Patents

Literature

233results about How to "Reduce disconnection rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

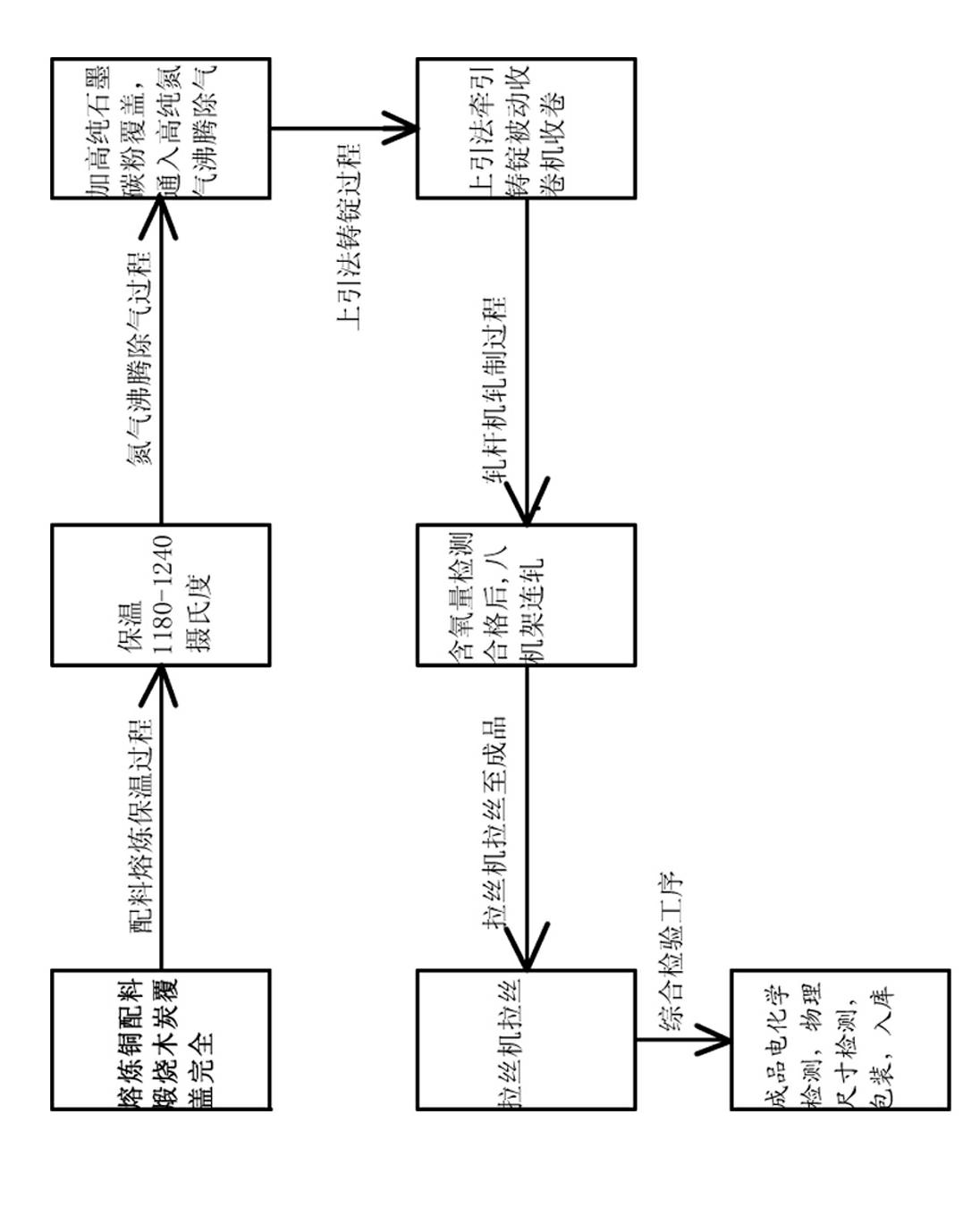

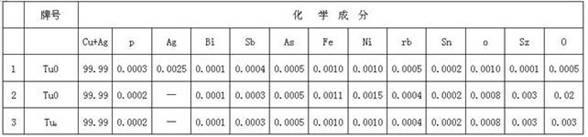

Upcast method for producing high-purity bright copper rod

ActiveCN102168180ALight weightFull reduction reactionProcess efficiency improvementGraphite carbonWinding machine

The invention relates to an upcast method for producing a high-purity bright copper rod. The method comprises the following steps of: drying smelting copper raw materials needed by smelting, mixing, adding the mixture into a smelting furnace, and covering firing charcoal with the thickness of between 100 and 150mm on starting molten copper until red copper is entirely molten, wherein molten copper constantly flows toward a heat preservation furnace under the action of fluid force; boiling the high-temperature molten copper and degassing before ingot guiding, adding prepared high-purity graphite carbon powder onto the liquid level of the molten red copper in the heat preservation furnace, and aerating high-purity nitrogen at the position which is 50 to 100mm lower than the liquid level of the heat preservation furnace; covering the firing charcoal after boiling and degassing, covering a furnace cover, performing draw casting operation, drawing a draw casting machine for draw casting bythe upcast method, cooling in a graphite crystallizer by the upcast method to obtain a qualified high-purity oxygen-free copper rod blank, and winding on a drawn cast ingot passive winding machine; and performing multi-pass rolling and fine-drawing on the high-purity oxygen-free high-brightness copper rod blank by an eight-rack rod cold rolling mill, and drawing the blank until the copper rod is obtained by a wire drawing machine, namely obtaining a finished product after the copper rod passes the inspection.

Owner:ZHONGTIAN ALLOY TECH

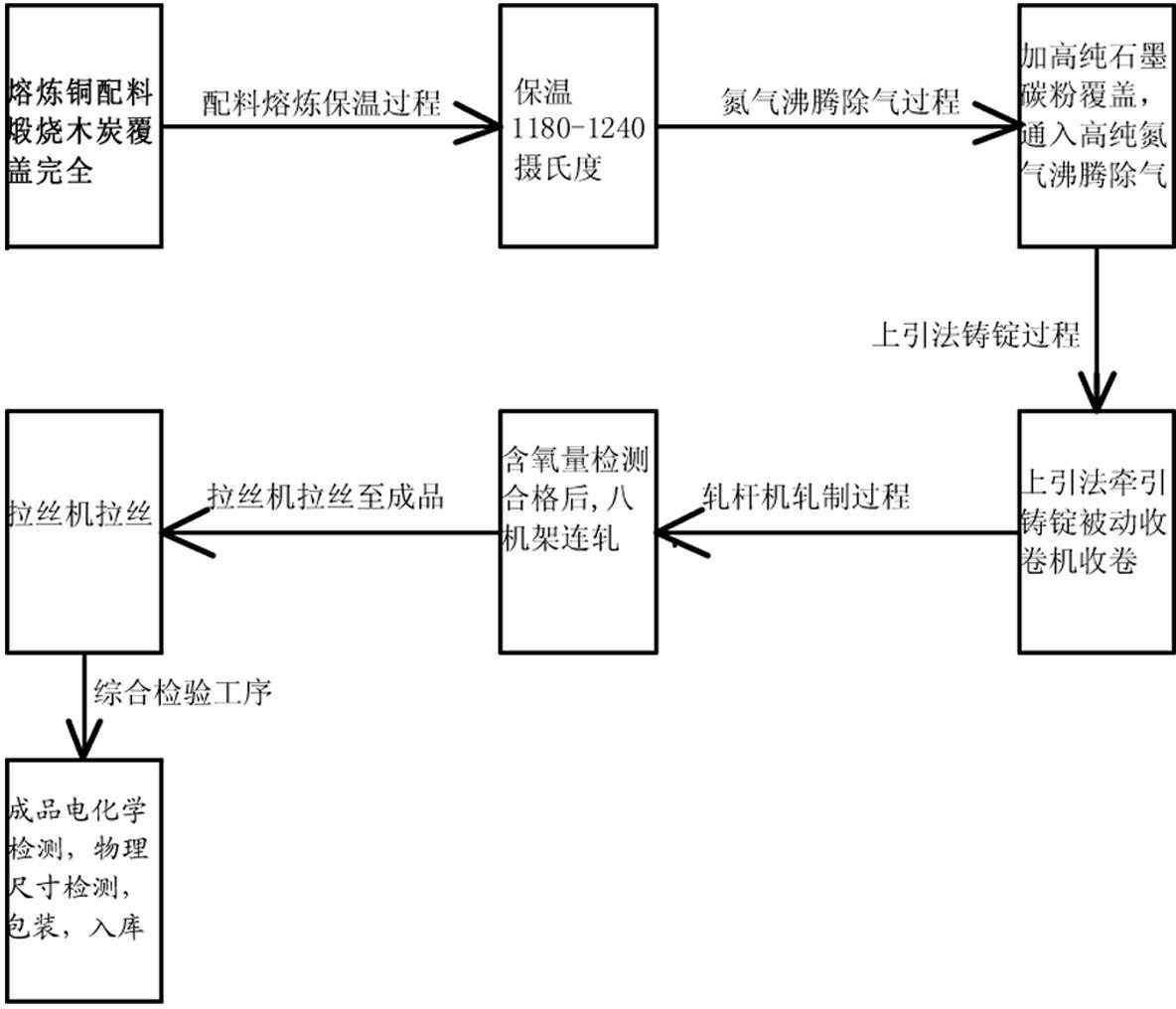

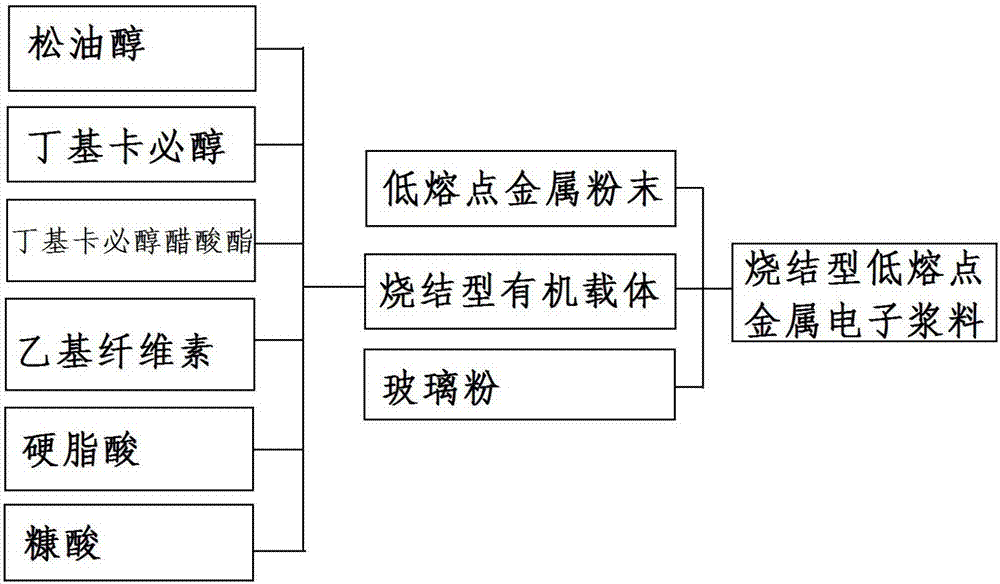

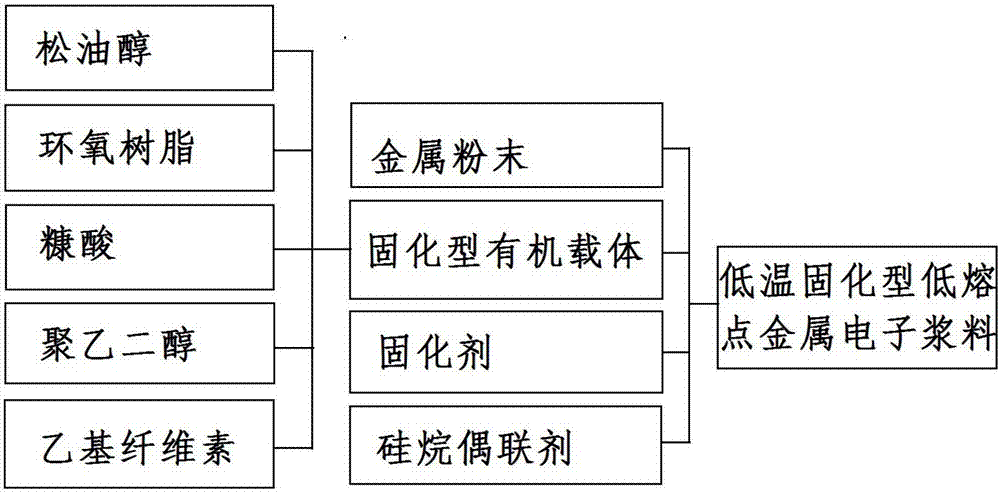

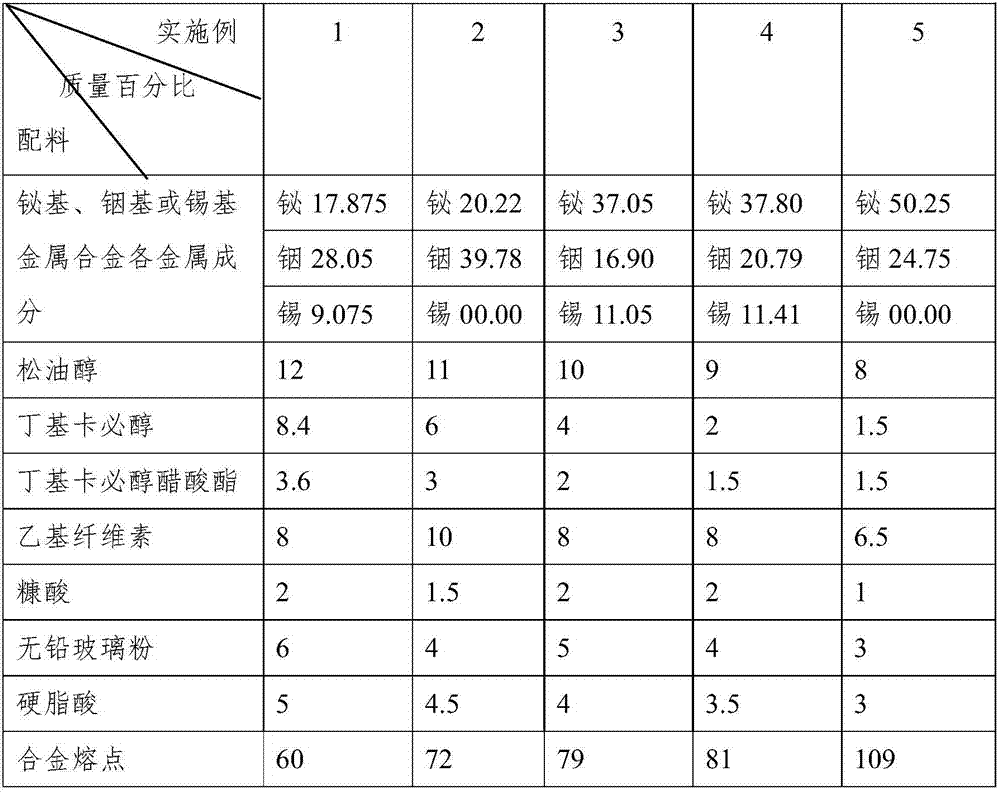

Electronic paste based on low-melting-point metal micro-nano powders and manufacture method thereof

ActiveCN107274965AImprove printing accuracyLower sintering temperatureNon-conductive material with dispersed conductive materialCable/conductor manufactureElectrical resistance and conductanceScreen printing

The invention provides an electronic paste based on low-melting-point metal micro-nano powders. The electronic paste is composed of low-melting-point metal micro-nano powders, a binder, a solvent and an auxiliary agent. The mass proportion of the low-melting-point metal micro-nano powders in the electronic paste is 45 to 90%. The melting point of low-melting-point metal is -78 to 232 degree centigrade. The electronic paste is suitable for traditional printing methods such as silk screen printing and can be widely used in printing electronic industry, such as front and back electrodes of solar panels, RFID tags, cell phone antennas, non-contact IC card antenna lines, and the like. The electronic paste has the advantages of high printing precision, low sintering temperature, no diffusion after sintering, low breaking rate, small contact resistance and low cost.

Owner:YUNNAN KEWEI LIQUID METAL VALLEY R & D CO LTD

Production technology of compound enamelled round aluminium wire with high heat resistance

ActiveCN101667477AGuaranteed cleanlinessImprove thermal shock resistanceInsulating conductors/cablesElectrical conductorFree cooling

The invention relates to a production technology of an enamelled wire, in particular to a production technology of a compound enamelled round aluminium wire with high heat resistance. Compared with the prior art, aluminum conductor surface is sprayed with 142 solvent before being painted with primer and finish paint except being washed with water to rewash residual aluminum powder, carbon depositor oil stain on the aluminum conductor surface, thus ensuring the cleanliness of the aluminum conductor surface; after annealing, the aluminum conductor is directly discharged into air by a big idlerpulley for naturally cooling without being cooled by cooling water and dried by a drying air duct, which prevents the tiny porcelain eye of the drying air duct from scraping the aluminum conductor surface, ensures the fineness of the aluminum conductor surface, improves paint film adhesiveness after coating, improves thermal shock, cut-through resistance and wire diameter uniformity and greatly lowers wire disconnection ratio in the production process; in addition, the invention lowers painting times, increases yield of unit time, effectively improves production efficiency and lowers production cost.

Owner:广州万宝漆包线有限公司

Rice noodle containing Chinese yam, and preparation method thereof

InactiveCN103284100AEasy to industrializeHigh nutritional valueFood preparationFood resourcesDioscorea polystachya

The invention belongs to the food field, and especially relates to a rice noodle containing Chinese yam, and a preparation method thereof. The rice noodle containing Chinese yam is characterized in that the raw materials of the rice noodle containing Chinese yam comprise 10-40 parts by weight of Chinese yam powder, 5-10 parts by weight of edible starch, 40-80 parts by weight of rice flour, and 5-10 parts by weight of a fruit and vegetable pulp. The preparation method of the rice noodle containing Chinese yam is characterized in that the method comprises the steps of peeling Chinese yam, protecting the color, drying, crushing to obtain the Chinese yam powder, immersing rice, milling to obtain the rice flour, adding the Chinese yam powder, the edible starch and the fruit and vegetable pulp, adding water, stirring, carrying out self-maturating extrusion, ageing, cutting, molding, drying, and packaging to obtain the rice noodle containing Chinese yam. In the invention, the food resource is widened, and the food has a shift in the nutrition level direction from an original simple meal energy providing effect.

