Pad printing mechanism, printing device and full-automatic silk-screen printer

A technology of pad printing and lateral movement, which is applied to screen printing machines, screen printing, printing machines, etc., and can solve the problems of unreasonable pad printing mechanism, low printing accuracy and good product rate, and easy inequality of screen printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Combine below Figure 1-Figure 11 The present invention is further described.

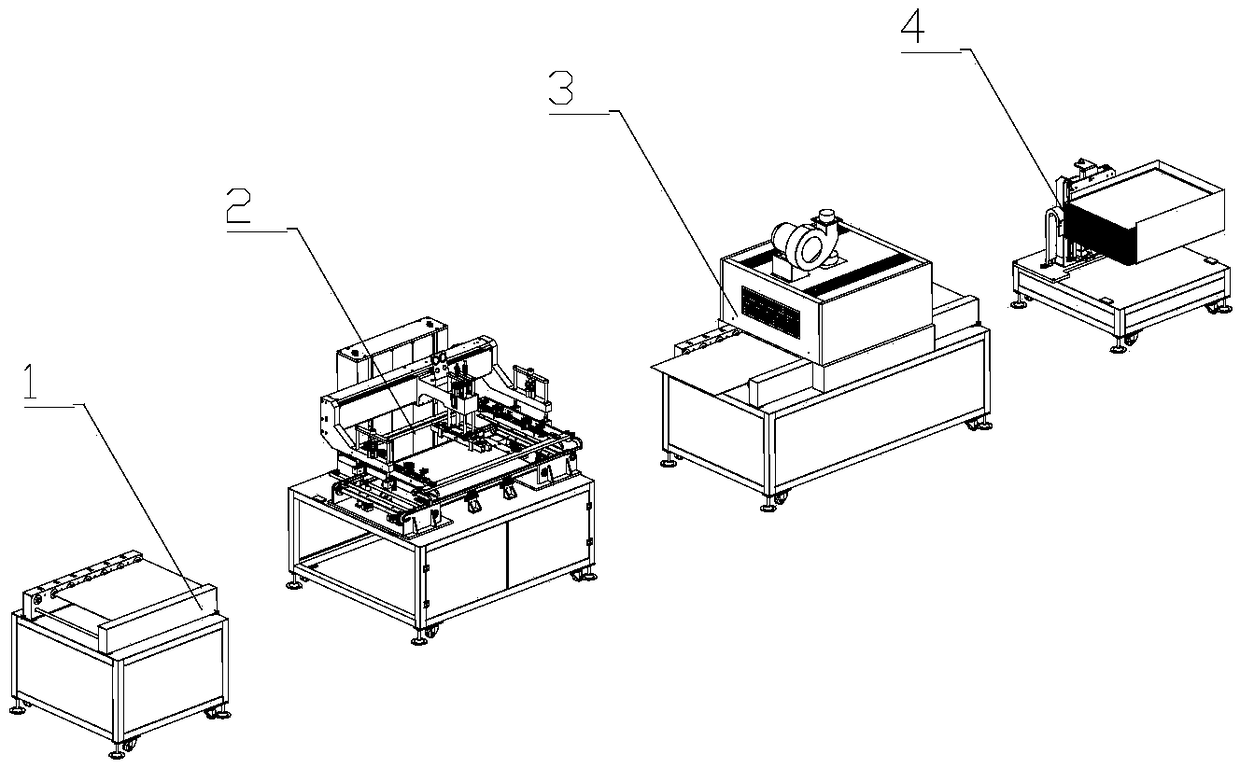

[0023] Such as Figure 1-Figure 11 The fully automatic screen printing machine shown includes a roller feeding device 1, a printing device 2, a baking and air-drying device 3 and a layered stacking device 4; along the direction of workpiece processing, the roller feeding device 1, printing device 2, drying The roasting and air-drying device 3 and the layered stacking device 4 are arranged sequentially; the roller feeding device 1 is used for loading the workpiece, so that it enters the printing device 2; the printing device 2 first positions the workpiece, and then prints it; baking The air-drying device 3 is used to bake and blow the printed workpiece to make it firmly bonded to the workpiece; finally, the workpiece enters the layered stacking device 4, where the layered collection is completed.

