Dual-clutch automated transmission

An automatic transmission and clutch technology, applied in clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of high manufacturing cost, difficult processing, complex support and lubrication structure, etc., and achieve simplified manufacturing and processing difficulty, transmission and The effect of high installation accuracy and small axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

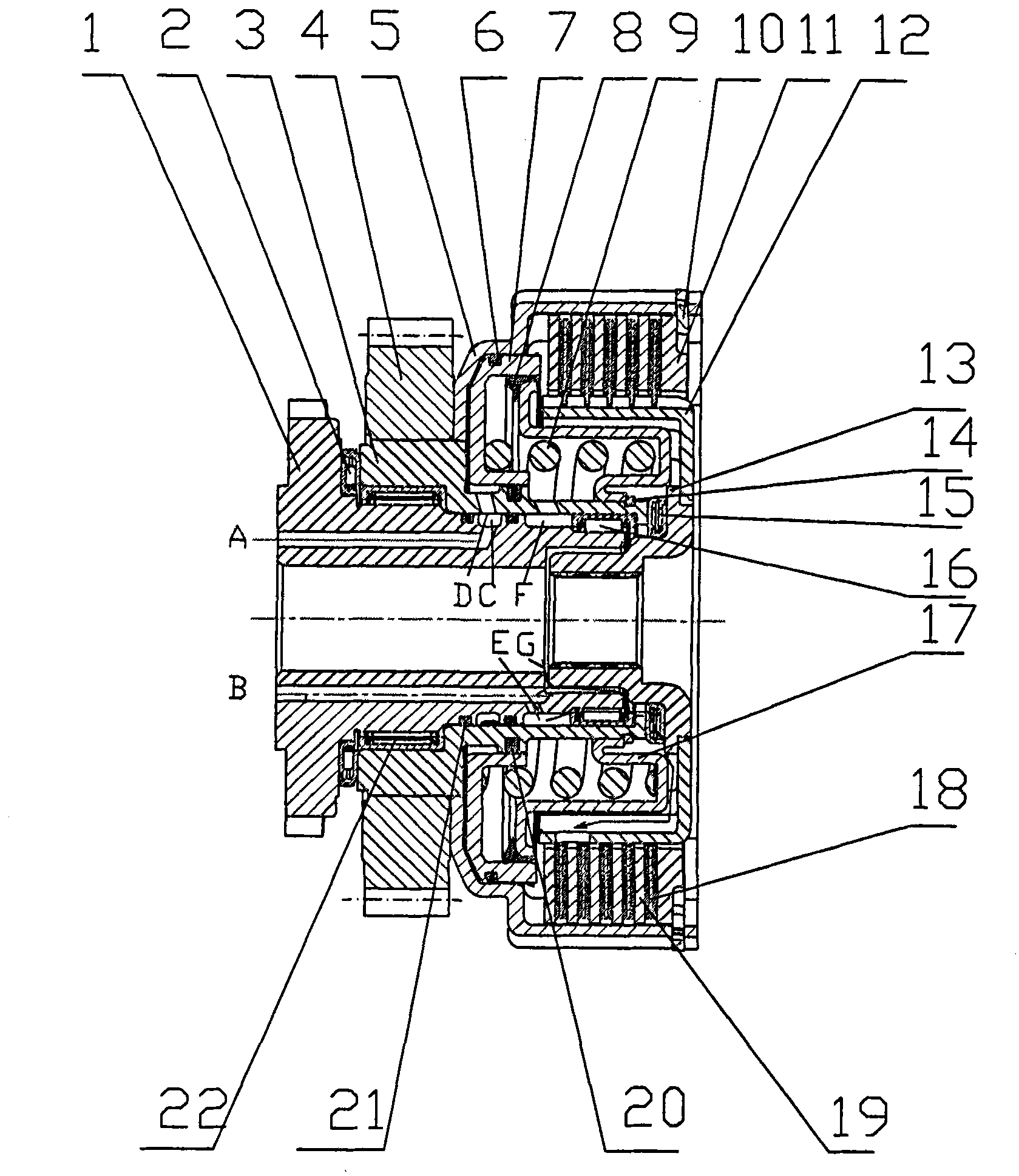

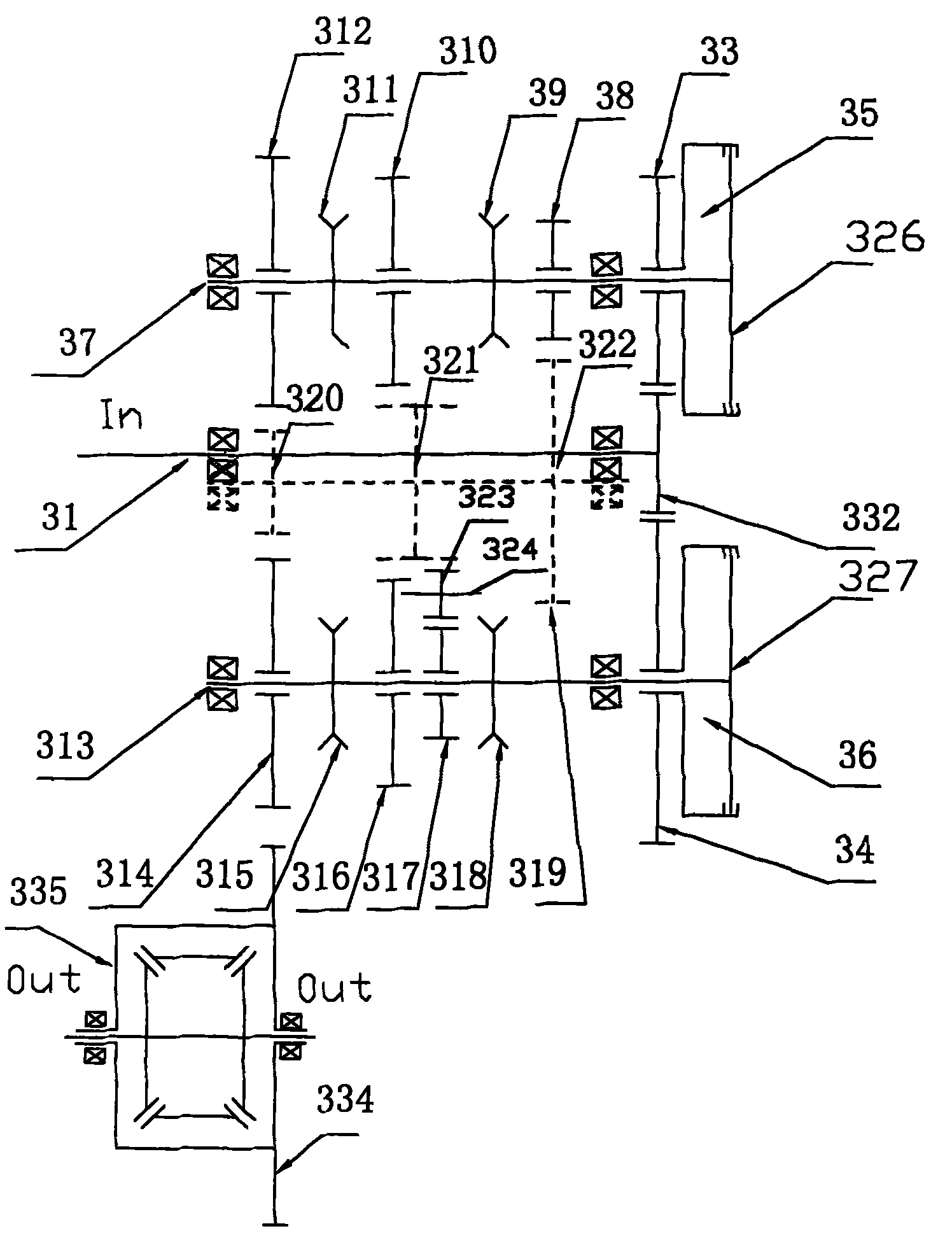