Owner:PANZHIHUA UNIV +1

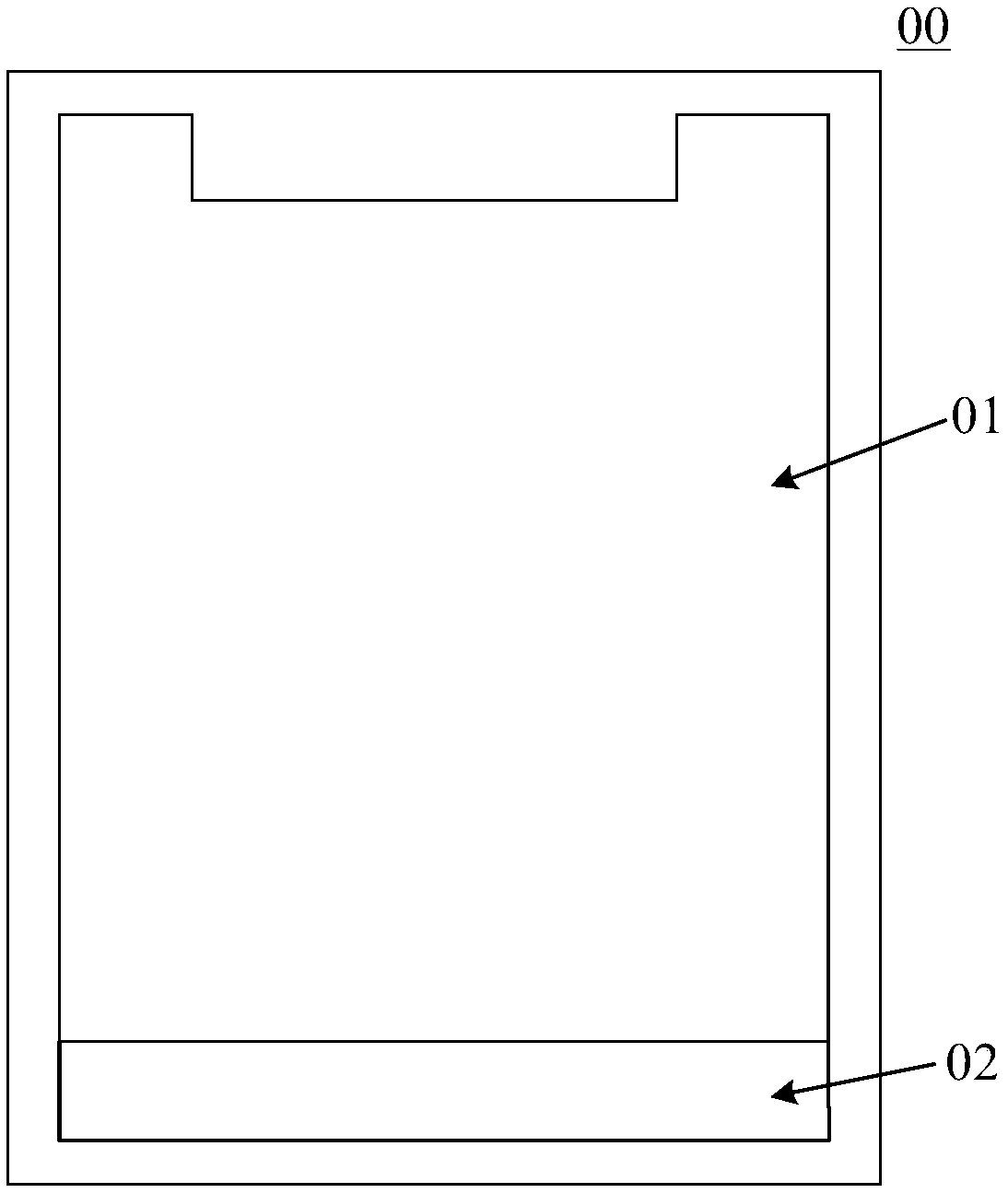

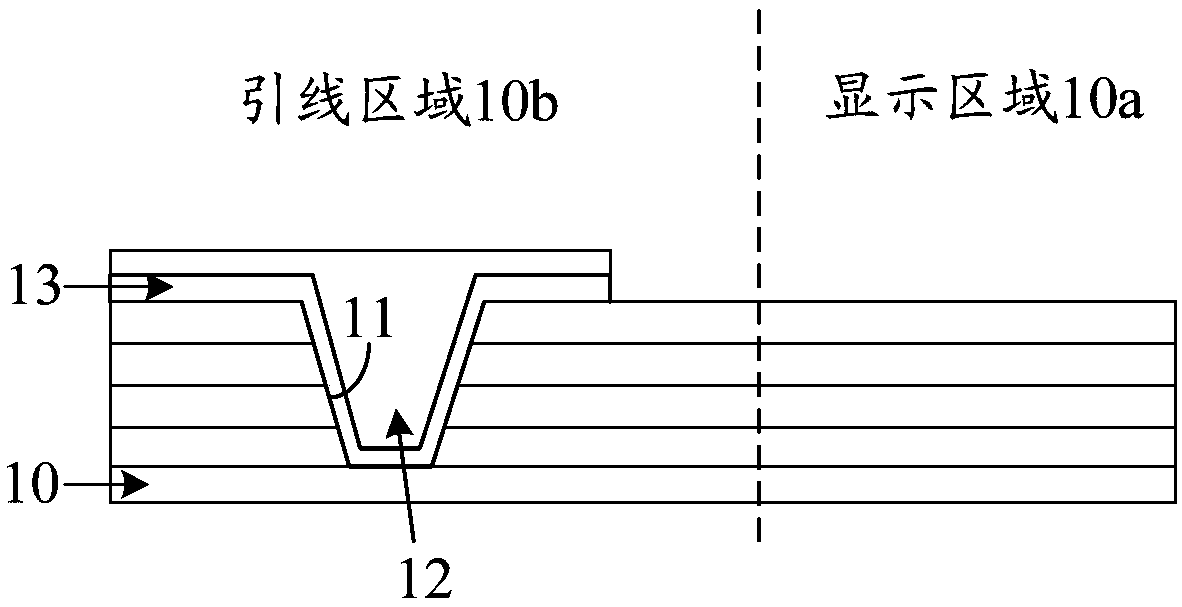

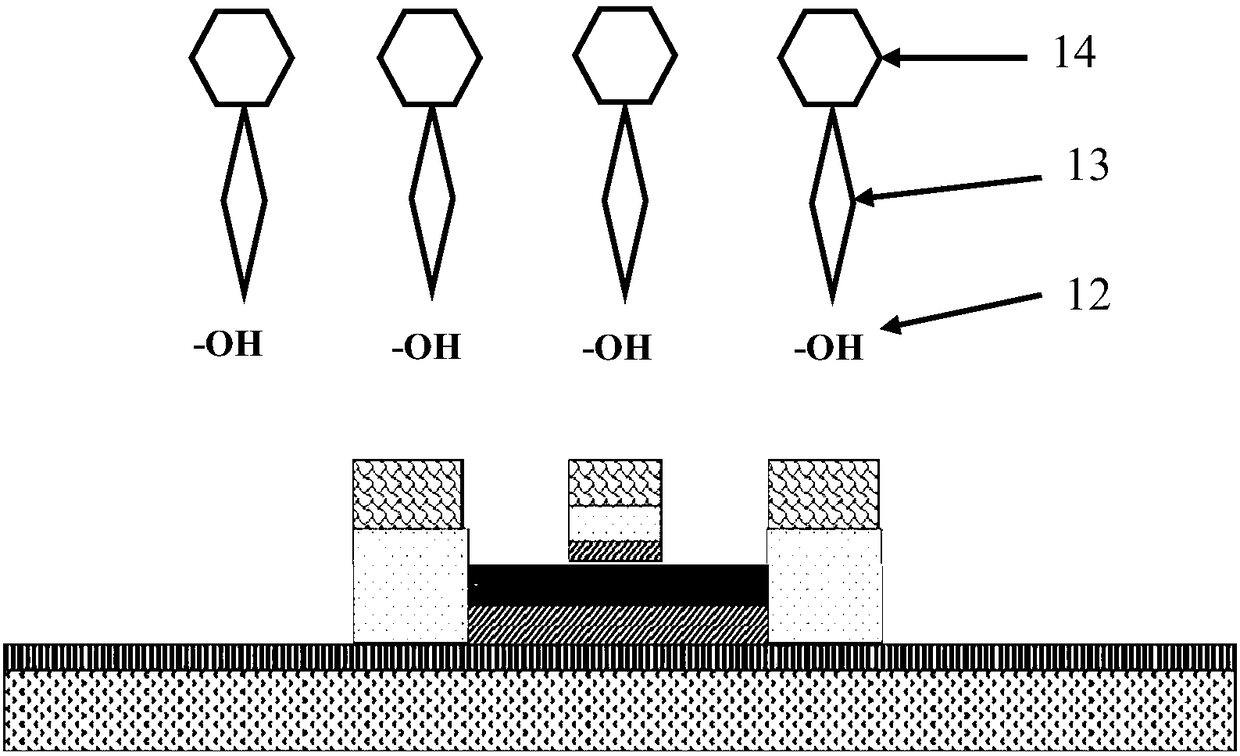

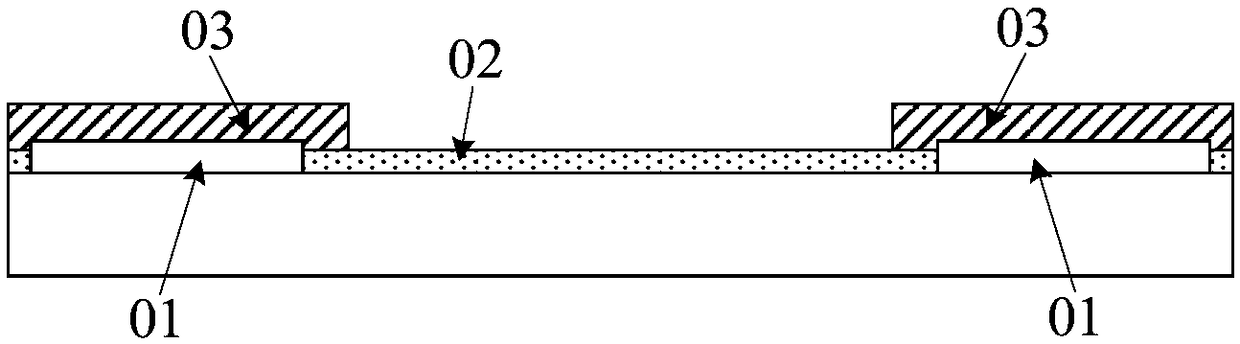

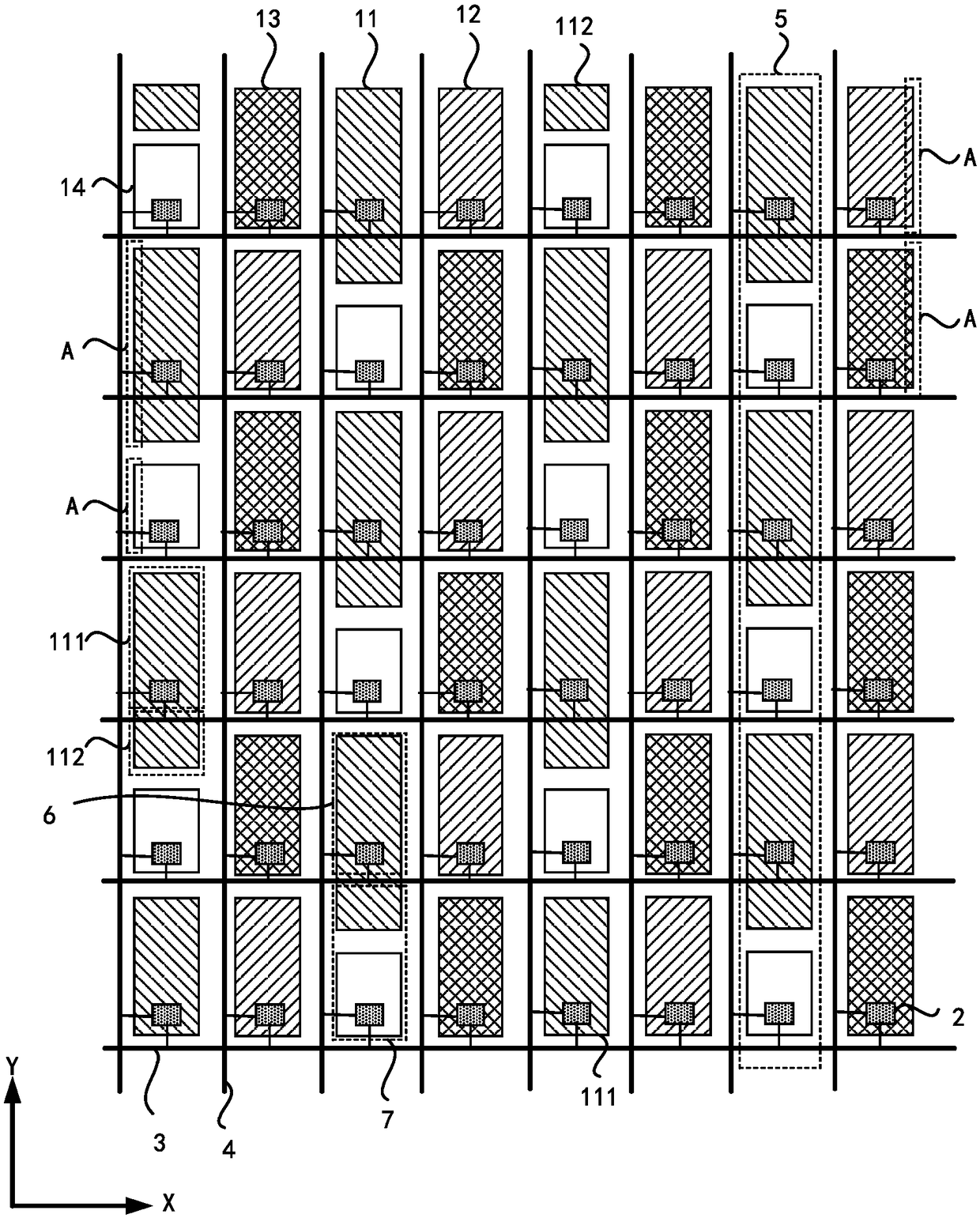

Array substrate as well as manufacture method and display device thereof

ActiveCN108899334AReduce disconnection rateResistivity effectSemiconductor/solid-state device detailsSolid-state devicesElectricityDisplay device

The invention discloses an array substrate as well as a manufacture method and display device thereof, belonging to the field of display technology. The array substrate comprises a substrate; the display area of the substrate is internally provided with a TFT (thin film transistor), the lead area of the substrate is internally provided with a through hole, and the through hole is internally provided with an organic filler; the lead area of the substrate is further internally provided with a connecting line, the connecting line is electrically connected with the TFT, and the materials for preparing the connecting line comprise a flexible conducting material. As the materials for preparing the connecting line comprise the flexible conducting material, the flexible conducing material has electrical conductivity and is difficult to fracture, therefore, when the lead area is bent, the probability that the connecting line is broken in the lead area is lowered, and the yield of display devices is effectively improved.

Owner:BOE TECH GRP CO LTD

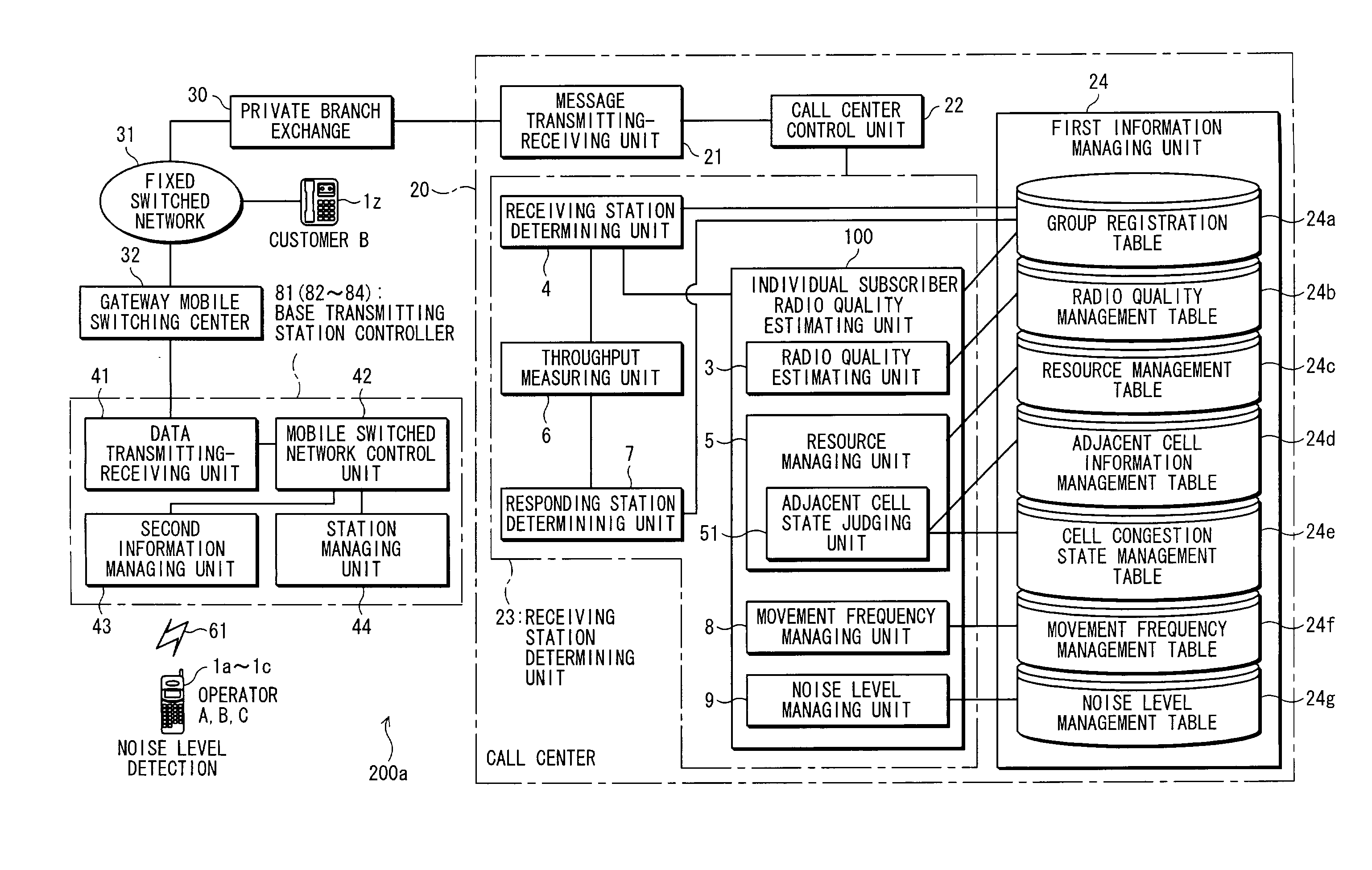

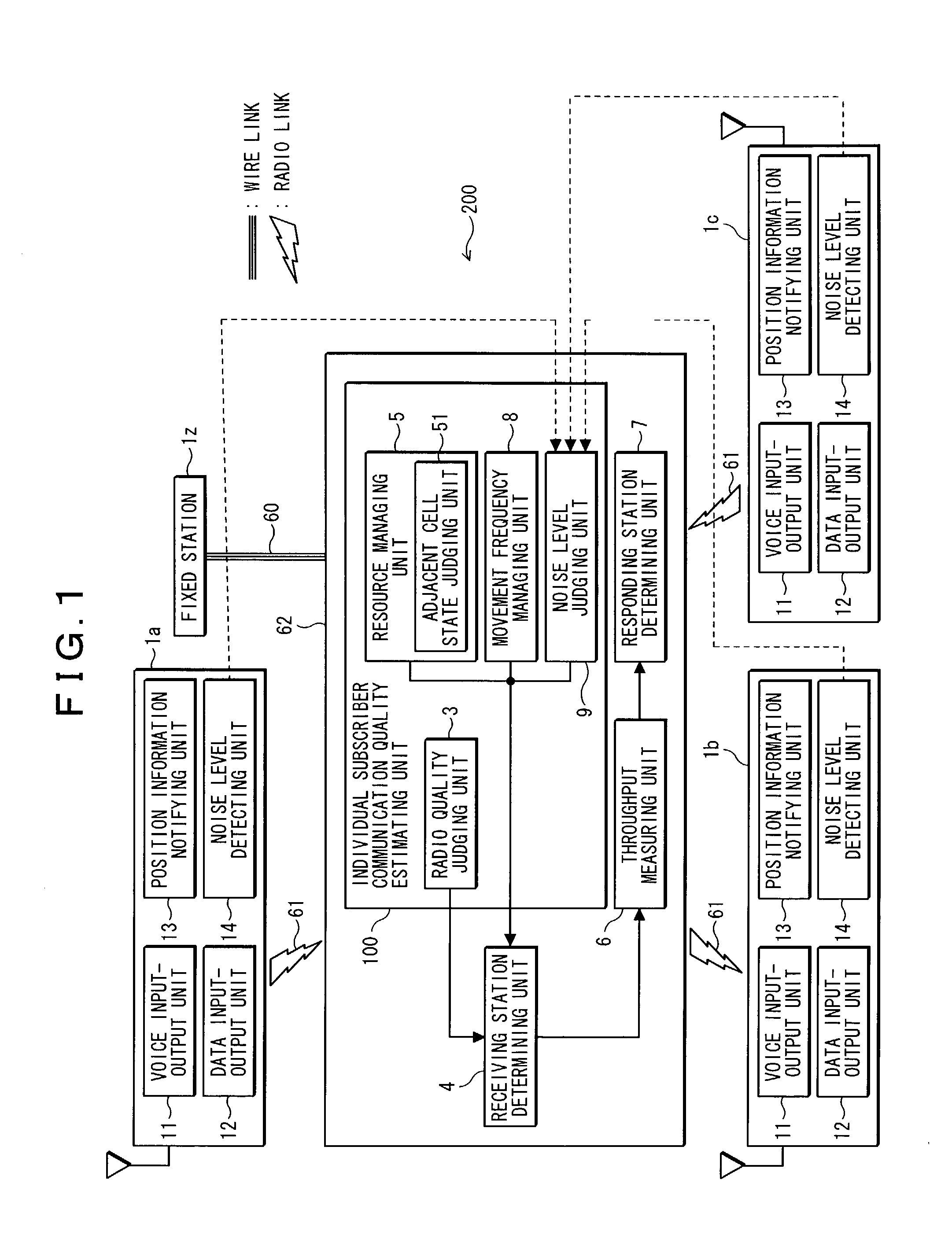

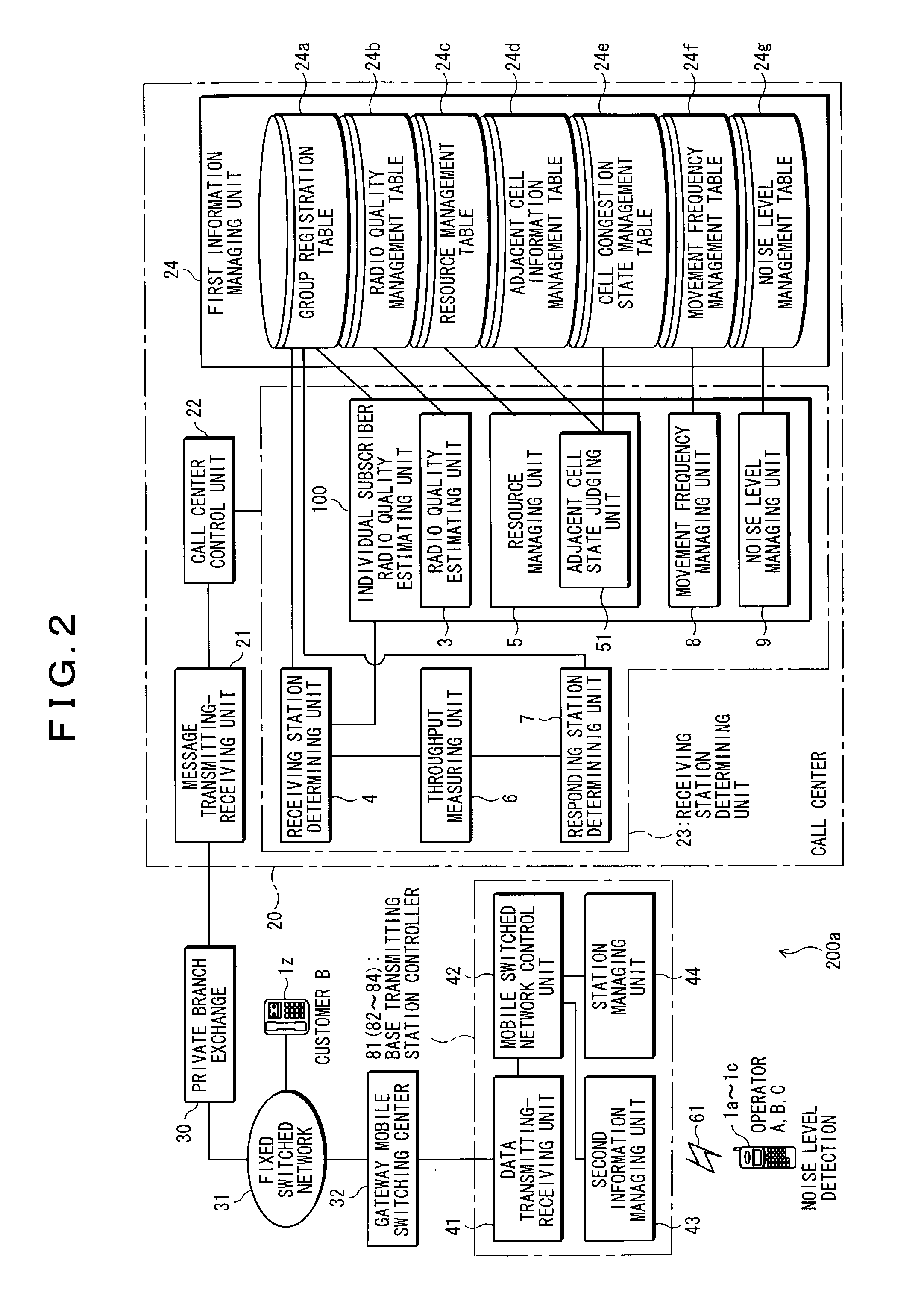

Incoming call radio distributing apparatus, mobile call center system and operator radio station

InactiveUS20030186654A1Reduce probabilityGood communication stateNetwork topologiesSpecial service for subscribersCommunication qualityCommunications system

An incoming call radio distributing apparatus provided in a communication system to distribute incoming calls to radio stations, which has a receiving station selecting unit selecting an available operator radio station for an incoming call among a plurality of operator radio stations for responding to incoming calls on the basis of states of communication of the plural operator radio stations, and an incoming call distributing unit preferentially connecting the incoming call to an operator radio station selected by the selecting unit. It is thereby possible to configure a mobile call center employing a mobile station as an operator station, provide station communications where calls are difficult to be disconnected, and high communication quality, a wide transmission band are available, and realize operator work not bound to a specific place.

