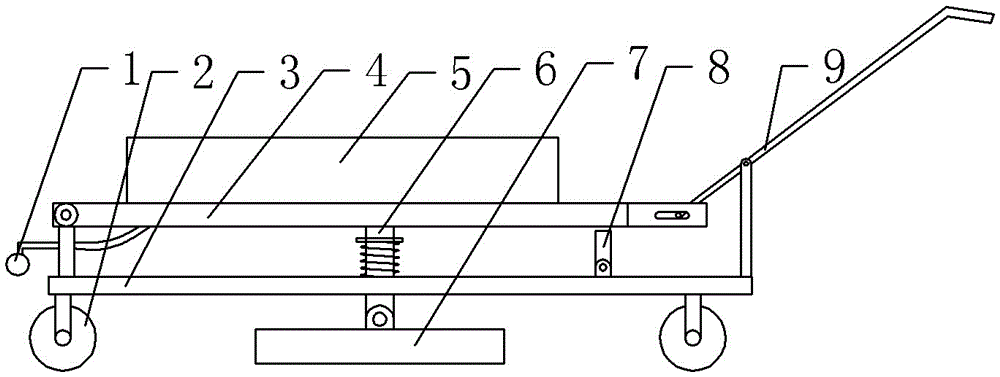

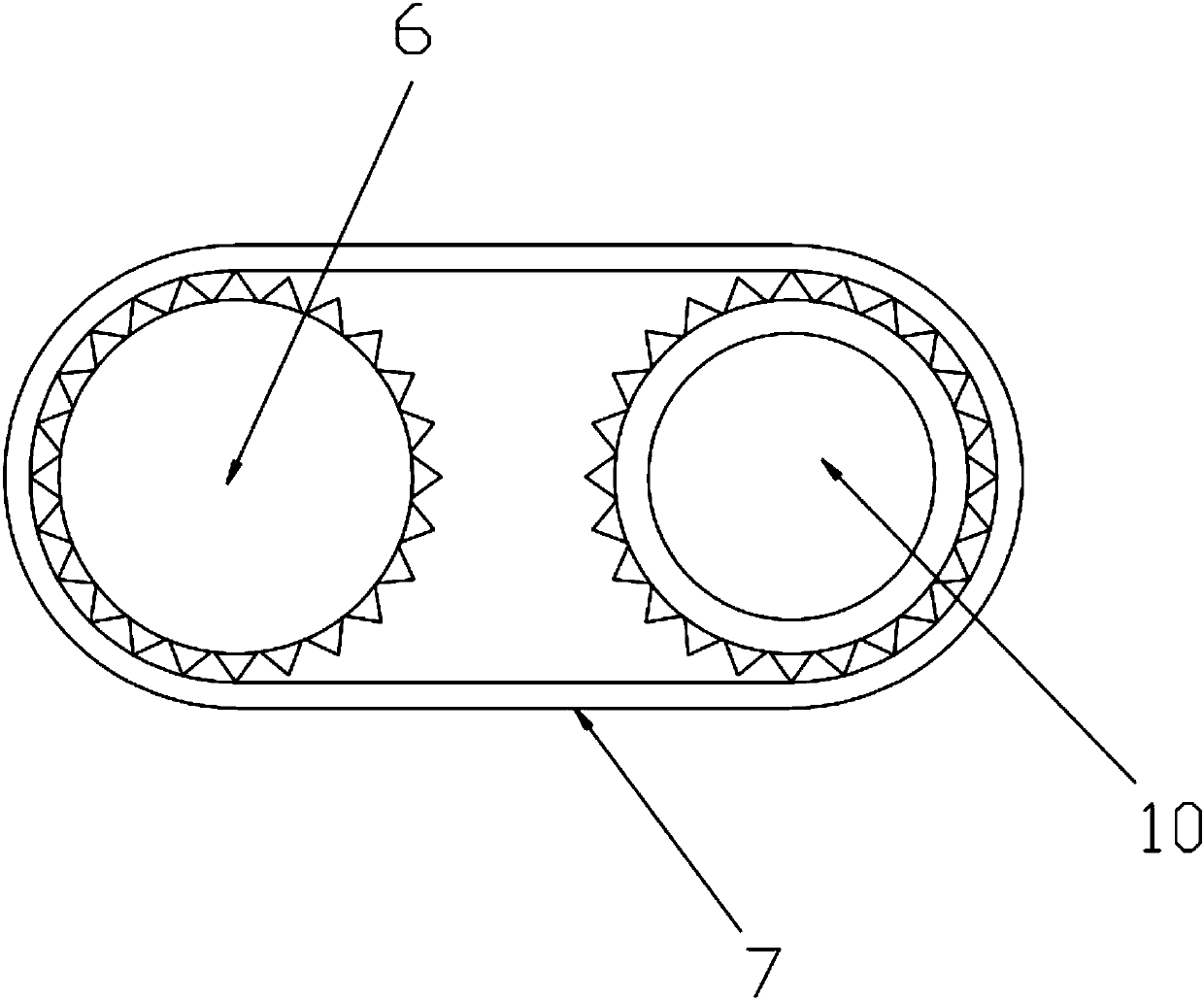

Novel double-wheel type flat ground rammer compactor

InactiveCN104141296ASimple structureGood compaction effectRoads maintainenceSoil preservationElectric machineMechanical equipment

The invention relates to a novel double-wheel type flat ground rammer compactor, in particular to the technical field of mechanical equipment. A motor case (2) is arranged on a chassis base (1), a motor set (3) is arranged inside the motor case (2), the two sides of the chassis base (1) are connected with compaction steel plates (4) through a movable bearing, round rotating wheels (5) are arranged on the compaction steel plates (4), eccentric arc-shaped wheels (6) are arranged on the outer sides of the round rotating wheels (5), the round rotating wheels (5) are connected with the motor set (3) through belt wheels, a handle (7) is connected to the middle of the chassis base (1), and a control switch (8) is arranged on the handle (7). The rammer compactor is simple in structure, a double-face compaction structure is adopted, and therefore the compaction effect is more obvious, the compaction efficiency is improved, and time is saved.

