Anti-vibration and anti-oscillation damping spring spacer

A technology of damping springs and spacers, which is applied in the direction of mechanical vibration attenuation devices, devices for maintaining the distance between parallel conductors, etc., to achieve the effects of strong adaptability, low cost and convenient selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

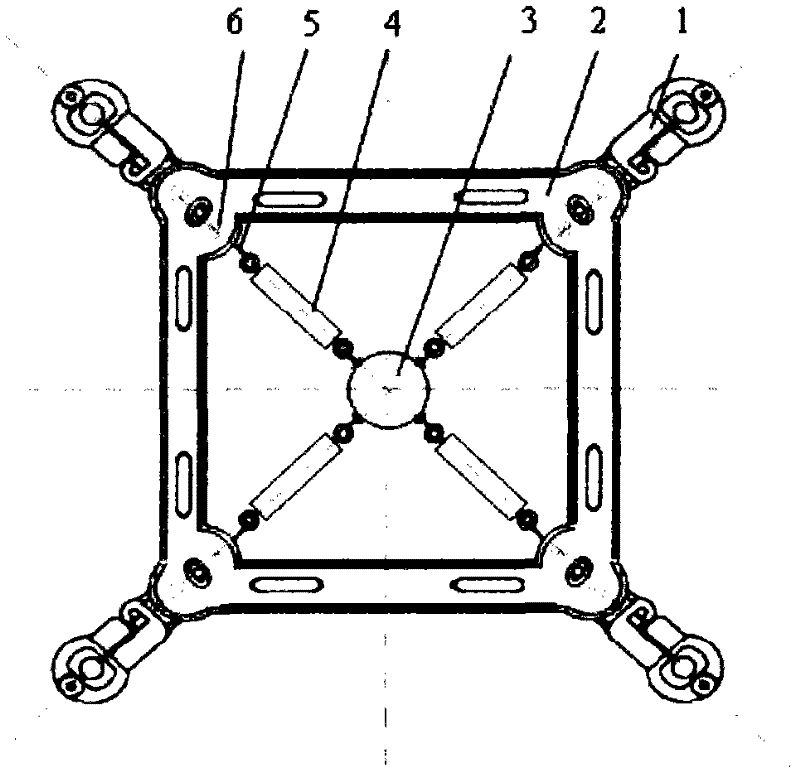

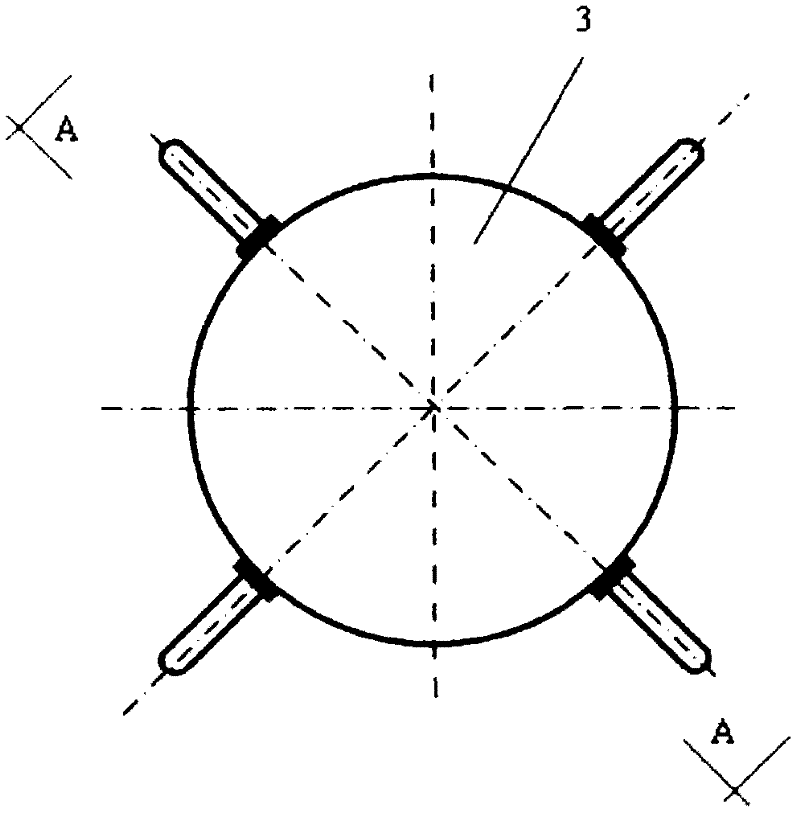

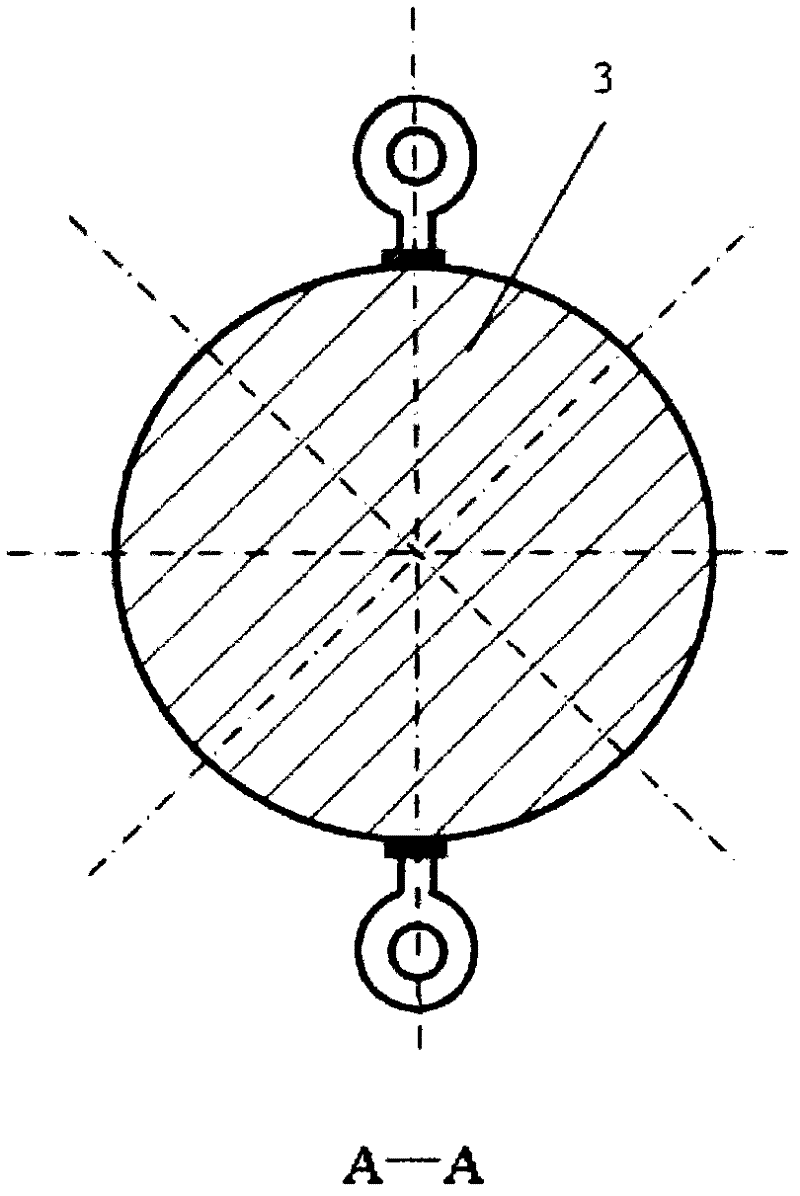

[0032] Embodiment 1: refer to Figure 1-6 , The present embodiment is a four-split vibration-damping and anti-galling damping spring spacer bar, which includes a frame 2 connected to four quartered clamps 1, and the frame 2 is a four-corner double frame. The body center of the frame 2 is provided with a heavy ball 3. The structures of the four damping spring shock absorbers 4 all include a cylinder 43, and one end of the cylinder 43 is connected with a spring hook 41 rotating with a fixed axis, and a built-in cylinder 43 Stretch out the piston-type spring hook 46 of this cylinder other end, the upper end of a section of piston-type spring hook in cylinder body 43 wears positioning plate 42, wears counterweight plate 47 at its lower end, between positioning plate 42 and A spring 44 and a damping rubber sleeve 45 are arranged between the weight plates 47 , and the damping rubber sleeve 45 is sleeved on the spring 44 . The four frame corners of the frame 2 are fixedly connected ...

Embodiment 2

[0033] Embodiment 2: refer to Figure 7 , A four-split vibration-damping and anti-galling damping spring spacer bar in embodiment 2 is basically the same in structure as embodiment 1, except that the frame 2 is a four-corner single frame.

Embodiment 3

[0034] Embodiment 3: refer to Figure 8 , a six-split anti-dancing damping spring spacer bar in embodiment 3 is basically the same structure as embodiment 1, the difference is that the frame 2 is a hexagonal double frame, and 6 clamps 1 and 6 damping springs are used for vibration reduction 4, 6 V-shaped rings 5, 6 self-locking bolts 6, the connection relationship is similar to that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com