Owner:FUJITSU LTD

Touch film layers, touch panel and touch display device thereof

ActiveCN108008862AImprove etching effectImprove the ability to resist disconnectionDigital data processing detailsSolid-state devicesOrganic filmDisplay device

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

MOS-pipe-based double-grid-regulation ultra-high-sensitivity biosensor

ActiveCN108169485AStable capacitance valueSmooth curveSemiconductor/solid-state device manufacturingNanosensorsCapacitanceLithographic artist

The invention discloses a MOS-pipe-based double-grid-regulation ultra-high-sensitivity biosensor, which is suitable for a series of early-stage tumour detection. The sensor is made from an SOI sheet,and a unique double-grid control structure is formed through ion implantation. The sensor is made via ultraviolet lithography combined with an NLD etching method and can detect a trace amount of a tumour marker immediately without labeling. Compared with a common sensor used for detecting current or conductance, the sensor can detect change of capacitance in a channel in an antigen-antibody combination process. A detection method related in the invention is stable and good in interference immunity, and can meet the requirements of detection range and sensitivity, has extremely outstanding performance particularly with respect to detection sensitivity, and can detect a sample with the lowest concentration in a range of 1 fg / ml-1 ng / ml.

Owner:WUXI PEOPLES HOSPITAL

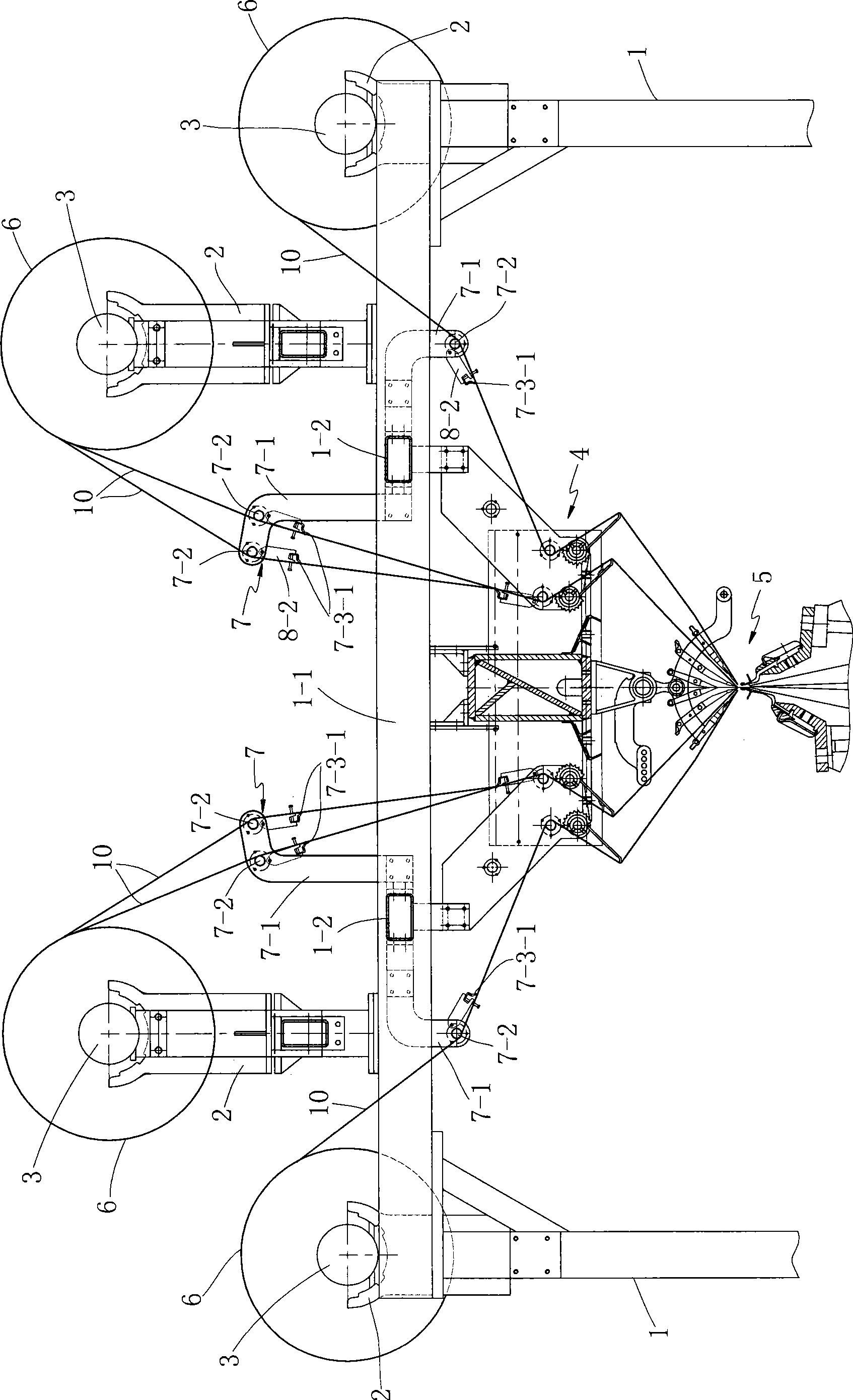

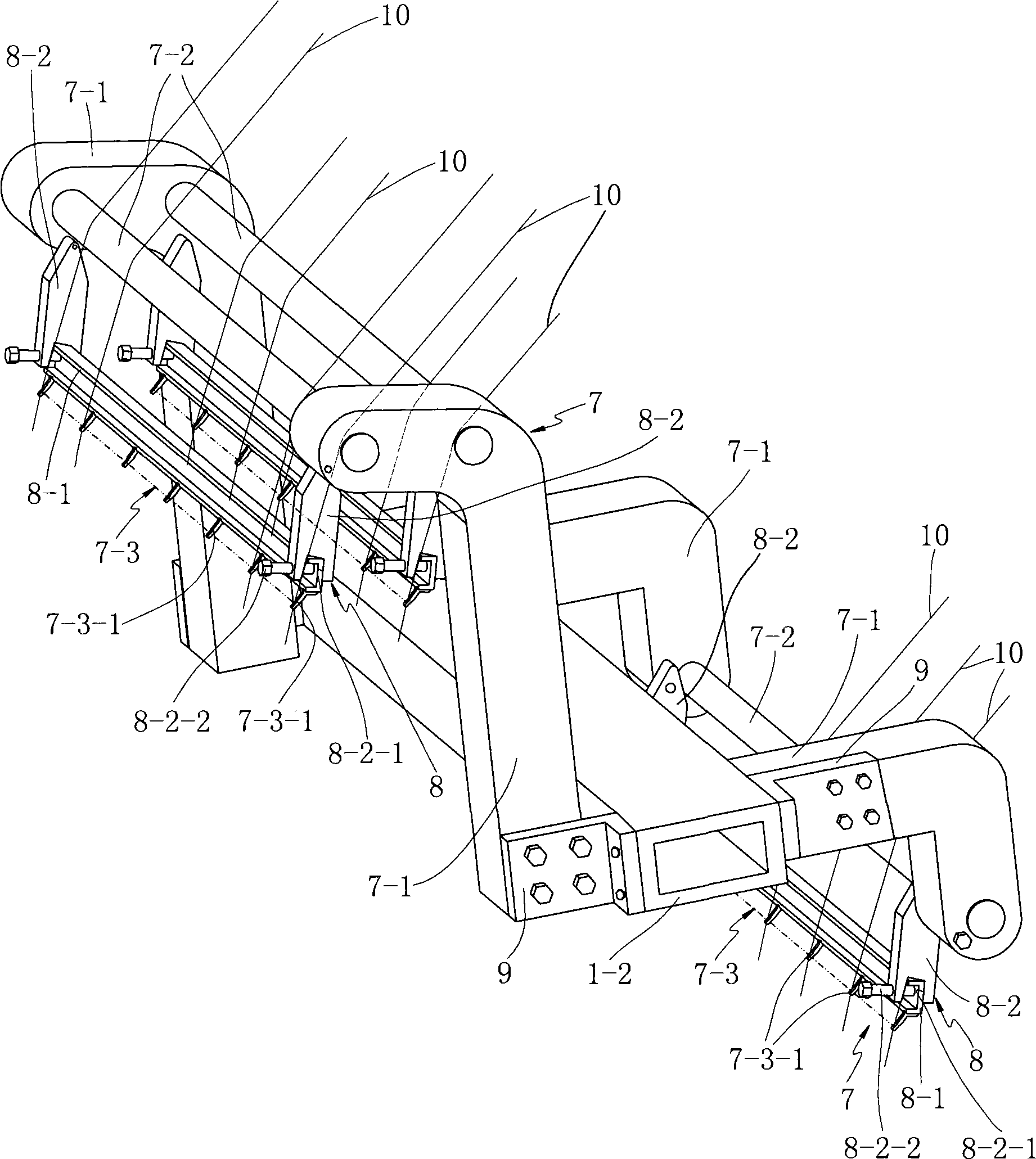

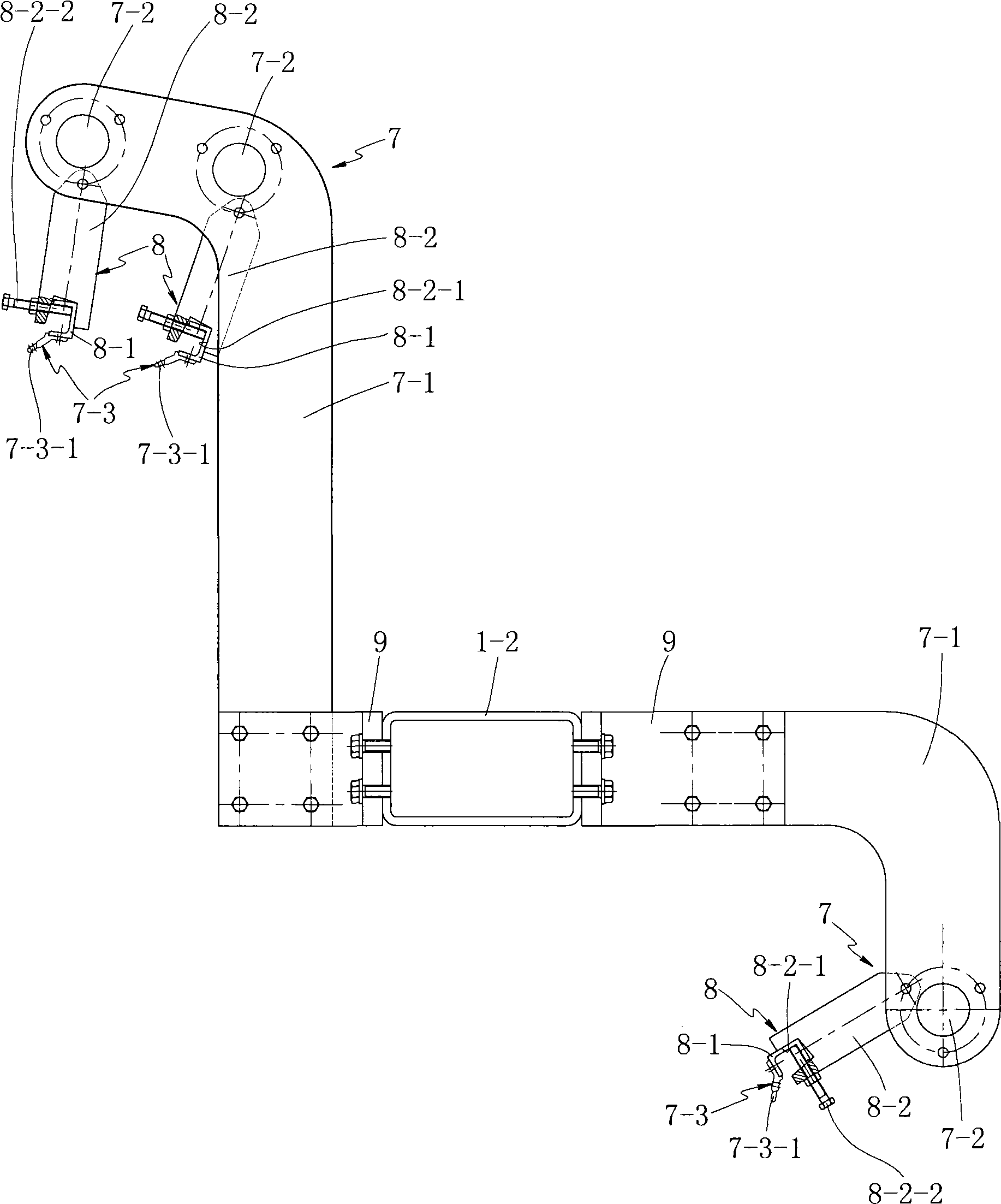

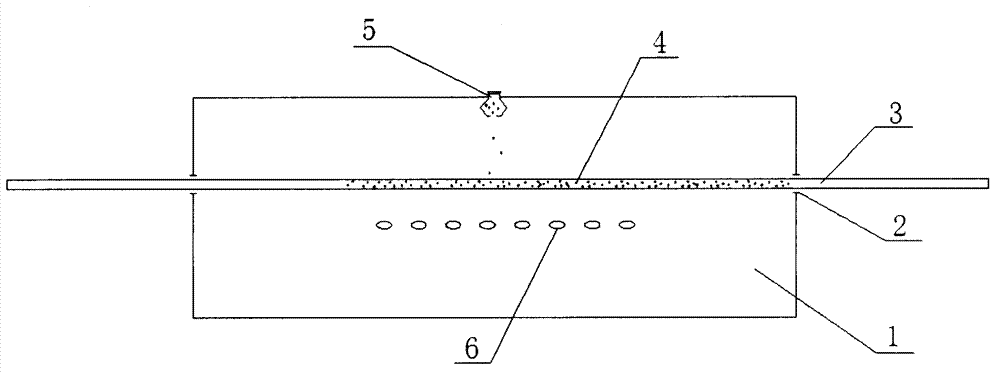

Warp let-off device of double rib warp loom

The invention discloses a loom let off device of a double neilsbed tricot machine which includes a plurality of pan head supporting seats fixed connected with transverse two sides of the double neilsbed tricot machine body, a plurality of warp beams connected with the pan head supporting seat and parallel each other, a yarn tension adjusting mechanism fixed connected with the machine body and a yarn ring mechanism, a plurality of pan heads are sleeved on the warp beam, a yarn dividing and guiding mechanism is set on corresponding each pan head respectively that fixed connects with the machine body and is composed of a yarn guiding roll seat set on transverse two sides of the machine body, at least one yarn guiding roll among the yarn guiding roll seats and at least one group yarn dividing needle composed of some yarn dividing needle fixed set on upper part or down part of the yarn guiding roll along the axis line direction. The double neilsbed tricot machine not only acts on tension action to yarn output from the pan head, but also easily finds yarn rupture and connects once more when partly yarn rupture, accordingly, the fabric quality can be ensured, productive efficiency is increased and the machine has better commercial prospect.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

