Patents

Literature

319results about How to "Reduce defective products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

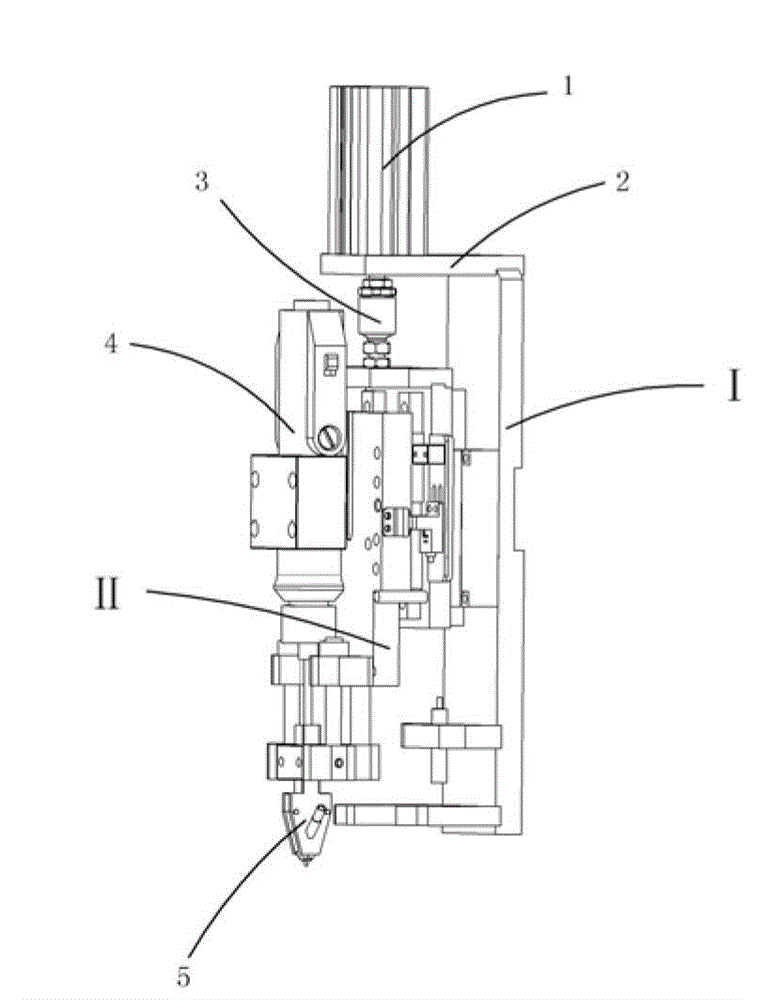

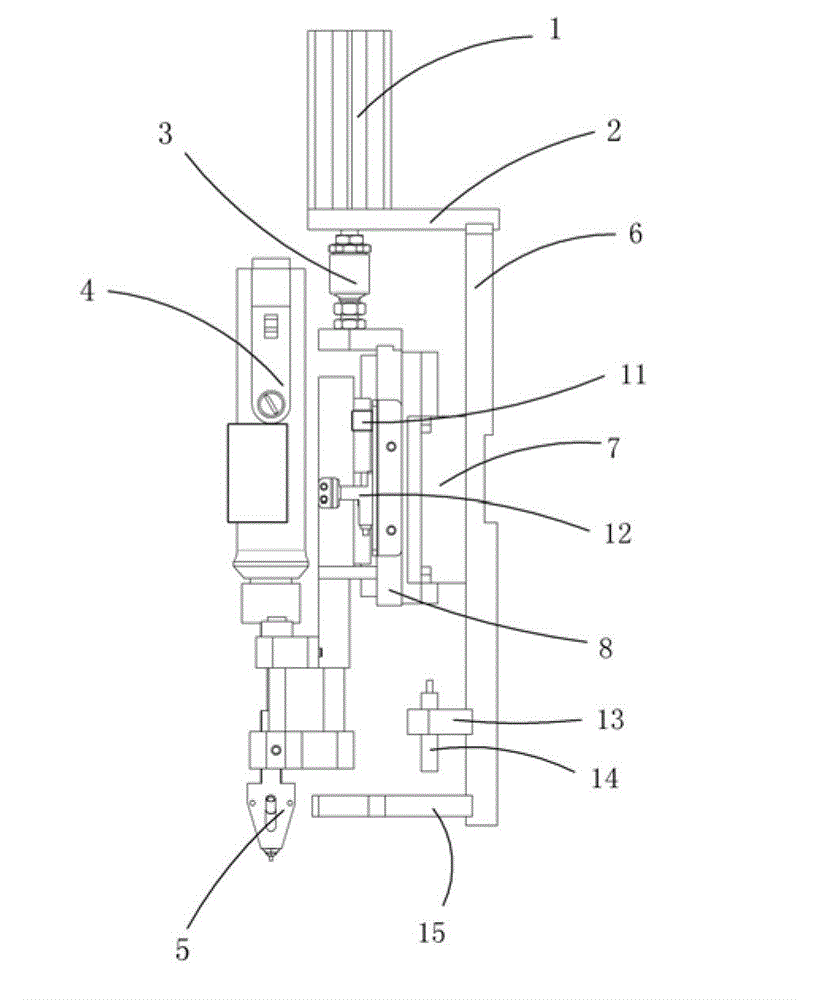

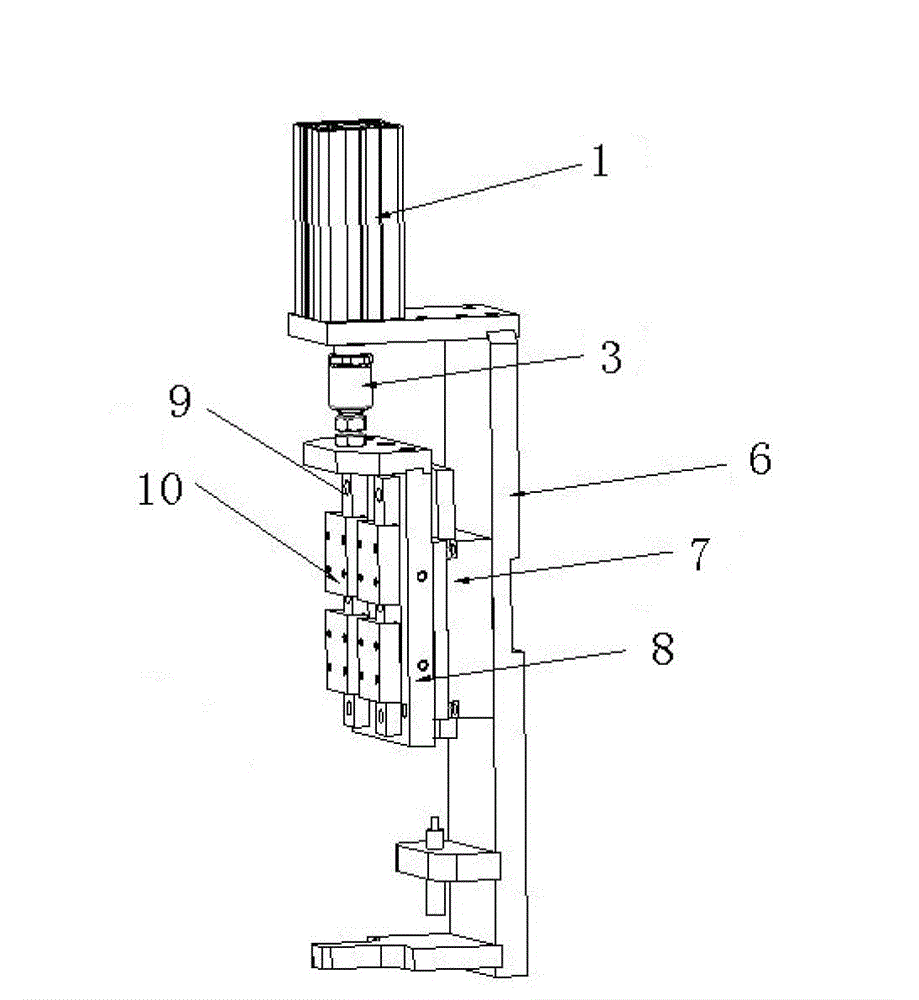

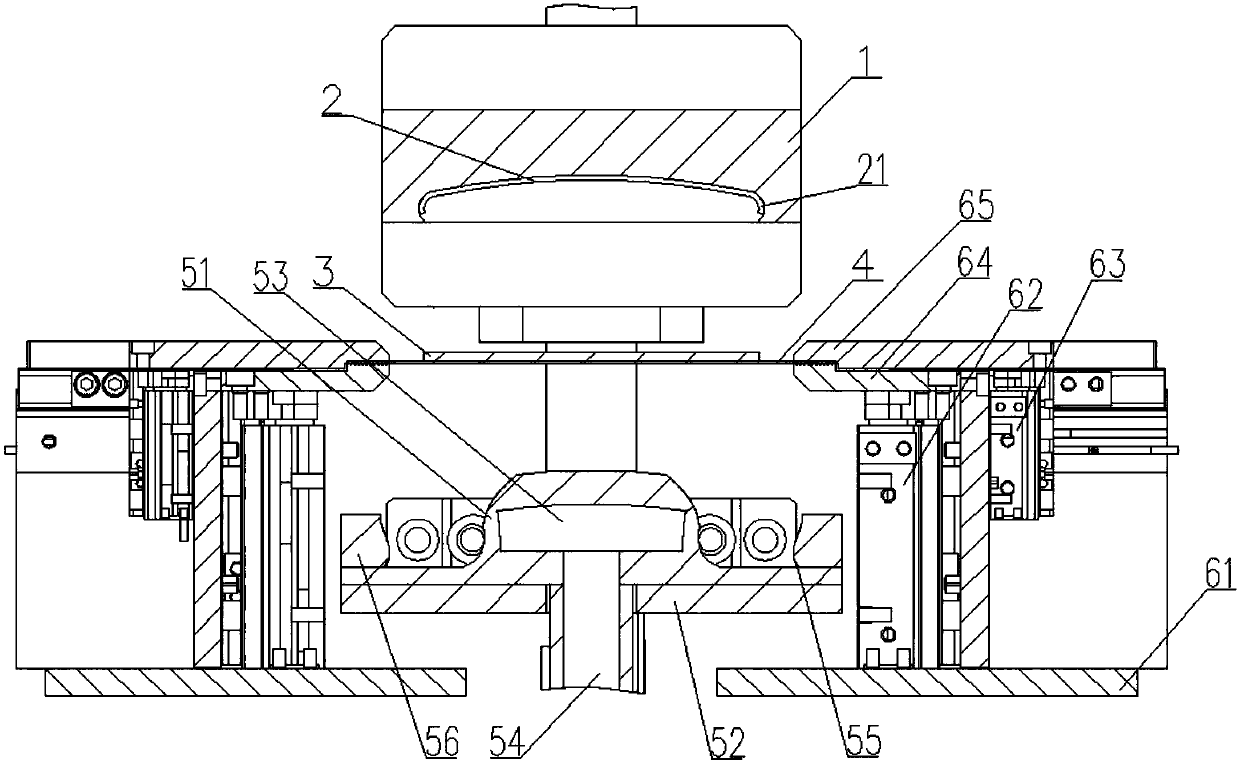

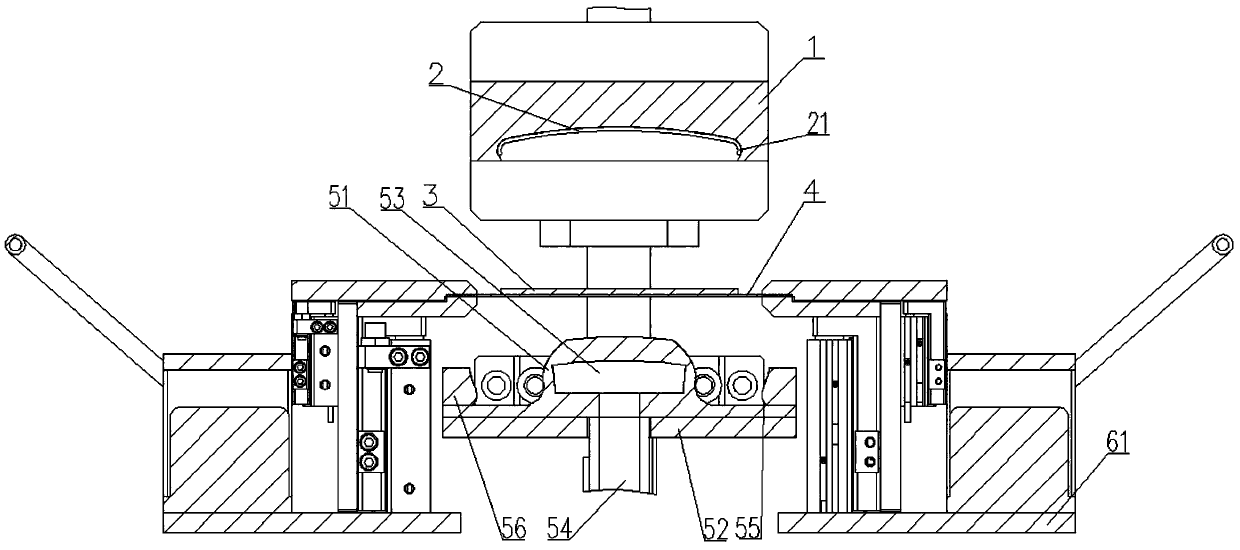

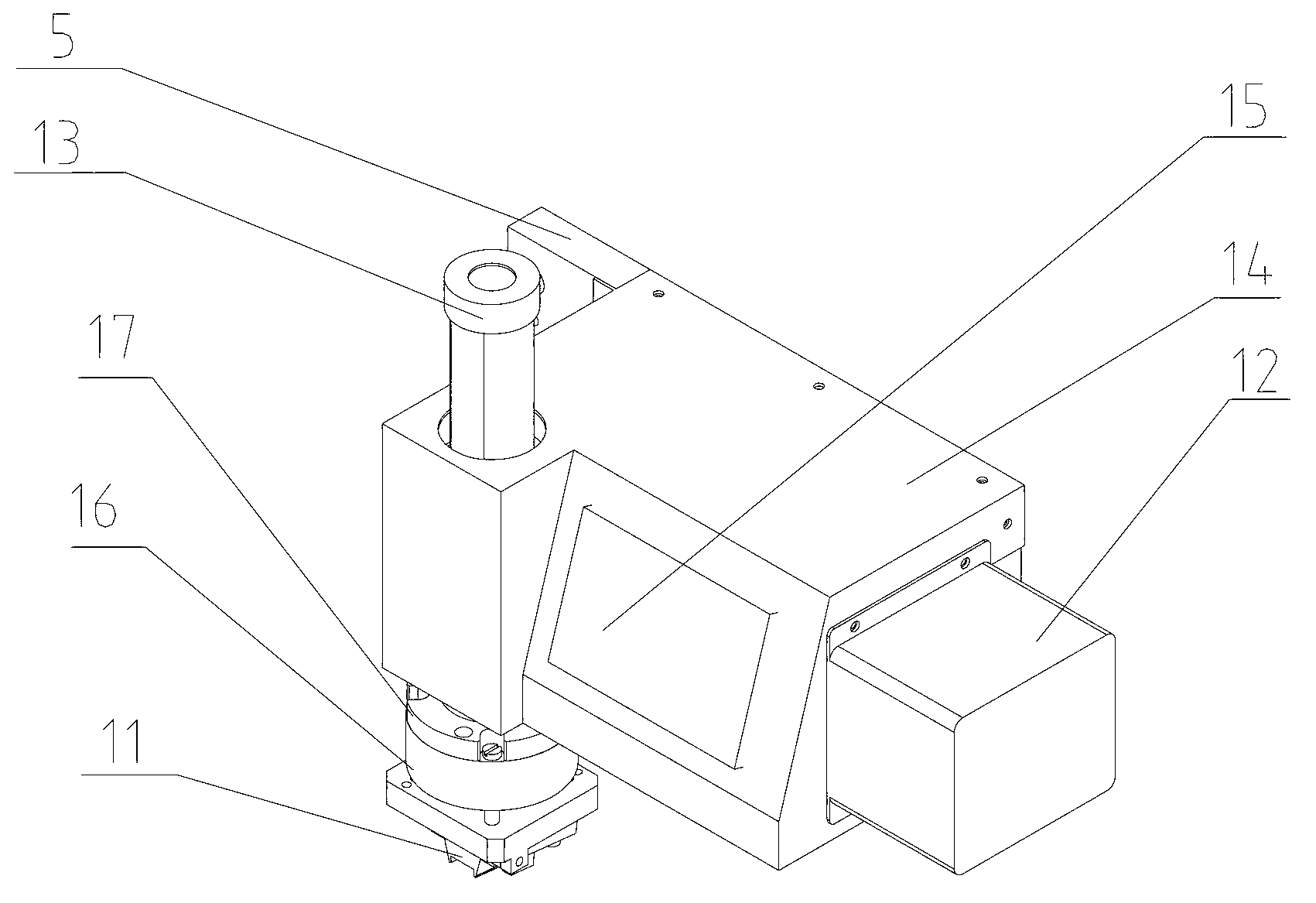

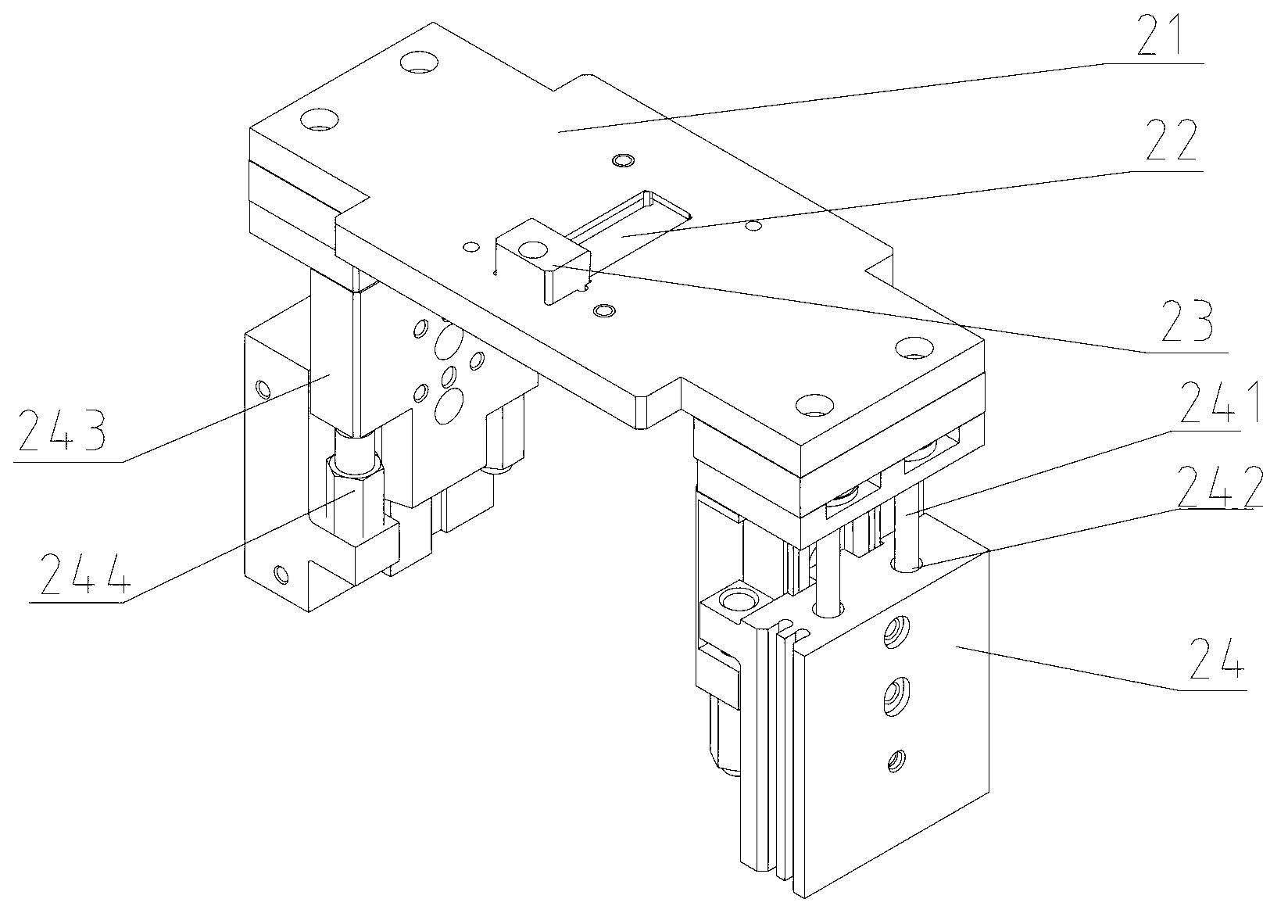

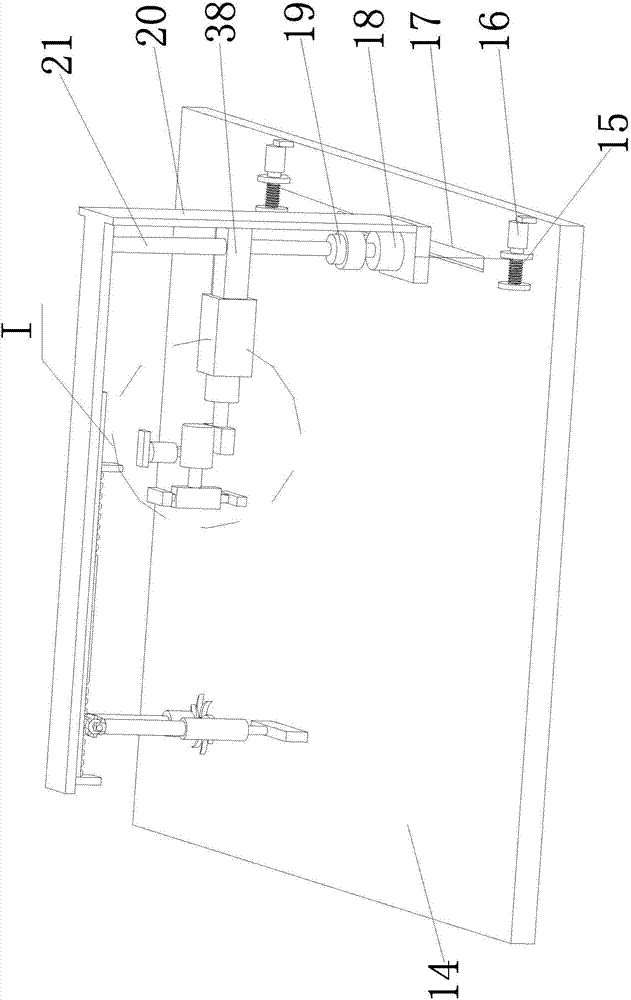

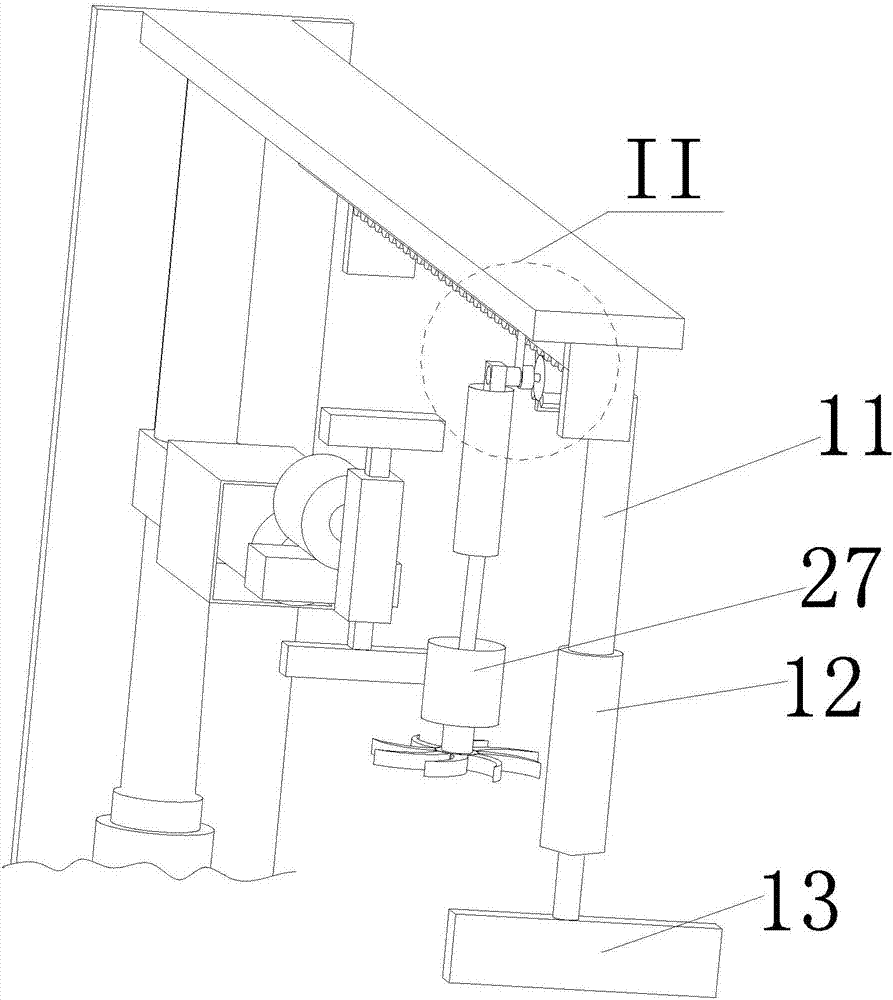

Automatic screw locking elastic mechanism

The invention relates to an automatic screw locking elastic mechanism, of which a downward pushing cylinder is connected with a Z-axis moving mechanism; a spring mechanism is arranged on the Z-axis moving mechanism; an electronic screwdriver bit is arranged on the spring mechanism, the lower end of the electric screwdriver bit is connected with a screw chuck; the upper end of a support plate of the Z-axis moving mechanism is connected with a cylinder installation plate, and the lower end of the support plate is connected with a limit plate; a guide plate is arranged on the support plate; a guide sliding plate is arranged on the guide plate, a slide rail is arranged on the guide sliding plate, and a side block is arranged on the slide rail in a matched manner, a moving plate is fixedly connected with the slide block; the upper part of the moving plate is connected with a fixing plate through springs a and b, and the lower part of the moving plate is connected with a buffer plate; a blind hole is arranged in the moving plate, and a spring c is arranged in the blind hole; and a buffer limit pillar penetrates through the buffer plate, is inserted in the blind hole and is in contact with the spring c. Through the driving of the downward pushing cylinder, the electric screwdriver bit is driven to move downwards, meanwhile, a screw is driven to move downwards and to be rotatably attached on a product in a locked manner, the spring mechanism has a protective effect on the screw and the product, and the whole mechanism stably operates.

