Slip motor automatic control device

An automatic control device, slip motor technology, applied in the control system, control of electromechanical brakes, electrical components, etc., can solve the problems of no closed-loop automatic detection and adjustment function, no pure torque function, unstable speed characteristics, etc., and achieve good Stall characteristics, unique performance, reasonable characteristics effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

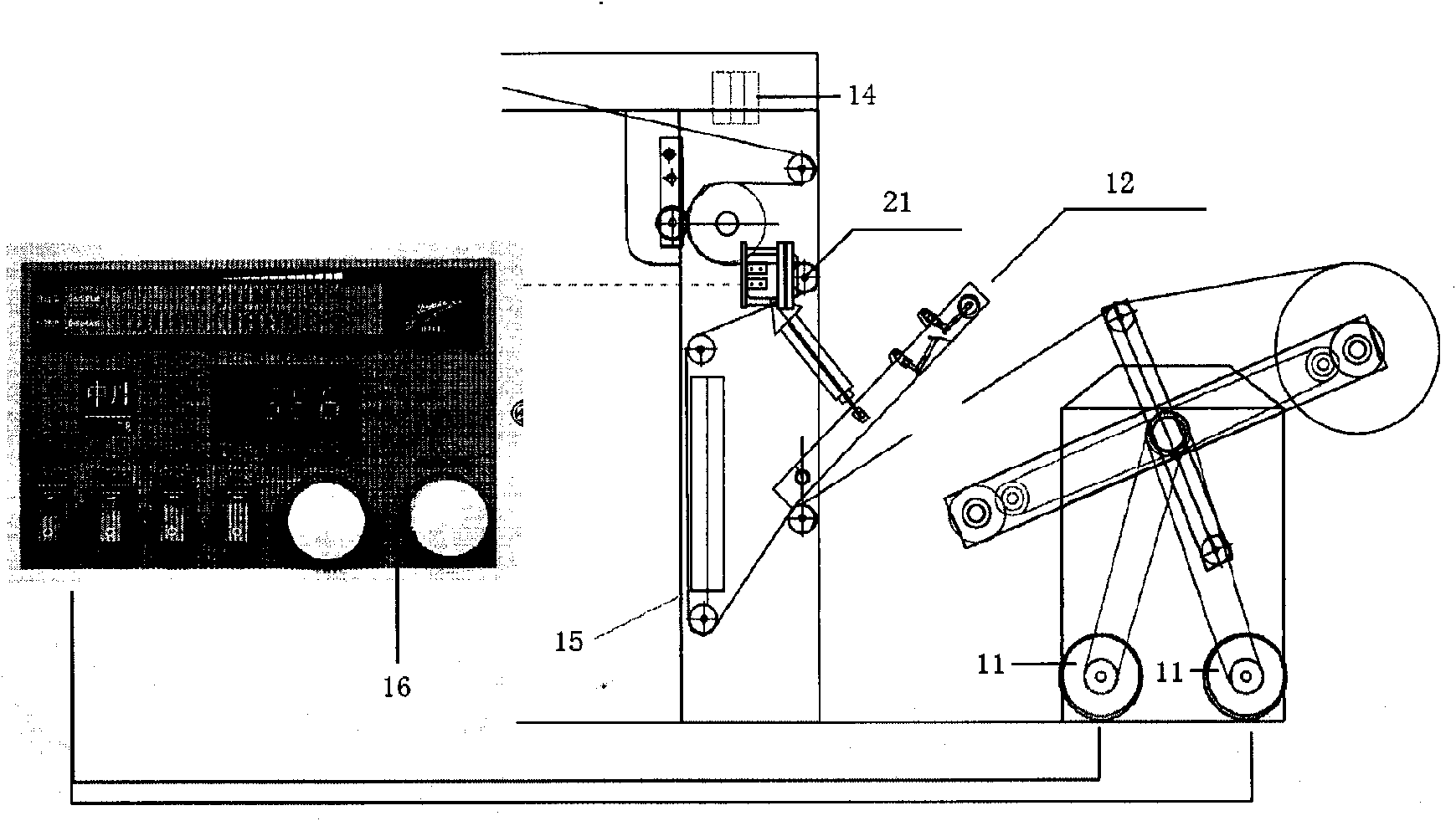

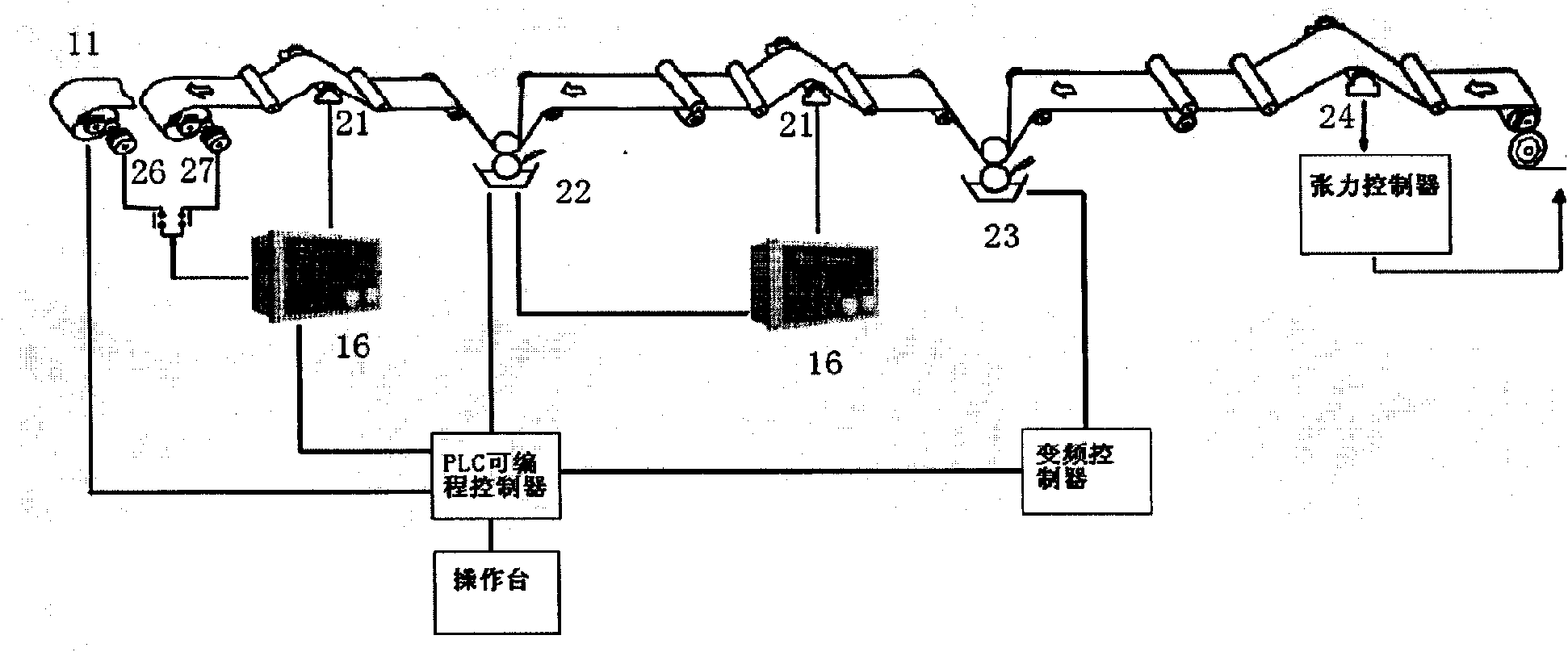