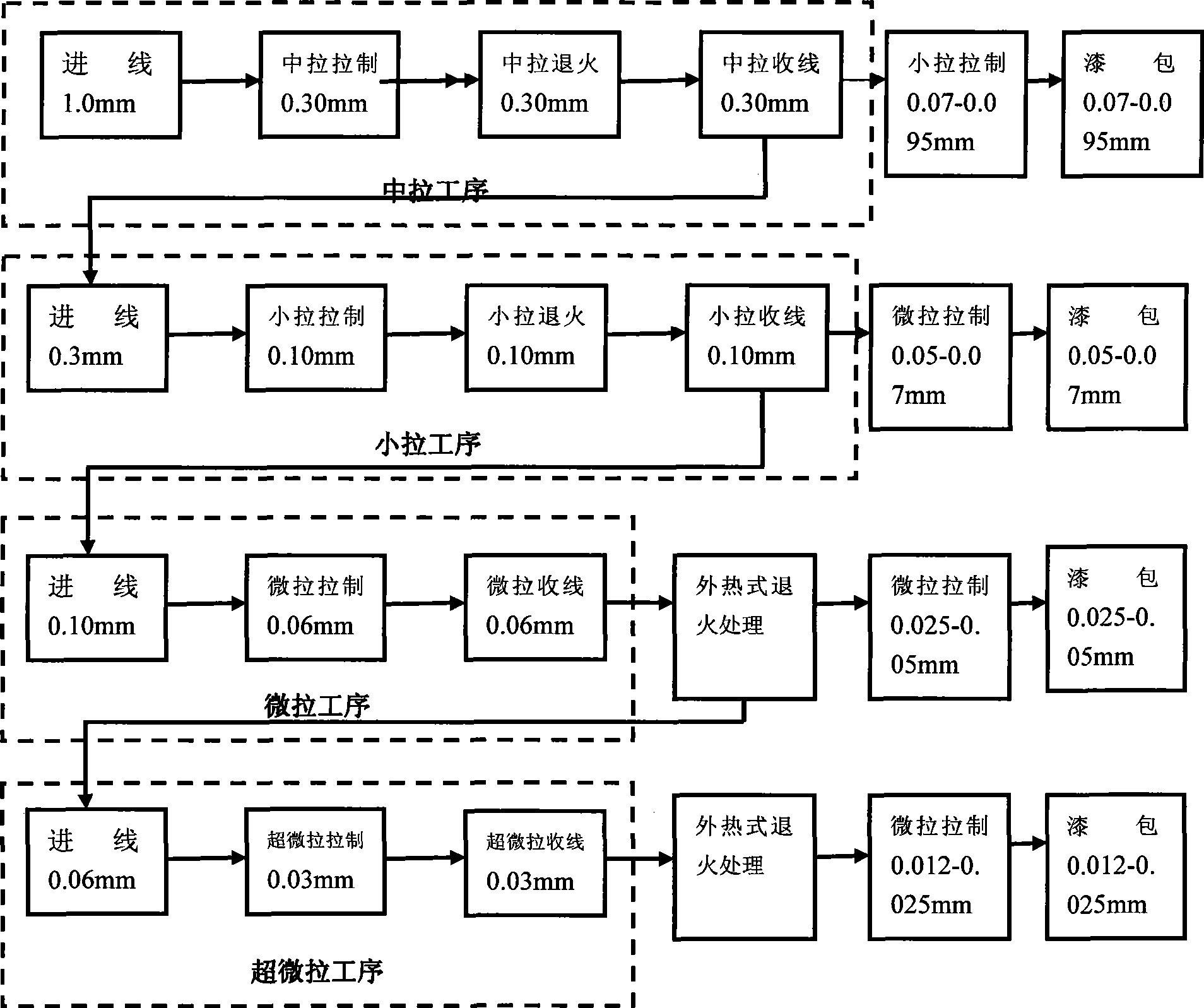

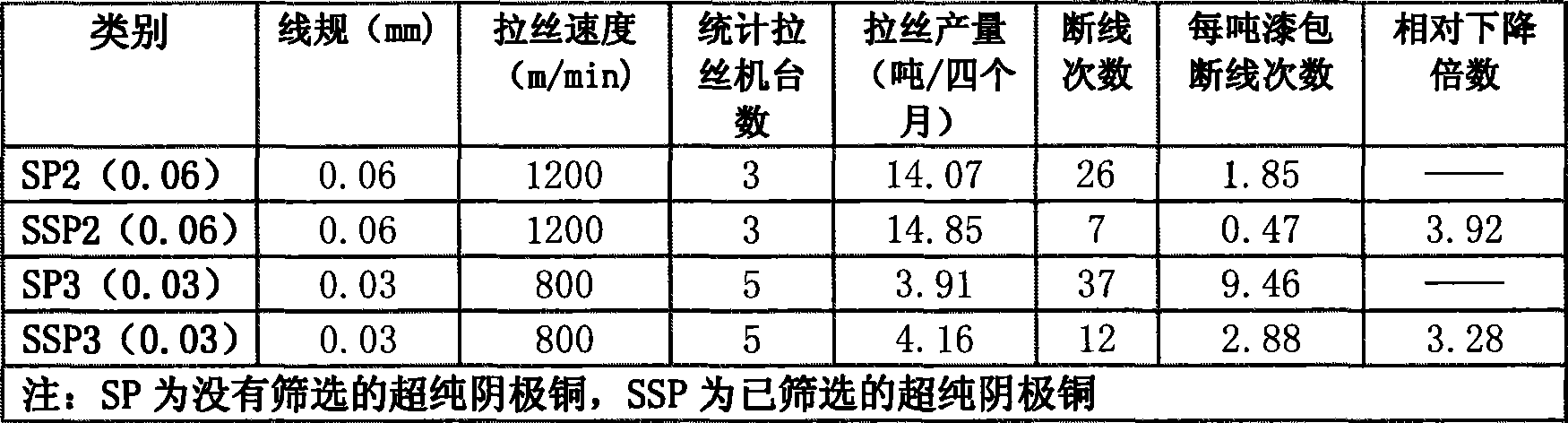

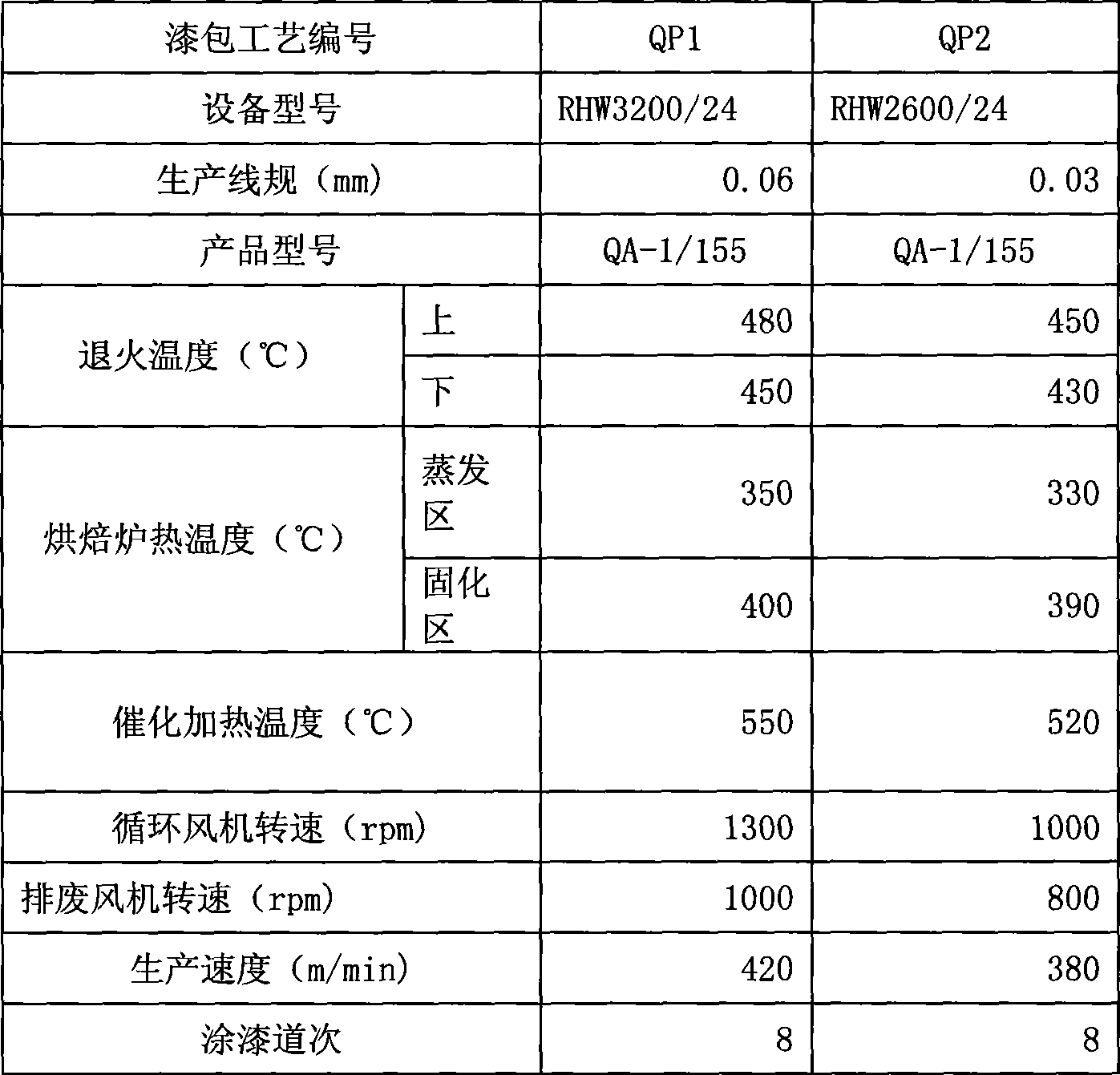

Technique for preparing ultramicro enamelling cuprum round line

ActiveCN101414498AReduce disconnection rateReduce the total deformation compression ratioMetal/alloy conductorsCable/conductor manufactureState of artCopper wire

The invention relates to a processing technology of an electromagnetic wire, in particular to a production process of an ultra-micro enameled copper round wire. The production process comprises a wire drawing procedure, an insulating layer coating procedure and an enameling procedure; in the wire drawing procedure, the copper wire goes through an intermediate drawing procedure, a small drawing procedure, a micro-drawing procedure and an ultra-micro drawing procedure, and an annealing technique is carried out in the micro-drawing procedure and the ultra-micro drawing procedure. The invention mainly provides the production process of the ultra-micro enameled copper round wire which can realize that the total unannealed deformation compression ratio of the copper wire is not more than 80% before enameling to further realize less micro-cracks of the drawn copper wire, even annealing components, lower wire drawing breakage and higher tensile strength of the ultra-micro fine wire. The process helps solve the technical problems of high breakage and low tensile strength of the enameled copper round wire in the prior art.

Owner:ROSHOW TECH

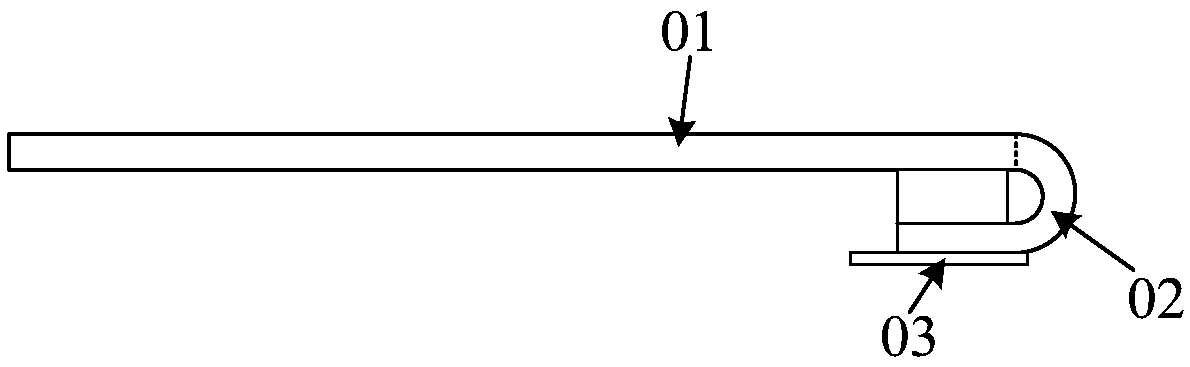

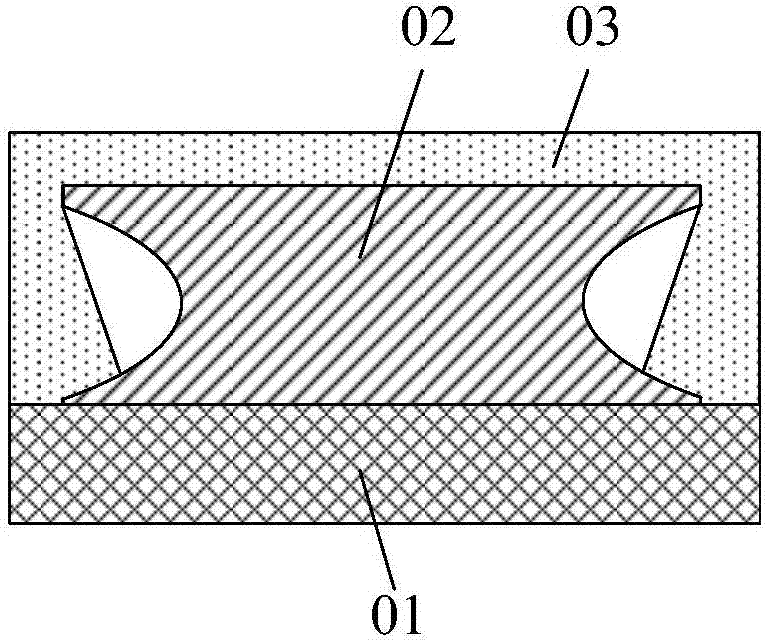

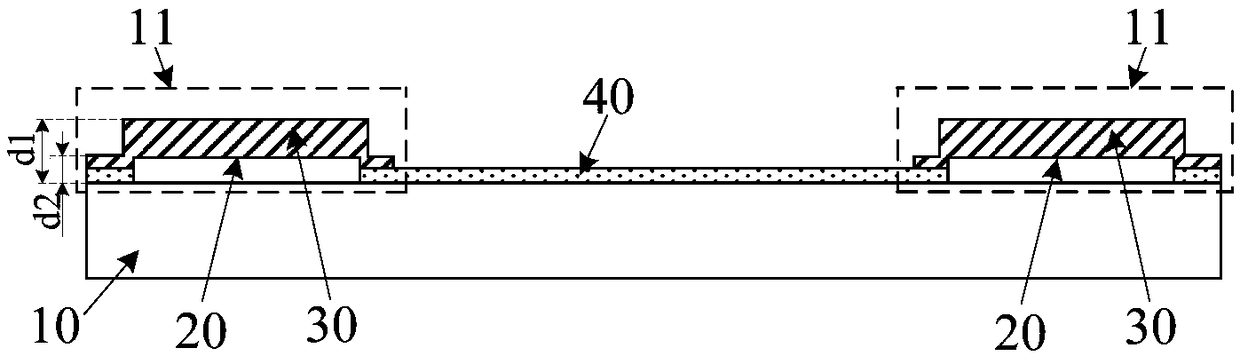

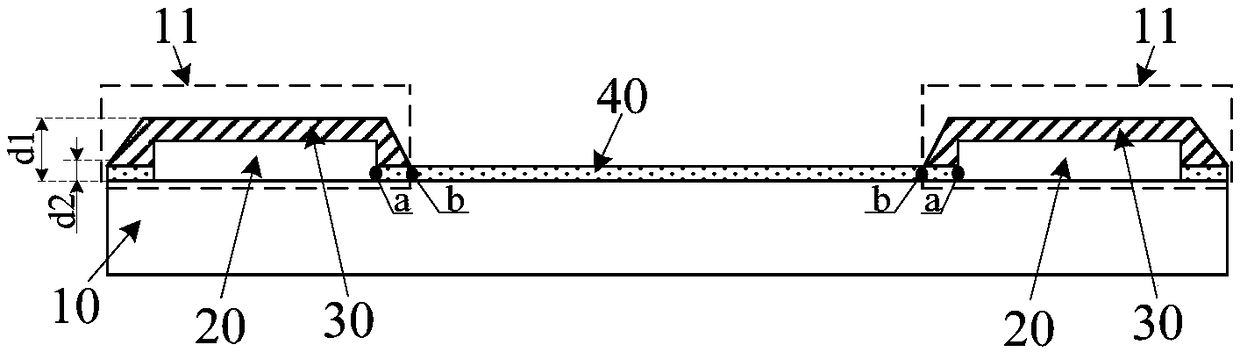

Flexible electronic device and manufacturing method thereof, and flexible display device

ActiveCN108807423AImprove protectionAvoid stress concentrationDigital data processing detailsSolid-state devicesEngineeringFlexible electronics

The invention discloses a flexible electronic device and a manufacturing method thereof, and a flexible display device, and belongs to the technical field of semiconductors. The flexible electronic device comprises a flexible substrate, wherein the flexible substrate is provided with a plurality of functional element regions arranged at intervals; each functional element region is internally provided with at least one TFT and a rigid protective layer for coating the exterior of the at least one TFT; a plurality of flexible wires are further arranged on the flexible substrate; the TFT in each functional element region is connected with the TFT in the other functional element region through at least one flexible wire, wherein the thickness of the central area of the rigid protective layer arranged in each functional element region is larger than the thickness of the edge area. The thickness of the edge region of the rigid protective layer in the flexible electronic device is small, so that the probability of breakage at the position where the flexible wire is in contact with the outer surface of the rigid protective layer is effectively lowered.

Owner:BOE TECH GRP CO LTD

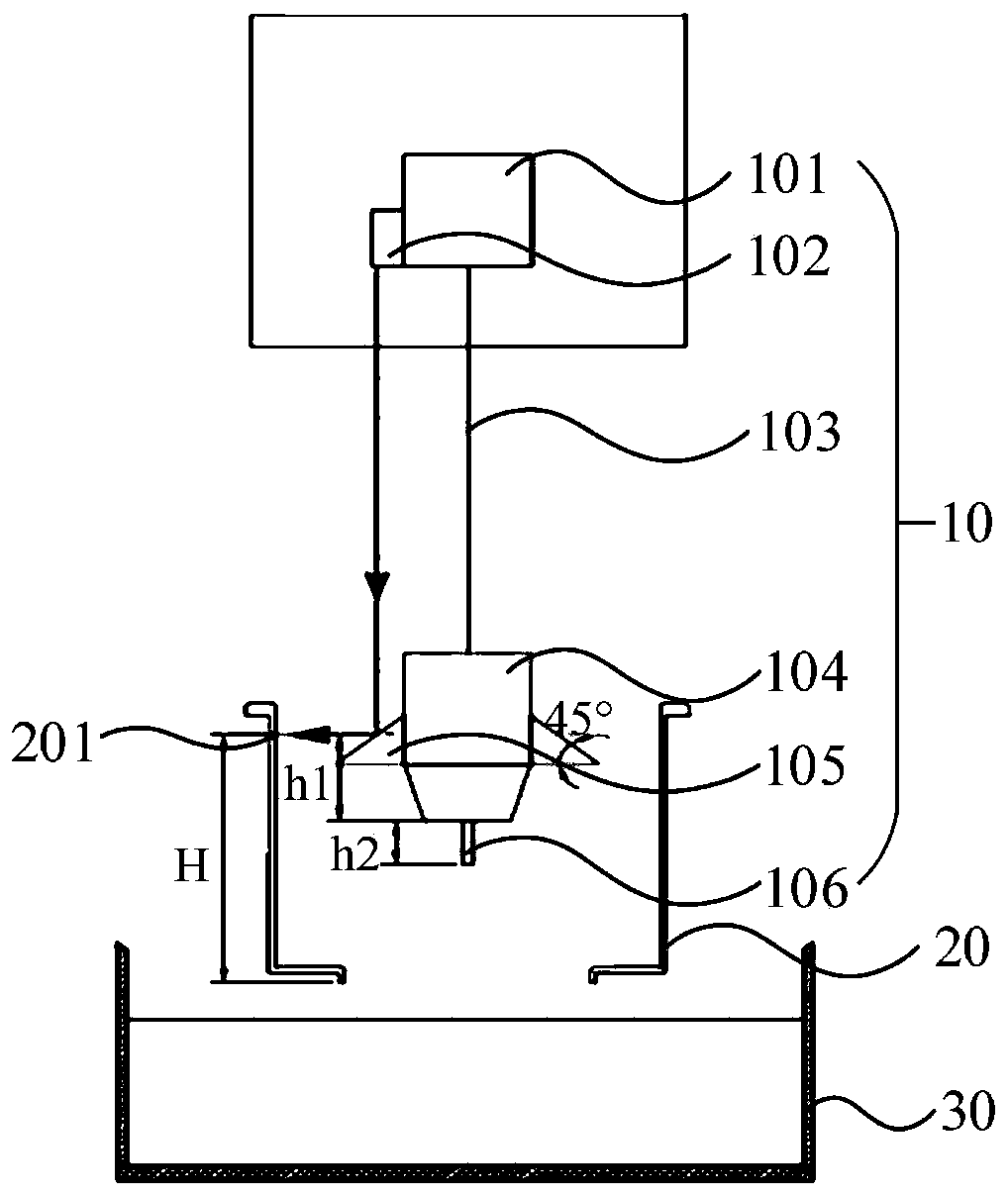

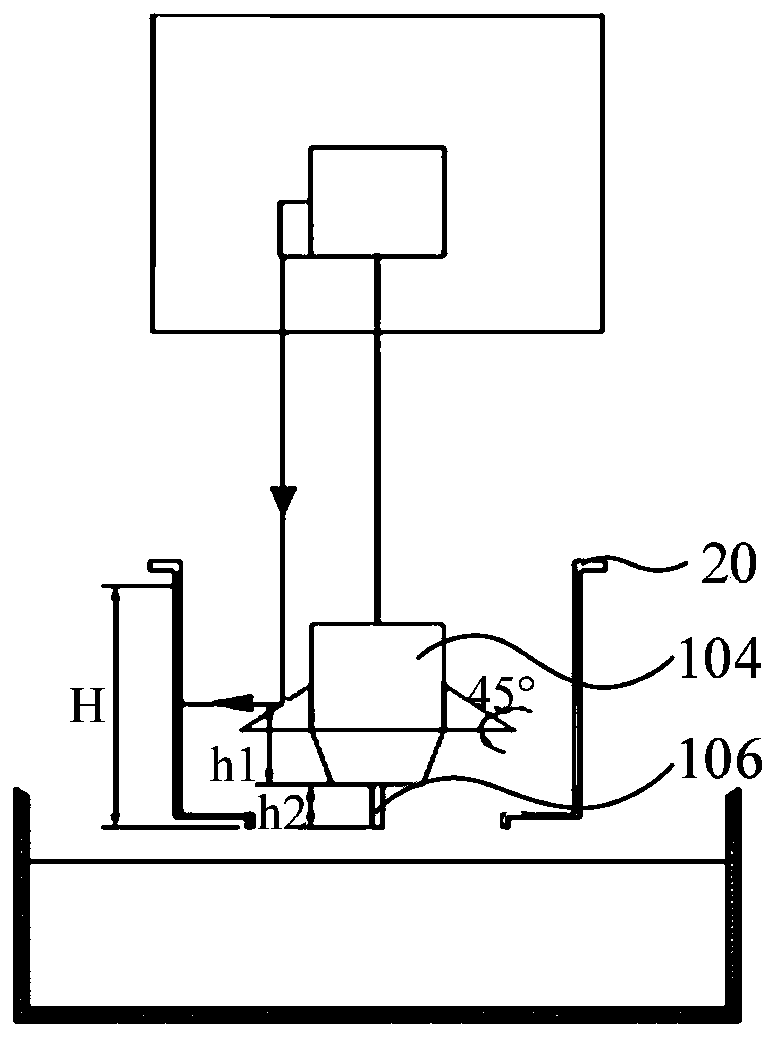

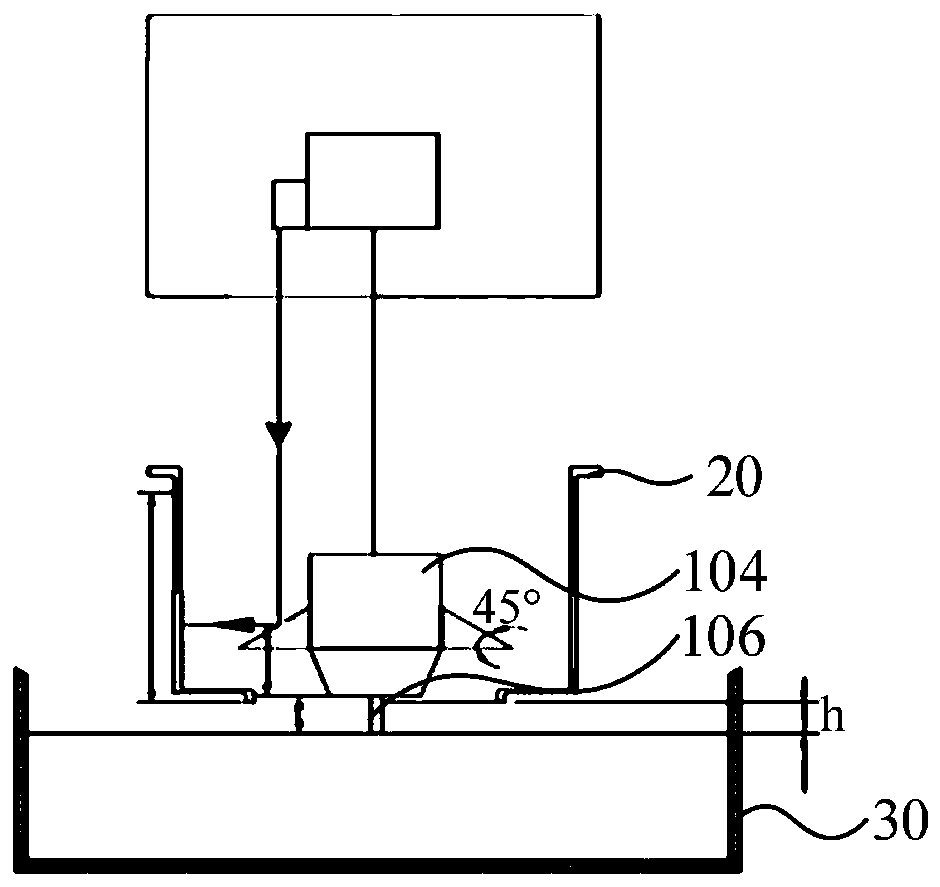

Liquid mouth distance positioning device and method, and single crystal furnace

ActiveCN110552059AHigh precisionReduce disconnection ratePolycrystalline material growthBy pulling from meltCrucibleLight beam

The invention provides a liquid mouth distance positioning device and method, and a single crystal furnace. The liquid mouth distance positioning device is arranged in the single crystal furnace, whena light beam emitted by a transmitter is reflected by a reflector and overlapped with a positioning hole, a counter weight is positioned to an initial position, and controlled to fall down a preset distance so as to make the counter weight reach a target position, a position of a crucible is adjusted so as to make the liquid level of a silicon solution be in contact with the lower edge of a positioning piece, and the distance between the liquid level of the silicon solution and the lower edge of a heat shield is a preset liquid mouth distance in this moment so as to achieve the purpose of positioning the liquid mouth distance. According to the liquid mouth distance positioning device, by controlling the falling distance of the counter weight, the liquid mouth distance is determined, position accuracy of the liquid mouth distance is high, and probability of crystal line disconnection in the process of crystal drawing is reduced.

