Technique for preparing ultramicro enamelling cuprum round line

A production process, enamelled copper technology, applied in the direction of metal/alloy conductors, electrical components, circuits, etc., can solve the problems of high breakage rate of enamelled copper round wire, low wire drawing breakage rate, and decrease in tensile strength. To achieve the effect of reducing the rate of enamelled wire breakage, reducing the rate of wire drawing wire breakage, and improving the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

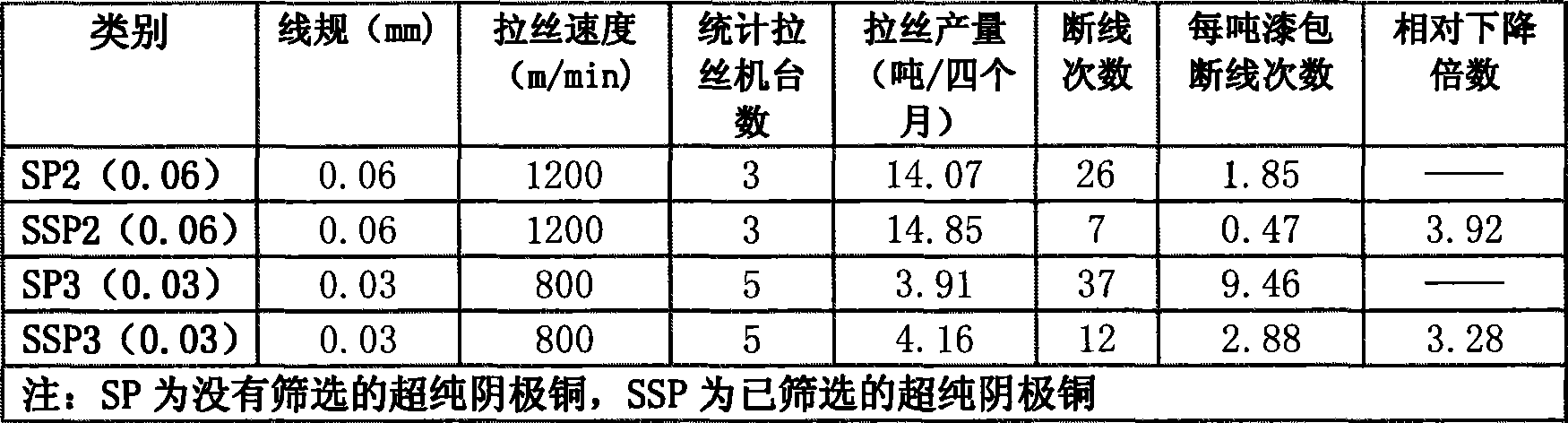

[0026] Such as figure 1 As shown, a production process of ultra-fine enamelled copper round wire, firstly, ultra-pure cathode copper is selected by ultra-fine wire drawing and screening method, and the components of ultra-pure cathode copper include, by weight percentage: the content of copper is 99.99% , the content of oxygen is 0.003%, the content of sulfur is 0.0004%, the content of phosphorus is 0.0002%, the content of silicon is 0.0003%, the content of iron is 0.0005%, the content of zinc is 0.0001%, the content of gold is 0.001%, The content of silver is 0.001%, and the rest are impurities.

