Low-carbon wire constant tension rewinding shaft device

A technology of constant tension and shaft device, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material handling, etc., can solve the problems of general speed regulation effect, etc., and achieve the effect of convenient operation, convenient operation, and stable pay-off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

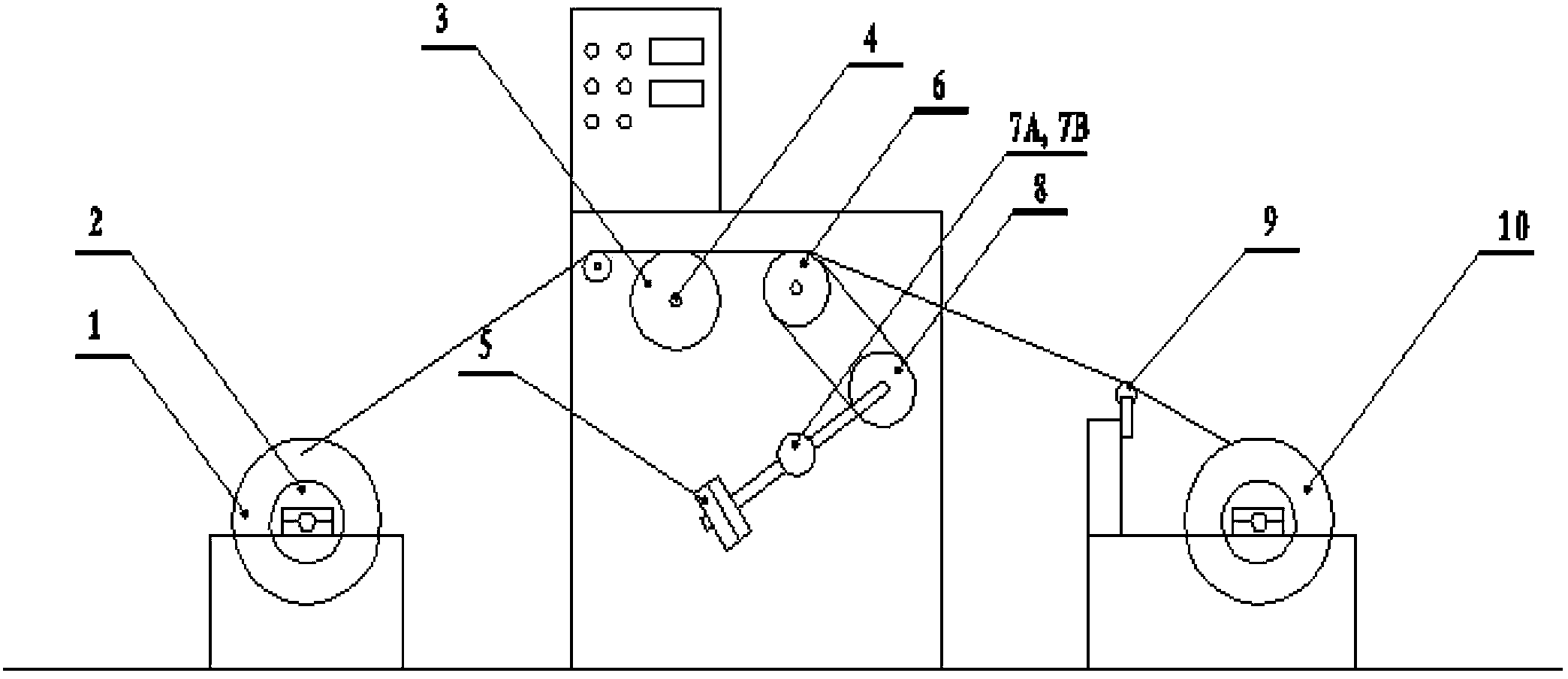

[0022] As shown in the figure, the semi-finished shaft wire 1 is placed on the pay-off frame, and the friction disc 2 is damped by the flexible damping belt. The damping can be adjusted. The pulley 3 is equipped with a variable frequency speed regulating motor driven pulley 4, which can be steplessly speed regulated and has a speed display.

[0023] The re-wound wire passes through the tension fixed wheel combination 6, and is reciprocally wound with the swing slave wheel 8 for 3 turns.

[0024] The tension arm transmits the swing angle through the fulcrum sleeve 7A, and the swing sensor 7B is arranged behind the box, and the control signal is sent to the frequency conversion speed regulating motor of the take-up I-shaped wheel 10, and the real-time speed is fine-tuned to achieve constant tension. One side of the tension arm is equipped with a tension counterweight balance wheel 5, which can be moved to change the size of the force arm and control the tension setting value.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com