3D ink-jet printer for printing electronic circuit board through ultrasonic atomization nanometer suspending liquid

A nano-suspension and electronic circuit board technology, which is applied in the field of semiconductor functional devices and 3D components, can solve the problem that the printing accuracy of ordinary inkjet printers is difficult to meet the requirements of industrial products, the flow and viscosity of liquids cannot be controlled online, and electronic products are not easy to realize and other issues, to achieve the effect of reducing production time, safe and convenient man-machine operation, and reducing environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

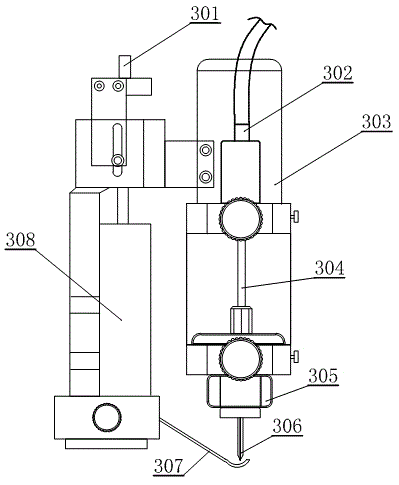

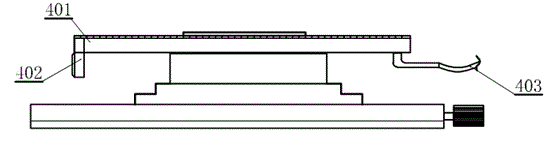

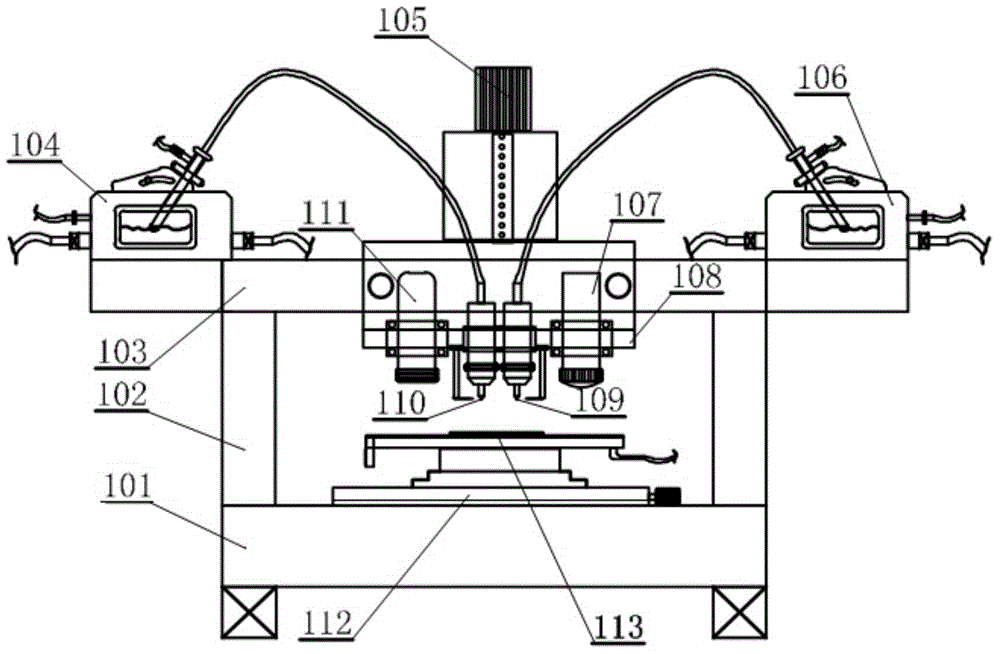

[0029] The invention provides an electronic circuit board 3D inkjet printer based on ultrasonic atomized nano suspension. exist figure 1 Among them, the printer includes a stable marble gantry frame composed of a marble base 101 , a marble column 102 and a marble beam 103 . A high-precision servo-driven XY cross slide 112 is fixed on the marble base 101, and a product table 113 is equipped on it, which can perform XY-axis interpolation motion. A Z-axis servo-driven sliding table 105 is installed on the marble column 102. This sliding table is equipped with a Z-axis sliding block and a fixture 108 for assembling an industrial camera positioner 111, a left nanosuspension printing device 110, and a right The nano-suspension printing device 109 and the infrared laser 107 can complete the functions of positioning, printing and laser sintering. The two sides of the marble frame are respectively equipped with a left ultrasonic nano-suspension atomization device 104 and a right ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com