Owner:KUNSHAN RUIHENGFENG TECH CONSULTING

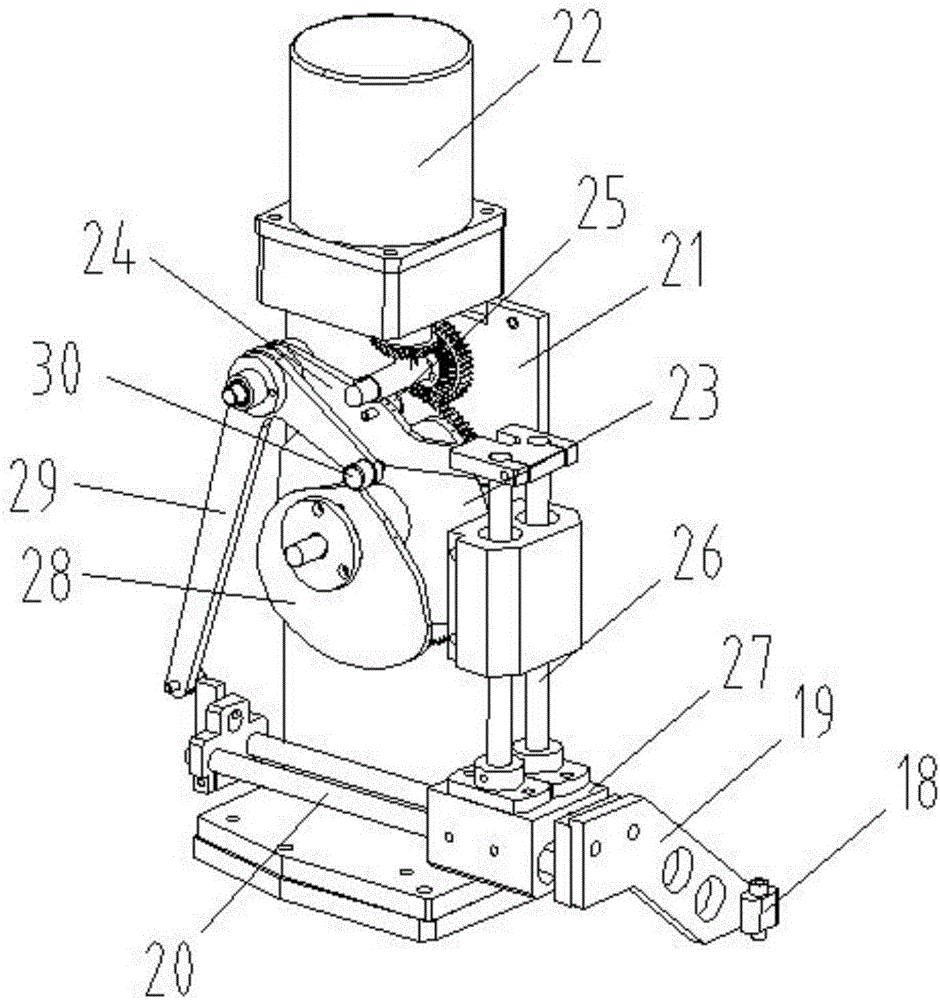

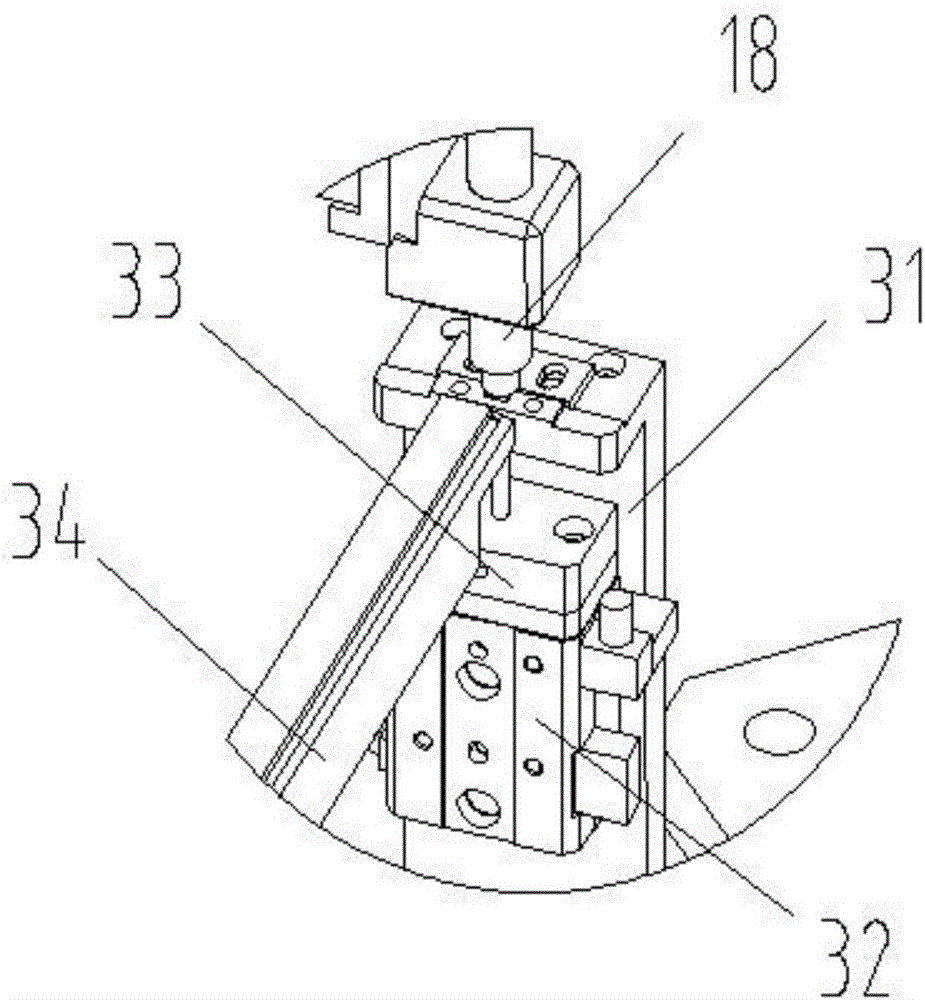

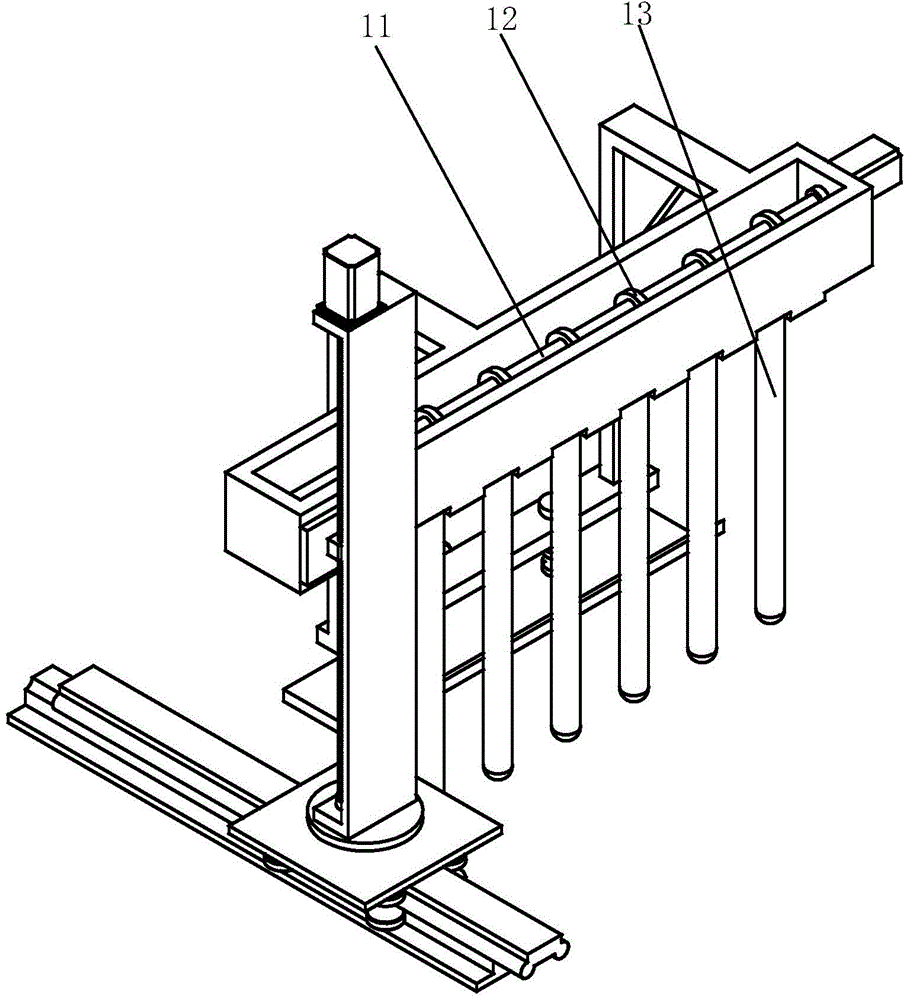

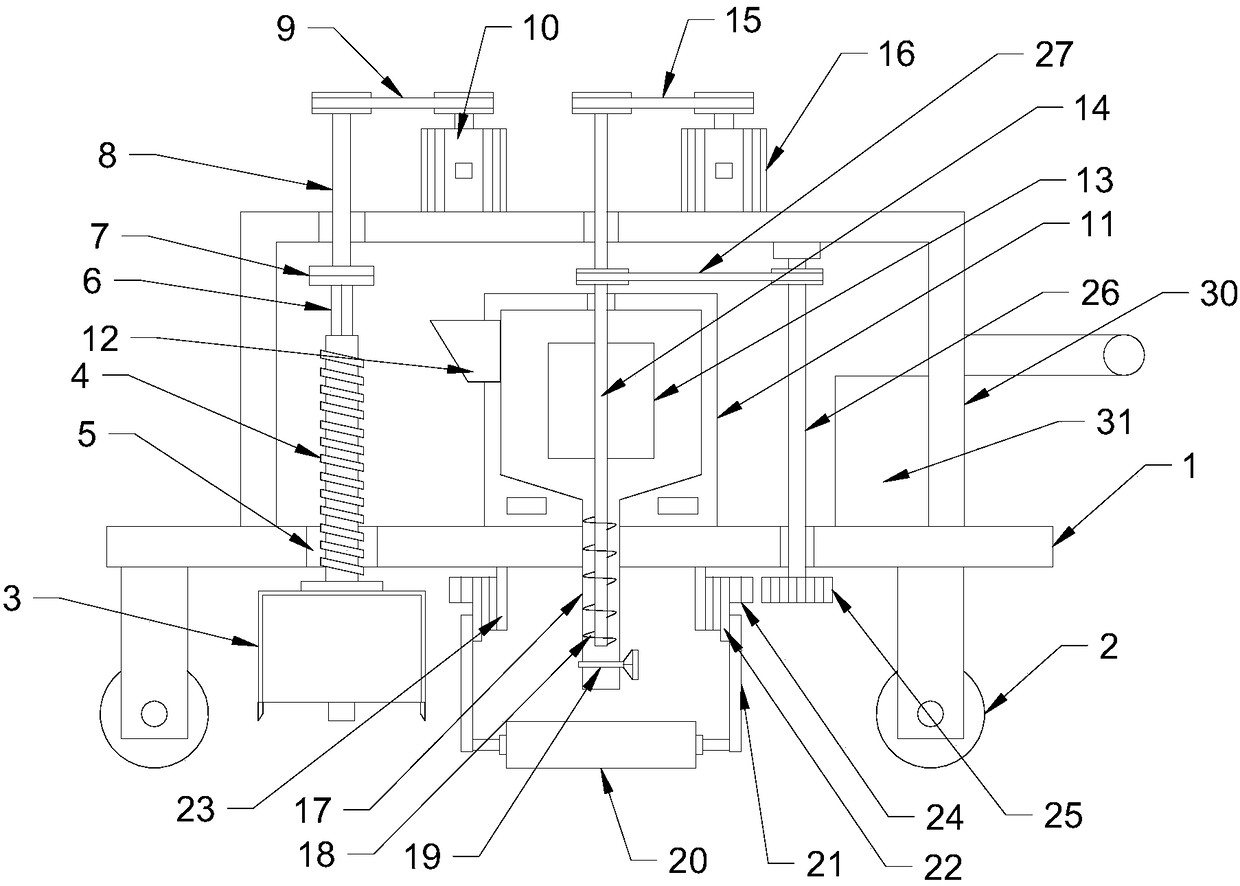

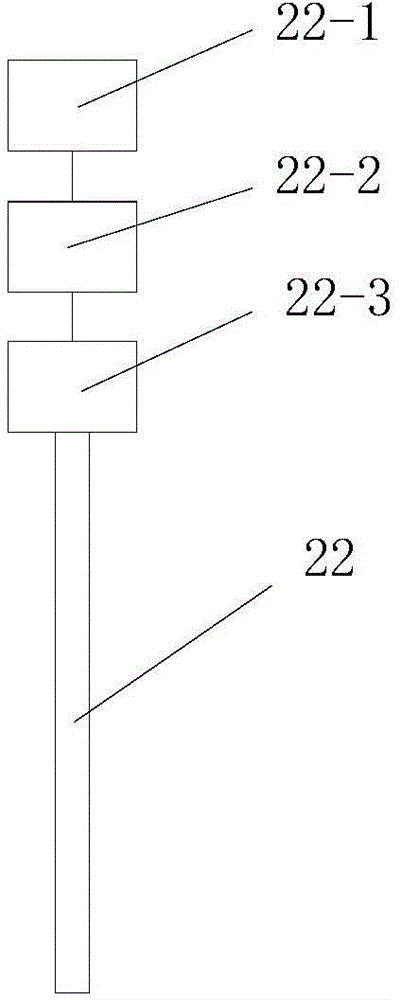

Full-automatic assembly machine of mechanical shaft

ActiveCN106736505AImprove installation efficiencyImprove the efficiency of installation, but also improve the utilization of equipmentAssembly machinesMetal working apparatusDistribution controlGear wheel

The invention relates to a full-automatic assembly machine of a mechanical shaft. The machine comprises a frame and a power distribution control box; the frame is provided with a shaft sleeve mounting mechanism and a gear mounting mechanism connected through a product conveying groove; a shaft sleeve mounting turntable is uniformly provided with loading holes matched with the shaft, and the outer side is provided with a shaft loading device, a shaft sleeve loading device, a screw rod loading device, a shaft sleeve pressing device and a shaft sleeve unloading device matched with the loading holes and connected to the power distribution control box in sequence; the gear mounting mechanism includes a gear mounting turntable arranged on the frame; the gear mounting turntable is uniformly provided with emptying holes matched with the shaft; and the outer side of the gear mounting turntable is provided with a gear loading device, a product loading device, a gear tightening device and a product unloading device matched with the emptying holes or a gear mounting carrier in sequence. The shaft sleeve mounting mechanism and the gear mounting mechanism are connected through the product conveying groove, so that the integral automatic installation is realized, and the mounting efficiency is greatly improved.

Owner:DONGGUAN UNIV OF TECH

Road surface tramper

InactiveCN107989018AImprove automation control rateImprove compaction efficiencySoil preservationLocking mechanismRoad surface

The invention discloses a road surface tramper. The road surface tramper comprises a device car body, and a tramper body fixedly mounted in the device car body; a first slide cavity is formed in the tramper body; a groove is formed in the bottom end surface of the tramper body rightly below the first slide cavity; a slide hole is inserted between the top of the groove and the bottom of the first slide cavity; a tramping block mechanism is slidingly matched and connected into the first slide cavity; a stable locking mechanism in locking cooperation connection with the tramping block mechanism is arranged in the inner wall of the left side of the first slide cavity; the stable locking mechanism comprises a locking slide cavity, and a locking slide block slidingly matched and connected into the locking slide cavity; first guide grooves are symmetrically arranged on the inner walls of the upper and lower sides of the left side section of the locking slide cavity; the first guide grooves onthe upper and lower sides are slidingly matched and connected with guide blocks; and the inner sides of the guide blocks on the upper and lower sides are fixedly connected with the outer walls of theupper and lower sides of the locking slide block. The road surface tramper is simple in structure and convenient to operate, reduces operation steps, improves the tramping efficiency, reduces the tramping construction cost, and meanwhile, prolongs the service life.