Owner:上海莘翔自动化科技有限公司

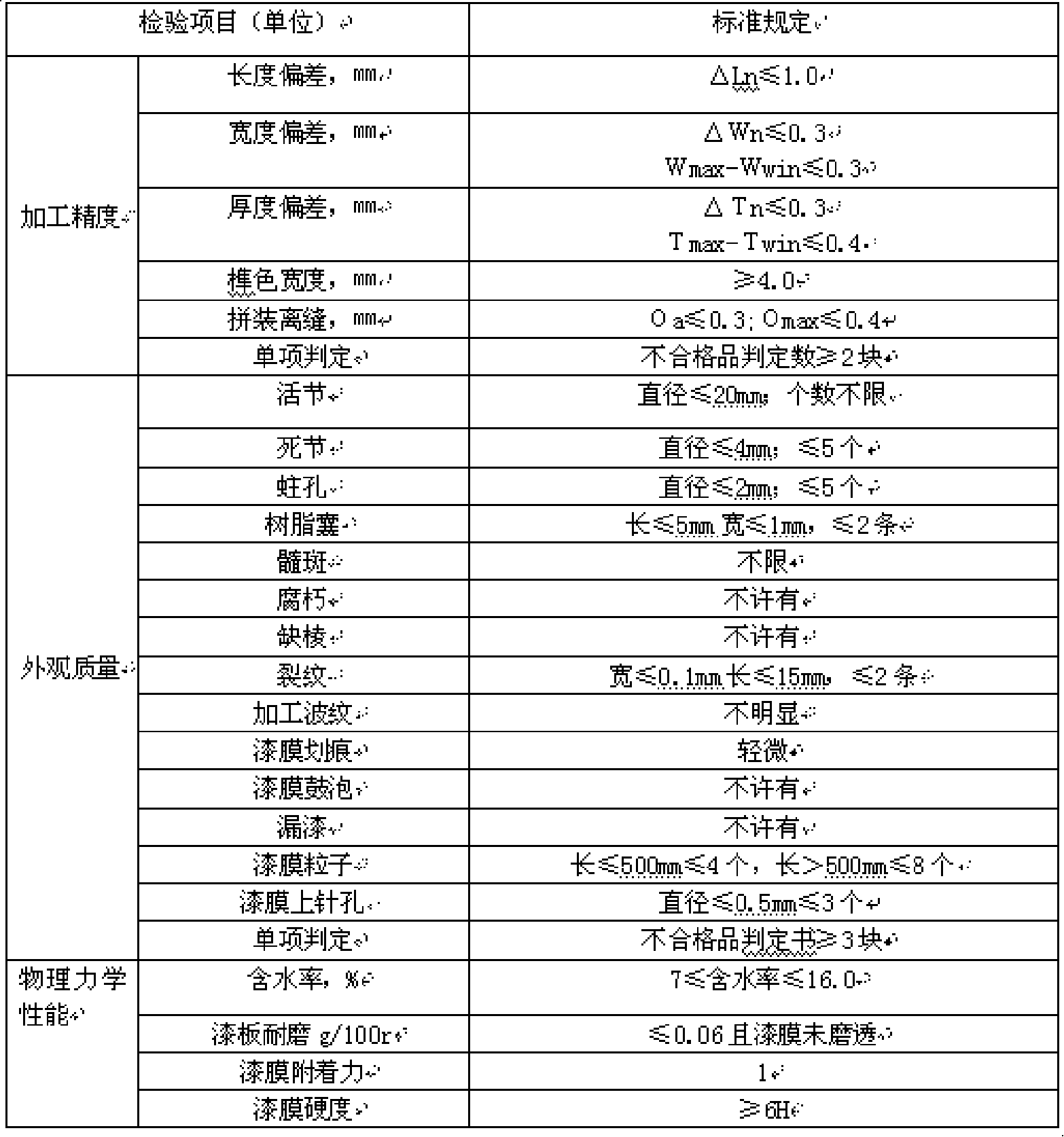

Method for producing wooden floor with platinum crystal surface

InactiveCN101301764ASolve the problem of insufficient adhesionIncrease pressureLiquid surface applicatorsWood treatment detailsPlatinumLacquer

The invention discloses a production method for a platinum crystal face wood floor, which comprises the production steps as follows: drying and curing of floor blank, blank processing, primer and paint painting. The invention adopts a vertical-lubrication penetration roller spraying technique, carries out the pre-heating disposal, drying disposal, balance disposal, humidifying treatment, temperature reduction kiln outgoing and curing to the floor blank, then processes the blank and paints the primer; the paint is then coated by adopting eight-bottom and four-surface so as to gain a finished product. The platinum crystal face wood floor prepared by the invention has the advantages that the paint adhesion of the tree with high grease (oil) content is improved; the floor has ultra-strong adhesion from the interior of the wood to the surface; a production process of eight-bottom and four-surface is adopted to combine an elastic, abration and friction resistance environmental protection paint; therefore, the surface filling of the floor is saturated, clear and natural, the chamfers are smoother and the wood floor is more scraping- resistant and wear-resistant; the one-off qualification rate of the product is improved and achieves 99.5 percent, thus improving the quality of the product.

Owner:浙江上臣家居科技有限公司

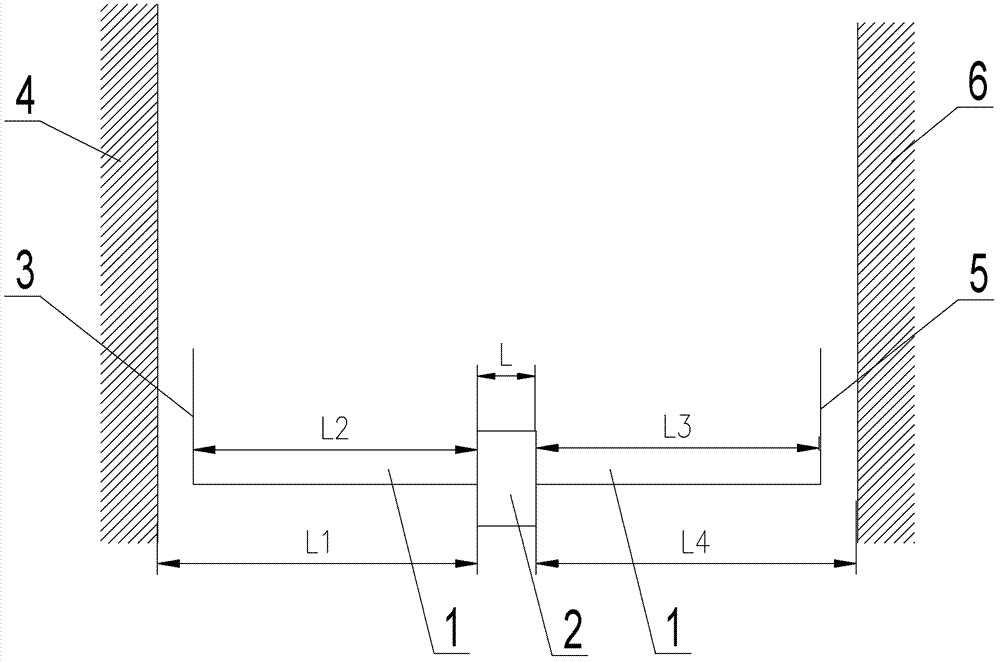

Method for calibrating center line of guide ruler

ActiveCN103191924AAvoid wear and tearReduce defective productsRolling equipment maintainenceGuiding/positioning/aligning arrangementsWaxEngineering

The invention relates to the field of hot rolled strip guide ruler centering, in particular to a method for calibrating the center line of a guide ruler. The method is characterized in that after maintenance is finished every time or strip steel with the thickness of 18 mm is rolled every time, the deviation of a transmission side and an operation side of the guide ruler is corrected in time to ensure the centering of the guide ruler. The method comprises the following specific operation steps: (1) measuring the width L of an extension strip at the middle part of the guide ruler, the distance L2 between the edge of the transmission side to a guiding plate on the transmission side of the extension strip, the distance L1 between the edge of the transmission side of the extension strip and an archway on the transmission side, the distance L3 between the edge of the operation side of the extension strip and the guiding plate on the operation side, and the distance L4 between the edge of the operation side of the extension strip and the archway on the operation side; (2) determining the deviation of the center of the extension strip; and (3) calibrating the center of the guide rule. Compared with the prior art, the method has the benefits that through in time correction of the deviation of the transmission side and the operation side of the guide rule after maintenance is finished every time or strip steel with the thickness of 18 mm is rolled every time, the wear and wax hanging phenomena of one side of the guide ruler, which is resulted from deviation of the guide ruler, are avoided.

Owner:ANGANG STEEL CO LTD

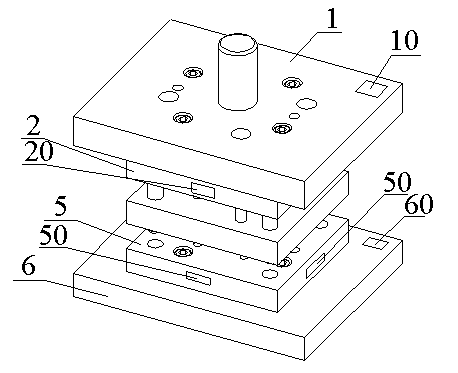

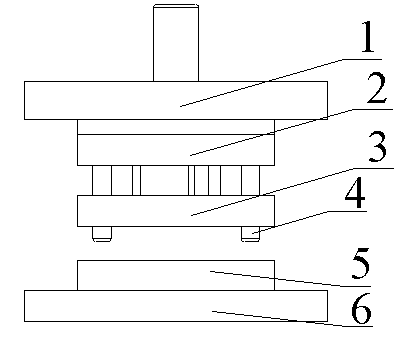

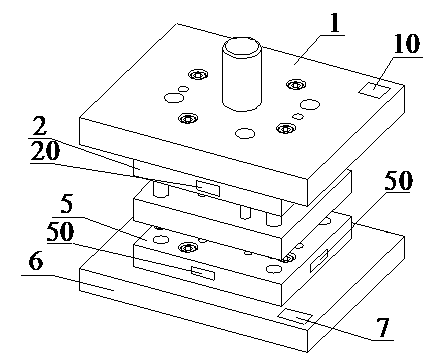

Embedded integrated intelligent die

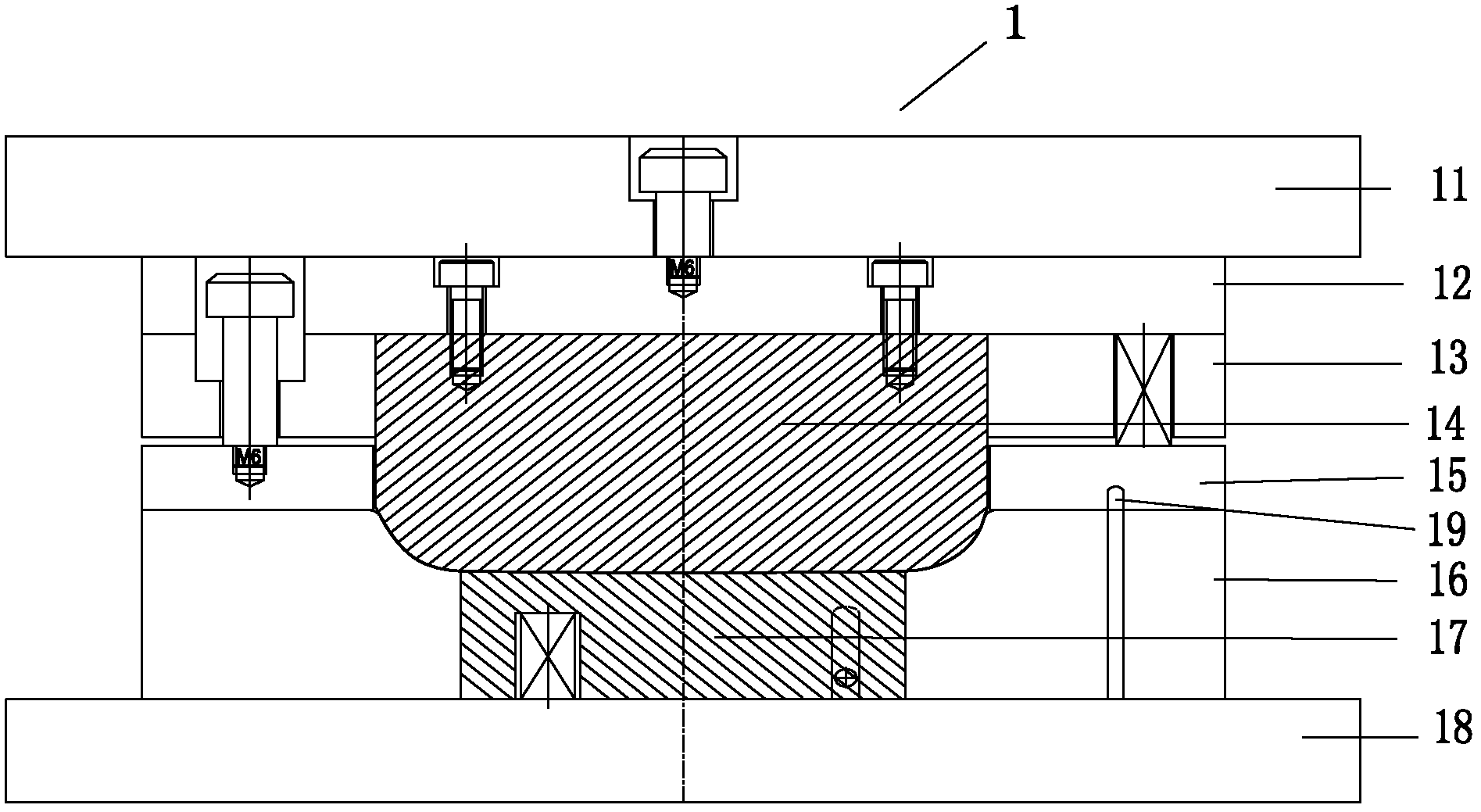

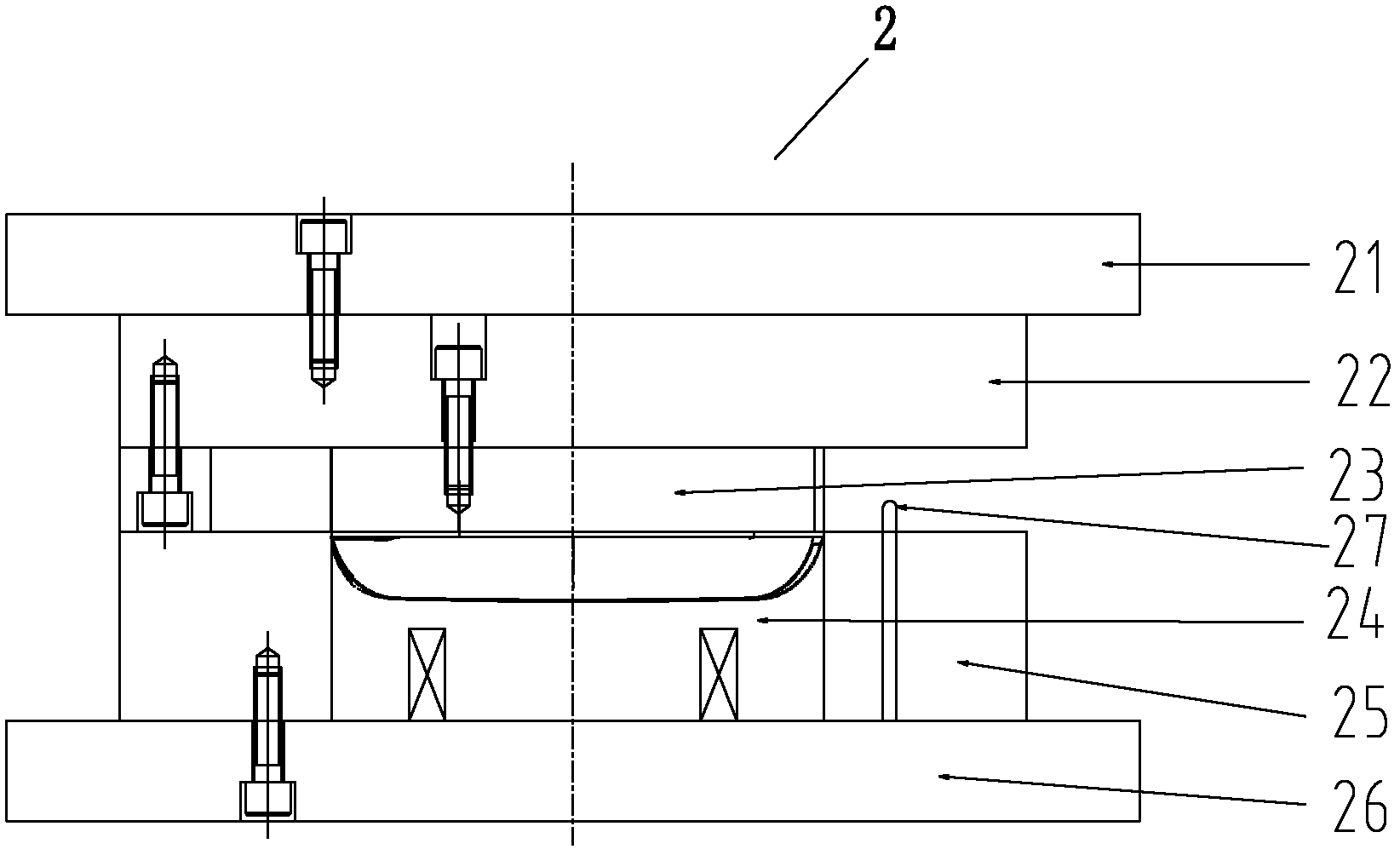

The invention discloses an embedded integrated intelligent die which comprises an upper die set plate, an upper die fixing plate, a guide pillar, a core die, a discharging plate, a lower die set plate and a cavity die. The cavity die is arranged on the lower die set plate; the upper die fixing plate is provided with the core die which is matched with the cavity die; the upper die fixing plate is arranged on the upper die set plate; the core die is arranged on the upper die set plate; the guide pillar which penetrates through the discharging plate to be fixed on the upper die set plate enters into the cavity die to guide and correct under the working state of the embedded integrated intelligent die; an elastic device is arranged between the discharging plate and a core die fixing plate; the discharging plate can move up and down along the guide pillar; and the upper die set plate, the cavity die and the lower die set plate are respectively provided with a sensor. Accordingly, the embedded integrated intelligent die has the advantages of being capable of utilizing the sensors which are embedded in the embedded integrated intelligent die to integratedly obtain various information on the embedded integrated intelligent die to adjust technical parameters when the embedded integrated intelligent die works, guaranteeing that die machining is under real-time monitoring and accurate machining conditions, reducing defective products and reducing the rate of the detective products by 20%, improving the working efficiency and being capable of reducing debugging time of the embedded integrated intelligent die by 50%.

Owner:SOHBI CRAFT CHANGSHU

Transparent shoe sole and making method thereof

The invention discloses a transparent shoe sole and a making method thereof and aims to provide a rubber shoe sole with extremely excellent transparence and a making method of the transparent shoe sole. The technical key points are as follows: the shoe sole is made from the following components in parts by mass: 30-40 parts of butadiene rubber, 5-10 parts of isoprene rubber, 10-20 parts of butadiene styrene rubber, 30-40 parts of ultra-fine white carbon black, 15-20 parts of operating oil, 0.2-0.5 part of stearic acid, 1-2 parts of antioxidant, 1-1.5 parts of coupling agent and 2-3 parts of bridging agent. The making method comprises the following steps of: (1) weighing all the components according to the parts by mass in the claim 1; (2) mixing all the components in an internal mixer; (3) sheeting by an external mixer according to thickness demands of various shoe soles, and cutting rubber materials by a cutter (4) vulcanizing in a mold; and (5) taking out the shoe soles from the mold after the vulcanizing reaction is finished. The transparent shoe sole and the making method thereof belong to the technical field of shoe making.

