Patents

Literature

54results about How to "Stable pay-off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-carbon wire constant tension rewinding shaft device

The invention relates to a low-carbon wire rewinding shaft device, in particular to a low-carbon wire constant tension rewinding shaft device. The low-carbon wire constant tension rewinding shaft device structurally comprises a flexible damping payoff mechanism, a constant speed traction mechanism, a tension control mechanism and a plastic finished product bobbin, wherein the flexible damping payoff mechanism, the constant speed traction mechanism, the tension control mechanism and the plastic finished product bobbin are arranged in the running direction of a rewound wire. According to the low-carbon wire constant tension rewinding shaft device, the take-up speed can be regulated to stabilize tension according to a tension change represented by the specification and strength of the wire, so that the phenomena of circle swinging, wire clamping and tightness non-uniformity of the rewound wire are avoided, and the quality of a product is greatly improved.

Owner:TIANJIN HUAYUAN WIRE PROD

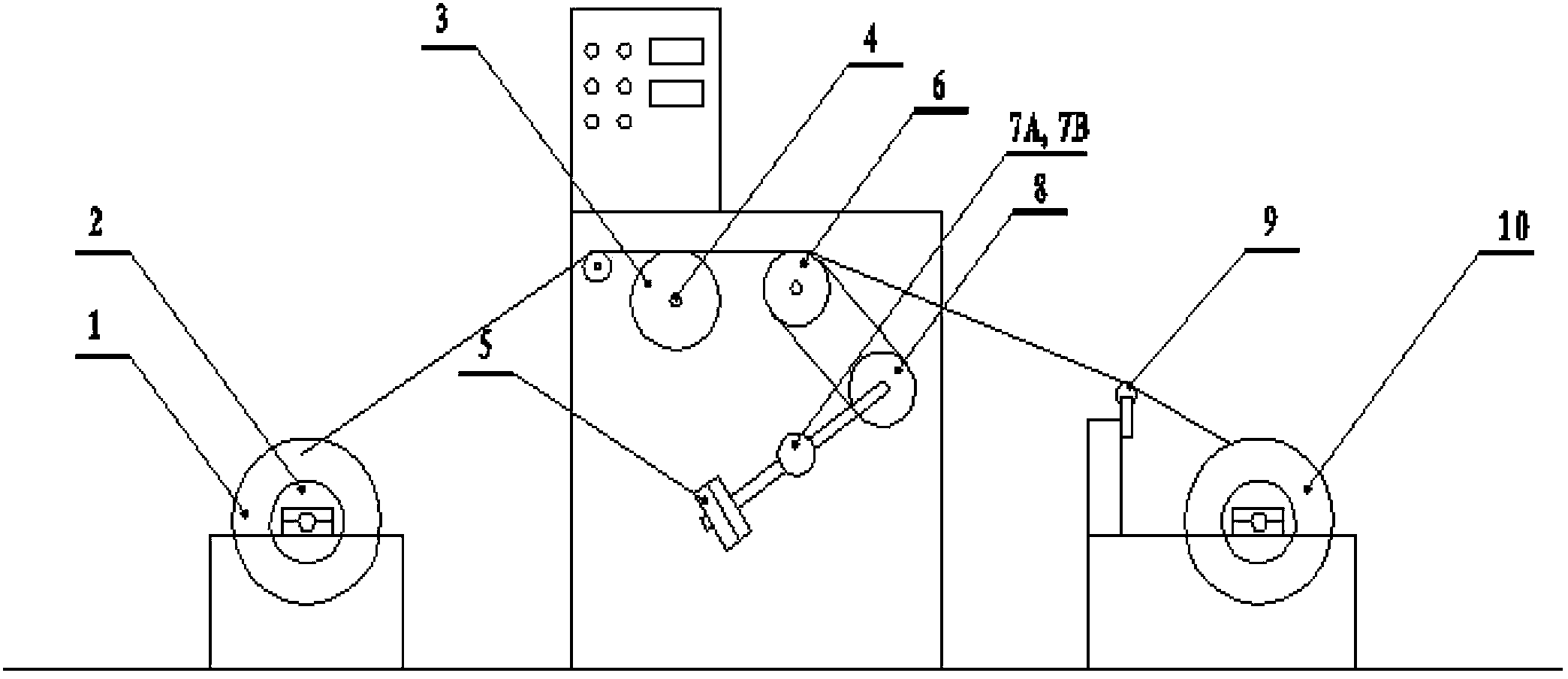

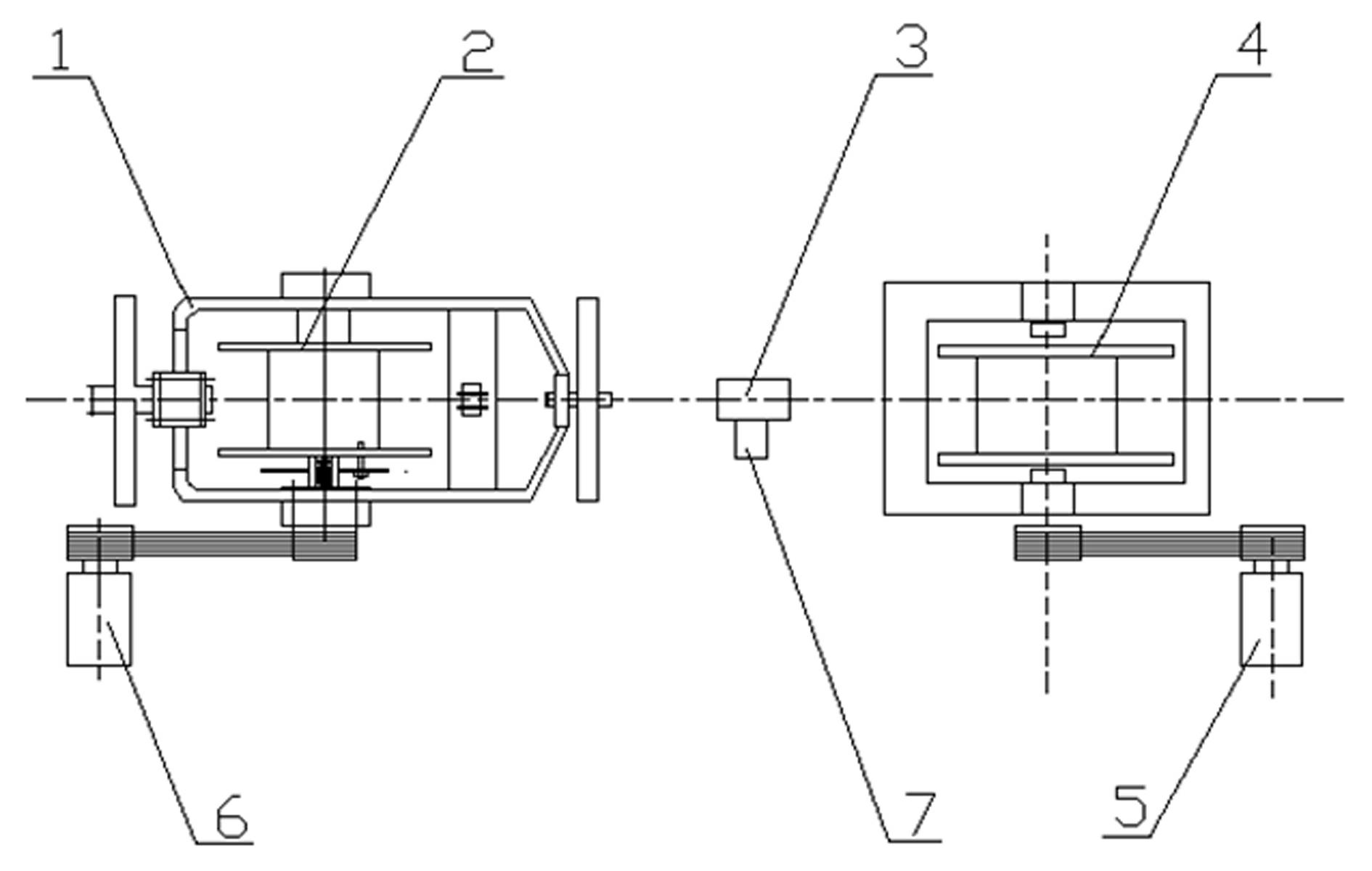

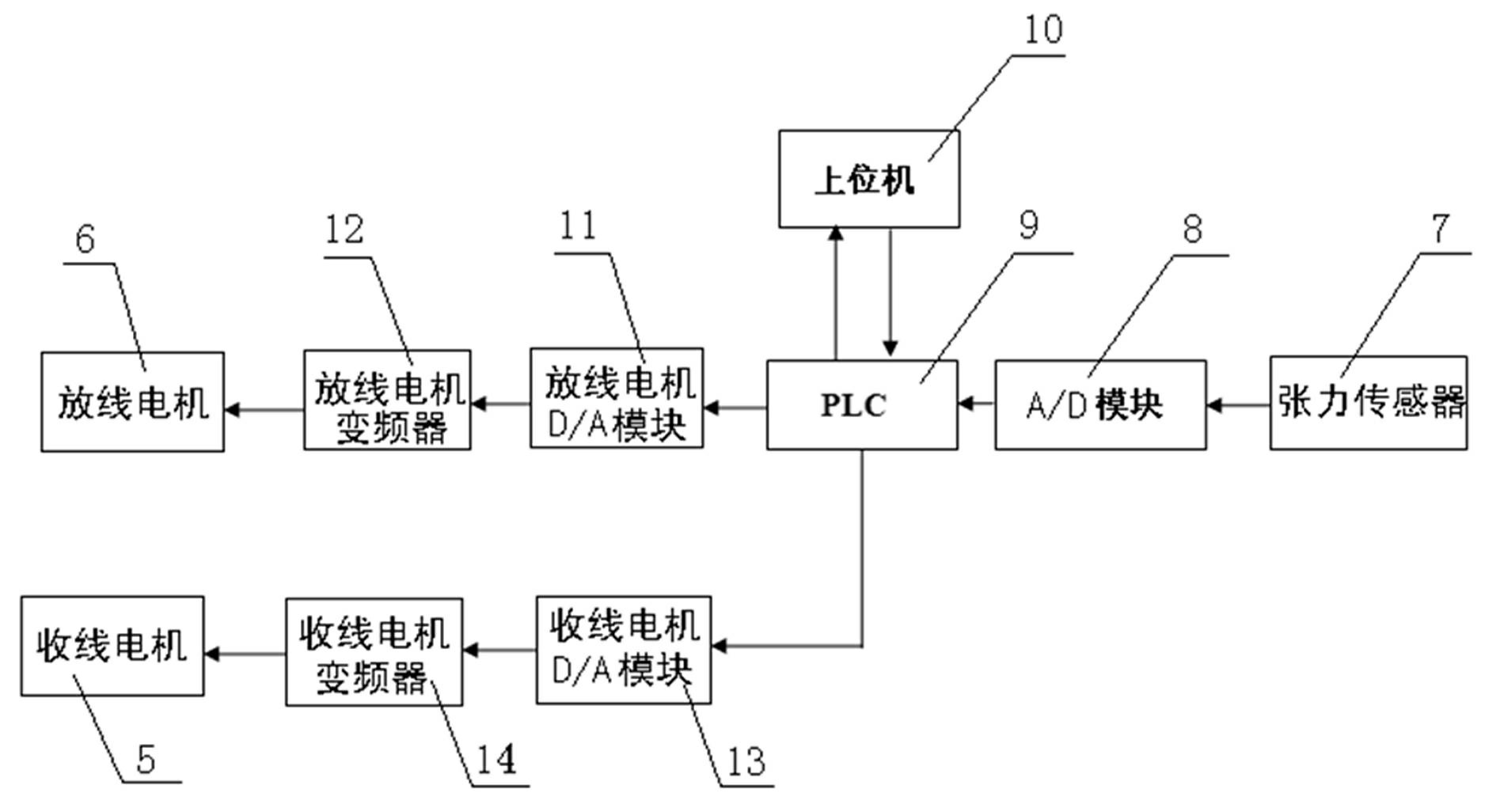

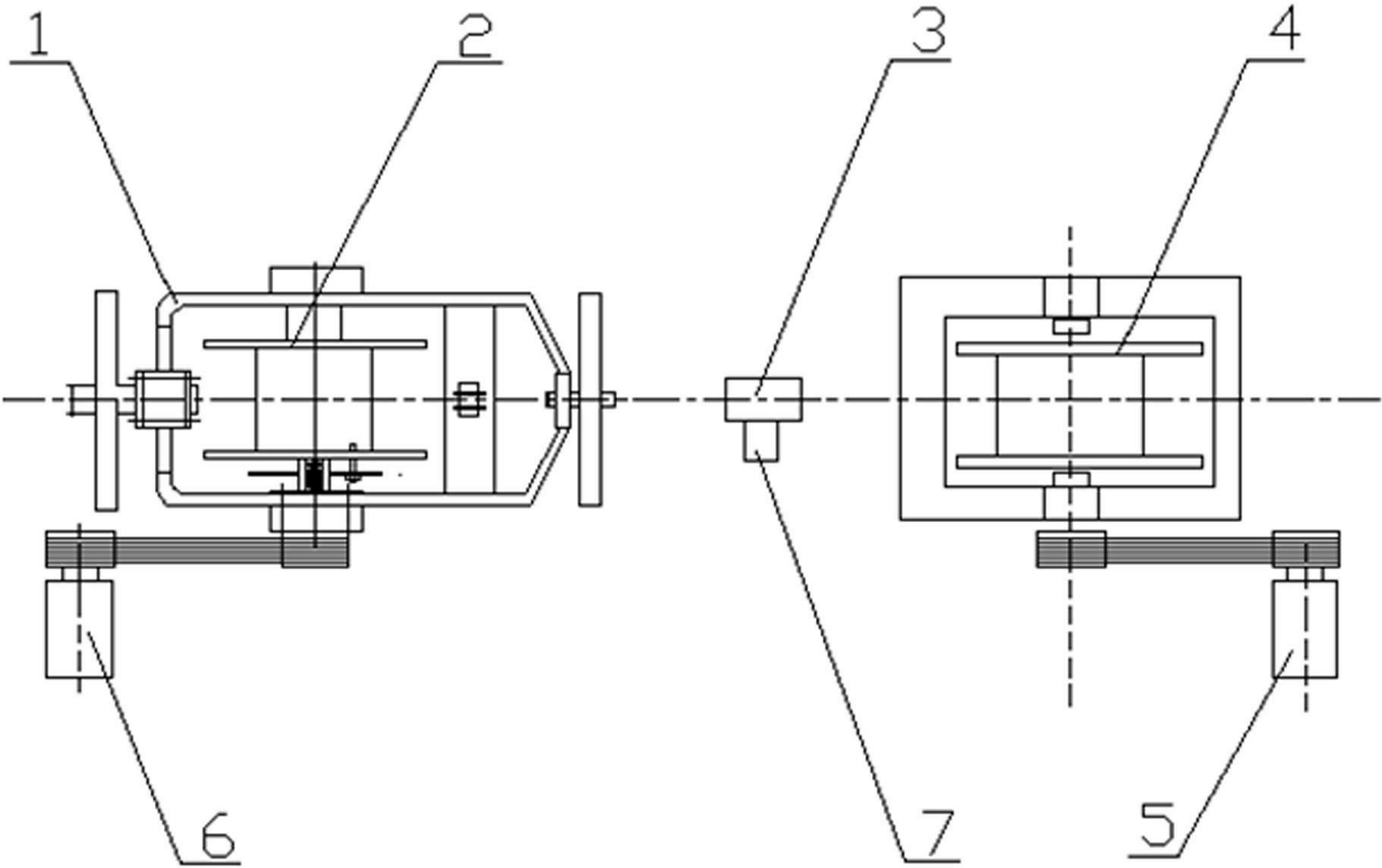

System for automatically controlling tension of stranded cables of superconducting conductor

InactiveCN102664078ASolve the problem that the precise control of the tension value cannot be satisfiedEasily brokenCable/conductor manufactureControl systemEngineering

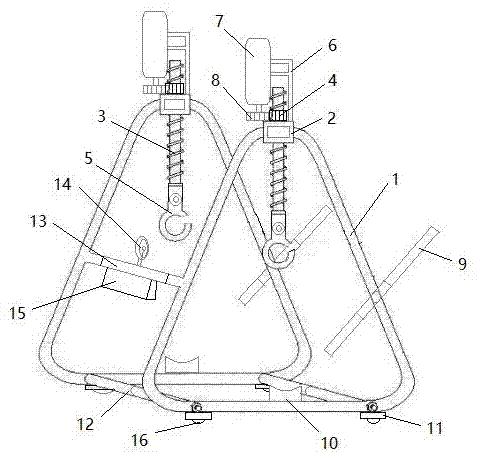

The invention discloses a system for automatically controlling the tension of stranded cables of a superconducting cable conductor. The system comprises a stranded wire frame, wherein a pay-off disk is arranged in the stranded wire frame through a rotating shaft; wire guiding wheels are arranged behind the stranded wire frame; a take-up disk is arranged behind the wire guiding wheels; and the take-up disk is connected with a take-up motor. The system also comprises a pay-off motor connected with the pay-off disk; a tension sensor is connected with the wire guiding wheels; signals of the tension sensor are switched in a control circuit in a control cabinet; and a frequency converter of the take-up motor and a frequency converter of the pay-off motor are respectively connected with the control circuit. By adoption of the system, the tension can be accurately controlled, so that wires can be paid off stably, the problem that a tension value cannot be accurately controlled during stranding of superconductive wires is solved, and the problems that the superconductive wires are loosen and nonuniform, are easily snapped and the like during stranding are solved.

Owner:BAIYIN NONFERROUS GROUP

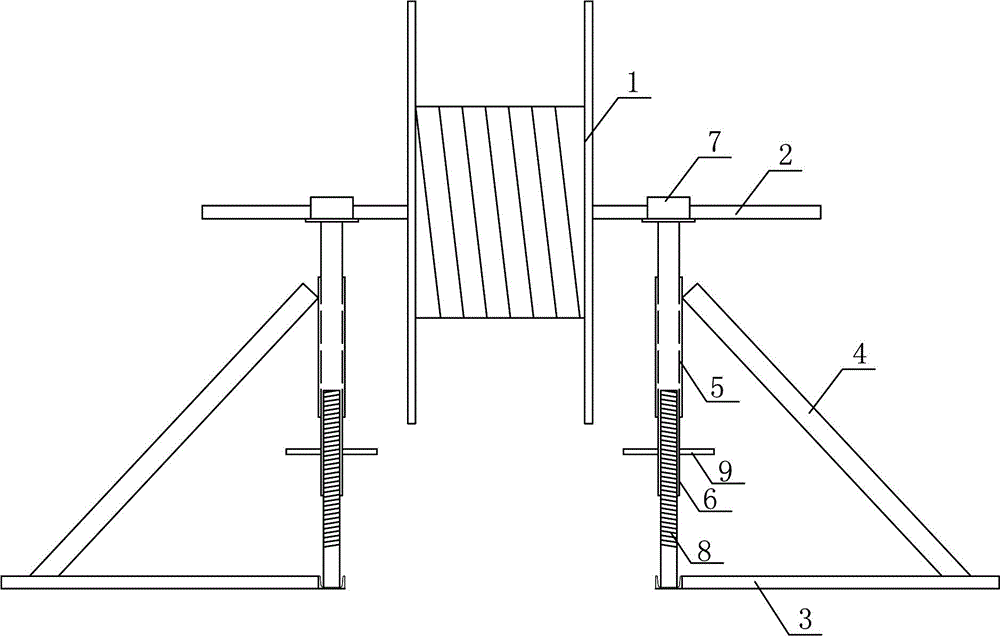

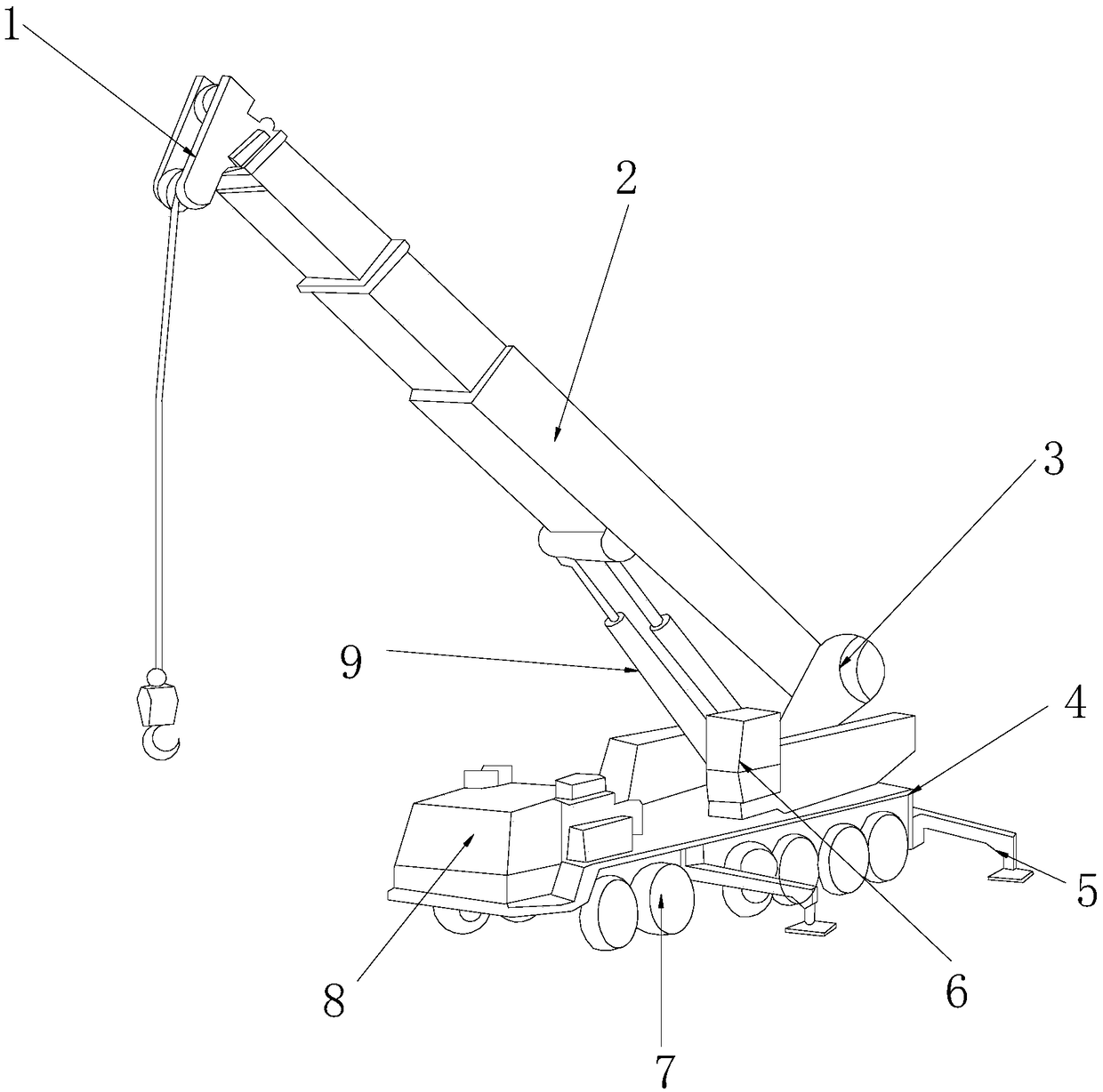

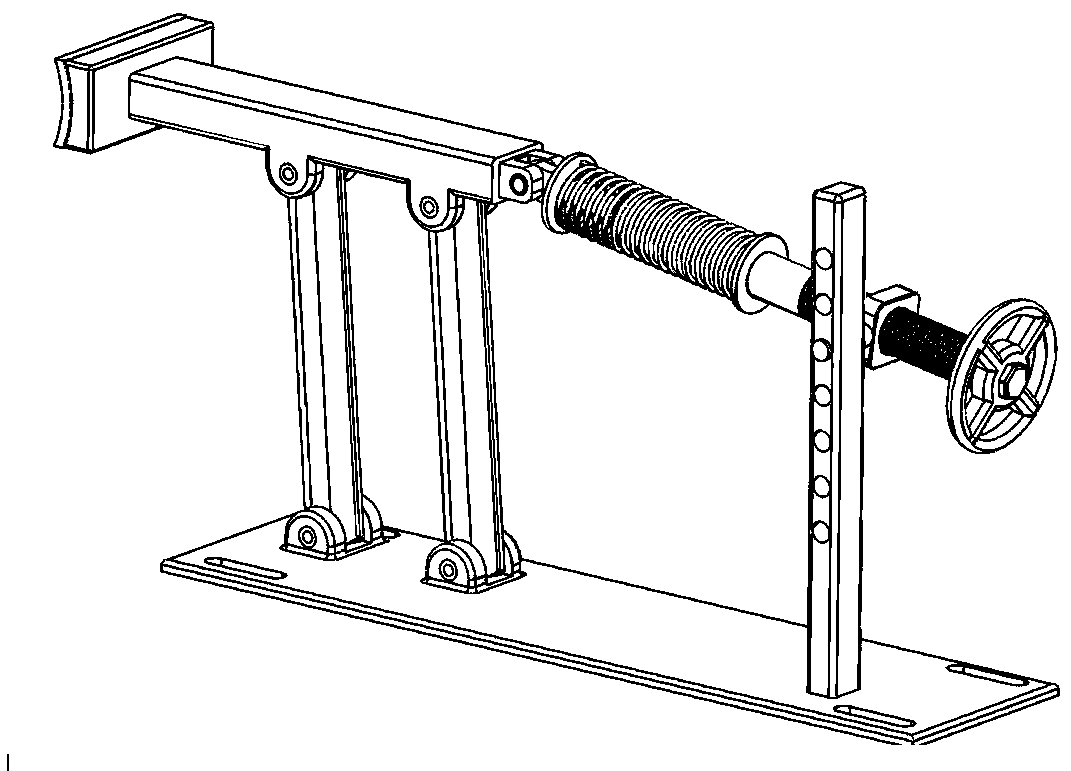

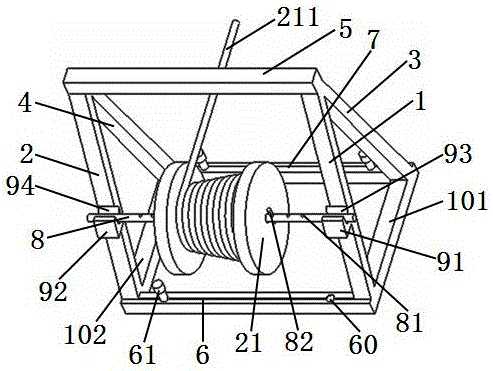

Adjustable cable coiler apparatus

InactiveCN105429056AStable pay-offSolve the problem of large construction cost investmentFilament handlingApparatus for laying cablesEngineering