Owner:NINGXIA LONGI SILICON MATERIALS

Method for cutting silicon wafer through 55-micrometer diamond wire

ActiveCN109808091AIncrease profitReduce processing timeWorking accessoriesFine working devicesMicrometerWire wheel

The invention relates to a method for cutting a silicon wafer through a 55-micrometer diamond wire. The method comprises the following steps that a cutting wire net is arranged in a cutting area between an upper wire wheel and a lower wire wheel, the wire net is in a Z shape, the distance between two wire guide wheels is M, the distance between the upper wire wheel and the lower wire wheel is N, and M is equal to M; tension and running speed of the cutting wire net, and the silicon bar motion speed are set; at the starting processing stage, the tension of the wire net is 8N, the workpiece motion speed is 2.3 to 2.4 mm / min, the diamond wire moving speed is 600m / min, and cooling liquid is prepared; in the continuous machining process, the tension of the wire net ranges from 9 to 10 N, the workpiece motion speed is 2.4 mm / min, and the motion speed of the diamond wire is 1500 m / min; at the finishing stage, the tension of the wire net is 12 N, the workpiece motion speed is 1.0 mm / min, and the diamond wire motion speed is 1300 to 1500 m / min; cooling liquid flow is set, wherein at the starting machining stage, the flow is 50 to 55 kg / min, at the continuous machining stage, the flow is 500kg / min, and at the finishing stage, the flow is 50 to 55 kg / min; and the wire arch of the cutting wire net and cutting strength of the extremely thin wire are matched, and the wire breaking problem is solved.

Owner:WUXI ZHONGHUAN APPLIED MATERIALS CO LTD

Diamond-wire slicing method for sapphire sheets

InactiveCN103640097AReduce disconnection rateHigh surface flatnessFine working devicesLubricant compositionSapphireCrystal orientation

The invention provides a diamond-wire slicing method for sapphire sheets. A sapphire crystal is stuck on the workpiece surface with the C-axis or M-axis center line as the bottom face, and the cut plane is the A-plane; cutting the sapphire crystal with the diamond wire to obtain sapphire sheets, wherein the diamond wire diameter is 0.25mm, and the diamond particle size is 30 microns to 40 microns, the wire tension is 35N, the wire speed is 12m / s, the workpiece feeding speed is 0.25 mm / min, and the cutting liquid flow is 350 ml / s. The diamond-wire slicing method is used for mobile phone panels, certain adhesive is required to stick crystal bars on a workpiece clamp capable of being fixed on a slicer according to the specific crystal orientation, the high rotation speed of a wire roller is used for driving the diamond wire to perform high-speed moving cutting from specific lattice planes.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

Method for bonding crystal bar splicing seams

InactiveCN101914813AReduce the number of rootsReduce scrap lengthAfter-treatment detailsEngineeringRejection rate

The invention discloses a method for bonding crystal bar splicing seams, which belongs to the technical field of crystal rod bonding. The invention aims to solve the problem of providing the method, which can effectively reduce the disconnection rate, for bonding the crystal bar splicing seams. An adopted technical scheme is that the method is implemented according to the following sequence: a, preparing bars, namely arranged at least two shorter crystal bars in pairs to satisfy the length required by slicing machine processing; b, preprocessing selected crystal bars to ensure that the end face verticality of the crystal bars is less than or equal to 1.5 mm, and the end faces are clean without impurities; c, bonding the crystal bars, namely applying glue water to the end face of one of the crystal bars and butting the two crystal bars; d, processing the crystal bars after bonding, namely cleaning residual glue on the surfaces of the crystal bars, and standing the well-bonded crystal bars for 20 minutes; and e, repeating the third step and the fourth step to bond all the crystal bars arranged in pairs. The method can effectively reduce the disconnection rate and the rejection rate of the crystal bars, and improve the rate of finished products to a great extent, so the production cost is reduced, and the method can be popularized and applied to the crystal bar bonding before crystal bar slicing.

Owner:山西天能科技股份有限公司

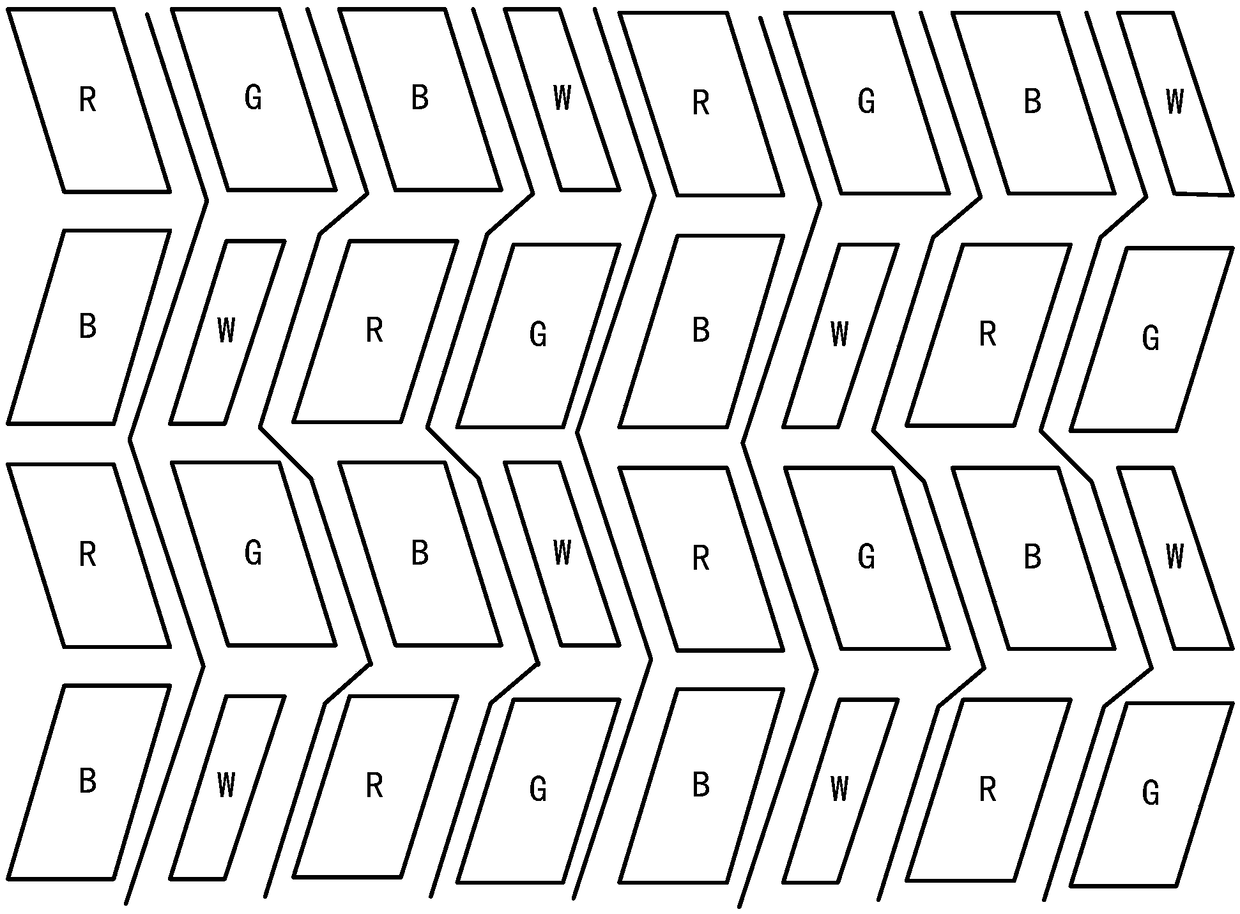

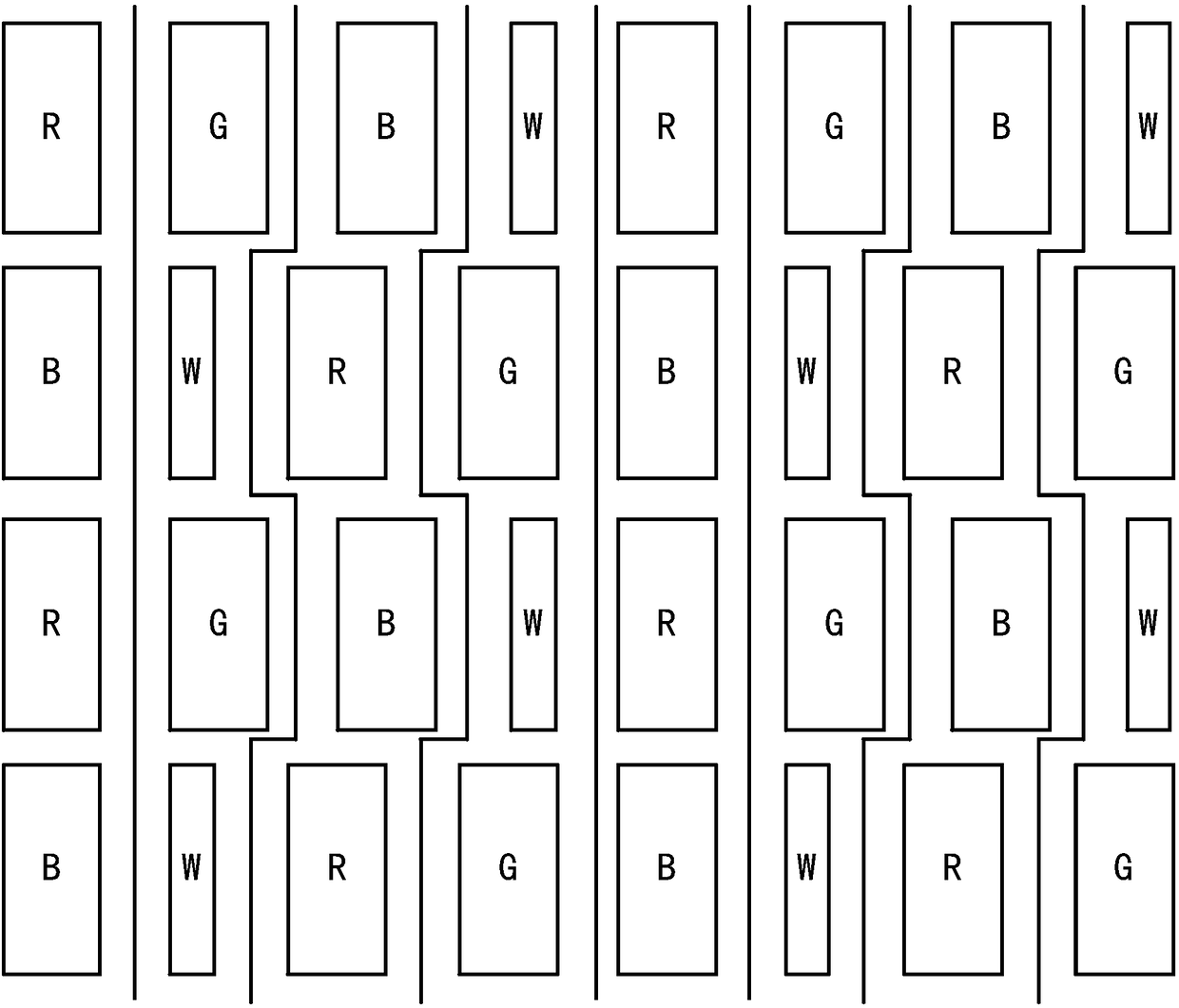

Display panel and display device

ActiveCN108227267ASimple arrangementReduce disconnection rateNon-linear opticsBreakage probabilityDisplay device

An embodiment of the invention provides a display panel and a display device. The display panel comprises white sub-pixel units, first sub-pixel units, second sub-pixel units and third sub-pixel units. Thin film transistors which correspond to the white sub-pixel units, the first sub-pixel units, the second sub-pixel units and the third sub-pixel units among each row of sub-pixel units are positioned on the same straight line; the widths of the white sub-pixel units are equal to those of the first sub-pixel units in row directions, the white sub-pixel units and the first sub-pixel units are alternately arranged in column directions, and the opening areas of the first sub-pixel units are larger than those of the white sub-pixel units. Compared with the prior art, the display panel and the display device in the embodiment of the invention have the advantage that the display panel and the display device in the designs are favorable for reducing the bending frequencies of partial data cables and accordingly are favorable for reducing the breakage probability of data cables in manufacturing procedures.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

High-efficiency production method of safety braid

ActiveCN104674567AEasy to operateHigh yarn stabilization efficiencySafety beltsAuxillary apparatusYarnAfter treatment

The invention discloses a high-efficiency production method of a safety braid. The high-efficiency production method comprises the following steps: (1) receiving and inspecting raw materials; (2) pre-treating the raw materials; (3) stabilizing yarns; (4) threading the yarns; (5) changing the yarns, and braiding; (6) preparing a dyeing solution; (7) carrying out dyeing pretreatment; (8) carrying out dyeing and color fixation; (9) carrying out dyeing after-treatment; (10) detecting a finished product braid; (11) cutting the braid; and (12) packaging the braid, and warehousing the packaged braid. The high-efficiency production method has beneficial effects that the operability is high, the yarn stabilizing efficiency is high, the yarn stabilizing effect is good, the accuracy and the intelligence in positioning are realized, the orderliness in processing and production is realized, the fault rate of machines is reduced, the dyeing effect is improved, the relatively high dyeing degree and the relatively attractive appearance are guaranteed, and the service life of the safety braid is prolonged.

Owner:LANGXI FEIMA IND FABRICS

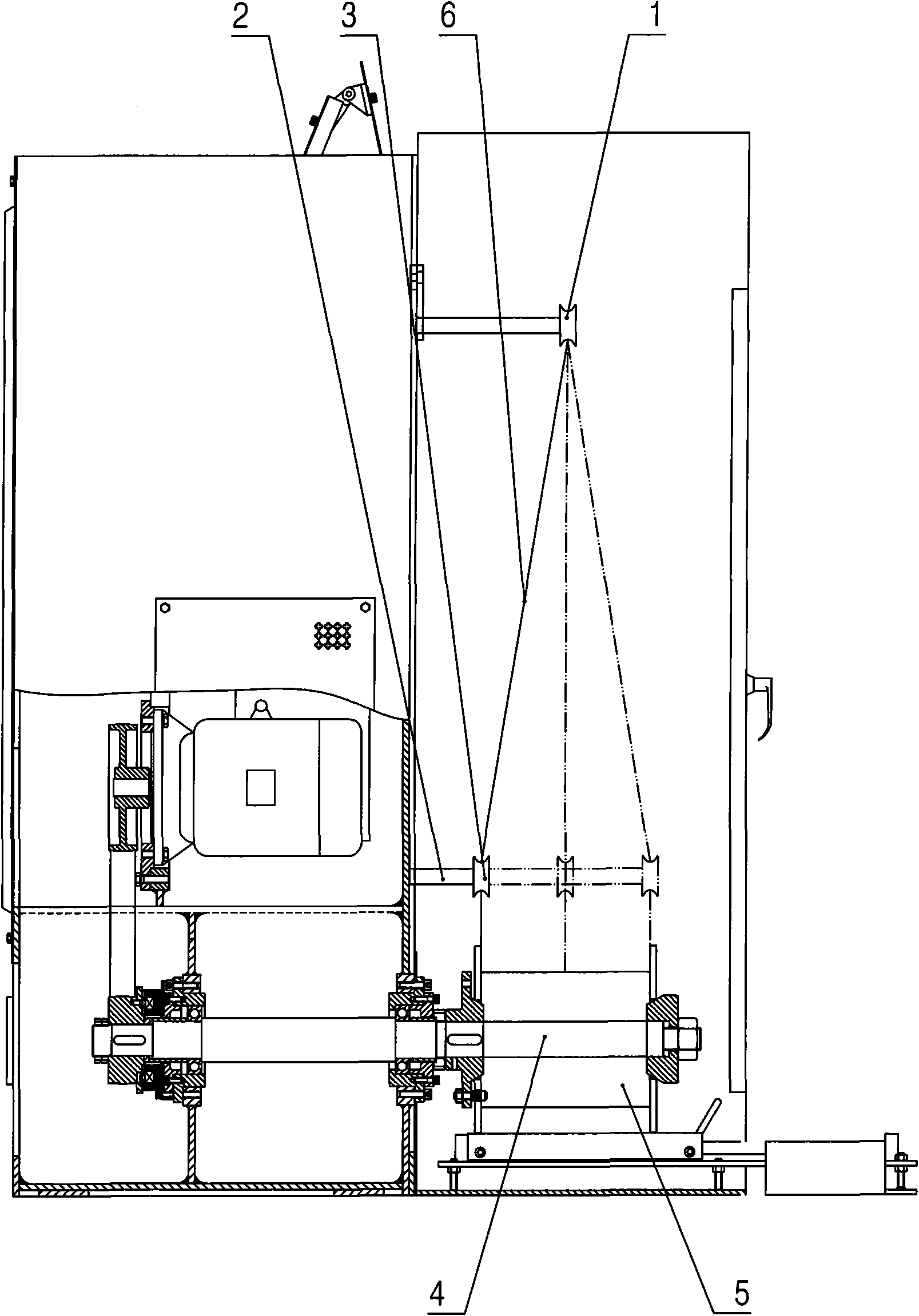

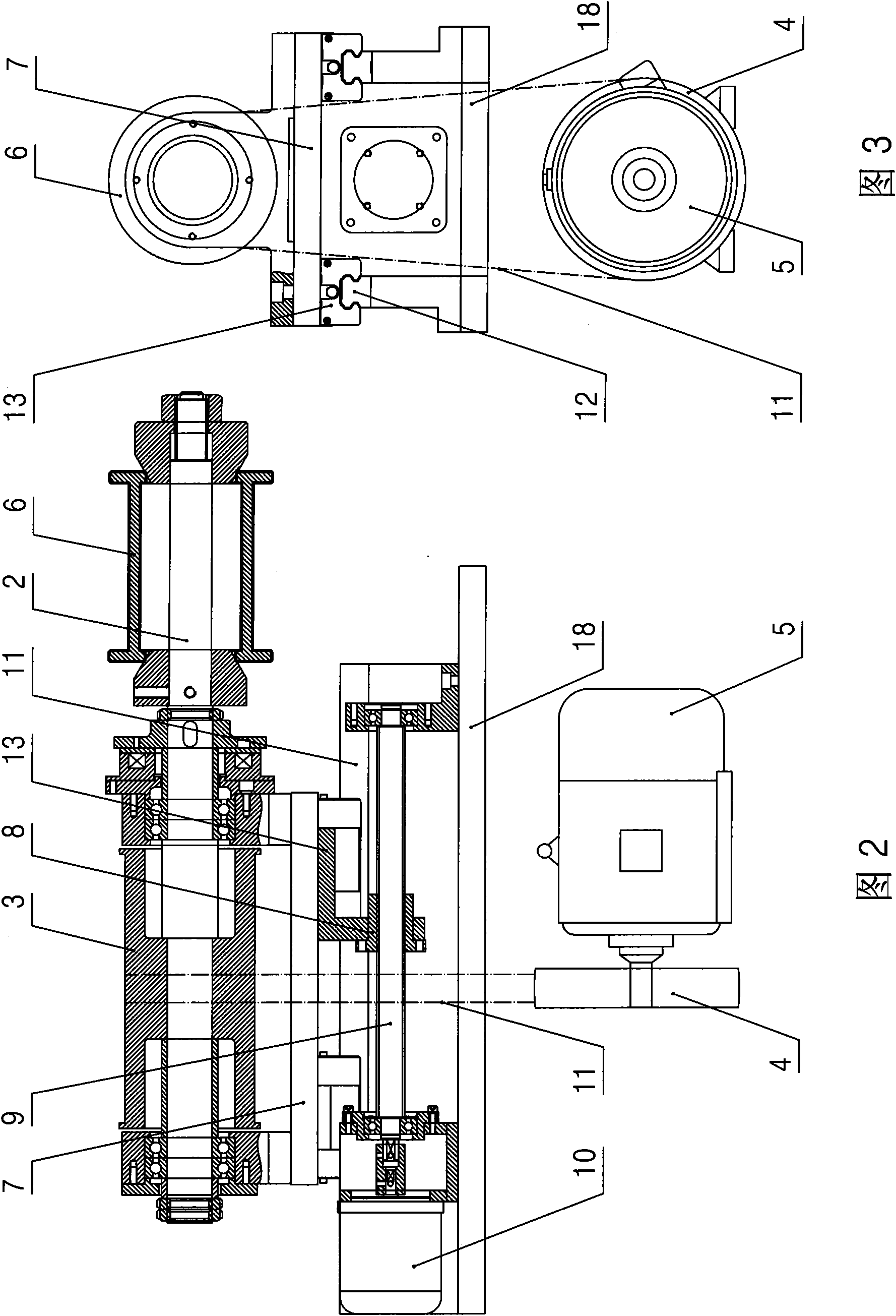

Method and device for fabricating self-rotating diamond wire saw

InactiveCN103173841AReduce disconnection rateEvenly distributedCellsElectrolytic coatingsPower flowTarget control

The invention relates to the technical field of diamond wire saw fabrication and especially discloses a method and a device for fabricating a self-rotating electroplated diamond wire saw. The method comprises the following steps of: firstly, enabling diamond particles pretreated previously to flow into an electroplating tank via a sand inlet; adjusting the airflow rate and the airflow direction of an airflow port, so that the diamond particles are evenly rotated in electroplating liquid; adjusting the current density of the electroplating liquid in the tank to a target control range, and turning on a metal wire movement control device when the temperature of the electroplating liquid in the tank reaches the target value; controlling the moving speed and the rotation direction of the metal wire and controlling the moving speed of the metal wire in the range of 2-50 m / min; and during the movement of the metal wire, solidifying the diamond particles on the surface of the metal wire evenly. A diamond wire which is even in diamond particle distribution and good in density distribution consistency is obtained through the process of the device; and the diamond wire is then subjected to processes such as thickening and on-line posttreatment.