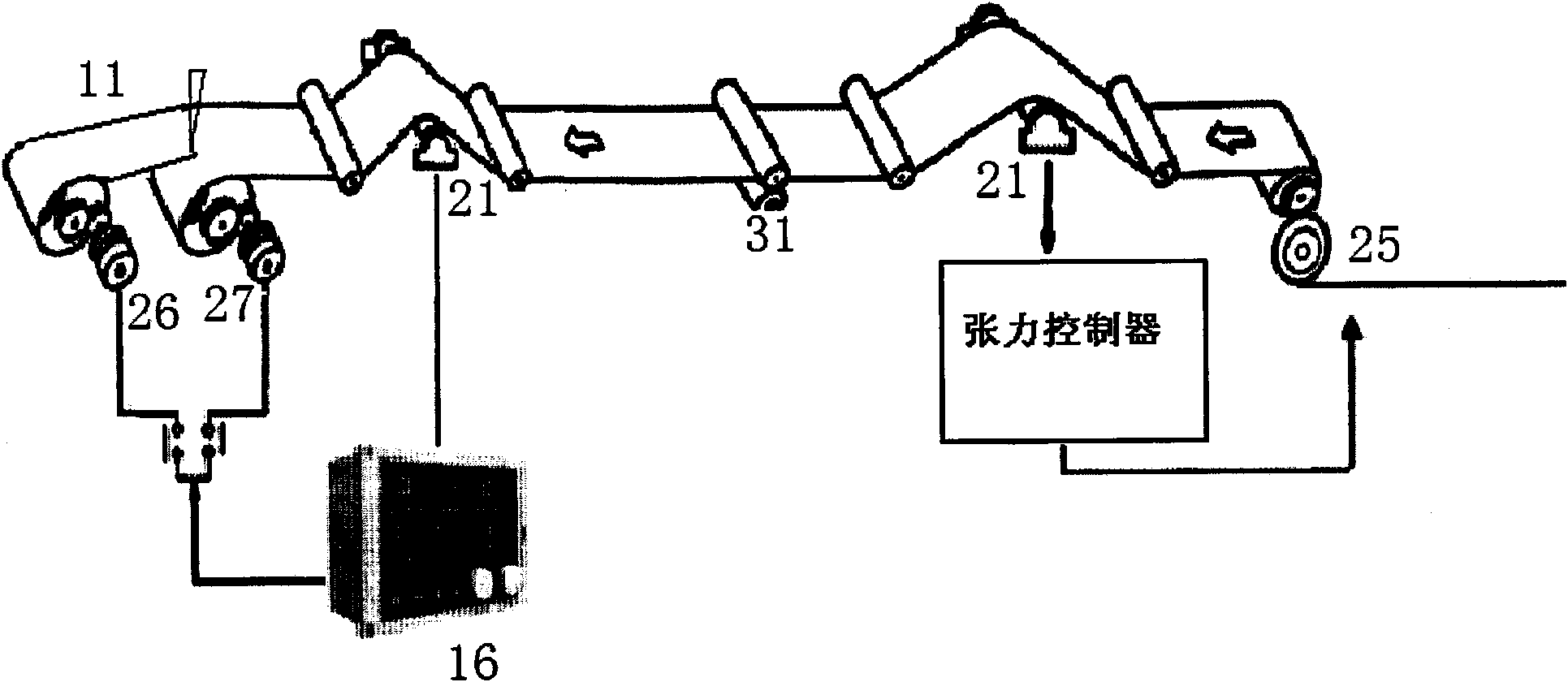

Embodiment Construction

[0042] Control principle: The tension developed by the material during the production and processing process is converted into an electrical signal through the pressure displacement sensor; or through the swing rod device composed of the cylinder, the rocking rod and the encoder, the position of the rocking rod that the material passes through is adjusted by adjusting the air pressure Change, calculate the number of pulses of the encoder, convert the pulse equivalent into an electrical signal, or convert the angle change of the potentiometer into an electrical signal in the same way; thus output a variable linear DC voltage DC 0V-5V (volts) Or 0V-10V (volt), current 0mA-200mA (milliampere) voltage and current, the tension effect on the material is converted into an electrical signal and then sent to the controller for comparison with the set standard value. When the detected value is greater than or less than the standard value When the value is set, the controller automaticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com