Damped pay-off device

A pay-off device and damping technology, which is applied in the field of wire drawing machine equipment, can solve problems such as uneven elongation of metal wires, easy breakage of metal wires, and waste of raw materials in production, and achieves convenient installation and replacement of I-shaped wheels, low cost, The effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

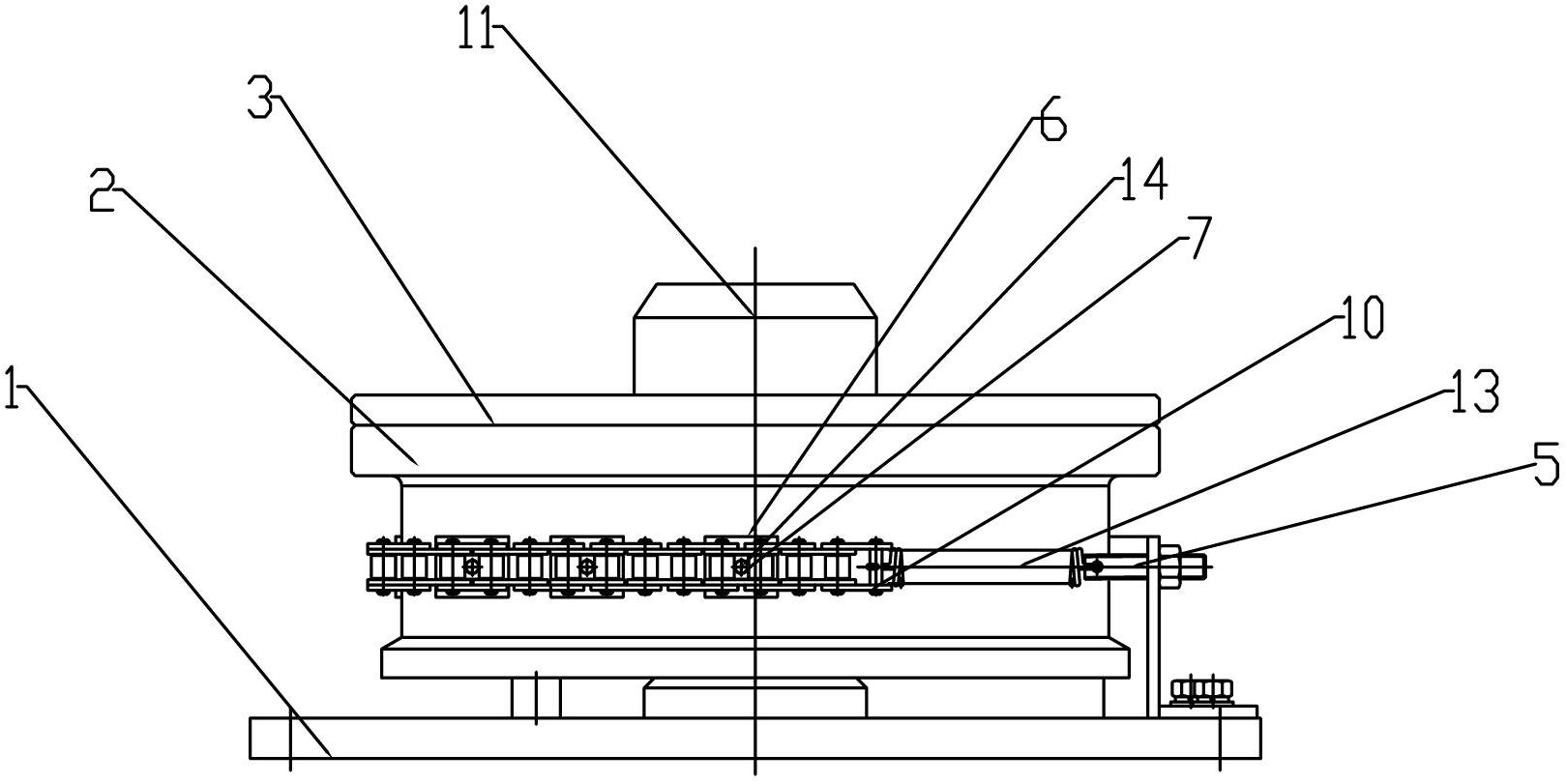

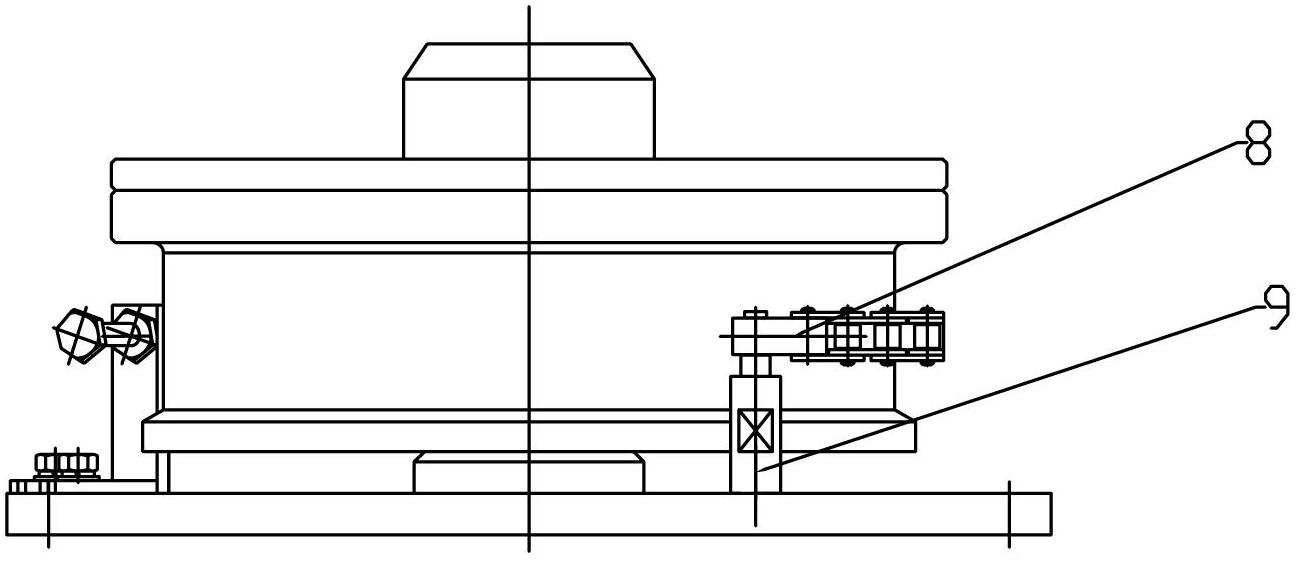

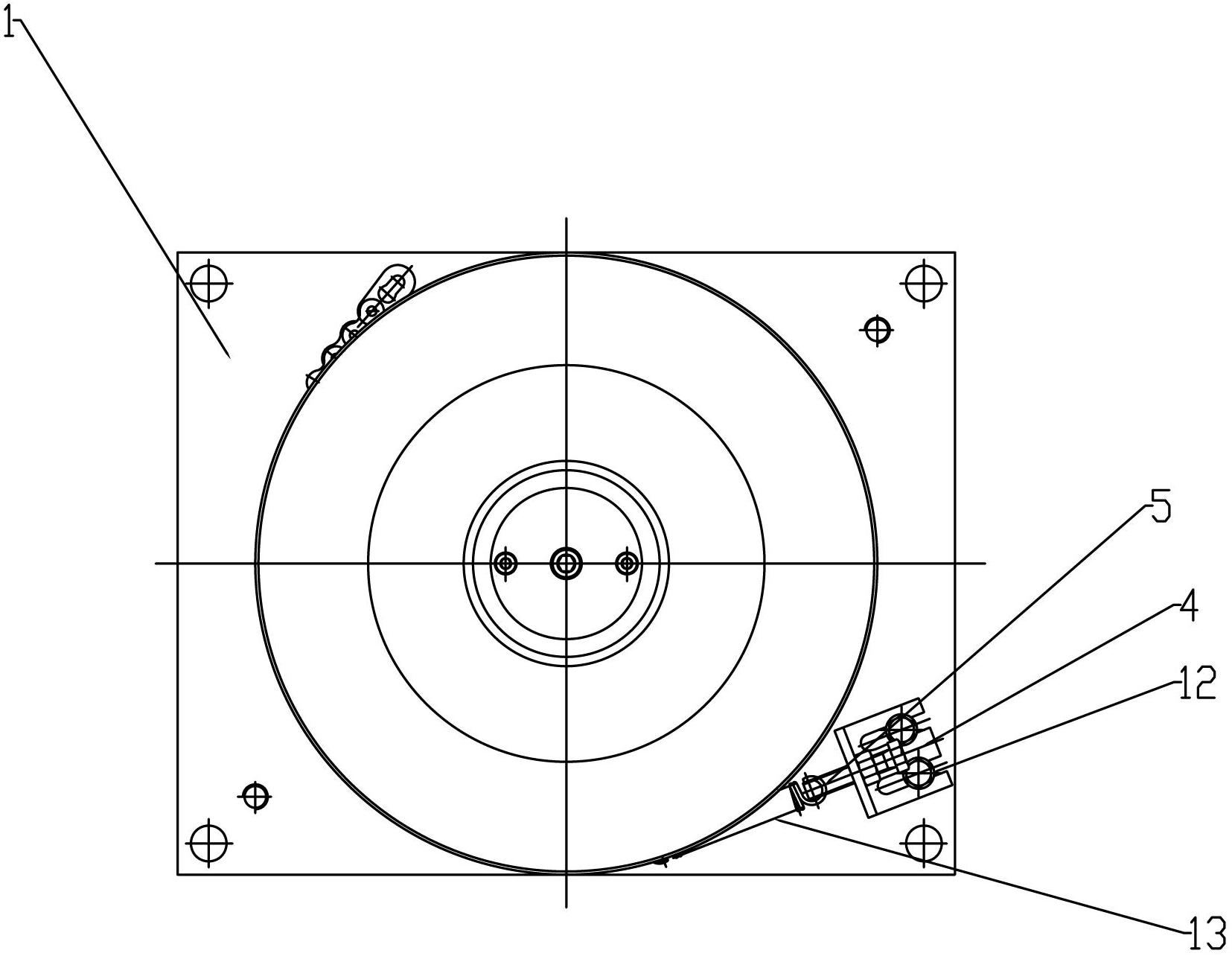

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0012] like Figure 1~3 As shown, the present invention mainly includes base 1, I-shaped wheel seat 2, shock absorbing seat 3, extension spring seat 4, screw rod 5, damping plate 6, pressure plate 7, connecting piece 8, pull rod 9, chain 10, main shaft 11 and pull Spring 13, main shaft 11 is installed in the center of described base 1, connects I-shaped wheel seat 2 on the main shaft 11, connects damping seat 3 on the I-shaped wheel seat 2, and I-shaped wheel seat 2 and shock absorbing seat 3 rotate together with main shaft 11. A tension spring seat 4 is installed at one end of the base 1 and fastened by screws 12 . Screw rod 5 is installed on the extension spring seat 4, and extension spring 13 is connected on the screw rod 5, and the other end of extension spring 13 is connected with chain 10. The other end of the chain 10 is connected with the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com