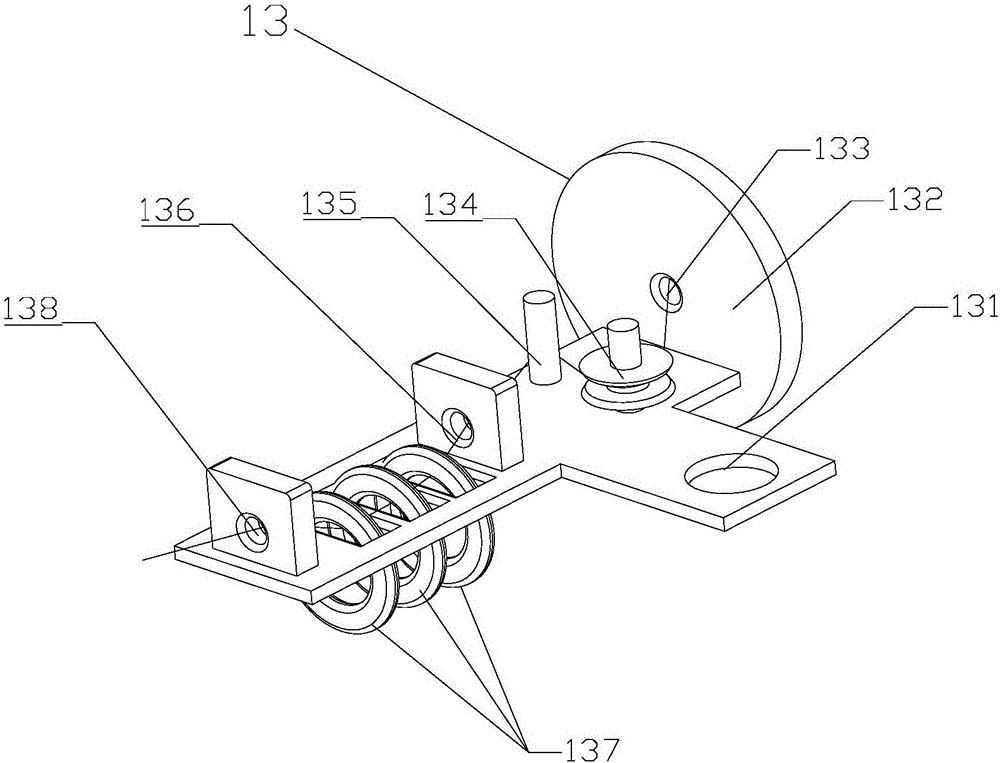

Disclosed is an adjustable cable coiler apparatus, which consists of two symmetrical triangular supports that match a cable drum. In terms of each triangular support, a vertical adjustable shaft rod is fixedly disposed in the middle of a triangular body formed by a T-shaped pedestal and multiple inclined struts, the vertical adjustable shaft rod is embedded into a vertical sleeve pipe, the lower segment of the vertical adjustable shaft rod is joint with a screw, a handle is fixedly disposed outside the adjustable shaft rod, a supporting plate is disposed at the top of the vertical adjustable shaft rod, and a horizontal shaft supporting the cable drum is placed inside the supporting plate. The height of each horizontal shaft at the top of one corresponding adjustable shaft rod is adjusted by the adjustable shaft rod disposed in the middle of one corresponding triangular support. In this way, the adjustable cable coiler apparatus can fit cable drums with different diameters, thereby solving the problem that the construction investment is high since different cable coilers need to be manufactured for cable drums with different diameters. Moreover, the adjustable cable coiler apparatus is flexible to configure, practical, and convenient to install and transport.

Owner:CHINA GEZHOUBA GROUP CO LTD

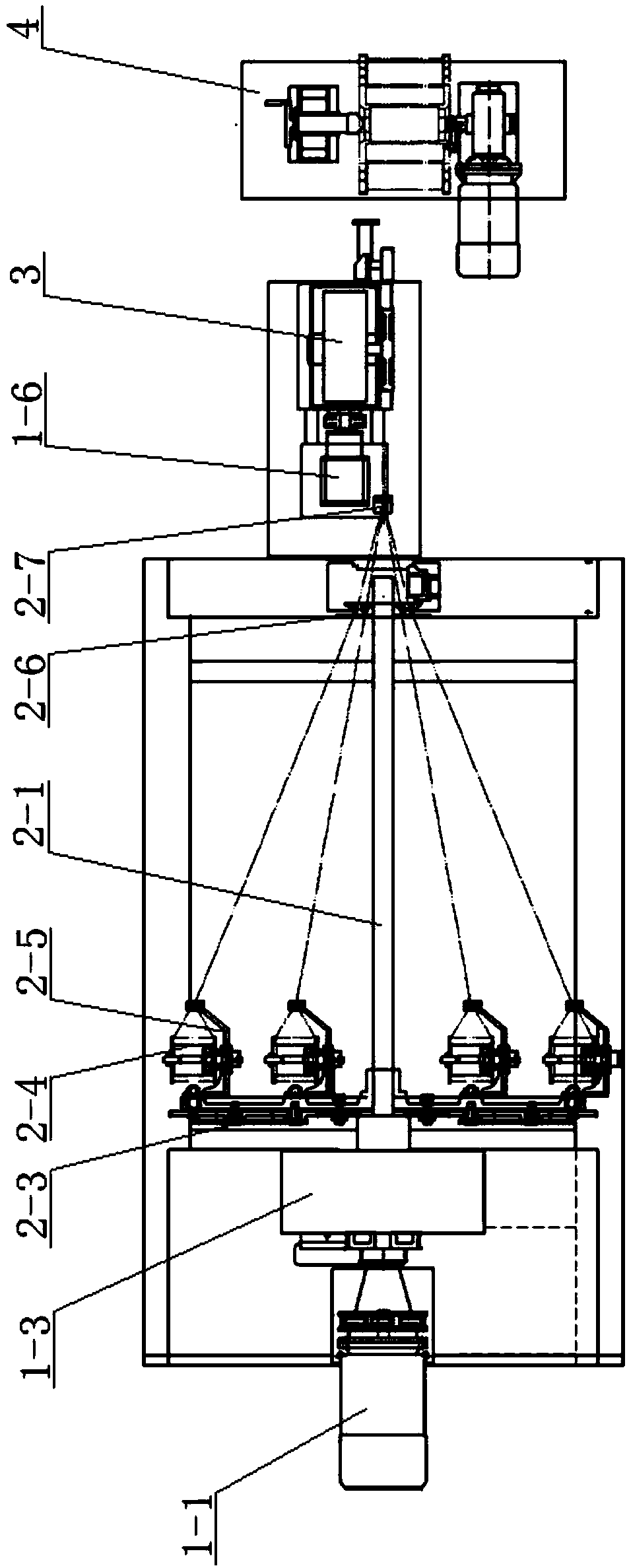

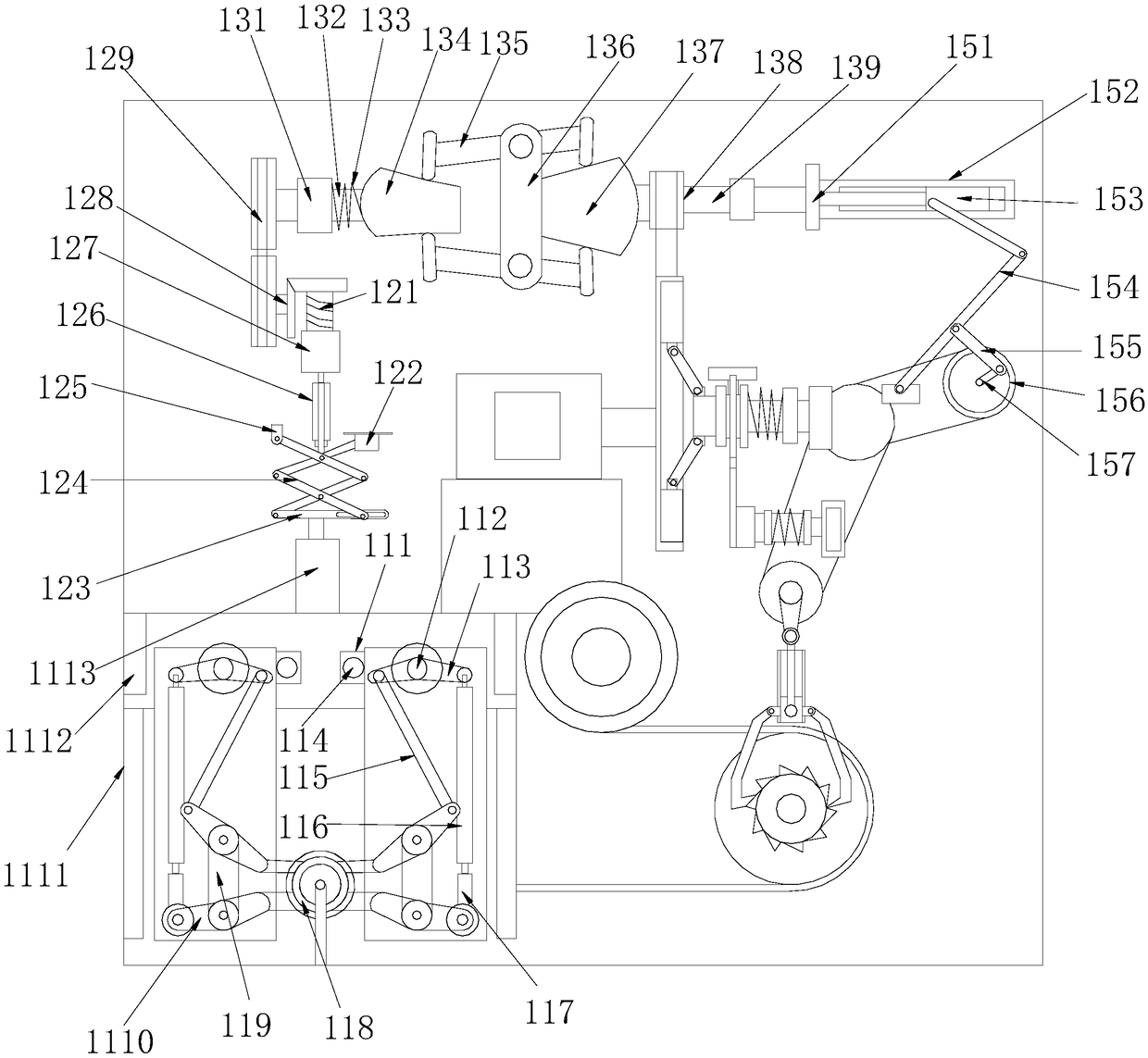

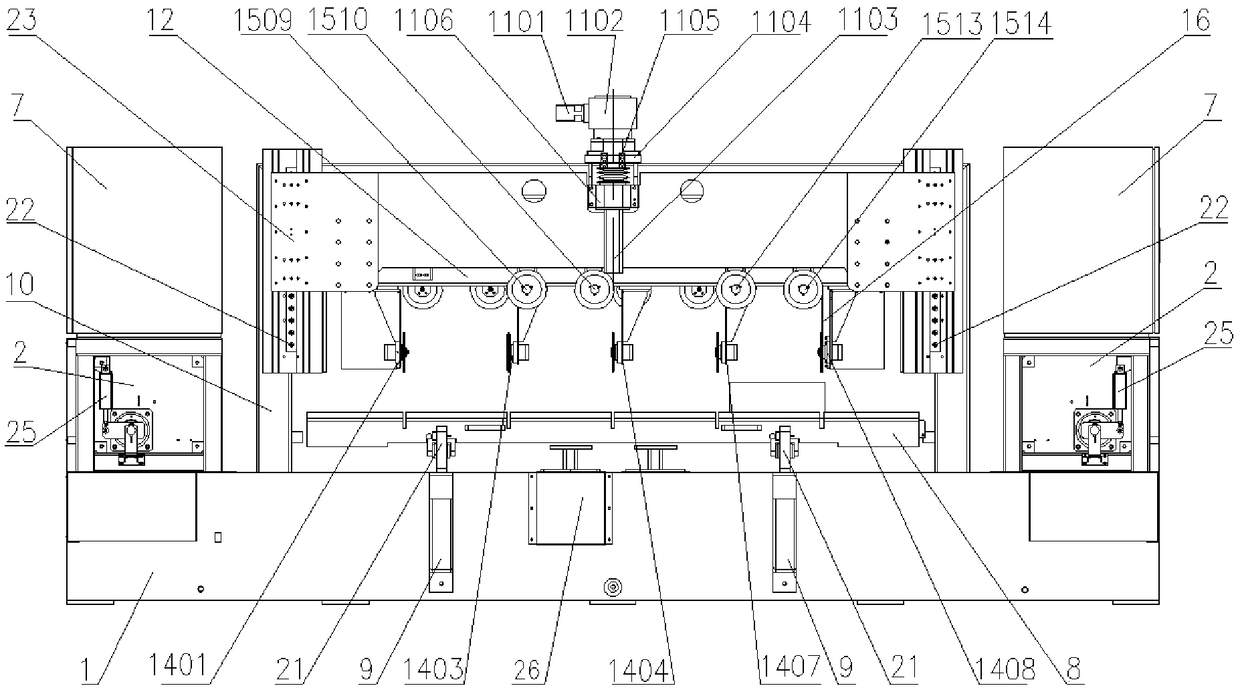

Multi-strand special conductor twisting and back-twisting cage wire stranding machine

PendingCN109509587AEnsure consistencyAvoid disconnectionCable/conductor manufactureElectrical conductorInstability

The invention discloses a multi-strand special conductor twisting and back-twisting cage wire stranding machine, belonging to the field of a cage wire stranding machine. The cage stranding machine ofthe invention comprises a power transmission mechanism, a conductor twisting mechanism, a conductor winding mechanism and a conductor take-up mechanism, wherein the power transmission mechanism is connected with the conductor twisting mechanism and the conductor winding mechanism, and a twisted conductor formed by the unwinding of the conductor twisting mechanism is coiled and winded in the conductor winding mechanism after being shaped by the conductor take-up mechanism. A multi-stage back-twisting gear set is utilized to always ensure that unwinding positions are fixed, and an infinitely variable transmission is cooperated to drive coiling and shaping of the conductor. In this way, the wire stranding machine effectively avoids problems of a broken stranded conductor, strand jumping, twisting, roundness of the cross section of the conductor and the like caused by unwinding instability of a conventional cage wire stranding machine, can accurately control the roundness of the cross section, the pitch and the stranding direction of the twisted conductor, is easy to operate, is high in safety factor, and is suitable for large-scale and high-efficiency stranding production of special conductors.

Owner:CHANGZHOU HENGFENG SPECIAL CONDUCTOR CO LTD +1

Unwinding equipment for cable machining

InactiveCN107032176APrevent looseningAvoid direct contactFilament handlingArchitectural engineeringMachining

The invention discloses a wire-releasing device for cable processing, which comprises a fixed seat, one end of the top end of the fixed seat is fixedly connected with the first column through the first base, and the other end of the top end of the fixed seat is fixedly connected with the second column through the second base. The top of the seat is provided with a slideway near the end of the first base, the first base is connected with the slideway through a pulley, one side of the first base is provided with a push rod motor, and the first base of the first base is connected with the push rod motor through a push rod , the bottom of the opposite side of the first column and the second column are provided with a fixed shaft, a bobbin is arranged between the two fixed shafts, the fixed shaft is connected with the bobbin through a buffer spring arranged on the movable shaft, and the second column is provided with a The chute, the second column is connected with the horizontal plate through the chute, the present invention is more convenient to use, suitable for various wire mandrels, simple to operate, saves time and labor, simple overall structure, low cost, strong practicability, and easy to popularize .

Owner:盐城三强线缆有限公司

Novel cable pay-off rack

InactiveCN103972822ARelease easilyQuick releaseFilament handlingApparatus for laying cablesClassical mechanicsEngineering

Owner:国网山东省电力公司沂水县供电公司

Cable pay-off device

Owner:广西和联胜电缆有限公司

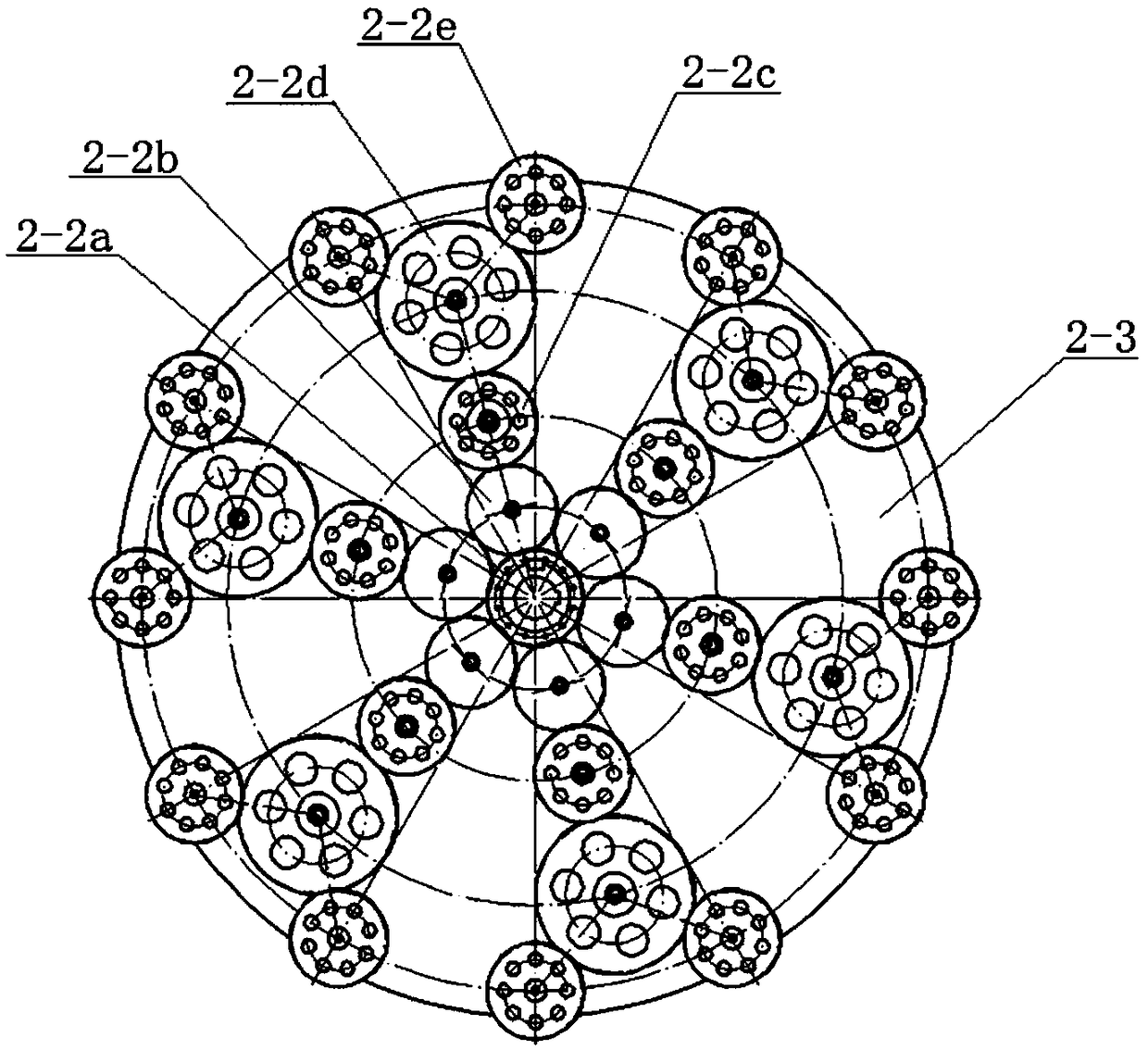

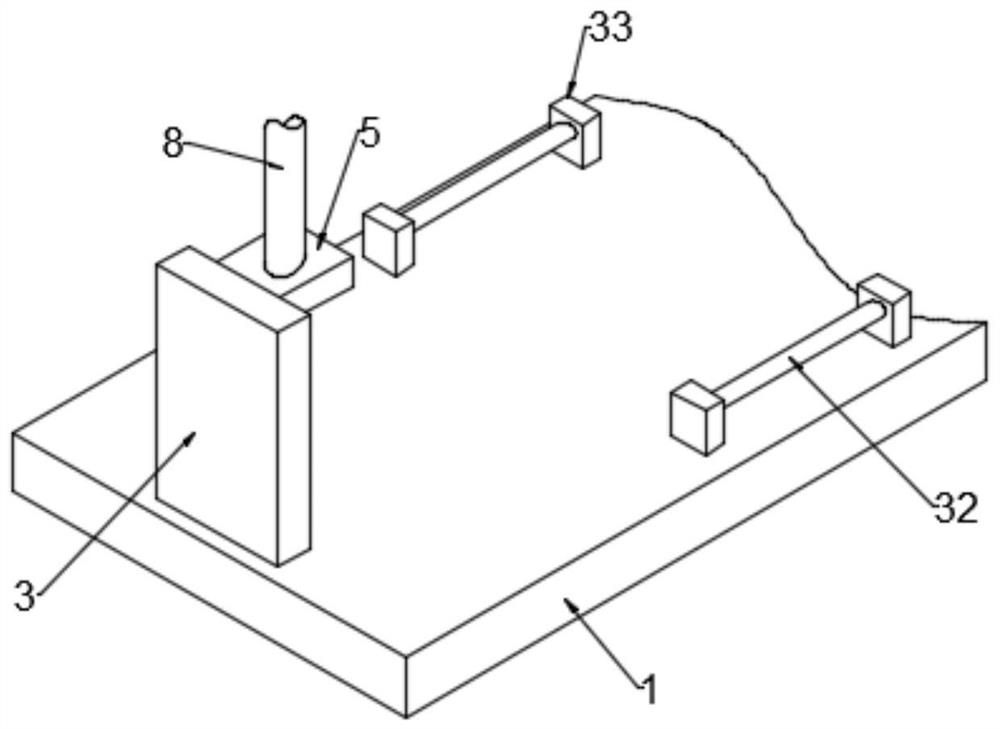

Method and device for manufacturing cable by using fine steel wires

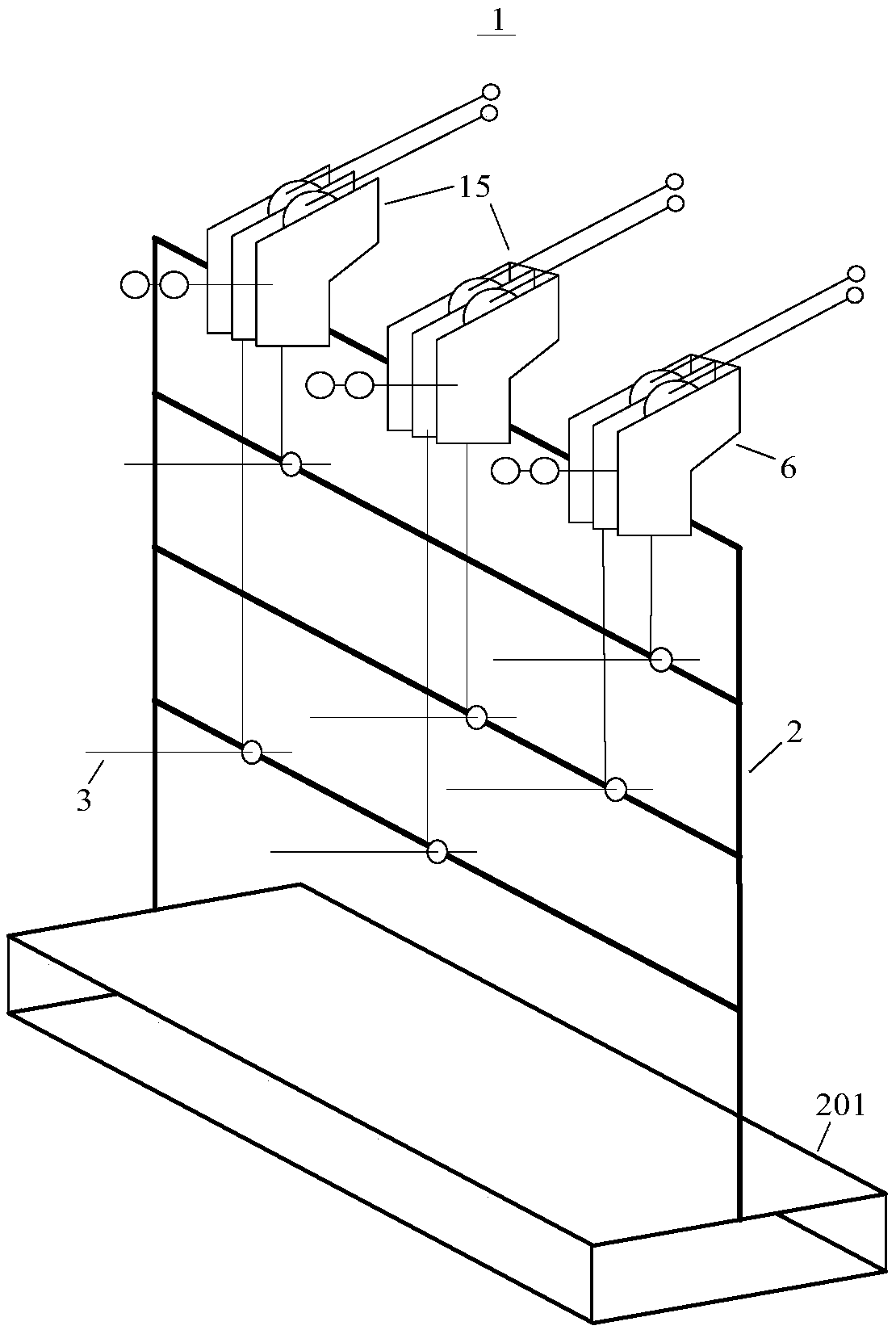

ActiveCN112813712AStable pay-offLine optimizationRope making machinesUltimate tensile strengthMaterials science