Owner:吴琼

Pavement compacting vehicle

The invention relates to a pavement compacting vehicle. A compacting device is arranged at the lower part of a vehicle chassis, and an engine drives an eccentric balance weight capable of sliding freely along a rotating shaft to rotate, so that the balance weight is constantly lifted and then slides during the moving process of the vehicle to continuously hammer the ground so as to compact a pavement. Compared with the traditional compacting device, the pavement compacting vehicle has the advantages that the use is simpler, the compacting efficiency is higher, and the more energy is saved as only one engine is used to supply energy.

Owner:TONGLING SANJIA TRANSFORMER

Double-ramming-head small-sized compacting machine

The invention discloses a double-ramming-head small-sized compacting machine. The double-ramming-head small-sized compacting machine comprises a rack, a power device, a walking mechanism and ramming devices, wherein the power device comprises a gasoline engine and a centrifugal clutch; a driven piece of the centrifugal clutch is provided with a belt wheel; the walking mechanism comprises a walking wheel and a high-speed shaft; the high-speed shaft is provided with a large belt wheel and the large belt wheel is connected with the belt wheel by a first belt; the two ramming devices are arranged on the front and rear ends of the rack respectively; each ramming device comprises a shell and a cover plate; a ramming head is arranged on the bottom of each shell and each shell is internally provided with a vibration shaft; the left and right ends of each shell are connected with the walking mechanism by swinging arms; the rack can be connected with the swinging arms by adjusting rods; a small belt wheel is mounted on the right end of the vibrating shaft; the small belt wheel is connected with the large belt wheel by a second belt; the vibrating shaft is provided with a first eccentric block and a second eccentric block; the first eccentric block has a first adjusting fixed hole; the second eccentric block has a plurality of second adjusting fixed holes. The double-ramming-head small-sized compacting machine disclosed by the invention is reasonable in design, high in compacting efficiency and convenient to transit.

Owner:CHANGAN UNIV

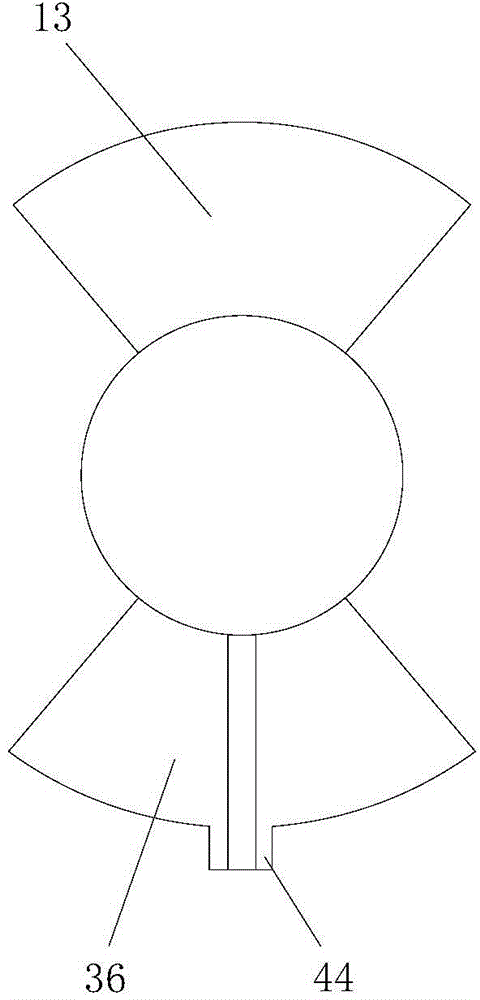

Garden soil treatment equipment for turf laying

InactiveCN109429919ARealize the effect of automatic compactionImprove compaction efficiencySievingHops/wine cultivationSoil treatmentEngineering

The invention discloses garden soil treatment equipment for turf laying. The equipment comprises a working vehicle for treating soil, wherein a separation mechanism for separating soil and stones is arranged on the working vehicle; the separation mechanism comprises a screen, a shaking device, a conveying device, a grass pressing machine, a grass pressing roller, two rotary wheels,; the screen isused for separating the soil and the stones; the shaking device is used for driving the screen to shake; the conveying device is used for conveying the soil to the ground; the grass pressing machine for compacting the turf; a grass pressing roller is used for compacting the turf; and the rotary wheels are used for moving the grass pressing machine. Through the arrangement of the structure, the automatic compaction effect of the paved turf can be effectively realized, the trouble of manual compaction is effectively avoided, manpower and material resources are saved, and the compaction efficiency of the turf is effectively improved.

Owner:HANGZHOU LVCHENG TECH CO LTD

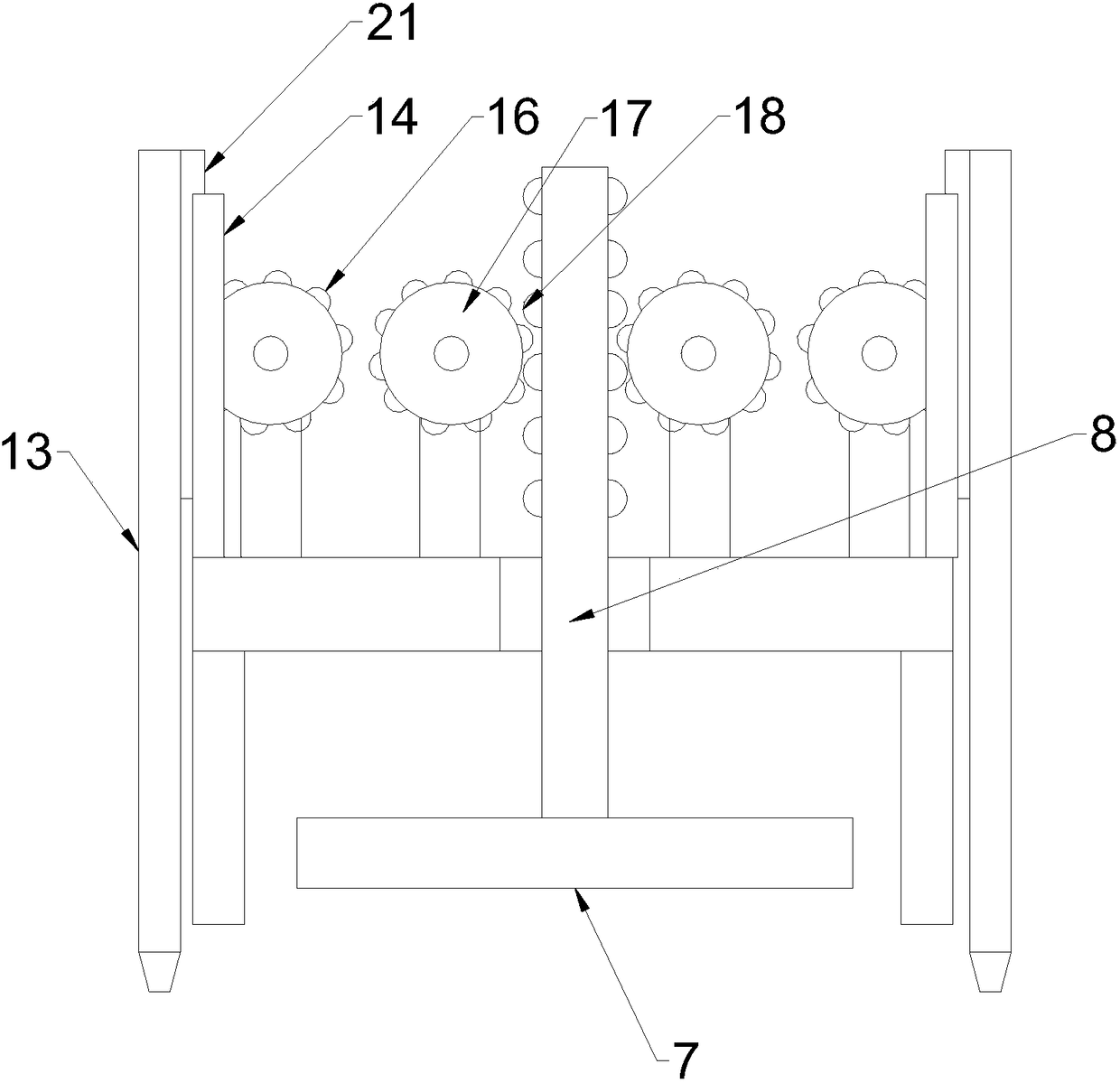

Reciprocating building tamping device

ActiveCN108708363AEasy to moveImprove compaction efficiencySoil preservationEngineeringDiesel engine

The invention discloses a reciprocating building tamping device. The reciprocating building tamping device comprises a vehicle body, a first tamping block, a diesel engine and a second tamping block;the first tamping block and the second tamping block which are arrayed transversely are arranged at the lower portion of the vehicle body, a vertical rod is fixedly connected with the upper end surface of the first tamping block, a rectangular through groove with the rectangular section is formed in the vertical rod, a rack is arranged on the inner wall on one side of the rectangular through groove, and the rack is meshed with a semicircle gear; and the semicircle gear is fixedly connected with a transverse shaft, and the transverse shaft is connected with the output shaft of the diesel enginethrough a transmission belt. According to the reciprocating building tamping device, by arranging the first tamping block and the second tamping block which are different in initial position and different in mass, reciprocating tamping is achieved, meanwhile, the tamping strength is increased along with the moving of the vehicle body, and the stamping effect is improved.