Owner:广州市邦尔福鞋材有限公司

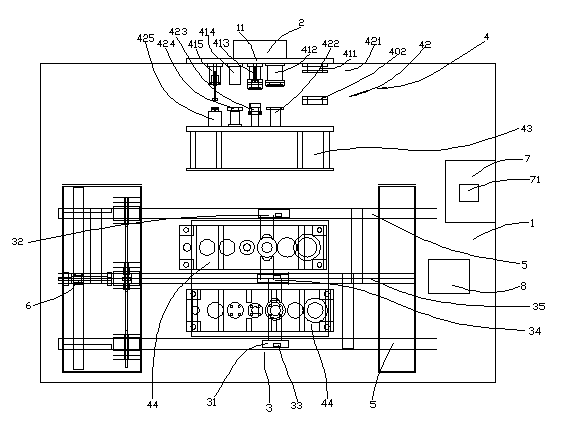

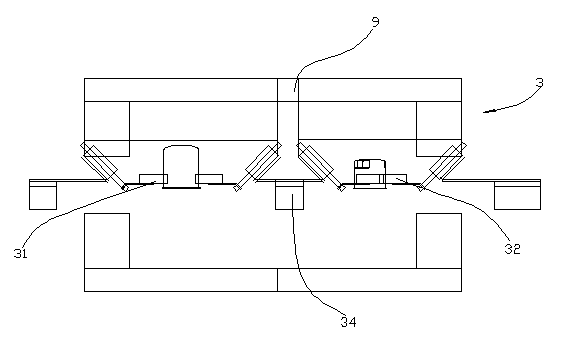

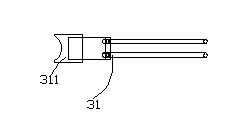

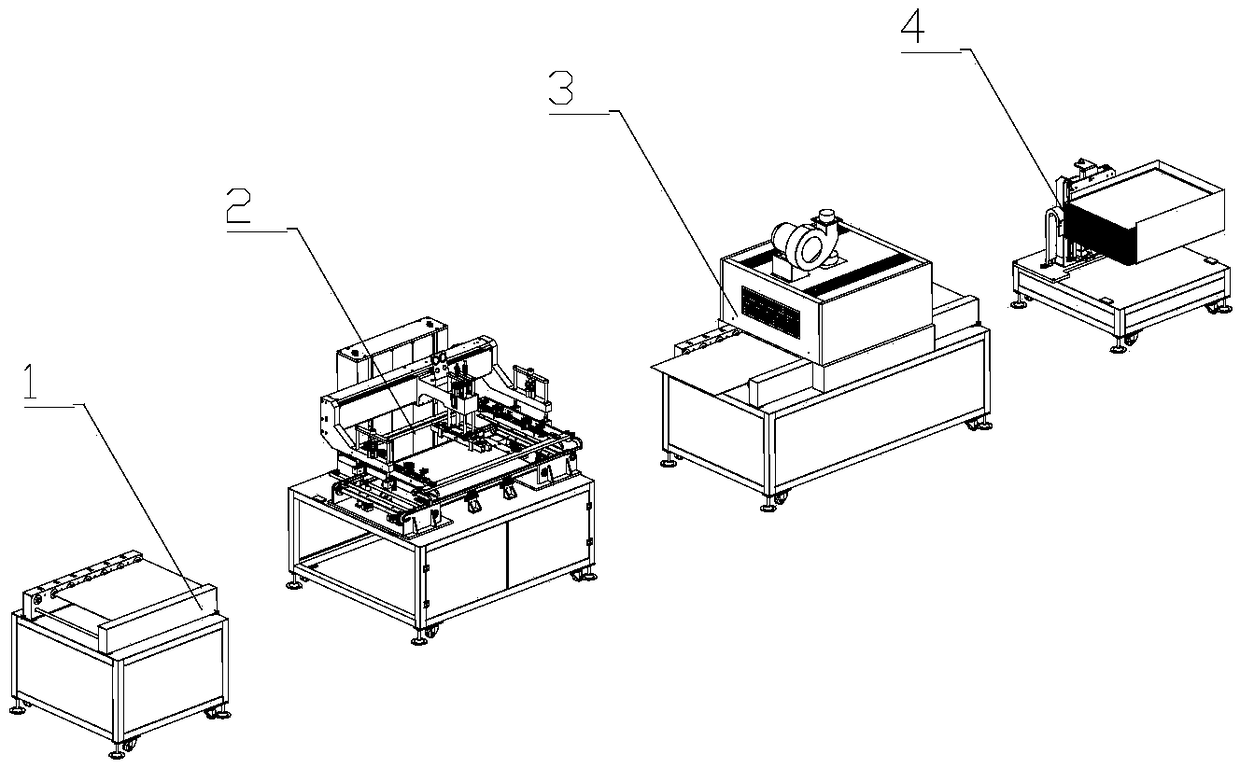

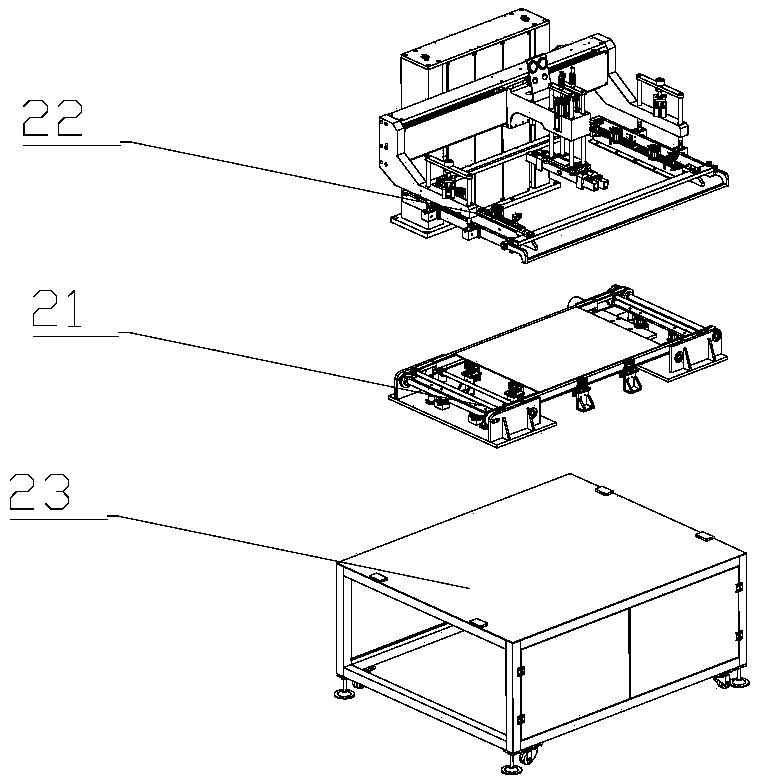

Automobile filter casing automatic production line

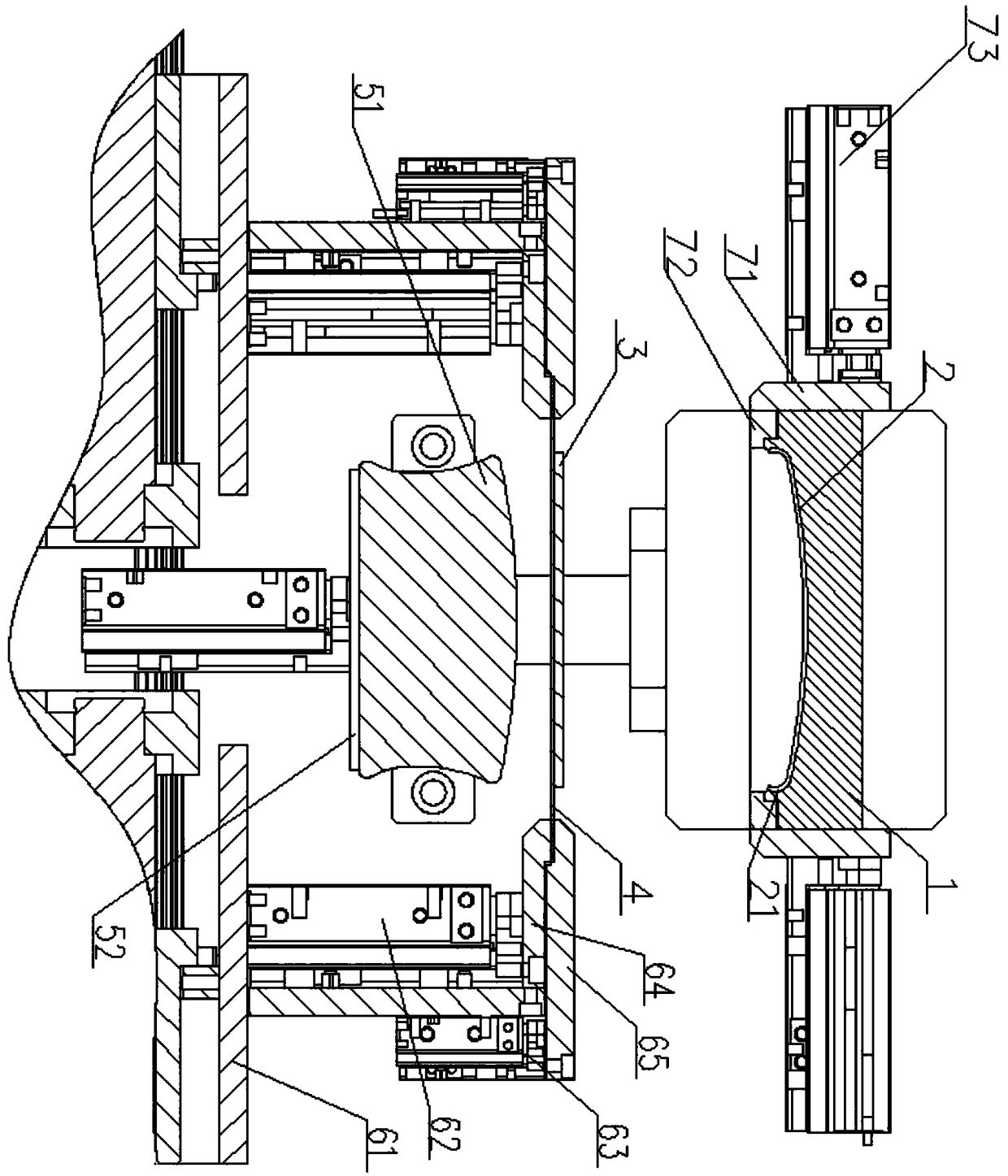

ActiveCN103286199AAvoid product damageReduce defective productsShaping toolsMetal-working feeding devicesAutomatic controlDrive motor

An automobile filter casing automatic production line comprises a machine tool body, an oil press, a manipulator and a die group, wherein the oil press is fixedly arranged above the machine tool body via an upper plate; the oil press drives the die group to act; the die group comprises an upper die group and a lower die group which are corresponding in positions; the manipulator is driven by a driving motor to move on guide rails in the horizontal direction; the manipulator comprises a left capturing clamp and a right capturing clamp, which are symmetrically arranged on the two sides of the die group; the production automation is achieved via the manipulator, and a photoelectricity sensing PLC automatic control system is additionally mounted at a machine control part to achieve automatic device platform control, the production efficiency is improved, dual-line and dual-die synchronous production can be realized via one set of oil press, the conventional process requiring ten procedures and ten machine platforms is changed into another process requiring ten producedures and only one set of machine platform, as a result, the problem of single die production mode is solved, the process that the traditional production mode is optimized and developed towards multi-product production entire process of an overall system is realized, and the production efficiency is improved 10 times.

Owner:厦门市欣成业工贸有限公司

Screen laminating device and laminating method

PendingCN109624296AAvoid Bubble WrinklesReduce defective productsDomestic articlesPhysicsAcute angle

The invention discloses a screen laminating device and a laminating method. The screen laminating device comprises an upper cavity body and a lower cavity body, wherein the upper cavity body and the lower cavity body are arranged in a matched mode, and the upper cavity body and the lower cavity body can move up and down; the upper cavity body is provided with a placement platform and a curved surface protection cover plate, and the lower cavity body is provided with a flexible film, a carrying belt and a lifting and pressurizing part; and the placement platform is used for placing the curved surface protection cover plate, the flexible film is placed on the carrying belt, the carrying belt is made of a flexible material, the carrying belt is placed on the lifting and pressurizing part, andthe flexible film and the curved surface protection cover plate are correspondingly arranged up and down. According to the screen laminating device and the laminating method, the flexible film is attached to the curved surface protection cover plate through adjusting the height positions of the placement platform and the lifting and pressurizing part; and for attaching the flexible film to the curved surface protection cover plate with right angle or acute angle edges, under the action of the expansion deformation of a pressing block and a pressing device, earlier contact between the end partof the flexible film and the curved surface edge position of the curved surface protection cover plate is avoided, and produced defective products are reduced.

Owner:汪恒坤

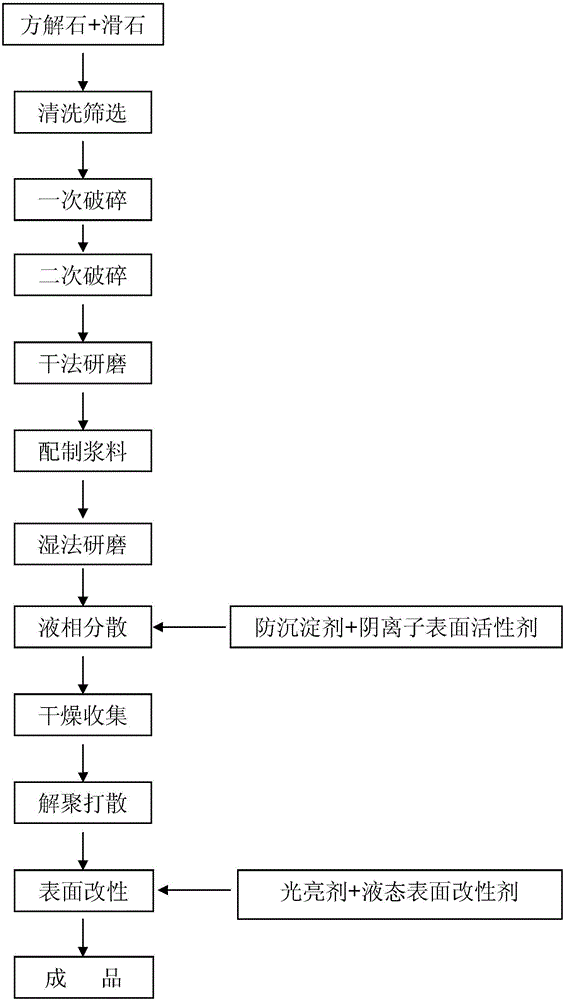

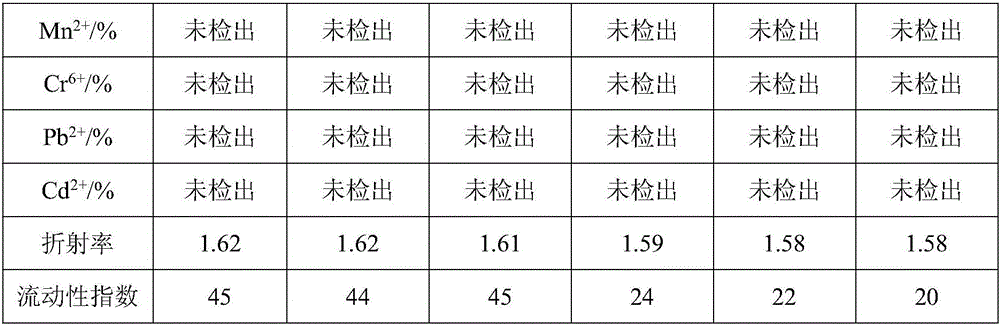

Preparation method of modified calcium carbonate

ActiveCN106317963AGood printabilityEvenly dispersedPigment treatment with organosilicon compoundsPigment physical treatmentDispersityCalcite

The invention provides a preparation method modified calcium carbonate. The preparation method includes: mixing and crushing calcite and talcum, performing dry grinding to obtain raw slurry with solid content being 70-75%, performing constant-temperature stirring and grinding to obtain processed slurry with average particle size being 0.9-1.1 micrometers, adding naphthalene sulfonate type anti-precipitation agent and anionic surfactant into the processed slurry to perform liquid-phase dispersing, drying, collecting, depolymerizing and dispersing, adding brightener and liquid surface modifier to perform wrapping treatment, and stirring to obtain the modified calcium carbonate. By the preparation method, the modified calcium carbonate which is good in printing performance, good in dispersity, good in surface brightness and applicable to films adhered to car bodies can be prepared.

Owner:JIANGXI GUANGYUAN CHEM

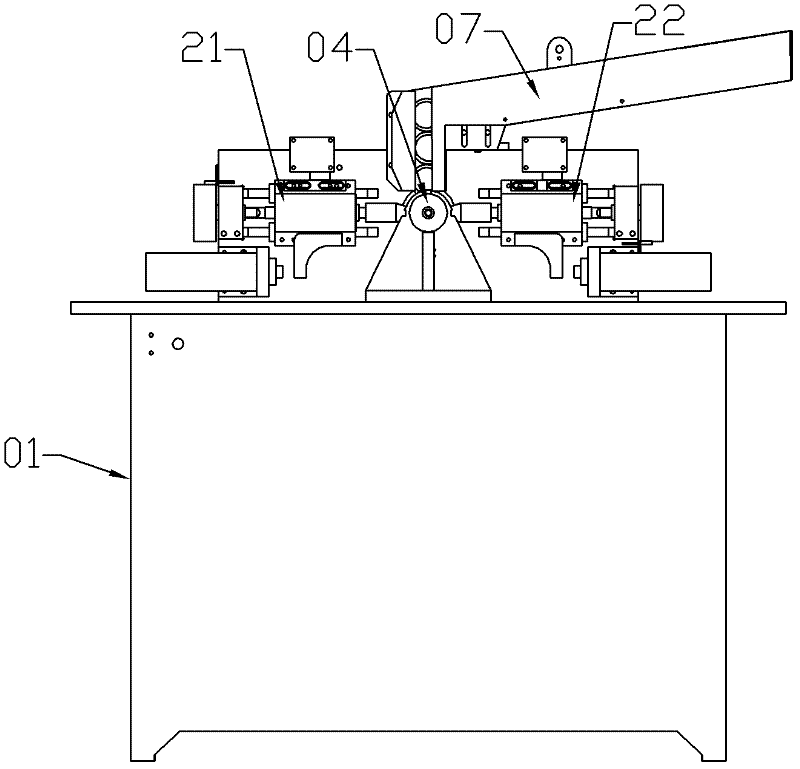

Dual-gun welding machine

InactiveCN103100812AReduce defective productsReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesHuman–machine interfaceEngineering

The invention discloses a dual-gun welding machine which comprises a first welding gun, a second welding gun, a welding gun moving mechanism and a workpiece rotary mechanism, wherein the welding gun moving mechanism and the workpiece rotary mechanism are matched; the welding gun moving mechanism comprises a first air cylinder and a welding gun installation frame; the first welding gun and the second welding gun are installed on the welding gun installation frame connected with a sliding end of the first air cylinder; the first air cylinder drives the welding gun installation frame to move in a flexible mode; and the welding gun installation frame drives the first welding gun and the second welding gun to move. Compared with the prior art, the dual-gun welding machine provided by the invention regulates the welding machine by adopting a dual-gun mechanism and arranging stepping motor parameters of an external man-machine interface, and further drives the welding gun moving mechanism and the workpiece rotary mechanism to operate in a matching way; welded workpieces are installed and clamped at one time; the welding gun welds workpieces automatically and comprehensively, so that the manual labor intensity is lowered; the welding efficiency is intensified; and defective workpieces are reduced.