Owner:何建久

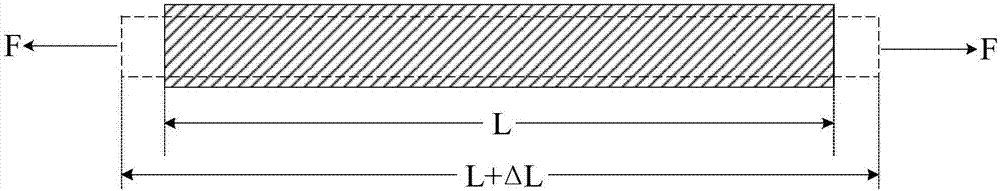

Ultra-fine aluminum magnesium alloy filament material and preparation method thereof

InactiveCN105489263AReduce lossReduce disconnection rateConductive materialMetal/alloy conductorsUltra fineUltimate tensile strength

The invention discloses an ultra-fine aluminum magnesium alloy filament material and a preparation method thereof. The ultra-fine aluminum magnesium alloy filament material comprises the following components of raw materials in percentages by weight: 2.8-3.8% of Mg, 0.2% of Mn, 0.1-0.2% of Zr, 0.1-0.2% of Cr, other impurities with the total content of smaller than 0.3% and the balance of Al. The preparation method comprises the following steps: smelting the raw materials of the aluminum magnesium alloy filament, carrying out flat leading rod casting to form a rod piece with the diameter of 8.5 mm, carrying out primary drawing to form an aluminum magnesium alloy filament material with the diameter of 5.0 mm, carrying out annealing, and preserving the temperature for 2-2.5 h; then carrying out secondary drawing to form a rod piece with the diameter of 1.16 mm, then carrying out secondary annealing, and preserving the temperature for 5-6 h; and then carrying out third drawing through a high-speed superfine wire drawing machine to form a finished product, aluminum magnesium alloy filament material with the diameter of 0.09 mm. Through the adoption of the preparation method disclosed by the invention, the strength and conductivity of the aluminum magnesium alloy filament are improved, the thread breaking rate and fineness of the filament material are also reduced, the performance of 5154-series aluminum magnesium alloy filament material is improved, and the quality of the product is improved.

Owner:BAISE UNIV

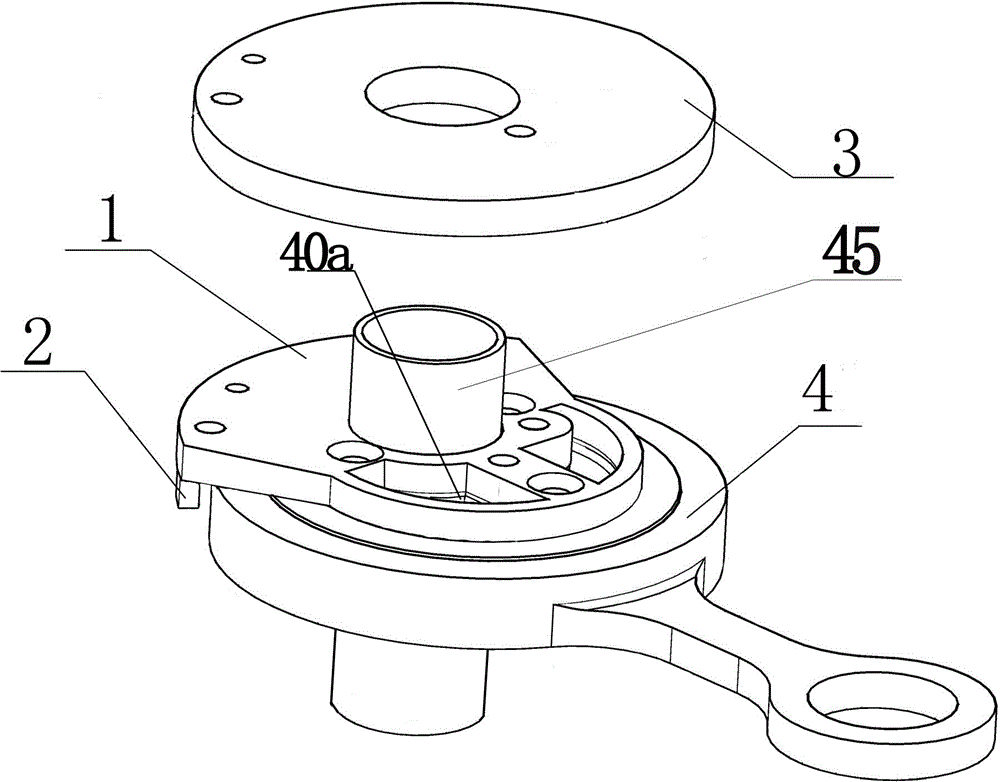

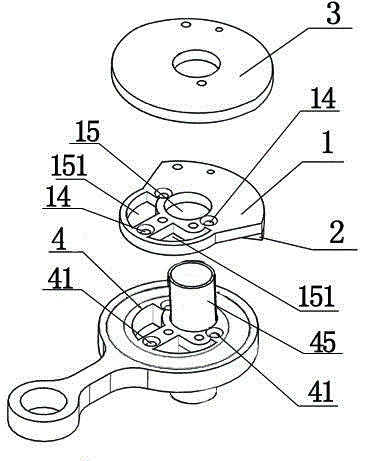

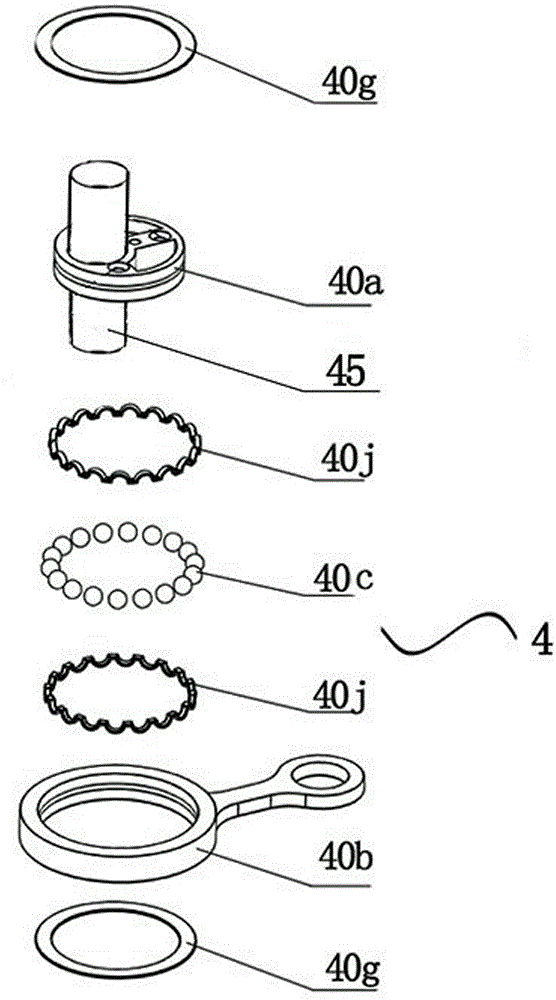

Computer embroider machine needle bar cam mechanism with balancing device

InactiveCN104480653AReduce vibrationVibration is reduced or even eliminatedEmbroidering machines apparatusEngineeringCentrifugal force

The invention discloses a computer embroider machine needle bar cam mechanism with a balancing device. The computer embroider machine needle bar cam mechanism with the balancing device comprises a needle bar transmission cam and a needle bar driving connecting rod, wherein the needle bar driving connecting rod, the needle bar transmission cam and a bearing between the needle bar driving connecting rod and the needle bar transmission cam are integrally designed and manufactured, the integrally manufactured component is an eccentric connecting rod bearing, the eccentric connecting rod bearing comprises an eccentric bearing inner ring, a cam cover plate is arranged on the eccentric bearing inner ring, a line-picking nylon cam is arranged on the cam cover plate, a balancing weight is arranged on the cam cover plate, and the cam cover plate and the balancing weight are used for balancing centrifugal force generated when the line-picking nylon cam and the eccentric connecting rod bearing run. The computer embroider machine needle bar cam mechanism with the balancing device has the beneficial effects that the assembly precision and the mechanical strength of the needle bar driving connecting rod are improved, the service life of an embroider machine head and the eccentric bearing between the needle bar cam and the line-picking nylon cam are prolonged, the reliability of the machine is improved, and the durability and the economical efficiency are improved.

Owner:浙江博盟精工机械有限公司

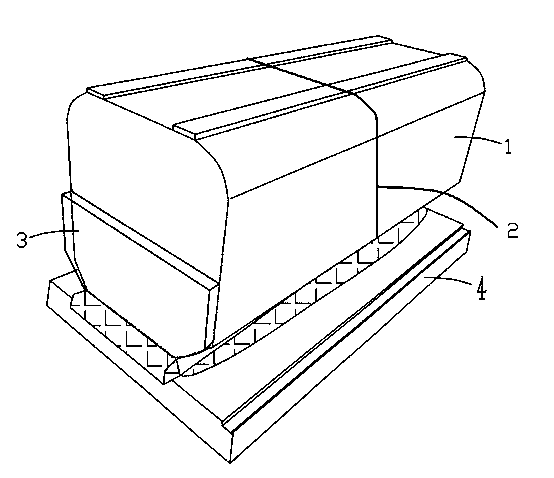

Silicon single crystal rod

InactiveCN102839419AImprove yieldReduce disconnection ratePolycrystalline material growthAfter-treatment detailsEpoxyWafering

The invention discloses a silicon single crystal rod. More than two silicon rod bodies are connected together through an end surface adhesion layer; the bottoms of the silicon rod bodies are adhered to a base through epoxy resin; baffles are arranged at the front end and the back end of each silicon rod body; the baffles are made of resin; and the baffles are all adhered to the silicon rod bodies through epoxy resin. According to the silicon single crystal rod provided by the invention, the fixed connection between the baffles at the two ends of each silicon rod body and monomers can protect the contact surfaces between chips at the two ends of each silicon rod body and the monomers in a cutting process, so that the yield is improved; and debris generated by butt end surfaces in the cutting process cannot fall down, so that the disconnection rate is reduced.

Owner:JIANGSU SHUNDA SEMICON DEV

Production technology of novel three-dimensional simulated hand-embroidered ornaments

InactiveCN101775718AReduce frictionEmbody roughnessEmbroidering machines apparatusViscoseEngineering

The invention relates to a production technology of novel three-dimensional simulated hand-embroidered ornaments, which comprises the following process steps: 1) binding a bottom lining in a machine frame of a computer plain embroidery machine, firstly embroidering the flower shape outline on the bottom lining, removing the bottom lining in the flower shape outline after pasting viscose glue on the periphery of the flower shape outline, gluing a non-woven lining capable of filling the flower outline, and gluing embroidered objects on the upper layer of the non-woven lining; 2) carrying out computer plate making according to flower shape patterns to be embroidered for obtaining a machine embroidering plate, and regulating the needle step length within a needle step length range between 3 and 35 mm during the plate making; 3) embroidering the flower shape patterns on the embroidered objects by the computer embroidery machine; and 4) trimming unnecessary threads of the front side of the embroidered objects after the embroidery is completed, and peeling off the non-woven lining of the back side of the embroidered objects. Compared with the prior art, the invention has the advantages that large needle hole board accessories are added on the original TMFD plain embroidery machine, so products have the function suitable for thick thread embroidery, the bold and generous effect of the hand embroidery can be embodied, the three-dimensional effect is strong, and patterns are lifelike, elegant and vivid.

Owner:利均刺绣(海宁)有限公司

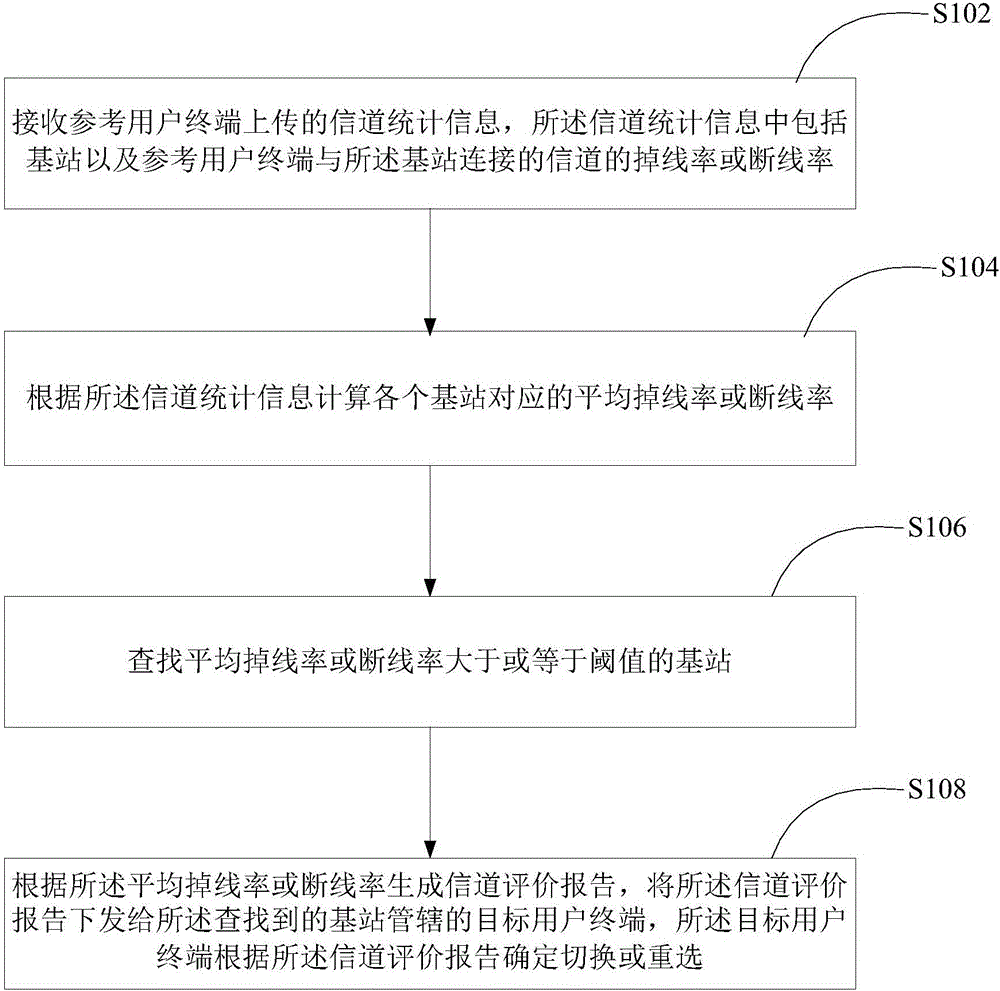

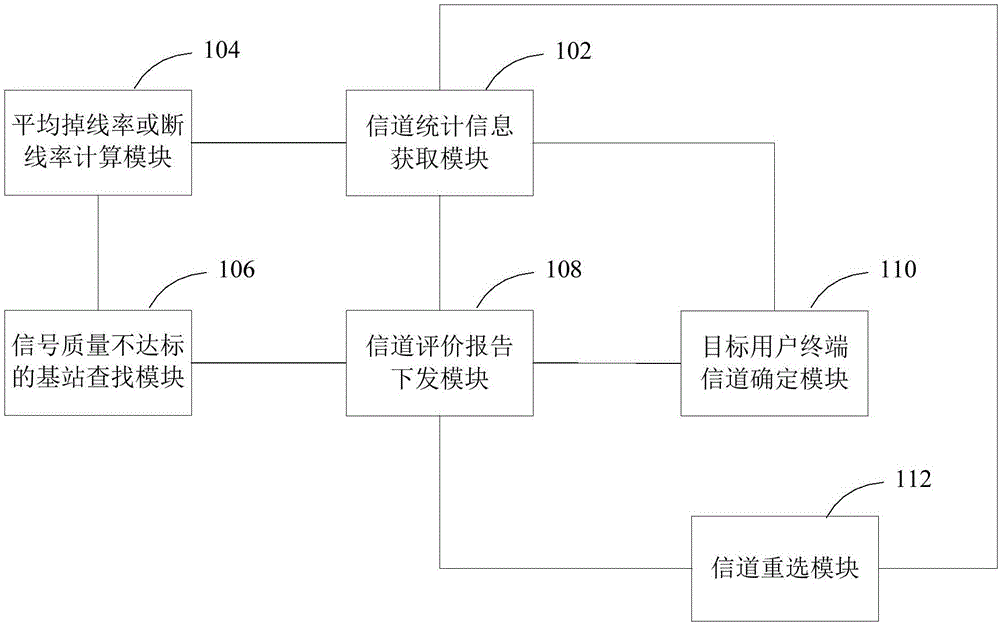

Base-station-signal-quality-based base station selection method and apparatus

ActiveCN106488495AGuarantee signal qualityReduce the probability of dropped callsAssess restrictionSignal qualityCommunication quality

The embodiment of the invention discloses a base-station-signal-quality-based base station selection method. The method comprises: channel statistic information uploaded by a reference user terminal is received, wherein the channel statistic information includes connection losing rates or disconnection rates of base stations and channels of connection between a reference user terminal and the base stations; according to the channel statistic information, average connection losing rates or average disconnection rates that correspond to all base stations are calculated; a base station with the average connection losing rate or disconnection rate larger than or equal to a threshold value is searched; and according to the average connection losing rate or disconnection rate, a channel evaluation report is generated and is issued to a target user terminal under jurisdiction of the searched base station, and the target user terminal determines switching or reselection based on the channel evaluation report. In addition, the embodiment of the invention also discloses a base-station-signal-quality-based base station selection apparatus. Using the method and apparatus provided by the invention, connection of a base station with a signal fault can be avoided and the communication quality of the terminal is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