Owner:临沂边锋自动化设备有限公司

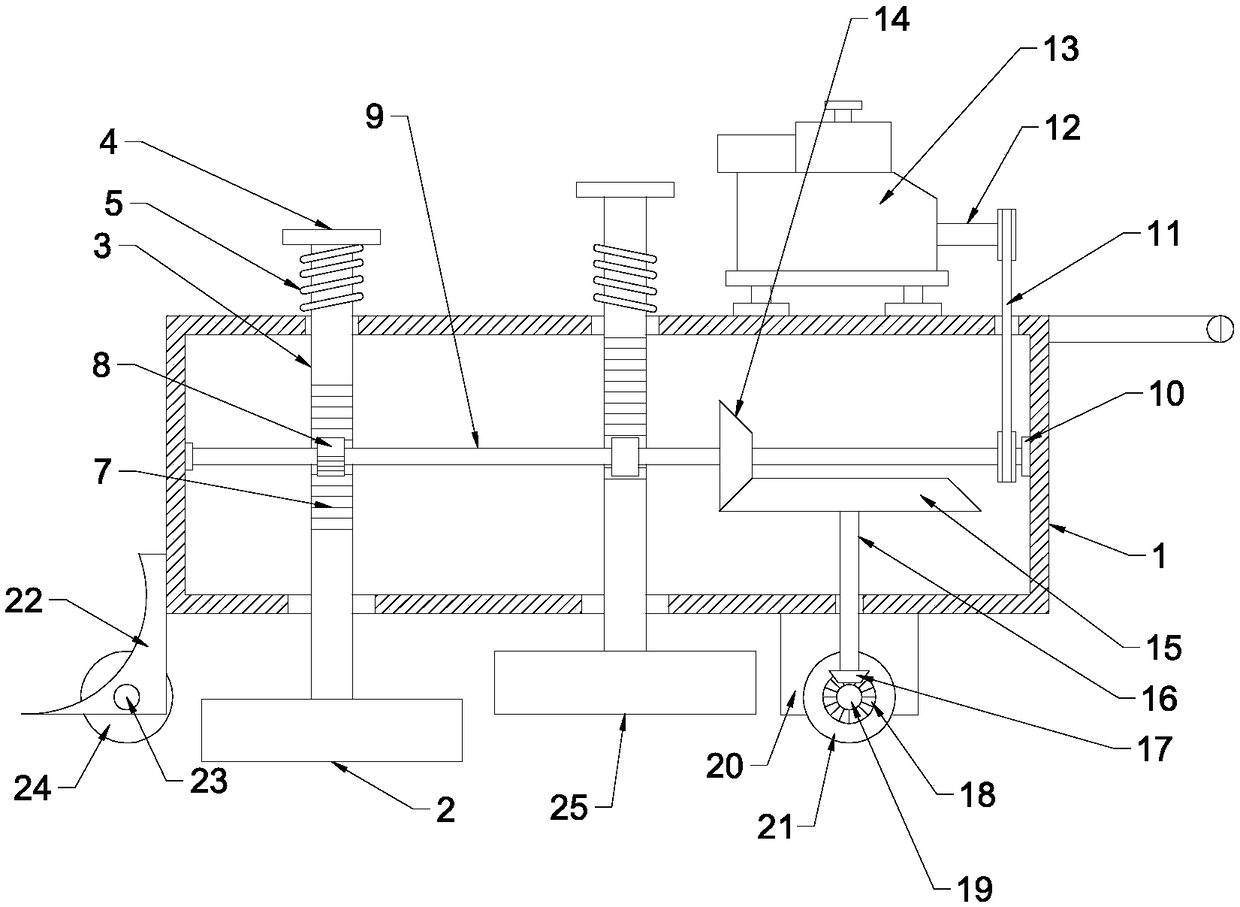

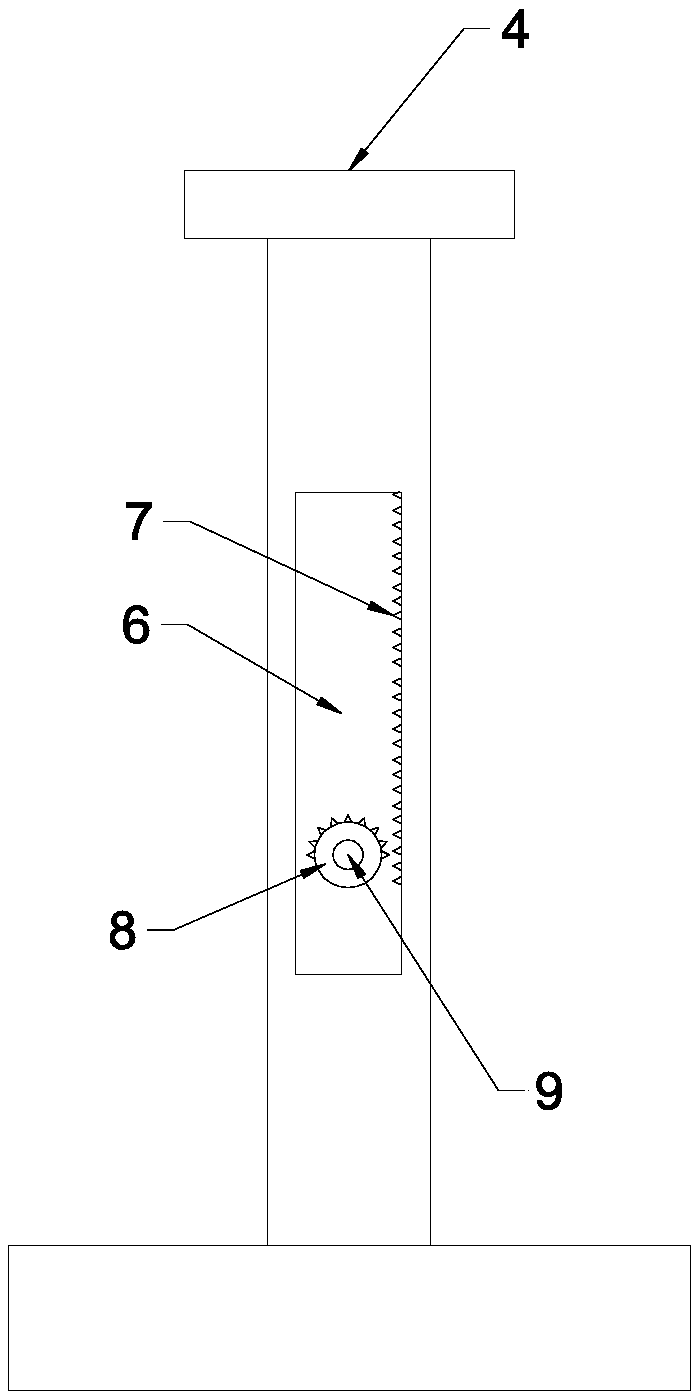

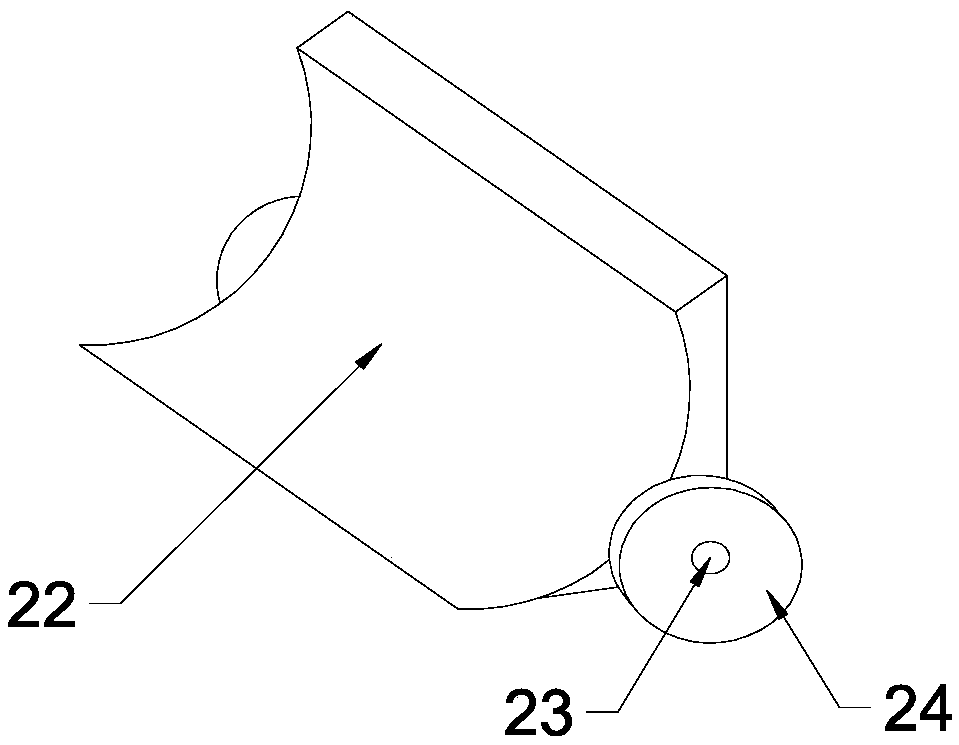

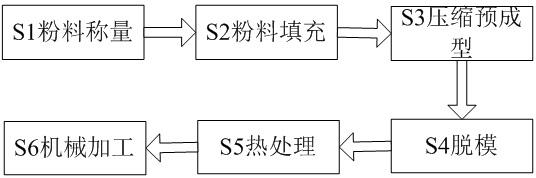

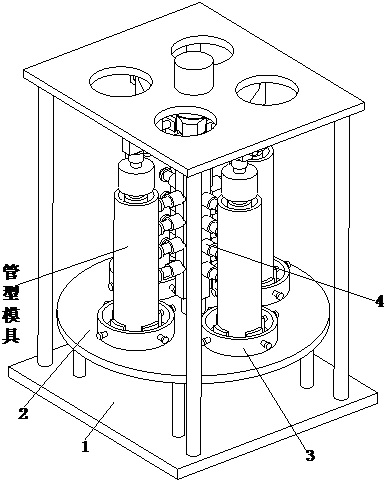

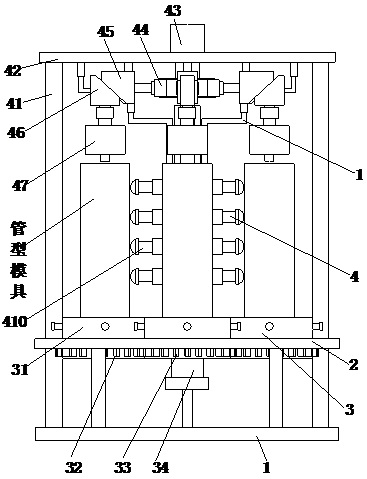

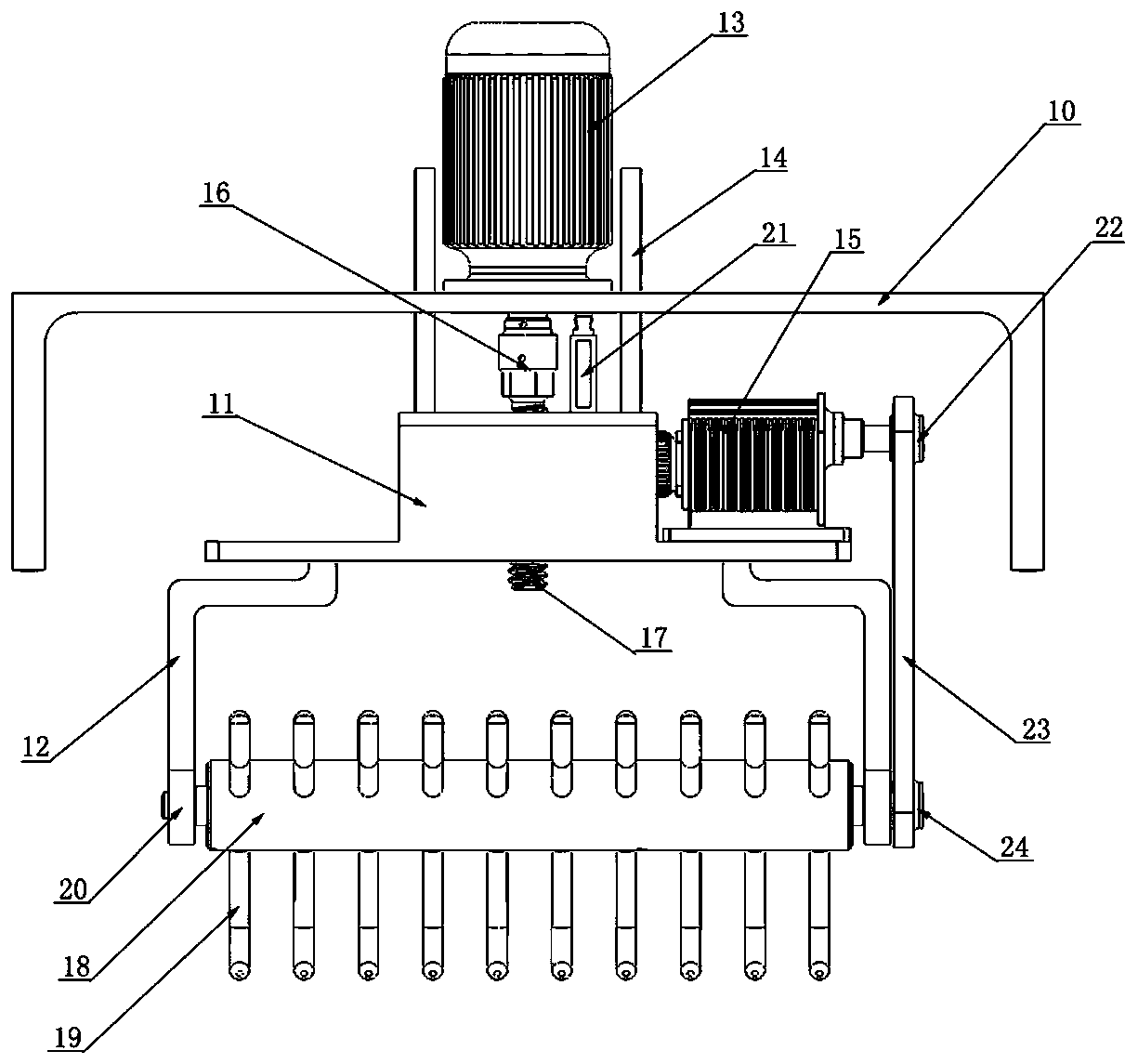

Production method of tubular target material

ActiveCN113275575AIncrease reachImprove compaction efficiencyElectric machineryStructural engineering

The invention relates to a production method of a tubular target material, which uses powder compaction equipment. The powder compaction equipment comprises a bottom plate, a workbench, a fixing device and a compaction device. The specific process of the method for producing the tubular target material by adopting the powder compaction equipment is as follows: powder weighing, powder filling, compression preforming, demolding, heat treatment and machining. The compaction device comprises supporting rods, a top plate, a driving motor, a driving cam, transverse moving blocks, lifting blocks, pressing rings, internal compaction frames, a fixing column and external compaction frames. According to the technical scheme, a plurality of tubular moulds are fixed through a material placing device, then compaction operation is respectively carried out from the upper parts, the inner parts and the outer parts of the moulds through the compaction device, so that the compaction efficiency is obviously improved, meanwhile, the tubular moulds can be driven to rotate in the compaction process, so that the contact range of the compaction device and the tubular moulds can be enlarged, and the compaction effect is improved.

Owner:WUHU YINGRI TECH CO LTD

Compaction device used on turf

InactiveCN105557333AIncrease pressureGuaranteed compaction effectHops/wine cultivationTurf growingEngineeringPulley

The invention discloses a compaction device used on turf. The device comprises a support plate. A handle is arranged on the support plate. The handle is hinged with the support plate. Rollers are arranged on the lower end of the support plate and are rotatably connected with the support plate. A vertical rod is arranged at the middle part of the support plate. The vertical rod penetrates through the support plate and is slidably connected with the support plate. A pressure plate is arranged on the lower end of the vertical rod. The pressure plate is connected with the vertical rod. A spring is arranged between the upper end of the vertical rod and the support plate. A movable plate is arranged above the support plate. One end of the movable plate is hinged with the support plate. A connection block is arranged on the movable plate at a position away from the hinge point. A bar-shaped hole is provided on the connection block. A pin which can slide along the length direction of the bar-shaped hole is arranged in the bar-shaped hole. The pin is fixedly connected with the handle. A water tank is fixedly connected on the movable plate. A water sprinkling mechanism is arranged on the water tank. With the device, turf planting efficiency is improved.