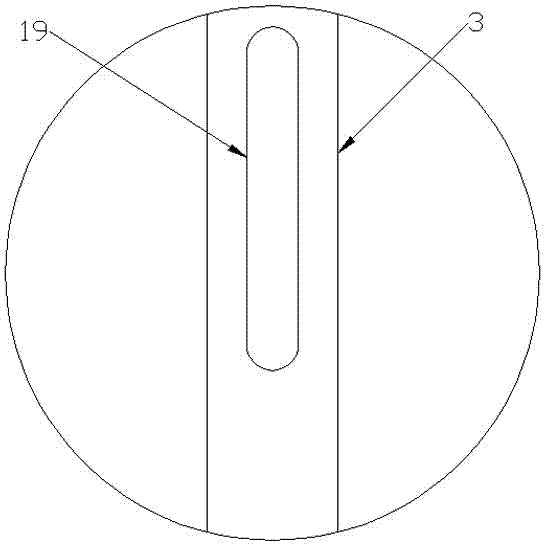

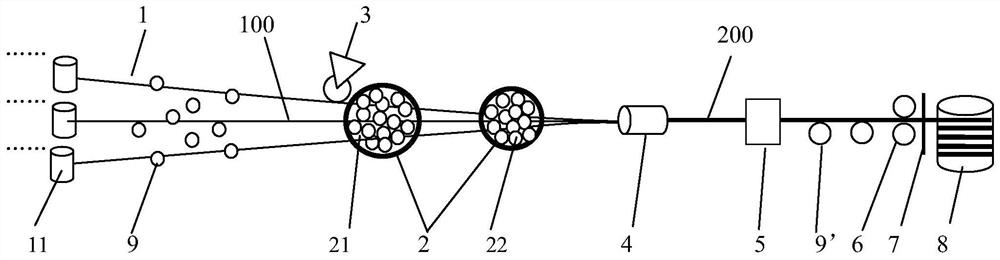

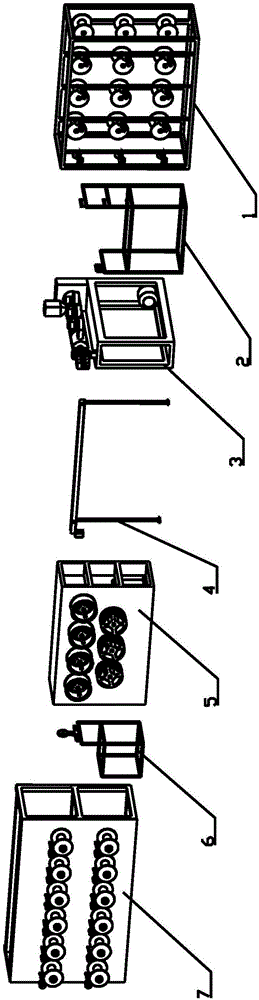

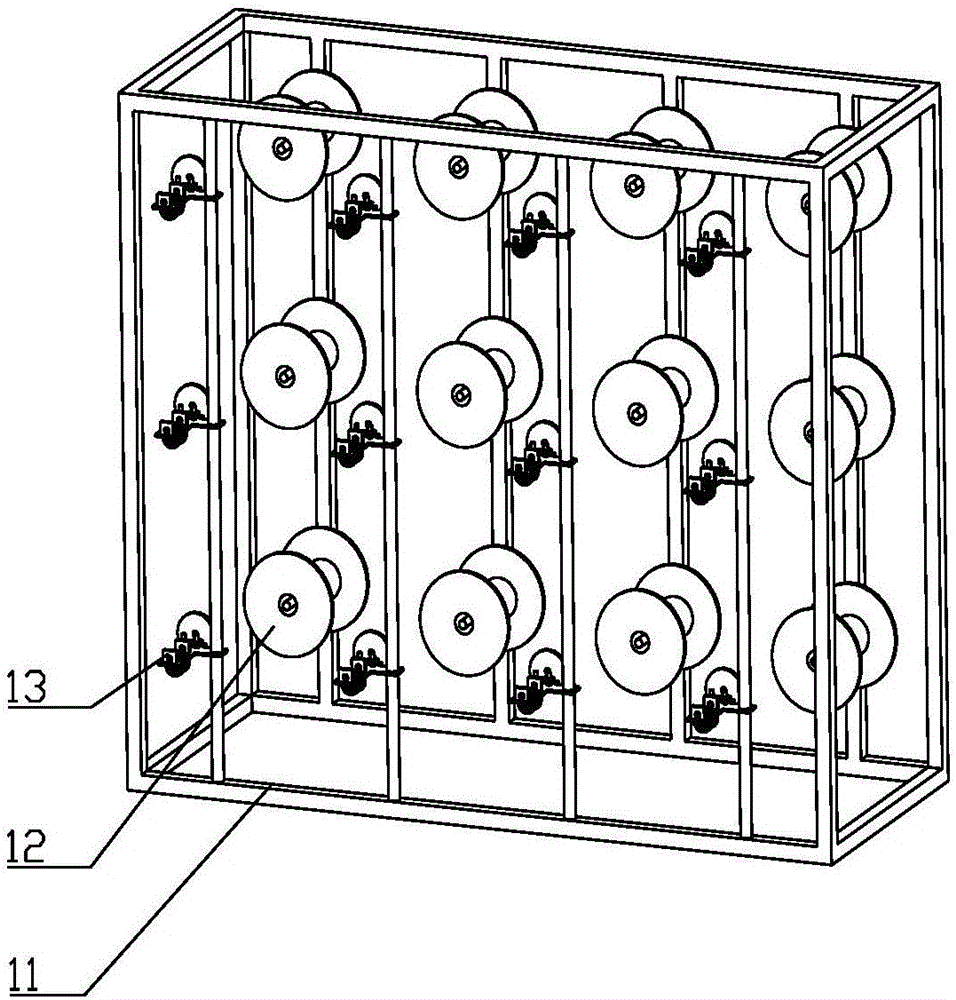

The invention discloses a method and a device for manufacturing a cable by using micro steel wires. The method comprises the following steps: stacking and paying off, wire separating and combing, tension control, stranding, winding, clamping and pulling, cutting and taking up, wherein in the step of stacking and paying off, the diameter of the steel wire for paying off ranges from 0.03 mm to 3.0 mm, and spools are adopted for paying off and are arranged in a multi-layer and multi-column stacking mode; in the step of wire separating and combing, at least four wire separating and combing discs are adopted and evenly arranged between paying-off and stranding at intervals, and all the wire separating and combing discs sequentially deflect by an angle along the axis, so that the steel wires are adjusted step by step in the circumferential direction for multiple times, and thus a torsional angle is achieved through accumulation; wire holes are uniformly formed in the wire separating and combing discs, the wire holes are in fillet transition, and R is larger than 10 mm; and the wire separating and combing discs are made of a non-steel material. According to the method, the ultrahigh-strength fine steel wires are used for manufacturing the cable, under the same cable force requirement, the cable strand sectional area (diameter) is reduced, the porosity is reduced, the cable strand compactness is improved, meanwhile, the cable strand dead weight is reduced, and the spanning capacity of the cable is enhanced.

Owner:BAOSTEEL METAL

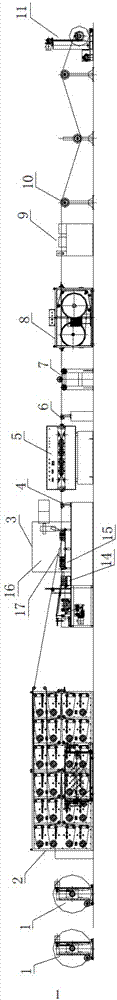

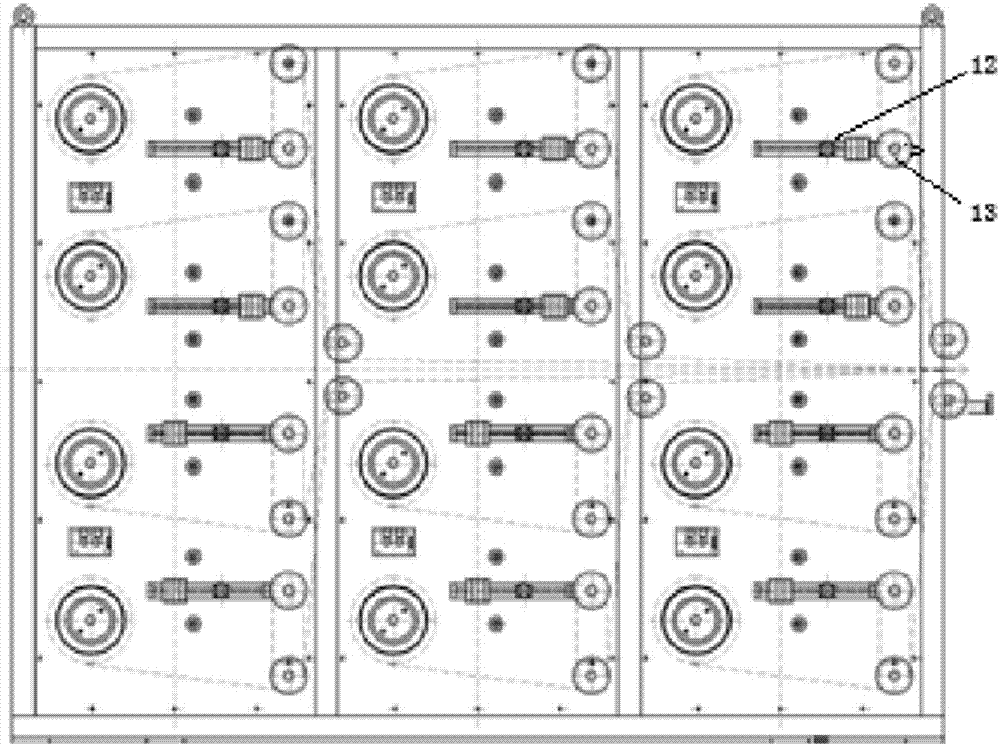

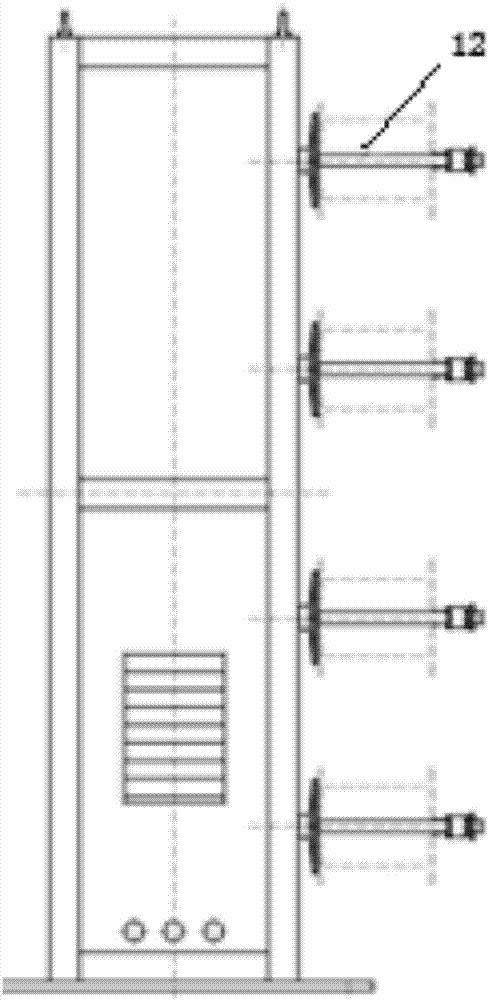

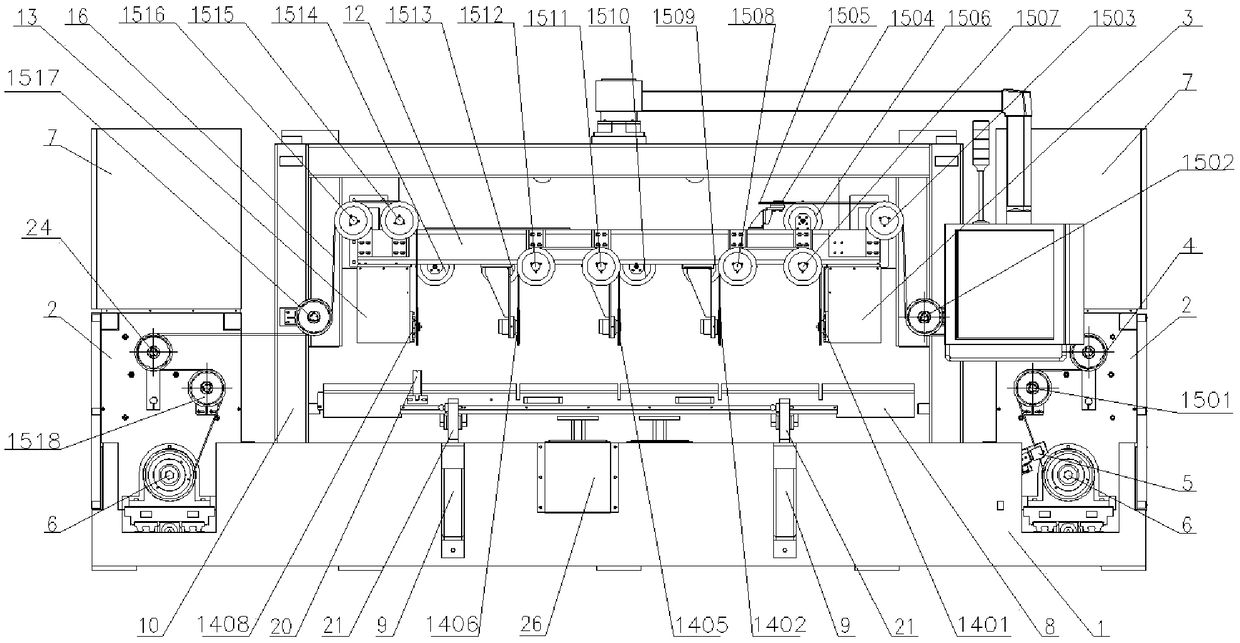

Plastic coating production line

ActiveCN106476189AIncrease productivityStable pay-offFilament handlingCoatingsProduction lineEngineering

The invention relates to the technical field of spinning, in particular to a plastic coating production line. The plastic coating production line comprises a pay-off machine for winding raw wires, a wire collecting machine for changing the directions of the raw wires and gathering the raw wires, a coating machine for coating molten plastic on the raw wires to form composite wires, a cooling tank for cooling the composite wires and penetrating through the composite wires, a drawing machine for drawing the composite wires to deform, a detector for detecting the diameter sizes of the composite wires, and a wire rewinding machine for storing the composite wires; and the pay-off machine, the wire collecting machine, the coating machine, the cooling tank, the drawing machine, the detector and the wire rewinding machine are arranged as a production line in sequence. The plastic coating production line integrates paying-off, wire collection, coating, cooling, drawing, detection and wire rewinding production processes on one production line, and is high in production efficiency.

Owner:CHANGZHOU INST OF NUMERICAL CONTROL TECH

Cable winding disc rolling rack for power industry

The invention discloses a cable winding disc rolling rack for a power industry. The cable winding disc rolling rack comprises two triangular supporting units which are symmetrically arranged in parallel, wherein each triangular supporting unit comprises a triangular frame, a supporting ring is arranged on the top of the triangular frame, a supporting rod provided with an external thread is vertically arranged in the supporting ring in a penetrating manner, the supporting rod is sleeved with a driving ring in a threaded manner, and the driving ring abuts against the upper end face of the supporting ring; and a driving gear is coaxially connected to an output shaft of each electric motor, a pressure sensor is arranged in each cushion block, and the electric motors and the pressure sensors are both connected to a central processing unit. According to the cable winding disc rolling rack for the power industry, in the winding or unwinding process, all the pressure sensors send data to the central processing unit, and the central processing unit controls the two electric motors to rotate differently, so that winding or unwinding is more stable, and the situation that cables on a winding disc topple in the winding or unwinding process due to serious gravity center shifting is avoided.