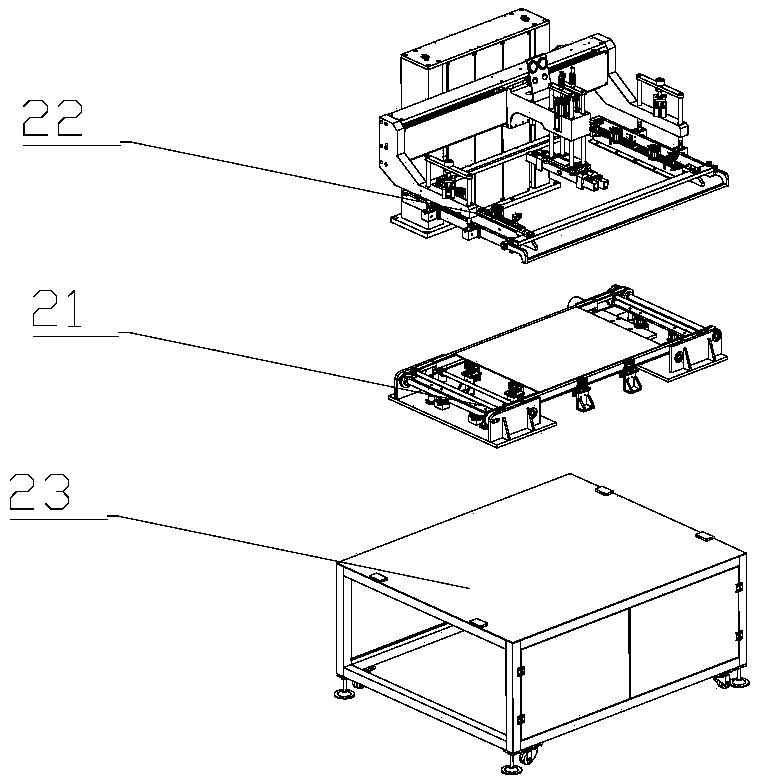

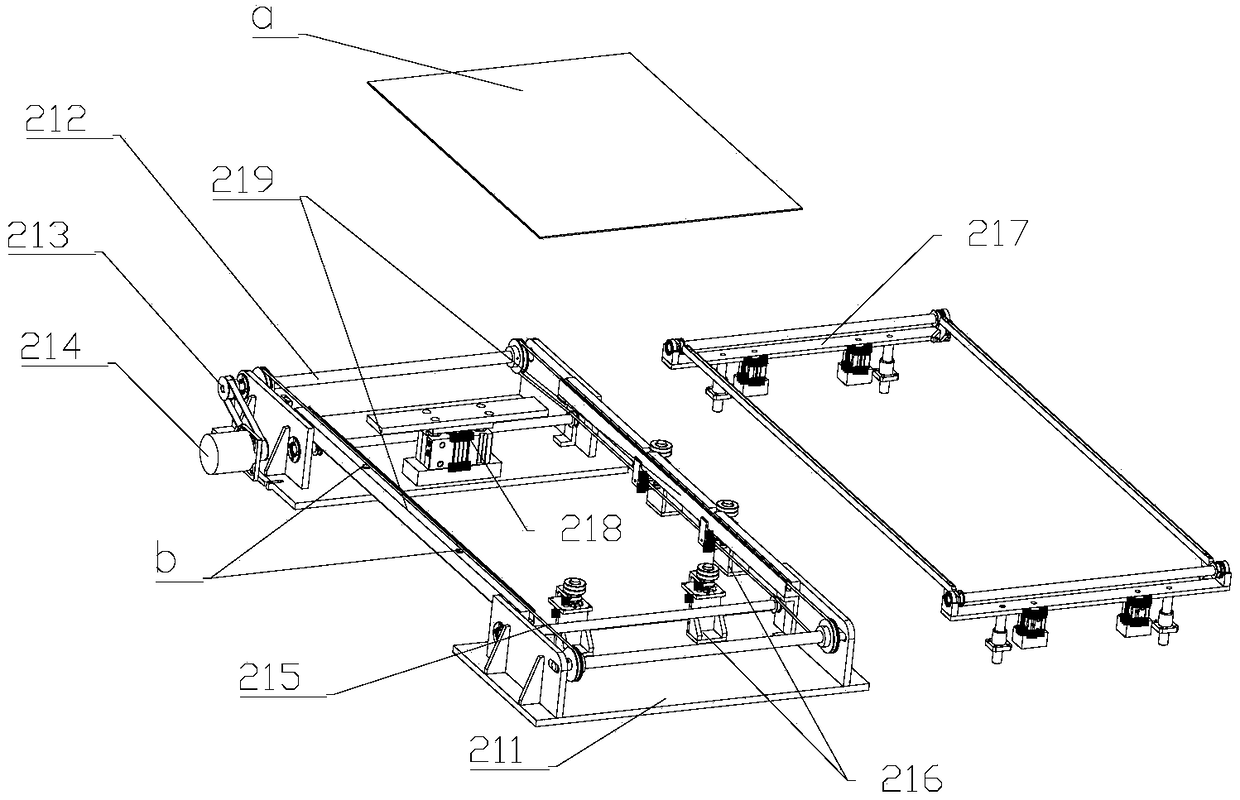

[0024] Such as figure 2 As shown, the printing device 2 includes a frame 23, a diversion p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com