Owner:浙煤(浙江)智能钻探装备股份有限公司

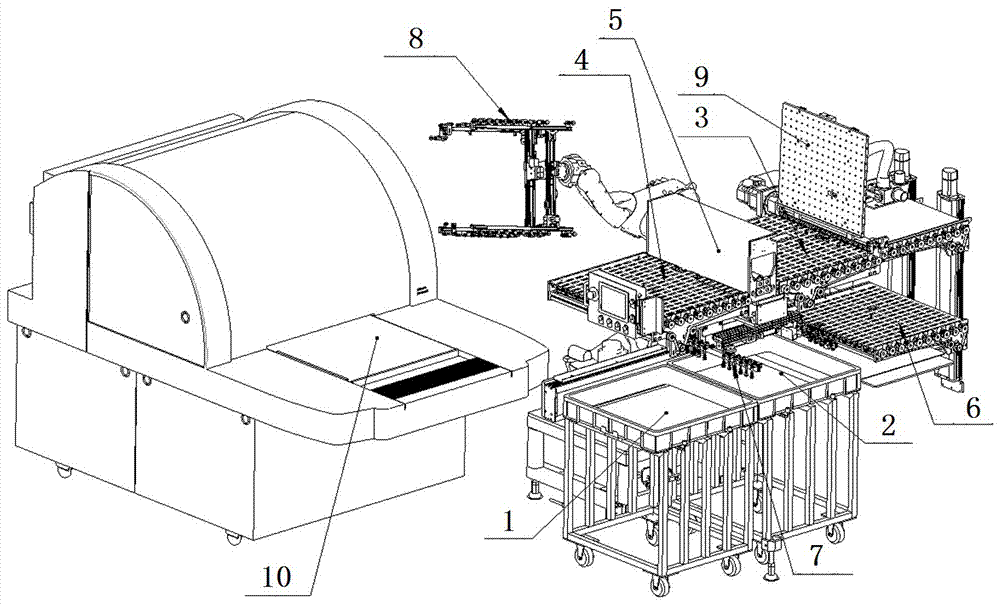

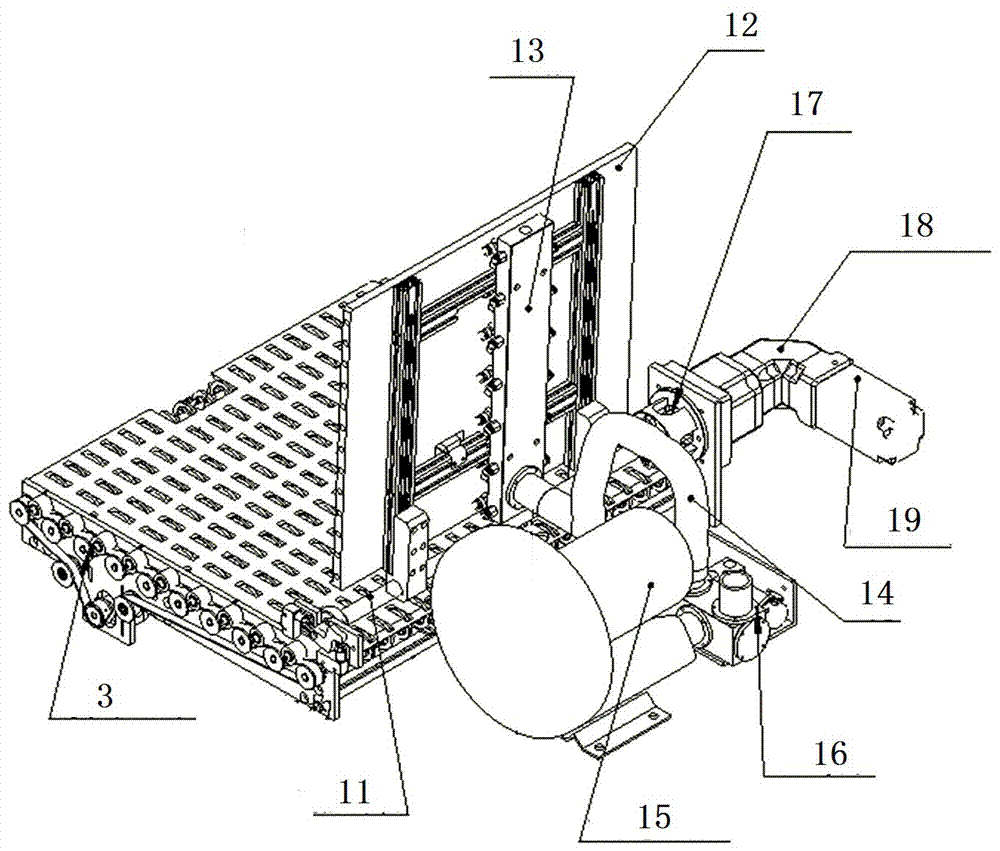

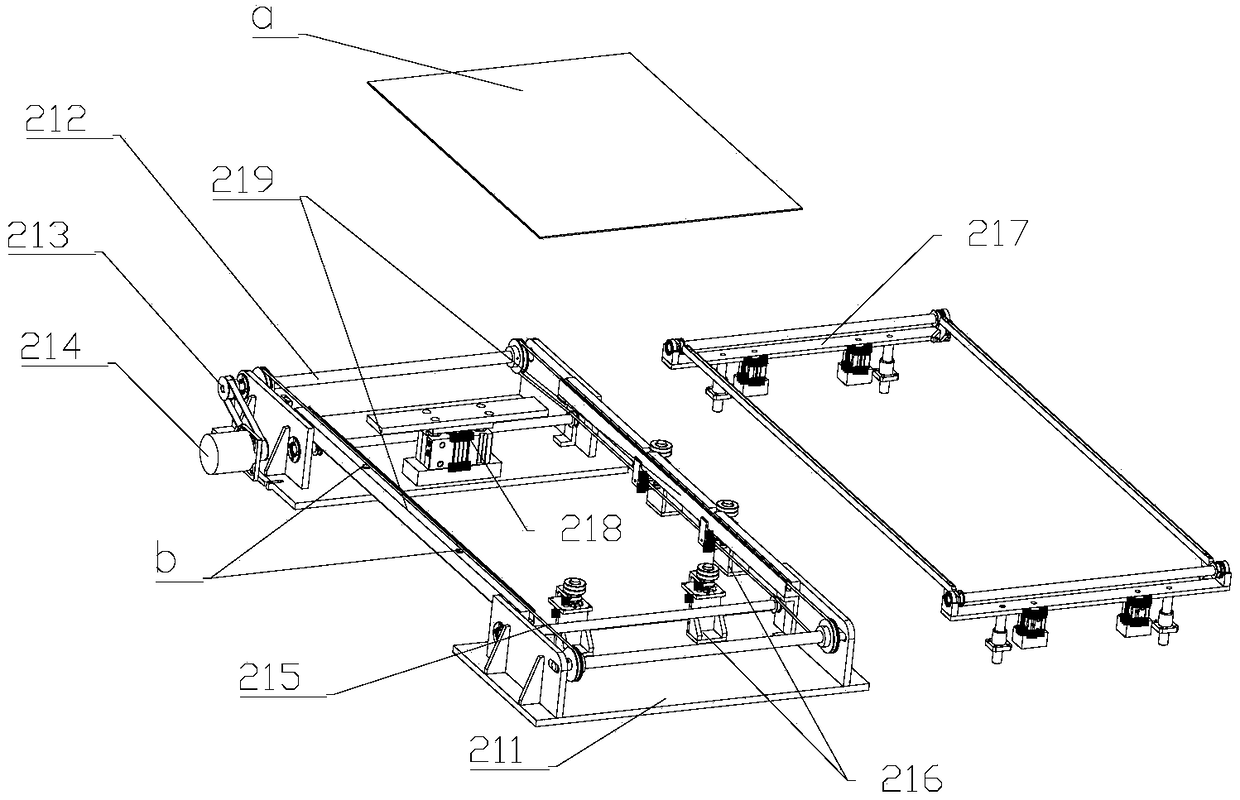

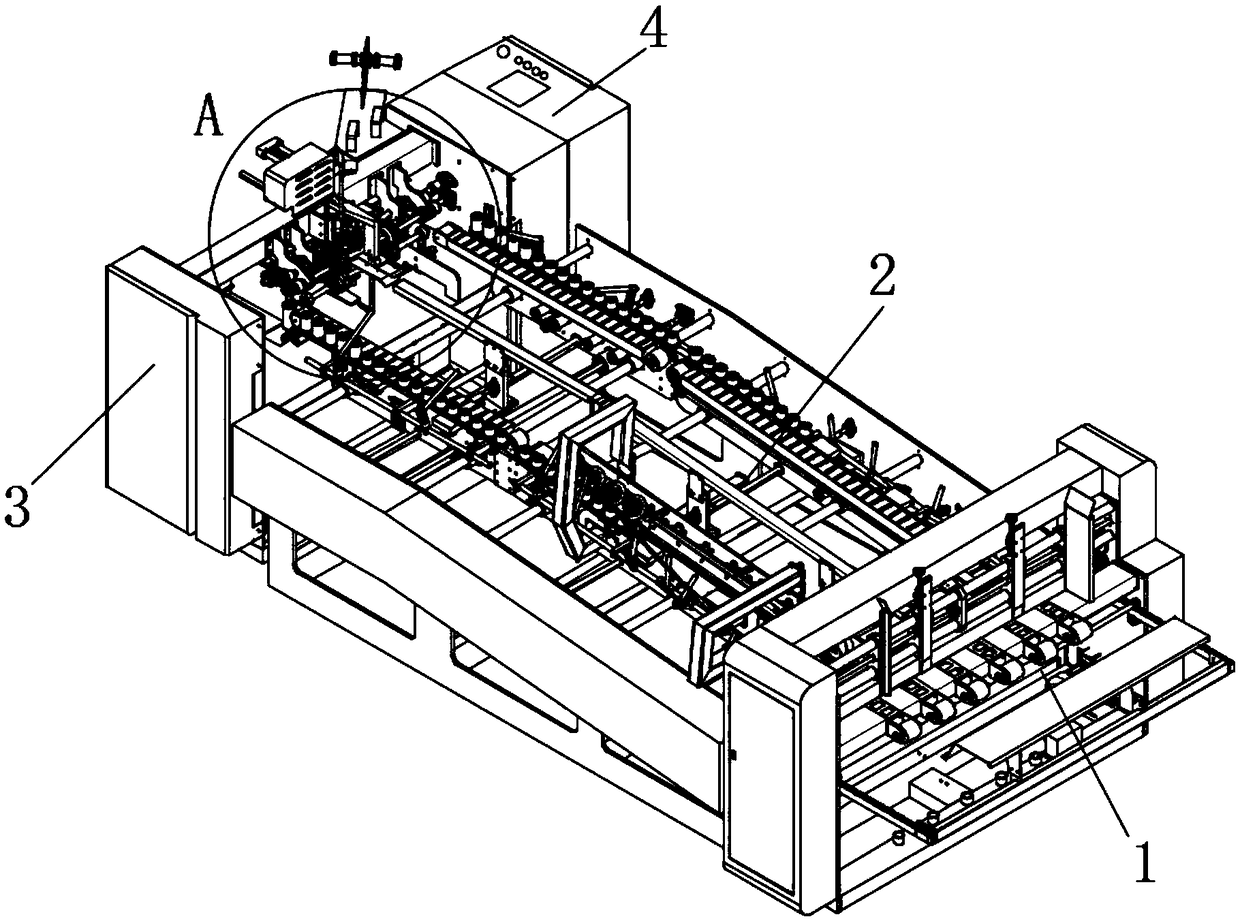

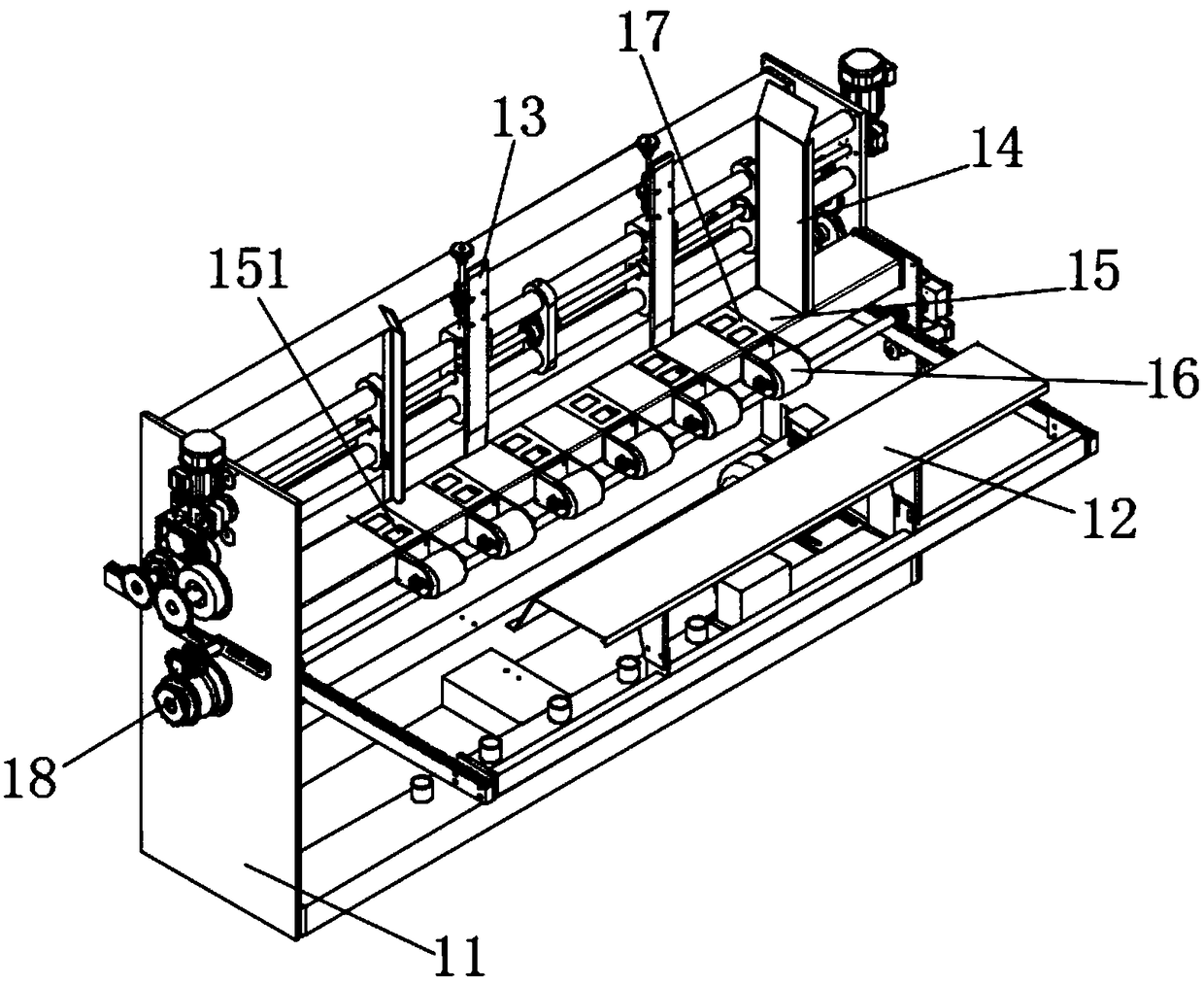

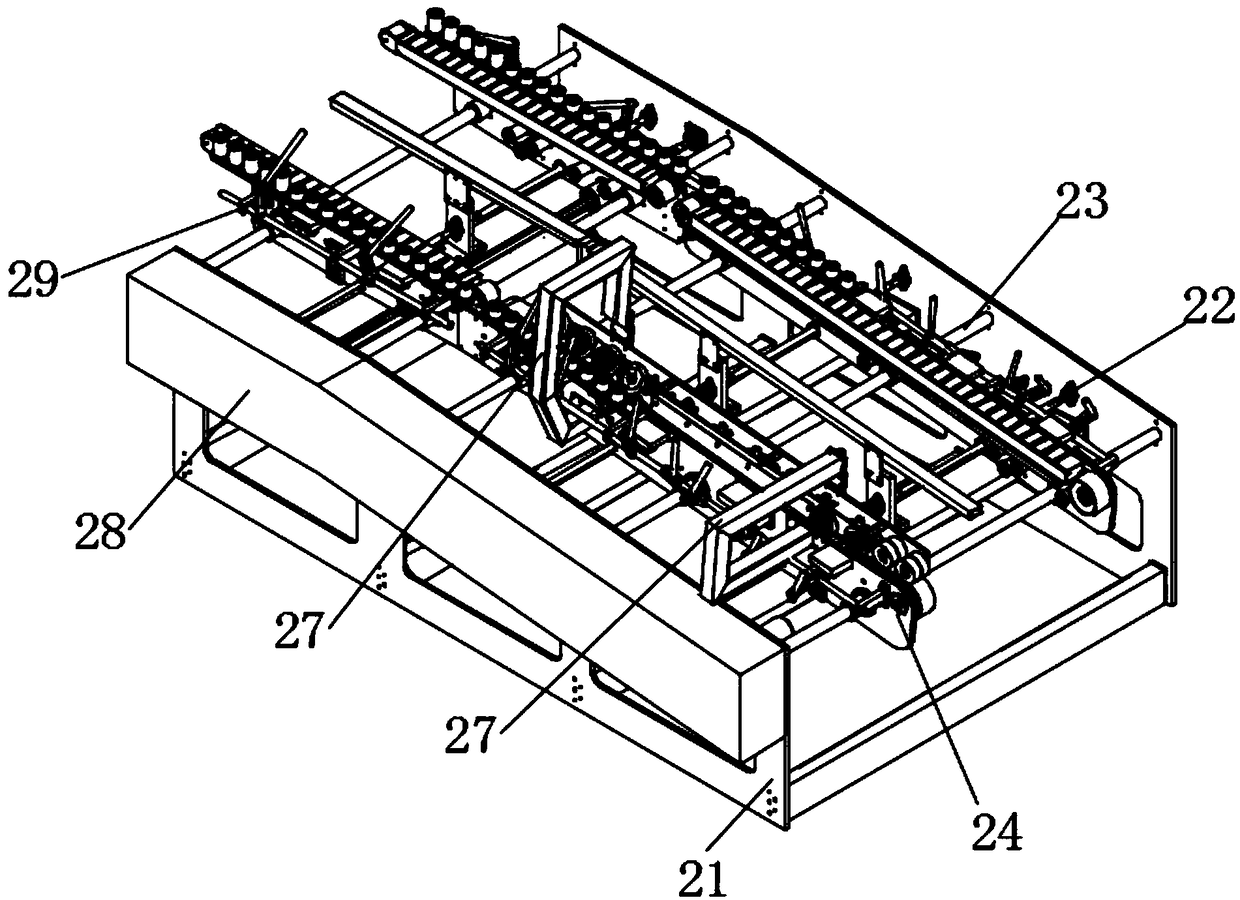

Double-layer circulation system used for AOI procedure of PCB

ActiveCN107472866AImprove uniform velocityImprove accuracyConveyorsControl devices for conveyorsControl engineeringStructural engineering

The invention relates to a double-layer circulation system used for the AOI procedure of a PCB. The system comprises a rack, a detected material box circulation vehicle and a to-be-detected material box circulation vehicle are arranged on the lower layer of the rack, a before-cleaning conveying segment and an after-cleaning conveying segment are arranged on the upper layer of the rack, a cleaning machine is arranged between the before-cleaning conveying segment and the after-cleaning conveying segment, the conveying face of a lifting conveying segment is driven by a synchronous liner module to do lifting motion, and therefore the conveying face is switched between the upper operation position flush with the upper layer of the rack and the lower operation position flush with the lower layer of the rack, a transverse moving suction cup set is arranged above the to-be-detected material box circulation vehicle, a six-axis robot is arranged on one side of the robot, a board turning suction plate is arranged at the input end of the before-cleaning conveying segment, and under the selective coordination of the six-shaft robot, the turning plate suction plate carries out PCB turning. The double-layer circulation system has the beneficial effects that the whole circulation system can more stably work, circulation is more smooth, and meanwhile possibility of alarming and disqualified product appearing is reduced.

Owner:SHANGHAI KAISER ELECTRONICS

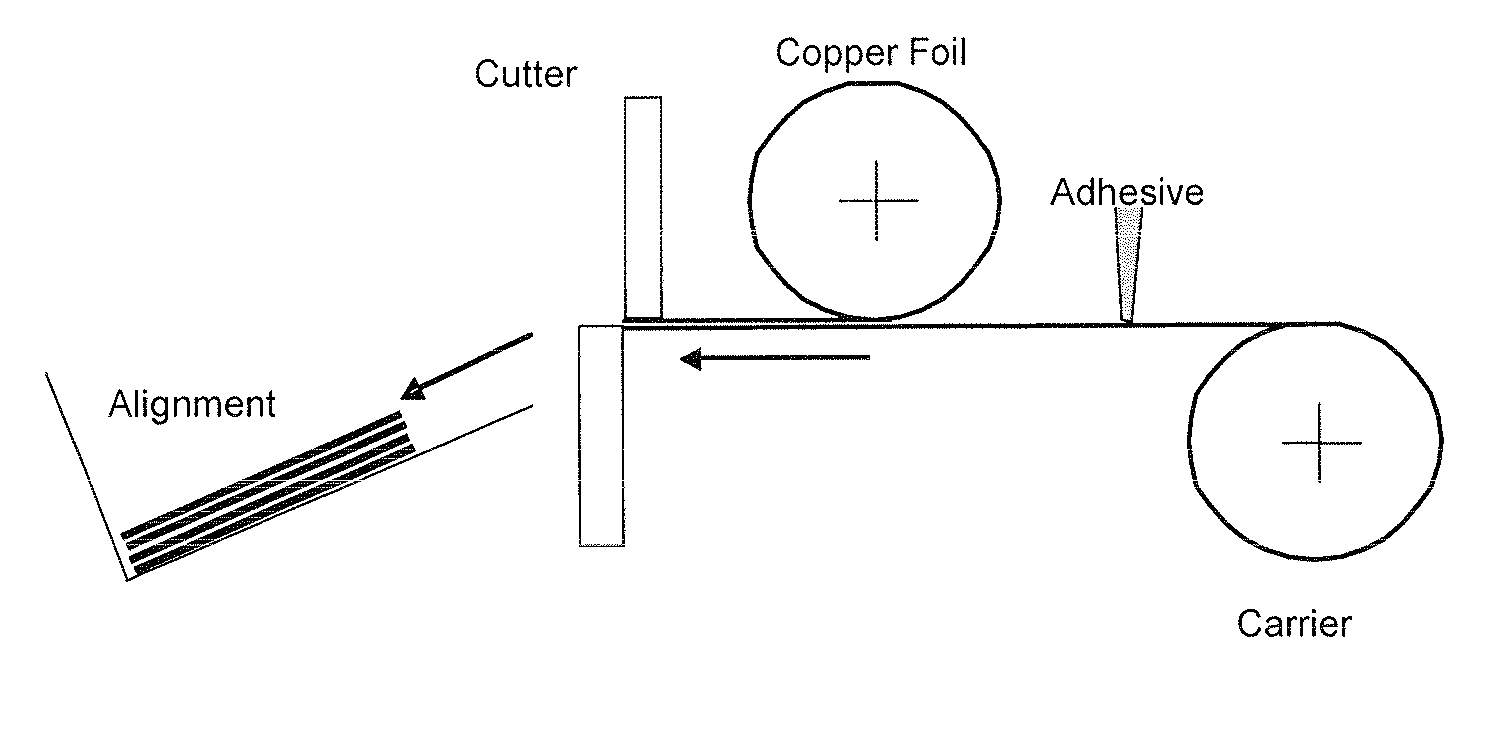

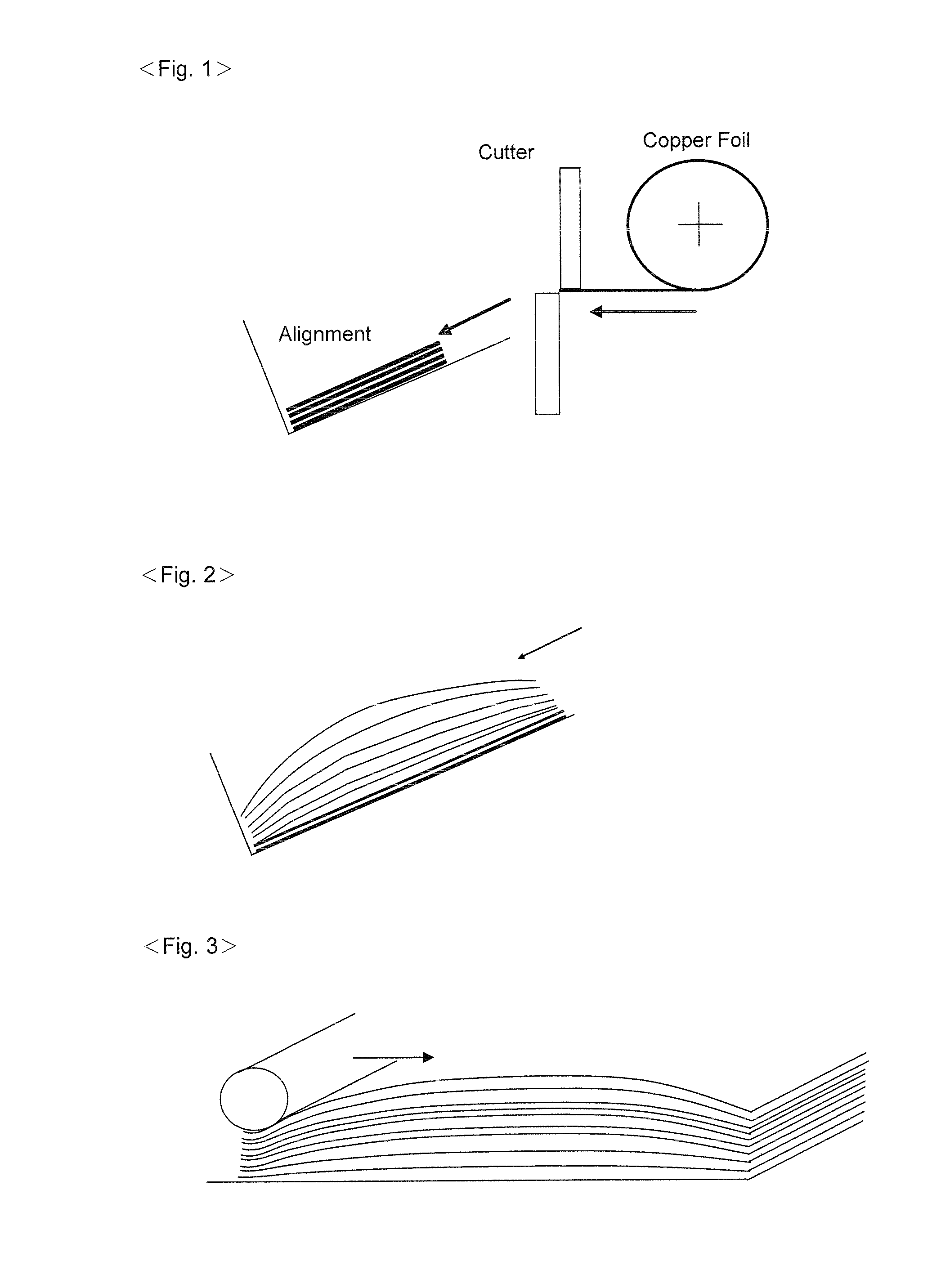

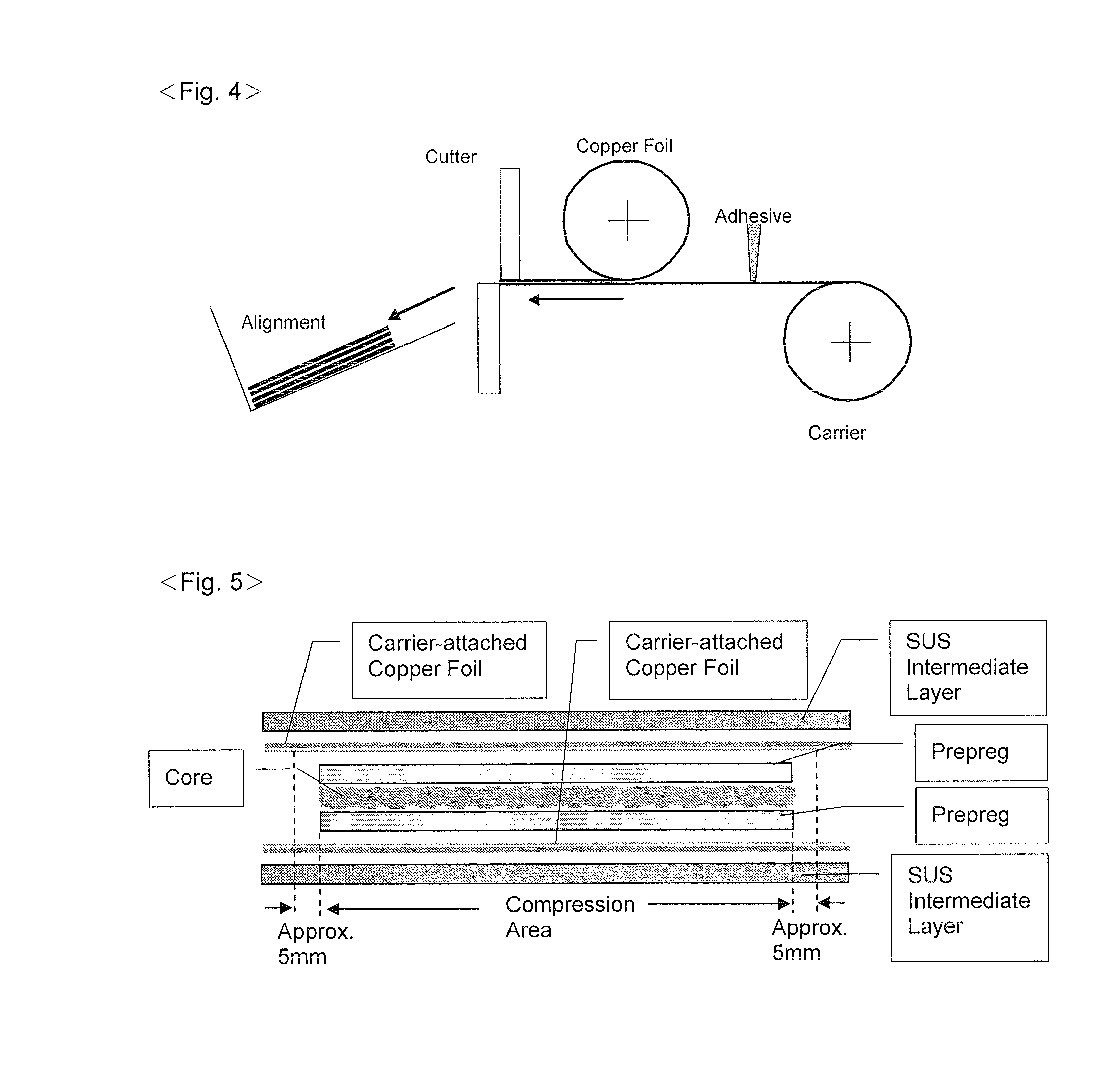

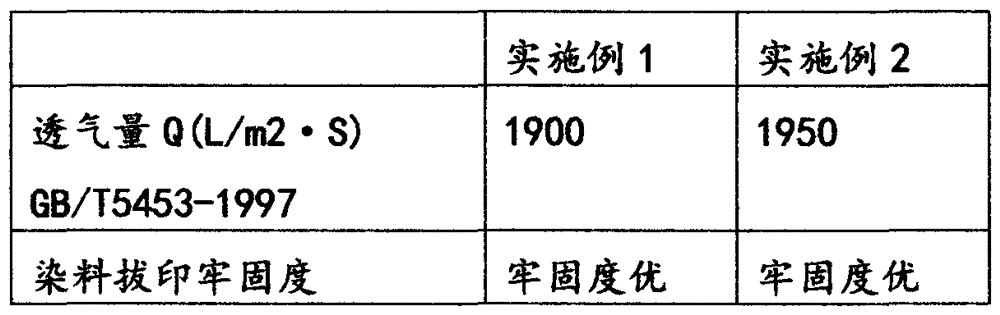

Method of Producing Laminated Body, and Laminated Body

InactiveUS20110262722A1Reduce defective productionEasy to handleLamination ancillary operationsLayered product treatmentBobbinAdhesive

Provided is a method of producing a laminated body, wherein, while winding off a carrier A from a bobbin, an adhesive is applied to both facing ends thereof, a metal foil B is laid on and bonded to a side to which the adhesive was applied while being wound off from a bobbin, the obtained laminated body is subsequently cut, the cut laminated bodies are aligned, a roller is applied from the top of an object to be cut configured from the aligned laminated bodies when the elevation of the center of the object to be cut becomes high to vent air existing between the objects to be cut and in the laminated bodies, and the adhesive is eventually hardened to mutually bond the laminated bodies. In particular, this invention provides a carrier-attached copper foil to be used upon producing a laminated plate, and aims to realize the improvement in the handling ability in the production process of a printed board and cost reduction based on an improved production yield.

Owner:JX NIPPON MINING& METALS CORP

Dyeing and finishing process of viscose woven fabric

InactiveCN107177992AThe texture is clear and firmMeet needsSucessive textile treatmentsDyeing processViscoseOil water

The invention relates to a dyeing and finishing process of viscose woven fabric. The dyeing and finishing process of the viscose woven fabric comprises the steps of dyeing and pretreating a viscose woven fabric semi-finished product: cooking the water-washed viscose woven fabric semi-finished product in a dyeing pretreatment solution, and carrying out discharge print on the sized viscose woven fabric semi-finished product by adopting a mixed dye of vasekine and rongalite, wherein the mass ratio of the rongalite to the vasekine is 1 to 1; adding table salt and sodium carbonate into a rope rinsing machine, wherein the masses of the table salt and the sodium carbonate are equal; placing the dyed viscose woven fabric into a color fixing agent, softening the color-fixed dyed viscose woven fabric by putting into 1g / L of Taigu oil water solution. A discharge print dyeing pattern obtained through the method provided by the invention is high in three-dimensional effect, firm in dye, and good in air permeability.