Owner:芜湖通恒信息技术有限公司

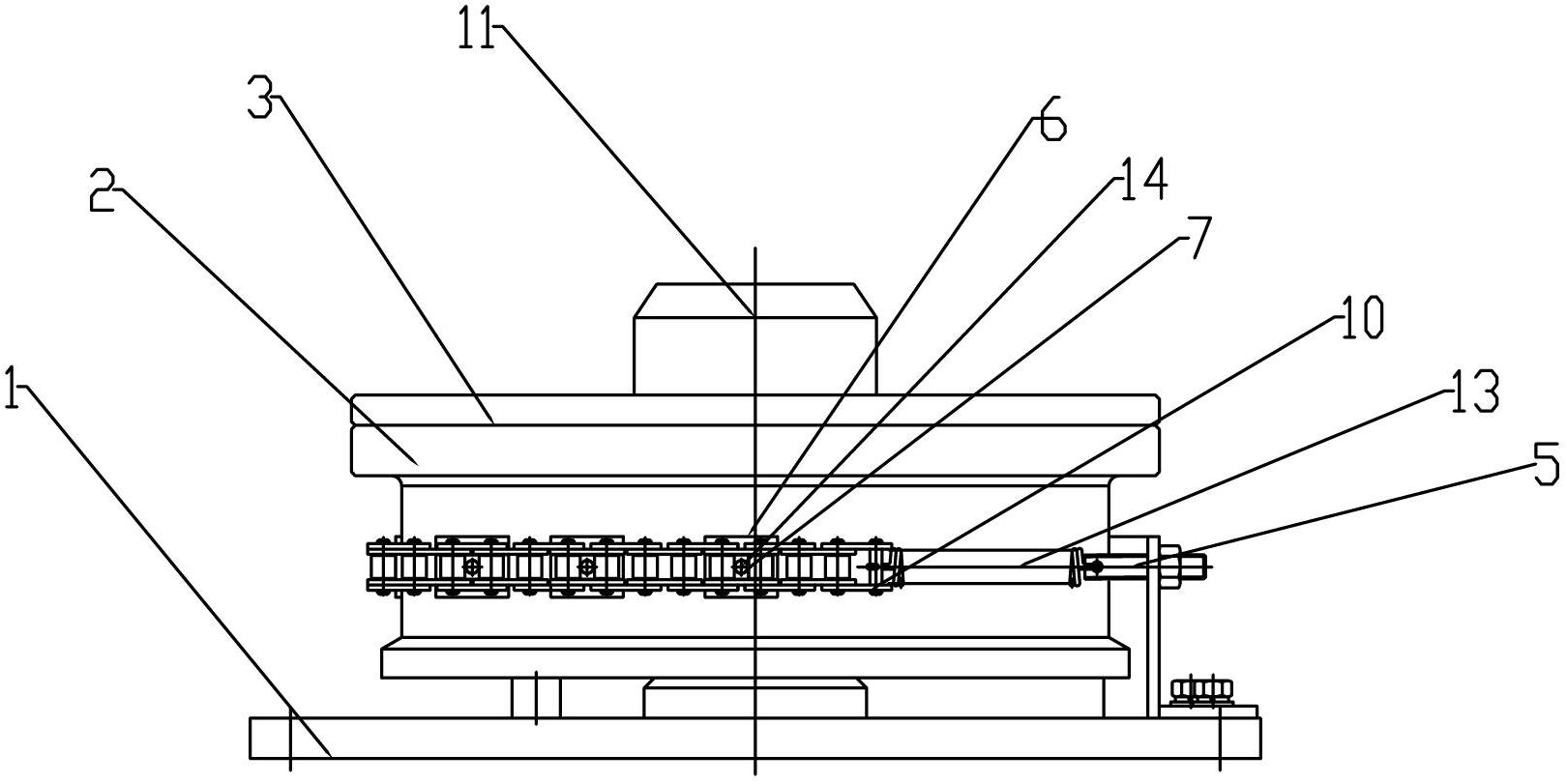

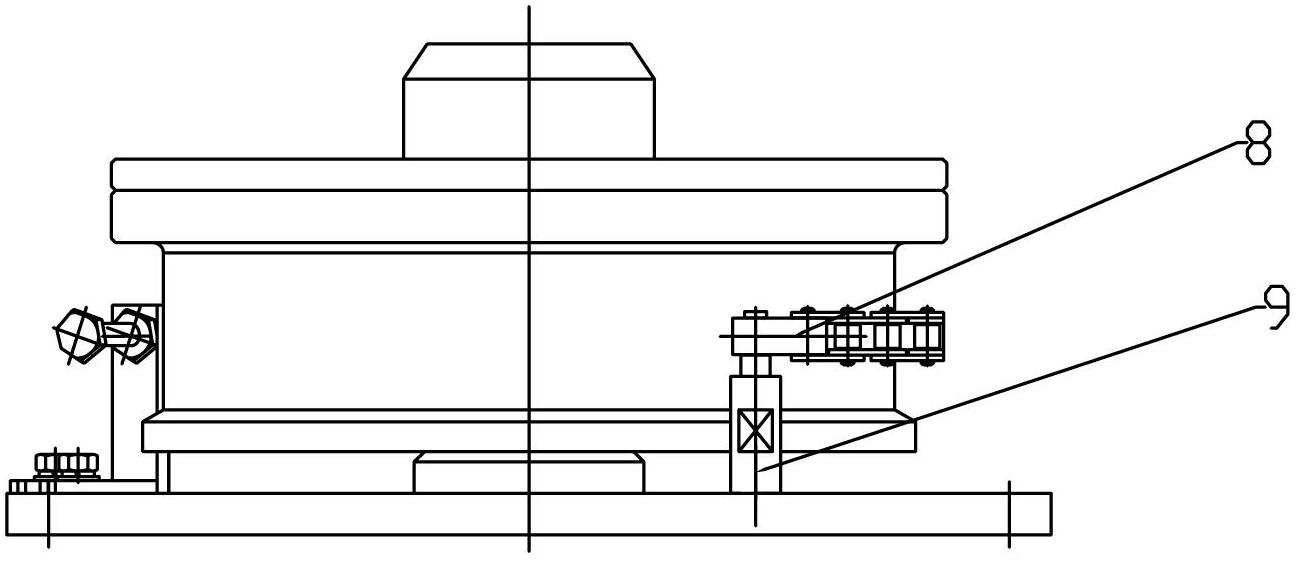

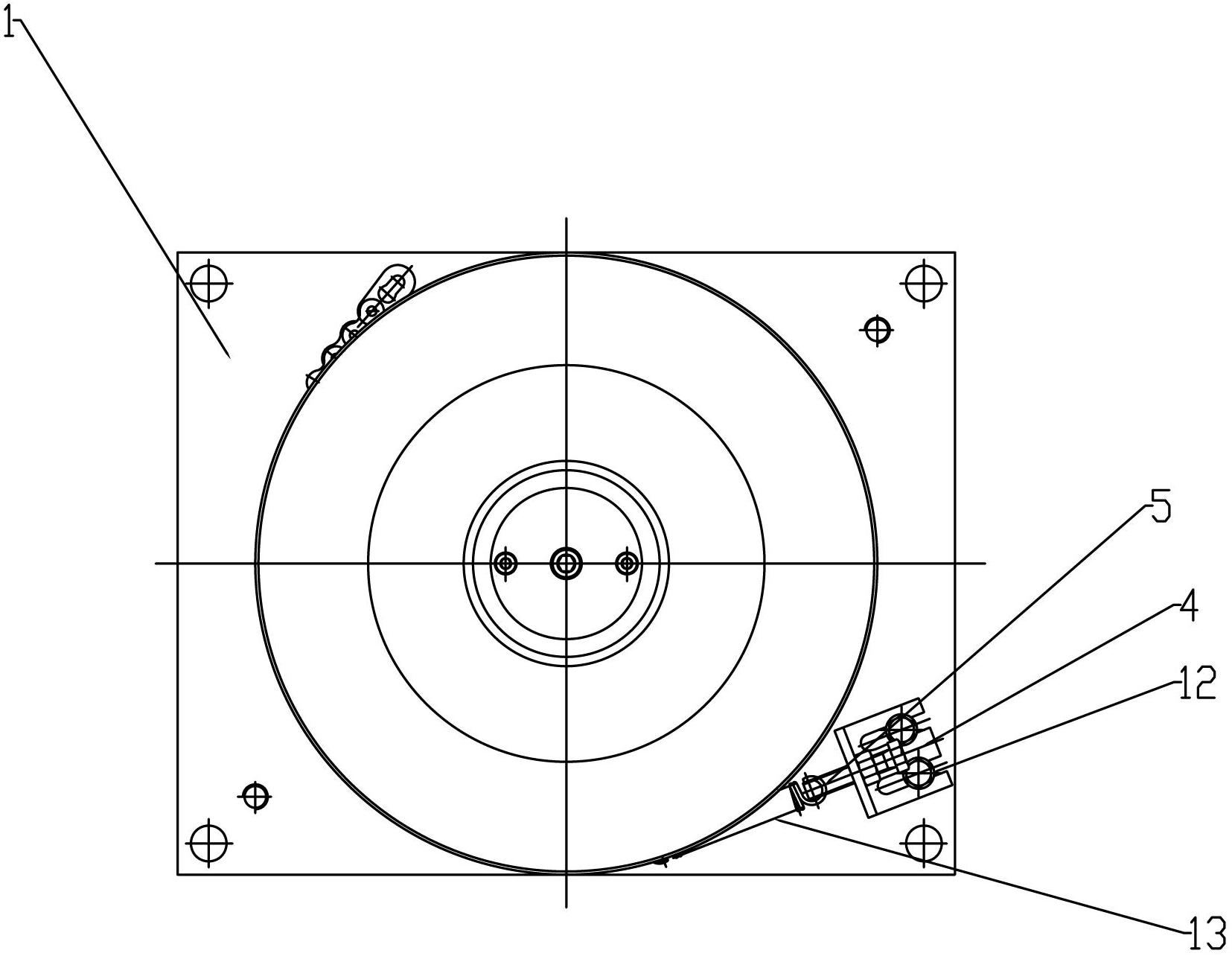

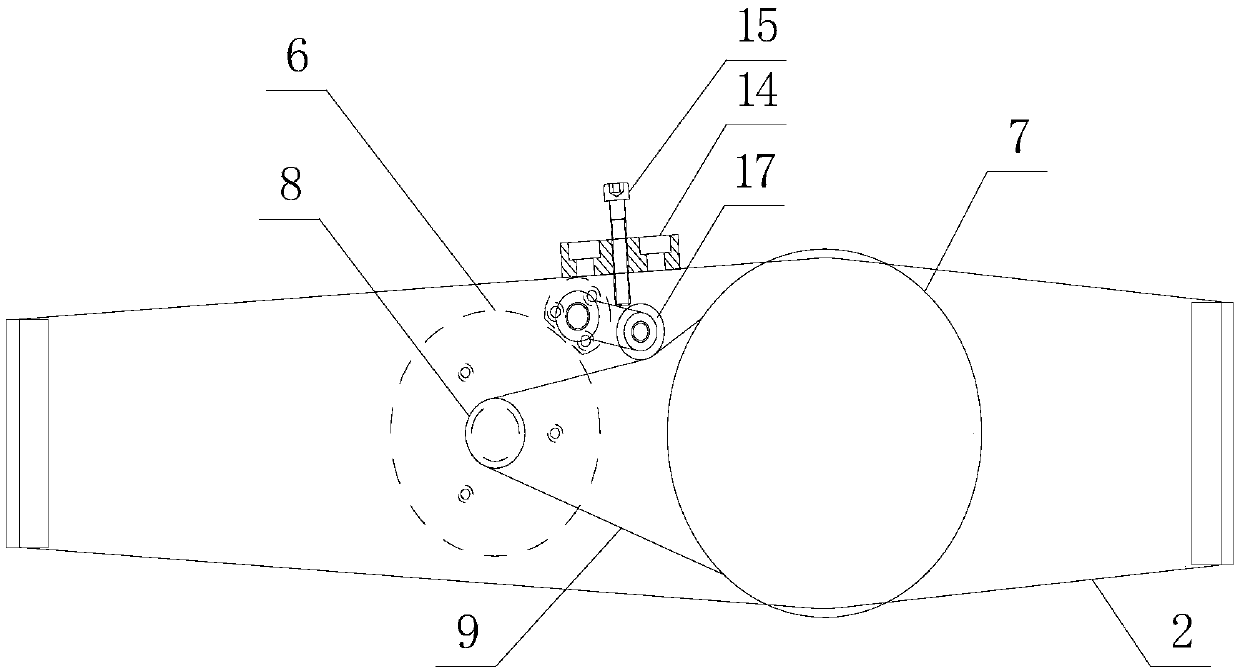

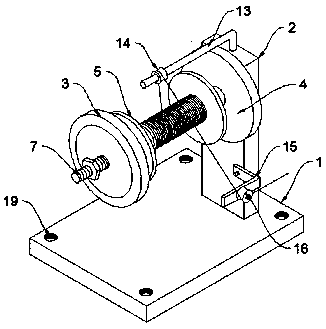

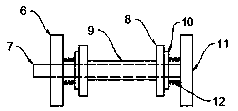

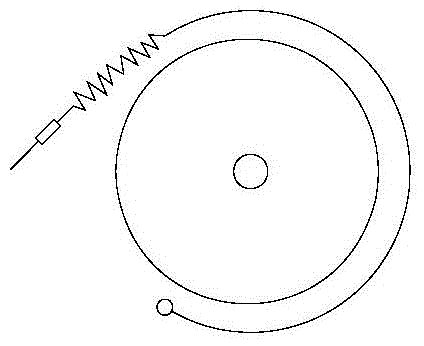

Damped pay-off device

The invention relates to a damped pay-off device, specifically relating to a device for passive paying off of a drawing machine and belonging to the technical field of the drawing machine equipment. The damped pay-off device mainly comprises a base, a spool seat, a shock-absorbing seat, a tension spring seat, a screw, a damping fin, a pressing plate, a connecting piece, a pull rod, a chain, a main shaft and a tension spring, wherein the main shaft is mounted at the center of the base; the spool seat is connected to the main shaft; the shock-absorbing seat is connected to the spool seat; the spool seat and the shock-absorbing seat rotate simultaneously along with the main shaft; the tension spring seat is mounted at one end of the base and fastened through a bolt; the screw is mounted on the tension spring seat; the tension spring is connected to the screw and the other end of the tension spring is connected to the chain; the other end of the chain is connected to the connecting piece; and the connecting piece is mounted on the pull rod. The damped pay-off device is simple, compact and rational in structure, small in floor area and low in cost, convenient for mounting and replacing the spool wheel, steady in paying off, capable of keeping straight in paying off, and not easy to cause breakage.

Owner:WUXI CHANGXIN TECH

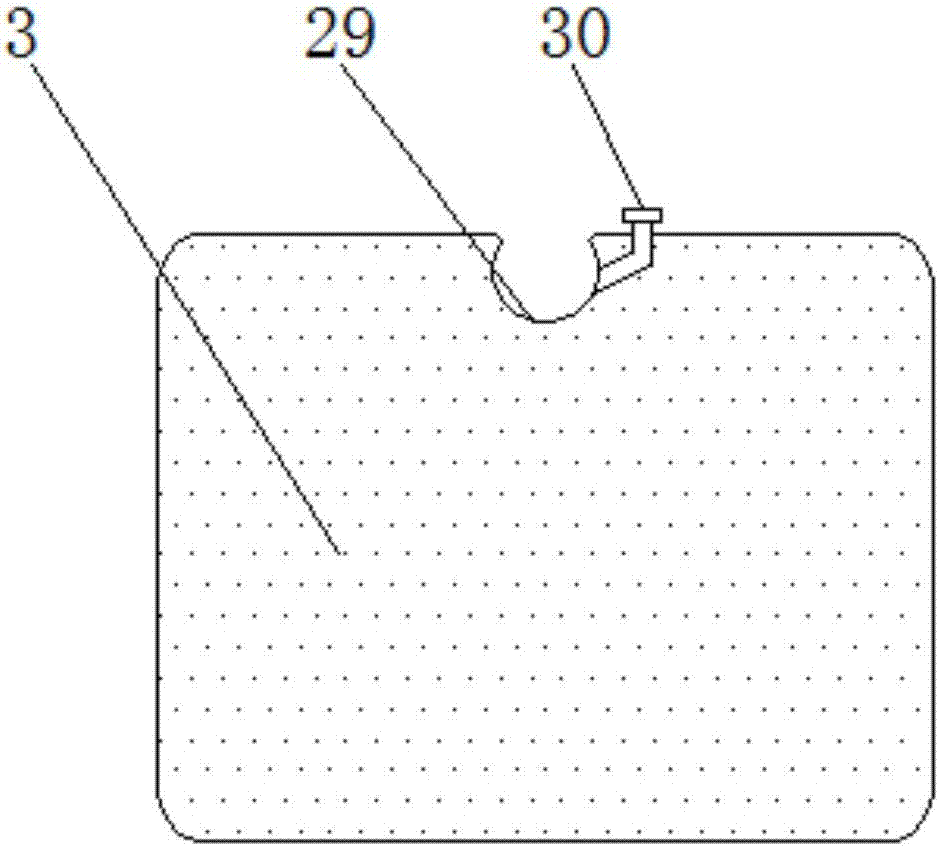

Pneumatic damping high-capacity pay-off technology for flat wire

InactiveCN102969084AReduce labor intensityReasonable structureInsulating conductors/cablesCylinder headEngineering

The invention relates to a pneumatic damping high-capacity pay-off device for a flat wire. The device comprises a frame which is provided with a sliding shaft. Supporting devices are arranged on the group on one side of the displacement frame at intervals. The device further comprises a rotary arm. One end of the rotary arm is sleeved on the sliding shaft while the other end of the rotary arm is connected with the supporting devices. The supporting device is structured by comprising a supporting base, wherein an idle wheel is installed at the bottom of the supporting base, a compression spring is installed on the idle wheel, a screw is connected to the supporting base, the screw is sleeved with a supporting rod, and the supporting rod is provided with a plurality of holes connected with one end of the rotary arm. An eccentric shaft is further installed on the rotary arm connected with the supporting device. A handle and a brake wheel which operate the eccentric shaft to rote are installed on the eccentric shaft. A pay-off disc is installed between a pair of supporting devices and is connected with the eccentric shaft. The rotary arm is further provided with a pneumatic control element, an air cylinder is further installed on the rotary arm on one side of the pneumatic control element, and an air cylinder head is connected with a brake belt matched in use with the brake wheel. The production efficiency is high.

Owner:无锡市梅达电工机械有限公司

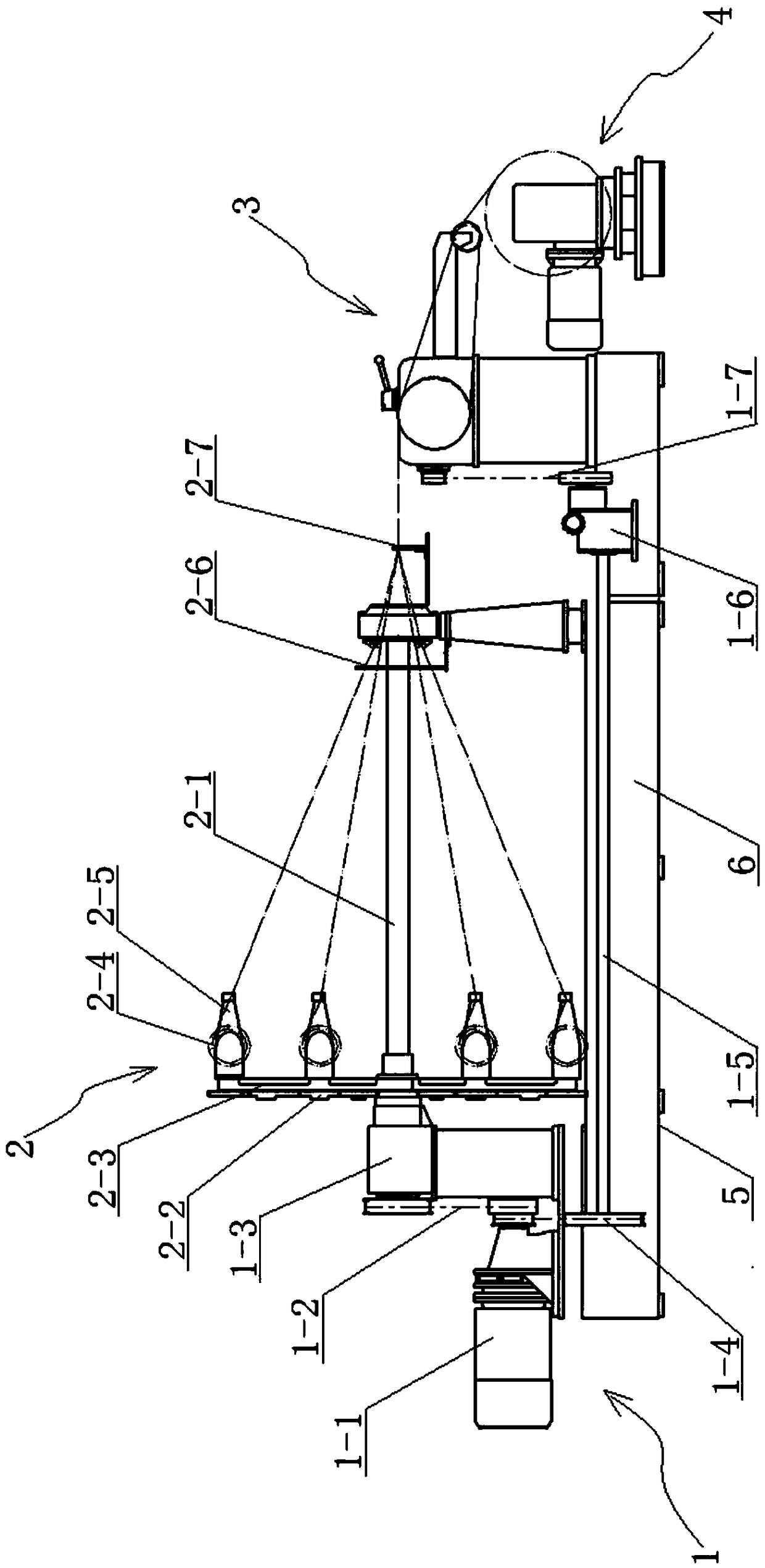

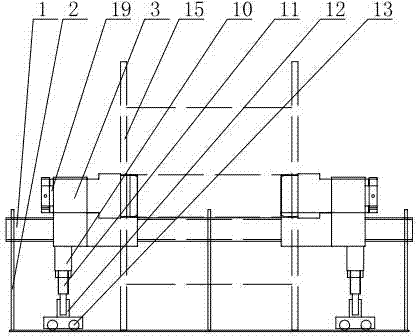

Electric power overhaul equipment hoisting device

InactiveCN108840255AOperational securityRate at which the rope is inhibited from being pulledCranesEngineeringElectric power

The invention discloses an electric power overhaul equipment hoisting device. The electric power overhaul equipment hoisting device structurally comprises an intelligent lifting-fixing-adjusting device, a telescopic rod, a rotary seat, a device shell, a fixing bracket, a rotary seat adjusting cabin, moveable wheels, a control cabin and hydraulic pressure rods. The intelligent lifting-fixing-adjusting device is located on the upper surface of the telescopic rod and connected with the telescopic rod to an integrated structure in a welding mode. The telescopic rod is arranged on the upper surfaceof the rotary seat and movably connected with the rotary seat synchronously. The rotary seat is connected to the right side of the upper surface of the device shell in a clearance fit mode. The rotary seat adjusting cabin is parallel to the rotary seat located on the rear side of the rotary seat adjusting cabin and electrically connected with the rotary seat. According to the electric power overhaul equipment hoisting device, the purpose that displacement-limited with fixation of the device can be carried out during hoisting equipment working to enable the declining speed to be limited, at the same time, the device is more stable during paying off, and thus the hoisting equipment is more improved is achieved.