Owner:CHONGQING GENYU GARDEN LANDSCAPE ENG CO LTD

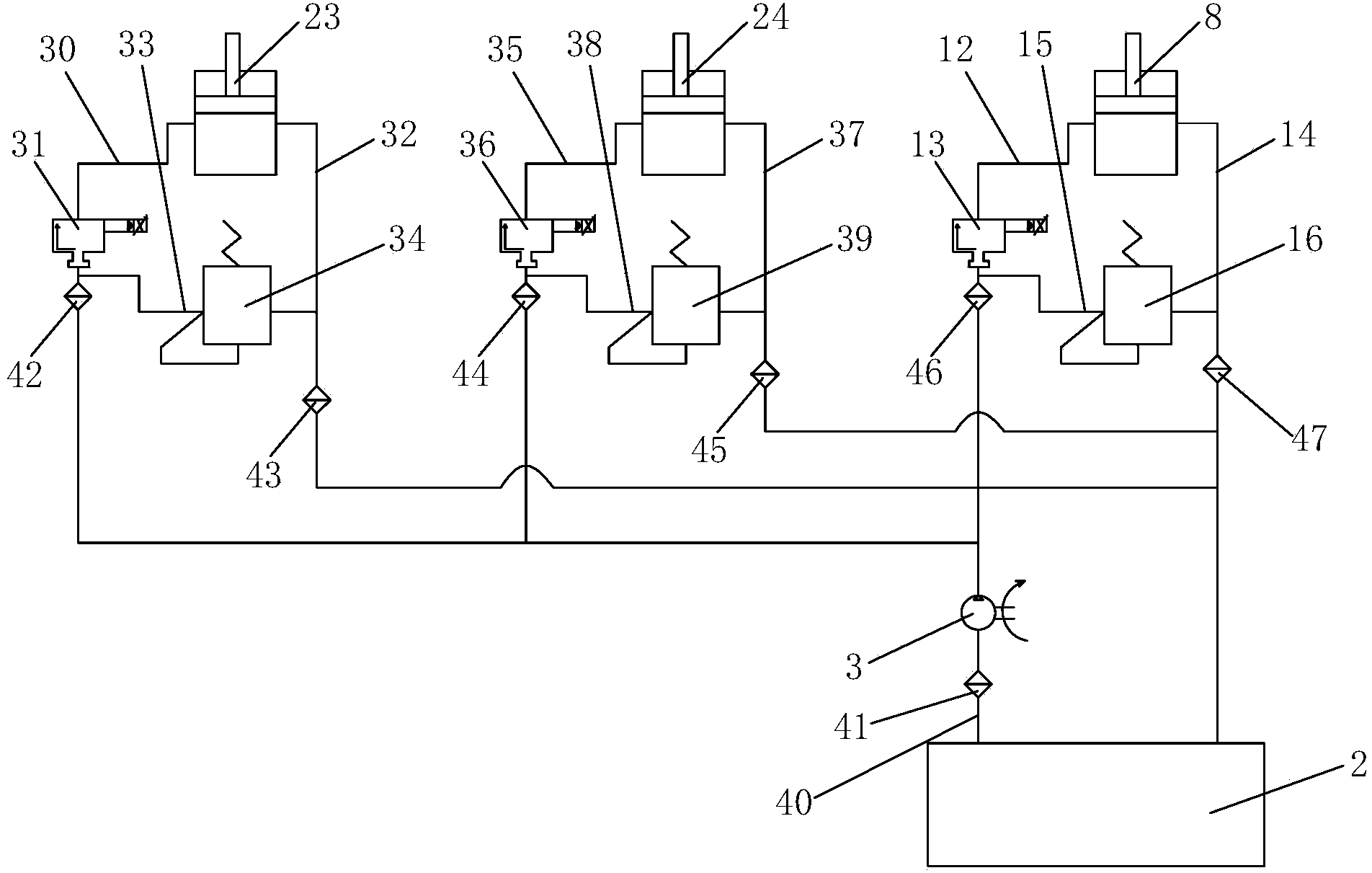

Vibration and oscillation composite type road roller steel wheel

The invention discloses a vibration and oscillation composite type road roller steel wheel which comprises a hollow wheel body, a hydraulic driving mechanism, two wheel racks, a vibration shaft and two oscillation shafts, wherein the hydraulic driving mechanism is used for driving the hollow wheel body; the wheel racks are symmetrically arranged on the left side and the right side of the hollow wheel body; the vibration shaft is mounted in the middle of the inner side of the hollow wheel body; the oscillation shafts are symmetrically distributed on two sides of the vibration shaft; an overrunning coupler is mounted on the vibration shaft; driven gears are mounted on the oscillation shafts and are connected with the overrunning coupler; eccentric mechanisms are arranged on the outer sides of the oscillation shafts; a left mounting plate and a right mounting plate are symmetrically arranged inside the hollow wheel body; a driving disc which is in transmission connection with the hydraulic driving mechanism is mounted on the left mounting plate; a clutch driving mechanism in transmission connection with the right end of the vibration shaft is mounted on the right wheel rack. The vibration and oscillation composition road roller steel wheel is simple in structure, reasonable in design, simple and convenient to operate, good in use effect and flexible in use and operation mode, vibration and oscillation functions are integrated, and the problem that a conventional road roller steel wheel can only vibrate or oscillate can be effectively solved.

Owner:CHANGAN UNIV

Efficient tamping equipment for electric power engineering construction

InactiveCN106930266AMeet the needs of compactionImprove compaction efficiencySoil preservationArchitectural engineeringElectric power

A high-efficiency tamping equipment for electric power engineering construction, the high-efficiency tamping equipment for electric power engineering construction includes a base plate, a support device located above the base plate, a counterweight device located on the right side of the support device, and a A tamping device on the device, a drive device above the support device. The high-efficiency tamping equipment for electric power engineering construction of the present invention can effectively tamp pole pits, has low labor intensity, high tamping efficiency, and ideal tamping effect, and can meet the need for tamping pole pits during electric power construction.

