Automatic material moving and feeding device for tobacco cutter

A technology of automatic feeding and feeding device, applied in the direction of cleaning device, packaging, conveyor, etc., can solve the problems of affecting the normal operation of the conveyor belt, uneven feeding flow of the conveyor belt, increasing the labor intensity of workers, etc. The effect of improving the quality of silk, improving the feeding efficiency and improving the compaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

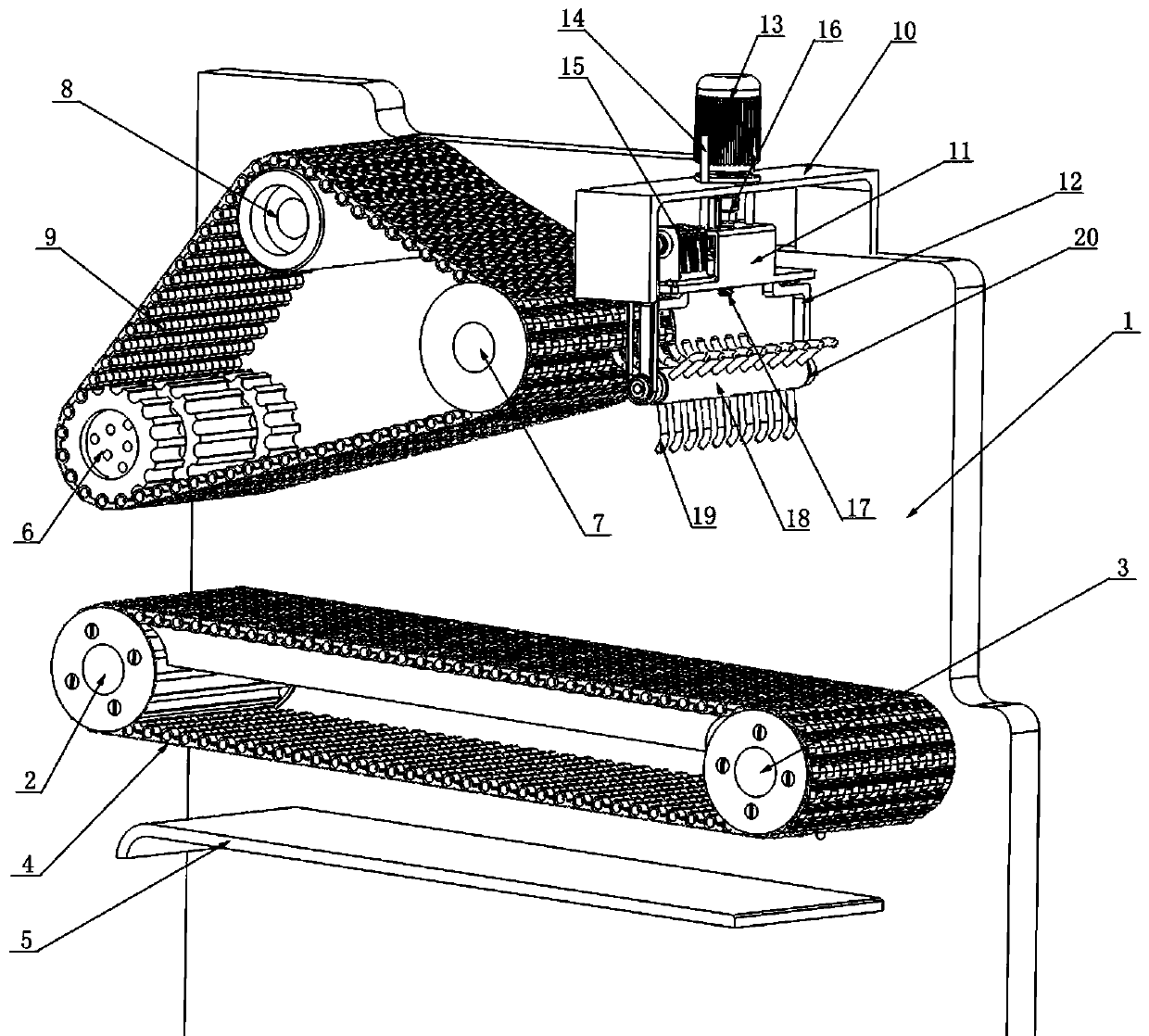

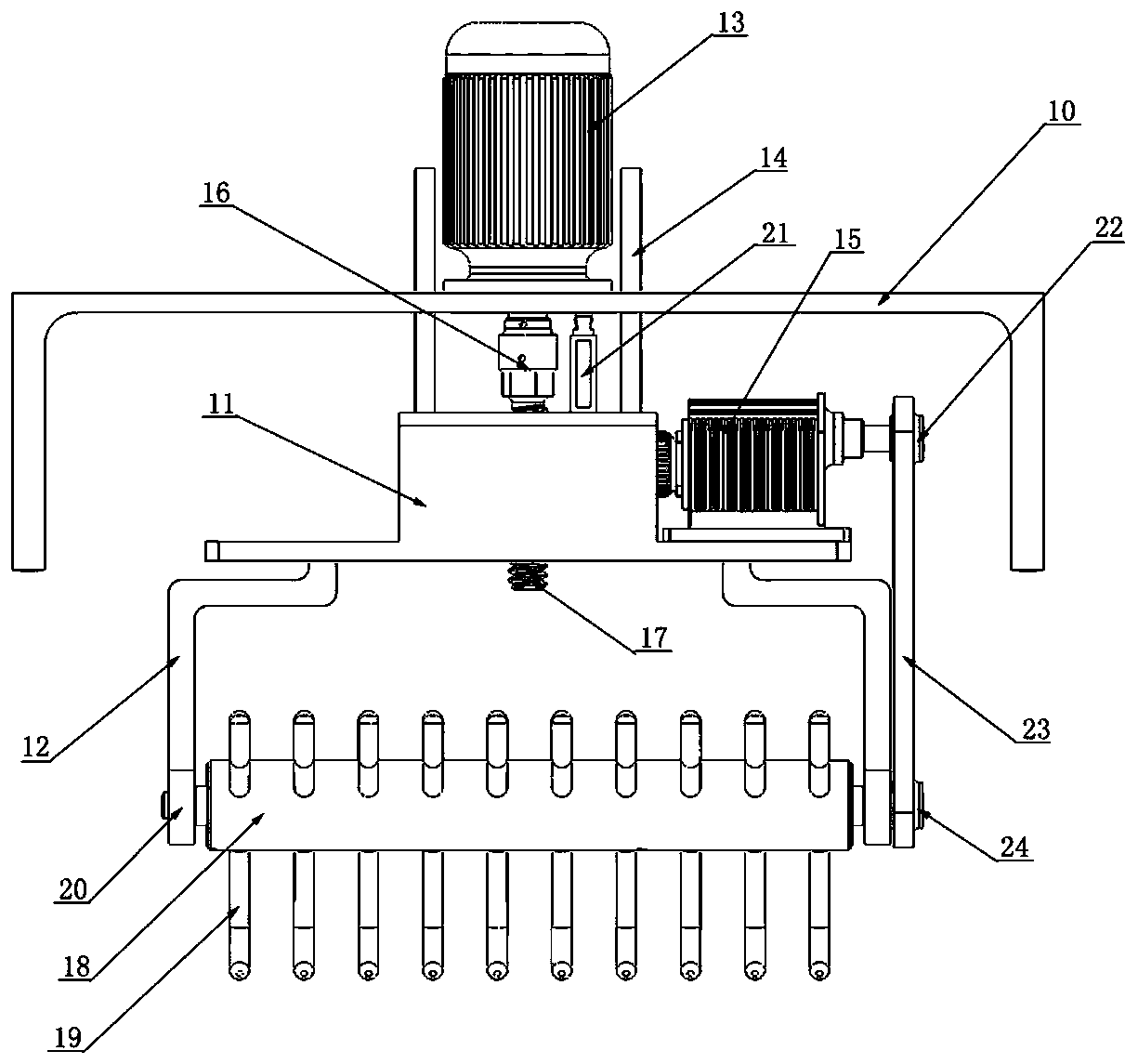

[0023] Such as figure 1 As shown in the figure, an automatic feeding device for a shredding machine includes a frame on which a horizontal chain conveying mechanism and a triangular chain conveying mechanism for extruding the materials conveyed by the horizontal chain conveying mechanism are arranged. , the frame includes two support plates 1 symmetrically arranged (in order to better show the internal structure, one of the support plates is not shown), the horizontal chain conveyor mechanism and the triangular chain conveyor mechanism are both arranged on the two support plates 1, the triangular chain conveying mechanism is set above the horizontal chain conveying mechanism, and the bottom edge of the triangular chain conveying mechanism is inclined from top to bottom along the material conveying direction of the horizontal chain conveying mechanism, which is beneficial for materials to enter the horizontal chain The compacting area between the conveying mechanism and the tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com