Owner:刘梦思

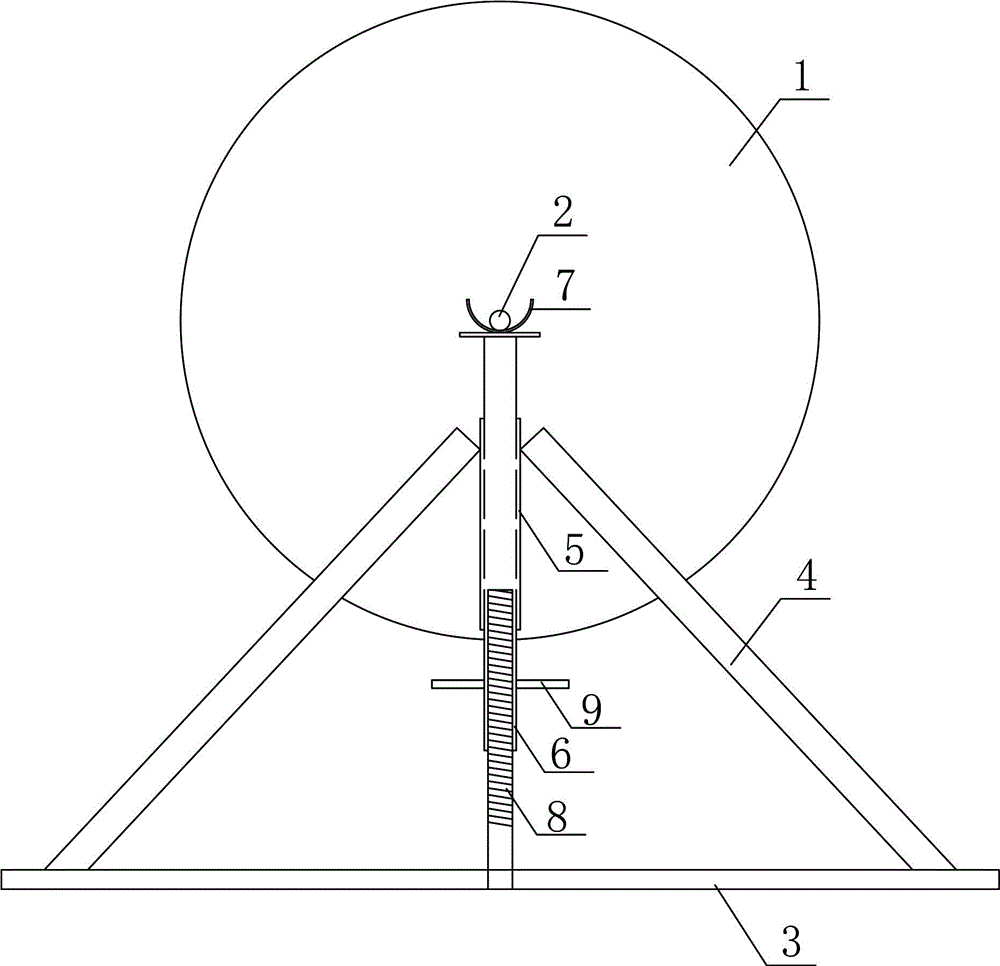

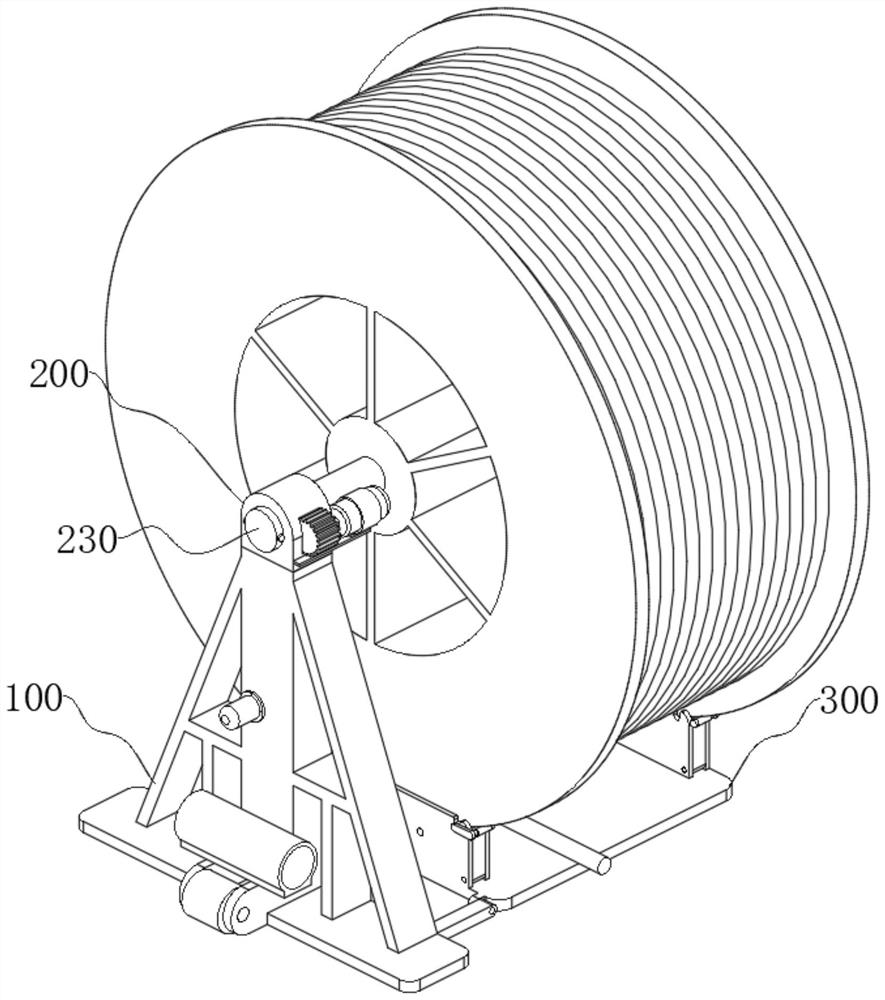

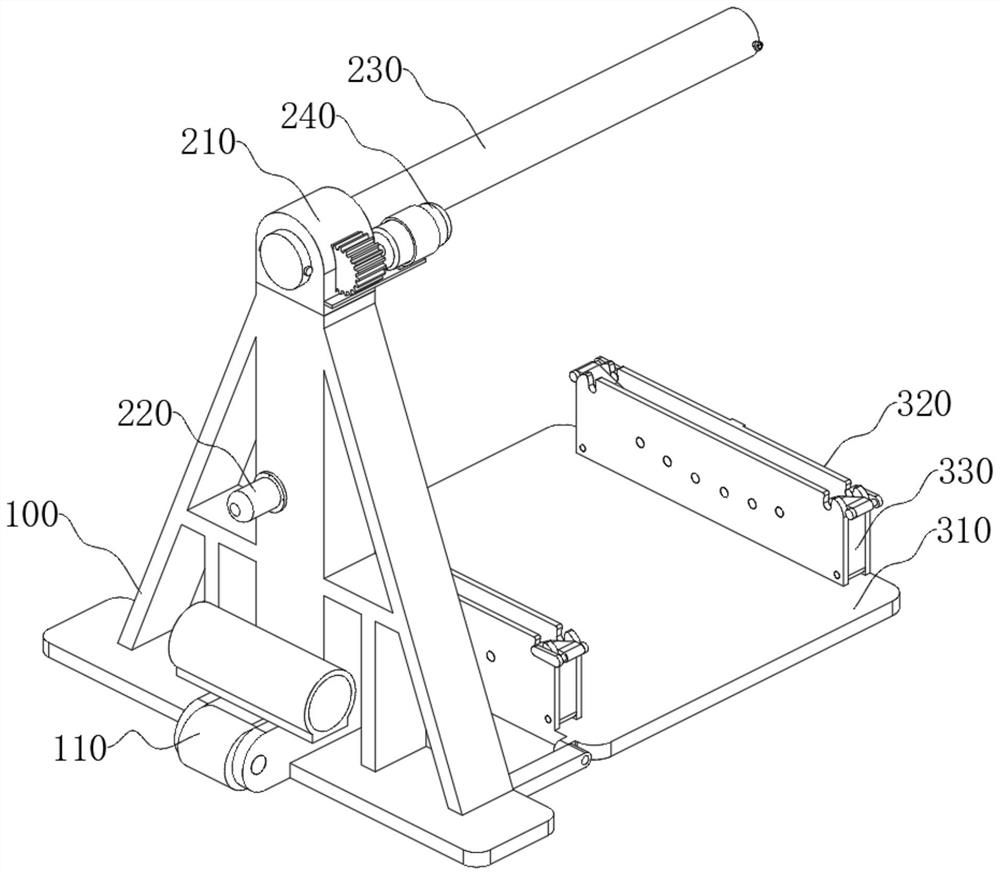

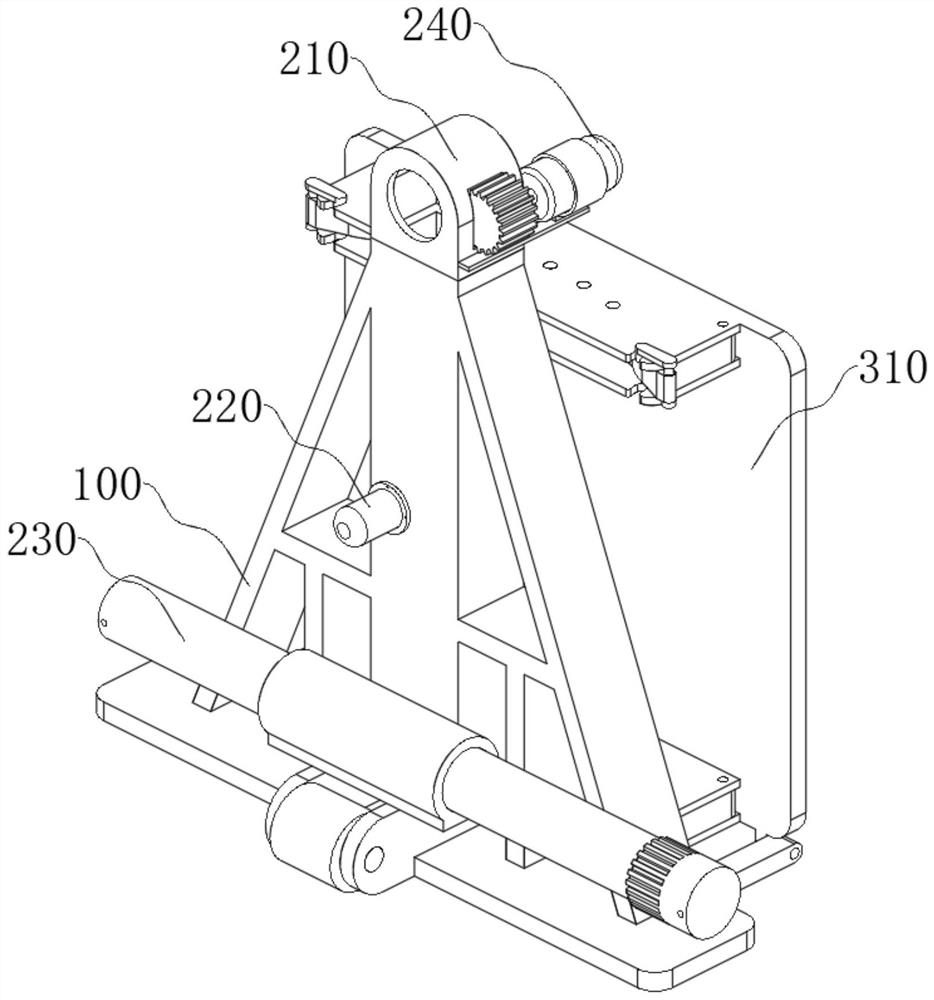

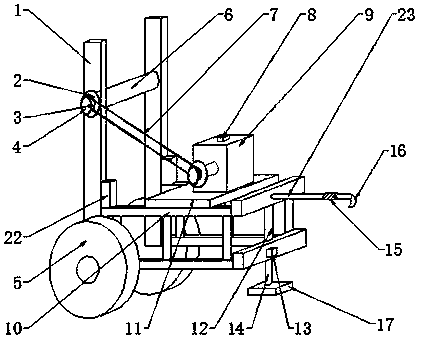

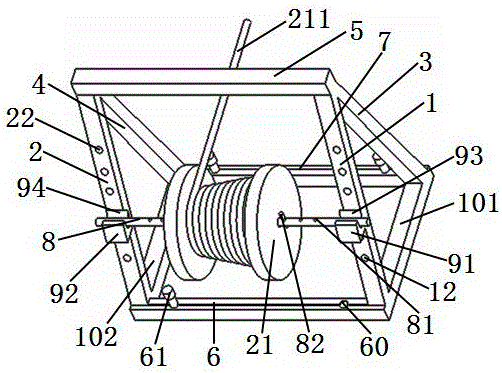

Pay-off labor-saving device for cable drum stand in electric power engineering installation

InactiveCN112332294AEasy to controlLabor-saving unwinding operationFilament handlingApparatus for overhead lines/cablesPower engineeringIdler-wheel

The invention discloses a pay-off labor-saving device for a cable drum stand in electric power engineering installation, which comprises a support frame with a triangular frame structure, a lifting and rotating device mounted at the top of the support frame and used for driving the cable drum stand to rotate and pay off, and a movable frame mounted on one side of the bottom of the support frame and used for supporting the cable drum stand to rotate, idler wheels are installed at the bottom of the support frame, and a servo motor driving the movable frame to rotate is installed on one side of the top of the lifting rotating device. The single movable support frame is arranged, the movable frame is arranged on one side of the bottom of the support frame and can support the cable reel frame to stably rotate, and meanwhile, the lifting rotating device is arranged at the top of the support frame and used for driving the cable reel frame to automatically rotate for paying off, so that labor-saving control of workers is realized, the device does not occupy a place and is high in practicability, the pay-off operation is labor-saving, and the practical value is achieved.

Owner:六安逸风羽信息科技有限公司

Pay-off device of tubular strander

InactiveCN105047326ARelieve pressureReduce disconnection frequencyCable/conductor manufactureEngineeringMechanical engineering

Owner:TIANJIN JINGWEI HUIKAI OPTOELECTRONICS CO LTD

Novel electric wire barrow

The invention discloses a new type electric wire pay-off vehicle, which comprises a vehicle frame and a support column. The vehicle frame is arranged on one side of the support column. The vehicle frame is vertically arranged on the side wall of the support column and passes through the support column. Screws are fixed, a pay-off shaft is arranged between the support columns, one end of the pay-off shaft is arranged on the side wall of the support column, and is movably connected with the support column, and a shock absorber is provided on one side of the support column , the shock absorber is arranged horizontally on the side of the support column, and is closely attached to the support column. When the wire car is unwound, it has the effect of shock absorption and protects the construction personnel on site. The hook can be hung on the transport vehicle to drive the pay-off car and bring it to the construction site.

Owner:威海红印食品有限公司

OPGW fiber stainless steel welded tube production line

InactiveCN107957612AStable pay-offReduce runoutFilament handlingFibre mechanical structuresMotor shaftEngineering

The invention discloses an OPGW optical fiber stainless steel welded pipe production line, which comprises a tape unwinding device, an optical fiber pay-off cabinet, forming equipment, a primary drawing die, a crawler tractor, a secondary drawing die, an excess length control device, and a main traction device arranged in sequence. Equipment, flaw detection equipment, tension control device and winding machine, the optical fiber pay-off cabinet is equipped with a pay-off motor, and the output shaft of the pay-off motor is equipped with an optical fiber pay-off reel. In the present invention, the optical fiber pay-off reel is directly set on the output shaft of the pay-off motor, the motor shaft is the pay-off shaft, the runout of the pay-off shaft is reduced, the optical fiber pay-off is stable, and the product cost is also reduced.

Owner:上海千一科技股份有限公司

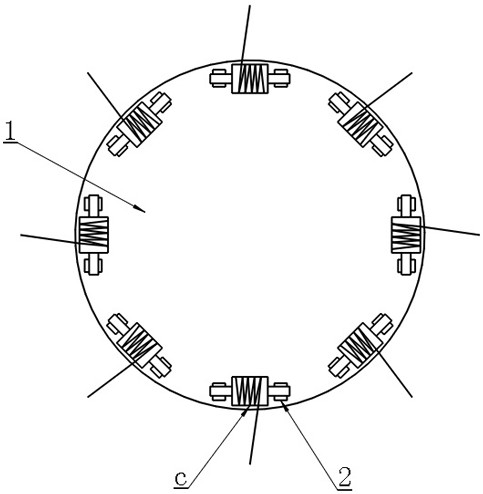

Cable hoist equipped with hysteresis tension cradle frame

PendingCN107749327ASmall attenuationStable pay-off tensionApparatus for feeding conductors/cablesHysteresisHysteresis band

The invention discloses a cable hoist equipped with a hysteresis tension cradle frame. The two ends of the cradle frame body are rotatably connected with a winch frame through rotating shafts, and oneof the rotating shafts is provided with a current collecting ring. The cradle frame body is provided with a hysteresis brake. The current collecting ring is electrically connected with the hysteresisbrake. A large synchronizing wheel is connected on a cable coil. The hysteresis brake drives the large synchronizing wheel to synchronously rotate. The advantages of the cable hoist are that constantand steady pay-off tension of the cable on the cable coil is realized by using the method of providing stable damping through the hysteresis brake, the tension of each cable on each cradle frame is maintained to be consistent and the cost of the hysteresis brake is inputted in one time so that the maintenance cost is almost zero; the trouble of subsequent manual adjustment can be omitted; and tension adjustment is convenient, time-saving and labor-saving and visual and easy to understand, and the tension on each cable is displayed by numbers and can be adjusted in real time so that the twisting requirements of the high-flexibility cable can be met.

Owner:PINGHU DIGONG MACHINERY MFG

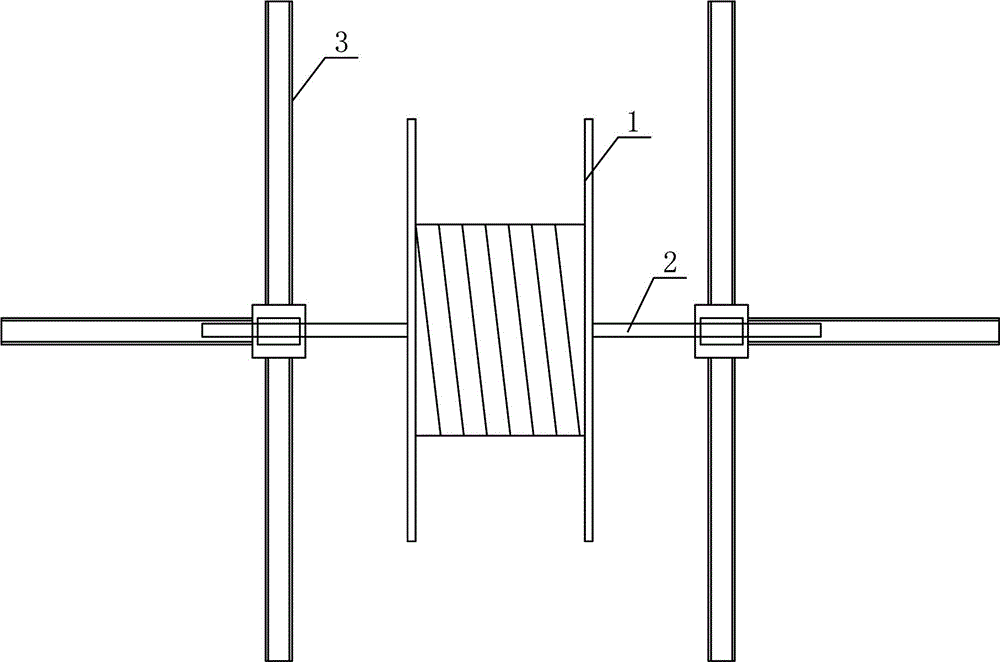

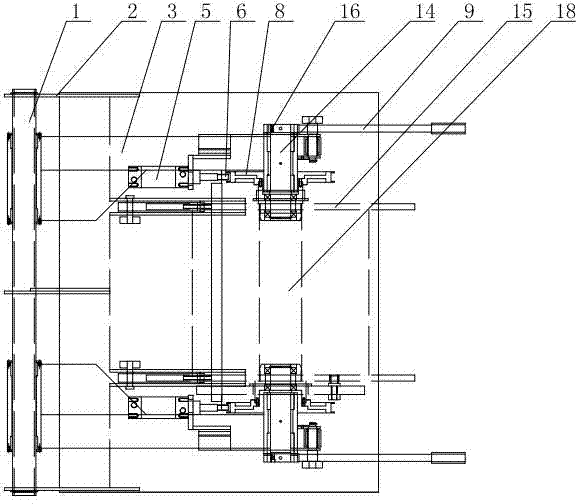

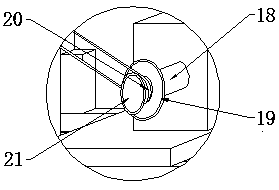

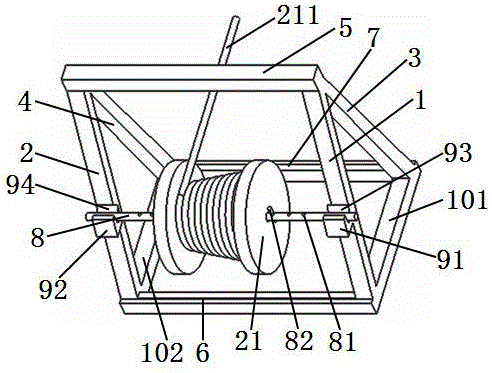

Pay-off mechanism for cabling machine

InactiveCN106251981AReasonable structural designStable pay-offCable/conductor manufactureCable machineAgricultural engineering

The invention provides a pay-off mechanism for a cabling machine, and relates to the field of cabling machine equipment. The pay-off mechanism comprises a pay-off rack, the pay-off rack comprises pay-off frames, rotating shafts are arranged on front and back sides in each pay-off frame, pay-off rollers are arranged on the rotating shafts, a connecting rod is arranged at the middle of each pay-off frame, a through hole is formed in each connecting rod, a left connecting shaft is arranged at a left end of each pay-off frame, a right connecting shaft is arranged at a right end of each pay-off frame, and the right connecting shaft is a hollow shaft. The pay-off mechanism provided by the invention is reasonable in structural design and is stable in pay-off.

Owner:CHAOHU JINYE ELECTRIC MACHINERY

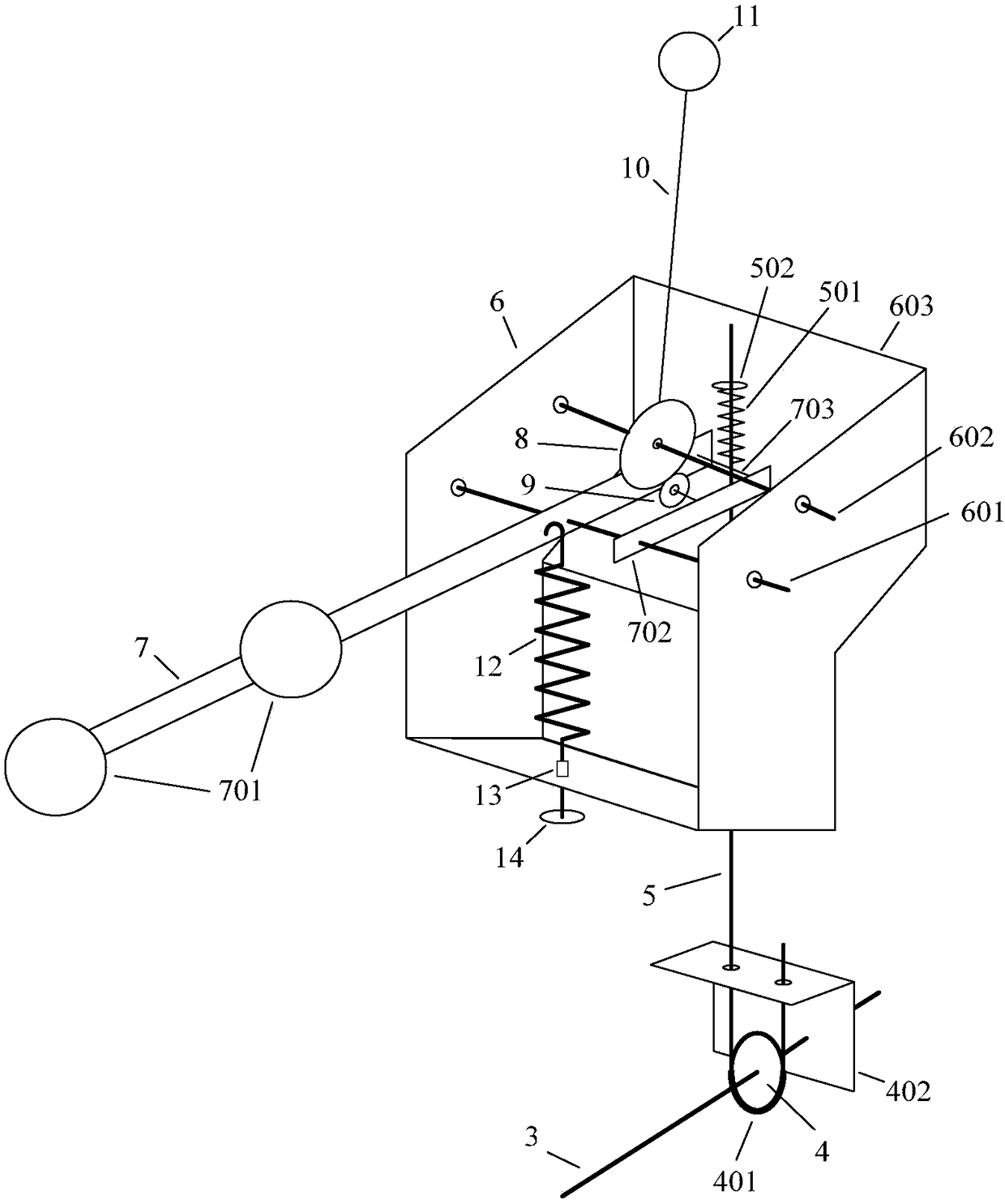

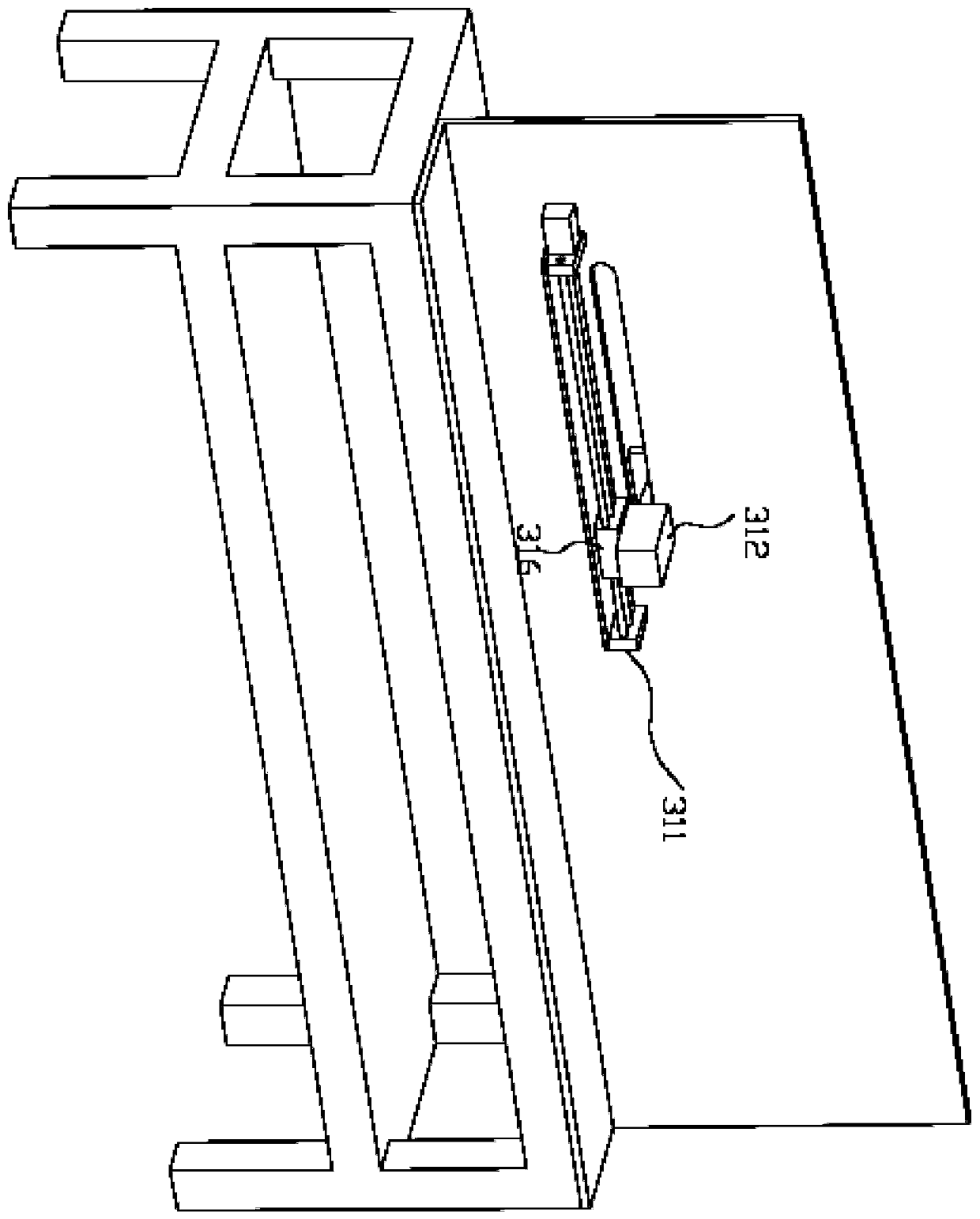

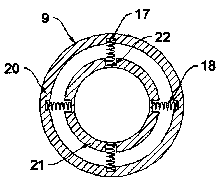

Passive pay-off rack

PendingCN109230865ASolve the technical problems of inconvenient tension adjustment and unstable pay-offPay-off tension automatic adjustmentFilament handlingEngineeringCycloid gear

The invention relates to a passive pay-off rack. The technical problem that for a traditional passive pay-off rack, tension adjustment is inconvenient, and paying off is unstable can be solved. The passive pay-off rack comprises a pay-off rack main body which comprises a bearing frame, a bearing rod and a tension adapter, and a pay-off shaft is arranged under the tension adapter; the tension adapter comprises a transversely arranged threading plate and a longitudinally arranged swing rod, a cycloid gear is arranged on the top of the swing rod, the bottom of the swing rod is fixed to an elliptic bearing which is fixed in a shell, a circular bearing is fixed to the threading plate, the elliptic bearing and the circular bearing are tangently arranged, and the elliptic bearing is arranged above the circular bearing; the passive pay-off rack further comprises a vertical screw rod which is fixedly connected with the threading plate, the bottom of the vertical screw rod is fixedly connected with one end of a brake strap, the other end of the brake strap is fixed to the bearing rod, and a brake wheel is arranged on the upper portion of the brake strap and connected with the pay-off shaft.The passive pay-off rack is firm in structure, very small in abrasion loss and stable in pay-off tension.