Owner:蒋宗霞

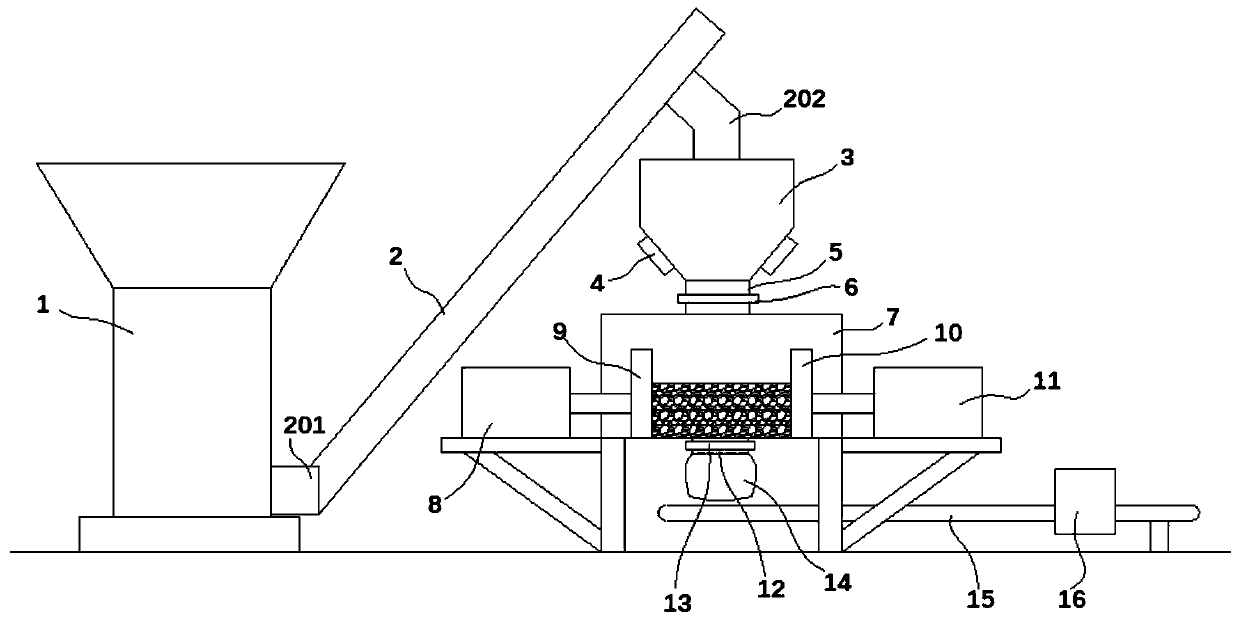

Continuous straw feed production line

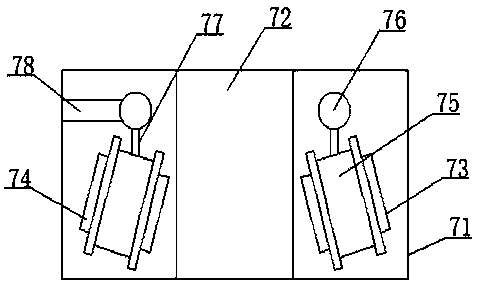

PendingCN110584173ASmall footprintEasy to storeFeeding-stuffFood processingContinuous productionEngineering

The invention discloses a continuous straw feed production line which comprises a crushing device, a material feeding device, a material collecting cabin, a straw compaction device, a finished productconveying device and a controller, wherein the inlet end of the material feeding device is connected with a material discharging opening of the crushing device; the outlet end of the material feedingdevice is connected with the material collecting cabin; a first material discharging passage is arranged at the bottom of the material collecting cabin; a first electric control material dischargingvalve is arranged on the first material discharging passage; the straw compaction device comprises a compaction cabin and a compaction mechanism used for compacting materials entering the compaction cabin; the material collecting cabin is arranged on the top of the compaction cabin; the first material discharging passage communicates with the compaction cabin; a second material discharging passageis arranged at the bottom of the compaction cabin; a second electric control material discharging valve is arranged on the second material discharging passage; the lower end of the second material discharging passage is provided with a compaction feed bag in a sleeved way; and the finished product conveying device is positioned under the second material discharging passage. The continuous straw feed production line has the advantages that the crushing, compaction and bag charging continuous production can be realized; the production efficiency is high; the occupied space of straw feed is reduced; and the transportation and the storage of the straw feed are facilitated.

Owner:陈建钧

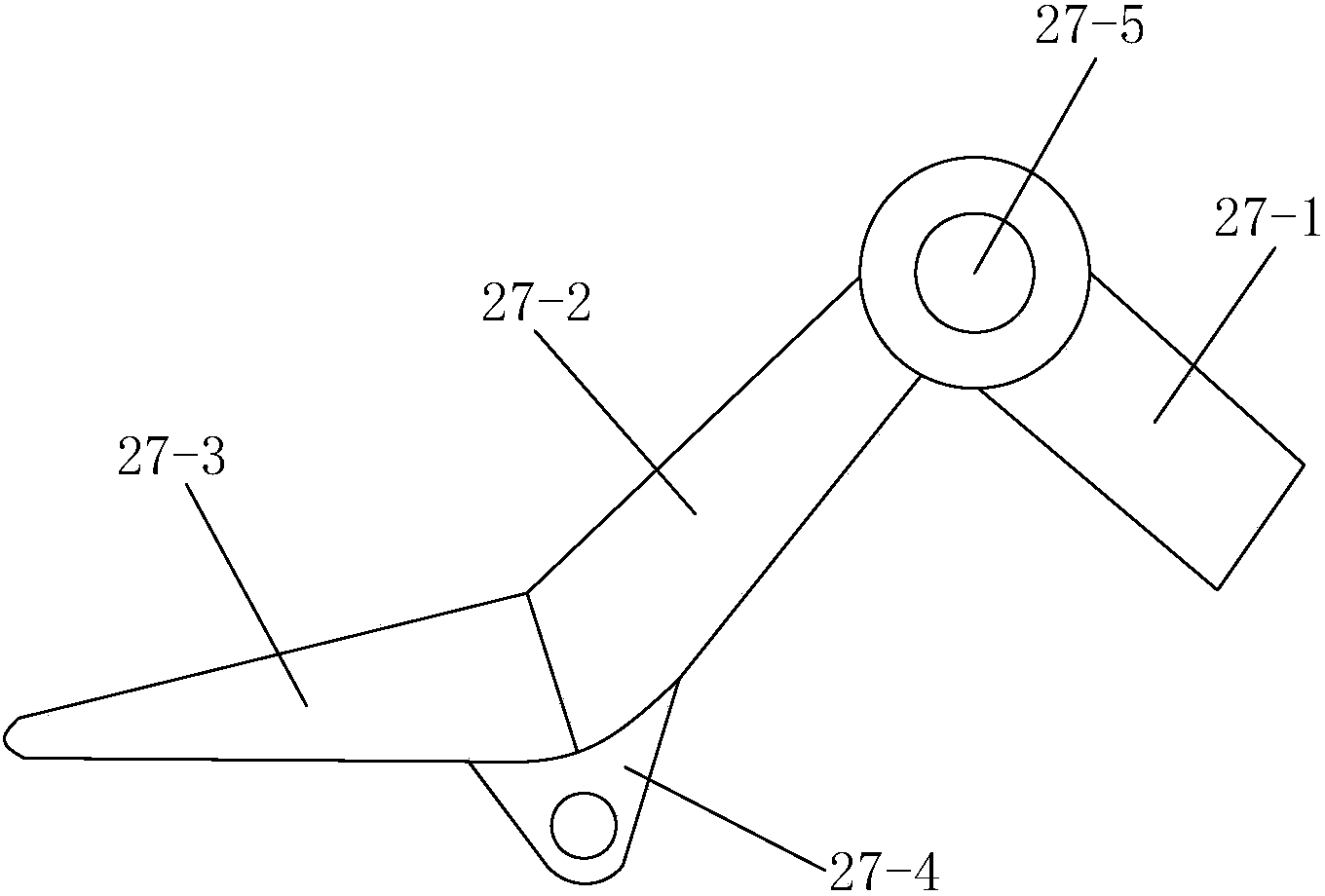

Longitudinal tamping device for building foundation tamping vehicle

ActiveCN108560529AStrong compaction effectImprove compaction efficiencyDynamo-electric machinesElectromagnetsHollow coreMagnet

The invention discloses a longitudinal tamping device for a building foundation tamping vehicle. The longitudinal tamping device comprises a main hollow shell. One side of the main hollow shell is provided with a main connecting plate, wherein the main hollow shell and the main connecting plate are of an integrated structure. Two opposite vertical plate structures are arranged on the top of the main hollow shell and are provided with a rotation disc in opposite plate bodies through a main rotation shaft. A movable space is arranged at the center in the main hollow shell, and the top of the main hollow shell is provided with a main through hole structure, wherein the upper portion of the main hollow shell communicates with the movable space through the main through hole structure. The magnetism generated at the bottom end of an iron core for an electromagnetic drive generation mechanism is the same as the magnetism of a permanent magnet plate on the opposite face, according to the principle that the same magnetism is in repulsion and different kinds of magnetism is in attraction, a bottom tamping plate rapidly moves downwards under the joint action of the gravity of a rectangular heavy object block and the magnetism of a permanent magnet, accordingly the tamping action is conducted on the ground, and since the drive force is generated through tamping under the joint action of the rectangular heavy object block and magnetic force, the one-time tamping effect is high, the tamping efficiency can be effectively improved, and practicability is high.

Owner:山东汶水城市建设发展有限公司

Tamping equipment for building construction

InactiveCN106522197ARamping is fast and effectiveImprove compaction efficiencySoil preservationArchitectural engineeringBuilding construction

The invention provides tamping equipment for building construction. The tamping equipment comprises a bottom plate, a support device, a fixing device, a motor device, a lever device, a positioning device and a tamping device. The bottom plate comprises first supporting blocks and first rolling wheels. The support device comprises a first supporting bar, a first diagonal bar, a first cross bar, a first vertical bar and a second cross bar. The fixing device comprises a first support, a second diagonal bar and a first bent bar. The motor device comprises a motor, a second support, an output shaft, a first fixing bar and a first pull cord. The lever device comprises a second supporting bar, a first fixed block, a lever, a first connecting ring and a second connecting ring. The positioning device comprises a second vertical bar, a first positioning bar, second rolling wheels and a third cross bar. The tamping device comprises a second pull cord, a tamping frame, a third connecting rig, a balancing weight and second fixing bars. The tamping equipment for building construction can quickly and effectively tamp bar pits and is high in tamping efficiency and good in tamping effect.

Owner:GUANGZHOU SONGBIN ENG TECH CO LTD

Extrusion device for edible fungi cultivation

InactiveCN105409589AExtended service lifeReduce frictionCultivating equipmentsMushroom cultivationGear wheelEngineering

The present invention relates to the field of extrusion devices, and discloses an extrusion device for edible fungi cultivation. The extrusion device comprises an upper pressing plate, a lower pressing plate is disposed below the upper pressing plate, the upper pressing plate is connected with a first rack, the first rack is engaged with a gear, the gear is engaged with a second rack connected with the lower pressing plate, the upper pressing plate and the lower pressing plate are slidably connected with a feeding hopper, a feeding opening is formed in one side of the feeding hopper, the bottom of the feeding hopper communicates with a pushing tube, a discharging opening is formed in a wall of one side, which is opposite to the pushing tube, of the feeding hopper, a pushing plate is slidably connected with the inside of the pushing tube, and is connected with a pushing bar, a swing rod is arranged on one side, which is away from the pushing plate, of the swing rod, one side of the swing rod is connected with a spring, the bottom of the swing rod is abutted to a cam, the swing rod is slidably connected with a slider, and the pushing bar is hinged to a sliding block. The present invention aims to provide the extrusion device for edible fungi cultivation, and compaction efficiency can be improved, so that a problem of low compaction efficiency of existing extrusion devices is solved.