Owner:SHAOXING SUBO TEXTILE CO LTD

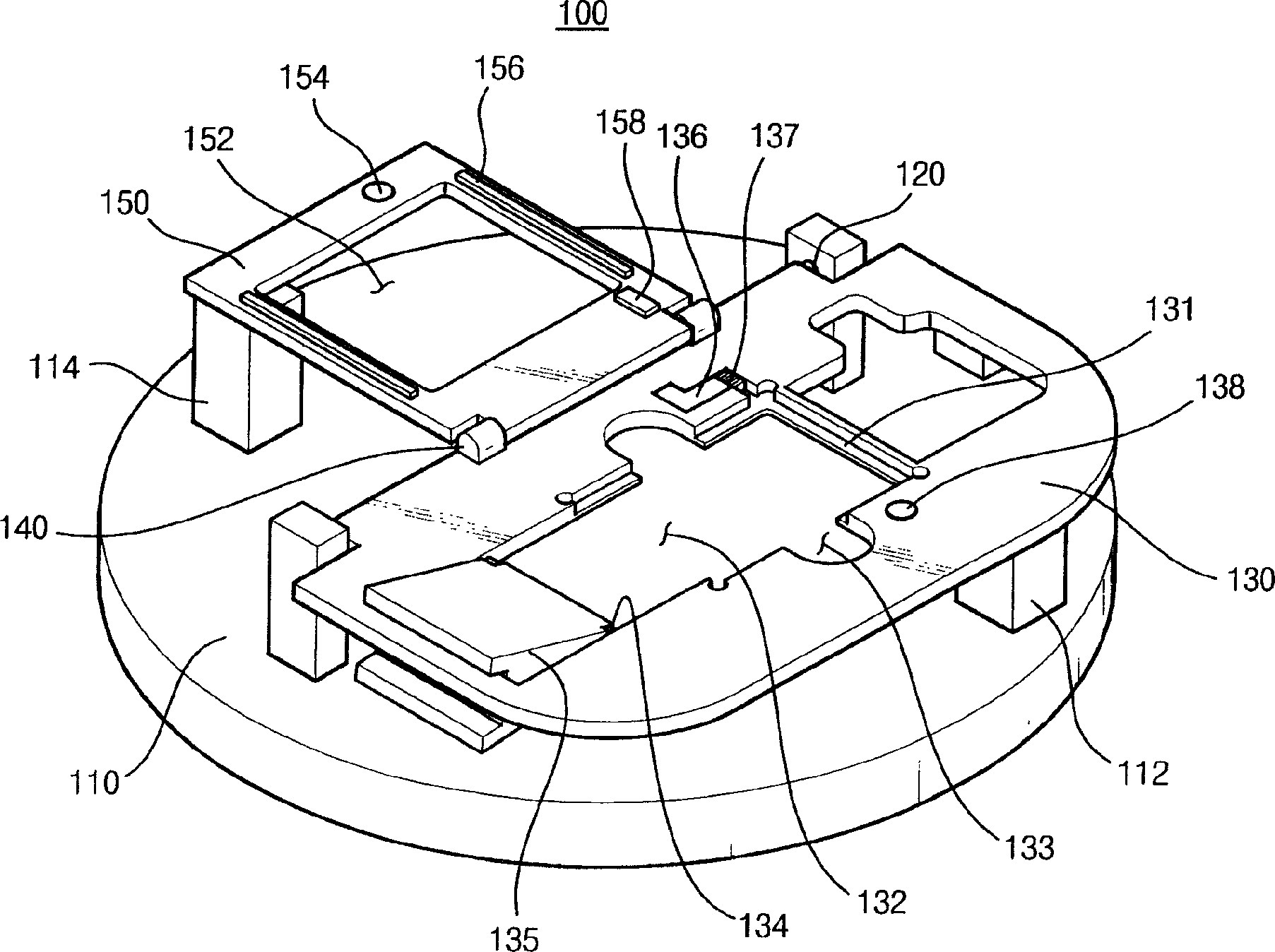

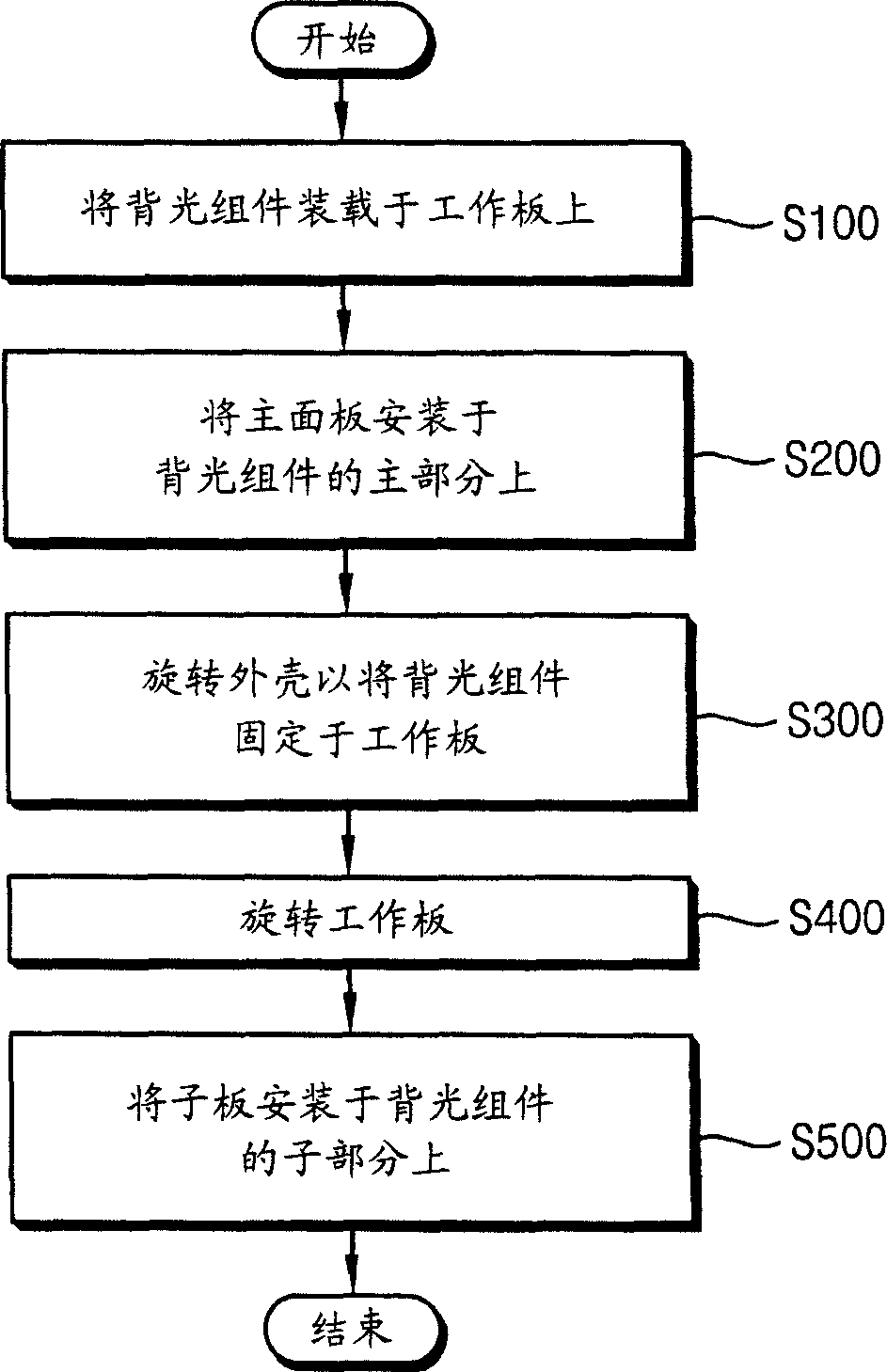

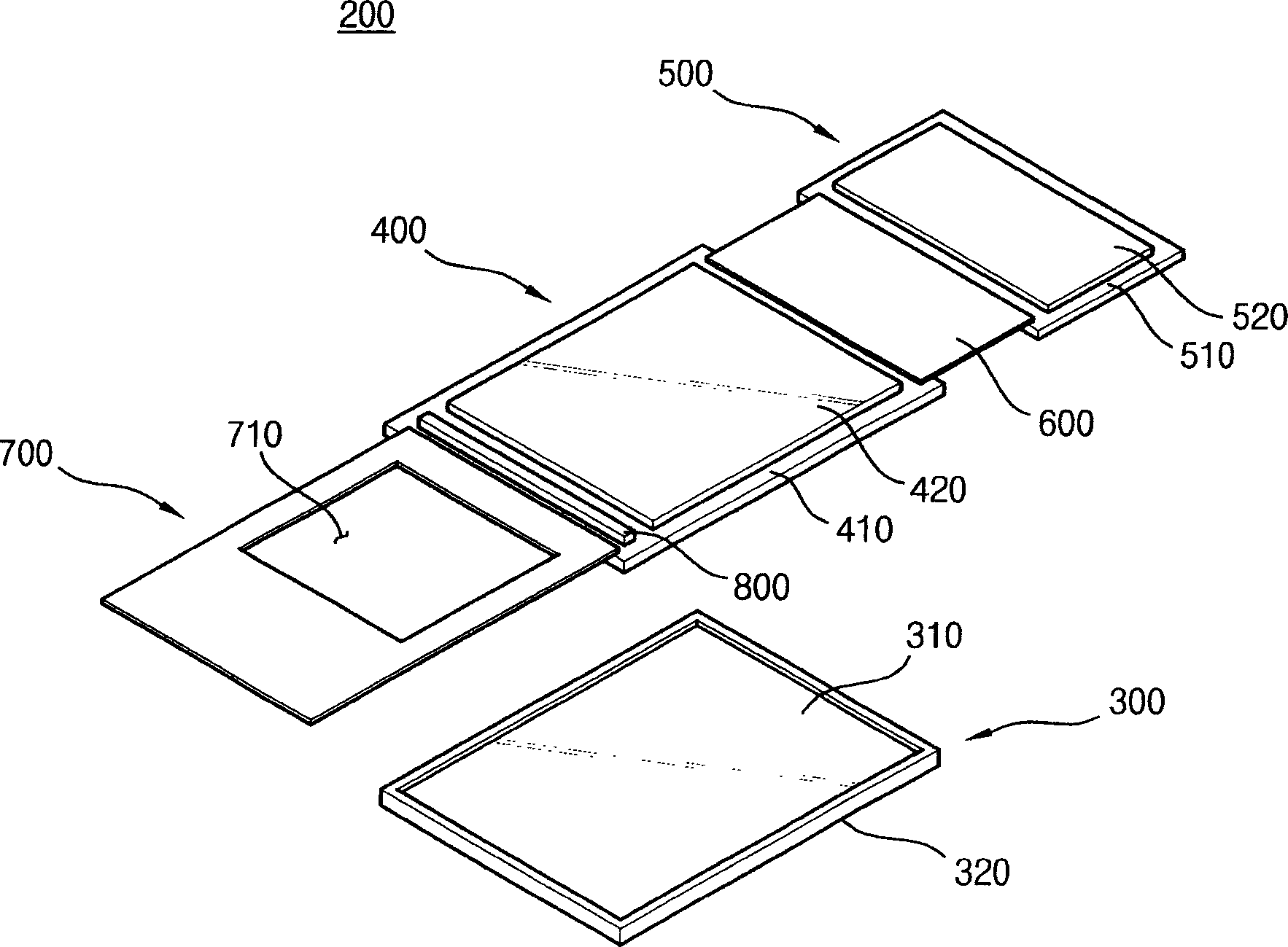

Jig and method of manufacturing a display device using the same

InactiveCN1762662AImprove assembly efficiencyReduce defective productsWork holdersNon-linear opticsDisplay deviceEngineering

The invention provides a jig for manufacturing a display device. In one embodiment, the clamp includes a first hinge part for rotating the working board on which the backlight assembly is fixed, and a second hinge part for rotating the housing to fix the backlight assembly on the working board. A method of manufacturing a display device using the jig includes loading a backlight assembly on a working plate of the jig, mounting a main panel on the main portion of the backlight assembly, rotating the housing to fix the backlight assembly to the working plate, rotating the working plate, and The subpanel is mounted on the subsection of the backlight assembly. In various embodiments, the use of the jig can improve the efficiency of assembly, reduce the number of product defects, and increase the throughput of display devices.

Owner:SAMSUNG ELECTRONICS CO LTD

Mobile phone screen rolling pressing device and attaching method

PendingCN109514967AAvoid undesirable defects such as air bubbles and wrinklesAvoid prior contactLaminationLamination apparatusAcute angleEngineering

The invention discloses a mobile phone screen rolling pressing device and an attaching method. The mobile phone screen rolling pressing device comprises an upper part assembly and a lower part assembly, wherein the lower part assembly is provided with a flowing roller way; a curve surface protection cover plate is fixedly arranged on the flowing roller way; the upper part assembly is provided witha flexible film and a carrying belt; the flexible film is attached onto the lower end surface of the carrying belt; through the upper part assembly, the shape of the carrying belt can be changed to enable the flexible film to form an arc-shaped surface, so that the center part of the flexible film is the lowest and is attached to the curve surface protection cover plate first; through the upper part assembly, the flexible film is gradually roll-pressed onto the curve surface protection cover plate so as to realize the attaching of the curve surface protection cover plate and the flexible film. The flexible film attaching is performed by aiming at the curve surface protection cover plate with the right-angular or acute angle edges; the adverse defects of bubble drapes and the like of the flexible film in the attaching process can be avoided; under the effect of a position limiting device, the first contact of the end part of the flexible film and the curve surface edge position of thecurve surface protection cover plate is avoided; the defective products are reduced.