Owner:安徽光纤光缆传输技术研究所

Portable movable cable reel

Owner:福建鼎力电缆科技有限公司

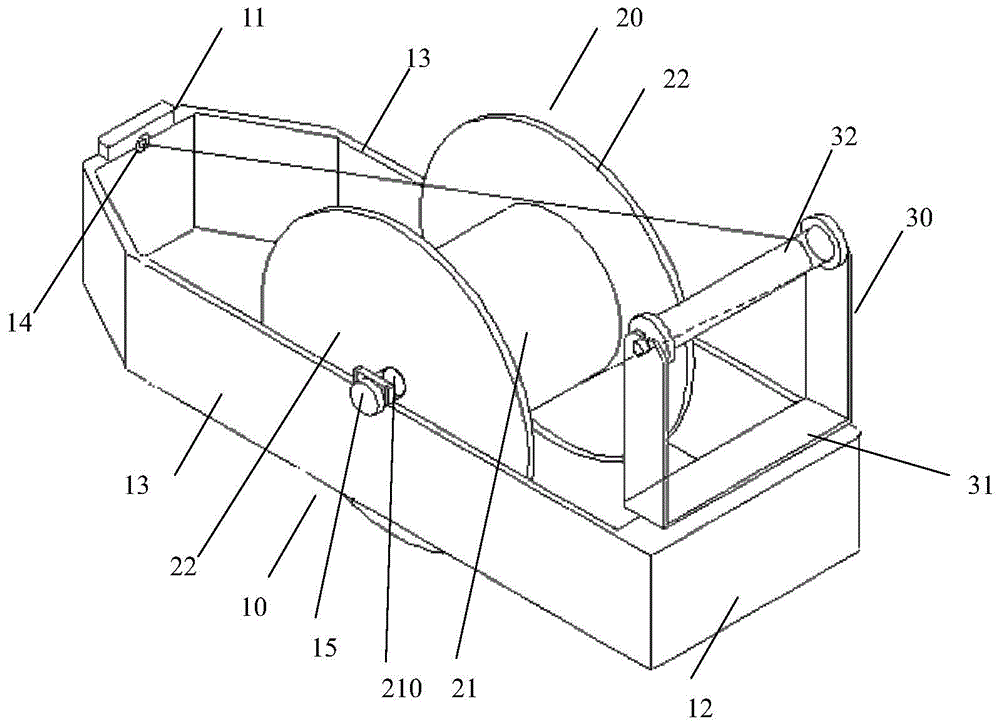

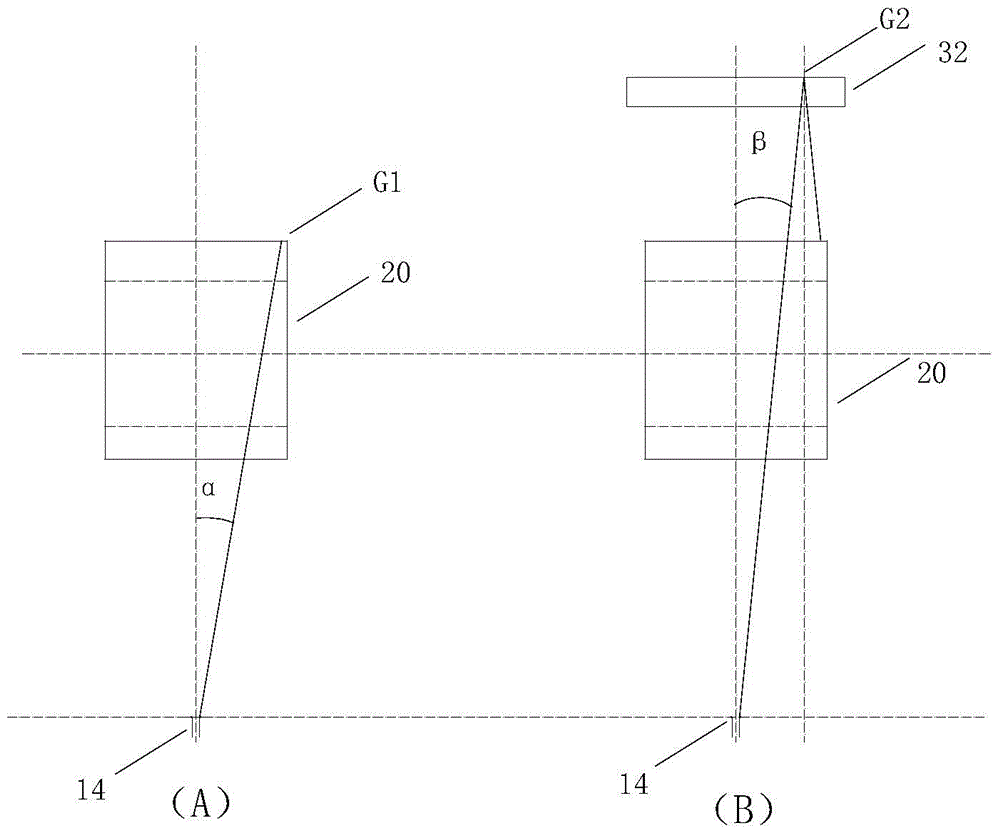

Coil tool unwinding cradle

The invention discloses a coil tool unwinding cradle. The coil tool unwinding cradle comprises a left supporting device, a right supporting device and a limiting device. The left supporting device isarranged on a left arm of a cradle, and comprises an air cylinder and a left supporting shaft. The piston end of the air cylinder is fixedly connected with a fixing block, the fixing block is arrangedon a left arm of the cradle in a left-and-right slide mode, and the left supporting shaft is installed on the fixing block in a rotating mode. The right supporting device is arranged on a right arm of the cradle, and comprises a fixing plate, a magnetic powder brake and a right supporting shaft. The middle of the right supporting shaft is installed on a right arm of the cradle in a rotating mode,the left portion of the right supporting shaft stretches out of the right arm of the cradle and is located on the left side, the fixing plate is fixedly installed on the left portion of the right supporting shaft, and the right end of the right supporting shaft is connected with the magnetic powder brake. The limiting device is installed on the portion, close to the center, of the fixing plate, and comprises a sleeve, a compression spring and a locating rod. The axis of the right supporting shaft and the axis of the left supporting shaft are consistent, and a coil tool is arranged between theright supporting shaft and the left supporting shaft in a clamped mode. By the adoption of the coil tool unwinding cradle, unwinding operation of the coil tool is achieved, rapid installation of thecoil tool is achieved, unwinding tension adjustment is facilitated, and the efficiency is higher.

Owner:徐州楚光能源科技有限公司

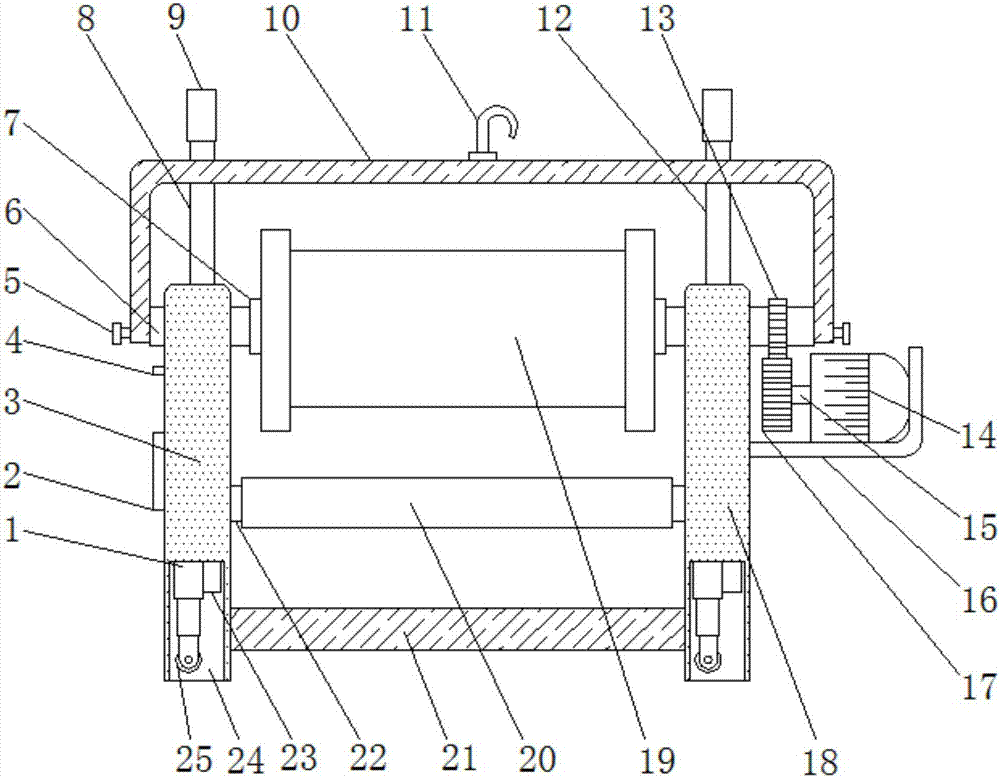

Cable pay-off device for communication engineering

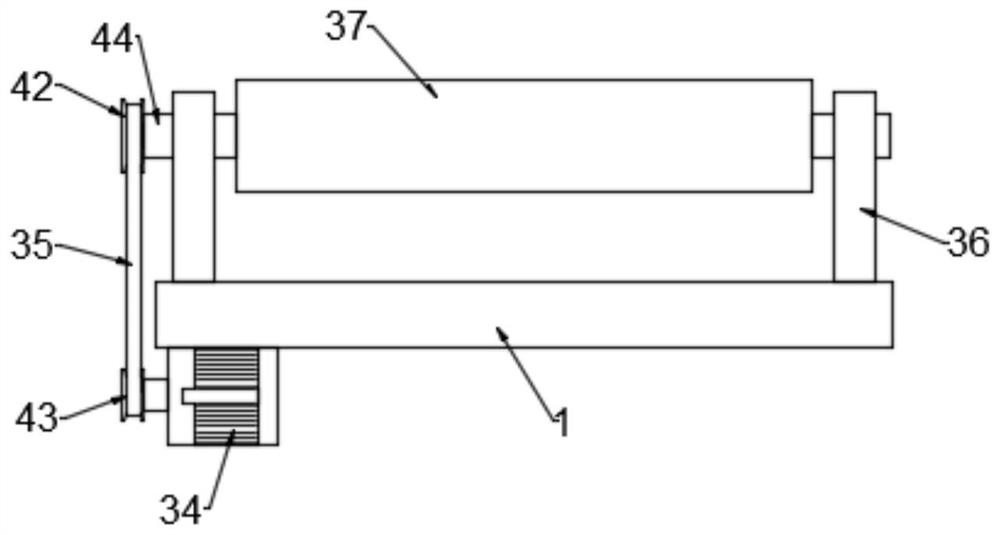

InactiveCN111703959AStable pay-offPrevent movementFilament handlingElectric machineryElectric cables

The invention relates to the technical field of communication, and provides a cable pay-off device for communication engineering. The cable pay-off device comprises a bearing plate, a first roller seat is fixed to the bearing plate, a driving roller is mounted on the first roller seat, a driving assembly for driving the driving roller to operate is arranged on the bearing plate, a second roller seat is arranged on the upper side of the bearing plate, a driven roller is mounted on the second roller seat, and an adjusting assembly for adjusting the position of the driven roller is further arranged on the bearing plate. According to the cable pay-off device for the communication engineering, the driving roller is driven to operate through a second motor, and the driving roller drives a winding reel to rotate so that a cable on the winding reel can be released; by moving a sliding block on a guide rod, the position of the driven roller can be adjusted, and the distance between the drivingroller and the driven roller is adjusted according to the specific size of the winding reel so as to be suitable for the winding reels of different sizes, and the application range is wide; and afterthe position is adjusted, a locking bolt is screwed to abut against the guide rod to fix the position of the sliding block.

