Plastic coating production line

A technology of production line and plastic bag, which is applied in the textile field, can solve the problems of the new process of plastic coating production line without unwinding, gathering, covering, cooling, drafting, testing, and taking up, so as to achieve high production efficiency and control precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

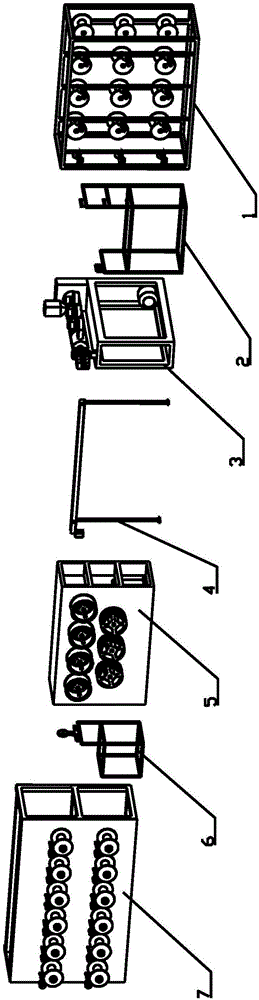

[0032] Such as figure 1 , a plastic coating production line, including a pay-off machine 1 for winding the original wire, a wire gathering machine 2 for changing the direction of the original wire and gathering them together, and for coating molten plastic on the original wire to form a composite Wire wrapping machine 3, cooling tank 4 for cooling composite wire passing through and cooling, drafting machine 5 for drawing and deforming composite wire, detector 6 for detecting composite wire diameter and storage The wire take-up machine 7 of the composite yarn, the wire pay-off machine 1, the wire collection machine 2, the coating machine 3, the cooling tank 4, the drafting machine 5, the detection machine 6 and the wire take-up machine 7 are arranged in a production line in sequence. A water tap is provided above the cooling tank 4 .

