Electronic paste based on low-melting-point metal micro-nano powders and manufacture method thereof

A low-melting point metal and electronic paste technology, which is applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of high melting point and large contact resistance, and achieve low sintering temperature, The effect of small contact resistance and low disconnection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 sintered slurry

[0028] An electronic paste based on low-melting-point metal micro-nano powder. The components in the paste are shown in Table 1. The bismuth-based alloy powder in Table 1 can have a particle size of 1 nm to 10 microns and is commercially available.

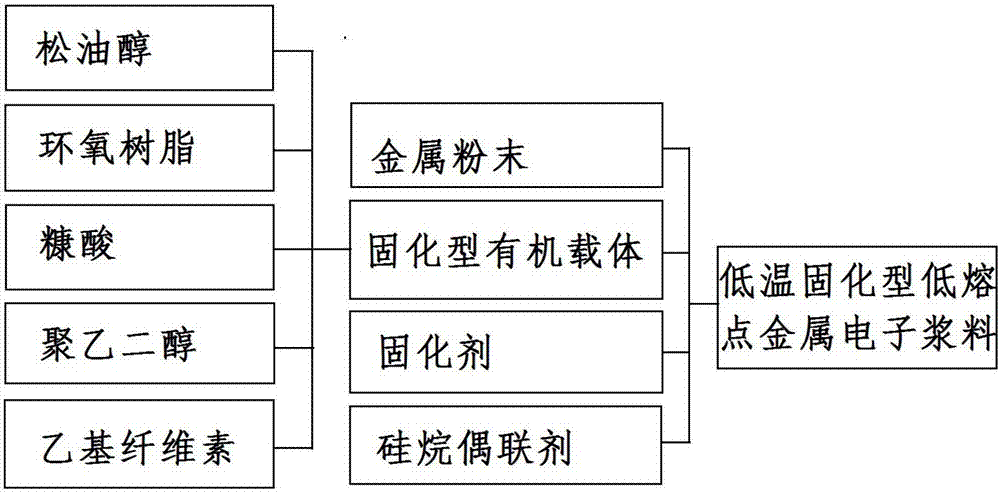

[0029] The preparation method of the electronic paste: select the low-melting-point metal micro-nano powder according to the required melting point value, dissolve the additive in the solvent according to the mass ratio to obtain an organic carrier, mix and roll the low-melting-point metal micro-nano powder, the organic carrier, and the adhesive into a uniform paste. The rolling equipment is a three-roll mill. Process see figure 1 , is the preparation method of organic solvent required for low temperature curing; ingredients can choose bisphenol A type epoxy resin acid, anhydride curing agent, butyl acetate, toluene, polyethylene glycol, silane coupling agent and so on.

Embodiment 2-5

[0031] The composition of each component in the slurry is shown in Table 1. The preparation method is the same as in Example 1.