Owner:赵建红

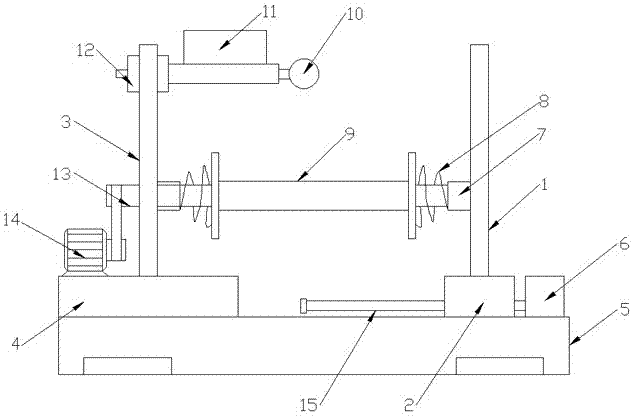

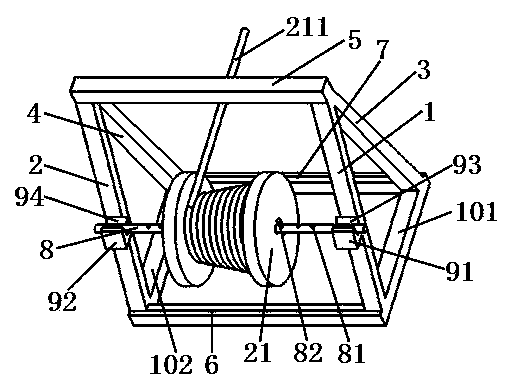

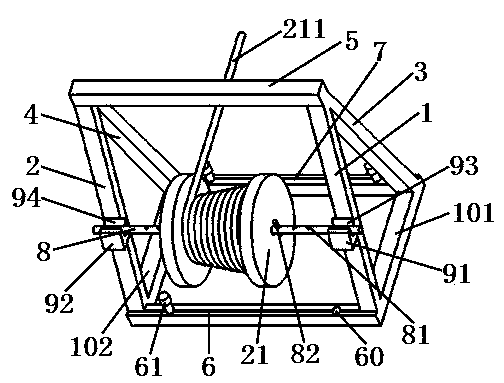

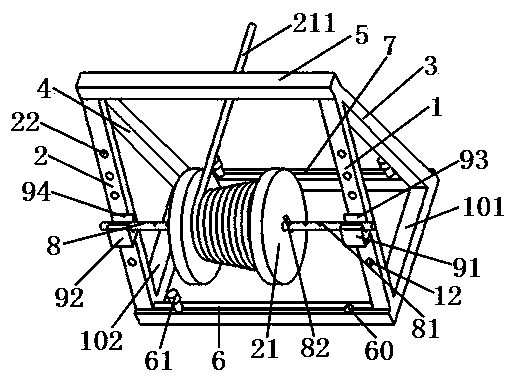

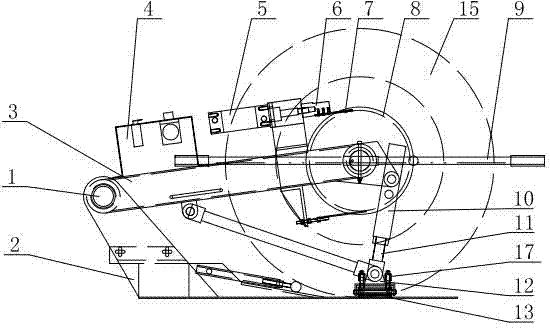

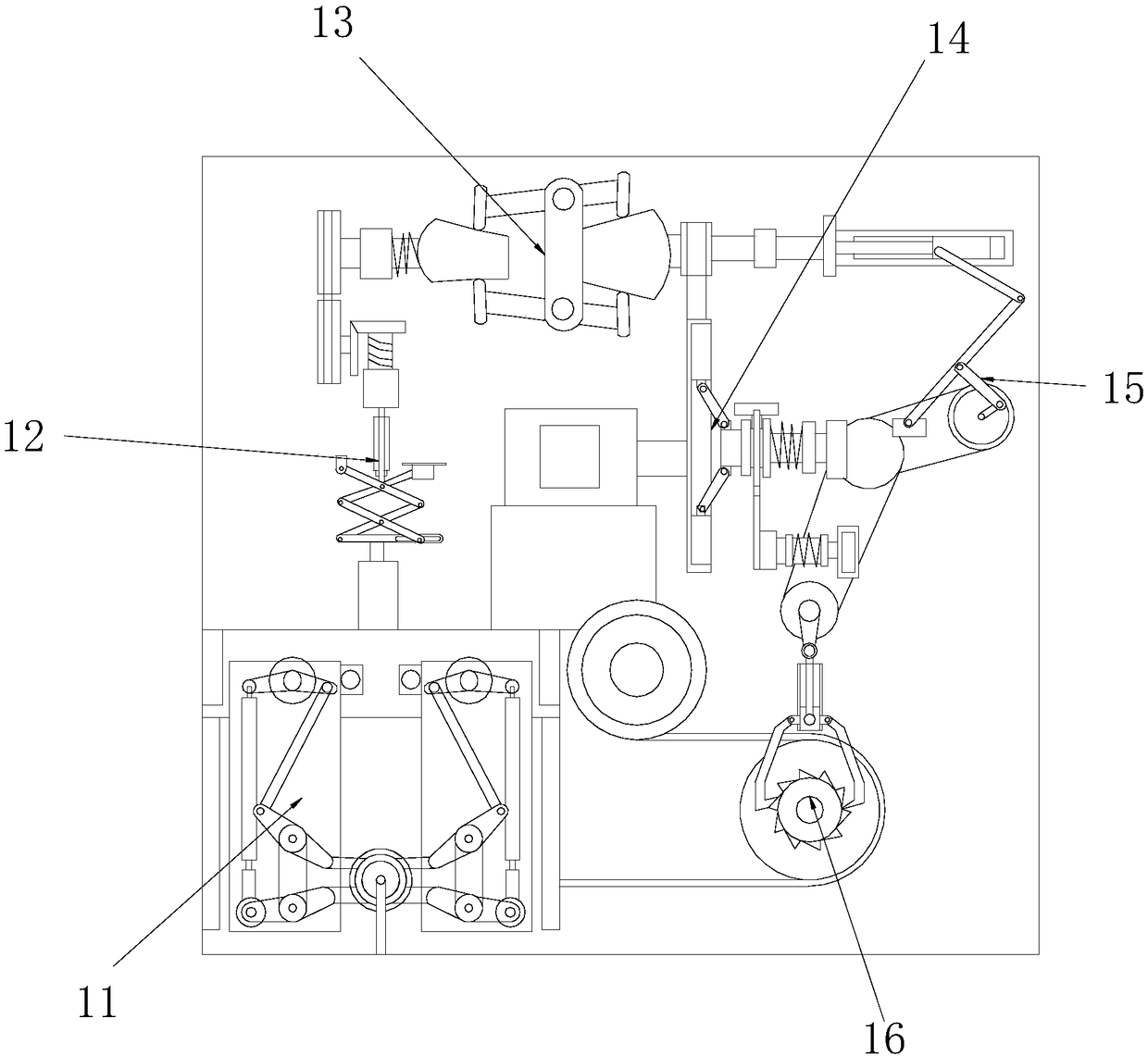

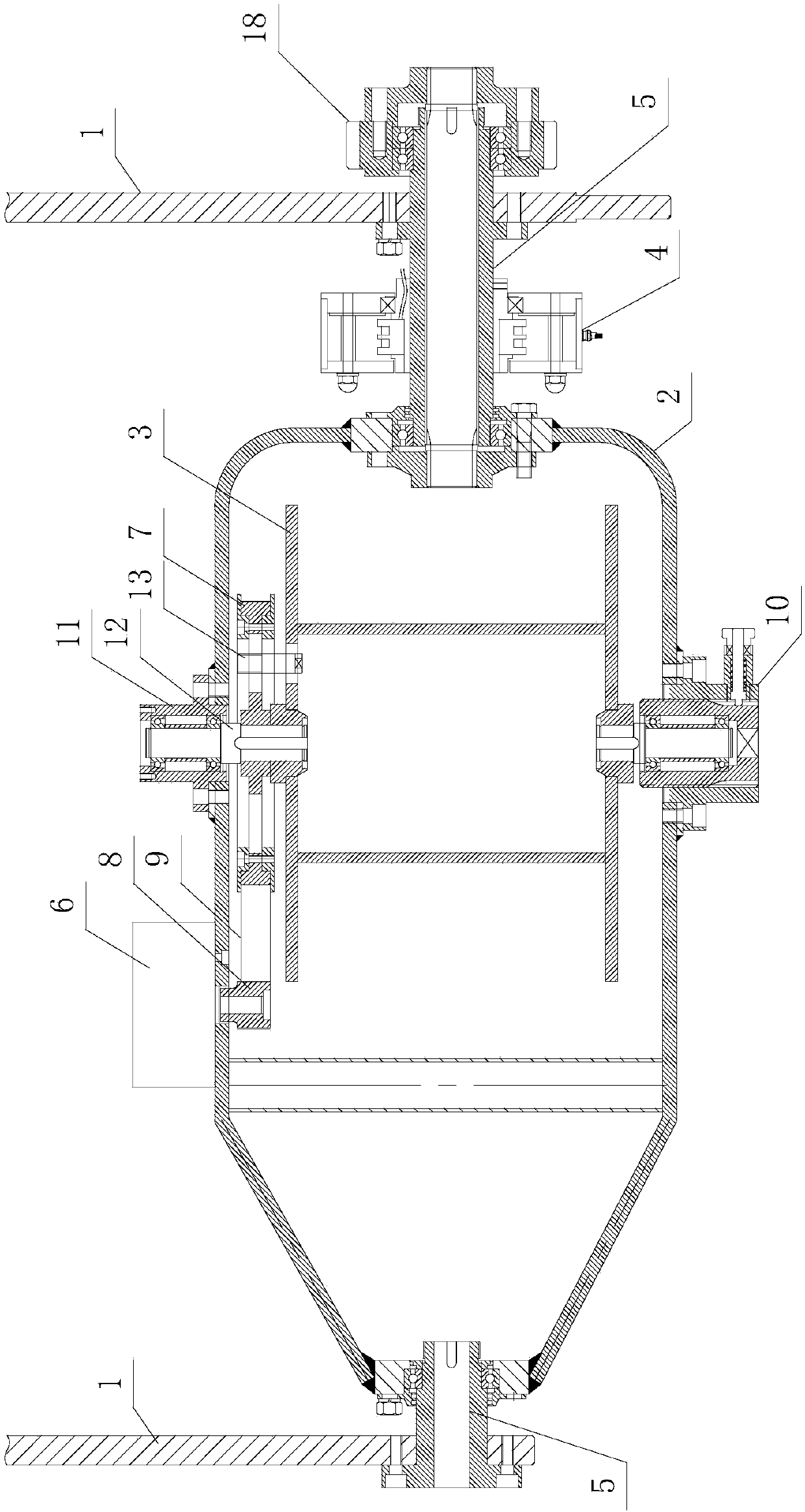

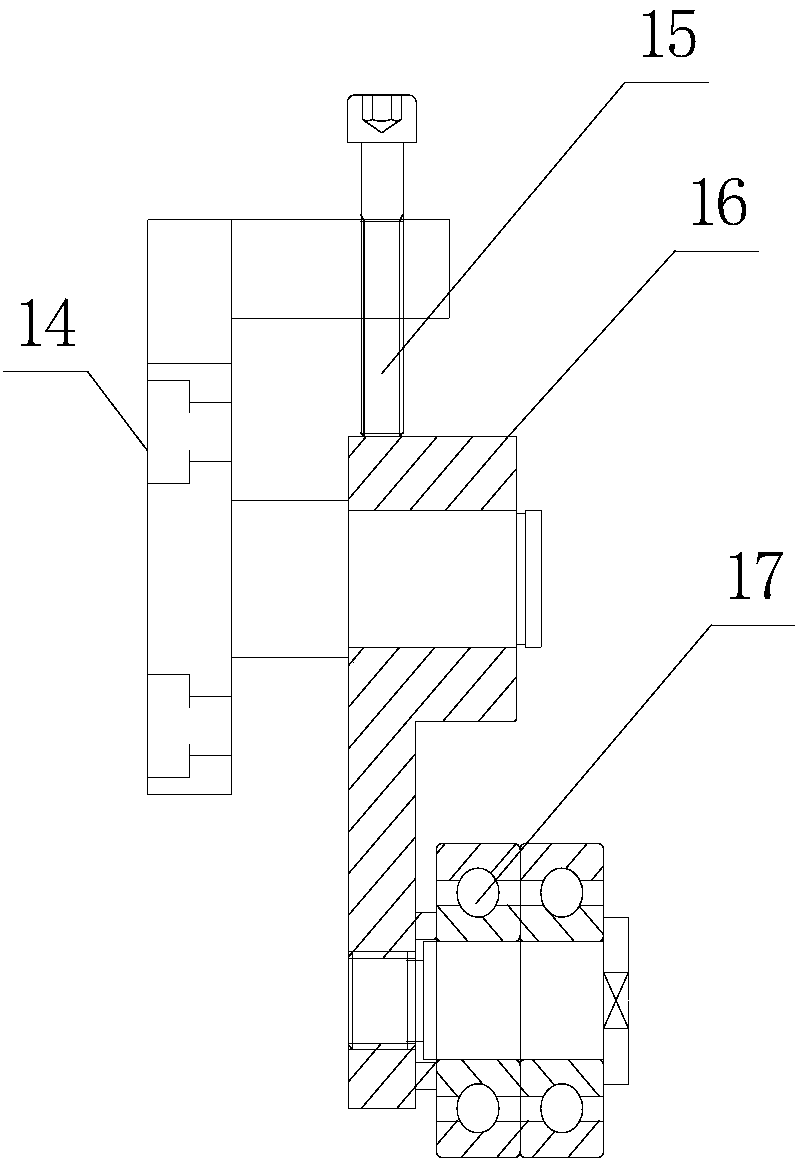

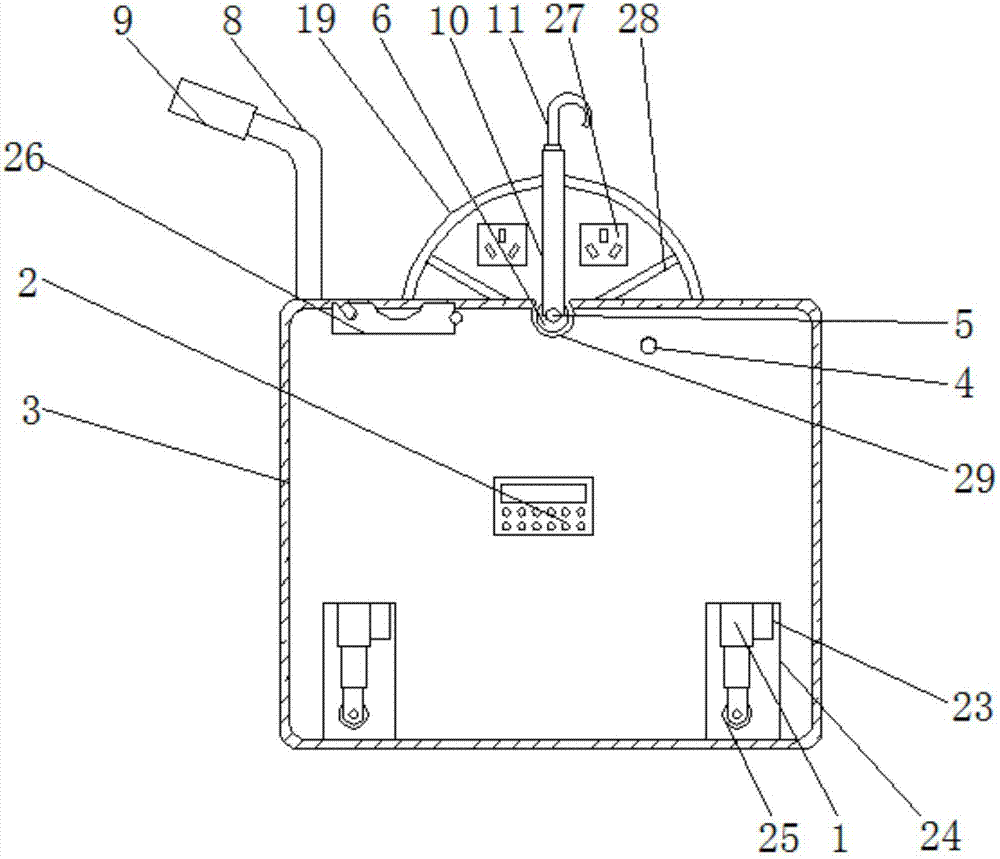

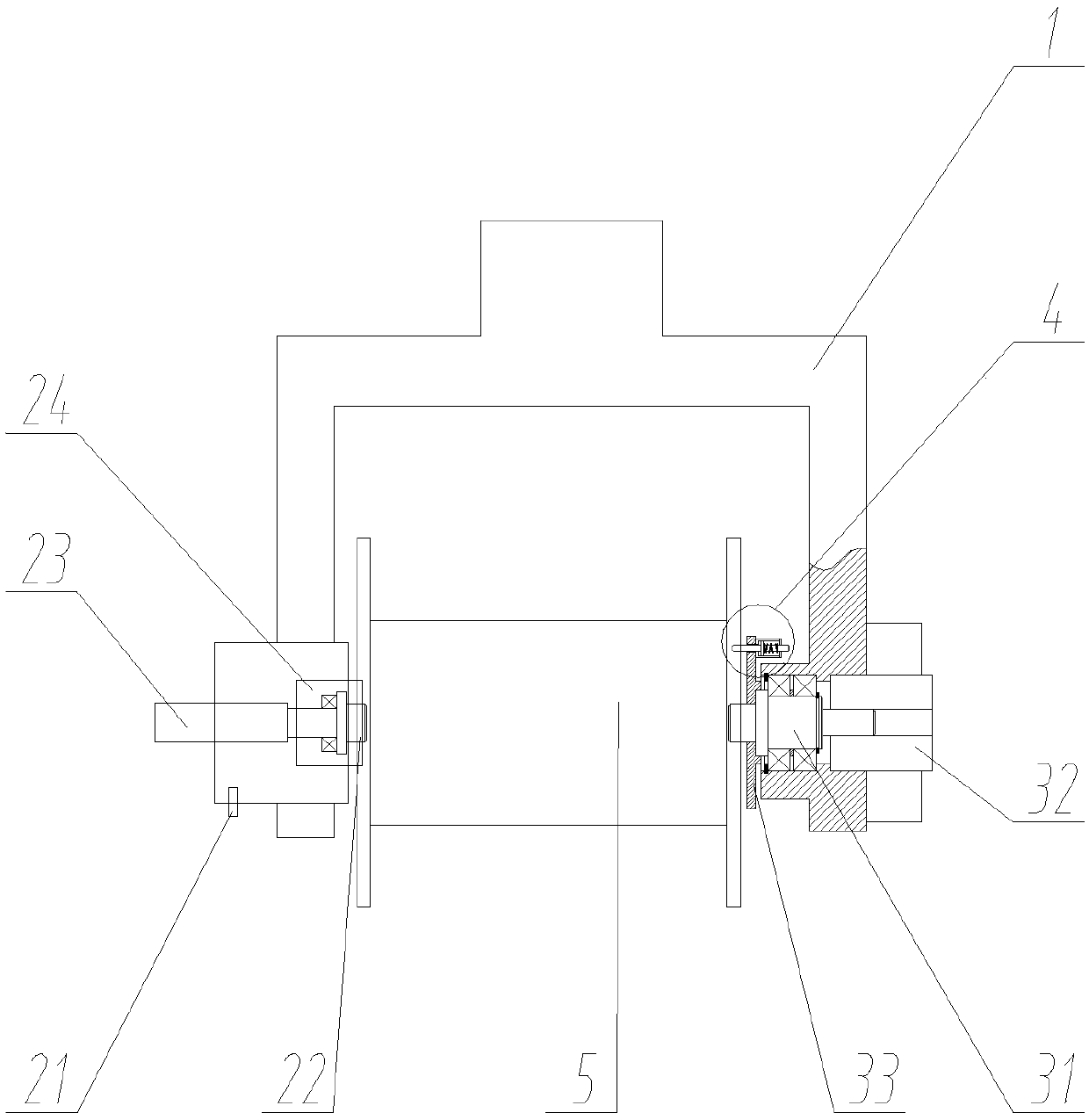

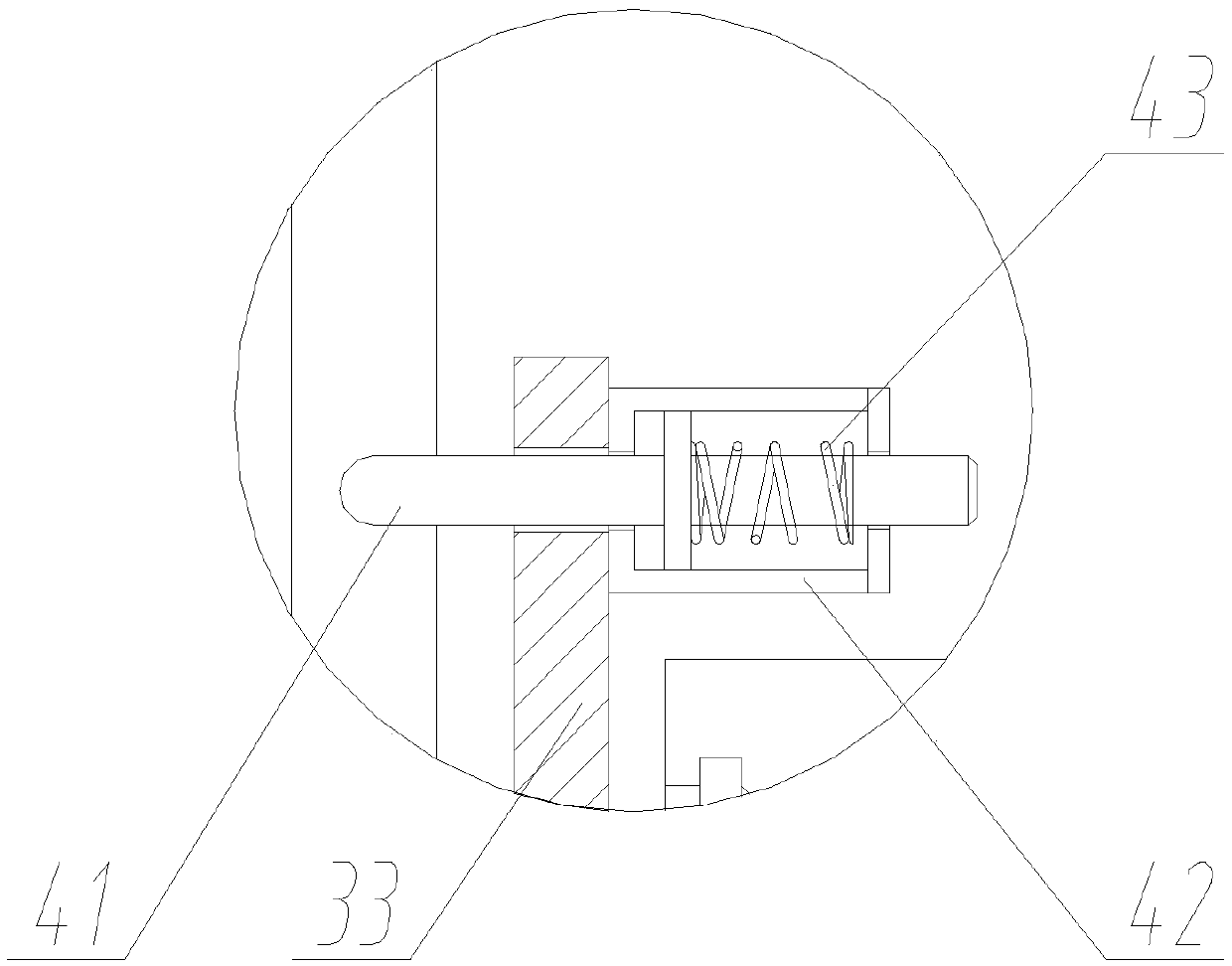

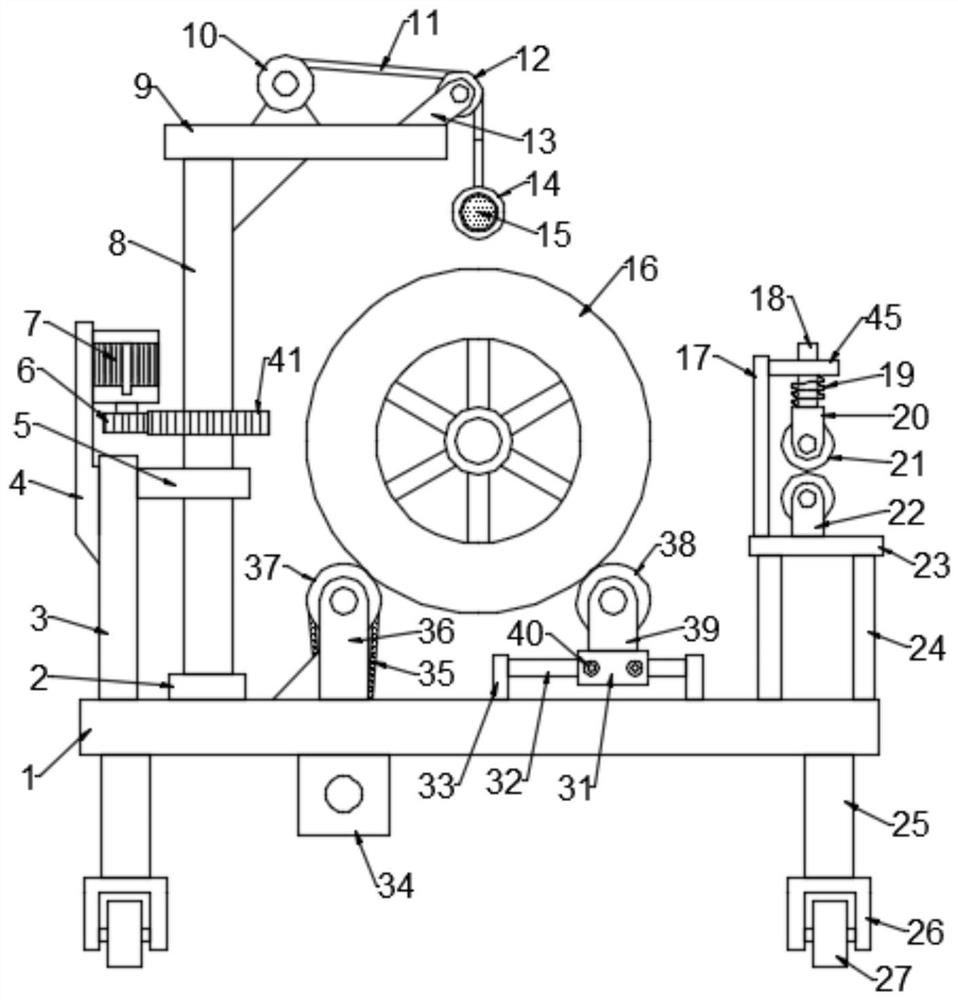

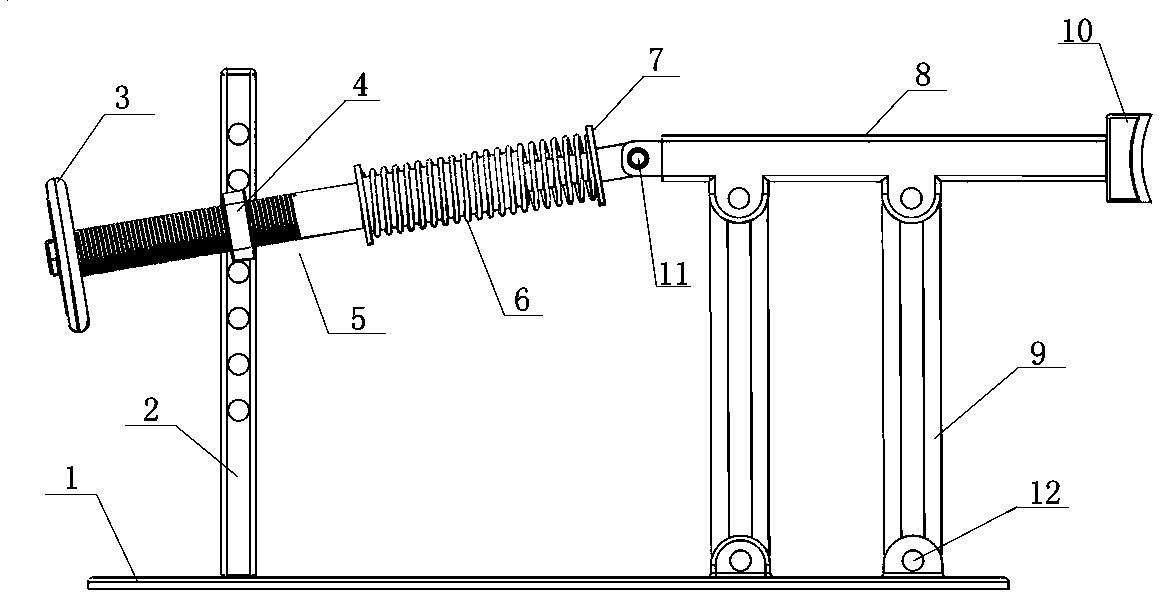

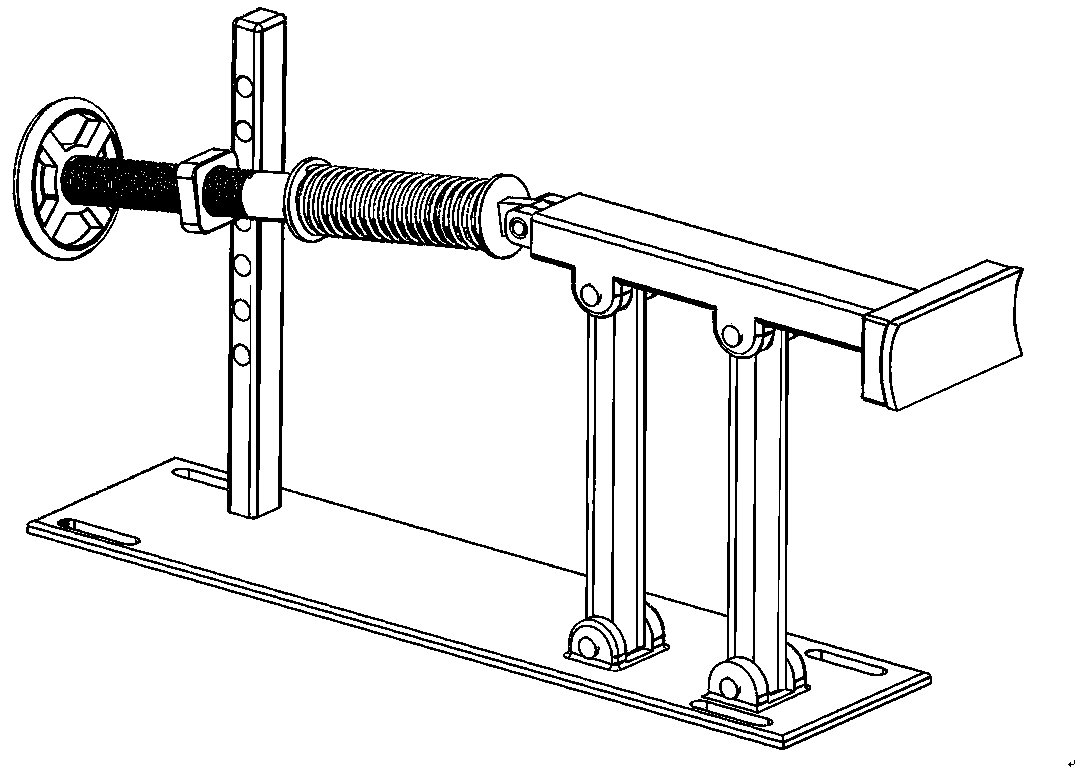

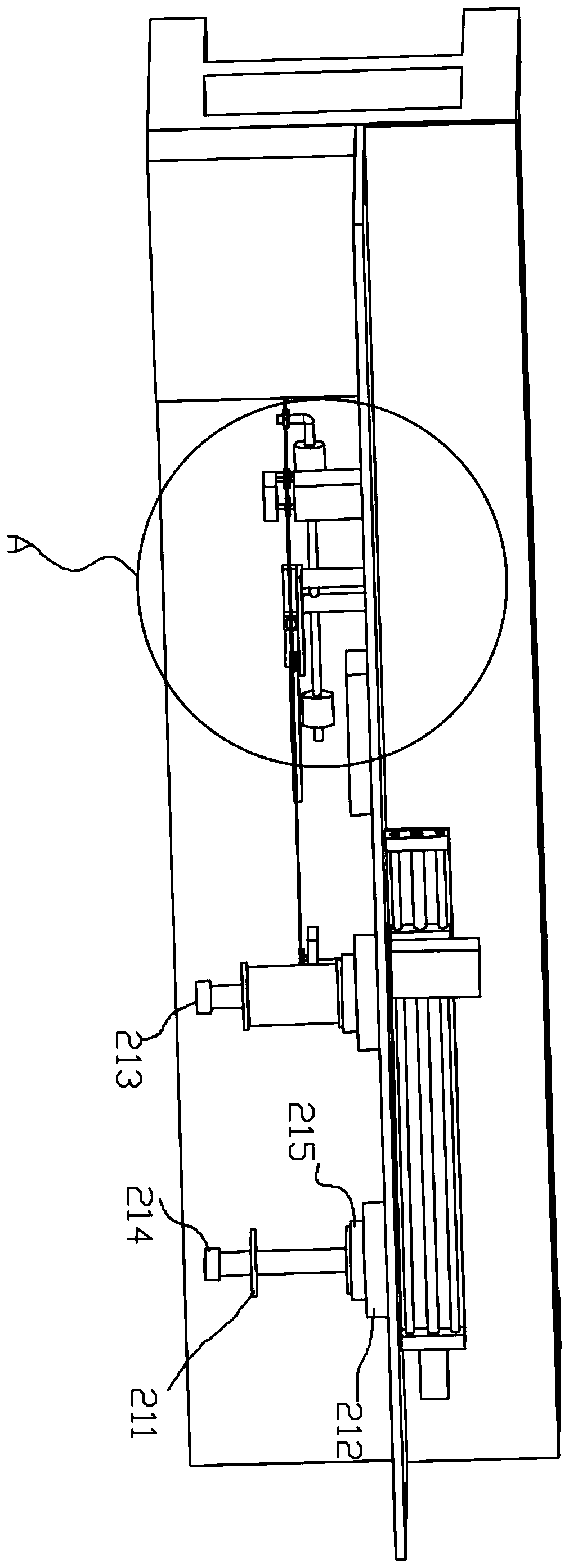

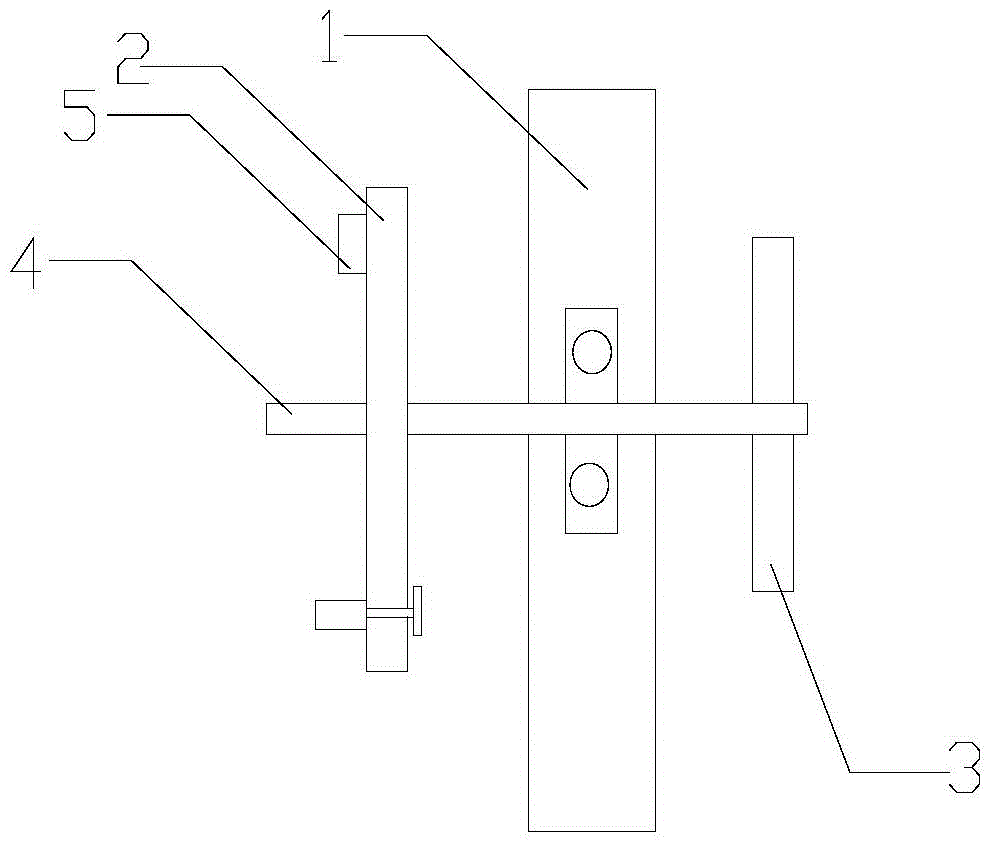

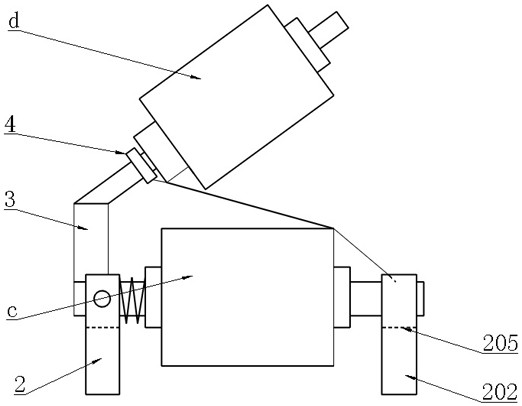

Constant tension paying-off brake device and using method thereof

PendingCN110668250AReduced precision requirementsAdvanced technologyFilament handlingInsulating conductors/cablesEngineeringAir compressor

The invention relates to a constant tension paying-off brake device and a using method thereof, and belongs to the technical field of production of enamel-cover winding wires for large-sized power transformers. According to the technical scheme, a height-adjustable supporting column (2) is provided with one or more placement holes, and a twistable nut (4) is arranged in the position holes of the height-adjustable supporting column (2); one end of an adjusting screw (5) is connected with the twistable nut (4) through a thread, the other end of the adjusting screw (5) is opened, the adjusting screw (5) is internally provided with a slide way communicated with the opening, one end of a slide rod (7) is slidably arranged in the slide way, the other end of the slide rod is hinged to a brake rod(8), and a spring (6) sleeves the adjusting screw and the slide rod; a brake sheet (10) is arranged at the top of the brake rod, the tops of two connecting rods are hinged to the brake rod, and the bottom of the two connecting rods are hinged to a base (1). According to the constant tension paying-off brake device, there is no need to provide compressed air for an air compressor, meanwhile, the requirement for the precision of a paying-off bobbin tool is not high, and a large amount of expenditure is reduced.

Owner:BAODING TIANWEI WIRE MFG

Winding displacement device for enameled wire production line

ActiveCN111584156AStable pay-offThe effect of preventing defective productsApparatus for feeding conductors/cablesInsulating conductors/cablesManufacturing lineElectrical and Electronics engineering

The invention discloses a wire arrangement device for an enameled wire production line. The device is positioned at the front side part of an operation table of enameled wire production equipment andcomprises two pay-off reels, a positioning device, a detection device and a control device, the two pay-off reels are located on the same horizontal straight line and used for containing pay-off reelswound with bare wires, and each pay-off reel is rotationally connected with the corresponding pay-off reel. The positioning device is positioned below the two pay-off reels, is in sliding connectionwith enameled wire production line equipment, and is used for positioning the bare wires when the bare wires are paid off by the pay-off reels; the detection device is located below the left side of the positioning device and used for detecting the thickness and speed of the bare wires passing through the detection device; and the control device is used for controlling the positioning device and the detection device. The device has the advantages of detecting the thickness of the bare wires, ensuring that the bare wires are released from the pay-off reels at a constant speed, and ensuring thatthe bare wires have enough tension when entering the enameled wire production equipment.

Owner:常州久藤电气有限公司

Setting out device for textile equipment with good damping effect

InactiveCN111137732AImprove shock absorptionImprove impact resistanceFilament handlingScrew threadEngineering

The invention discloses a setting out device for textile equipment with good damping effect. The setting out device for the textile equipment with the good damping effect comprises a base and a substrate fixedly arranged on one side of the top end of the base, a setting out mechanism is fixedly arranged at the top of one side of the substrate, the setting out mechanism is composed of a damping structure and a winding structure, the winding structure is located on the inner side of the damping structure and is movably connected with the damping structure, the damping structure is composed of two damping plates and a rotating shaft, one end of the rotating shaft is located in the middle part of one end face of one of the damping plates and is fixedly connected with the damping plate, and theother end of the rotating shaft penetrates through the middle part of the end face of the other damping plate and is connected with the other damping plate in a threaded mode. According to the setting out device for the textile equipment with the good damping effect, the winding structure rotates when the winding structure works, the damping effect of left side and the right side of the winding structure can be enhanced by arranging a damping assembly, a second damping spring can be arranged between the relative end faces of the hollow winding shaft by arranging a winding shaft with a hollowstructure, and when the winding shaft rotates, the anti-collision ability of the winding shaft can be enhanced.

