Constant tension paying-off brake device and using method thereof

A braking device, constant tension technology, used in transportation and packaging, insulation of conductors/cables, electrical components, etc., can solve problems such as high energy consumption, high maintenance costs, and increase waste wire rate, and achieve low accuracy requirements, The effect of improving process level and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

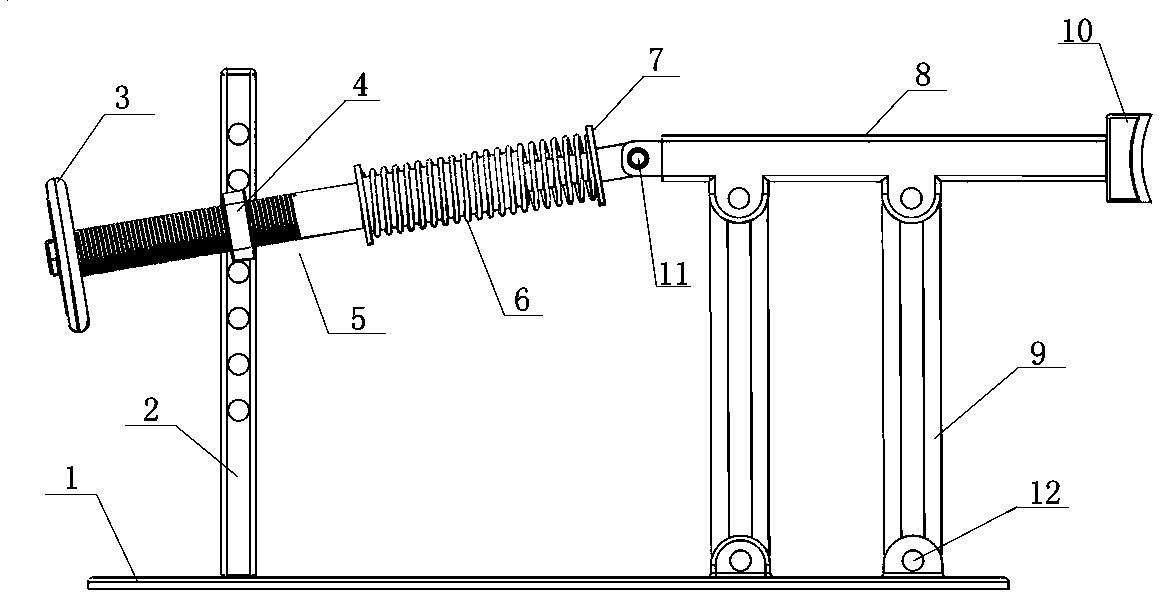

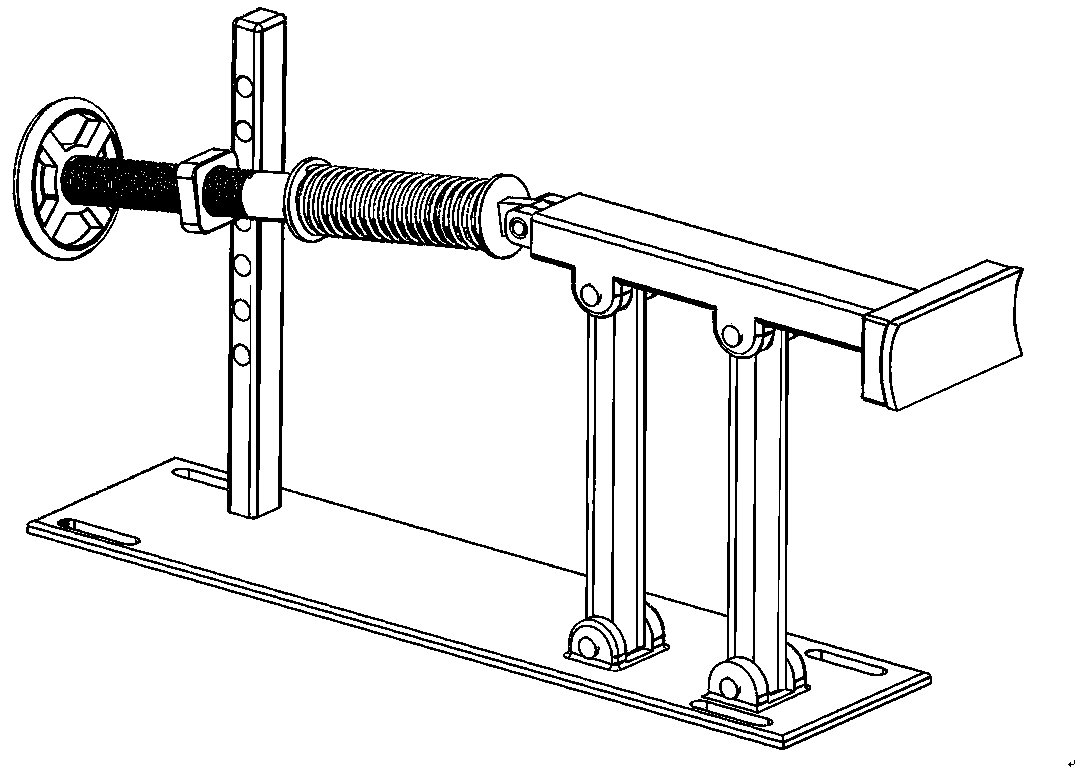

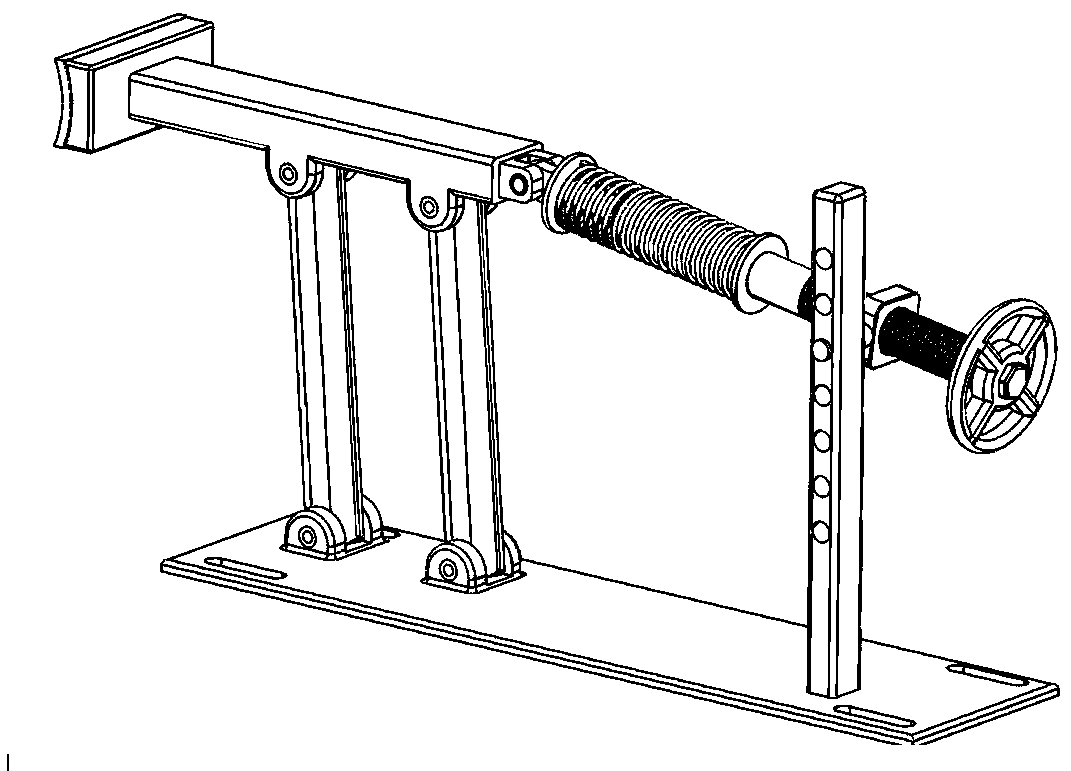

[0018] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] A constant tension release brake device, comprising a base 1, a height-adjustable support column 2, a twistable nut 4, a brake lever 8, a parallel double link 9, a brake pad 10 and a tension adjustment mechanism, the height-adjustable support column 2 is arranged on the base 1, and the height-adjustable support column 2 is provided with more than one position hole, and the twistable nut 4 is arranged in the position hole of the height-adjustable support column 2; the tension adjustment mechanism includes an adjustment screw rod 5, a spring 6 and a slide Rod 7, one end of adjusting screw rod 5 is connected with twistable nut 4 by thread, and the other end of adjusting screw rod 5 is open, and the inside is provided with the slideway that communicates with opening, slide bar 7 one end is slidably arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com