Railway axle box bearing routine testing machine and bearing routine testing method

A technology for axle box bearings and routine testing, which is applied in mechanical bearing testing, testing of mechanical components, testing of machine/structural components, etc. It can solve the problem of bearing installation accuracy affecting the accuracy of test results, bearing disassembly and assembly difficulties, and inapplicability Routine test of quick dismounting bearings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

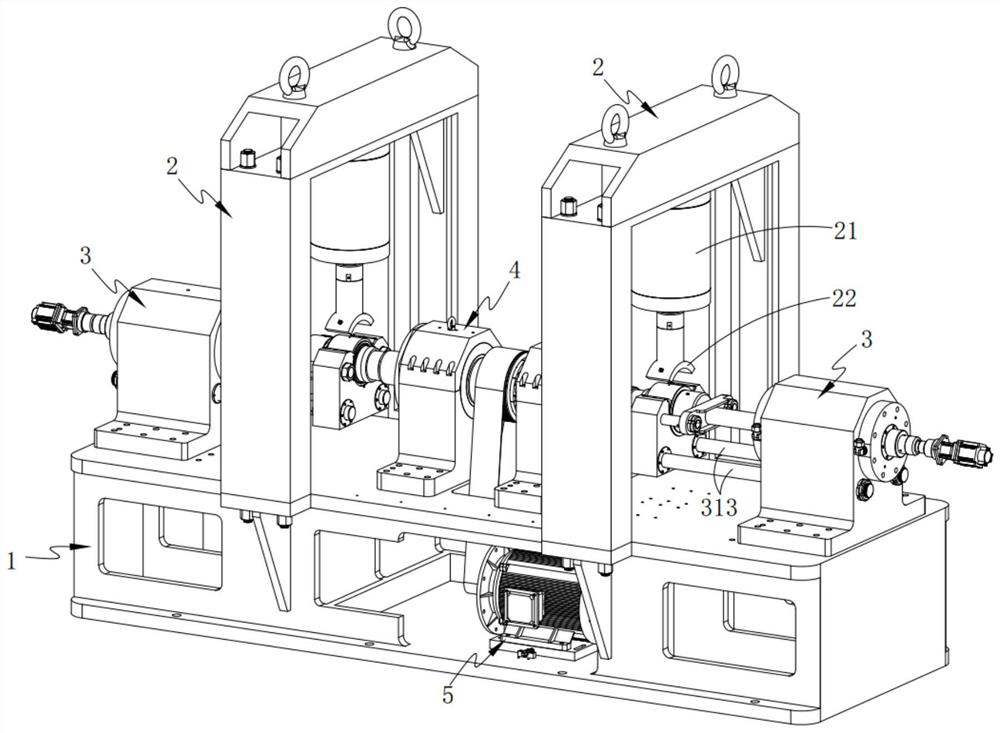

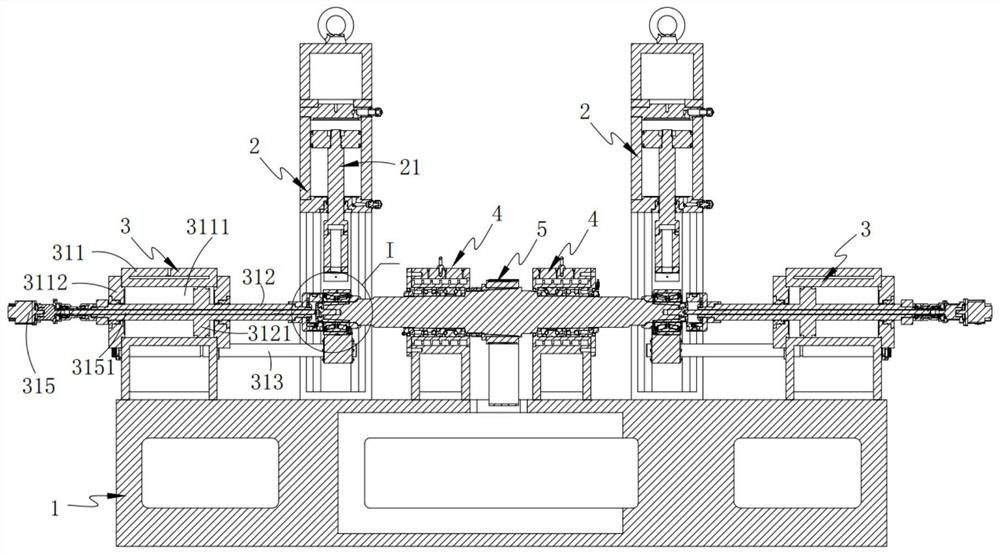

[0068] Such as Figure 1-2 As shown, the railway axle box bearing routine testing machine includes a frame 1 and two groups of radial loading systems 2 symmetrically arranged on the frame 1, and is characterized in that it also includes two symmetrically arranged on the frame 1. A set of loading tooling assemblies 3, a support system 4 arranged between two sets of loading tooling assemblies 3, and a drive system 5 connected to the supporting system 4;