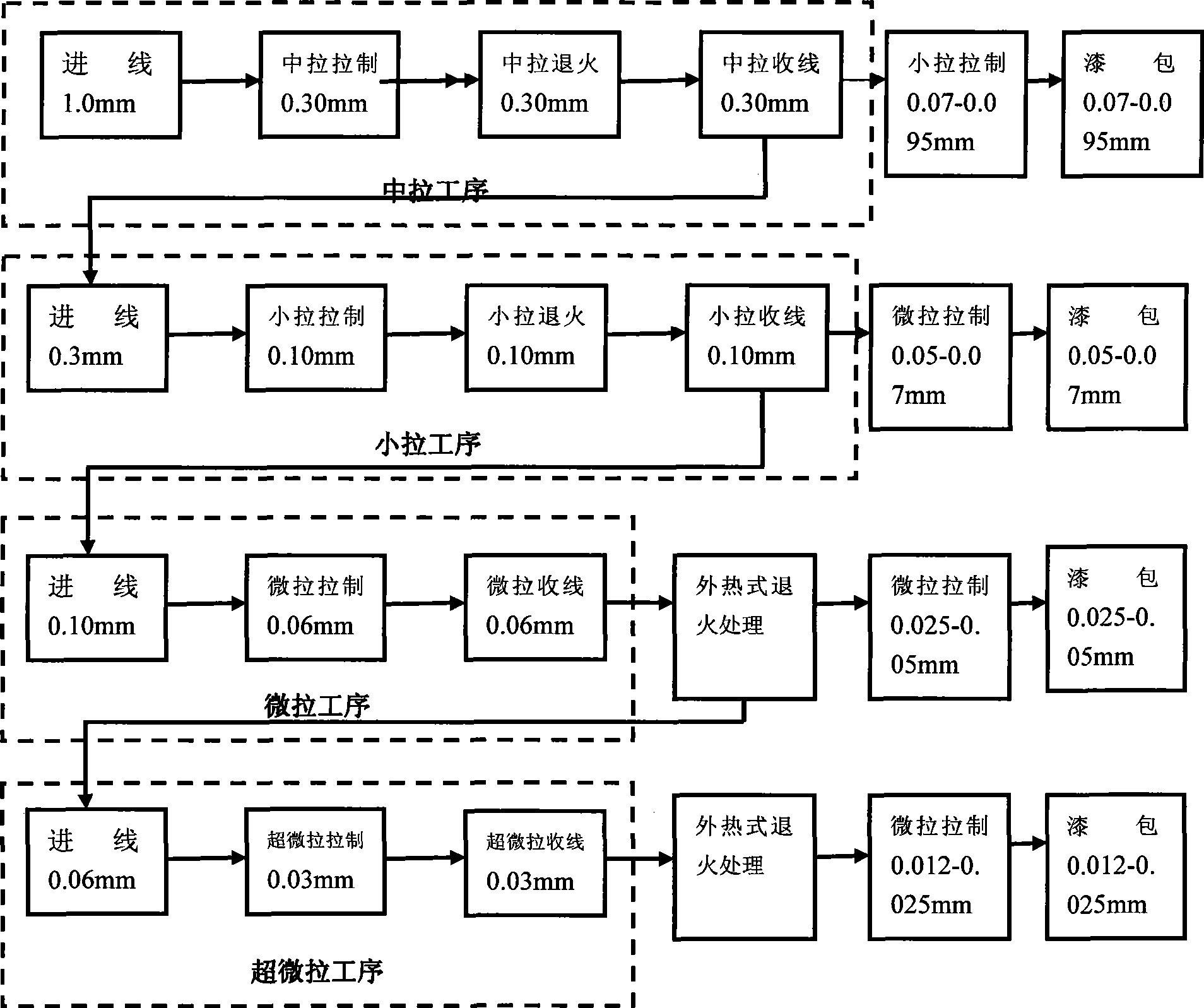

[0027] The selected copper wire is drawn, and the drawing process includes a middle drawing step, a small drawing step and a micro drawing step in sequence. Among them, the diameter of the incoming wire in the middle drawing step is 1.0mm, and the middle drawing is 0.3mm, and then the middle drawing annealing and the middle drawing take-up are carried out; then enter the small draw...