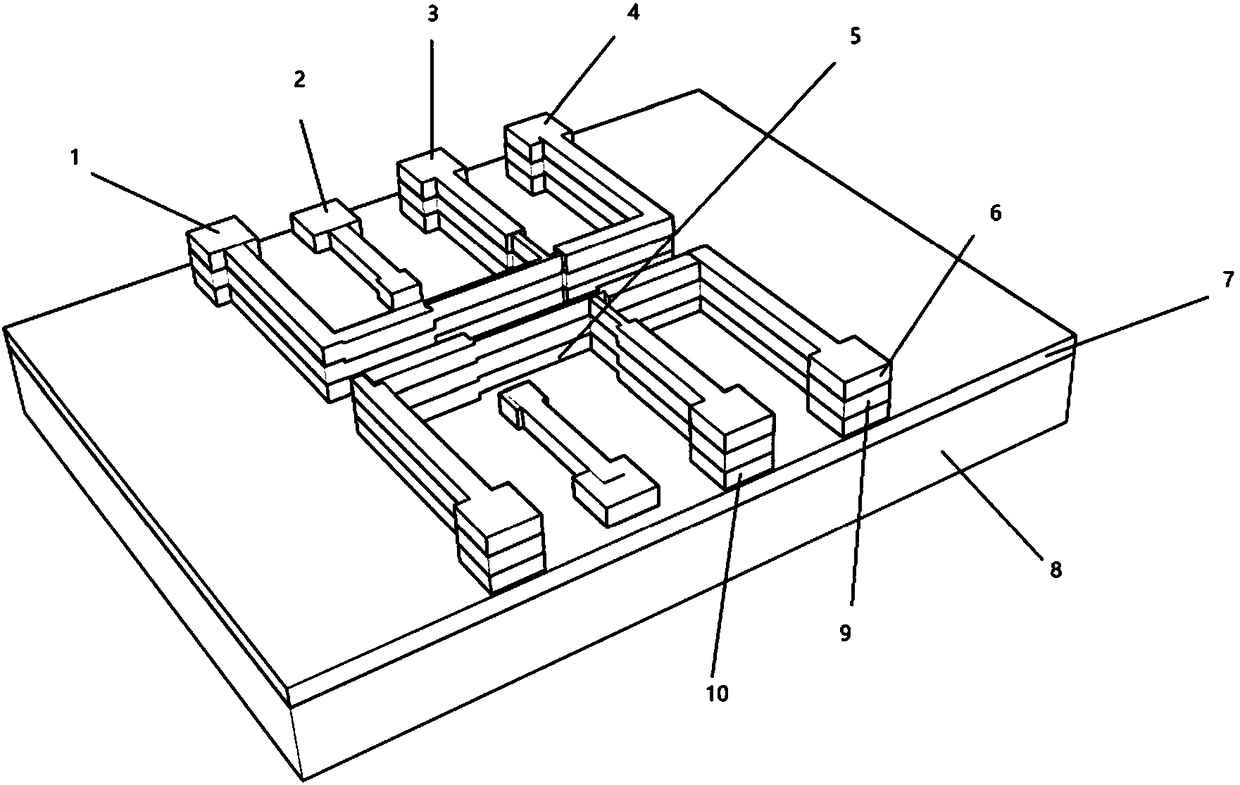

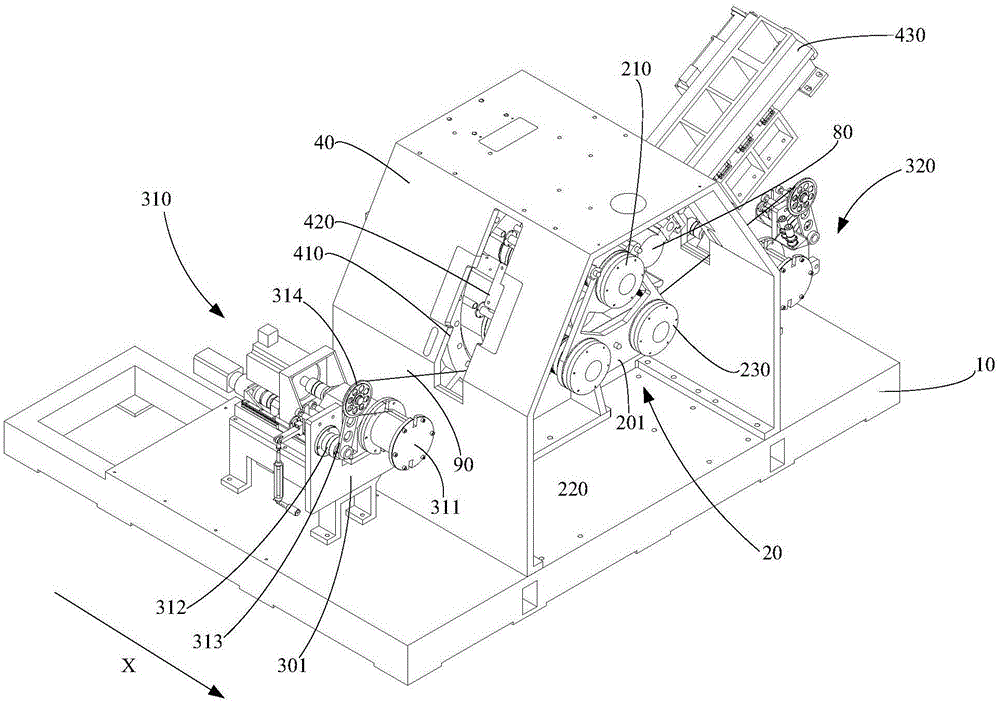

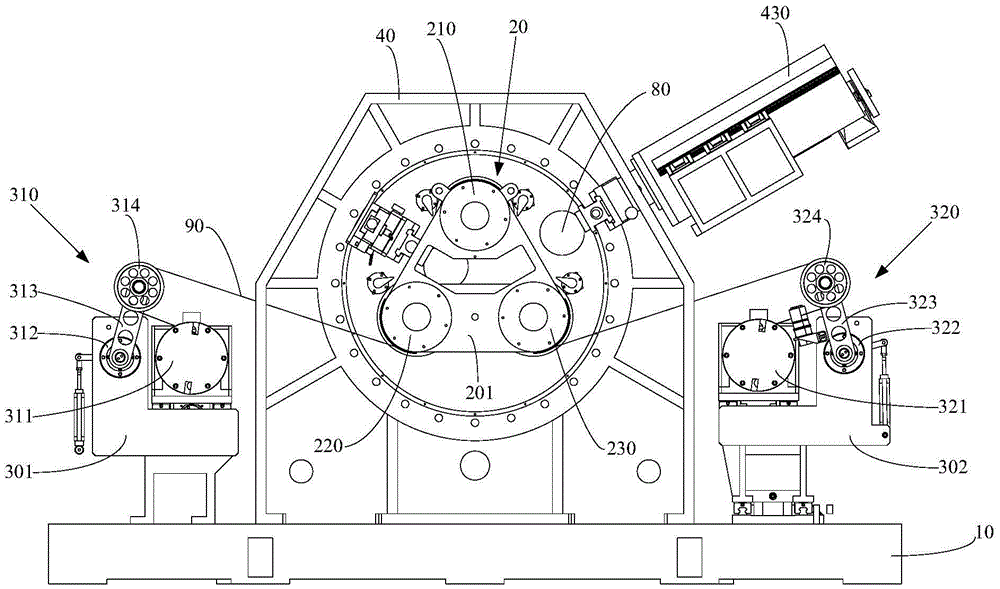

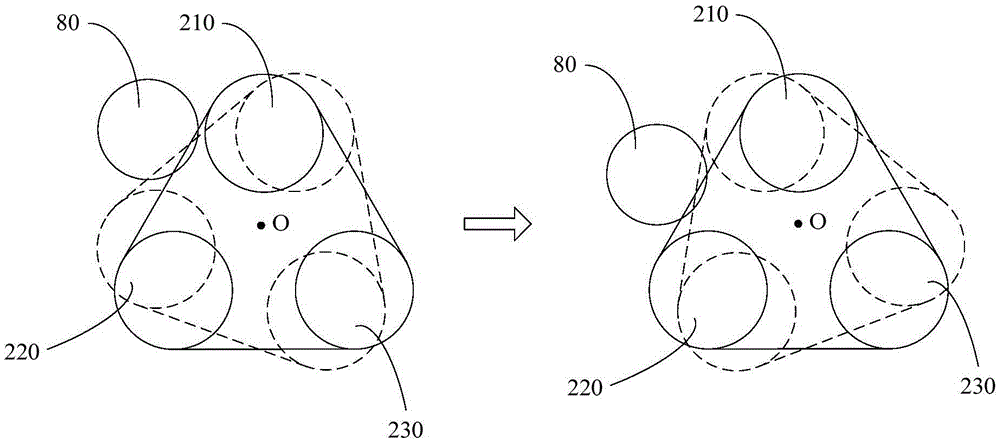

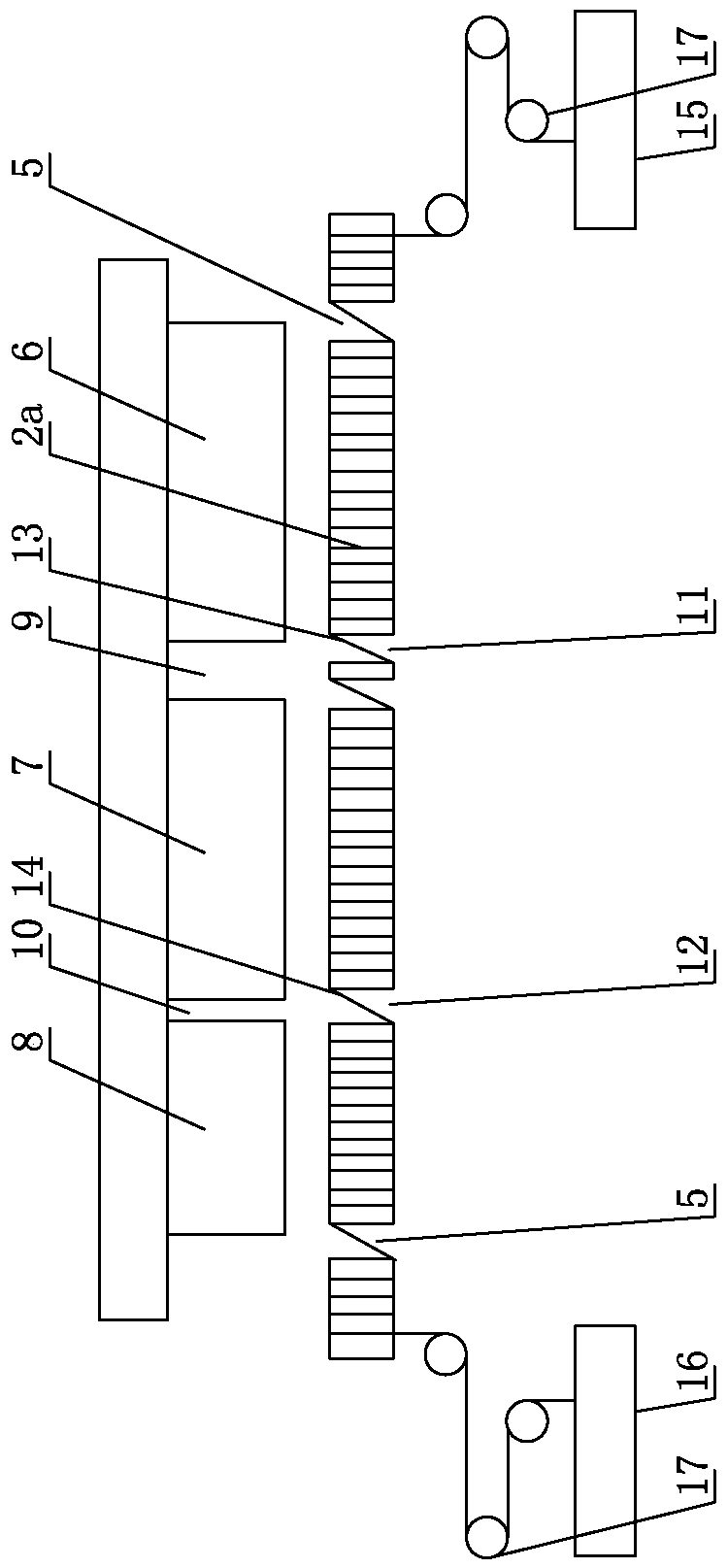

Multiwire cutting equipment and wire mesh tension control mechanism for same

ActiveCN105538525AReduce disconnection rateLess consumablesFine working devicesEngineeringConductor Coil

The invention discloses multiwire cutting equipment and a wire mesh tension control mechanism for the same. The multiwire cutting equipment comprises a base, a cutting assembly, a first tensioning mechanism and a second tensioning mechanism; the cutting assembly comprises a first cutting roller , a second cutting roller and a third cutting roller which are arranged to be shaped like a triangle; the first tensioning mechanism comprises a first winding drum, a first rotating motor and a first adjusting assembly provided with a first tension transition wheel; the second tensioning mechanism comprises a second winding drum, a second rotating motor and a second adjusting assembly provided with a second tension transition wheel. A cutting wire starts from the first winding drum and is wound around the first adjusting assembly, the first cutting roller, the second cutting roller, the third cutting roller and the second adjusting assembly and then wound on the second winding drum; when cutting is conducted, the first winding drum is matched with the first tension transition wheel, so that it is guaranteed that the cutting wire is in a tension balance state; the second winding drum is matched with the second tension transition wheel, so that it is guaranteed that the cutting wire is in the tension balance state.

Owner:海宁市日进科技有限公司

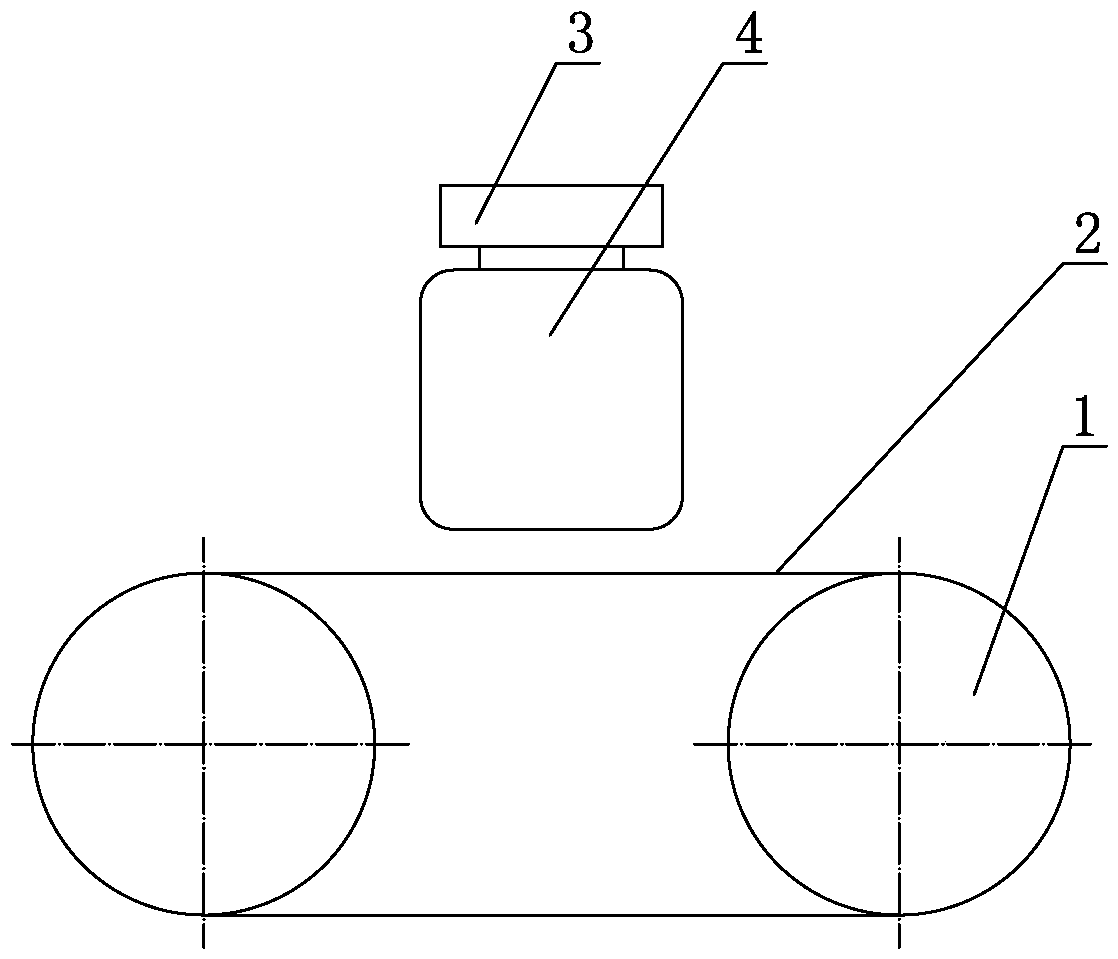

Wire arranging and collecting device in wire drawing machine

InactiveCN101670957AReduce resistanceReduce disconnection rateFilament handlingEngineeringWire drawing

The invention discloses a wire arranging and collecting device in a wire drawing machine, which can reduce the resistance to wires in the process of arranging and collecting the wires. The wire arranging and collecting device comprises a rotary shaft and a machine frame; a wire passing wheel and a wire collecting motor are arranged on the machine frame, wherein the wire passing wheel is positionedabove the rotary shaft; a wire arranging motor is also arranged on the machine frame; an output shaft of the wire arranging motor is connected with a ball feed screw which is movably arranged on themachine frame; a slide block is arranged on the ball feed screw, and is fixed with a mounting seat which is arranged on the machine frame in a sliding mode; the rotary shaft is movably arranged on themounting seat; and the output shaft of the wire collecting motor is connected with the rotary shaft through a transmission gear. The wire arranging and collecting device adopts a shaft driving type wire collecting and arranging mode, namely, the shaft (the rotary shaft) is moved, while the wires are not moved, so the resistance to the wires in the process of arranging and collecting the wires canbe greatly reduced, the possibility of breaking the wires is greatly lowered, and the application range of the wire drawing machine is extended.

Owner:JIANGSU JIACHENG TECH

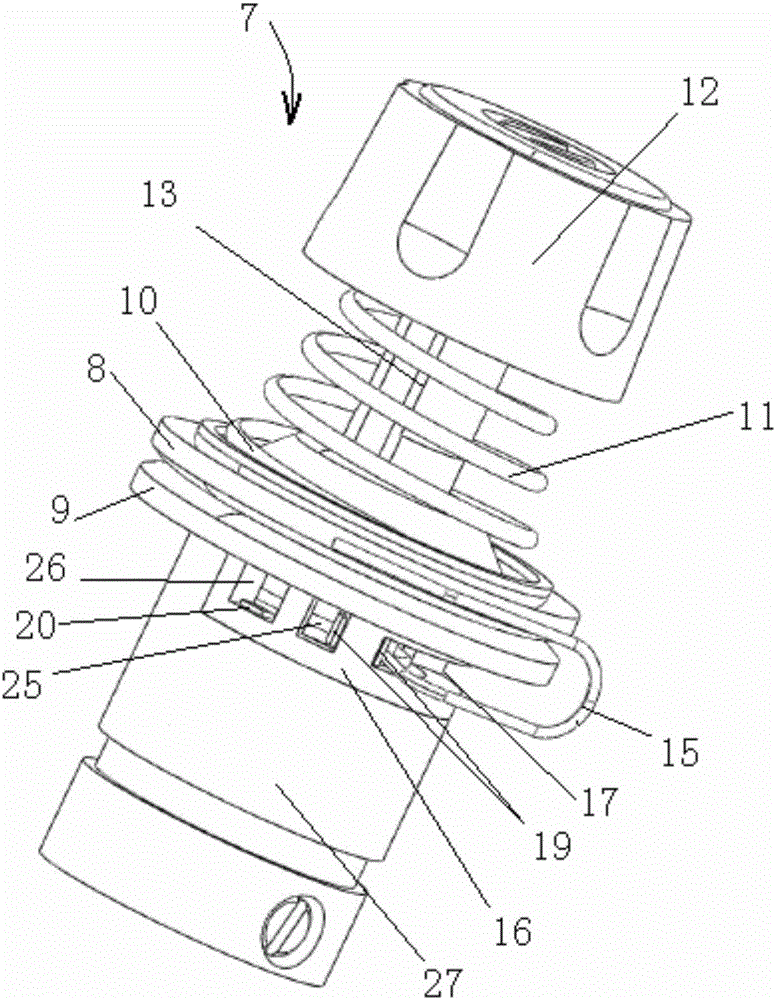

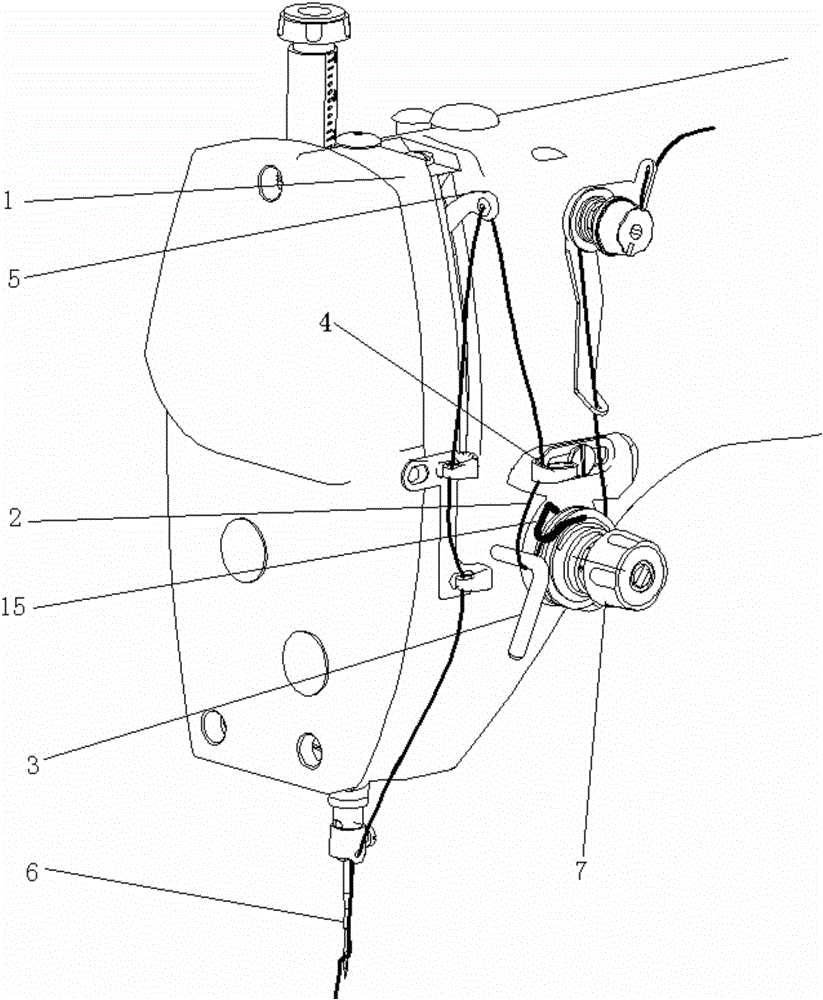

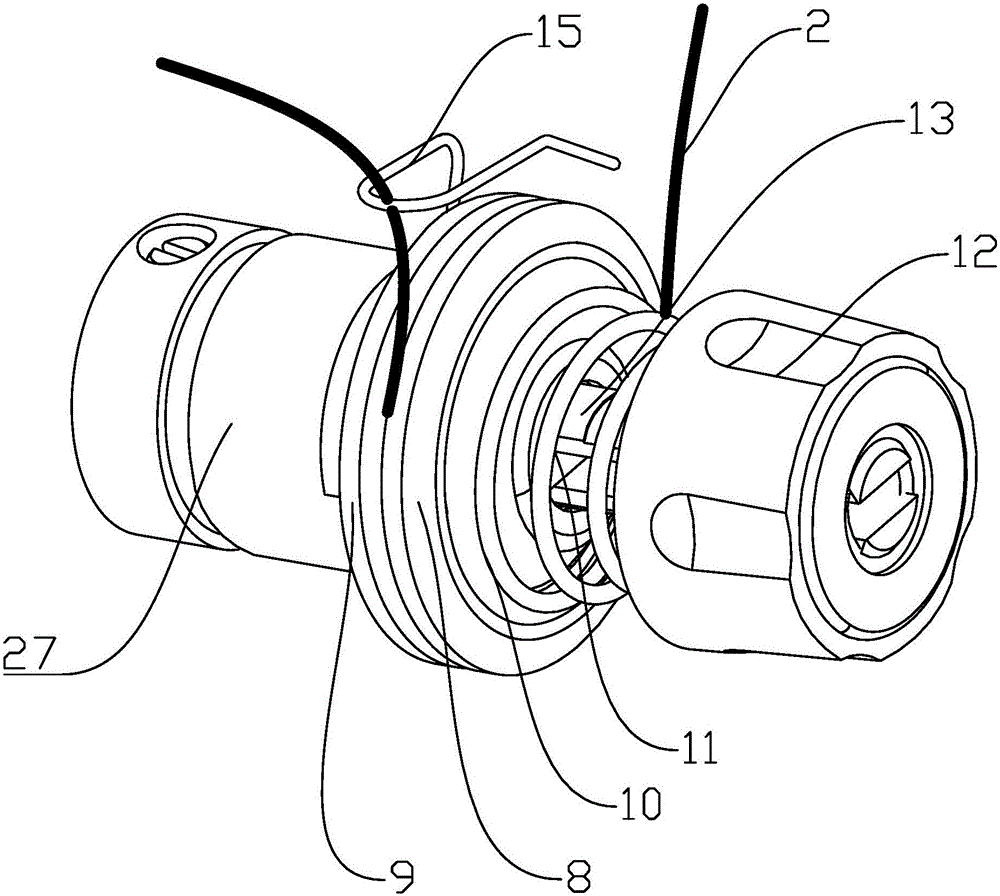

Sewing machine and broken stitch detection mechanism thereof

InactiveCN105937101ADoes not increase tensionLow failure rateThread-break detectorsTensioning devicesEngineeringFault rate

The invention provides a broken stitch detection mechanism of a sewing machine. A stitch clamping screw of an existing stitch trapper of a sewing machine body is sleeved with a stitch take-up spring. The stitch take-up spring is sleeved with an insulation cylinder base. A stitch take-up hook of the stitch take-up spring stretches out from a stretching window in the insulation cylinder base through a section of a stretching arm; under the effect of pre-tensioning twisting force of the stitch take-up spring, the stretching arm makes elastic contact with a first detection piece in the stretching window, and the insulation cylinder base is further provided with a second detection piece electrically connected with the stitch take-up spring; when a stitch exists on the stitch take-up hook of the stitch take-up spring, and the stitch take-up hook is pulled so that the stretching arm can deflect to be disconnected with the first detection piece; when the stitch is broken, the stretching arm recovers to make contact with the first detection piece under the effect of the stitch take-up spring. Accordingly, according to the broken stitch detection mechanism of the sewing machine, the stitch take-up spring on the existing stitch trapper of the sewing machine is used for generating broken stitch detection signals, tension of the stitch will not be increased, the broken stitch probability is reduced, and the sewing working fault rate is lowered.

