Cutting device suitable for adjustment of diamond wire mesh and cutting method

A technology of cutting device and cutting method, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc. It can solve the problems of tension fluctuation, long operation time, and disconnection of winding and unwinding wires, so as to avoid stress concentration and tension distribution Uniform, reduce the effect of disconnection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

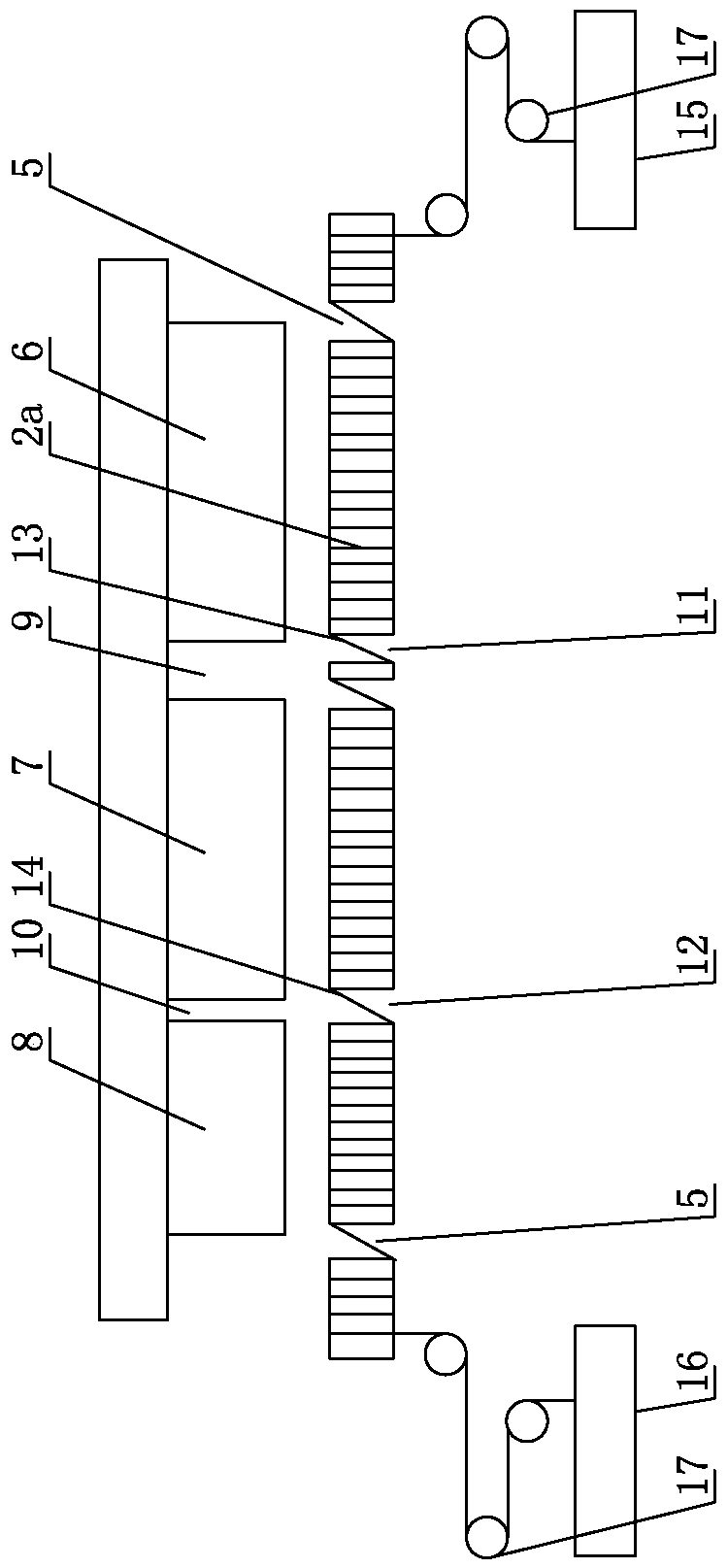

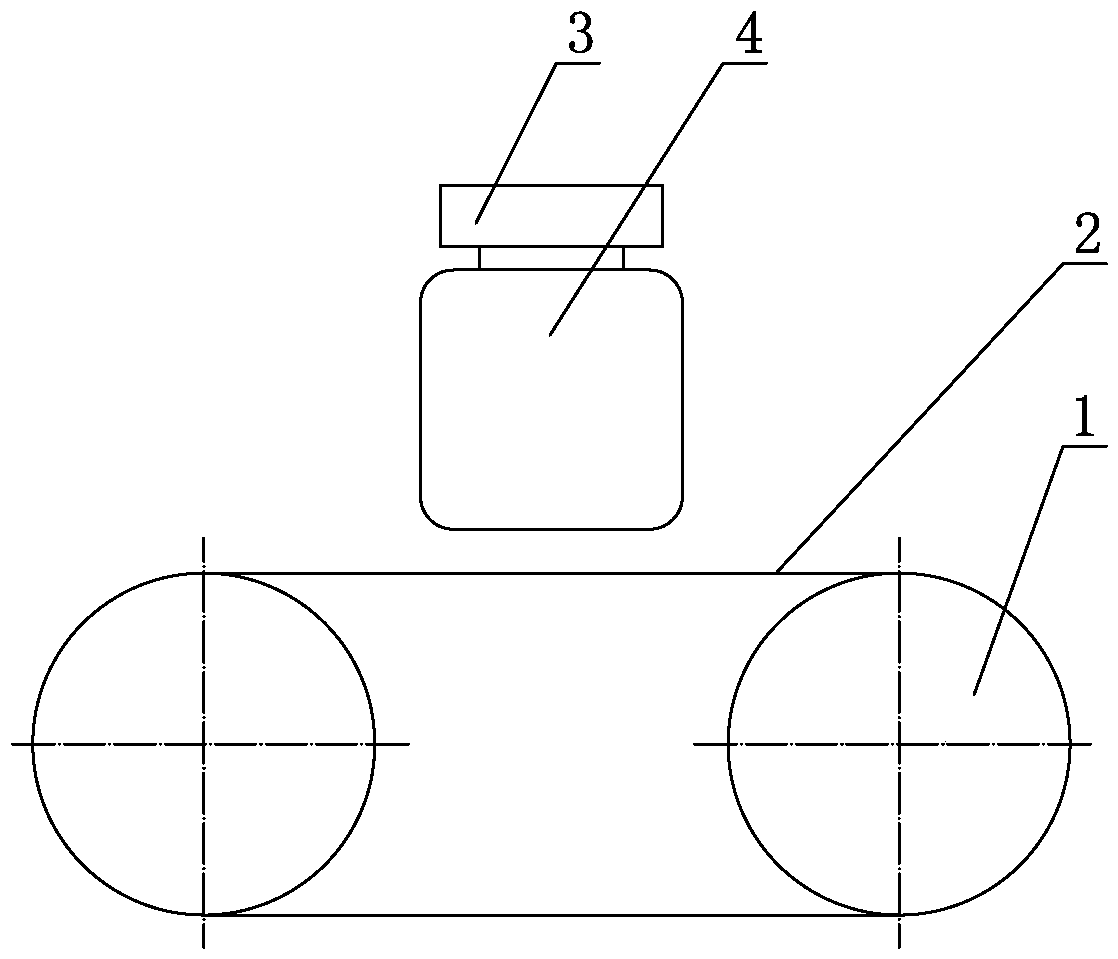

[0023] Such as figure 1 and 2As shown, it is a cutting device suitable for diamond wire mesh adjustment, including two guide wheels 1 correspondingly arranged at the front and back, the axes of the two guide wheels 1 are parallel to each other, and a cutting wire net is arranged between the two guide wheels 1 2. The wire inlet and outlet ends of the cutting wire net 2 are respectively located at the head end and the tail end of the guide wheel 1, and a crystal support 3 is arranged above the cutting wire net 2, and a number of crystal brackets distributed at intervals are fixedly installed on the crystal bracket 3. Rod 4, the axis of each crystal rod 4 coincides, the axis of crystal rod 4 is parallel to the axis of guide wheel 1, the projection area of each crystal rod 4 is located in the coverage of cutting wire mesh 2, and cutting wire mesh 2 is located at the edge of guide wheel 1 Both the head end and the tail end are provided with edge cutting slits 5, and the two edge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com