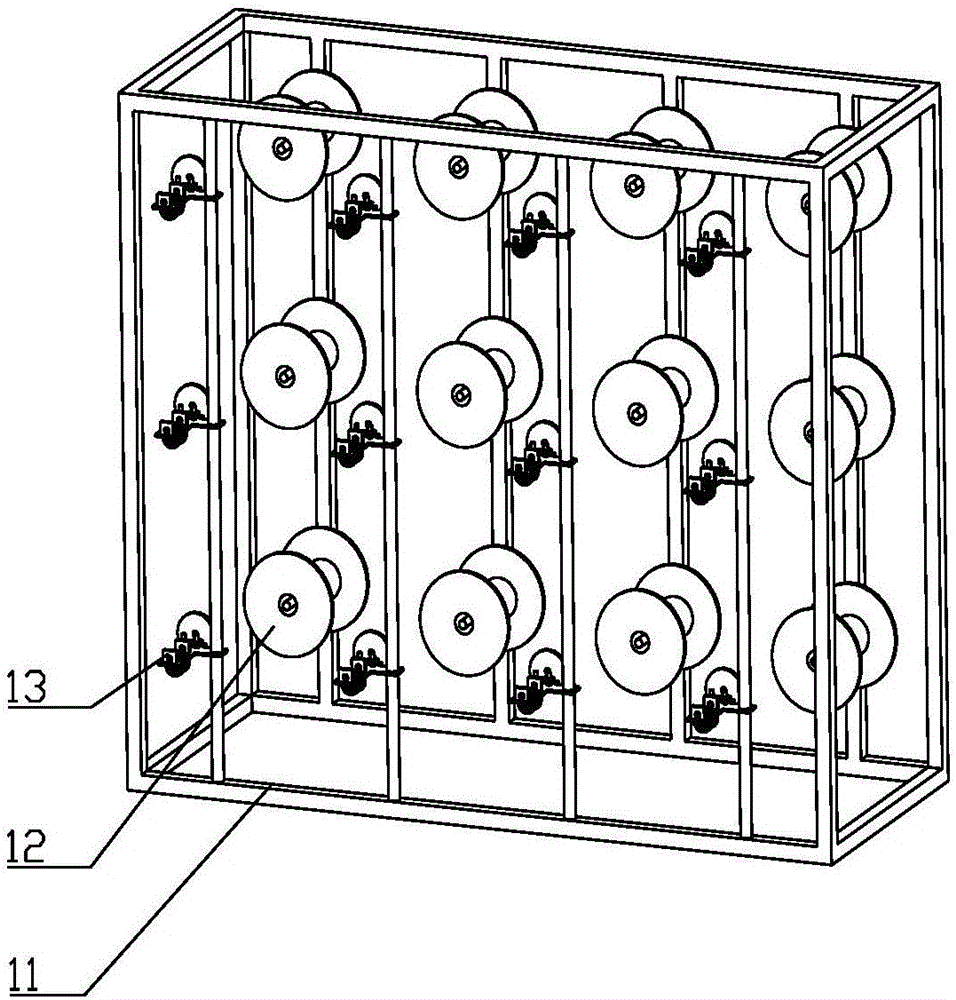

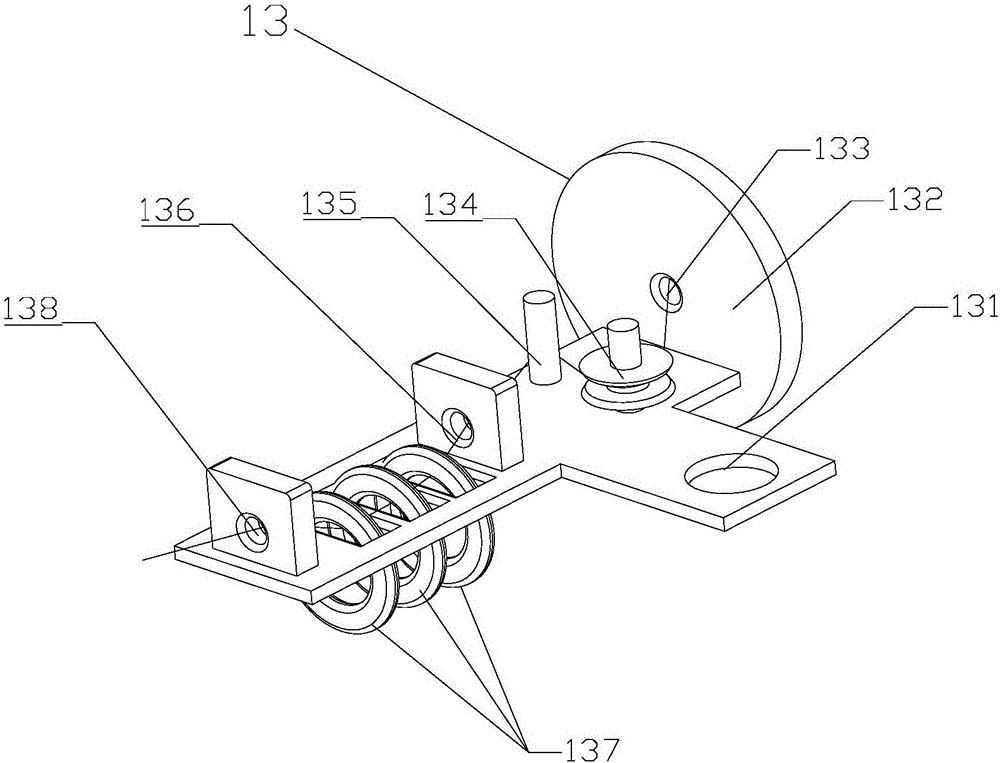

[0033] Such as Figure 2-3 , pay-off machine 1 comprises pay-off stand 11, is hung with several row pay-off wire reels 12 on the pay-off stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com