Owner:汪恒坤

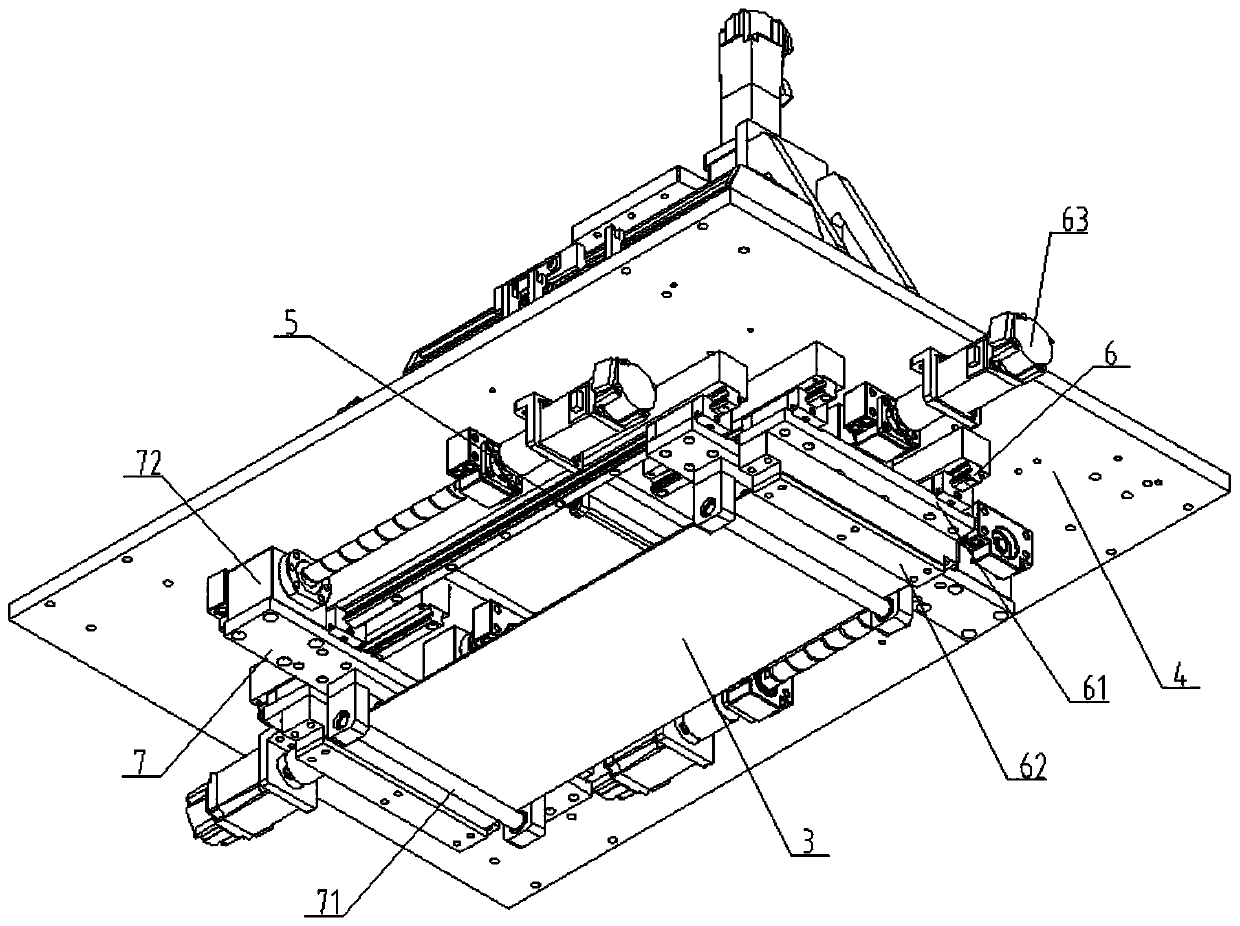

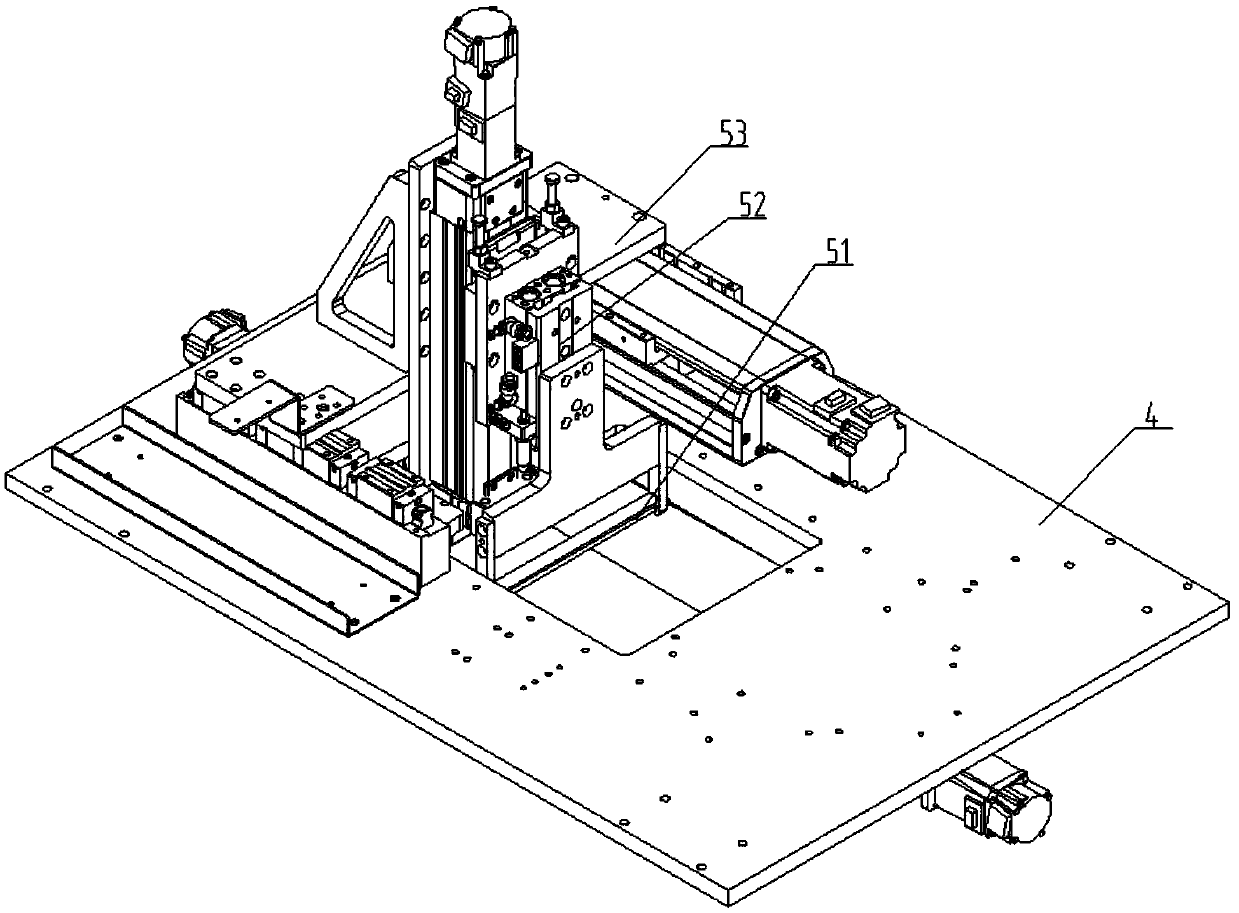

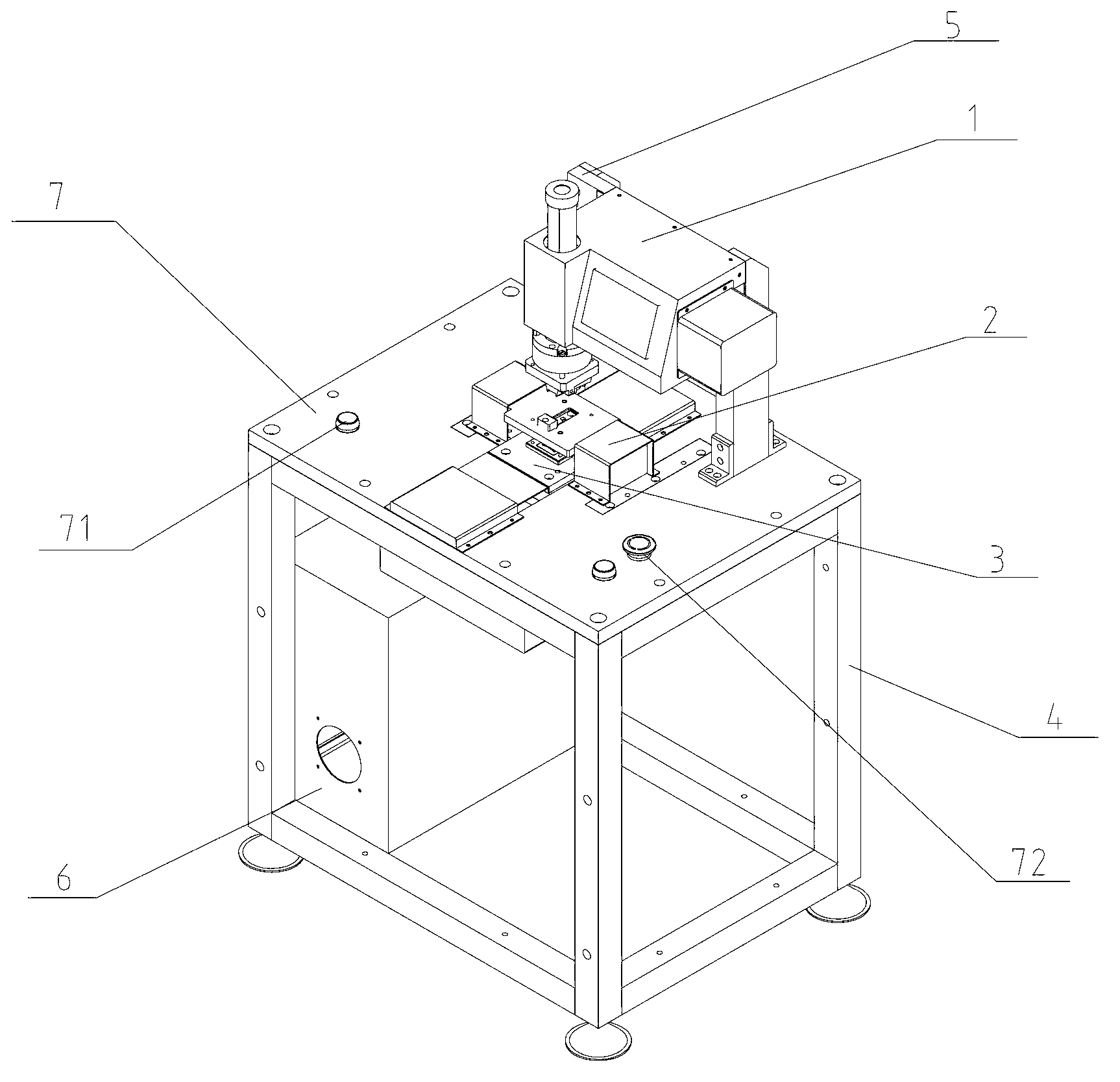

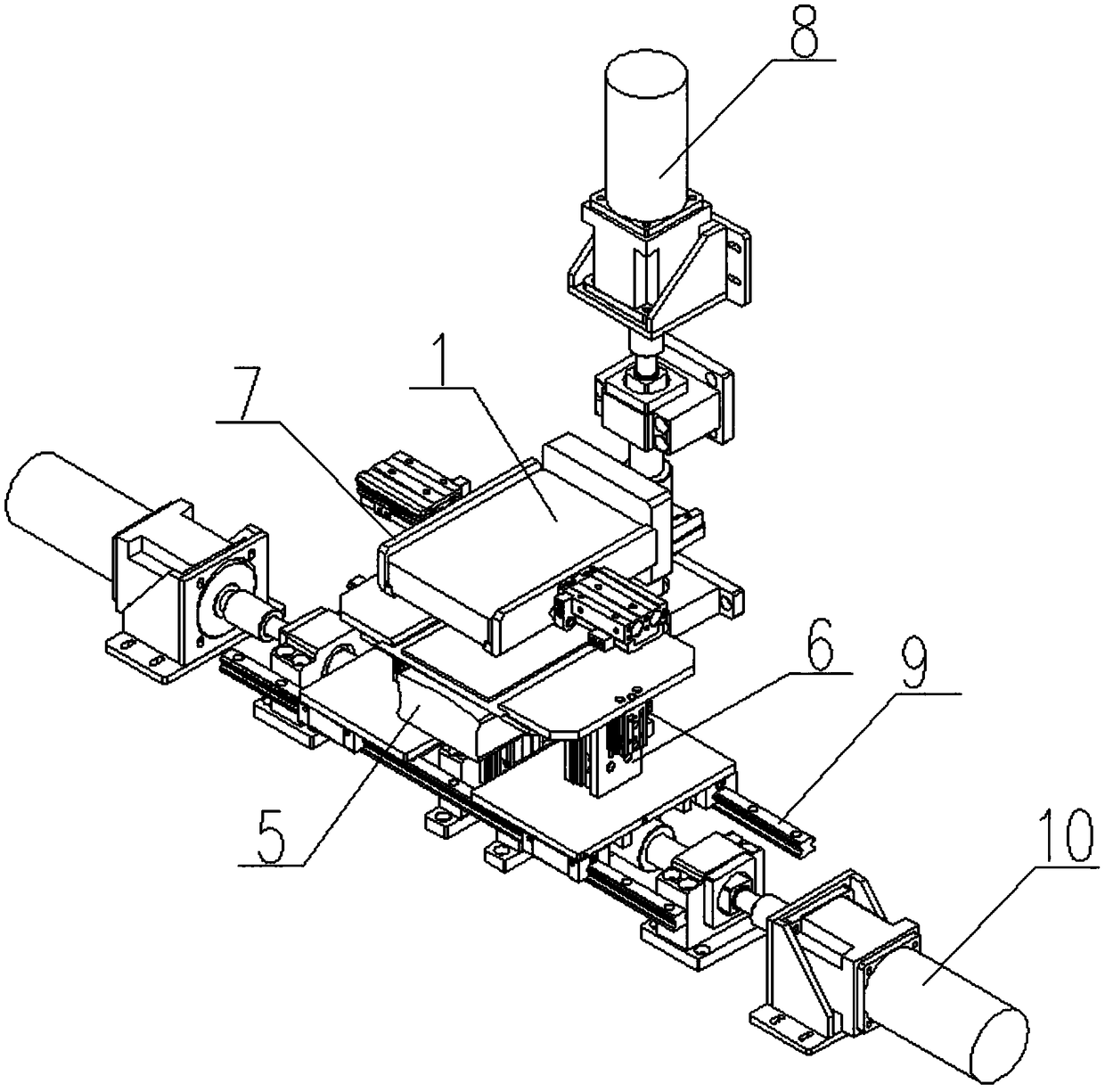

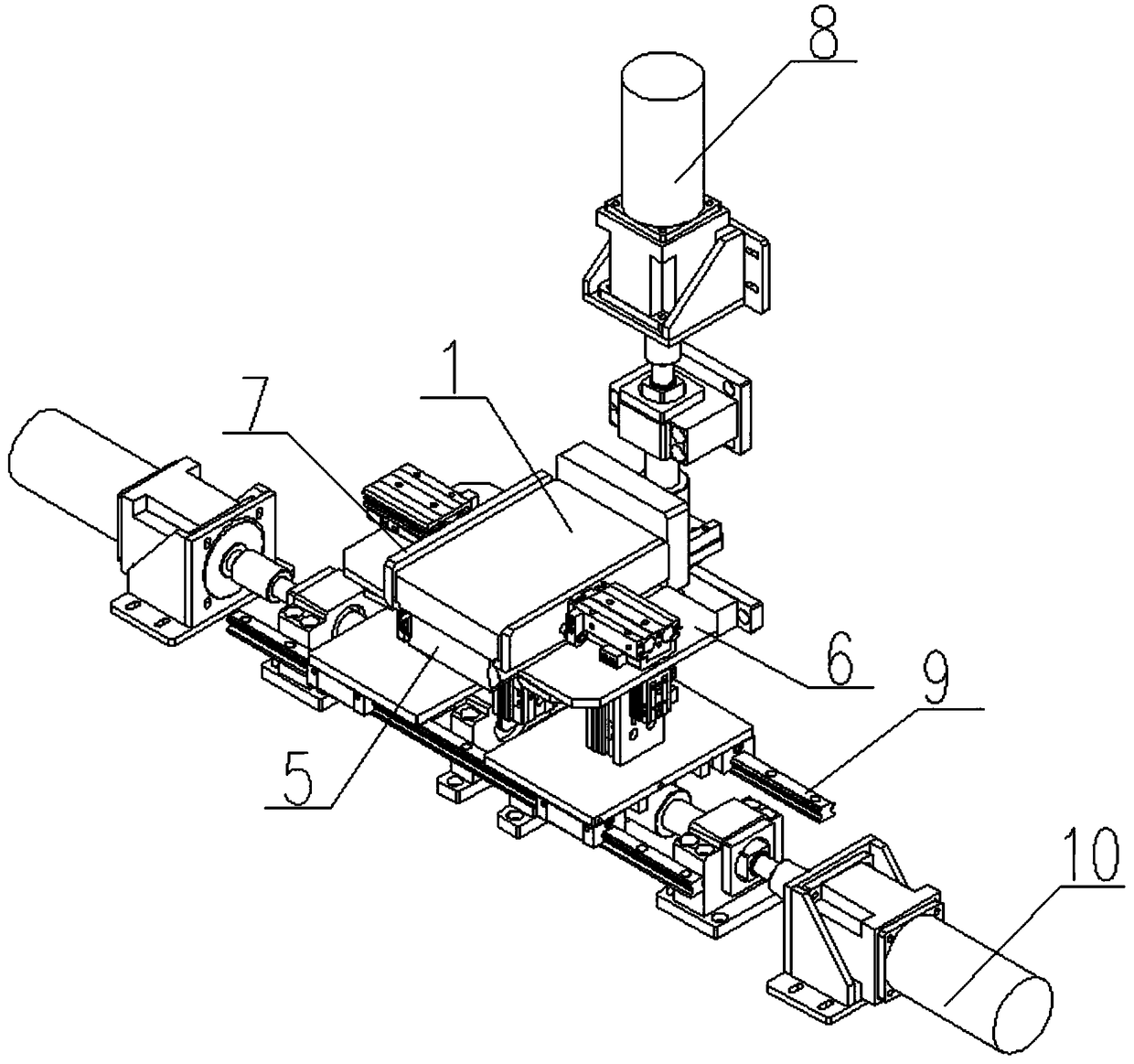

MP3 product shell pressing and assembling device

InactiveCN102794636AImprove assembly efficiencyImprove product qualityMetal working apparatusStructural engineeringVertical motion

The invention discloses an MP3 product shell pressing and assembling device, which is characterized by comprising a product input / output device, a pressing head pressing device and a pressing head, wherein the product input / output device is provided with a fixing base for fixing MP3 products, and a slide platform cylinder which can horizontally move front and back is arranged at the lower end of the fixing base; the pressing head pressing device is arranged at the upper end of the product input / output device; and the pressing head is fixedly connected with a vertical movement mechanism and is driven by the vertical movement mechanism to press and assemble the MP3 products which are not provided with shells in the fixing seat. The MP3 product shell pressing and assembling device disclosed by the invention can greatly improve the assembling efficiency, reduce safety accidents in the assembling process, and ensure the stable quality, uniformity and low reject ratio of the assembled products.

Owner:昆山市圣吉川工业自动化设备有限公司

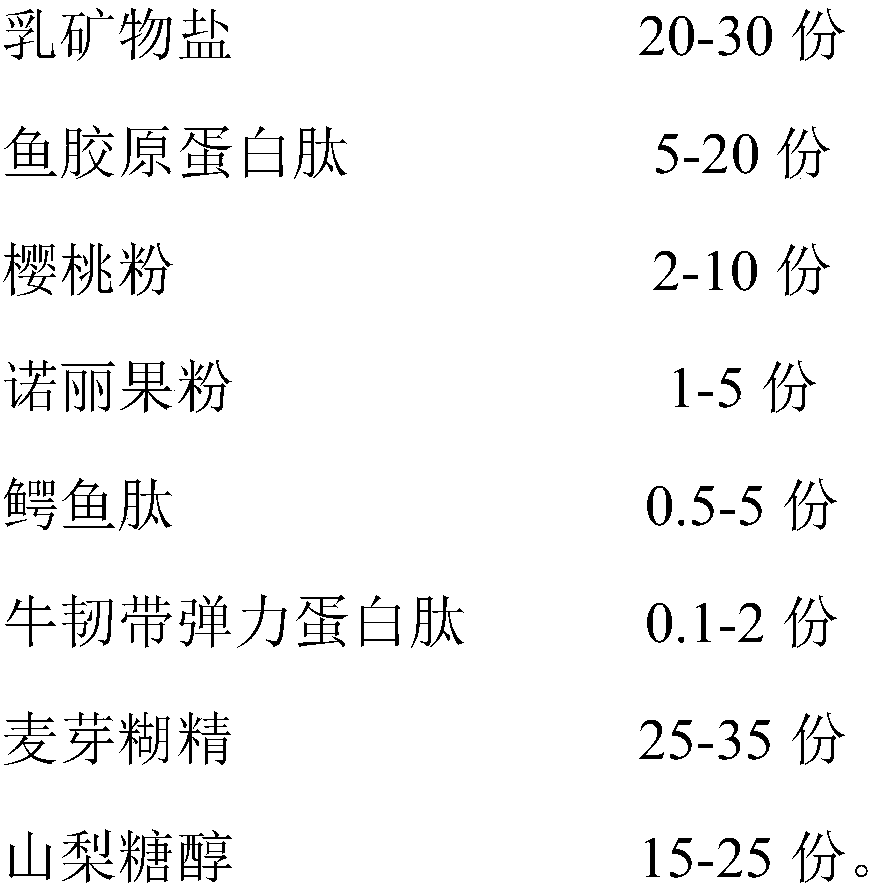

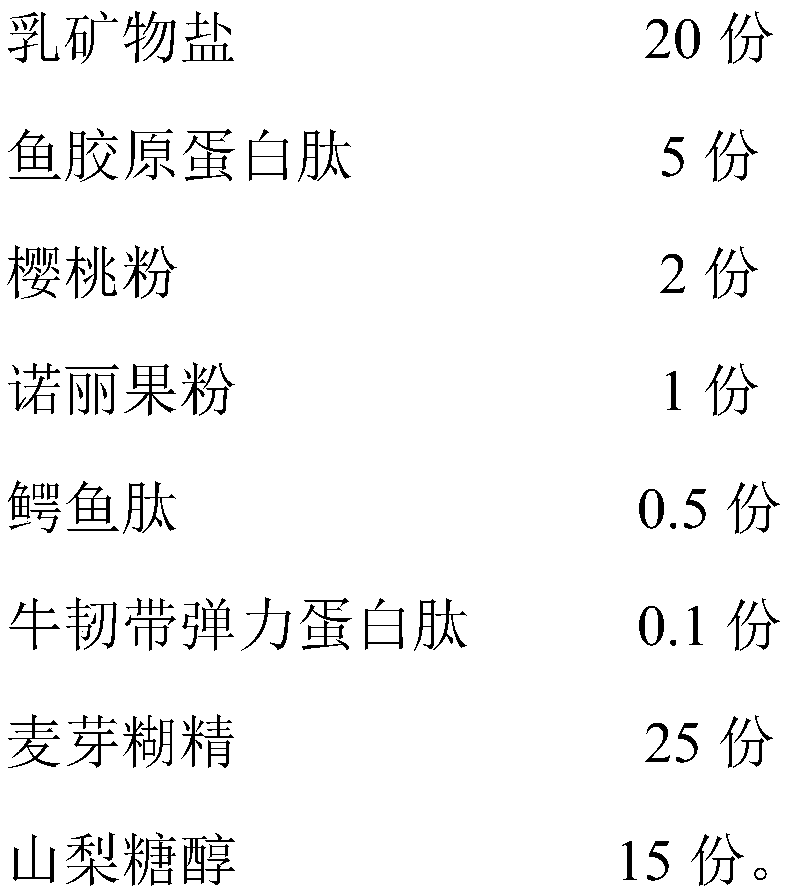

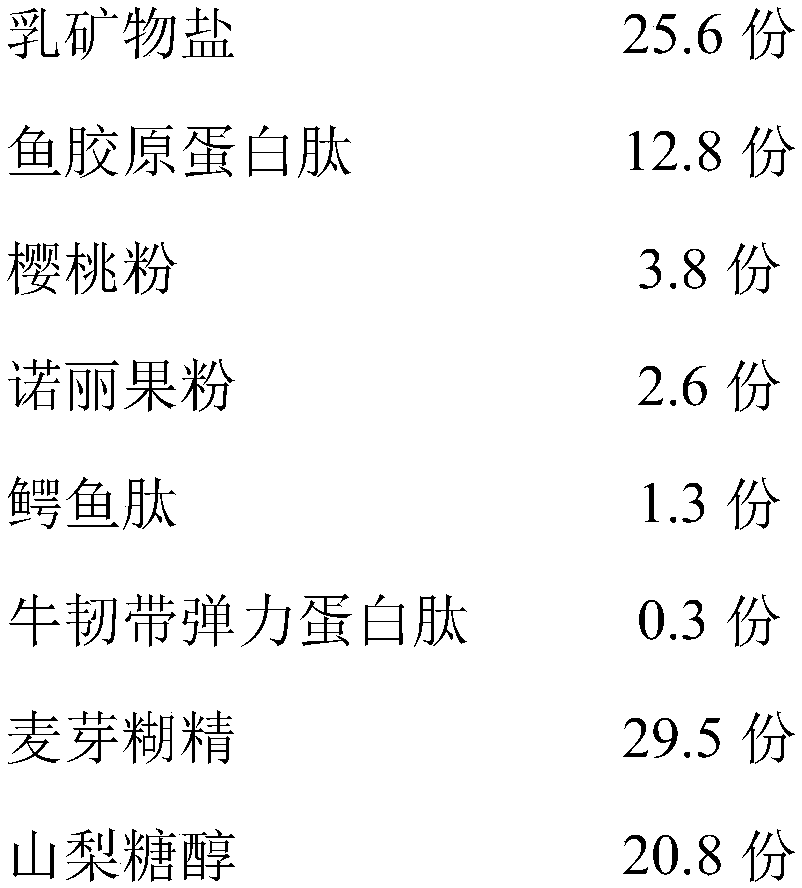

Collagen product and preparation method thereof

The invention relates to the technical field of healthcare food, and specifically discloses a collagen product and a preparation method thereof. The collagen product is prepared from the following components in parts by weight: 20 to 30 parts of milk mineral, 5 to 20 parts of fish collagen peptide, 2 to 10 parts of cherry powder, 1 to 5 parts of noni powder, 0.5 to 5 parts of crocodile peptide, 0.1 to 2 parts of cattle ligament elastin peptide, 25 to 35 parts of maltodextrin and 15 to 25 parts of sorbitol. The collagen product provided by the invention has a synergistic effect in multiple aspects of basic nutrition safeguard, multi-path oxidation resistance, calcium element supplementation and the like through a scientific and reasonable formula, and has multiple healthcare functions on skin, skeletons and the like of a human body.

Owner:孙语彤

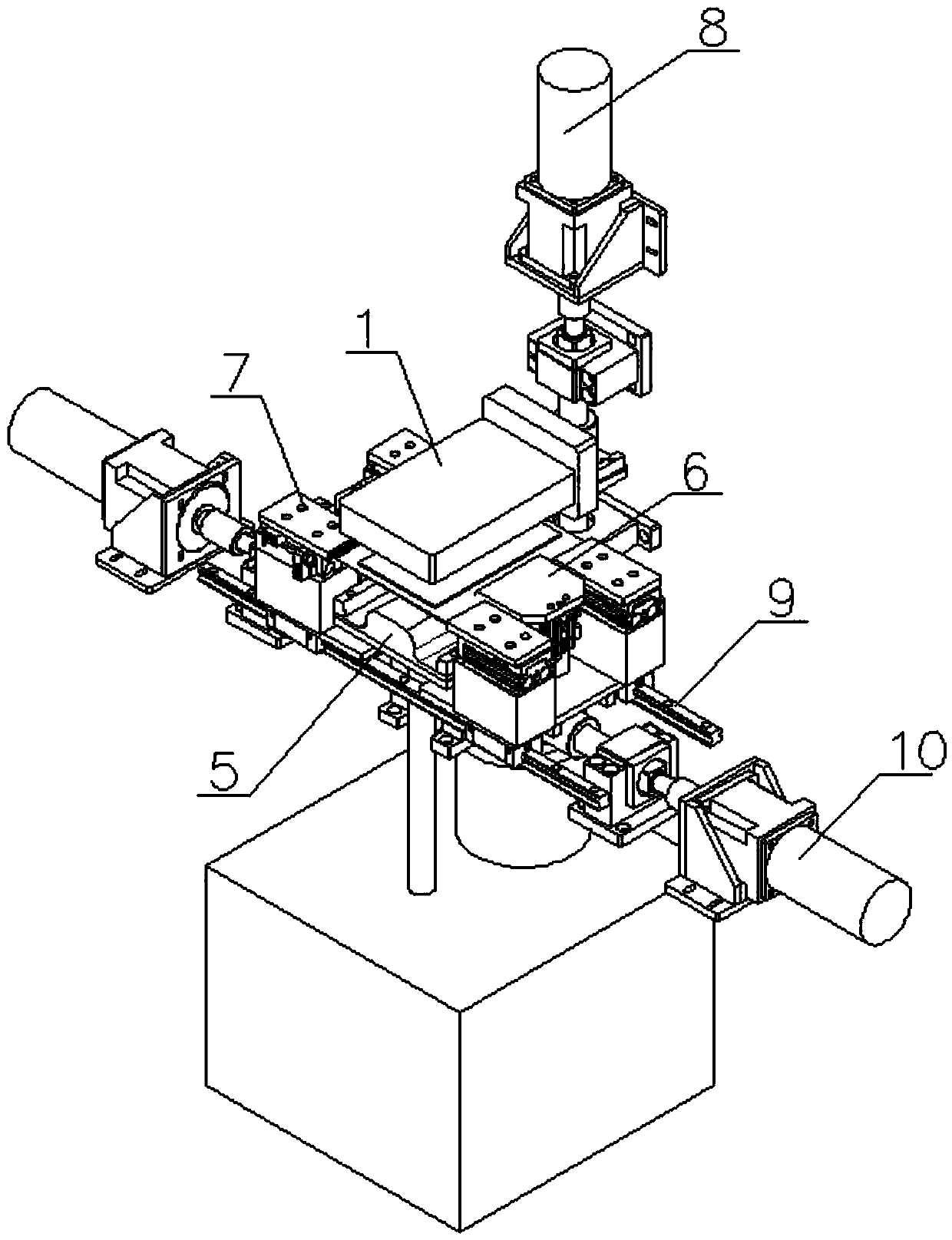

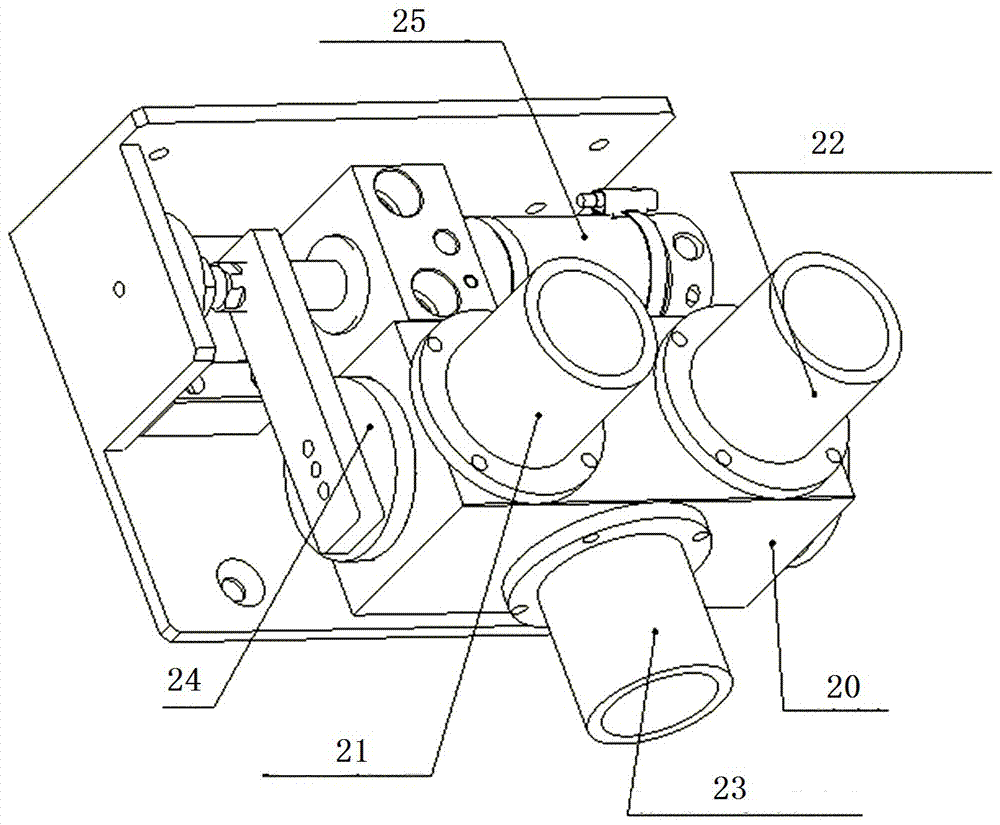

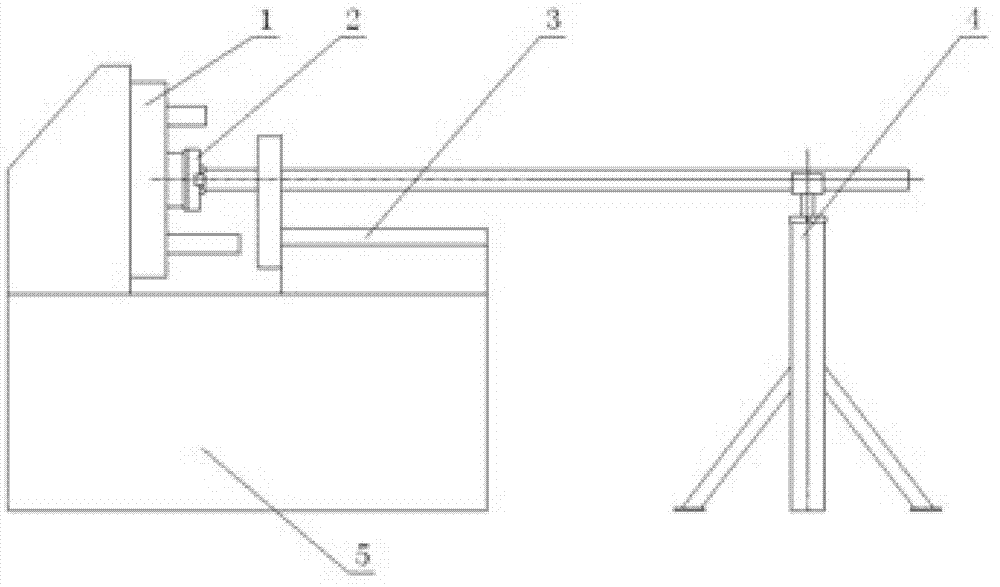

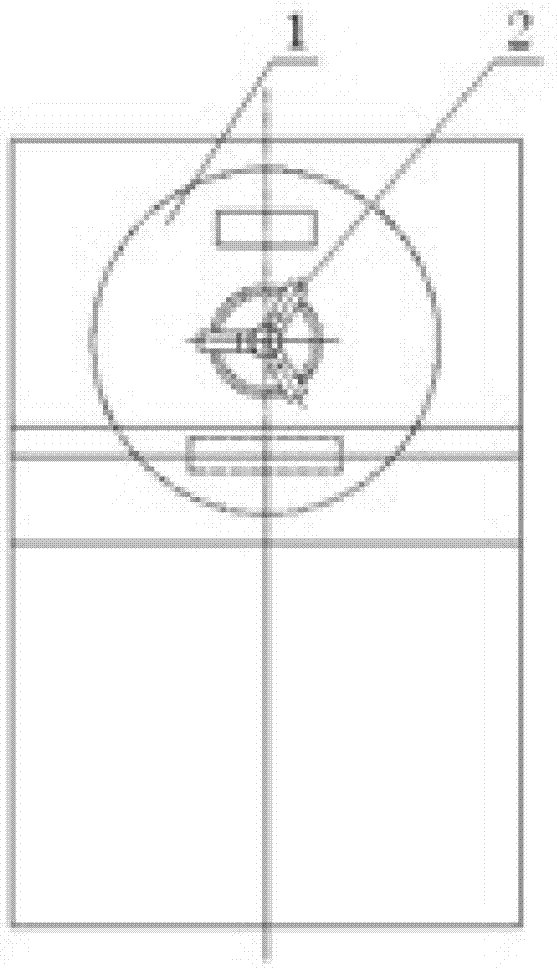

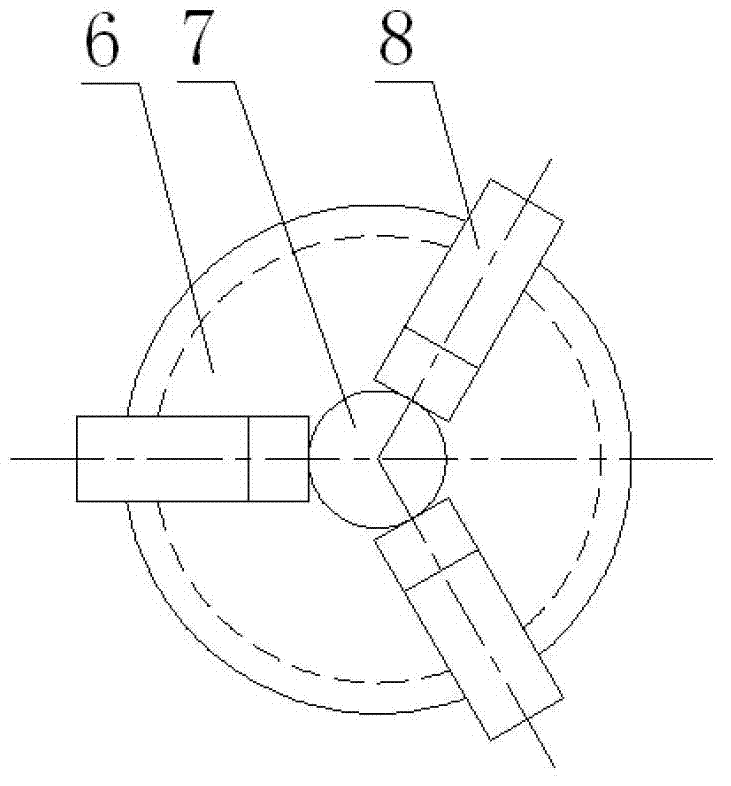

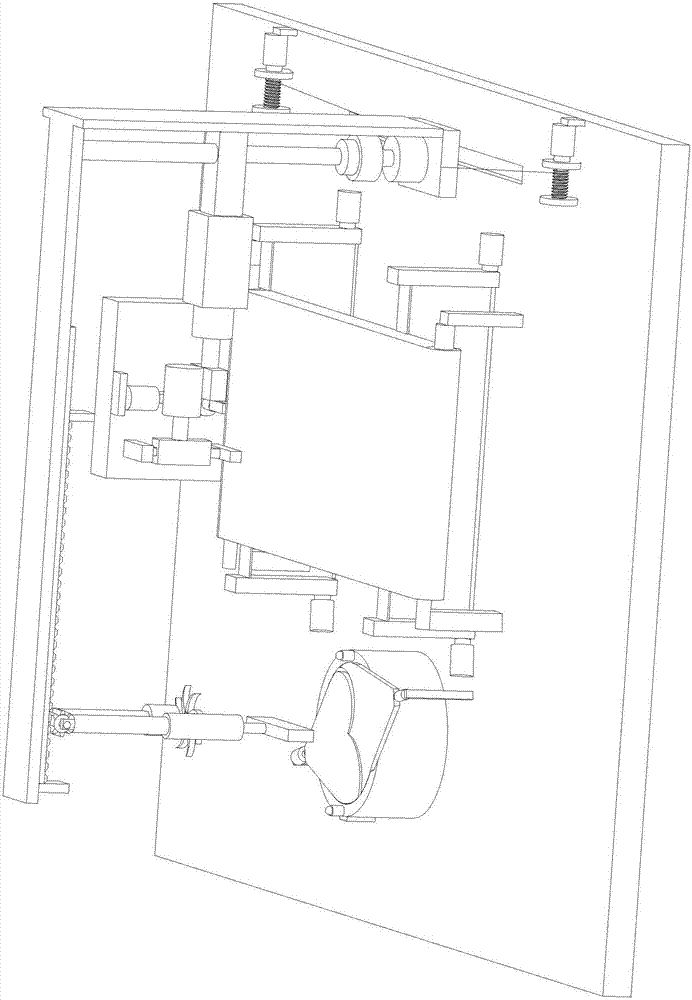

Railway wagon brake pipe system joint body all-position welding device

ActiveCN102773650AGuaranteed relative sizeGuaranteed positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTruck

The invention discloses a railway wagon brake pipe system joint body all-position welding device, belongs to welding production equipment, and in particular relates to a welding device of a long and large brake pipe system. The railway wagon brake pipe system joint body all-position welding device comprises a support platform. The key technology is that a pneumatic three-jaw chuck and a rotary platform driven by a direct-current motor are fixedly installed on the support platform; the rotary platform and the pneumatic three-jaw chuck are coaxial, and the rotary platform rotates relative to the pneumatic three-jaw chuck; a pneumatic V-shaped clamping component is arranged in a position on the support platform, which is corresponding to the pneumatic three-jaw chuck; and an auxiliary bracket is arranged in a position corresponding to the pneumatic V-shaped clamping component. According to the invention, a brake pipe system can be welded in a convenient, safe and labor-saving way in all positions; the positioning accuracy is high; the production safety is ensured; the welding quality is high; unqualified products are reduced; and the production efficiency is high.

