Wood plate press-fit device for furniture production

A technology of pressing device and wood board, applied in the direction of veneer press, plywood press, manufacturing tools, etc., can solve the problems of uneven pressure, uneven spread of glue, etc., to improve compaction efficiency and reduce compaction Difficulty, the effect of improving the bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

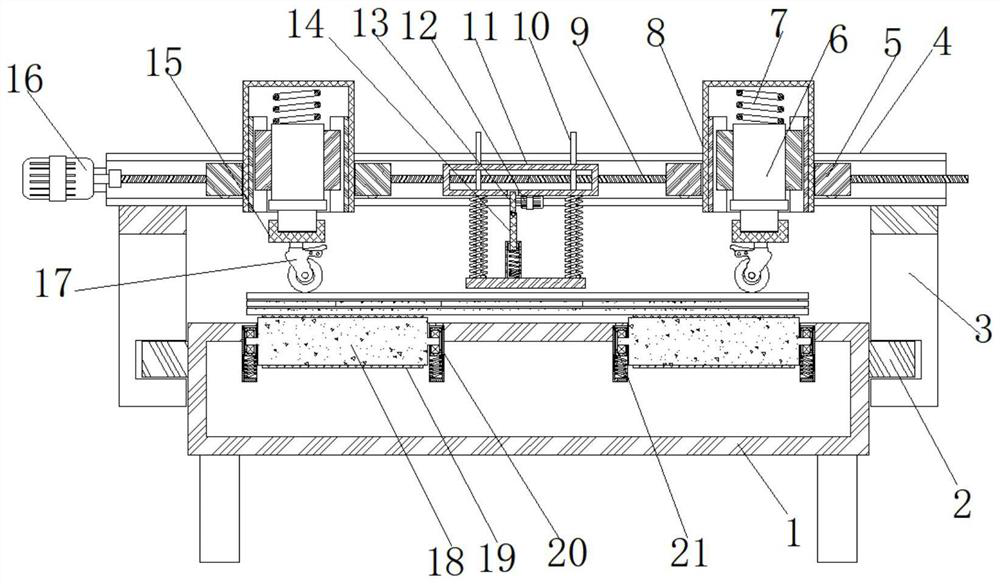

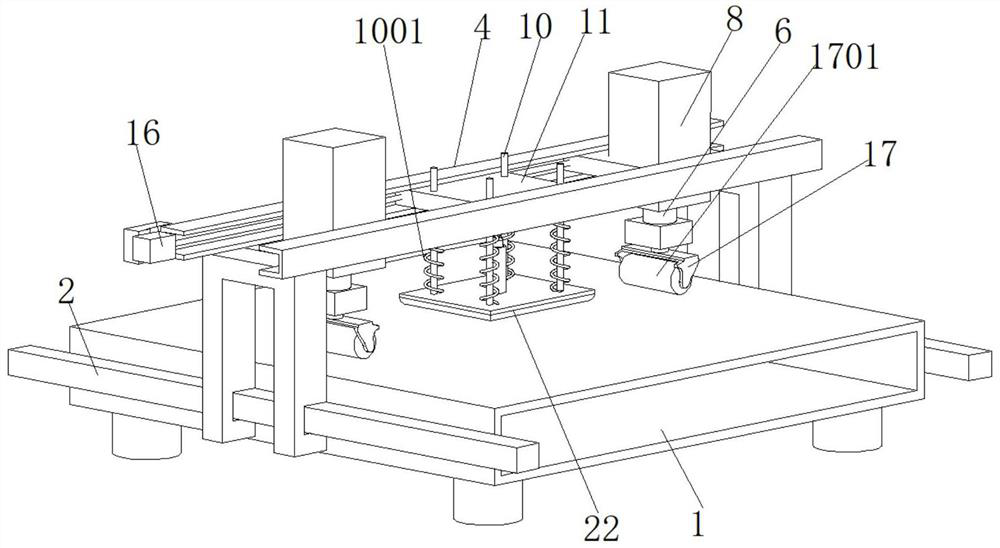

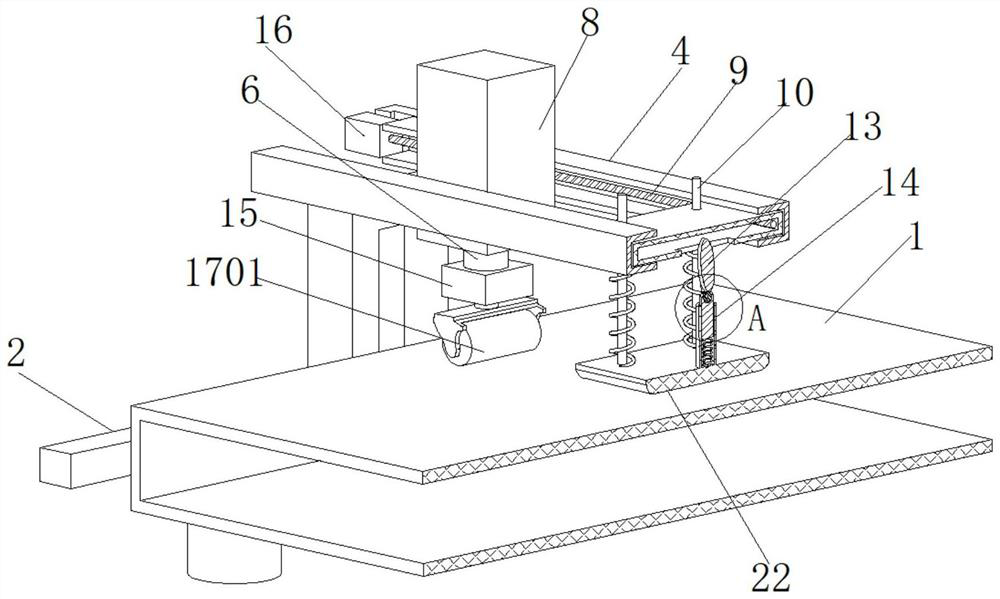

[0030] refer to Figure 1-5 , a wood board pressing device for furniture production, comprising a base 1 with a cavity in a square tubular structure, slide rail bars 2 are fixed on opposite sides of the base 1, and the upper surfaces of the two slide rail bars 2 are Slidingly connected with a sliding frame 3 in a bow-shaped structure, two channel steel beams 4 with opposite openings are fixed between the tops of the two sliding frames 3, and a fixed box 11 is fixed between the middle parts of the two channel steel beams 4, and fixed The upper and lower surfaces of the four corners of the box 11 are all embedded with sliding bearings, and the four corners of the fixed box 11 are all slidably connected with guide rods 10, and the bottom ends of the four guide rods 10 are fixed with the same compacting plate 22, and the four guide rods The outer walls of 10 are all sleeved with back-moving springs 1001, the lower surface of the fixed box 11 is fixed with a drive motor 12 near the...

Embodiment 2

[0040] refer to figure 1 and Figure 5 , a wooden board pressing device for furniture production. Compared with Embodiment 1, this embodiment also includes rectangular holes distributed equidistantly on the upper surface of the base 1, and both ends of the rectangular holes are clamped with opposite openings. The C-shaped steel columns 20 are provided with supporting rollers 18 between the two C-shaped steel columns 20 with opposite openings.

[0041] Wherein, both ends of the idler 18 are fixed with bearing housings, and the lower surface of the bearing housings are fixed with compression springs 2101, the bottom ends of the C-shaped steel columns 20 are fixed with stoppers, and the outer peripheral walls of the idler 18 are sleeved with Anti-slip layer, so that when the board needs to be compacted during use, only need to reserve space to slowly roll the board along the upper surface of the idler roller 17 to the working position, and when the pressure drops, the board can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com