Embodiment 2

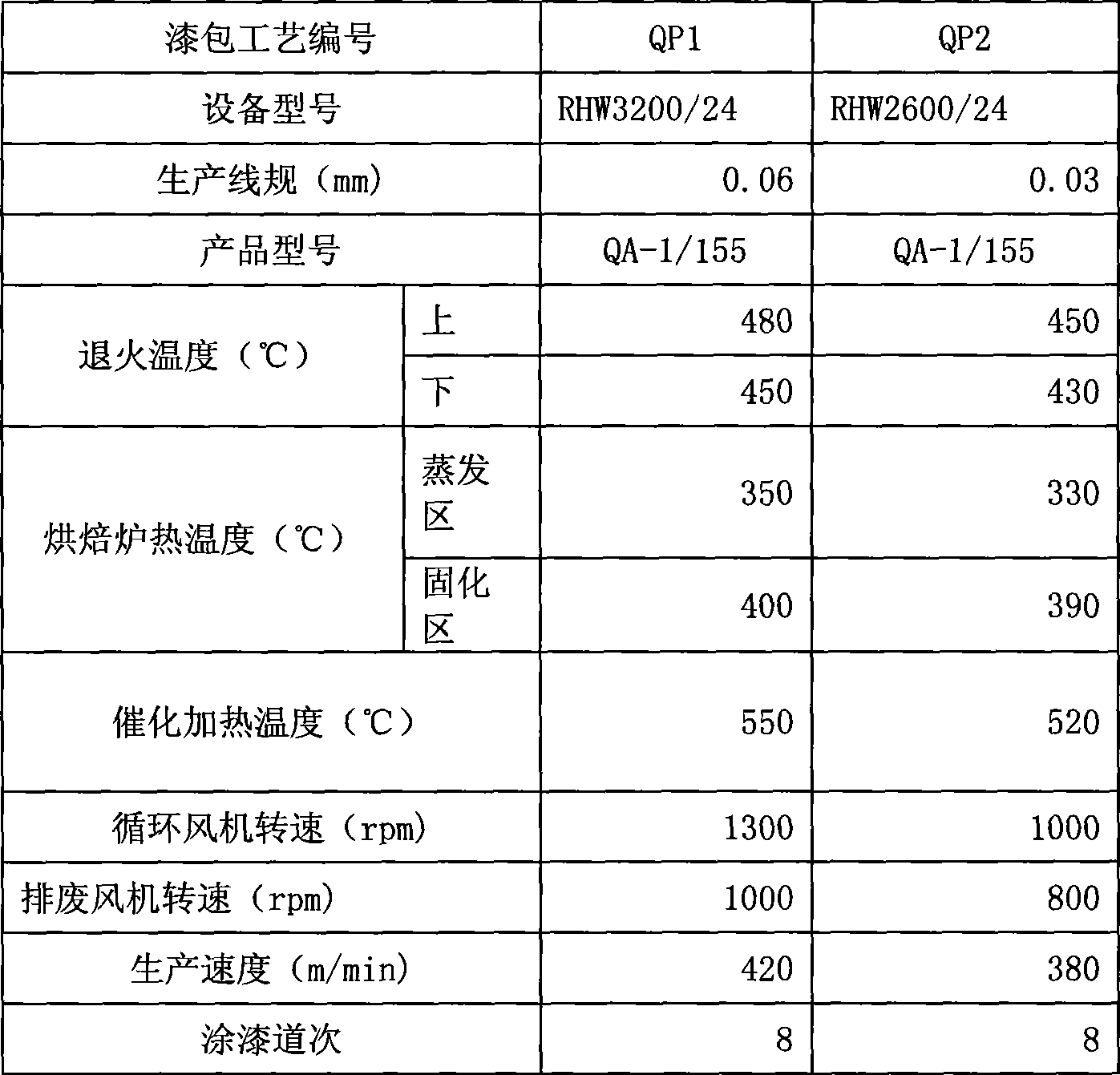

[0031] Such as figure 1 As shown, a production process of ultra-fine enamelled copper round wire, in the wire drawing process, includes a medium drawing step, a small drawing step, a micro drawing step and an ultra micro drawing step. The annealing voltage in the small drawing step is 19V, the production speed is 1200m / min, and the relative annealing degree is 55.92%; the annealing temperature in the micro-drawing step is 480°C, the production speed is 600m / min, and the relative annealing degree is 99%; The annealing temperature in the micro-drawing step is 450° C., the production speed is 600 m / min, and the relative annealing degree is 94.16%. All the other are the same with embodiment 1. According to the relevant performance parameters of the 0.06mm enameled wire produced by the above process, it is obtained through testing: the average elongation at break is 23.88%, and the average tensile strength is 263.10N / mm 2 , the average resistivity at 20°C is 0.01651Ω / mm 2 .m. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com