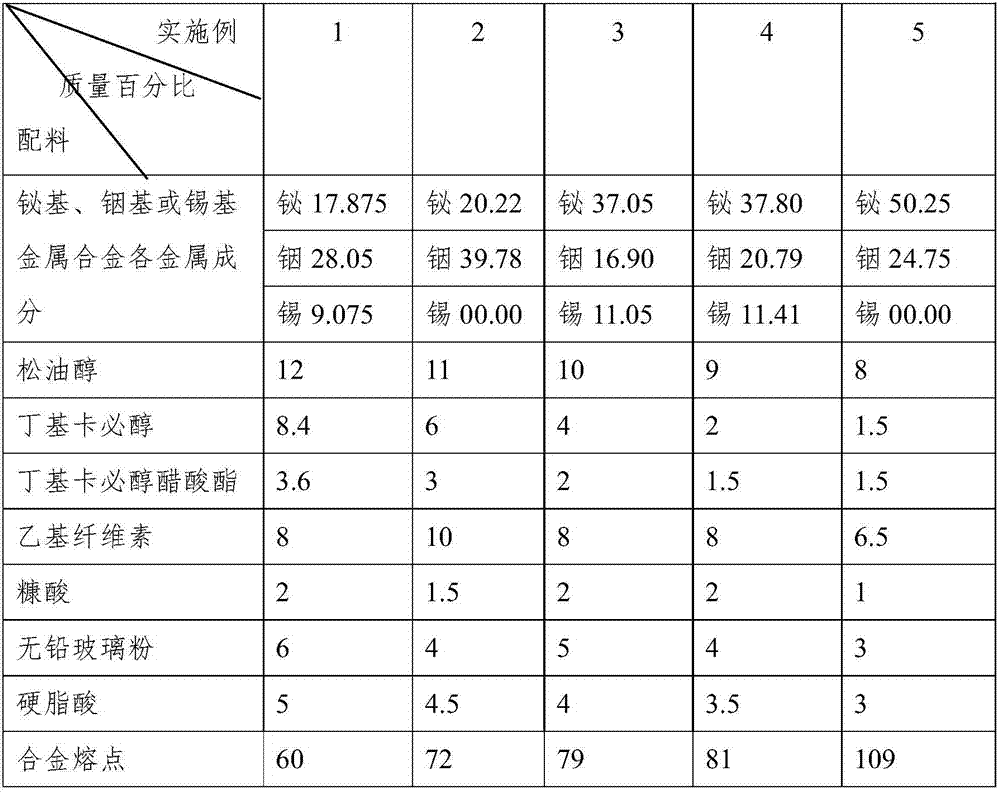

[0032] Table 1: Composition of Electronic Paste in Examples 1-5

[0033]

[0034] Table 2: Performance of the electronic paste of Examples 1-5

[0035]

[0036]

[0037] The above-mentioned examples are high-temperature sintered bismuth-based electronic pastes. From Example 1 to Example 5, the content of the bismuth-based alloy increases from 55% to 75%, and the electrical conductivity of the electronic paste is improved. It can also be adjusted between 45% and 90% according to actual needs.

[0038] In the above examples, from Example 1 to Example 5, the melting point of the alloy has been increasing. In actual production, the proportion structure of the alloy can be adjusted according to the demand to reach the required melting point value. For example, add or replace one or more of cadmium, lead, zinc, silver, gallium, copper, etc. in...

Embodiment 6-10

[0041] Embodiment 6-10 Low-temperature curable slurry

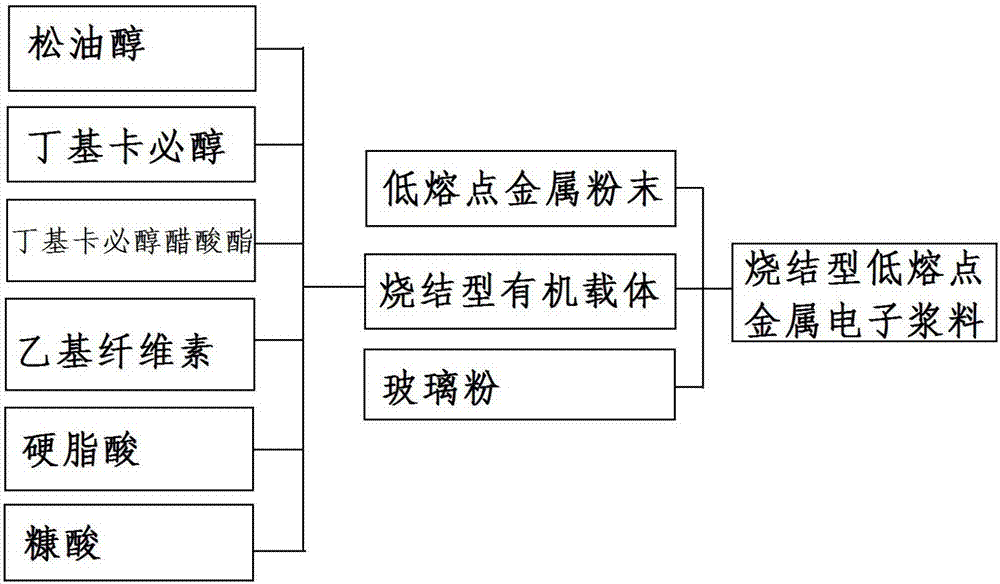

[0042] The preparation method of the electronic paste: select the low-melting-point metal micro-nano powder according to the required melting point value, dissolve the additive in the solvent according to the mass ratio to obtain an organic carrier, mix and roll the low-melting-point metal micro-nano powder, the organic carrier, and the adhesive into a uniform paste. The rolling equipment is a three-roll mill. Process see figure 2 , for the preparation of organic solvents required for high-temperature sintering; raw materials can choose terpineol, ethyl cellulose, furoic acid, nickel powder, toluene, etc.

[0043] Table 3 Electronic Paste Composition

[0044]

[0045] Table 4 Embodiment 6-10 electronic paste performance

[0046]

[0047]

[0048] The above-mentioned examples are low-temperature curing bismuth-based electronic pastes. From Example 6 to Example 10, the content of the bismuth-based alloy increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com