Owner:江苏三联新材料股份有限公司

A cable rack

InactiveCN103972822BRelease easilyQuick releaseFilament handlingApparatus for laying cablesEngineeringElectric cables

Owner:国网山东省电力公司沂水县供电公司

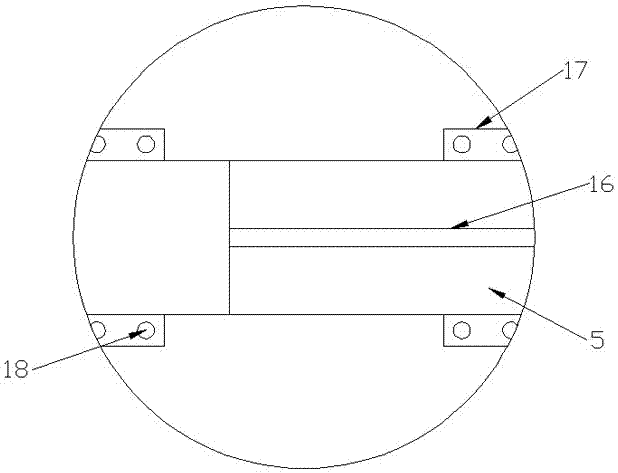

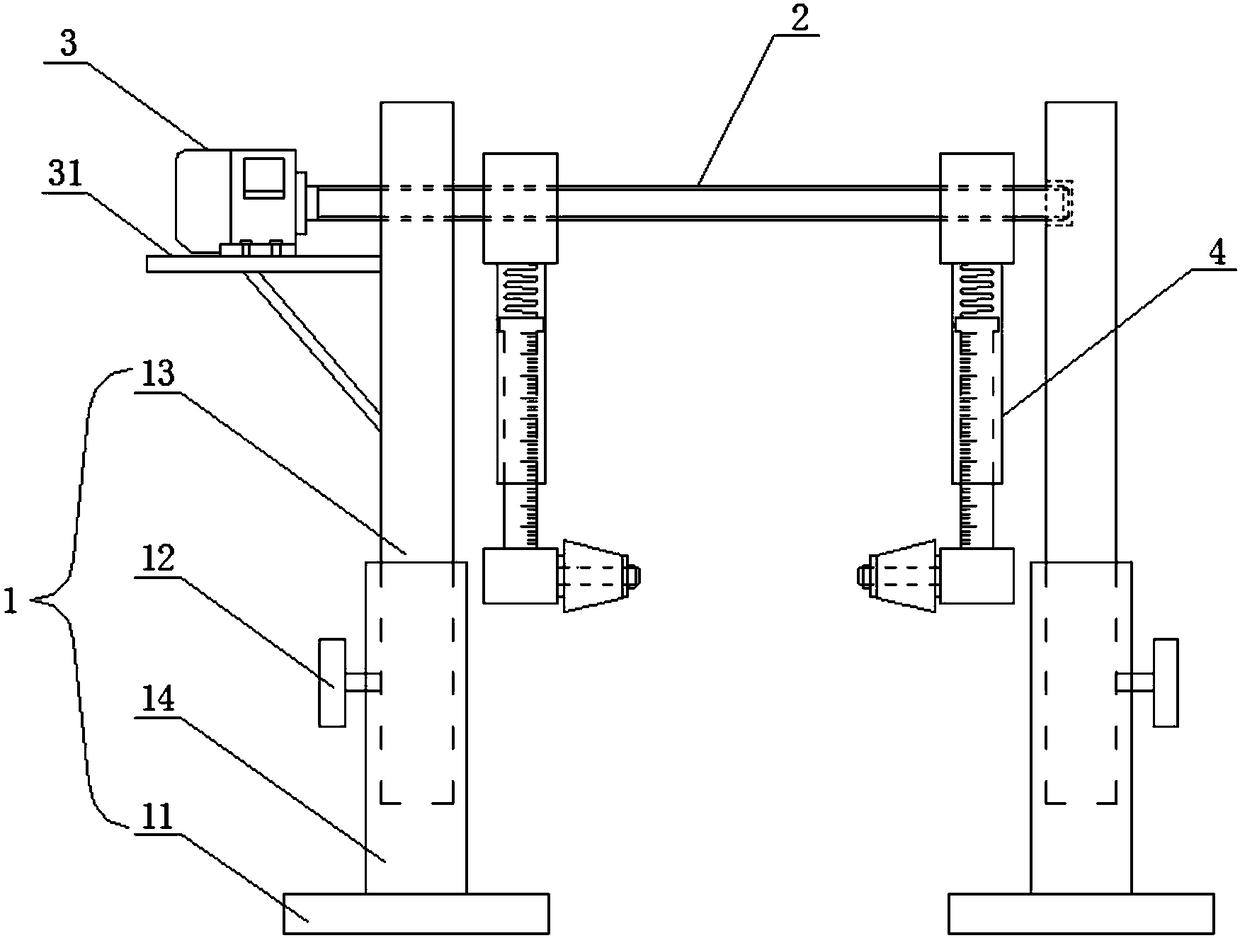

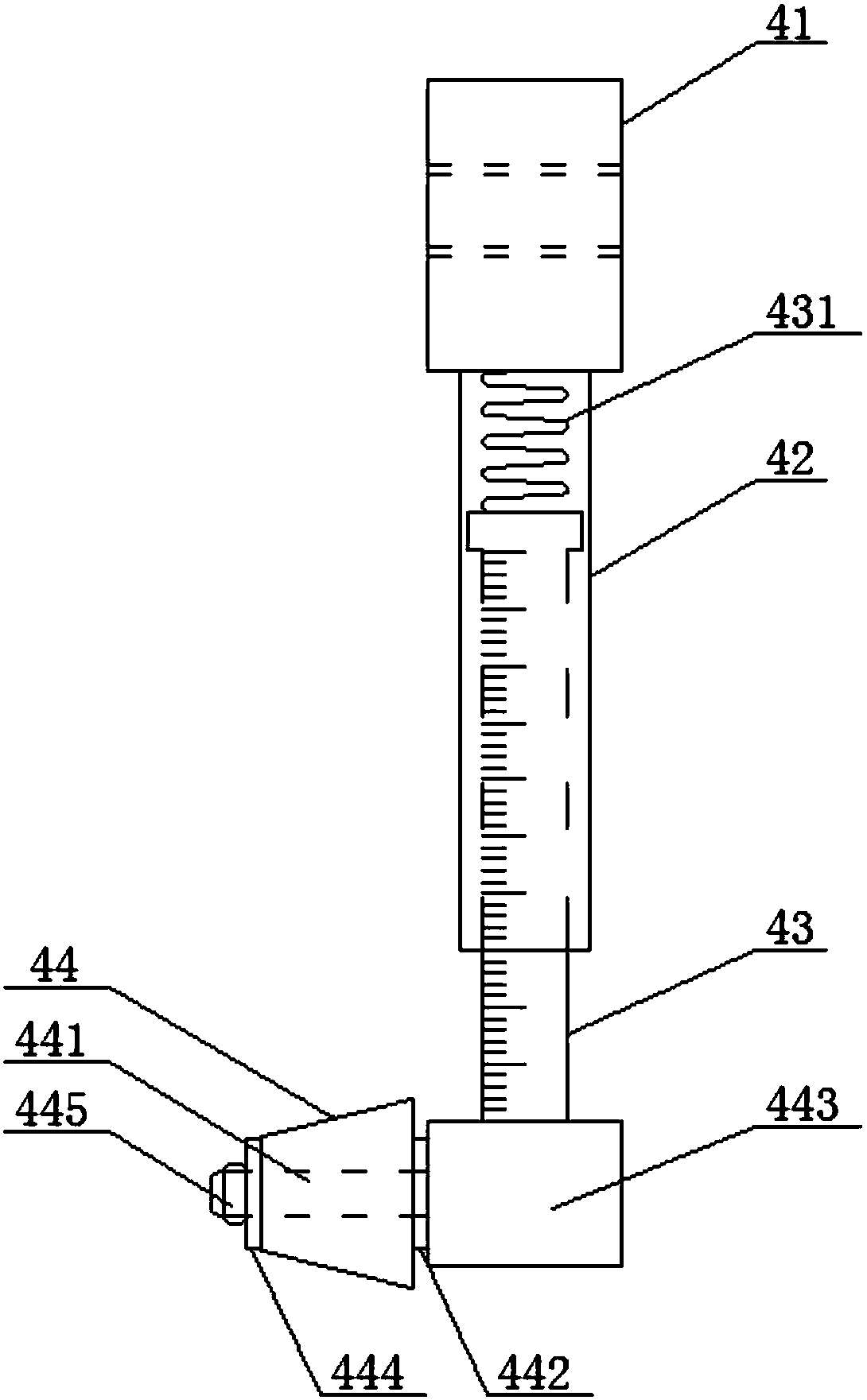

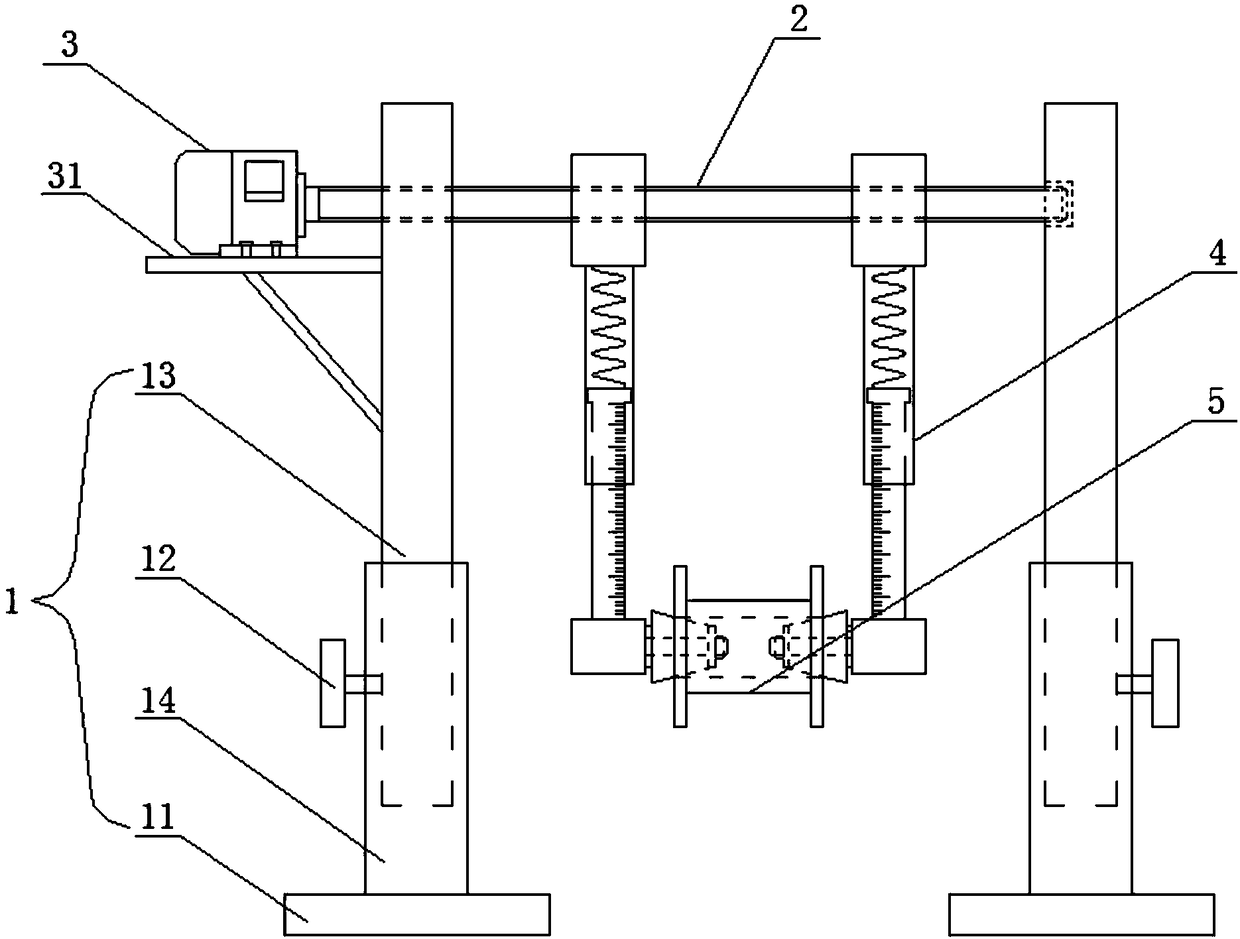

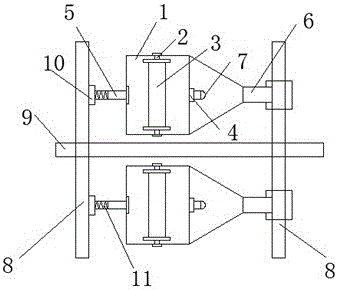

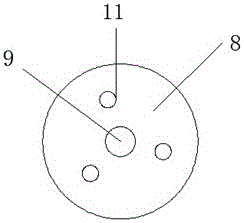

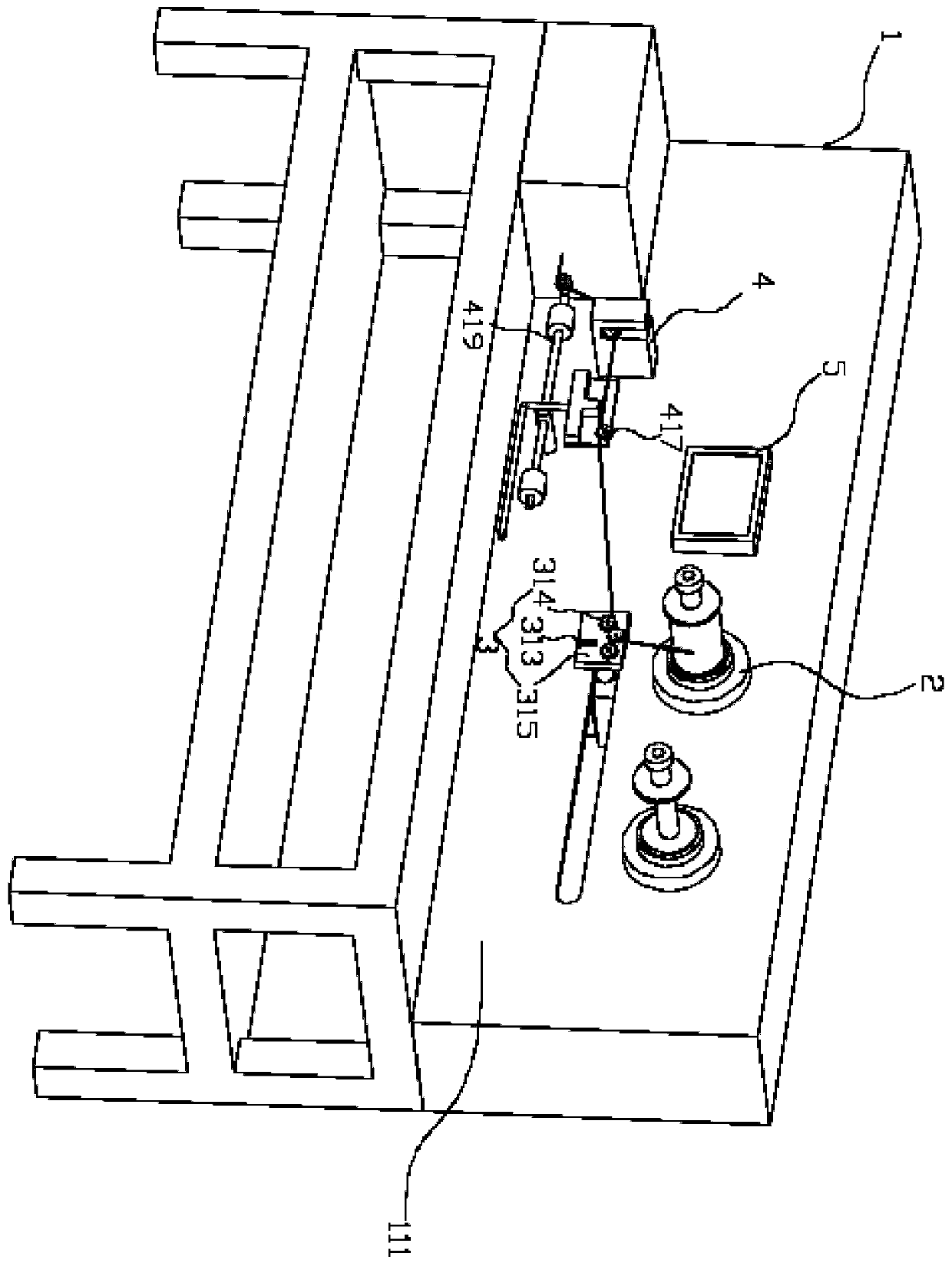

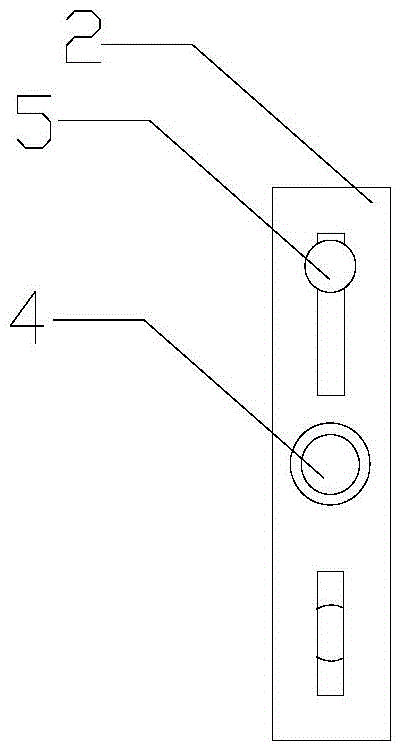

An extrusion forming machine pay-off stand

InactiveCN105702383AStable pay-offImpulsivityApparatus for feeding conductors/cablesDrive shaftEngineering

The invention discloses an extrusion forming machine pay-off stand comprising a body (1), a driven wheel (2), a driving unit (3) and a transmission shaft (4). The transmission shaft (4) penetrates through the body (1), and the driven wheel (2) and the driving unit (3) are respectively arranged on the two ends of the transmission shaft (4). The end surfaces of the two sides of the driven wheel (2) are respectively provided with clump weights (5). The driving unit (3) can drive the driven wheel (2) to rotate in an axial direction around the transmission shaft (4) through the transmission shaft (4).

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

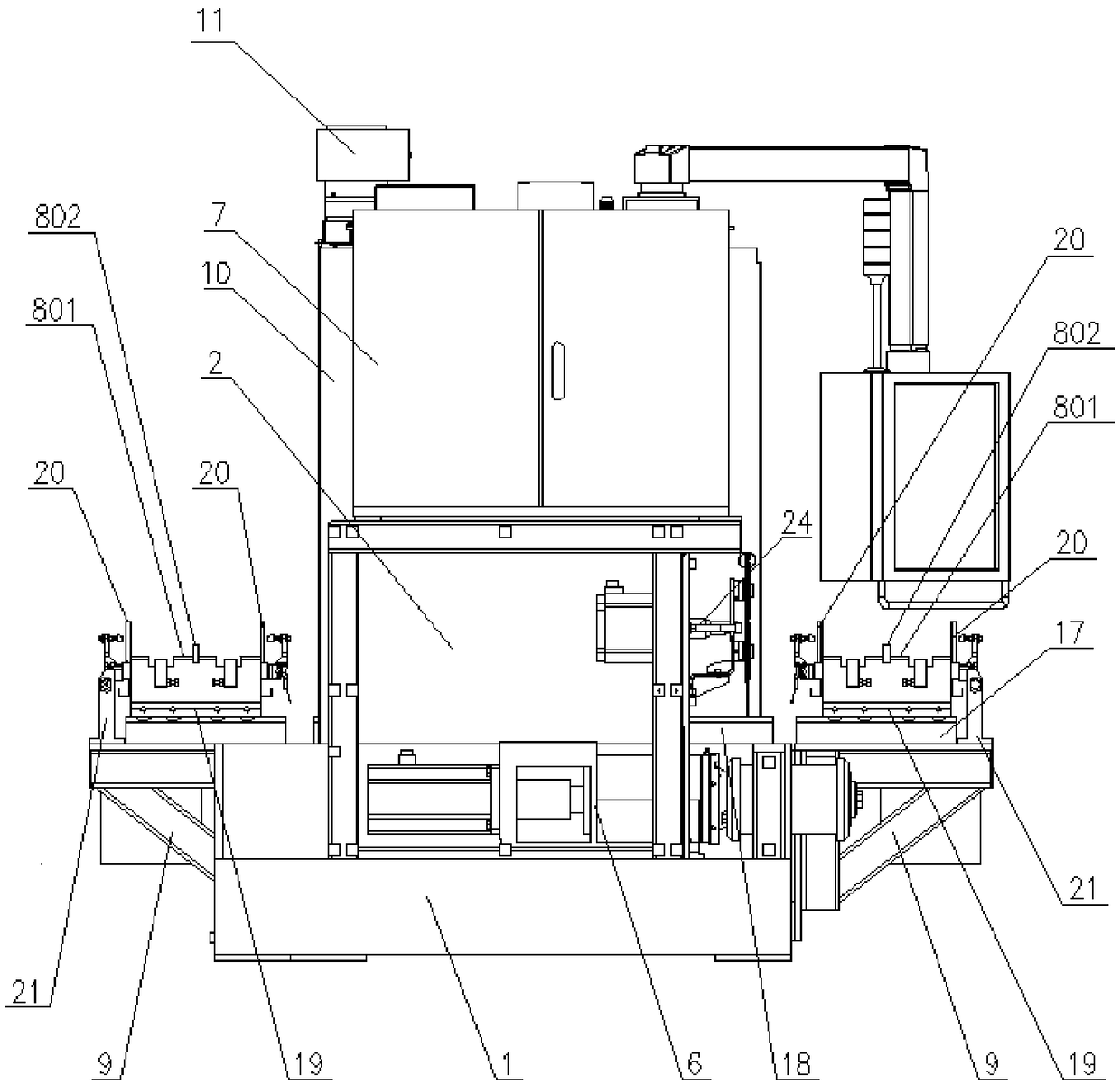

Numerical control polycrystalline silicon diamond wire high-speed cutting-off machine

The invention relates to a numerical control polycrystalline silicon diamond wire high-speed cutting-off machine which comprises a lathe bed and taking-up and paying-off chambers installed at the twoends of the lathe bed. An electric box is fixedly installed on the upper portion of each taking-up and paying-off chamber. Stand columns are installed on the four corners of the lathe bed correspondingly. Two working tables are installed between the two stand columns located on the two sides of the lathe bed through guide rail supports correspondingly. The guide rail supports and the working tables are connected through short steel guide rails. Sliding plates are installed on the two stand columns located on the rear side through linear guide rails correspondingly. The sliding plates drive a cutting wire frame fixed to the lower portions of the sliding plates to move up and down. A first datum motor and a second datum motor are installed at the two ends of the cutting wire frame correspondingly. Multiple diamond wire passing wheels are installed on the two sides of the cutting wire frame. Multiple diamond wire cutting wheels are installed below the cutting wire frame. Diamond wires areguided out from the taking-up and paying-off chamber at one end and sequentially wound around the multiple diamond wire cutting wheels and the diamond wire passing wheels into the taking-up and paying-off chamber at the other end. According to the machine, the diamond wire taking-up, paying-off and distributing quality is improved, and the operation stability and the production efficiency of equipment are improved.

Owner:WUXI SHANGJI AUTOMATION

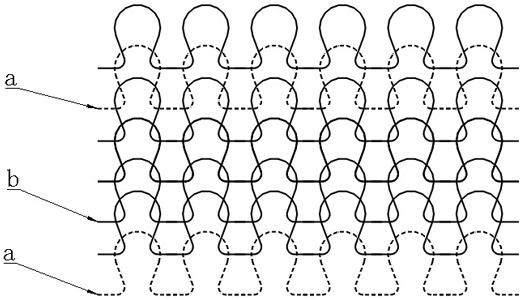

A kind of weft-knitted cotton and linen fabric, and its production process

The invention belongs to the technical field of knitted fabrics, and in particular relates to a weft-knitted cotton and linen fabric and a production process thereof. The present invention has a small amount of high-denier cotton yarn and a relatively large amount of low-denier hemp yarn after blending, the fabric has sufficient softness, good air permeability and moisture permeability, good antistatic effect, and the respective advantages of cotton and hemp yarn are properly combined, and The circular weft knitting machine used in the weft knitting process has the advantages of stable pay-off of the upper bobbin, the bobbin is not easy to fall, the rotation is stable, the bobbin is easy to replace, the pay-off degree of the working bobbin is easy to check, and the whole weft knitting process has the advantages of high efficiency and convenient operation .

Owner:福建省新宏港纺织科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com