Owner:JACK SEWING MASCH CO LTD

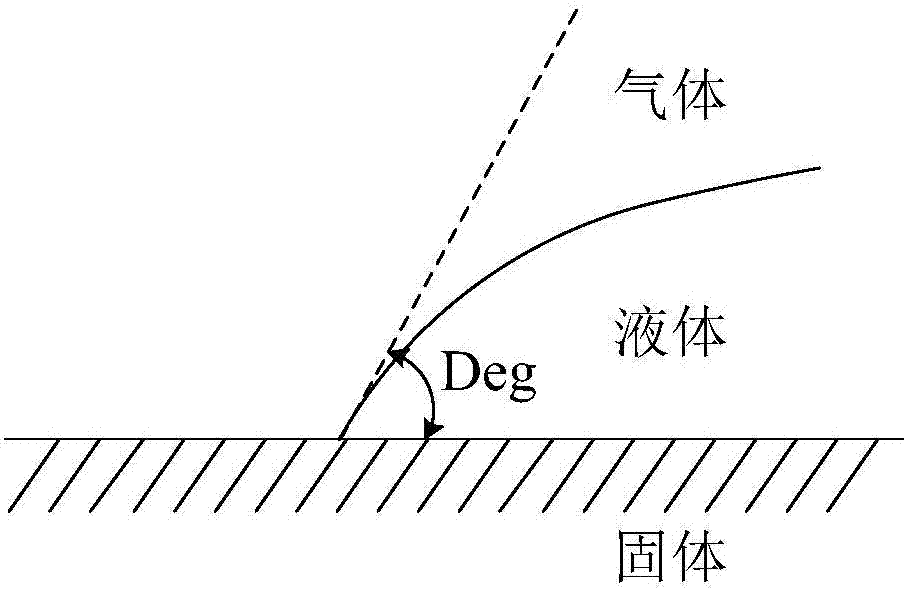

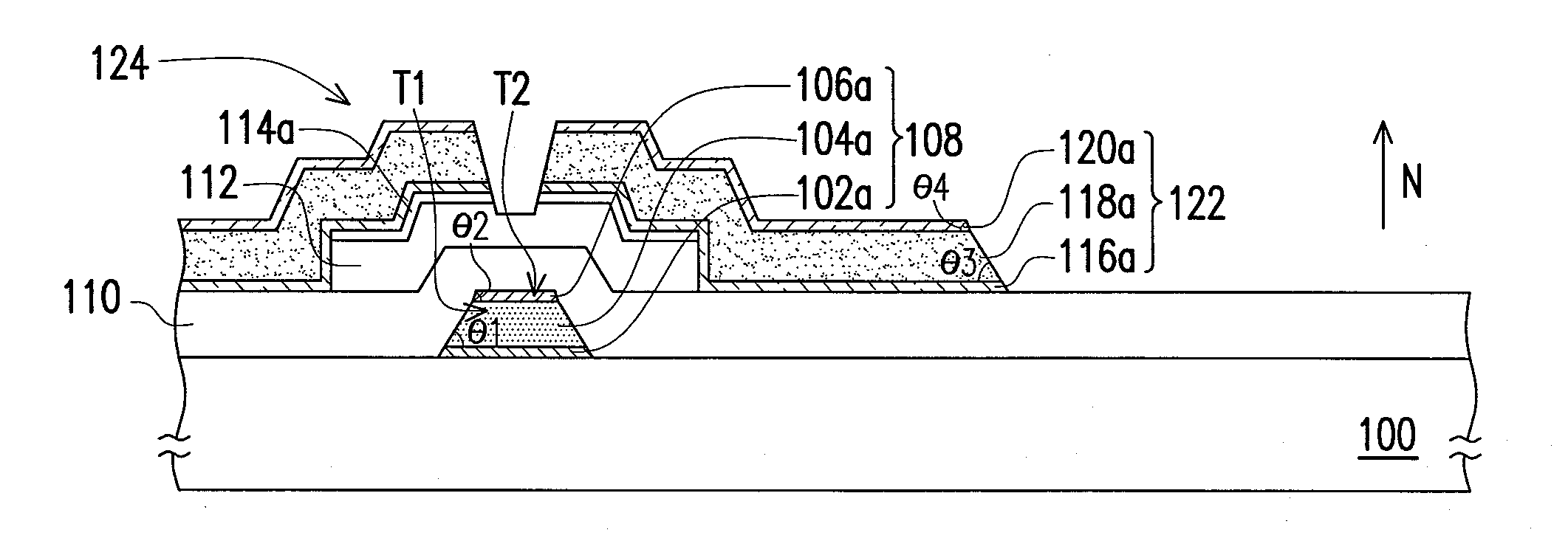

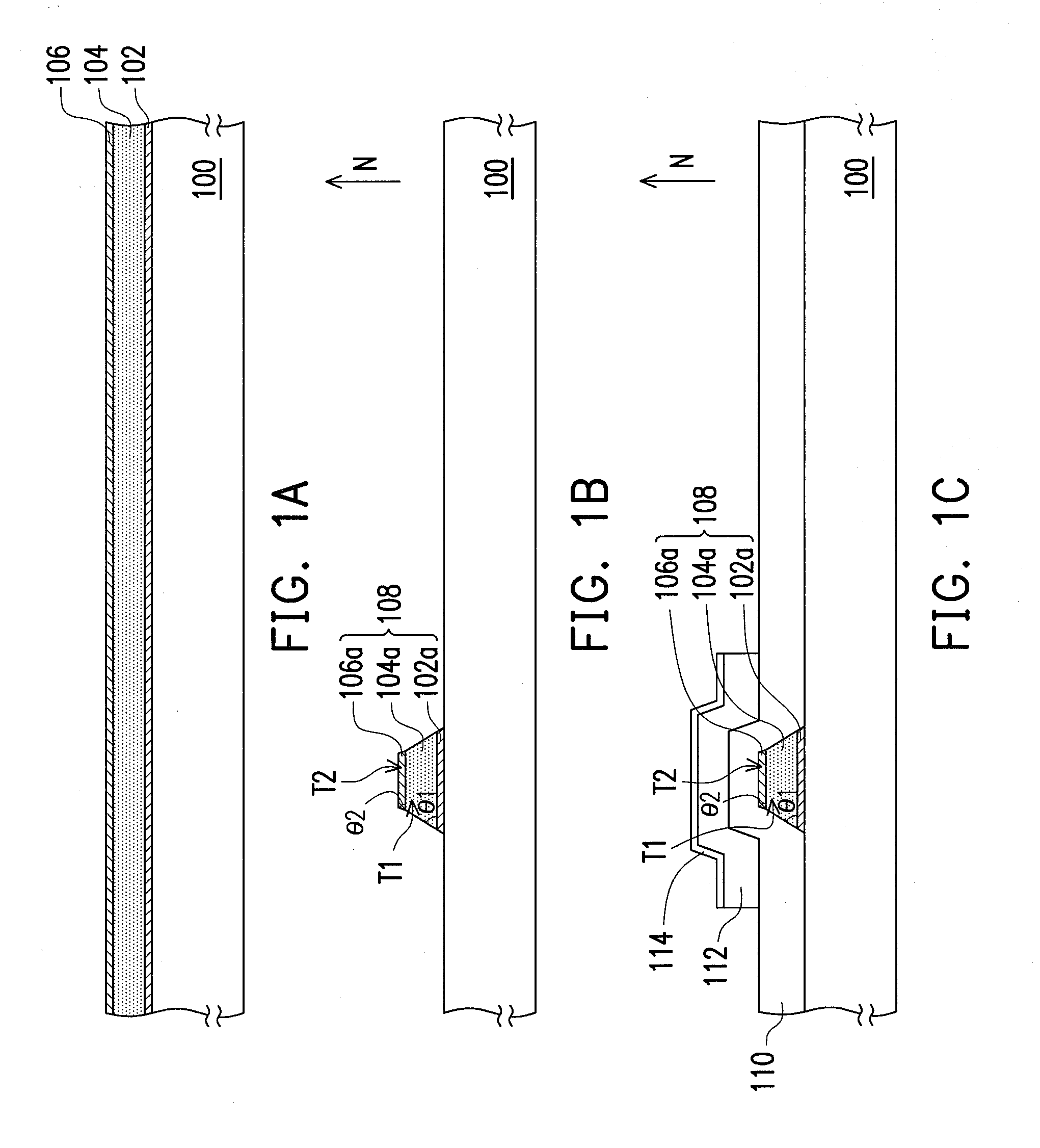

Active device array substrate and fabricating method thereof

ActiveUS20110228502A1Improve electrical characteristicsElectrical characteristicElectrically conductive connectionsSemiconductor/solid-state device detailsAcute angleCopper

An active device array substrate has at least one patterned conductive layer. The patterned conductive layer includes a copper layer. A cross-section of the copper layer which is parallel to a normal line direction of the copper layer includes a first trapezoid and a second trapezoid stacked on the first trapezoid. A base angle of the first trapezoid and a base angle of the second trapezoid are acute angles, and a difference between the base angle of the first trapezoid and the base angle of the second trapezoid is from about 5° to about 30°.

Owner:AU OPTRONICS CORP

Device for raising alarm about disconnection and wire arch abnormality at middle part of wire cutting machine

InactiveCN101774229AAvoid damageControl disconnection rateStone-like material working toolsFixed frameWire cutting

The invention relates to a device for raising an alarm about the disconnection and wire arch abnormality at the middle part of a wire cutting machine. The device comprises a disconnection alarm circuit, wherein a disconnection / wire arch abnormality alarm device arranged in a cutting chamber comprises a disconnection rod fixing frame and a stainless steel rod; two parallel through-holes and mounting / fixing through-holes are formed on the disconnection rod fixing frame; two stainless steel rods are arranged in the through-holes; and the tail ends of the two stainless steel rods are connected with the disconnection alarm circuit. Accordingly, the invention can solve the problem of the disconnection and wire arch abnormality at the middle part of the wire cutting machine, effectively prevent the guide wheel for cutting the disconnected wire from being damaged and effectively control the disconnection rate of the abnormal wire arch; and the invention has the characteristic of simple structure, reduces the disconnection rate, prolongs the service life of devices and guarantees the normal production capacity.

Owner:JIANGXI SORNID HI TECH

Cutting device suitable for adjustment of diamond wire mesh and cutting method

InactiveCN110466082AStable tensionUniform tension distributionFine working devicesMechanical engineeringWire mesh

The invention discloses a cutting device suitable for adjustment of a diamond wire mesh and a cutting method, and belongs to the field of photovoltaic products. According to the cutting device, the cutting wire mesh is arranged between two wire guiding wheels, a plurality of crystal rods are fixedly mounted on a crystal holder, edge cutting gaps are formed in the first end and the tail end, at thewire guiding wheels, of the cutting wire mesh correspondingly, the two edge cutting gaps correspond to the edge of the left side of the crystal rod located on the left side, and the edge of the rightside of the crystal rod located on the right side correspondingly, and a first diamond wire at the wire inlet end and a first diamond wire at the wire outlet end of the cutting wire mesh are arrangedwith the corresponding crystal rods in a staggered mode. The method comprises the steps that the crystal holder moves downwards, thus all the crystal rods descend at the speed of 2.0-2.2 mm / min, allthe crystal rods start to be cut after making contact with the cutting wire mesh, and the first crystal rod, the second crystal rod and the third crystal rod are cut simultaneously through the cuttingwire mesh. The first wire at the wire inlet end and the first wire at the wire outlet end of the cutting wire mesh can be prevented from being broken; and by adjusting the length of the cutting gaps,the crystal rods of different lengths can be quickly switched to be cut.

Owner:扬州续笙新能源科技有限公司

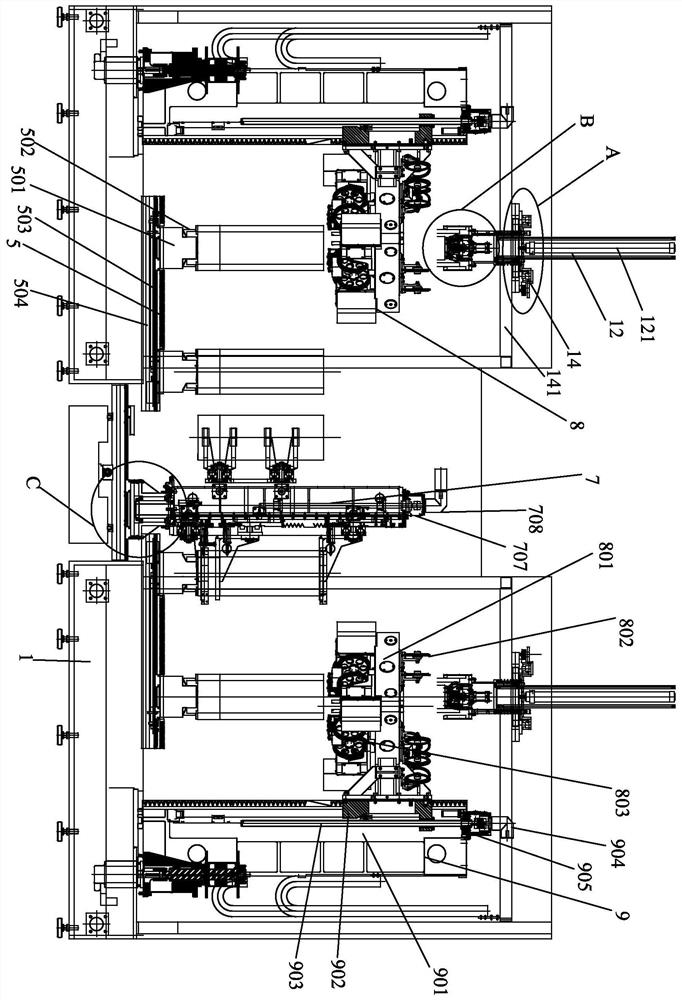

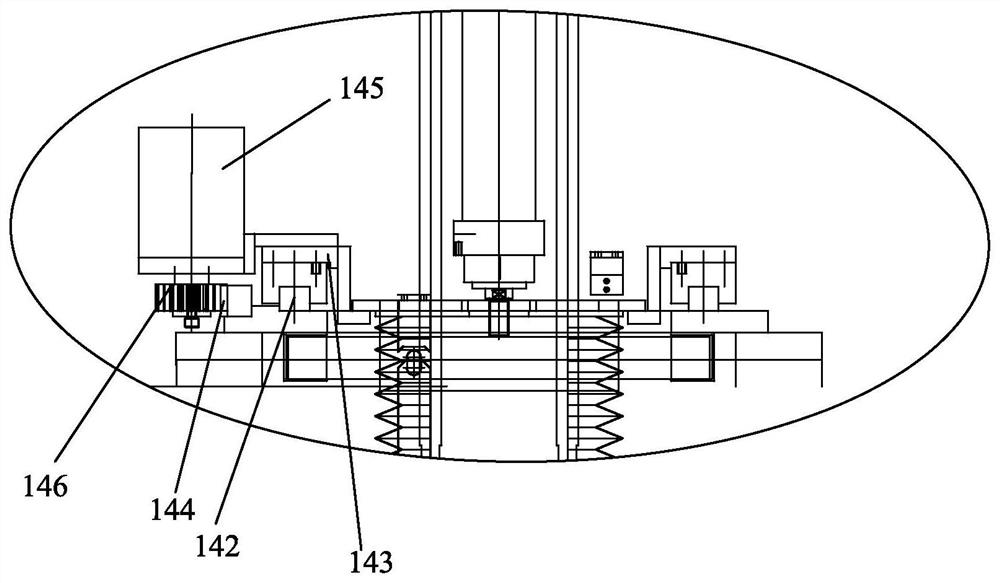

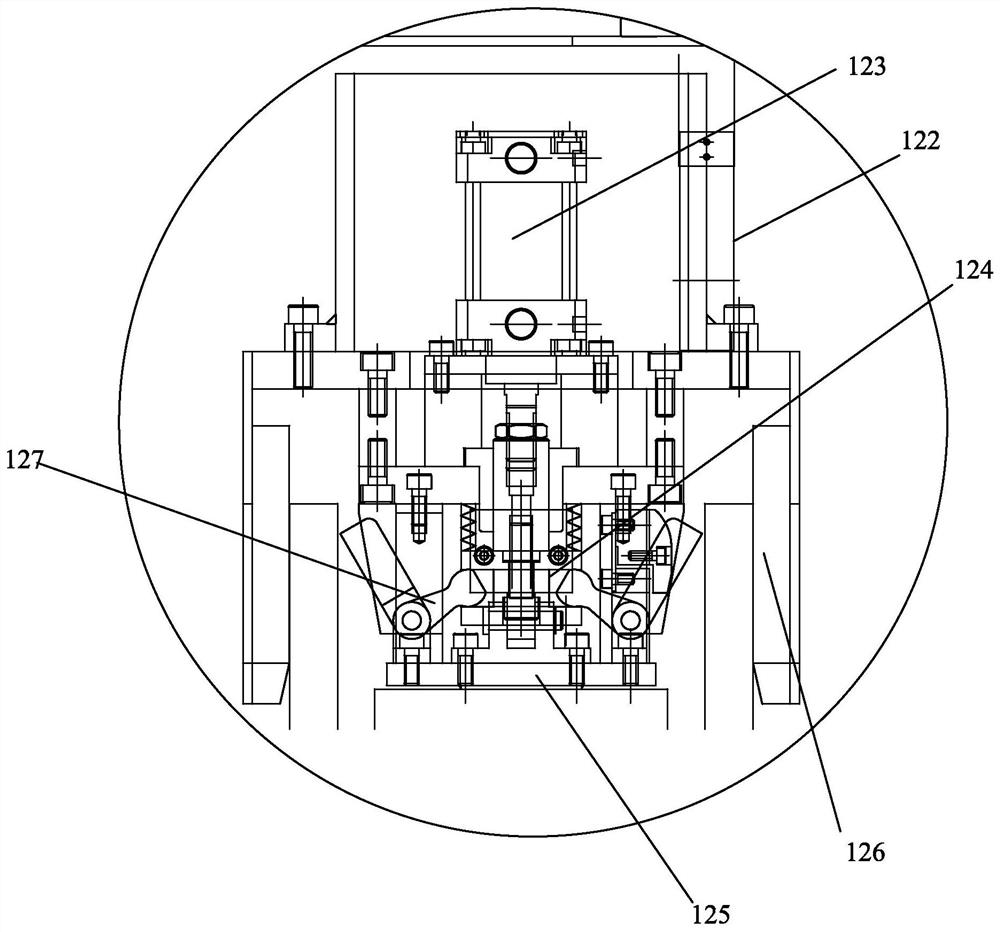

Double-silicon-rod diamond wire squaring machine

PendingCN111619026AImprove flowGood cutting precisionWorking accessoriesFine working devicesRobot handEngineering

The invention provides a double-silicon-rod diamond wire squaring machine comprising a lathe bed extending in the left-right direction. Single-silicon-rod cutting systems are symmetrically arranged onthe left side and the right side of the lathe bed. A feed system and a discharge system are arranged on the front side of the middle portion of the lathe bed. A crystal line detection system used fordetecting silicon rod crystal lines is arranged on the rear side of the middle portion of the lathe bed. A cross slide table system is arranged on the middle portion of the lathe bed and comprises alower slide table system extending in the front-back direction and an upper slide table system extending in the left-right direction. A silicon rod grabbing mechanical hand system used for grabbing silicon rods is installed on the upper slide table system. Two squaring machines share one crystal line detection device and one silicon rod grabbing mechanical hand system, and meanwhile cutting nets of the two squaring machines do not influence each other.

Owner:DALIAN LIANCHENG NUMERICAL CONTROL MACHINE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com