Owner:CRRC MEISHAN

Painting and leveling device

The invention relates to the field of wood processing, in particular to a painting and leveling device. The painting and leveling device comprises a bottom plate; one end of the bottom plate is provided with a position adjusting device which can generate relative sliding and is connected with a painting mechanism; and the other end of the bottom plate is provided with an inductive paint bucket mechanism. A conveying mechanism is arranged between the inductive paint bucket mechanism and the position adjusting device; the two sides of the conveying mechanism are each provided with two clamping mechanisms; and the tail end of the conveying mechanism is provided with a turn-over device. An air blower device is additionally arranged, thus the paint drying time is shortened, and the working efficiency is improved. An inductive device and an umbrella-shaped end cover which can be folded are arranged on a paint bucket, when not used, the end cover can be automatically closed, the time of paintmaking contact with air is reduced, defective products are reduced, and meanwhile the cost is also reduced. Two-time leveling is conducted, the workpiece quality can be guaranteed, and the passing rate is increased. The turn-over device is arranged for turning-over a workpiece, the working time is reduced, and the working efficiency is improved.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

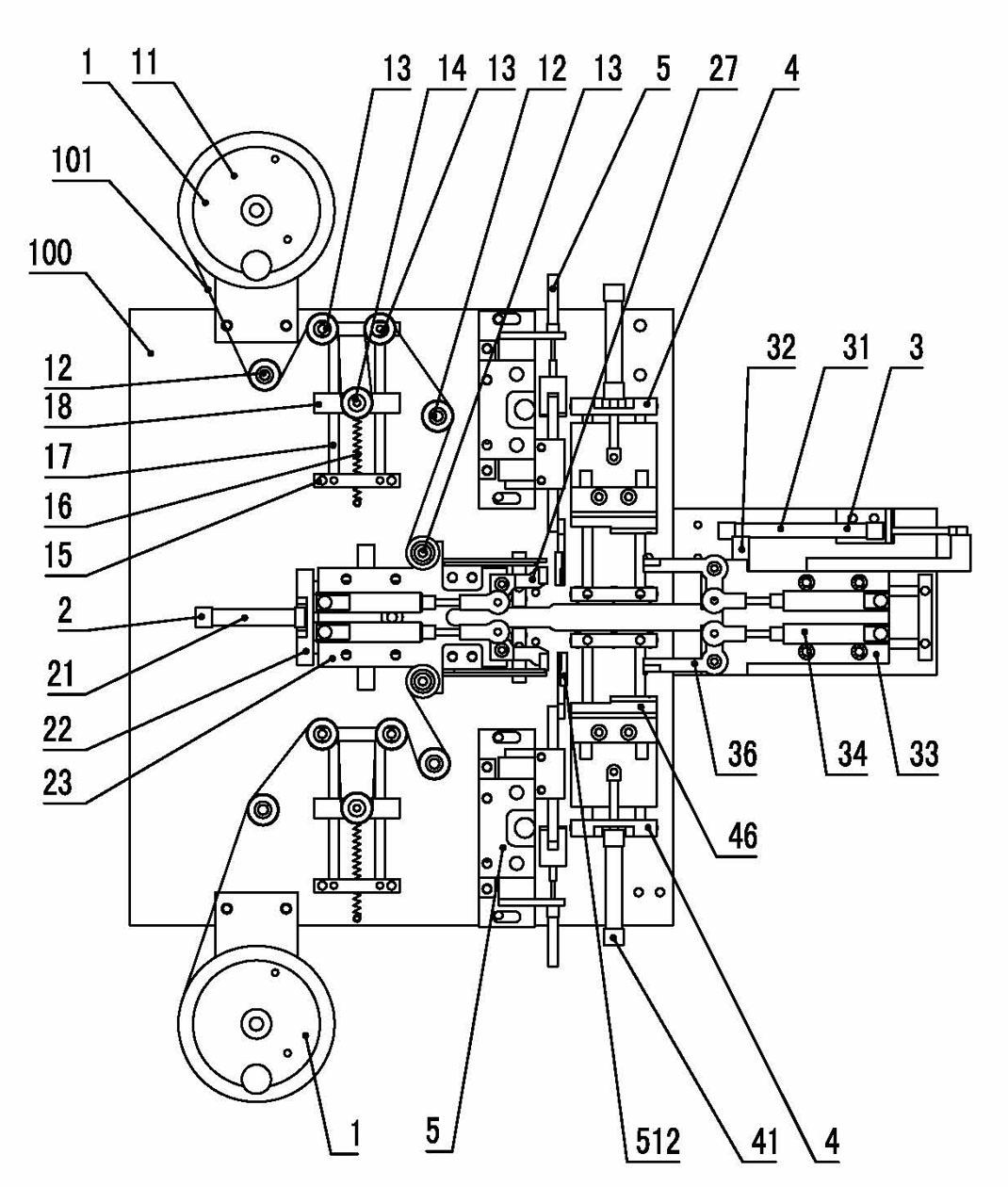

Paper sticking device of battery machine and battery machine adopting paper sticking device

The invention relates to a paper sticking device, in particular to a paper sticking device of a battery machine and a battery machine adopting the paper sticking device. The invention provides the paper sticking device of the battery machine, which comprises a machine base, wherein a sticking paper conveying mechanism, a first paper pressing mechanism, a second paper pressing mechanism, an adsorption mechanism and a cutting mechanism are arranged on the machine base, the sticking paper conveying mechanism is used for conveying sticky paper strips, the first paper pressing mechanism is used for tightly pressing the sticky paper strips for cutting, the second paper pressing mechanism is used for tightly pressing the sticky paper strips for cutting, the adsorption mechanism is used for adsorbing the sticky paper strips, and the cutting mechanism is used for cutting the sticky paper strips. The invention also provides the battery machine with the paper sticking device. The paper sticking device and the battery machine have the beneficial effects that after guide pins are pricked and riveted on aluminum foils, a layer of sticking paper is stuck, the aluminum foil scratch caused by burrs left during the pricking and the riveting of the guide pins is prevented, the quality of batteries is favorably improved, defective products are reduced, and the production cost is lowered.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

Ferrule perforation method

ActiveCN102335774AImprove efficiencyReduce defective productsAutomatic control devicesFeeding apparatusElectrical controlProcessing accuracy

The invention discloses a ferrule perforation method, belonging to a machining method. The traditional operation of perforating a ferrule is finished manually, which has the disadvantages of low efficiency, more inferior-quality products and inconsistent machining precision. The ferrule perforation method is characterized in that a feed channel conveys a ferrule to a material supporting rack; an electrical control system controls a clamping device to move to a backer, the electrical control system and the backer oppositely clamp two end surfaces of the ferrule on the material supporting rack so as to clamp the ferrule on a perforation workstation; electrical control system controls a perforation device to feed to radially perforate the ferrule on the punching workstation; and after the operation of perforation is finished, the electrical control system controls the perforation device to retract, the clamping device is reset, and a charging ram pushes down processed ferrule from the material supporting rack. With the ferrule perforation method, equipment replaces manpower to machine the ferrule, the electrical control system control equipment to work, efficiency is improved, inferior-quality products are reduced, and machining precision is guaranteed to be consistent.

Owner:XINCHANG JINCHENG PML PRECISIION MECHANISM CO LTD

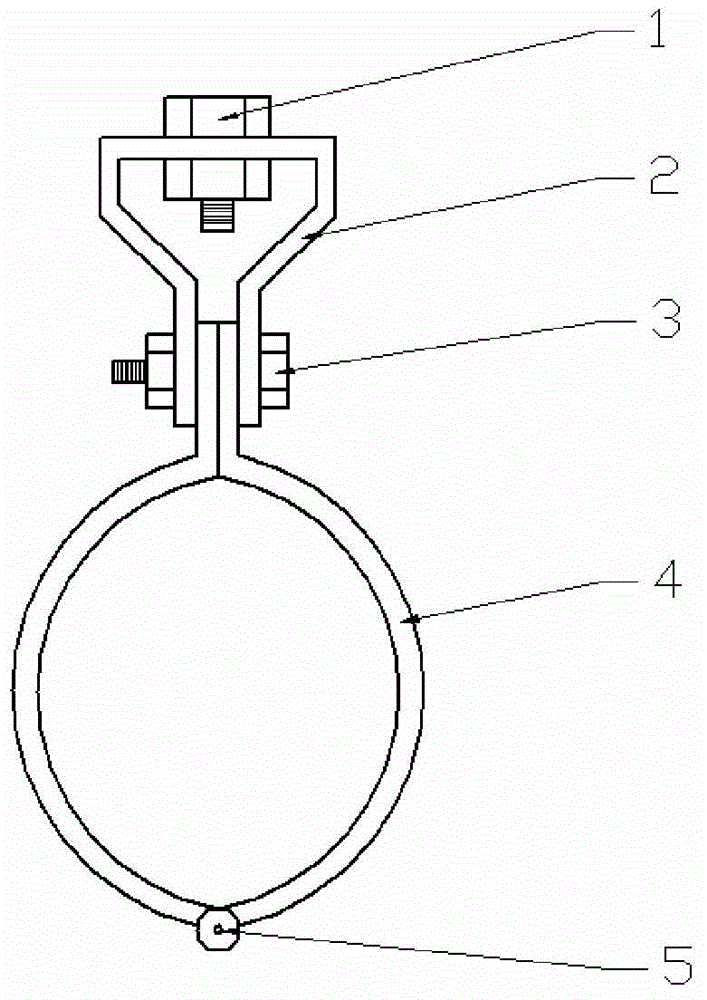

Corrosion-resistant high-strength support/hanger assembly and manufacturing technology thereof

ActiveCN105042191AGood plastic deformation stabilityUniform materialPipe supportsManufacturing technologyEngineering

The invention discloses a corrosion-resistant high-strength support / hanger assembly. The support / hanger assembly comprises a tube clamp and a connecting part arranged at the lower end part of the tube clamp, wherein the tube clamp comprises two clamp pliers which are in the same shape and are symmetrically arranged; each clamp plier comprises a connecting end, a circular arc section and a clamping section; the connecting ends of the two clamping pliers are connected together in a rotating manner; the arc mouth ends of the circular arc sections of the two clap pliers are oppositely arranged; fastening holes are respectively formed in the clamping sections of the two clamp pliers, and the two fastening holes correspond to each other. The invention further discloses a manufacturing technology of the corrosion-resistant high-strength support / hanger assembly. The support / hanger assembly disclosed by the invention is simple and reasonable in tube clamp structure, scientific in design, high in strength, hardness and toughness, resistant to acid and alkaline corrosion, not liable to deform under high temperature and high pressure, and long in service life.

