Asphalt spreading device for building

A construction and asphalt technology, which is applied in the field of construction asphalt paving equipment, can solve the problems of long operation period and many machines, and achieve the effect of high cutting efficiency and high compaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

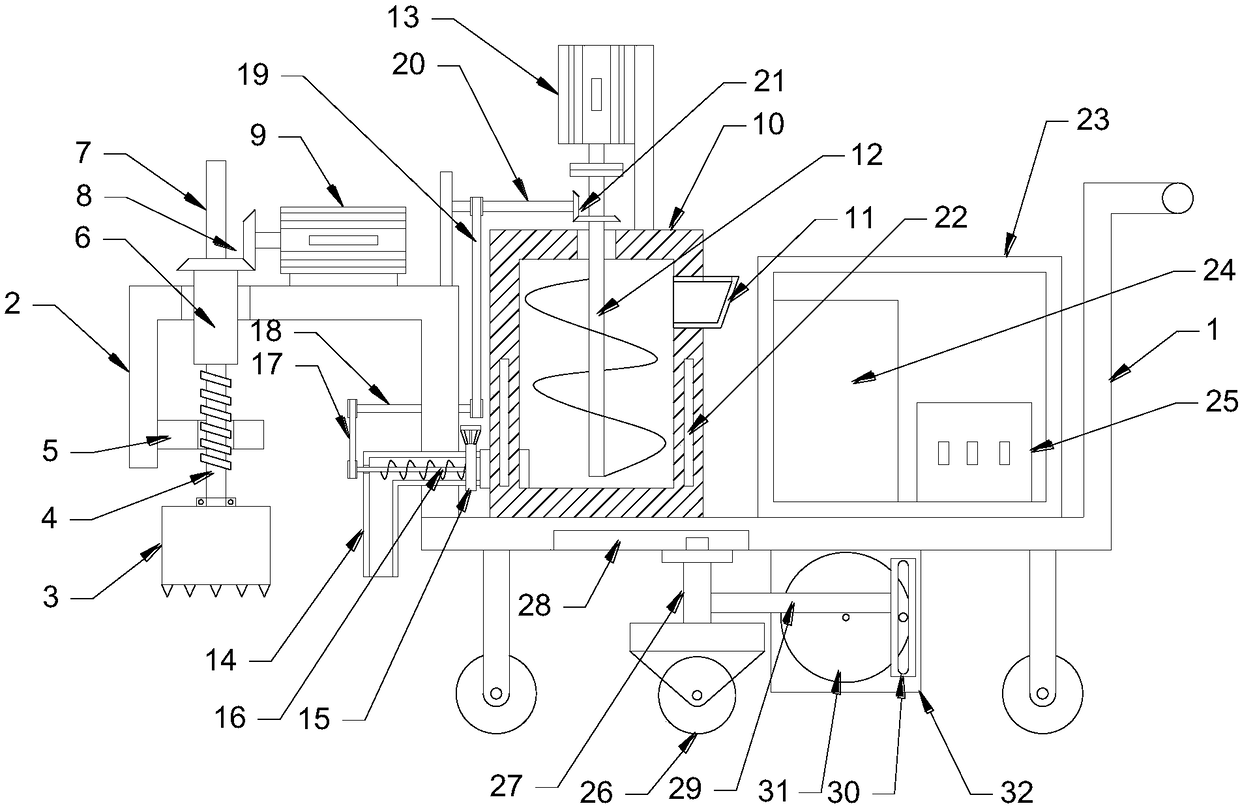

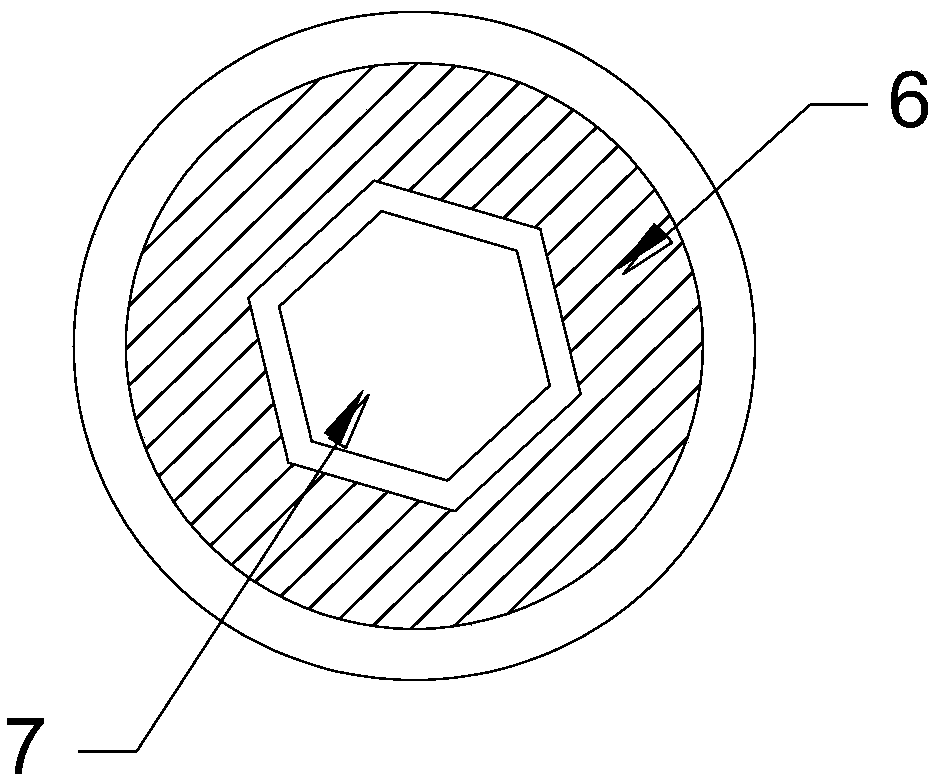

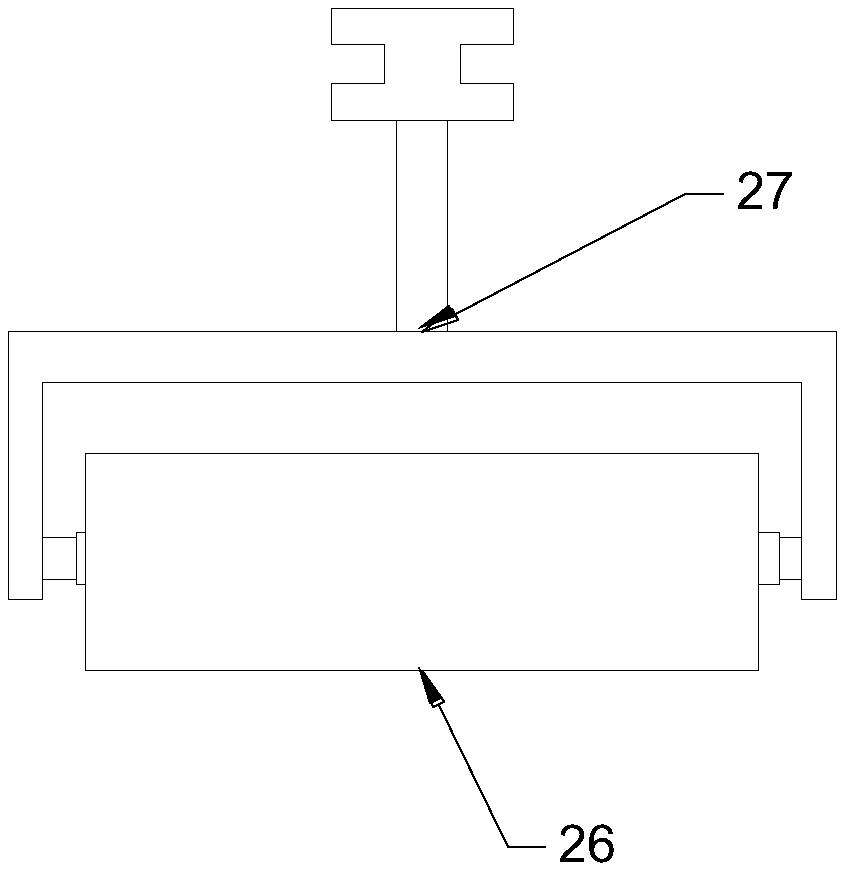

[0023] see Figure 1~3 , in an embodiment of the present invention, an asphalt paving device for construction includes a car body 1, a drilling mechanism, a stirring and discharging mechanism and a compacting mechanism; the front end of the car body 1 is provided with a drilling mechanism, and the drilling mechanism includes The front cantilever 2 and the drill barrel 3, the top of the drill barrel 3 is fixedly connected with a threaded rod 4 by bolts, the threaded rod 4 runs through a threaded plate 5 and is threaded with the threaded plate 5, and the threaded plate 5 is fixedly connected with the front cantilever 2; A prismatic rod 7 is fixedly connected to the top of the rod 4, and the prismatic rod 7 runs through the rotating cylinder 6 and is slidingly connected with the rotating cylinder 6. The rotating cylinder 6 is nested in the front cantilever 2 and is rotatably connected with the front cantilever 2 through a bearing; The drum 6 is connected to the output shaft of th...

Embodiment 2

[0028] see Figure 4 The difference between this embodiment and Embodiment 1 is that: the bottom of the car body 1 is provided with a roller, and the roller at the rear end is connected with a fourth drive motor 34 through a third transmission belt 33, and the fourth drive motor 34 is connected to the vehicle power supply 24 and the switch The control panels 25 are connected in series to facilitate the movement of the vehicle body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com