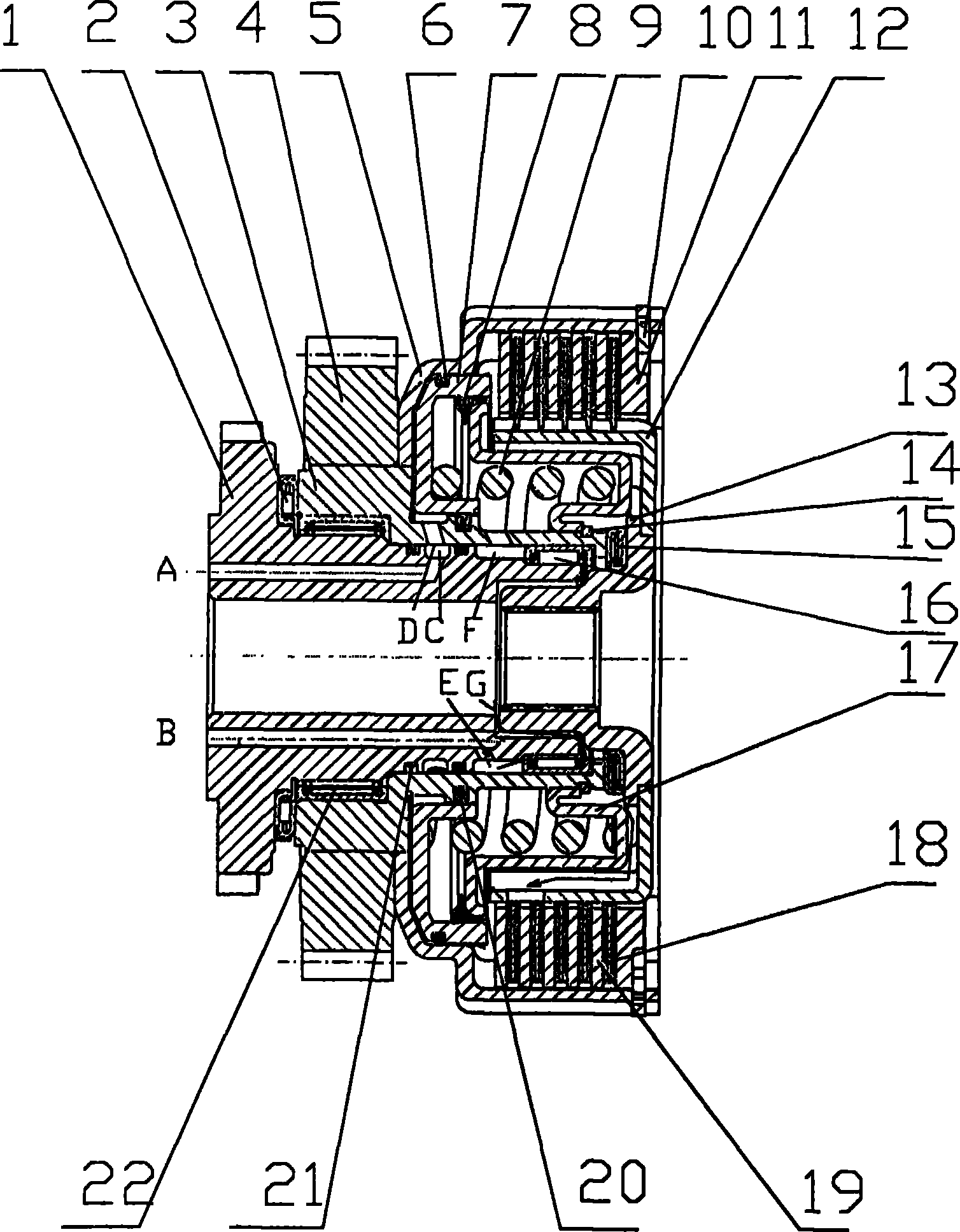

[0019] see Figure 1-2 , dual clutch automatic transmission such as figure 1 As shown, the input shaft gear 332 is installed on the engine input shaft 31, which includes two independent single clutches 35, 36, wherein the driving gear 33 of the odd-numbered gear clutch 35 and the driving gear 34 of the even-numbered gear clutch 36 are respectively different. The transmission ratio meshes with the input shaft gear 332, the odd-numbered gear clutch driving gear 33 is fixed on the first countershaft 37, the even-numbered gear clutch driving gear 34 is fixed on the second countershaft 313, the first countershaft 37 and the second countershaft 313 They are respectively arranged on two sides of the input shaft 31 and are all parallel to the input shaft 31 .

[0020] The odd-numbered gear clutch 35 and the even-numbered gear clutch 36 are respectively fixedly mounted on the right ends of the first countershaft 37 and the second countershaft 313 through the internal odd-numbered fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com