Loading tool assembly for bearing testing machine and method for loading test bearing

A bearing test and axial loading technology, applied in the direction of mechanical bearing testing, etc., can solve the problems affecting the accuracy of test results, unable to guarantee installation accuracy, not suitable for quick disassembly, etc., to solve automation and rapid installation, and improve data accuracy. And, to solve the effect of easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

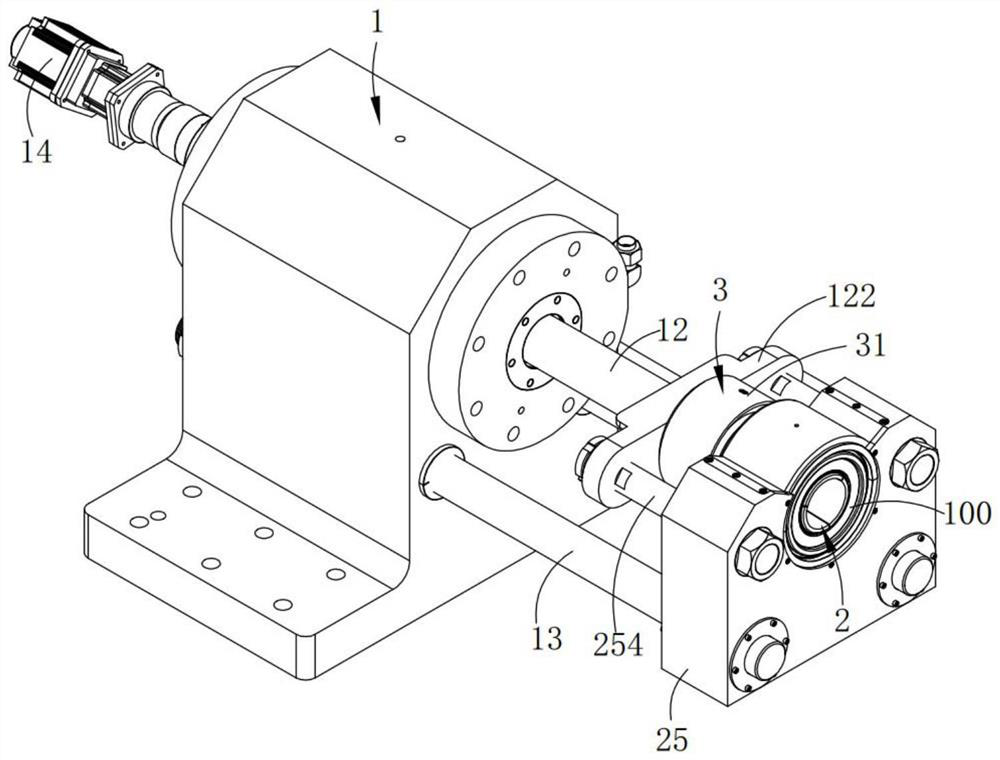

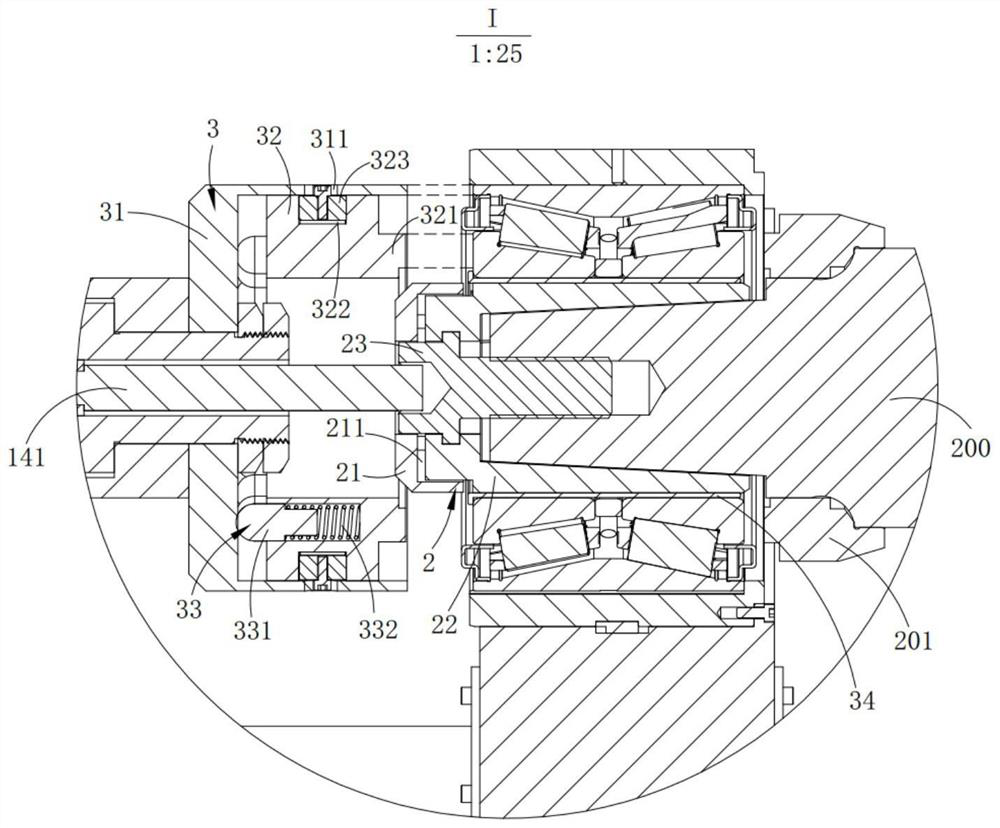

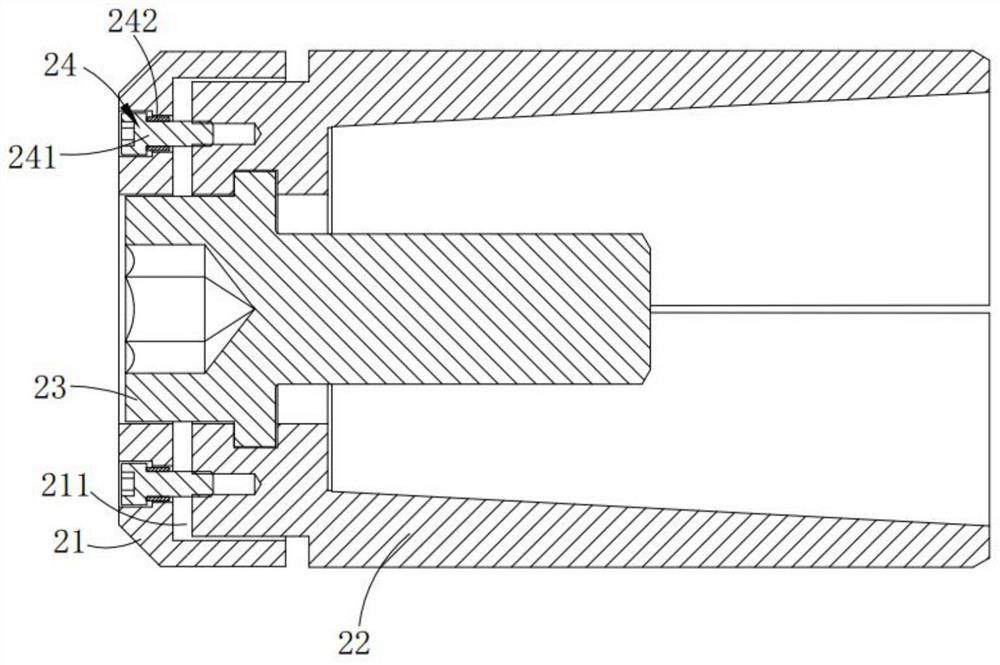

[0052] Such as figure 1 As shown, a loading tool assembly for a bearing testing machine includes a power assembly 1, an expansion assembly 2, and an axial loading assembly 3 arranged on one side of the expansion assembly 2; the expansion assembly 2 is arranged on the bearing to be tested The inner diameter of the axial loading assembly 3 is arranged at the output end of the power assembly 1; the power assembly 1, the expansion assembly 2 and the axial loading assembly 3 are arranged coaxially;

[0053] When working, after the axial loading assembly 3 pre-fixes the bearing 100 to be tested, driven by the power assembly 1, the compression expansion assembly 2 tightens the inner diameter of the bearing 100 to be tested and the support shaft 200, and at the same time, the axial loading assembly 3 Axial loading of the bearing;

[0054] It should be noted that the support shaft 200 is used to support the bearing 100 to be tested and to drive the bearing 100 to be tested to rotate; ...

Embodiment 2

[0085] A method for loading and testing bearings using a loading tooling assembly for a bearing testing machine described in the technical solution of the first embodiment above includes the following steps:

[0086] Step 1, pre-installation of the bearing to be tested 100, the bearing to be tested 100 is installed on the working position 251 on the support seat 25; 2521 perform pre-positioning;

[0087] Step 2: pre-fix the bearing 100 to be tested, the inner ring loading die 32 protrudes from the outer ring loading die 31 under the action of the limit assembly, start the power assembly 1, drive the axial loading assembly 3 to move to the right, and make the bearing 100 to be tested Cooperate with the support shaft 200, and at the same time, the boss 321 of the inner ring loading die 32 is in contact with the inner ring of the bearing to be tested 100, the position of the inner ring and the outer ring of the bearing to be tested 100 is adjusted, and the axial loading assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com