[0069] Described radial loading system 2 comprises the hydraulic unit 21 that is located at frame top, and the output end of described hydraulic unit 21 is provided with the indenter 22 that matches the outer diameter of bearing to be tested; The output force of described hydraulic unit 21 passes through The force sensor and the computer form a closed-loop control;

[0070] The loading tool assembly 3 is used to quickly clamp the bearing 100 to be tested and provide axial loading force;

[0071] The radial loading system 2 is...

Embodiment 2

[0106] Such as Figure 11-16 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0107] In this example, if Figure 11-12 As shown, the support unit 41 includes:

[0108] A bracket 411, the bracket 411 is connected with the frame 1;

[0109] cooling lubricating housing 412, such as Figure 14-15 As shown, the cooling and lubricating housing 412 is arranged on the bracket 411, and its two ends are respectively provided with a liquid inlet 4121 and a liquid outlet 4122, and its outer diameter surface is provided with a number of annular passages 4123 for the circulation of the cooling medium A notch 4124 is opened on the adjacent annular channel 4123, and the two adjacent notches 4124 are a...

Embodiment 3

[0115] Adopt the railway axle box bearing routine testing machine described in the above-mentioned embodiment one or embodiment two technical schemes to carry out the method for bearing routine test, comprise the following steps:

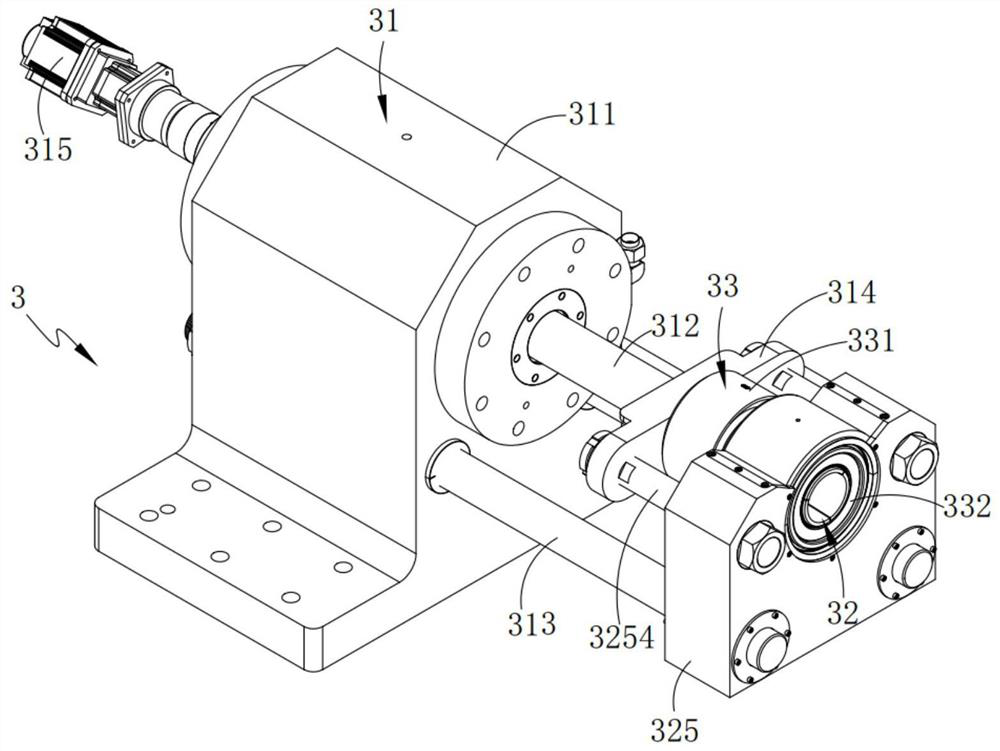

[0116] Step 1, the pre-installation of the bearings to be tested, respectively install the two bearings 100 to be tested on the working positions 3251 on the support bases 325 at both ends; The positioning boss 32521 for pre-positioning;

[0117] Step 2: pre-fix the bearing to be tested, the inner ring loading die 332 protrudes from the outer ring loading die 331 under the action of the limiter assembly 333, start the power assembly 31, drive the axial loading assembly 33 to move inward, and make the bearing to be tested 100 cooperates with the support shaft 421, and at the same time, the boss 3321 of the inner ring loading die 332 is in contact with the inner ring of the bearing to be tested 100, the position of the inner ring and the outer ring of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com