Owner:CHONGQING CITY CHANGSHOU DISTRICT AGRI PROD COMMERCE CIRCULATION ASSOC

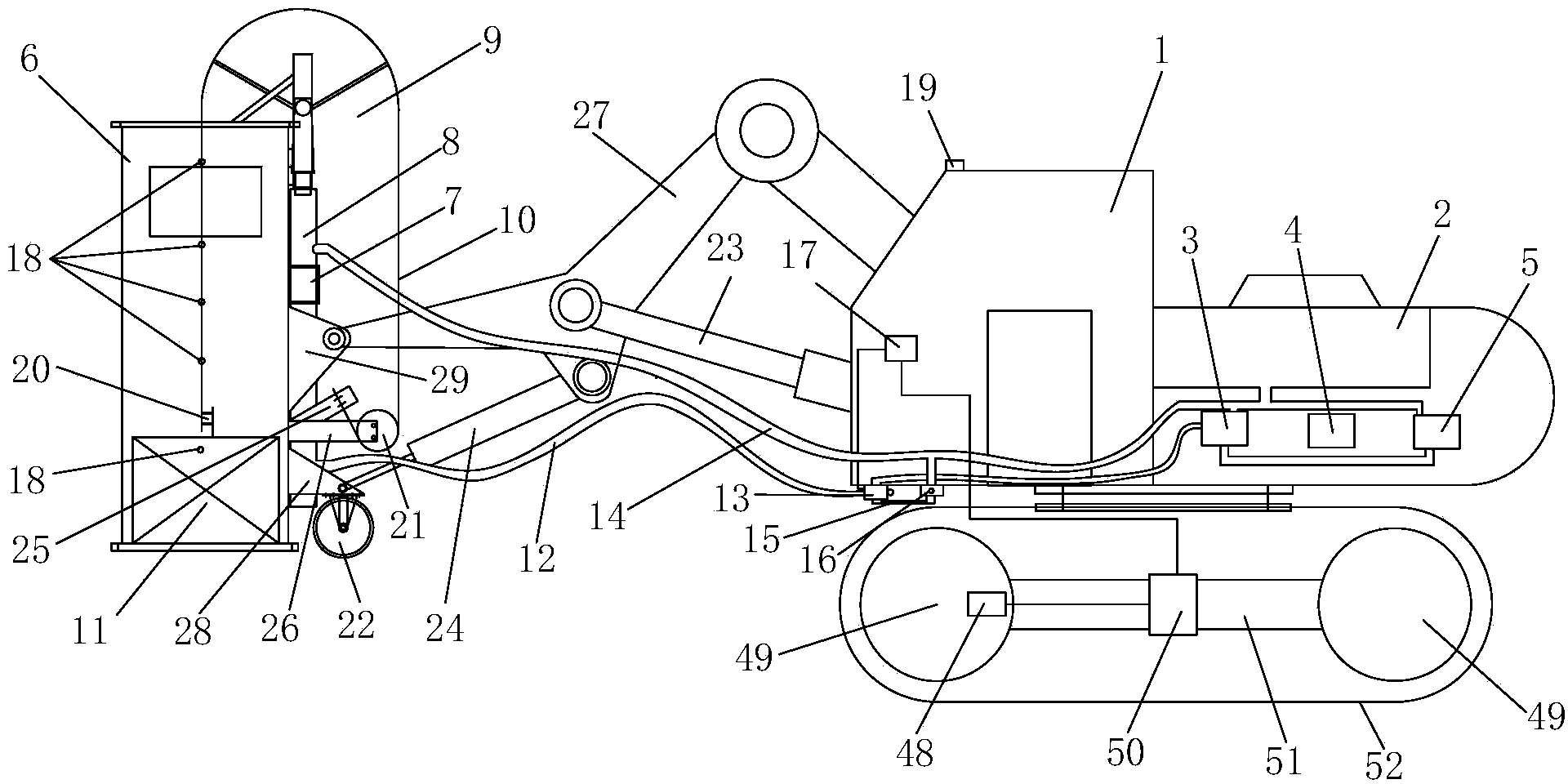

Self-traveling type intelligent continuous dynamic compactor

ActiveCN103741669ACompact structureNovel and reasonable designIn situ soil foundationSoil preservationAgricultural engineeringExcavator

The invention discloses a self-traveling type intelligent continuous dynamic compactor which comprises a crawler excavator, a crawler excavator power system, a crawler excavator self-traveling mechanism and a compaction mechanism, wherein the crawler excavator power system comprises an oil tank, an oil pump, a heat dissipater and an engine; the crawler excavator self-traveling mechanism comprises a traveling frame, traveling wheels, a traveling crawler and a self-traveling control system; the compaction mechanism comprises a stander, a third oil cylinder, a movable pulley, a soft connection body, a fixed pulley and a rammer; a stander is connected with a supporting wheel and is provided with a compaction density detection system; a hydraulic system and an intelligent control system are arranged on the crawler excavator; a third connection plate is connected to the stander; one end of a connection arm is connected with the crawler excavator, and the other end of the connection arm is connected with the third connection plate. The self-traveling type intelligent continuous dynamic compactor is easy to use and operate, has a self-traveling function and can intelligently realize continuous compaction; furthermore, the compaction power is higher, and the compaction thickness and the compaction influence depth are large; the self-traveling type intelligent continuous dynamic compactor can accurately detect the compaction density and work stably and reliably.

Owner:西安长大公路养护技术有限公司

High-efficiency rammer used for municipal construction

InactiveCN108035218ACleverly structuredReasonable arrangementRoads maintainenceFixed bearingSprocket

The invention discloses a high-efficiency rammer used for municipal construction. The high-efficiency rammer used for municipal construction comprises a machine shell. Baffles are laterally symmetrically arranged at the bottom of the machine shell. An axle is sleeved between the two baffles. Walking wheels are arranged on the axle. The axle is sleeved with fixing bearings arranged in the corresponding positions of the baffles and extends out of the baffles. The axle is sleeved with driven chain wheels. The machine shell is sleeved with driving chain wheels. A walking motor for driving the driving chain wheels is arranged in the machine shell. The driving chain wheels and the driven chain wheels are sleeved with chain belts. A rotary barrel is arranged in the middle position of the bottom of the machine shell. The top end of the rotary barrel is sleeved with a bearing seat arranged in the corresponding position of the machine shell. A rotary barrel rotation drive mechanism is arranged in the machine shell. A piston rod is sleeved with the top end of the rotary barrel, penetrates through the bearing seat at the top end of the rotary barrel and extends into the rotary barrel. The provided high-efficiency rammer used for municipal construction is ingenious in structure setting, reasonable in arrangement, convenient to walk and capable of ramming earth with high efficiency.