Owner:BEIDELI ENERGY EQUIP JIANGSU CO LTD

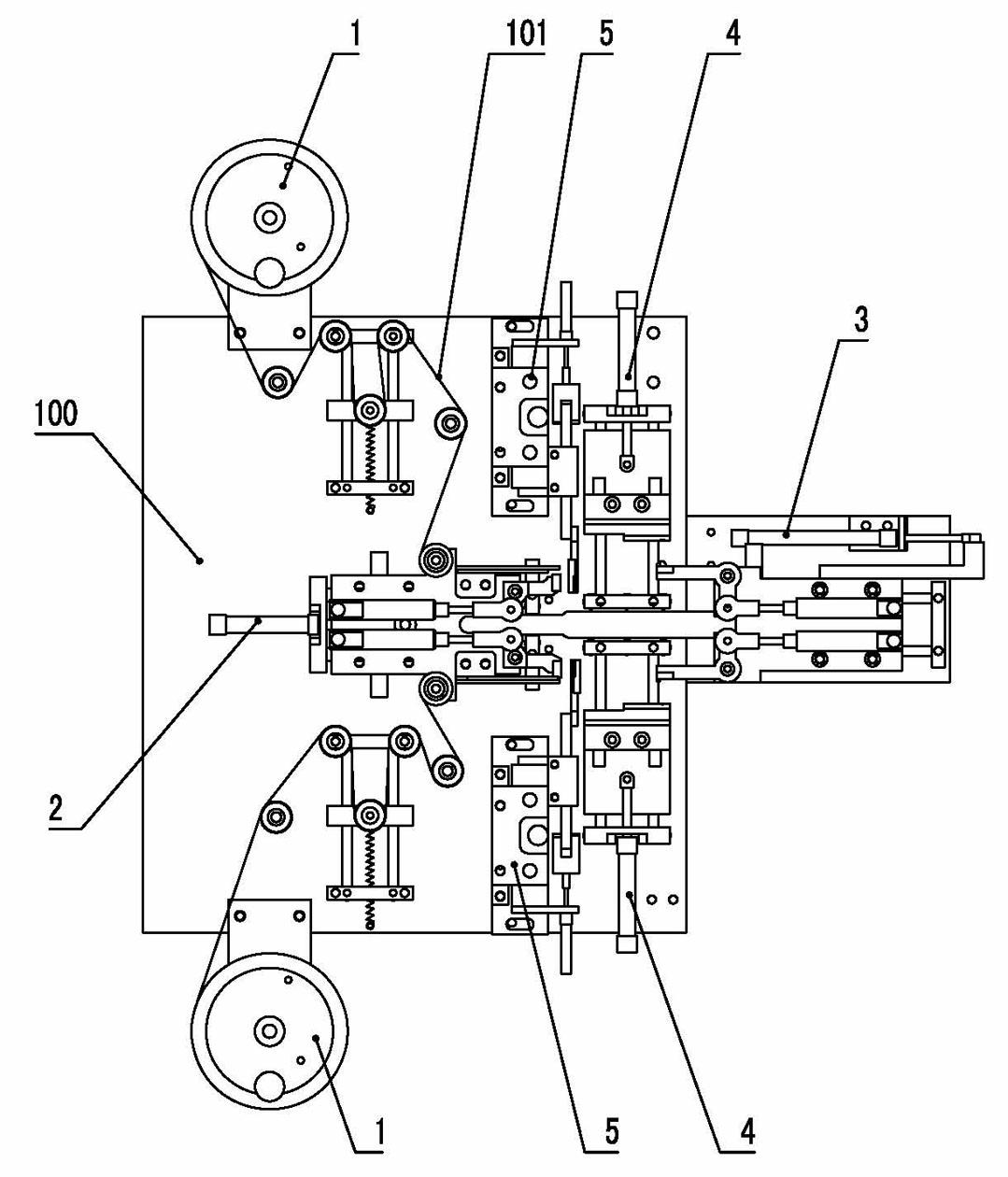

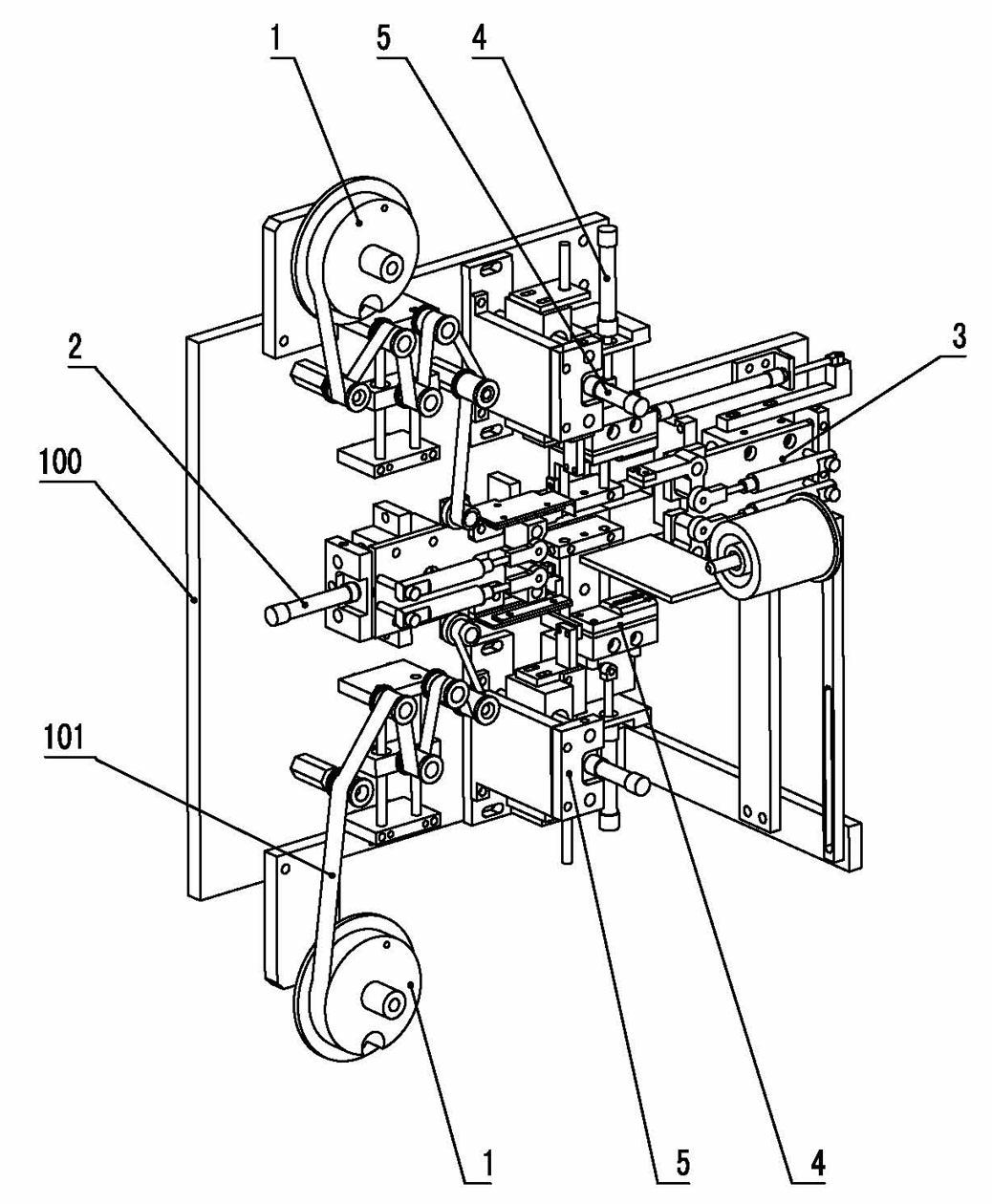

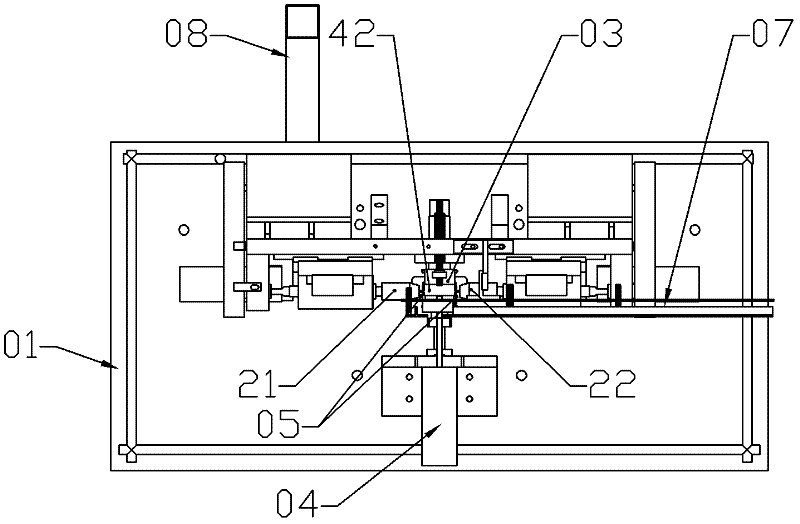

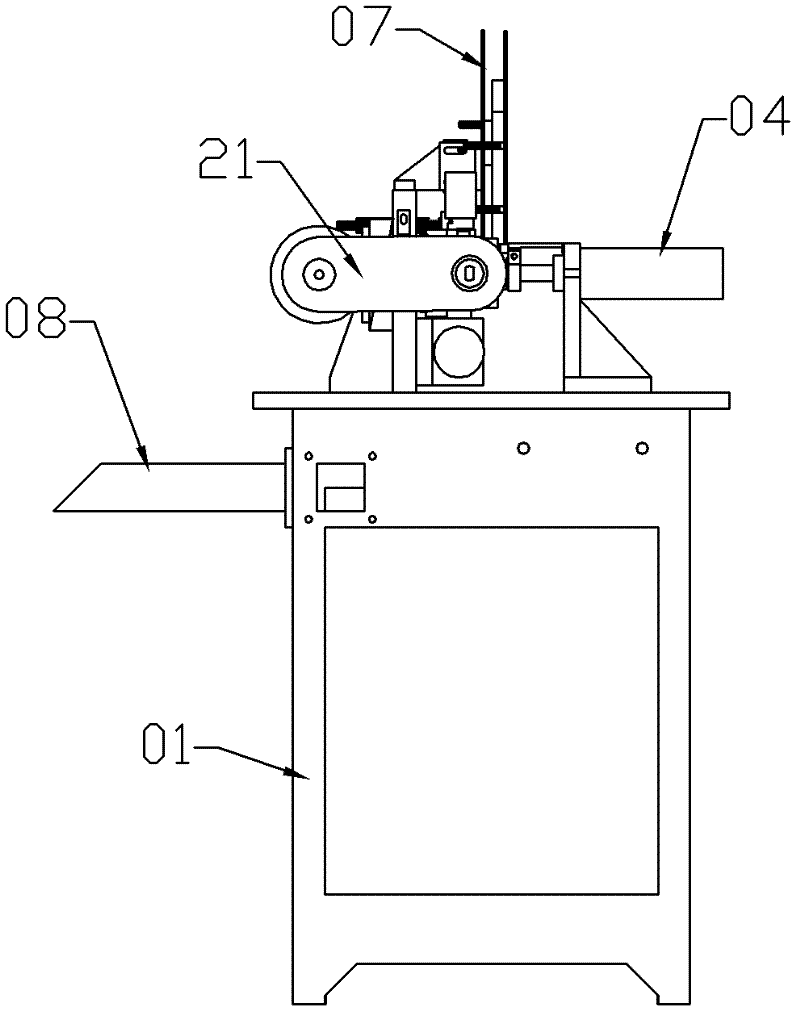

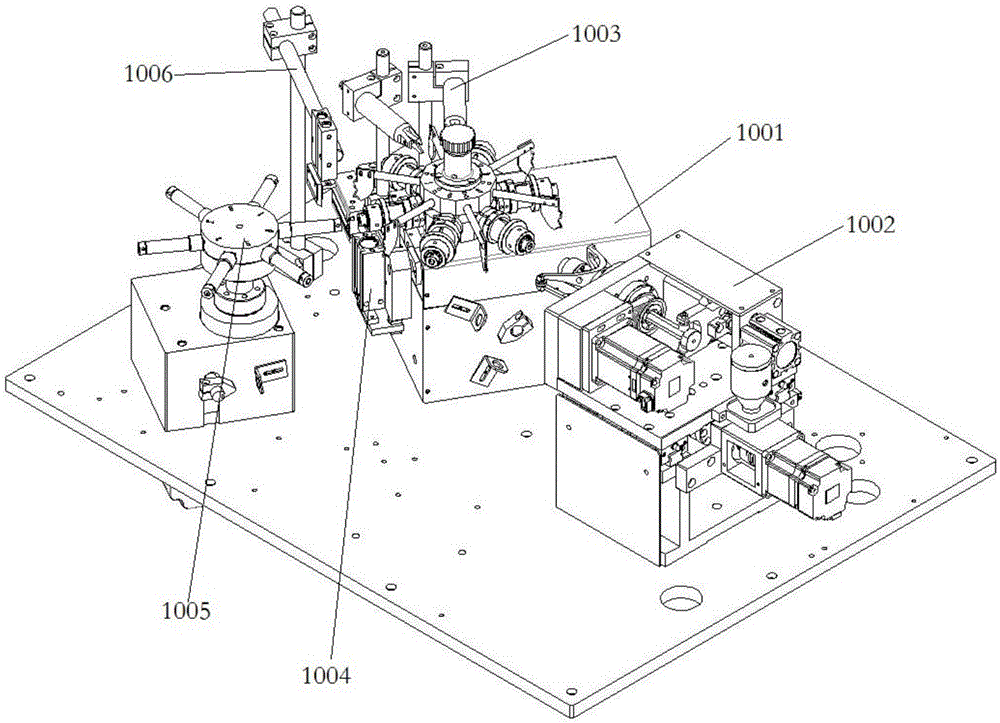

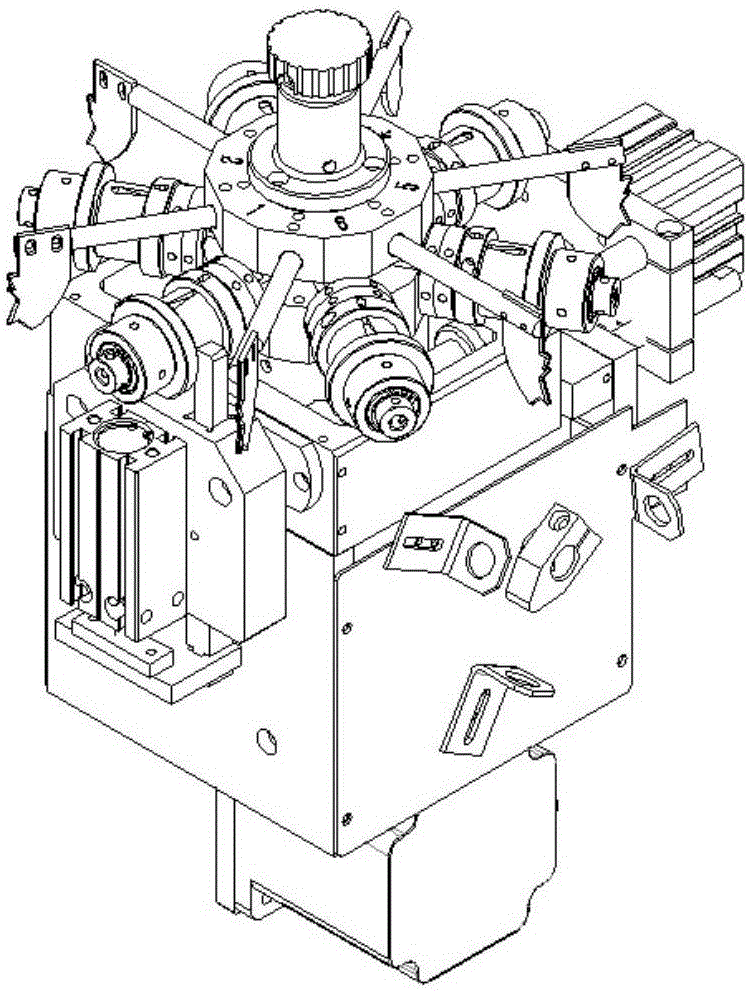

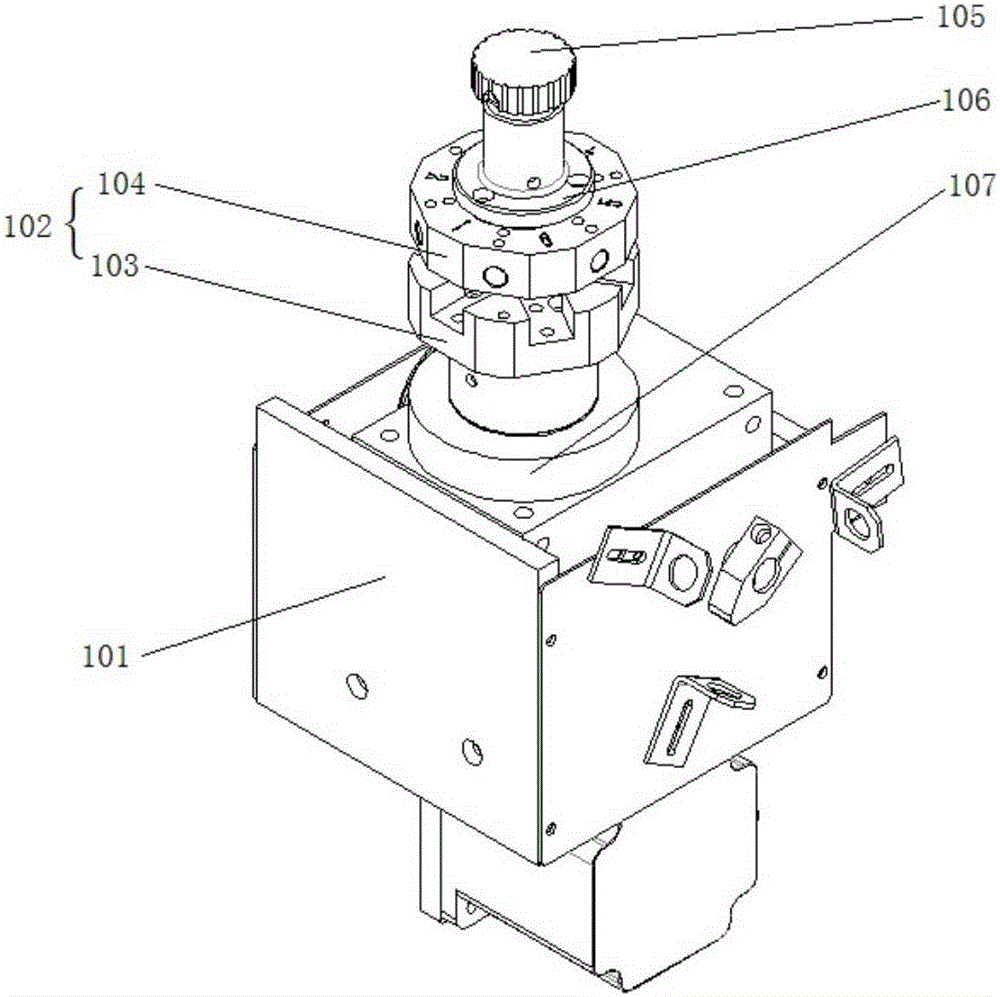

Six-shaft flying fork type winding machine with six-shaft discharging mechanism

ActiveCN106504890AReduce defective productsStable Coil ParametersCoils manufactureWinding machineEngineering

The invention discloses a six-shaft flying fork type winding machine with a six-shaft discharging mechanism. The six-shaft flying fork type winding machine comprises a six-shaft mechanism, a flying fork type winding mechanism, a pneumatic cutting mechanism, a discharging mechanism, the six-shaft discharging mechanism and a press mechanism, wherein the six-shaft mechanism is used for converting a station, the flying fork type winding mechanism is used for winding a coil, the pneumatic cutting mechanism is used for cutting a line, the discharging mechanism is used for pushing the coil, the six-shaft discharging mechanism is used for transmitting the discharging coil, and the press mechanism is used for pressing during coil discharging and transferring. By the six-shaft flying fork type winding machine, operation of loading, line cutting and discharging during coil winding can be completely and automatically finished, the six-shaft flying fork type winding machine has the characteristics of high efficiency and high yield, the coil cannot directly drop to a material disc after being discharged by matching of the six-shaft discharging mechanism and the press mechanism, and defective products are reduced.

Owner:华南智能机器人创新研究院

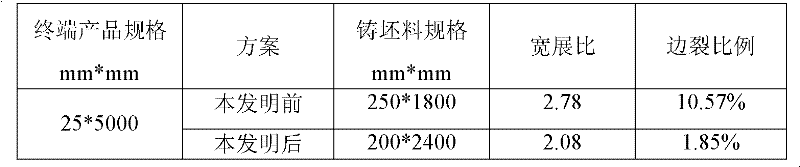

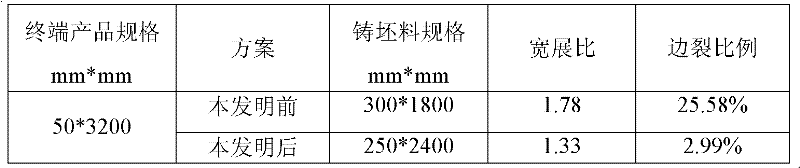

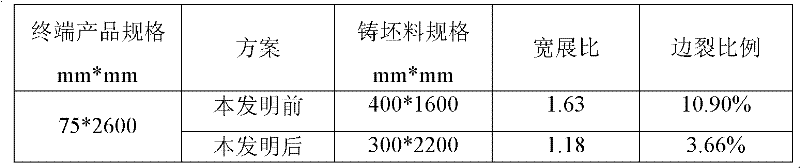

Method for controlling edge cracks of peritectic steel containing niobium or boron

The invention relates to a method for controlling incidence and generation position of edge cracks of a peritectic steel medium plate containing niobium or boron. The method comprises the following steps: smelting and controlling the contents of the following components in molten steel by weight percent: 0.14-0.17% of C, 0.015-0.035% of Nb or 0.0009-0.0013% of B; continuously casting and forming blanks; selecting the blanks, namely conventionally heating the casting blanks; rolling; and conventionally carrying out post processes. The method can be used for controlling the extension of the edge cracks of the medium plate to the center from angle parts by optimizing the size of the casting blank material under the condition that the existing continuous casting machine equipment and process are not changed, thereby reducing the quantity of disqualified products caused by the edge cracks of the medium plate, reducing the edge cutting amount of the medium plate, and further improving the yield.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

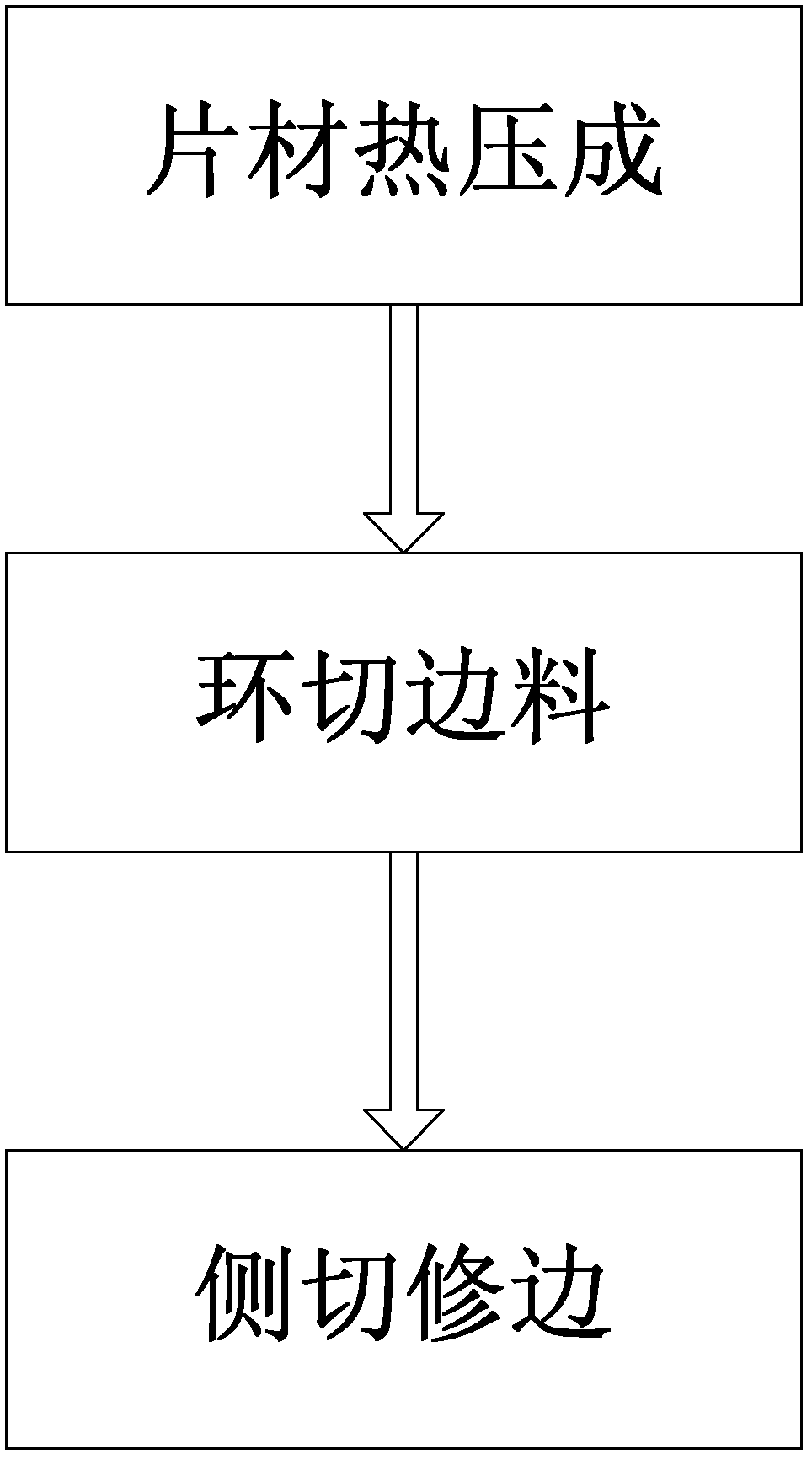

Three-dimensional side cutting method and die for stereoscopic high stretch formed film

ActiveCN103203858AReduce defective productsReduce defective rateMetal working apparatusControl systemWork in process

The invention discloses a three-dimensional side cutting method and a die for a stereoscopic high stretch formed film. The method is realized by the steps of: S1: conducting hot-pressing stretching on a sheet in a hot-pressing forming mould to form a semi-finished sheet with an arc; S2: placing the semi-finished sheet in a circular cutting mould to conduct circular cutting on the rim material, thus forming a shaped sheet; S3: carrying out side accurate cutting on the rim material of the shaped sheet in a side cutting mould to obtain a cut formed sheet. The die includes: the hot-pressing forming mould, which performs hot-pressing stretching on the sheet with a printed pattern and a punched positioning hole so as to form the semi-finished sheet with an arc; the circular cutting mould, which cuts the redundant rims materials around the semi-finished sheet; and the side cutting mould, which is controlled by a side cutting equipment control system and conducts side cutting on the remaining sheet of the shaped sheet. The three-dimensional side cutting method and the die provided in the invention can broaden the film thickness selection region during cutting and reduce the defective rate of products.

Owner:QUNDA PLASTIC ELECTRONICS SHENZHEN

Pad printing mechanism, printing device and full-automatic silk-screen printer

InactiveCN109177452AImprove printing accuracyImprove yield rateScreen printersScreen printingElectrical and Electronics engineeringSilk-screen printer

The invention relates to the field of silk-screen printing devices and provides a pad printing mechanism comprising a supporting stand column, an adjusting lifting assembly, a transverse movement module, suspended extension arms, a screen holding assembly and a movable scraper blade assembly. The pad printing mechanism has the advantages that a screen is flat and convenient to replace, and the printing precision and the yield are high.

Owner:吴连根

Full-automatic nailing machine

PendingCN108501445AAvoid deflectionReduce maintenance workloadPaper-makingBox making operationsPaperboardPulp and paper industry

The invention discloses a full-automatic nailing machine. The machine comprises a control box, a paper feeding device, a box folding device and a nailing device; the box folding device and the nailingdevice are both provided with detection cameras used for detecting card paper; the full-automatic nailing machine integrates piece-by-piece feeding, line pressing, shaping bending, conveying, nailingand card paper detection, failures are automatically detected, segmented machine stop is achieved, maintaining workloads are reduced, during box folding, a shaping wheel is arranged, a paper board isprevented from deflecting during paperboard folding, non-performing products are reduced, production efficiency is improved, and production automation is achieved.

Owner:昆山英立德机械有限公司

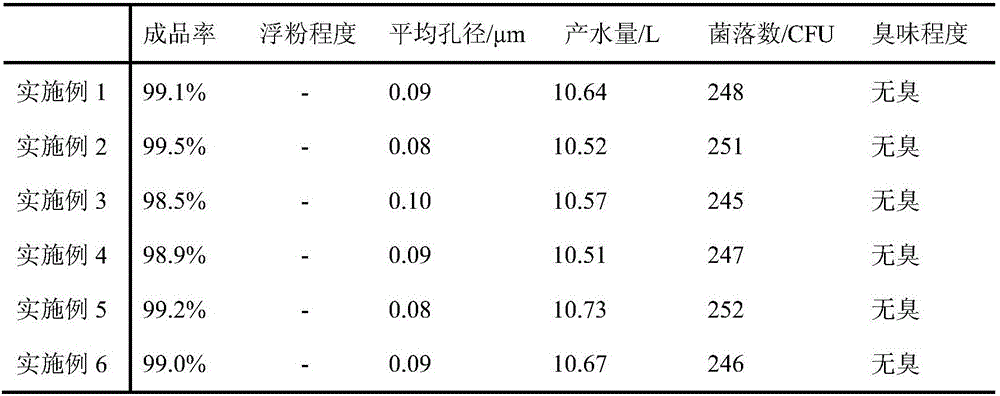

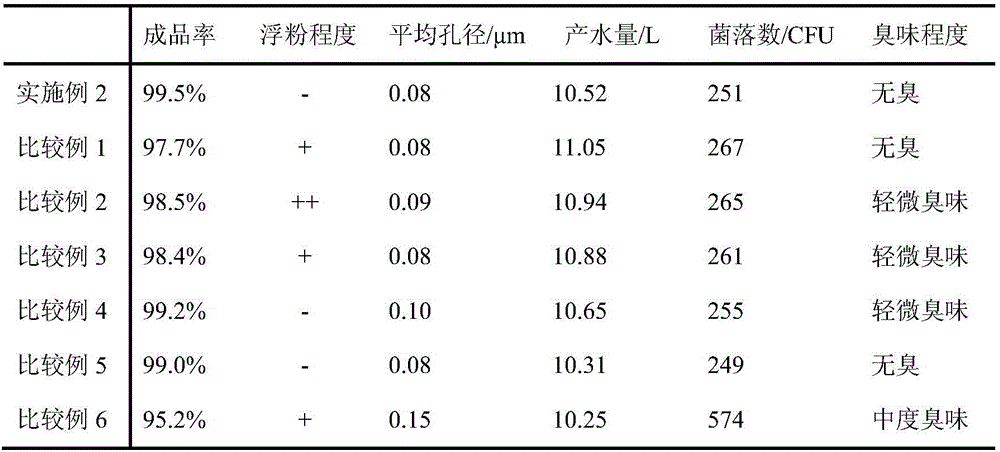

Composite filter element containing kieselguhr and starch and manufacturing method of composite filter element

ActiveCN106552459AImprove yieldReduce defective productsOther chemical processesFiltration separationMolecular sieveCellulose acetate

The invention discloses a composite filter element containing kieselguhr and starch and a manufacturing method of the composite filter element. By means of the composite filter element and the manufacturing method thereof, the problem that due to the fact that a ceramic filter element has quite different capture rates for foul gas, foul smell complex in constituent cannot be handled well is solved. According to the technical scheme, the composite filter element containing the kieselguhr and the starch is made of the modified kieselguhr, the mixed starch, cellulose acetate, molecular sieve raw powder, aluminum oxide, montmorillonite and a flocculating agent. The effect of removing the foul smell in water is achieved.

Owner:宁波杜康陶瓷有限公司

Lamination device for mobile phone screen and pasting method

PendingCN109435412AAvoid undesirable defects such as air bubbles and wrinklesAvoid prior contactLamination ancillary operationsLaminationWrinkle skinMechanical engineering

The invention discloses a lamination device for a mobile phone screen and a pasting method. The lamination device comprises a holding platform, a curved surface protection cover plate, a flexible film, a carrying belt and a lifting pressurizing part, wherein the holding platform is used for holding the curved surface protection cover plate; the flexible film is placed on the carrying belt; the carrying belt is of an elastic and soft tabulate structure; the carrying belt is placed on the lifting pressurizing part; the flexible film and the curved surface protection cover plate are correspondingly arranged up and down; a pair of clamping claw devices are further arranged on a lower cavity; the clamping claw devices are arranged on both sides of the lifting pressurizing part; a limiting device is arranged on an upper cavity; and the limiting device is used for limiting positions of both ends of the carrying belt. By adopting the lamination device, the flexible film is pasted to the curvedsurface protection cover plate with an included angle bent edge, and bubbles, wrinkles and other defects can be prevented in the pasting process of the flexible film; under the action of the limitingdevice, prior contact between an end part of the flexible film with a curved surface edge position of the curved surface protection cover plate is avoided, and defective products can be reduced.

Owner:汪恒坤

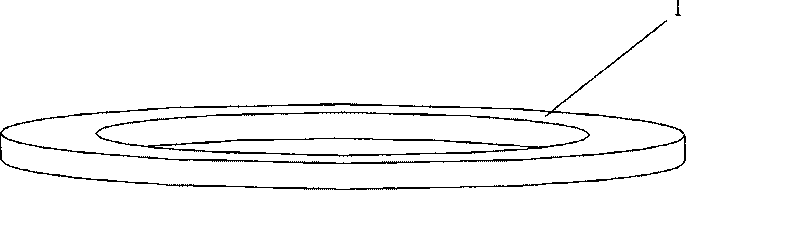

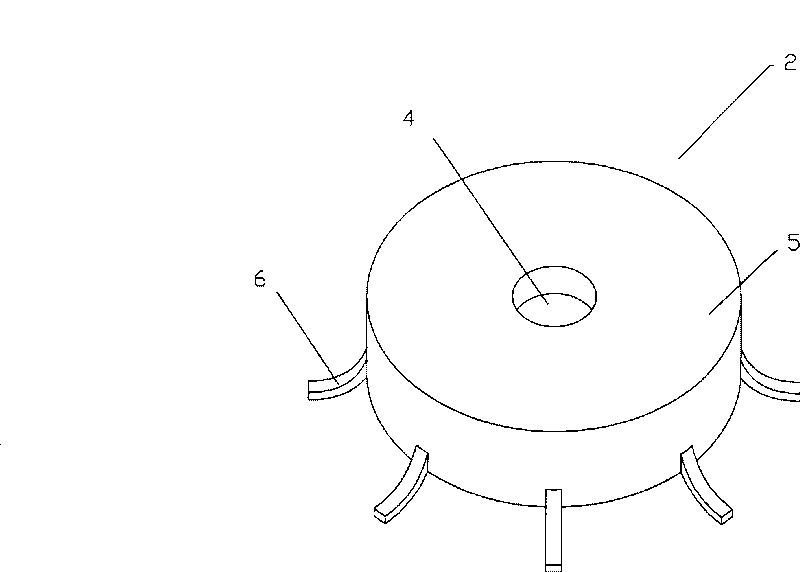

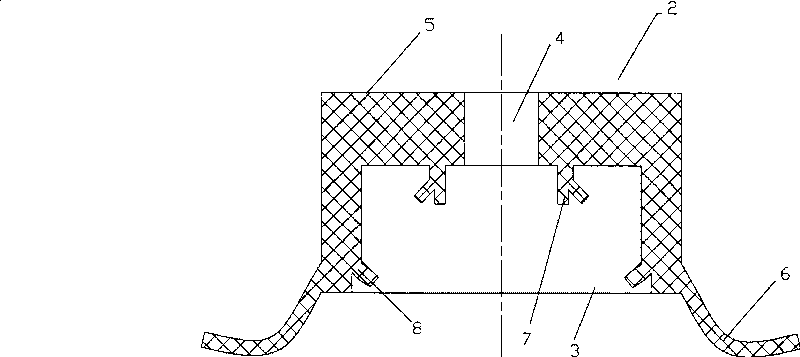

Production method of graphite plane commutator

ActiveCN101369708BGuaranteed electrical conductivityGuaranteed service lifeCommutators manufactureCopper platingGraphite

The invention relates to a method for manufacturing graphitic plane commutator, which includes the following steps:(1) making an accurate cuprum case; (2) plating nickel on one surface of a molded annular graphite sheet matched with an operation end of the accurate cuprum case, and then plating copper, to form a connection end of the annular graphite sheet; (3) Connecting the accurate cuprum caseand the annular graphite sheet by welding mode, wherein the connection surfaces are the operation end of the accurate cuprum case and the connection end of the annular graphite sheet, to obtain a composite piece; (4) compression-injection molding the composite piece, and milling groove as well as hooking to obtain the completed product graphitic plane commutator. The graphitic commutator made by the method, is characterized in that the connection of the graphite sheet and the accurate cuprum case is firm, the electroconductivity is well, the performance is stabile and the longevity is long.

Owner:SHENZHEN KAIZHONG PRECISION TECH CO LTD

Instant cubilose processed by ready-to-stew raw material and preparation method of instant cubilose

ActiveCN108041575AFeel crystal clearModerate smooth mouthfeelFood preservationNatural extract food ingredientsAdditive ingredientRose flower

The invention discloses instant cubilose processed by a ready-to-stew raw material. The instant cubilose is prepared from the following raw materials in parts by weight: 40-80 parts of ready-to-stew cubilose, 20-40 parts of syrup and 1-5 parts of natural plant extract. The natural plant extract is one or more of milk-vetch root extract, eucommia leaf extract and rose flower extract, and is preferably a mixture of the milk-vetch root extract, the eucommia leaf extract and the rose flower extract with a mass ratio of 3:2:1. According to the product of the invention, the ready-to-stew raw material is processed into the instant cubilose through advanced technologies, refers to a no-clean, no-soaking, no-feather picking and high-cleanliness material, is directly fed into a glass container, or abag container, or a bowl container, and is prepared into the final product through a process of syrup filling, vacuum cover sealing and high-temperature sterilization, so that the final product has no visible extraneous impurity visible to naked eyes, is crystal clear in appearance, has a smooth and moderate mouth feel, and is rich in collagen elasticity. The method reserves collagen fragrance and a special component of sialic acid in the instant cubilose product, realizes commercial sterility, and meanwhile, greatly shortens high-temperature sterilization time.

Owner:广州龙标心燕食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com