Device for batching gray fabric of loom

A technology for looms and grey fabrics, used in looms, textiles, textiles and papermaking, etc., can solve the problems of inconvenient operation and maintenance, complex equipment structure, and high equipment failure rate, and achieve high safety performance, low equipment failure rate, and energy efficiency. low consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

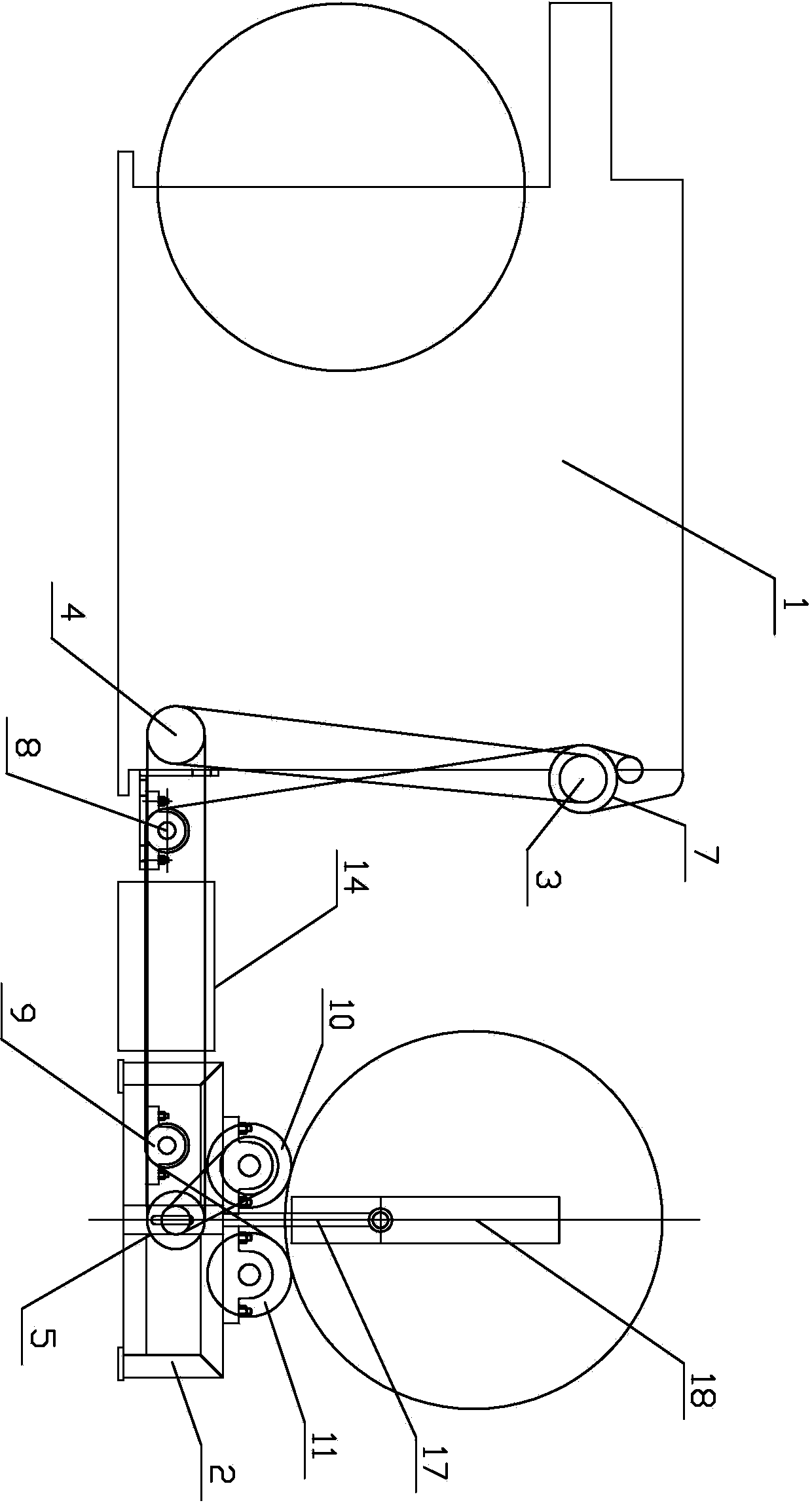

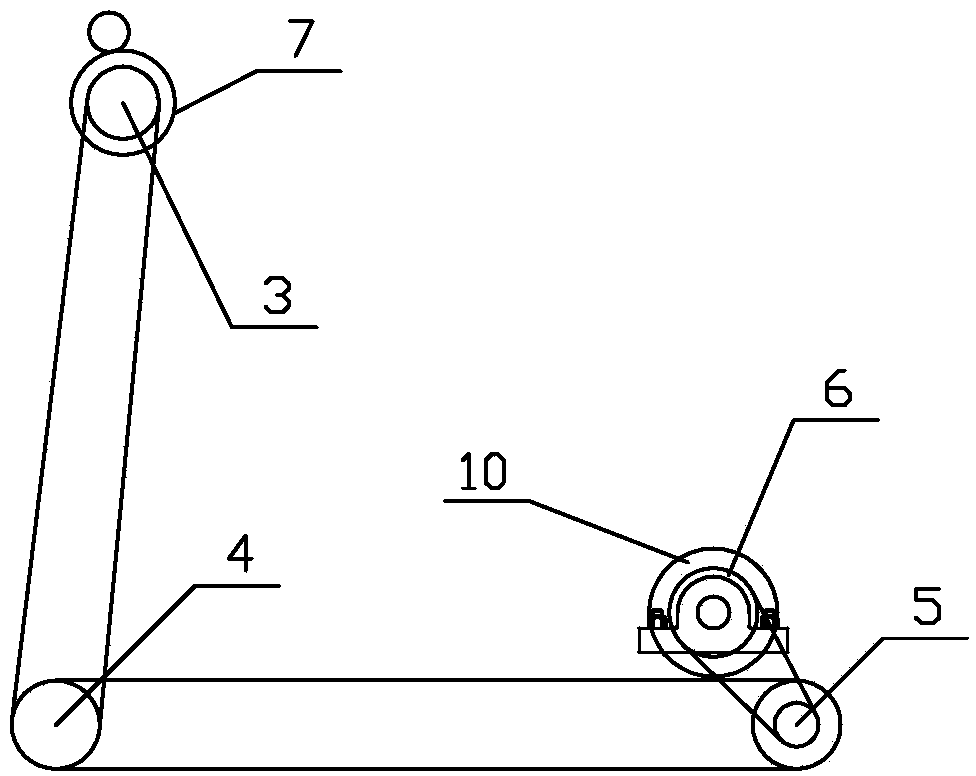

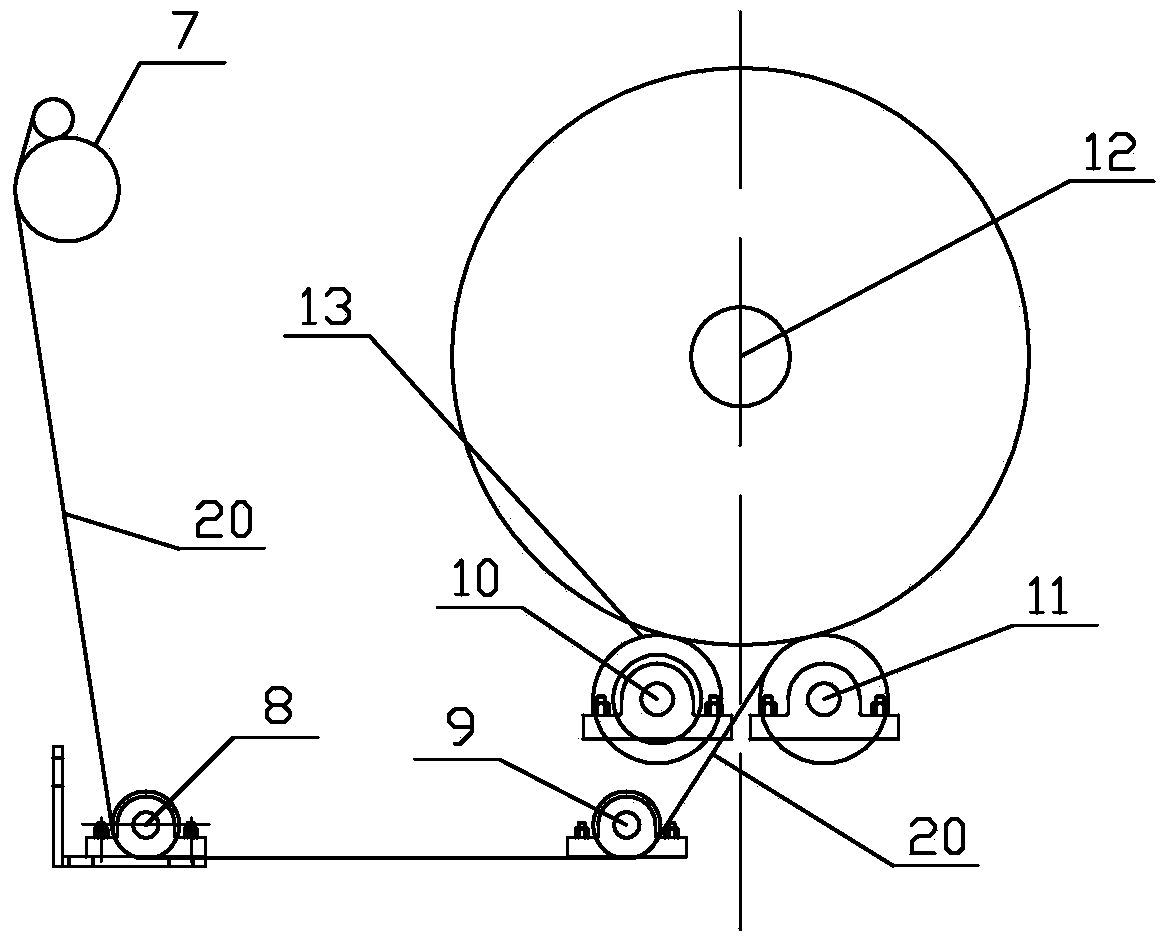

[0021] As shown in the figure, the present invention provides a device for rolling the gray cloth of a loom into a large roll, which includes a machine base 2 arranged outside the loom, a cloth rolling mechanism arranged on the machine base 2, and a device for The transmission mechanism that connects the loom 1 and the cloth rolling mechanism, the transmission mechanism is a multi-stage chain transmission mechanism, and the transmission mechanism is connected with the original loom take-up licker-in roller 7 on the loom. The transmission mechanism includes a single-row sprocket 3, a double-row constant-velocity sprocket 4, a double-row variable-speed sprocket 5, and a driving roller sprocket 6. The single-row sprocket 3 is fixed on the coiling bar of the original loom The roller 7 is synchronously driven, and the single-row sprocket 3 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com