Owner:杨仙君

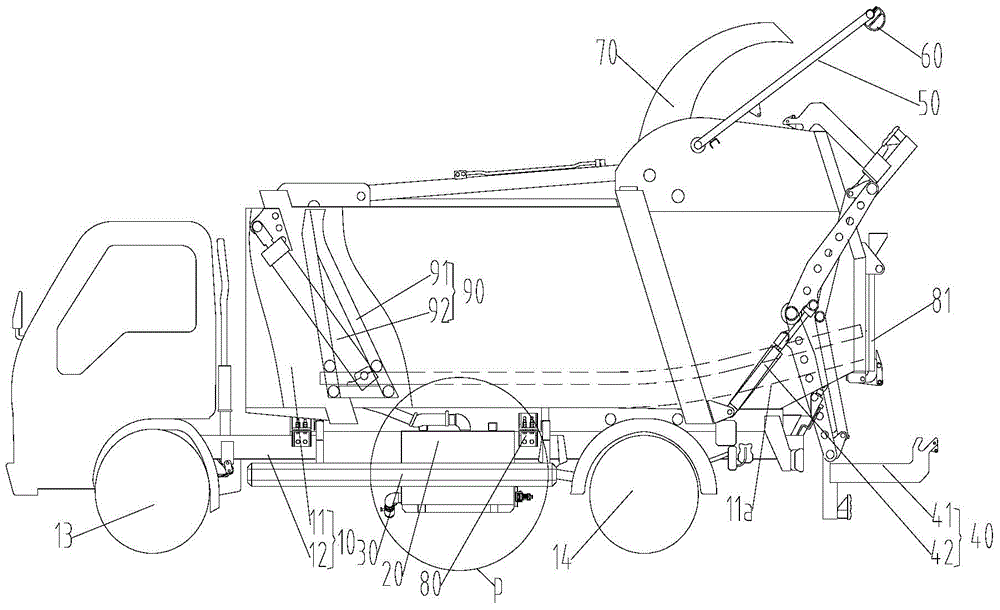

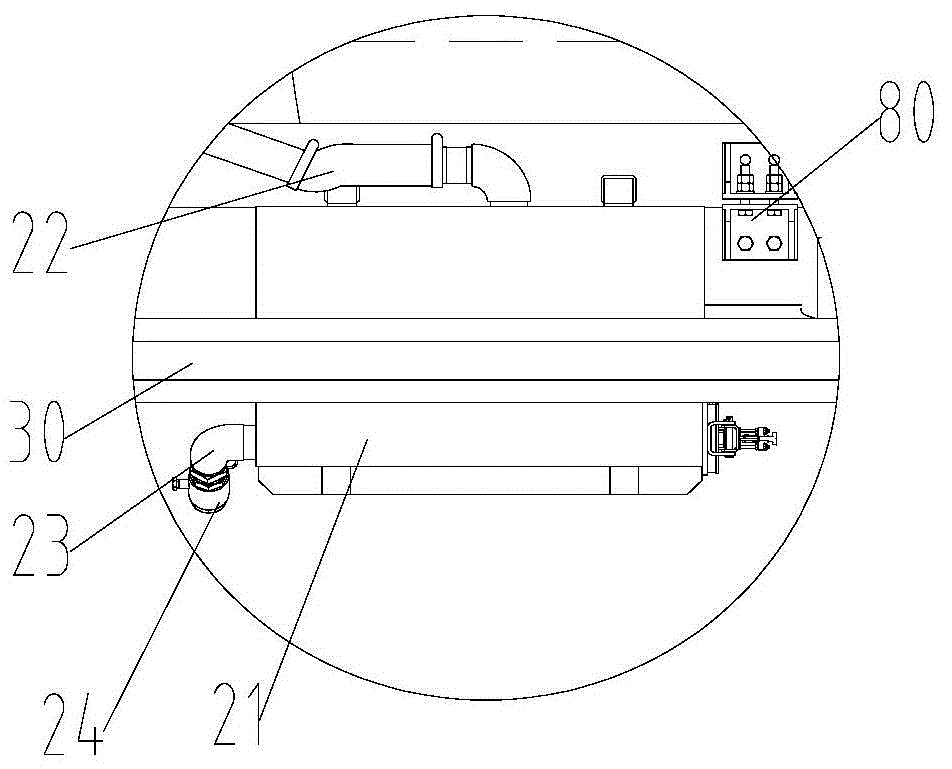

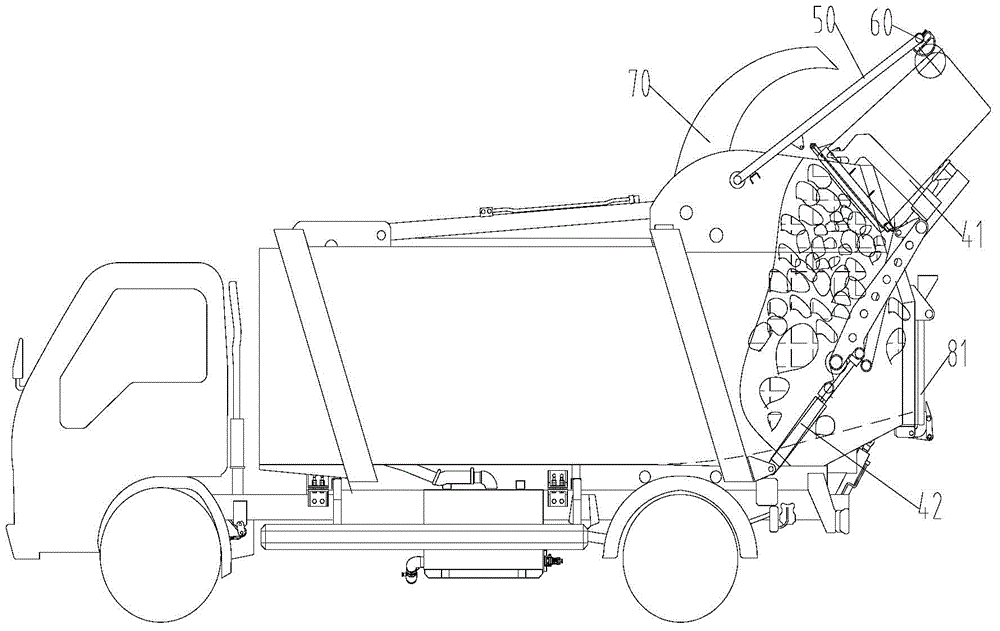

Pressure filling equipment and garbage truck

The invention provides a piece of pressure filling equipment and a garbage truck. The pressure filling equipment comprises a pressure filling bin which has a material inlet and outlet hole, and a material pressure filling mechanism which is reversibly arranged at the material inlet and outlet hole of the pressure filling bin and is turned over into the pressure filling bin to roll and press materials in the pressure filling bin. As the material pressure filling mechanism can be turned over into the pressure filling bin to roll and press materials in the pressure filling bin, materials can be compressed effectively, the pressure filling bin can contain more materials, the efficiency of material pressure filling is improved, and proper material pressure filling is ensured. When the pressure filling equipment is applied to the garbage truck, the transporting efficiency of the garbage truck can be improved. Moreover, the material pressure filling mechanism can cover the material inlet and outlet hole effectively to avoid overflow of garbage from the material inlet and outlet hole, and the sealing performance of the garbage truck is improved.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Quick pressing mechanism for mechanical manufacturing equipment

ActiveCN111168444AImprove compaction efficiencyFast pressing heightPositioning apparatusMetal-working holdersMachine buildingElectric machinery

The invention relates to the technical field of machining, and particularly discloses a quick pressing mechanism for mechanical manufacturing equipment. The quick pressing mechanism for the mechanicalmanufacturing equipment comprises a turnover assembly, a sliding assembly arranged at the upper end of the turnover assembly and a downward pressing assembly arranged at the upper end of the slidingassembly, wherein the sliding assembly is composed of a fixed seat of a groove body structure, a sliding seat, a worm and a driving motor; and the downward pressing assembly consists of a lifting electric cylinder, a fixed plate, an extension plate, a downward pressing electric cylinder and a pressing plate. According to the quick pressing mechanism for the mechanical manufacturing equipment, thetelescopic length of the downward pressing electric cylinder can be directly set through a touch display screen, so that the pressing height of the pressing plate at the lower end of the downward pressing electric cylinder is controlled; the worm is driven by the driving motor to be engaged with a transmission turbine tooth head for transmission, so that the sliding seat moves left and right in the fixed seat along the guide of a guide groove, and the pressing length of the pressing plate relative to a workpiece can be quickly adjusted; and the pressing angle of the whole mechanism can also beeffectively adjusted, and rapid pressing can be realized by using the quick pressing mechanism.

Owner:CHANGZHOU INST OF MECHATRONIC TECH +1

Tamping device for road engineering

InactiveCN108589475AImprove the compaction effectImprove compaction efficiencyRoads maintainenceDiesel engineTransmission belt

The invention discloses a tamping device for road engineering. The tamping device for road engineering comprises a vehicle board, compaction rollers and a diesel engine; the bilaterally symmetrical compaction rollers are arranged under the vehicle board; an output shaft of the diesel engine is connected to the compaction roller through a first transmission belt; and a compaction block is arrangedbetween the compaction rollers. According to the tamping device for road engineering, through adoption of the compaction rollers and the diesel engine, the diesel engine drives the compaction rollersto rotate to compact soils in a mobile manner; by arranging the compaction block and using a limiting plate which is linked with a mobile rod through a transmission mechanism, materials which extrudedoutwards during tamping the compaction block are limited to improve the tamping effect, avoid manual cleaning and enhance the tamping efficiency; and the tamping device for road engineering has the advantages that the structure is simple, the volume is small, the tamping device can adapt to multiple operation scenes, and the practicability is high.

Owner:FOSHAN XINLAI ENG TECH CO LTD

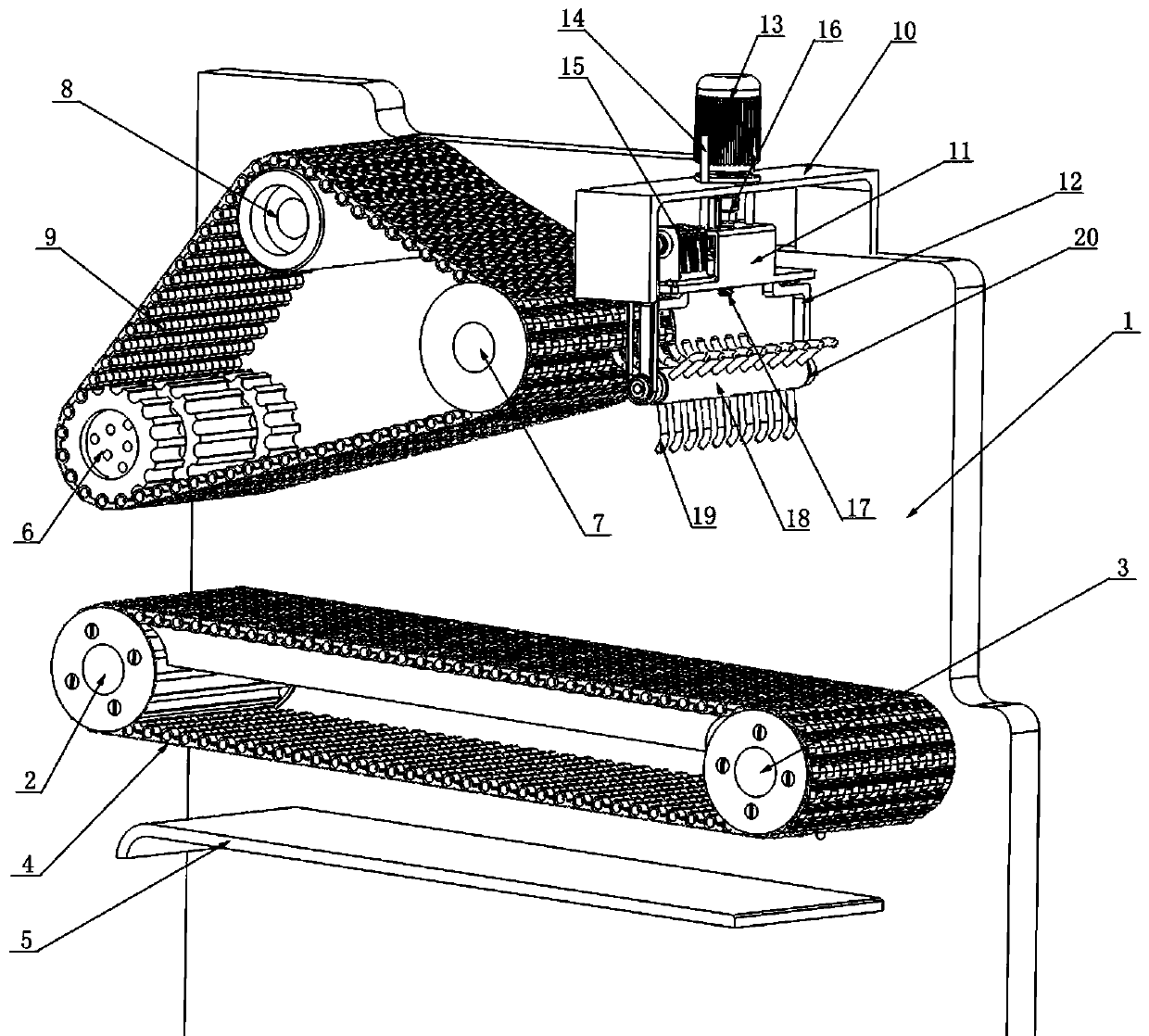

Automatic material moving and feeding device for tobacco cutter

ActiveCN107712999AAvoid skiddingImprove shredding qualityConveyorsTobacco treatmentChain conveyorReducer

The invention discloses an automatic material moving and feeding device for a tobacco cutter. The automatic material moving and feeding device comprises a frame and is characterized in that the frameis provided with a horizontal chain conveying mechanism and a triangular chain conveying mechanism, the triangular chain conveying mechanism is arranged above the horizontal chain conveying mechanism,and the frame is further provided with a material moving device used for moving materials adhered to the triangular chain conveying mechanism off the triangular chain conveying mechanism; the material moving device comprises a mounting support and a material moving mechanism, the material moving mechanism comprises a connecting support rack, a reducer, a material moving roller positioning and mounting support and a material moving roller arranged on the material moving roller positioning and mounting support, the reducer is arranged on the connecting support rack, the material moving roller positioning and mounting support is arranged at the lower end of the connecting support rack, and the reducer is in transmission connection with the material moving roller through a transmission device. The automatic material moving and feeding device has the advantages that the materials adhered to the triangular chain conveying mechanism can be moved off the triangular chain conveying mechanism through the material moving roller of the material moving device, worker labor intensity is relieved while slipping of the triangular chain conveying mechanism during material compacting can be avoided, and material conveying efficiency and quality are increased.

Owner:CHINA TOBACCO HENAN IND

Wood plate press-fit device for furniture production

InactiveCN111975891AImprove bonding efficiencyAdjustable lengthPlywood pressesVeneer pressesSlider bearingAdhesive glue

The invention belongs to the technical field of composite plate production and particularly provides a wood plate press-fit device for furniture production. Aiming at the problem of uneven diffusion of glue inside plate materials caused by the uneven downward-pressing intensity of existing press-fit devices, the following scheme is presently proposed that the wood plate press-fit device comprisesa base which is internally provided with a cavity and is of a square tubular structure, the two opposite sides of the base are both fixedly provided with sliding rail strips, and the upper surfaces ofthe two sliding rail strips are both slidably connected with sliding racks of arch structures, two channel steel horizontal beams with opposite openings are fixedly arranged between the top ends of the two sliding racks, a fixed box is fixedly arranged between the middle portions of the two channel steel horizontal beams, and the upper end lower surfaces of four corners of the fixed box are all provided with sliding bearings in an embedded manner. According to the wood plate press-fit device for the furniture production, when wood plates need to be compacted, the wood plate press-fit device can perform vibration compaction on all positions of the wood plates just needing to start a driving motor in coordination with the sliding racks and the fixed box capable of sliding horizontally alongthe channel steel horizontal beams when being used, so that the glue between the plate materials is evenly smeared and spread, and the bonding efficiency is improved.

Owner:赖家发

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com