Container wharf RTG and RMG lower container truck alignment guide system and method

An alignment guidance method and guidance system technology, applied in the field of container loading and unloading, can solve problems such as the inability to fully identify the actual operating conditions of collection trucks, the failure of the system to reach the level of practical application, and the inability to effectively detect the location of collection trucks, etc., to achieve Ensure safety, ensure installation accuracy, and meet the effect of accurate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

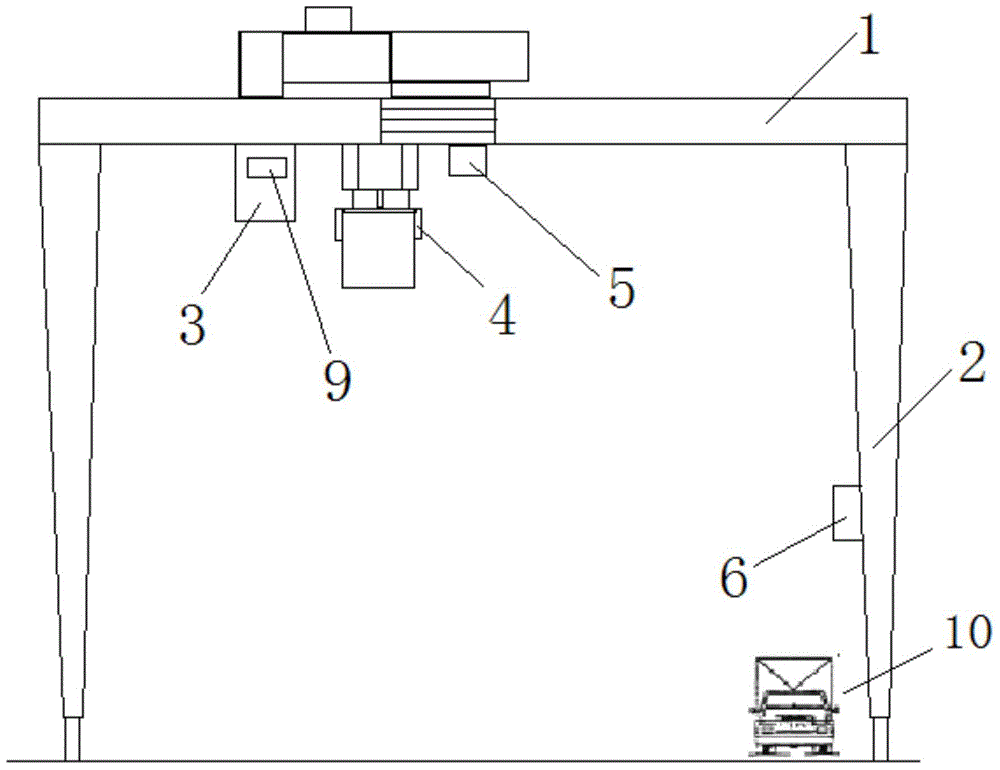

[0035] A container terminal RTG, RMG lower set card alignment guidance system, such as figure 1 and figure 2 As shown, it includes: gantry crane main body 1, outrigger 2, driver's cab 3, spreader 4, laser scanning rangefinder 5, LED display and loudspeaker 6, high-speed embedded controller 7, PLC8, console LCD Screen 9, collection truck and its container 10, etc., among which:

[0036] The laser scanning range finder 5 is fixedly installed on the upper platform of the RTG / RMG power room or the electrical room; the LED display screen and the loudspeaker 6 are installed on the outrigger 2, which is convenient for the truck driver to receive information; the high-speed embedded control Device 7 is installed in the electrical room or in the control box near the laser scanning range finder 5; PLC8 is installed in the electrical room; console LCD screen 9 is installed in the driver's cab 3.

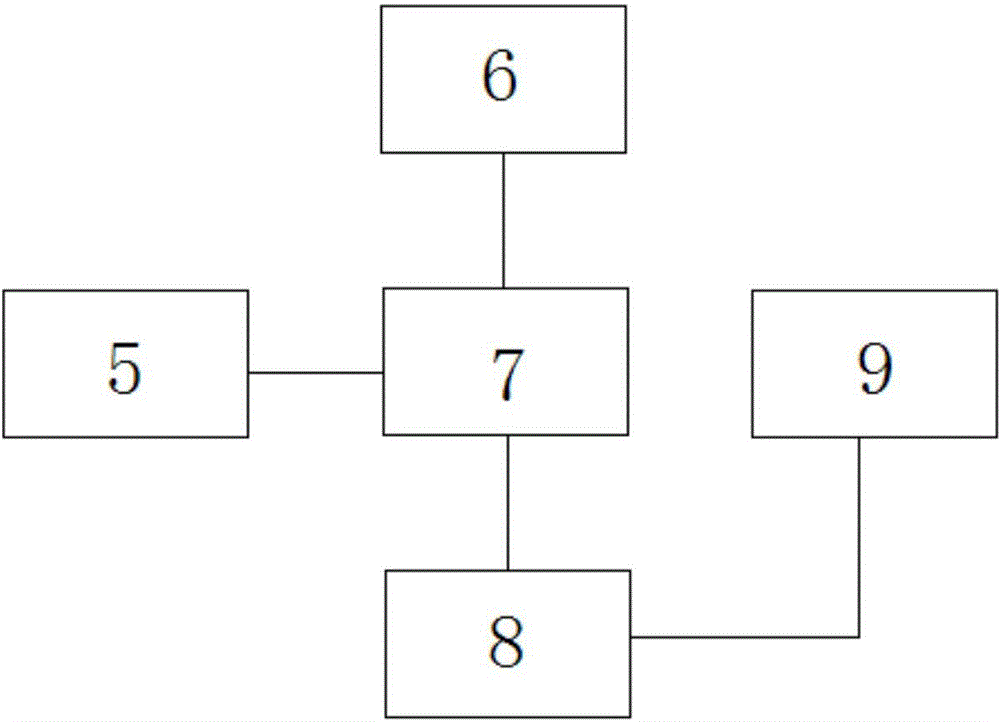

[0037] The high-speed embedded controller 7 is respectively wired with the laser scanning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com